EP0805941B1 - Heat and cold-generating machine - Google Patents

Heat and cold-generating machine Download PDFInfo

- Publication number

- EP0805941B1 EP0805941B1 EP96900320A EP96900320A EP0805941B1 EP 0805941 B1 EP0805941 B1 EP 0805941B1 EP 96900320 A EP96900320 A EP 96900320A EP 96900320 A EP96900320 A EP 96900320A EP 0805941 B1 EP0805941 B1 EP 0805941B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- heat exchanger

- cold

- regenerator

- bypass

- heating

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000000034 method Methods 0.000 claims abstract description 21

- 230000001172 regenerating effect Effects 0.000 claims abstract description 9

- 238000010438 heat treatment Methods 0.000 claims description 14

- 238000007710 freezing Methods 0.000 abstract description 12

- 230000008014 freezing Effects 0.000 abstract description 12

- 238000001816 cooling Methods 0.000 description 9

- 238000005482 strain hardening Methods 0.000 description 6

- 238000002485 combustion reaction Methods 0.000 description 2

- 230000006378 damage Effects 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 238000004378 air conditioning Methods 0.000 description 1

- 230000005540 biological transmission Effects 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 239000000284 extract Substances 0.000 description 1

- 230000002631 hypothermal effect Effects 0.000 description 1

- 230000007257 malfunction Effects 0.000 description 1

- 230000001360 synchronised effect Effects 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B9/00—Compression machines, plants or systems, in which the refrigerant is air or other gas of low boiling point

- F25B9/14—Compression machines, plants or systems, in which the refrigerant is air or other gas of low boiling point characterised by the cycle used, e.g. Stirling cycle

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B9/00—Compression machines, plants or systems, in which the refrigerant is air or other gas of low boiling point

Definitions

- the invention relates to a working according to a regenerative gas cycle process Heating and cooling machine with at least two pistons, the minimum three process rooms, each with at least one heat exchanger and at least one regenerator connected in series with this separate from each other.

- the invention has for its object one after a regenerative gas cycle process to create working heating and cooling machine in which the Risk of freezing of the cold heat exchanger with design and control technology is simply eliminated in an energetically meaningful manner.

- the solution to this problem by the invention is characterized in that that at least one of the cold process room assigned Regenerators to change the cold heat exchange circuit amount of heat transferred between process gas and environment with at least a bypass containing a control valve is provided.

- the inventive formation of a bypass to at least one of the regenerators assigned to the cold heat exchanger is activated the bypass valve of icing on the air heat exchanger is limited in time opened so that the process gas in this bypassed bypass Regenerator no heat is removed and in this way the in the machine arranged cold heat exchangers through the from the warm process room amount of heat coming to a temperature above freezing is brought, with which the air heat exchanger is de-iced at the same time. Also in the event of a failure of the circulation pump in the one belonging to the cold heat exchanger In this way, the cycle becomes active even when the machine is running freezing of the cold heat exchanger avoided.

- the bypass line is in Formed a through opening in the regenerator, the two Ends are closed during normal operation of the machine. This results in a dead space-free design of this regenerator.

- bypass line is passed through closed a plunger, which is countered by an electromagnet Force of a return spring is movable.

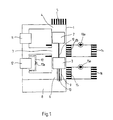

- the heating and cooling machine shown schematically in Figure 1 includes a pressure-tight housing 1, in which a hot piston 2 and a cold piston 3 are arranged linearly movable.

- the hot piston 2 limits a hot working volume 4, to which heat is supplied, for example by a gas-heated one Combustion chamber 5.

- the cold piston 3 limits a cold working volume 6.

- Both pistons 2 and 3 limit a warm working volume 7.

- a gear 8 is provided, which is connected to the cold via a hollow piston rod 9 Piston 3 and another piston rod 10 with the hot piston 2 connected is.

- a regenerator 11 or 12 is arranged.

- the warm working volume 7 is also assigned a warm heat exchanger 14, which is connected in series with the regenerator 11 and as well this is flowed through by the process gas. From this warm heat exchanger 13 is heated in the closed circuit via a circulation pump 13a a heat exchanger designed as a heater 14, for example.

- the cold working volume 6 is also in series with the regenerator 12 assigned cold heat exchanger 15 through which process gas flows, the one with an air heat exchanger 16 in a closed circuit is arranged.

- a circulation pump 15a is located in this circuit.

- the heating and cooling machine is the one assigned to the cold working volume 6

- Regenerator 12 is provided with a bypass 17, in which a bypass valve 17a is arranged. In normal operation, this bypass valve 17a is closed, see above that the bypass 17 has no effect on the after a regenerative gas cycle process working heating and cooling machine.

- the bypass valve is also to be eliminated if the circulation pump 15a fails 17a opened at least for a limited time.

- the process gas is due the lower flow resistance, the regenerator 12 through the Bypass bypass 17 so that the process gas in the regenerator 12 no heat is withdrawn. Since the cold heat exchanger 15 is connected in series to the regenerator 12 is switched, the cold heat exchanger 15 by the from the warm Working volume 7 coming amount of heat at a temperature above the Freezing point brought or held.

- FIG. 2 shows an embodiment of the regenerator 12 in one Longitudinal section.

- the regenerator 12 stands with the cold working volume 6 of the machine via an annular channel 18 and is in series switched to the cold heat exchanger 15, part of which is also in Figure 2 is shown.

- the part of the regenerator 12 shown in FIG. 2 is further provided with a through hole 12a through a plunger 19 is closable. In the closed position, the plunger 19 fills the through opening 12a of regenerator 12 acting as a bypass, see above that there is no dead space in the normal operation of the machine due to the bypass.

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Mechanical Engineering (AREA)

- Thermal Sciences (AREA)

- General Engineering & Computer Science (AREA)

- Sorption Type Refrigeration Machines (AREA)

- Fluid-Pressure Circuits (AREA)

- Engine Equipment That Uses Special Cycles (AREA)

- Compressor (AREA)

- Compressors, Vaccum Pumps And Other Relevant Systems (AREA)

- Devices That Are Associated With Refrigeration Equipment (AREA)

Abstract

Description

Die Erfindung betrifft eine nach einem regenerativen Gaskreisprozeß arbeitende Wärme- und Kältemaschine mit mindestens zwei Kolben, die mindestens drei Prozeßräume unter Zwischenschaltung jeweils mindestens eines Wärmetauschers und mindestens eines mit diesem in Reihe geschalteten Regenerators voneinander trennen.The invention relates to a working according to a regenerative gas cycle process Heating and cooling machine with at least two pistons, the minimum three process rooms, each with at least one heat exchanger and at least one regenerator connected in series with this separate from each other.

Nach einem regenerativen Gaskreisprozeß, beispielsweise nach dem Stirling- oder Vuilleumier-Kreisprozeß arbeitende Wärme- und Kältemaschinen sind seit langer Zeit bekannt, beispielsweise aus der GB-PS 136 195. Derartige Maschinen haben zwei in einem druckdichten Gehäuse linear bewegliche Kolben, die gemeinsam ein warmes Arbeitsvolumen begrenzen und von denen der eine Kolben im Gehäuse ein heißes, mit Wärme beaufschlagtes Arbeitsvolumen und der andere Kolben ein kaltes Arbeitsvolumen begrenzt, wobei die drei Arbeitsvolumina unter Zwischenschaltung von Regeneratoren und Wärmeübertragern miteinander verbunden sind und ein Antrieb und/oder eine Steuerung für die Kolben vorgesehen ist.After a regenerative gas cycle process, for example after the Stirling or Vuilleumier cycle heating and cooling machines have been known for a long time, for example from GB-PS 136 195. Such machines have two pistons that move linearly in a pressure-tight housing, which together limit a warm work volume and of which one Piston in the housing has a hot, heated working volume and the other piston limits a cold working volume, the three working volumes with the interposition of regenerators and heat exchangers are interconnected and a drive and / or a controller for the Piston is provided.

Trotz der unbestreitbaren Vorteile der nach einem regenerativen Gaskreisprozeß arbeitenden Wärme- und Kältemaschinen haben diese bisher keinen Eingang in die Praxis gefunden, und zwar hauptsächlich wegen konstruktiver Schwierigkeiten, die die Realisierung der theoretischen Vorteile derartiger Maschinen in der Praxis bisher verhinderten.Despite the undeniable advantages of having a regenerative gas cycle working heating and cooling machines have so far no entrance found in practice, mainly because of constructive Difficulties in realizing the theoretical advantages of such machines prevented in practice so far.

Bei den nach einem regenerativen Gaskreisprozeß arbeitenden Wärme- und Kältemaschinen, die für die Heizung und Klimatisierung von Gebäuden und Fahrzeugen eingesetzt und mit einem von der atmosphärischen Luft beaufschlagten, als Wärmequelle betriebenen Wärmeübertrager ausgestattet sind, besteht die Gefahr, daß bei Lufttemperaturen um den Gefrierpunkt und bei hoher Luftfeuchtigkeit der Luftwärmetauscher einfriert. In diesem Fall erfolgt durch den weiteren Betrieb der Maschine auch ein Einfrieren des kalten Wärmetauschers der Maschine. Diese Einfriergefahr besteht auch dann, wenn Störungen im kalten Kreislauf der Maschine auftreten, zum Beispiel durch Ausfall der Umwälzpumpe.When working on a regenerative gas cycle process heat and Chillers used for heating and air conditioning buildings and Vehicles used and with an atmospheric air are equipped as heat sources operated heat exchangers, there is a risk that at air temperatures around freezing and at high air humidity of the air heat exchanger freezes. In this case as the machine continues to operate, the cold heat exchanger also freezes the machine. This risk of freezing also exists when there are faults occur in the cold cycle of the machine, for example due to failure the circulation pump.

Um diese Gefahr zu beseitigen, ist es bekannt, den Luftwärmetauscher abzutauen bzw. vor dem Einfrieren zu beheizen. Dies erfordert aufwendige Heizeinrichtungen, die nicht nur energetisch unerwünscht sind, sondern auch aufwendige Steuerungen erfordern, die normalerweise auch ein Abschalten der gesamten Maschine bewirken.To eliminate this danger, it is known to defrost the air heat exchanger or to be heated before freezing. This requires complex heating devices which are not only energetically undesirable, but also complex Controls that normally also require a shutdown of the effect entire machine.

Der Erfindung liegt die Aufgabe zugrunde, eine nach einem regenerativen Gaskreisprozeß arbeitende Wärme- und Kältemaschine zu schaffen, bei der die Einfriergefahr des kalten Wärmetauschers mit konstruktiv und regeltechnisch einfachen Mitteln auf energetisch sinnvolle Weise beseitigt wird.The invention has for its object one after a regenerative gas cycle process to create working heating and cooling machine in which the Risk of freezing of the cold heat exchanger with design and control technology is simply eliminated in an energetically meaningful manner.

Die Lösung dieser Aufgabenstellung durch die Erfindung ist dadurch gekennzeichnet, daß mindestens einer der dem kalten Prozeßraum zugeordneten Regeneratoren zur Veränderung der über den kalten Wärmetauscherkreislauf zwischen Prozeßgas und Umgebung übertragenen Wärmemenge mit mindestens einem ein Steuerventil enthaltenen Bypass versehen ist.The solution to this problem by the invention is characterized in that that at least one of the cold process room assigned Regenerators to change the cold heat exchange circuit amount of heat transferred between process gas and environment with at least a bypass containing a control valve is provided.

Durch die erfindungsgemäße Ausbildung eines Bypasses zu mindestens einem der dem kalten Wärmetauscher zugeordneten Regeneratoren wird beim Auftreten von Vereisungen am Luftwärmetauscher das Bypassventil zeitlich begrenzt geöffnet, so daß dem Prozeßgas in diesem durch den Bypass umgangenen Regenerator keine Wärme entzogen und auf diese Weise der in der Maschine angeordnete kalte Wärmetauscher durch die aus dem warmen Prozeßraum kommende Wärmemenge auf eine Temperatur oberhalb des Gefrierpunktes gebracht wird, womit zugleich der Luftwärmetauscher enteist wird. Auch bei einem Ausfall der Umwälzpumpe in dem zum kalten Wärmetauscher gehörenden Kreislauf wird auf diese Weise selbst bei weiterlaufender Maschine ein Einfrieren des kalten Wärmetauschers vermieden. The inventive formation of a bypass to at least one of the regenerators assigned to the cold heat exchanger is activated the bypass valve of icing on the air heat exchanger is limited in time opened so that the process gas in this bypassed bypass Regenerator no heat is removed and in this way the in the machine arranged cold heat exchangers through the from the warm process room amount of heat coming to a temperature above freezing is brought, with which the air heat exchanger is de-iced at the same time. Also in the event of a failure of the circulation pump in the one belonging to the cold heat exchanger In this way, the cycle becomes active even when the machine is running freezing of the cold heat exchanger avoided.

Bei einer bevorzugten Ausführungsform der Erfindung ist die Bypassleitung in Form einer Durchgangsöffnung im Regenerator ausgebildet, die an beiden Enden im Normalbetrieb der Maschine verschlossen ist. Hierdurch ergibt sich eine totraumfreie Ausgestaltung dieses Regenerators.In a preferred embodiment of the invention, the bypass line is in Formed a through opening in the regenerator, the two Ends are closed during normal operation of the machine. This results in a dead space-free design of this regenerator.

Gemäß einem weiteren Merkmal der Erfindung wird die Bypassleitung durch einen Tauchkolben verschlossen, der über einen Elektromagnet entgegen der Kraft einer Rückzugsfeder bewegbar ist. Diese erfindungsgemäße Weiterbildung ergibt eine besonders einfache und funktionssichere Konstruktion mit geringem Raumbedarf.According to a further feature of the invention, the bypass line is passed through closed a plunger, which is countered by an electromagnet Force of a return spring is movable. This invention Further training results in a particularly simple and reliable construction with little space requirement.

Auf der Zeichnung ist außer einem schematischen Ausführungsbeispiel einer nach einem regenerativen Gaskreisprozeß arbeitenden Wärme- und Kältemaschine eine konstruktive Ausführungsmöglichkeit der Erfindung dargestellt und zwar zeigen:

Figur 1- eine schematische Darstellung einer Wärme- und Kältemaschine und

Figur 2- einen Längsschnitt durch ein Ausführungsbeispiel eines mit einem Bypass versehenden Regenerators

- Figure 1

- a schematic representation of a heating and cooling machine and

- Figure 2

- a longitudinal section through an embodiment of a regenerator provided with a bypass

Die in Figur 1 schematisch dargestellte Wärme- und Kältemaschine umfaßt ein

druckdichtes Gehäuse 1, in dem ein heißer Kolben 2 und ein kalter Kolben 3

linear beweglich angeordnet sind. Der heiße Kolben 2 begrenzt ein heißes Arbeitsvolumen

4, dem Wärme zugeführt wird, beispielsweise durch eine gasbeheizte

Brennkammer 5. Der kalte Kolben 3 begrenzt ein kaltes Arbeitsvolumen

6. Beide Kolben 2 und 3 begrenzen ein warmes Arbeitsvolumen 7. Für die

synchronisierte Bewegung der Kolben 2 und 3 ist beim Ausführungsbeispiel

ein Getriebe 8 vorgesehen, das über eine hohle Kolbenstange 9 mit dem kalten

Kolben 3 und über eine weitere Kolbenstange 10 mit dem heißen Kolben 2

verbunden ist.The heating and cooling machine shown schematically in Figure 1 includes a

pressure-

Sowohl zwischen dem heißen Arbeitsvolumen 4 und dem warmen Arbeitsvolumen

7 als auch zwischen dem warmen Arbeitsvolumen 7 und dem kalten

Arbeitsvolumen 6 ist jeweils ein Regenerator 11 bzw. 12 angeordnet. Dem

warmen Arbeitsvolumen 7 ist weiterhin ein warmer Wärmetauscher 14 zugeordnet,

der mit dem Regenerator 11 in Reihe geschaltet ist und ebenso wie

dieser vom Prozeßgas durchströmt wird. Aus diesem warmen Wärmetauscher

13 wird im geschlossenen Kreislauf über eine Umwälzpumpe 13a Wärme an

einen beispielsweise als Heizung 14 ausgebildeten Wärmetauscher abgegeben.Both between the hot working volume 4 and the warm working

Auch dem kalten Arbeitsvolumen 6 ist ein mit dem Regenerator 12 in Reihe

geschalteter, von Prozeßgas durchströmter kalter Wärmetauscher 15 zugeordnet,

der mit einem Luftwärmetauscher 16 in einem geschlossenen Kreislauf

angeordnet ist. In diesem Kreislauf befindet sich eine Umwälzpumpe 15a.The cold working

Bei dem in Figur 1 schematisch dargestellten Ausführungsbeispiel einer

Wärme- und Kältemaschine ist der dem kalten Arbeitsvolumen 6 zugeordnete

Regenerator 12 mit einem Bypass 17 versehen, in dem ein Bypassventil 17a

angeordnet ist. Im Normalbetrieb ist dieses Bypassventil 17a geschlossen, so

daß der Bypass 17 keinen Einfluß auf die nach einem regenerativen Gaskreisprozeß

arbeitende Wärme- und Kältemaschine hat.In the embodiment shown schematically in Figure 1

The heating and cooling machine is the one assigned to the cold working

Da der Luftwärmetauscher 16 der atmosphärischen Luft Wärme entzieht, besteht

die Gefahr, daß bei Lufttemperaturen um den Gefrierpunkt und bei hoher

Luftfeuchtigkeit dieser Luftwärmetauscher 16 einfriert. In diesem Fall würde

bei einem weiteren Betrieb der Maschine auch der kalte Wärmetauscher 15 in

der Maschine einfrieren. Hierdurch würde nicht nur der Gaskreisprozeß beeinträchtigt,

sondern eine derart starke Absenkung der Temperatur im kalten Arbeitsvolumen

7 auftreten, so daß die Gefahr einer Zerstörung der Maschine

besteht. Diese Gefahr entsteht auch dann, wenn beispielsweise durch eine

Störung der Umwälzpumpe 1 5a der Wärmeaustausch im kalten

Wärmetauscher 15 behindert wird.Since the

Um diese Einfriergefahr des Luftwärmetauschers 16 und damit des kalten

Wärmetauschers 15 nicht nur bei Lufttemperaturen um den Gefrierpunkt, sondern

auch beim Ausfall der Umwälzpumpe 15a zu beseitigen, wird das Bypassventil

17a zumindest zeitlich begrenzt geöffnet. Das Prozeßgas wird aufgrund

des geringeren Strömungswiderstandes den Regenerator 12 durch den

Bypass 17 umgehen, so daß dem Prozeßgas im Regenerator 12 keine Wärme

entzogen wird. Da der kalte Wärmetauscher 15 in Reihe zum Regenerator 12

geschaltet ist, wird der kalte Wärmetauscher 15 durch die aus dem warmen

Arbeitsvolumen 7 kommende Wärmemenge auf einer Temperatur oberhalb des

Gefrierpunktes gebracht bzw. gehalten.To this risk of freezing the

Hierdurch wird beim Auftreten von Vereisungen des Luftwärmetauschers 16

dieser abgetaut bzw. vor dem Einfrieren geschützt, vorausgesetzt daß die

Umwälzpumpe 15a arbeitet. Sollte die Umwälzpumpe 15a ausfallen, wodurch

zugleich eine Unterkühlung des Luftwärmetauschers 16 unterbleibt, sorgt die

aus dem warmen Arbeitsraum 7 kommende Wärme dafür, daß bei einer trotz

Ausfalls der Umwälzpumpe 15a weiterbetriebenen Maschine keine

Unterkühlung des kalten Wärmetauschers 15 stattfindet, die zu einer

Zerstörung der Maschine führen würde.As a result, when icing of the

Die Figur 2 zeigt ein Ausführungsbeispiel des Regenerators 12 in einem

Längsschnitt.FIG. 2 shows an embodiment of the

Auf der Zeichnung ist ein Teil des Gehäuses 1 und des kalten Kolbens 3 der

Maschine zu erkennen. Der Regenerator 12 steht mit dem kalten Arbeitsvolumen

6 der Maschine über einen Ringkanal 18 in Verbindung und ist in Reihe

mit dem kalten Wärmetauscher 15 geschaltet, von dem ebenfalls ein Teil in

Figur 2 dargestellt ist. Der in Figur 2 gezeigte Teil des Regenerators 12 ist

weiterhin mit einer Durchgangsöffnung 12a versehen, die durch einen Tauchkolben

19 verschließbar ist. In der Schließstellung füllt der Tauchkolben 19 die

als Bypass wirkende Durchgangsöffnung 12a des Regenerators 12 aus, so

daß sich durch den Bypass kein Totraum im Normalbetrieb der Maschine ergibt.In the drawing, part of the

Der in Verbindung mit der Durchgangsöffnung 12a das Bypassventil bildende

Tauchkolben 19 kann aus seiner in Figur 2 dargestellten Schließstellung entgegen

der Kraft einer Rückstellfeder 21 durch einen Elektromagneten 20 herausbewegt

werden. Diese Freigabestellung und damit die Öffnung des Bypasses

ist gestrichelt in Figur 2 eingezeichnet. In dieser gestrichelten Stellung

wird das Prozeßgas im wesentlichen unter Umgehung des Regenerators 12

dessen Durchgangsöffnung 12a durchströmen, um auf diese Weise ein Einfrieren

des kalten Wärmetauschers 15 und damit des in Figur 2 nicht dargestellten

Luftwärmetauschers 16 zu verhindern. The one forming the bypass valve in connection with the through opening 12a

Plunger 19 can counter from its closed position shown in Figure 2

the force of a

- 11

- Gehäusecasing

- 22nd

- heißer Kolbenhot piston

- 33rd

- kalter Kolbencold flask

- 44th

- heißes Arbeitsvolumenhot working volume

- 55

- BrennkammerCombustion chamber

- 66

- kaltes Arbeitsvolumencold working volume

- 77

- warmes Arbeitsvolumenwarm working volume

- 88th

- Getriebetransmission

- 99

- hohle Kolbenstangehollow piston rod

- 1010th

- KolbenstangePiston rod

- 1111

- Regeneratorregenerator

- 1212th

- Regeneratorregenerator

- 12a12a

- DurchgangsöffnungThrough opening

- 1313

- warmer Wärmetauscherwarm heat exchanger

- 13a13a

- UmwälzpumpeCirculation pump

- 1414

- Heizungheater

- 1515

- kalter Wärmetauschercold heat exchanger

- 15a15a

- UmwälzpumpeCirculation pump

- 1616

- LuftwärmetauscherAir heat exchanger

- 1717th

- Bypassbypass

- 17a17a

- BypassventilBypass valve

- 1818th

- RingkanalRing channel

- 1919th

- TauchkolbenPlunger

- 2020th

- ElektromagnetElectromagnet

- 2121

- RückstellfederReturn spring

Claims (3)

- Heating and refrigerating machine operating in accordance with a regenerative gas cycle, having at least two pistons (2, 3), which separate at least three process spaces (4, 6, 7) from one another with the interposition in each case of at least one heat exchanger (13, 15) and at least one regenerator (11, 12) connected in series with the said heat exchangers, characterized in that at least one of the regenerators (12) assigned to the cold process space (6) is provided with at least one bypass (17) containing a control valve (17a) to vary the amount of heat that is transferred between the process gas and the environment by the cold heat exchanger circuit.

- Heating and refrigerating machine according to Claim 1, characterized in that the bypass line (17) is constructed in the form of a passage opening (12a) in the regenerator (12), this opening being closed at both ends during normal operation of the machine.

- Heating and refrigerating machine according to Claim 1 or 2, characterized in that the bypass line (17) can be closed by a plunger piston (19), which can be moved by an electromagnet (20) counter to the force of a return spring (21).

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19502190 | 1995-01-25 | ||

| DE19502190A DE19502190C2 (en) | 1995-01-25 | 1995-01-25 | Heating and cooling machine |

| PCT/EP1996/000134 WO1996023182A1 (en) | 1995-01-25 | 1996-01-13 | Heat and cold-generating machine |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0805941A1 EP0805941A1 (en) | 1997-11-12 |

| EP0805941B1 true EP0805941B1 (en) | 1999-11-03 |

Family

ID=7752259

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP96900320A Expired - Lifetime EP0805941B1 (en) | 1995-01-25 | 1996-01-13 | Heat and cold-generating machine |

Country Status (8)

| Country | Link |

|---|---|

| US (1) | US6029449A (en) |

| EP (1) | EP0805941B1 (en) |

| JP (1) | JPH11503511A (en) |

| KR (1) | KR19980701775A (en) |

| AT (1) | ATE186391T1 (en) |

| DE (2) | DE19502190C2 (en) |

| ES (1) | ES2139327T3 (en) |

| WO (1) | WO1996023182A1 (en) |

Families Citing this family (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE19746838A1 (en) * | 1997-10-23 | 1999-04-29 | Bosch Gmbh Robert | Operating hot- and cold-energy machine working according to regenerative gas circuit process, especially Vuilleumier heat pump |

| JPH11193967A (en) * | 1997-12-26 | 1999-07-21 | Zexel:Kk | Refrigerating cycle |

| US20060093977A1 (en) * | 2003-07-01 | 2006-05-04 | Pellizzari Roberto O | Recuperator and combustor for use in external combustion engines and system for generating power employing same |

| DE102008009782A1 (en) * | 2008-02-19 | 2009-08-27 | BSH Bosch und Siemens Hausgeräte GmbH | Domestic appliance for drying a moist material with a cooling arrangement and a heating arrangement |

| DE102009023968A1 (en) * | 2009-06-05 | 2010-12-09 | Danfoss Compressors Gmbh | Displacement unit of a Stirling cooling device and Stirling cooling device |

| DE112015000894T5 (en) * | 2014-02-22 | 2016-11-24 | Thermolift Inc. | Thermally operated heat pump with a heat exchanger arranged between displacement bodies |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1275507A (en) * | 1917-01-29 | 1918-08-13 | Rudolph Vuilleumier | Method and apparatus for inducing heat changes. |

| NL7000001A (en) * | 1970-01-02 | 1971-07-06 | ||

| DE2156773C3 (en) * | 1971-11-16 | 1974-09-19 | Motoren Werke Mannheim Ag | Process for load-dependent control of the power of a double-acting hot gas engine |

| DE3536710A1 (en) * | 1985-10-15 | 1987-04-23 | Schneider Christian Dipl Ing | Heat converter and method of operating it |

| US5400599A (en) * | 1991-12-09 | 1995-03-28 | Sanyo Electric Co., Ltd. | Hot gas machine |

| JPH06101922A (en) * | 1992-09-17 | 1994-04-12 | Daikin Ind Ltd | Vuilleumier heat pump apparatus |

-

1995

- 1995-01-25 DE DE19502190A patent/DE19502190C2/en not_active Expired - Fee Related

-

1996

- 1996-01-13 US US08/860,211 patent/US6029449A/en not_active Expired - Fee Related

- 1996-01-13 AT AT96900320T patent/ATE186391T1/en not_active IP Right Cessation

- 1996-01-13 DE DE59603564T patent/DE59603564D1/en not_active Expired - Fee Related

- 1996-01-13 JP JP8522582A patent/JPH11503511A/en active Pending

- 1996-01-13 KR KR1019970705172A patent/KR19980701775A/en active IP Right Grant

- 1996-01-13 WO PCT/EP1996/000134 patent/WO1996023182A1/en active IP Right Grant

- 1996-01-13 EP EP96900320A patent/EP0805941B1/en not_active Expired - Lifetime

- 1996-01-13 ES ES96900320T patent/ES2139327T3/en not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| WO1996023182A1 (en) | 1996-08-01 |

| DE19502190A1 (en) | 1996-08-01 |

| ATE186391T1 (en) | 1999-11-15 |

| ES2139327T3 (en) | 2000-02-01 |

| DE59603564D1 (en) | 1999-12-09 |

| EP0805941A1 (en) | 1997-11-12 |

| DE19502190C2 (en) | 1998-03-19 |

| JPH11503511A (en) | 1999-03-26 |

| KR19980701775A (en) | 1998-06-25 |

| US6029449A (en) | 2000-02-29 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0945291B1 (en) | Means and method for heating and colling a utility space of a motor vehicle | |

| DE10123830A1 (en) | Vehicle air conditioning system uses a heat pump action with the evaporator as the heat source, in the heating mode, for a rapid heating of the interior without loss and heating of the motor to its working temperature | |

| DE60018751T2 (en) | REFRIGERATOR OR FREEZER WITH AIRFLOW CONTROL | |

| EP0216237A2 (en) | Intermittently operating sorption accumulator with a solid-containing absorber | |

| DE3907859C2 (en) | Air-cooled refrigeration unit with a coolant circuit | |

| DE1251493B (en) | ||

| DE102014106725A1 (en) | DRIVE TRAVEL COOLING SYSTEM WITH COOLING AND HEATING MODES FOR HEAT EXCHANGERS | |

| EP0805941B1 (en) | Heat and cold-generating machine | |

| DE2826430A1 (en) | PASSENGER AREA HEATING AND AIR CONDITIONING SYSTEM FOR MOTOR VEHICLES WITH A LOW COOLANT TEMPERATURE ENGINE COOLING SYSTEM | |

| DE10313850B4 (en) | Refrigerant circuit with two-stage compression for a combined refrigeration system and heat pump operation, especially for motor vehicles | |

| EP2321592B1 (en) | Heat pump or refrigeration device and method for operating a heat pump or refrigeration device | |

| DE2923621A1 (en) | THERMAL DRIVE | |

| DE3313371A1 (en) | DEEP TEMPERATURE REFRIGERATOR | |

| DE69120376T2 (en) | Cooling system | |

| DE102007047642B4 (en) | refrigeration machine | |

| DE69611717T2 (en) | Vuillermier free piston machine | |

| DE3803439A1 (en) | Air-conditioning system for a motor vehicle | |

| DE2231769B2 (en) | ||

| DE19913154A1 (en) | Wobble plate Stirling cooler with reduced size and weight and increased cooling performance | |

| DE1501098A1 (en) | System for generating cold at low temperatures and for use in this system well-suited cold gas cooling machine | |

| DE102018002120A1 (en) | Device for tempering filter-cleaned liquid medium | |

| DE2422150C3 (en) | Hot gas piston machine with a device for regulating the weight of the working medium present in a working space | |

| EP1808655A2 (en) | Refrigeration system | |

| DE10163865A1 (en) | Stirling cycle gas cooler has cold finger terminal through which gas is pumped through gas cooler in alternate directions | |

| DE102020110589A1 (en) | Oil collector for a refrigeration circuit |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19970825 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT CH DE ES FR GB IT LI NL |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| 17Q | First examination report despatched |

Effective date: 19990129 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT CH DE ES FR GB IT LI NL |

|

| REF | Corresponds to: |

Ref document number: 186391 Country of ref document: AT Date of ref document: 19991115 Kind code of ref document: T |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: SCINTILLA AG, DIREKTION Ref country code: CH Ref legal event code: EP |

|

| REF | Corresponds to: |

Ref document number: 59603564 Country of ref document: DE Date of ref document: 19991209 |

|

| ET | Fr: translation filed | ||

| ITF | It: translation for a ep patent filed | ||

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2139327 Country of ref document: ES Kind code of ref document: T3 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20000113 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20030117 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20030121 Year of fee payment: 8 Ref country code: AT Payment date: 20030121 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20030123 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20030124 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20030225 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20031231 Year of fee payment: 9 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040113 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040114 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040131 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040131 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040801 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040803 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040930 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 20040801 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050113 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050113 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20040114 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20050113 |