EP0802384A2 - Heat exchanger - Google Patents

Heat exchanger Download PDFInfo

- Publication number

- EP0802384A2 EP0802384A2 EP97103857A EP97103857A EP0802384A2 EP 0802384 A2 EP0802384 A2 EP 0802384A2 EP 97103857 A EP97103857 A EP 97103857A EP 97103857 A EP97103857 A EP 97103857A EP 0802384 A2 EP0802384 A2 EP 0802384A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- heat exchanger

- tube

- transfer fluid

- heat transfer

- heat

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F28—HEAT EXCHANGE IN GENERAL

- F28D—HEAT-EXCHANGE APPARATUS, NOT PROVIDED FOR IN ANOTHER SUBCLASS, IN WHICH THE HEAT-EXCHANGE MEDIA DO NOT COME INTO DIRECT CONTACT

- F28D13/00—Heat-exchange apparatus using a fluidised bed

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F26—DRYING

- F26B—DRYING SOLID MATERIALS OR OBJECTS BY REMOVING LIQUID THEREFROM

- F26B3/00—Drying solid materials or objects by processes involving the application of heat

- F26B3/02—Drying solid materials or objects by processes involving the application of heat by convection, i.e. heat being conveyed from a heat source to the materials or objects to be dried by a gas or vapour, e.g. air

- F26B3/06—Drying solid materials or objects by processes involving the application of heat by convection, i.e. heat being conveyed from a heat source to the materials or objects to be dried by a gas or vapour, e.g. air the gas or vapour flowing through the materials or objects to be dried

- F26B3/08—Drying solid materials or objects by processes involving the application of heat by convection, i.e. heat being conveyed from a heat source to the materials or objects to be dried by a gas or vapour, e.g. air the gas or vapour flowing through the materials or objects to be dried so as to loosen them, e.g. to form a fluidised bed

- F26B3/084—Drying solid materials or objects by processes involving the application of heat by convection, i.e. heat being conveyed from a heat source to the materials or objects to be dried by a gas or vapour, e.g. air the gas or vapour flowing through the materials or objects to be dried so as to loosen them, e.g. to form a fluidised bed with heat exchange taking place in the fluidised bed, e.g. combined direct and indirect heat exchange

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F28—HEAT EXCHANGE IN GENERAL

- F28D—HEAT-EXCHANGE APPARATUS, NOT PROVIDED FOR IN ANOTHER SUBCLASS, IN WHICH THE HEAT-EXCHANGE MEDIA DO NOT COME INTO DIRECT CONTACT

- F28D7/00—Heat-exchange apparatus having stationary tubular conduit assemblies for both heat-exchange media, the media being in contact with different sides of a conduit wall

- F28D7/10—Heat-exchange apparatus having stationary tubular conduit assemblies for both heat-exchange media, the media being in contact with different sides of a conduit wall the conduits being arranged one within the other, e.g. concentrically

- F28D7/12—Heat-exchange apparatus having stationary tubular conduit assemblies for both heat-exchange media, the media being in contact with different sides of a conduit wall the conduits being arranged one within the other, e.g. concentrically the surrounding tube being closed at one end, e.g. return type

Definitions

- the invention relates to a heat exchanger, in particular for use in fluidized bed dryers, with at least one feed and outlet for the heat transfer fluid and at least one heat exchanger tube through which the heat transfer fluid flows, and a fluidized bed dryer.

- Conventional heat exchangers are provided with a plurality of pipes through which the heat transfer fluid flows and which are supplied at one end with heated heat exchange fluid, for example hot water or steam, via a feed with a distribution system. As this fluid passes through the pipes, it gives off part of its heat to the medium flowing around the heat exchanger and is in a cooled state - if steam can also be used in a condensed state - via a collection system and at least one discharge at the other end of the heat exchanger pipes dissipated again.

- heated heat exchange fluid for example hot water or steam

- the transverse distributor pipes form a constriction of the free passage cross-section and, especially when the flow is perpendicular to the distributor level, disturb the flow through the heat exchanger.

- the distribution system forms a significant disturbance in the flow of the the fluidizing fluidizing fluidized bed and thus the fluidized bed itself. Due to the distribution pipes lying in the fluidized bed - aggravated by the narrowing of the flow cross-section - there is a risk of the goods to be dried being packed onto the heat exchanger.

- the object of the present invention was therefore a heat exchanger, the heat exchanger tubes of which are easily accessible for inspection, maintenance and repair and in which the distribution or discharge system for the heat transfer fluid influences the flow through the heat exchanger as little as possible, in particular when the flow is transverse to the distribution or lead system.

- the heat exchanger is said to be particularly suitable for use in the fluidized bed of fluidized-bed dryers in that the flow of the fluidizing medium remains as unobstructed as possible and the material to be dried is prevented from accumulating to a large extent.

- Another object of the invention is an easy-to-maintain or repairable fluidized bed dryer, the fluidized bed flow of which remains as undisturbed as possible and is unhindered by the heat exchanger.

- a heat exchanger of the type mentioned at the outset is characterized in that the or each heat exchanger tube is connected to a supply for heat transfer fluid at only one of its ends and is closed at the other end and contains at least a second tube of smaller diameter in its interior which has at least one opening in the region of the closed end of the heat transfer tube and the other end of which opens into a discharge line.

- each existing heat exchanger tube is from one end for inspection, maintenance and repair, if necessary also for easier replacement, accessible.

- the flow through the heat exchanger is less disturbed due to the lack of distribution systems for the heat transfer fluid at one end of the tubes than in conventional heat exchanger designs.

- the risk of being tackled by the free flow through the free ends of the heat exchanger tubes is largely avoided.

- the inner tube and the subsequent line sections can be kept very small, since it only has to remove slip steam and air.

- the condensed steam is also discharged through the steam supply. If a feed for heat transfer fluid is mentioned below, in the case of hot steam this also means the simultaneous discharge for the condensate. The supply only takes on this one function in the case of non-condensing fluids.

- a second tube is advantageously arranged concentrically in the interior of the heat exchanger tube in order to ensure a uniform heat exchange over the entire surface of the tube.

- the opening of the second tube lies exactly at its end, the plane of the opening preferably being oriented obliquely to the axial direction, the flow of the heat transfer fluid through the heat exchanger tube is ensured over its entire length.

- the possible inclination of the inlet opening into the inner tube permits a stabilizing contact at the end of the inner tube at the end of the heat transfer tube and, in the case of variants with an inflow of the, adjusts the heat exchange cooled heat transfer fluid for its removal also a favorable flow pattern in the pipe safely.

- the second tube is passed through the supply for the heat transfer fluid and opens into a discharge line for the heat transfer fluid or discharge line for air and slip steam parallel to this supply line.

- a plurality of heat exchanger tubes are provided next to one another along a preferably straight supply for heat transfer fluid, possibly also a parallel discharge, by means of which combination or combination of the supply or discharge for the heat transfer fluid / and or air and slip steam further reduces the area of the distribution system and that Flow through the heat exchanger can be improved.

- At least two feeds for heat transfer fluid each lead to a plurality of adjacent heat exchanger tubes in a common manifold.

- the or each heat exchanger tube is essentially vertical and the or each feed and discharge are provided at the lower end of the tube. This enables the heat exchanger with its upper heat exchanger tubes in the fluidized fluidized bed that are free of supply and discharge lines be without the fluidizing flow through the heat exchanger being hindered, the flow area being reduced and the risk of material to be dried being tackled on the heat exchanger being present.

- the second object is achieved by a fluidized bed dryer with a substantially vertical dryer housing and at least one heat exchanger located therein, which is characterized in that this heat exchanger is designed according to one of the preceding paragraphs.

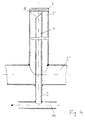

- FIG. 1 shows a conventional heat exchanger in a side view

- FIG. 2 shows a heat exchanger according to the invention in a side view

- FIG. 3 is a top view of the heat exchanger of FIG. 2

- FIG. 4 is an enlarged illustration of a heat exchanger tube in an advantageous embodiment 5 shows a schematic side view of a fluidized bed dryer according to the invention.

- a manifold 1 for supplying hot steam as the heat transfer fluid is provided on the upper side thereof.

- Several straight distribution lines 2 extend laterally from the collecting line 1 and lead the hot steam into essentially vertical heat exchanger tubes 3.

- the upper part of the heat exchanger is located in the region of the fluidized bed W and is to be dried by means of an air flow from below (arrow direction) Well.

- the heat transfer fluid After the heat transfer fluid has given up its thermal energy to this material in the fluidized bed W and has essentially been completely condensed, the heat transfer fluid emerges from several pipes 3 lying next to one another as condensate into lower exhaust lines 4.

- Several exhaust lines 4 open into a lower area of the heat exchanger, common collection drain line 5.

- the manifold 1 'for supplying the heated heat transfer fluid is located in its lower region. Also from this manifold 1 'are laterally essentially horizontal distribution lines 2' which supply several vertically standing heat exchanger tubes 3 '. These tubes 3 ′ are free at their upper end 3 ′′ and, when used in a fluidized bed dryer, protrude into the fluidized bed W with this free end 3 ′′, preferably closed off by a flat plate 6.

- the heat exchanger tube 3 In the interior of the heat exchanger tube 3 'there is concentrically a second tube 7 with an outer diameter which is smaller than that of the heat exchanger tube 3'. After the heat transfer fluid has flowed up in the tube 3 'and thereby released its thermal energy to the material to be dried in the fluidized bed W, it also condenses in the space between the inner tube 7 and the inside of the heat exchanger tube 3'. The condensate gets back into the distribution line 2 'and the collecting line 1', both of which also act as condensate drains here. Hatching steam and / or air enters the inner tube 7 through at least one opening 8 and is guided downwards therein.

- inner tube 7 with an extension 9 passed through the distribution line 2 ' At the lower end of the heat exchanger tube 3 ' second, inner tube 7 with an extension 9 passed through the distribution line 2 '.

- all inner tubes 7 of the heat exchanger tubes 3 'connected to a distributor line 2' are also connected to a common lower derivative 10, which preferably leads below but parallel to the distributor line 2 'to a collecting derivative 11 for air and slip steam .

- This collecting line 11 also preferably runs below the collecting line 1 ', preferably parallel to it.

- a plurality of essentially straight, essentially horizontally lying and parallel distributor lines 2 ' are connected to a collecting line 1' - and also a collecting line 11 '.

- Each of these distribution lines 2 ' carries a plurality of vertical heat exchanger tubes 3', the upper ends of which protrude into the fluidized bed W.

- a single heat exchanger tube 3 'according to the invention is shown on a larger scale in Fig. 4.

- This pipe 3 ' is connected upright to the distribution line 2', welded to it in the simplest manner, and if necessary also attached removably.

- the inlet opening 8 for air or slip steam lies obliquely with respect to the axial direction, the inner tube 7 resting on the inside of the end plate 6 stabilizing the inner tube 7 in the heat transfer tube 3 '.

- the discharge line 10, 11 is of course larger in size and the distribution line 2 ', which now no longer has to serve to return condensate, can be made smaller.

- the inner, second tube 7 is extended through the distribution line 2 'and opens with this extension 9, which extends a little further downward beyond the underside of this line 2', into which the line 2 'is preferably parallel. running discharge line 10 for air or slip steam or cooled heat transfer fluid.

- a fluidized bed dryer with the heat exchanger WT according to the invention for drying the material fluidized in the fluidized bed W is shown schematically by way of example and in FIG.

- the air for fluidization is blown into the tower-shaped, preferably upwardly widening housing 12 of the dryer by means of a supply air fan 13. It passes the heat exchanger WT with its vertically standing heat exchanger tubes 3 ', to which superheated steam is supplied as heat transfer fluid via the manifold 1' and the condensate is removed. Slip vapor and air are discharged via line 10 and then 11.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Microbiology (AREA)

- Heat-Exchange Devices With Radiators And Conduit Assemblies (AREA)

Abstract

Wärmetauscher, insbesondere zur Verwendung in Wirbelschichttrocknern, mit zumindest einer Zuführung 1', 2' und einer Ableitung für das Wärmeträgerfluid und zumindest einem vom Wärmeträgerfluid durchströmten Wärmetauscherrohr 3'. Um die Wärmetauscherrohre 3' gut zugänglich zu machen, und die Strömung durch den Wärmetauscher durch das Verteilungs- oder Ableitsystem für das Wärmeträgerfluid so wenig wie möglich zu beeinflussen, ist vorgesehen, daß das oder jedes Wärmetauscherrohr 3' an lediglich einem seiner Enden mit einer Zuführung 2' für Wärmeträgerfluid verbunden und am anderen Ende 3'' geschlossen ist, in seinem Inneren zumindest ein zweites Rohr 7 mit kleinerem Durchmesser enthält, welches zumindest eine Öffnung 8 im Bereich des geschlossenen Endes 3'' des Wärmeträgerrohres 3' aufweist und dessen anderes Ende 9 in die Ableitung 10, 11 für das Wärmeträgerfluid mündet. Heat exchanger, in particular for use in fluidized bed dryers, with at least one feed 1 ', 2' and a discharge line for the heat transfer fluid and at least one heat exchanger tube 3 'through which the heat transfer fluid flows. In order to make the heat exchanger tubes 3 'easily accessible and to influence the flow through the heat exchanger through the distribution or discharge system for the heat transfer fluid as little as possible, it is provided that the or each heat exchanger tube 3' has only one end with a feed 2 'for heat transfer fluid and is closed at the other end 3'', contains at least a second tube 7 with a smaller diameter in its interior, which has at least one opening 8 in the region of the closed end 3''of the heat transfer tube 3' and the other end thereof 9 opens into the discharge line 10, 11 for the heat transfer fluid.

Description

Die Erfindung betrifft einen Wärmetauscher, insbesondere zur Verwendung in Wirbelschichttrocknern, mit zumindest einer Zuführung und einer Ableitung für das Wärmeträgerfluid und zumindest einem vom Wärmeträgerfluid durchströmten Wärmetauscherrohr, sowie einen Wirbelschichttrockner.The invention relates to a heat exchanger, in particular for use in fluidized bed dryers, with at least one feed and outlet for the heat transfer fluid and at least one heat exchanger tube through which the heat transfer fluid flows, and a fluidized bed dryer.

Konventionelle Wärmetauscher sind mit mehreren vom Wärmeträgerfluid durchströmten Rohren versehen, die über eine Zuführung mit Verteilersystem an einem Ende mit erwärmtem Wärmetauschertluid, beispielsweise Heißwasser oder Dampf, versorgt werden. Während dieses Fluid die Rohre passiert, gibt es einen Teil seiner Wärme an das den Wärmetauscher umströmende Medium ab und wird in abgekühltem Zustand - bei Verwendung von Dampf kann dies auch in kondensiertem Zustand erfolgen - über ein Sammelsystem und zumindest eine Ableitung am anderen Ende der Wärmetauscherrohre wieder abgeführt.Conventional heat exchangers are provided with a plurality of pipes through which the heat transfer fluid flows and which are supplied at one end with heated heat exchange fluid, for example hot water or steam, via a feed with a distribution system. As this fluid passes through the pipes, it gives off part of its heat to the medium flowing around the heat exchanger and is in a cooled state - if steam can also be used in a condensed state - via a collection system and at least one discharge at the other end of the heat exchanger pipes dissipated again.

Durch das an einer Seite der Wärmetauscherrohre vorgesehene Verteilungssystem für das Wärmeträgerfluid sind diese Wärmetauscherrohre beispielsweise für die Reinigung oder Reparatur schlecht zugänglich. Weiters bilden die quer liegenden Verteilerrohre eine Einengung des freien Durchtrittsquerschnittes und speziell bei Durchströmung senkrecht auf die Verteilerebene eine Störung der Strömung durch den Wärmetauscher. Bei Verwendung eines derartigen Wärmetauschers in Wirbelschichttrocknungsanlagen liegt dieser zumindest mit seinem oberen Abschnitt im Wirbelbett, an welches die Wärme des Wärmeträgerfluids abgegeben werden soll. Das Verteilersystem bildet dabei eine erhebliche Störung der Strömung des das Wirbelbett fluidisierenden Mediums und damit des Wirbelbettes selbst. Durch die im Wirbelbett liegenden Verteilerrohre - verschärft durch die Einengung des Durchströmquerschnittes - ist dabei die Gefahr der Anpackung des zu trocknenden Gutes an den Wärmetauscher gegeben.Due to the distribution system for the heat transfer fluid provided on one side of the heat exchanger tubes, these heat exchanger tubes are difficult to access, for example, for cleaning or repair. Furthermore, the transverse distributor pipes form a constriction of the free passage cross-section and, especially when the flow is perpendicular to the distributor level, disturb the flow through the heat exchanger. When using such a heat exchanger in fluidized bed drying plants, this lies at least with its upper section in the fluidized bed to which the heat of the heat transfer fluid is to be given off. The distribution system forms a significant disturbance in the flow of the the fluidizing fluidizing fluidized bed and thus the fluidized bed itself. Due to the distribution pipes lying in the fluidized bed - aggravated by the narrowing of the flow cross-section - there is a risk of the goods to be dried being packed onto the heat exchanger.

Die Aufgabe der vorliegenden Erfindung war daher ein Wärmetauscher, dessen Wärmetauscherrohre zur Inspektion, Wartung und Reparatur gut zugänglich sind und bei dem das Verteilungs- oder Ableitsystem für das Wärmeträgerfluid die Strömung durch den Wärmetauscher so wenig wie möglich beeinflußt, insbesondere bei Durchströmung quer zum Verteilungs- oder Ableitsystem. Der Wärmetauscher soll besonders geeignet für die Verwendung in der Wirbelschicht von Wirbelschichttrocknern sein, indem die Strömung des fluidisierenden Mediums so ungehindert wie möglich bleibt und Anpackungen des zu trocknenden Gutes weitgehende verhindert werden. Eine weitere Aufgabe der Erfindung ist ein einfach zu wartender bzw. reparierbarer Wirbelschichttrockner, dessen Wirbelschichtströmung möglichst ungestört und durch den Wärmetauscher ungehindert bleibt.The object of the present invention was therefore a heat exchanger, the heat exchanger tubes of which are easily accessible for inspection, maintenance and repair and in which the distribution or discharge system for the heat transfer fluid influences the flow through the heat exchanger as little as possible, in particular when the flow is transverse to the distribution or lead system. The heat exchanger is said to be particularly suitable for use in the fluidized bed of fluidized-bed dryers in that the flow of the fluidizing medium remains as unobstructed as possible and the material to be dried is prevented from accumulating to a large extent. Another object of the invention is an easy-to-maintain or repairable fluidized bed dryer, the fluidized bed flow of which remains as undisturbed as possible and is unhindered by the heat exchanger.

Zur Lösung der ersten Aufgabe ist ein Wärmetauscher der eingangs angeführten Art erfindungsgemäß dadurch gekennzeichnet, daß das oder jedes Wärmetauscherrohr an lediglich einem seiner Enden mit einer Zuführung für Wärmeträgerfluid verbunden und am anderen Ende geschlossen ist, in seinem Inneren zumindest ein zweites Rohr mit kleinerem Durchmesser enthält, welches zumindest eine Öffnung im Bereich des geschlossenen Endes des Wärmeträgerrohres aufweist und dessen anderes Ende in eine Ableitung mündet. Damit ist jedes vorhandene Wärmetauscherrohr von einem Ende her für die Inspektion, Wartung und Reparatur, allenfalls auch für einen leichteren Austausch, zugänglich. Die Strömung durch den Wärmetauscher ist aufgrund an einem Ende der Rohre fehlender Verteilersysteme für das Wärmeträgerfluid weniger gestört als bei herkömmlichen Wärmetauscherkonstruktionen. Bei Verwendung des erfindungsgemäßen Wärmetauschers in einem Wirbelschichttrockner ist die Gefahr des Anpackens durch die freie Durchströmbarkeit um die freien Enden der Wärmetauscherrohre weitestgehend vermieden. Bei Verwendung von heißem Dampf als Wärmeträgerfluid können das innere Rohr und die nachfolgenden Leitungsabschnitte sehr klein gehalten werden, da es nur Schlupfdampf und Luft abführen muß. Der kondensierte Dampf wird hier durch die Dampfzuführung auch wieder abgeleitet. Wenn im folgenden von einer Zuführung für Wärmeträgerfluid die Rede ist, ist im Fall von heißem Dampf damit auch die gleichzeitige Ableitung für das Kondensat gemeint. Nur bei nicht kondensierenden Fluids übernimmt die Zuführung nur diese eine Funktion.To solve the first problem, a heat exchanger of the type mentioned at the outset is characterized in that the or each heat exchanger tube is connected to a supply for heat transfer fluid at only one of its ends and is closed at the other end and contains at least a second tube of smaller diameter in its interior which has at least one opening in the region of the closed end of the heat transfer tube and the other end of which opens into a discharge line. This means that each existing heat exchanger tube is from one end for inspection, maintenance and repair, if necessary also for easier replacement, accessible. The flow through the heat exchanger is less disturbed due to the lack of distribution systems for the heat transfer fluid at one end of the tubes than in conventional heat exchanger designs. When using the heat exchanger according to the invention in a fluidized bed dryer, the risk of being tackled by the free flow through the free ends of the heat exchanger tubes is largely avoided. When using hot steam as the heat transfer fluid, the inner tube and the subsequent line sections can be kept very small, since it only has to remove slip steam and air. The condensed steam is also discharged through the steam supply. If a feed for heat transfer fluid is mentioned below, in the case of hot steam this also means the simultaneous discharge for the condensate. The supply only takes on this one function in the case of non-condensing fluids.

Vorteilhafterweise ist ein zweites Rohr konzentrisch im Inneren des Wärmetauscherrohres angeordnet, um einen gleichmäßigen Wärmeaustausch über die gesamte Oberfläche des Rohres sicherzustellen.A second tube is advantageously arranged concentrically in the interior of the heat exchanger tube in order to ensure a uniform heat exchange over the entire surface of the tube.

Wenn die Öffnung des zweiten Rohres genau an dessen Ende liegt, wobei die Ebene der Öffnung vorzugsweise schräg auf die Achsrichtung orientiert ist, ist die Strömung des Wärmeträgerfluids durch das Wärmetauscherrohr über dessen gesamte Länge sichergestellt. Die allfällige Schrägstellung der Eintrittsöffnung in das innere Rohr gestattet ein stabilisierendes Anliegen am Ende des inneren Rohres am Ende des Wärmeträgerrohres und stellt bei Varianten mit Einströmung des nach dem Wärmetausch abgekühlten Wärmeträgerfluids zu dessen Abfuhr überdies ein günstiges Strömungsbild im Rohr sicher.If the opening of the second tube lies exactly at its end, the plane of the opening preferably being oriented obliquely to the axial direction, the flow of the heat transfer fluid through the heat exchanger tube is ensured over its entire length. The possible inclination of the inlet opening into the inner tube permits a stabilizing contact at the end of the inner tube at the end of the heat transfer tube and, in the case of variants with an inflow of the, adjusts the heat exchange cooled heat transfer fluid for its removal also a favorable flow pattern in the pipe safely.

Gemäß einem weiteren Erfindungsmerkmal ist vorgesehen, daß das zweite Rohr durch die Zuführung für das Wärmeträgerfluid hindurch geführt ist und in eine zu dieser Zuführung parallele Ableitung für das Wärmeträgerfluid oder Ableitung für Luft und Schlupfdampf mündet. Damit ist eine relativ einfache und stabile Ausführung gegeben.According to a further feature of the invention, it is provided that the second tube is passed through the supply for the heat transfer fluid and opens into a discharge line for the heat transfer fluid or discharge line for air and slip steam parallel to this supply line. This provides a relatively simple and stable design.

Vorteilhafterweise sind mehrere Wärmetauscherrohre nebeneinander entlang einer vorzugsweise geraden Zuführung für Wärmeträgerfluid, allenfalls auch einer parallelen Ableitung, vorgesehen, durch welche Kombination bzw. Zusammenfassung der Zu- bzw. Ableitung für das Wärmeträgerfluid/und oder Luft und Schlupfdampf die Fläche der Verteilersystem nochmals verkleinert und die Durchströmung des Wärmetauschers verbessert werden kann.Advantageously, a plurality of heat exchanger tubes are provided next to one another along a preferably straight supply for heat transfer fluid, possibly also a parallel discharge, by means of which combination or combination of the supply or discharge for the heat transfer fluid / and or air and slip steam further reduces the area of the distribution system and that Flow through the heat exchanger can be improved.

Um eine weitere Vereinfachung und Flächenverminderung des Wärmeträgerfluidsystems zu erzielen, münden gemäß einem weiteren Merkmal der Erfindung zumindest zwei Zuführungen für Wärmeträgerfluid, allenfalls auch parallele Ableitungen, für jeweils mehrere nebeneinanderliegende Wärmetauscherrohre in eine gemeinsame Sammelleitung.In order to further simplify and reduce the area of the heat transfer fluid system, according to a further feature of the invention, at least two feeds for heat transfer fluid, possibly also parallel discharges, each lead to a plurality of adjacent heat exchanger tubes in a common manifold.

Zur optimalen Verwendung in einem Wirbelschichttrockner ist das oder jedes Wärmetauscherrohr im wesentlichen vertikal stehend und sind die bzw. jede Zuführung und Ableitung am unteren Ende des Rohres vorgesehen. Damit kann der Wärmetauscher mit seinem oberen, von Zu- bzw Ableitungen freien Wärmetauscherrohren im fluidisierten Wirbelbett sein, ohne daß die fluidisierende Strömung durch den Wärmetauscher behindert, die Durchströmungsfläche verkleinert und die Gefahr des Anpackens von zu trocknendem Gut am Wärmetauscher gegeben ist.For optimal use in a fluidized bed dryer, the or each heat exchanger tube is essentially vertical and the or each feed and discharge are provided at the lower end of the tube. This enables the heat exchanger with its upper heat exchanger tubes in the fluidized fluidized bed that are free of supply and discharge lines be without the fluidizing flow through the heat exchanger being hindered, the flow area being reduced and the risk of material to be dried being tackled on the heat exchanger being present.

Die zweite genannte Aufgabe wird durch einen Wirbelschichttrockner mit einem im wesentlichen vertikalen Trocknergehäuse und zumindest einem darin befindlichen Wärmetauscher gelöst, der dadurch gekennzeichnet ist, daß dieser Wärmetauscher gemäß einem der vorhergehenden Absätze ausgebildet ist.The second object is achieved by a fluidized bed dryer with a substantially vertical dryer housing and at least one heat exchanger located therein, which is characterized in that this heat exchanger is designed according to one of the preceding paragraphs.

In der nachfolgenden Beschreibung soll die Erfindung, weitere Merkmale und Vorteile unter Bezugnahme auf die beigefügten Zeichnungen näher erläutert werden.In the following description, the invention, further features and advantages will be explained in more detail with reference to the accompanying drawings.

Dabei zeigt Fig. 1 einen herkömmlichen Wärmetauscher in der Seitenansicht, Fig. 2 stellt einen erfindungsgemäßen Wärmetauscher in der Seitenansicht, Fig. 3 ist eine Draufsicht auf den Wärmetauscher der Fig. 2, Fig. 4 ist eine vergrößerte Darstellung eines Wärmetauscherrohres in einer vorteilhaften Ausführungsform gemäß der Erfindung und Fig. 5 zeigt eine schematische Seitenansicht eines erfindungsgemäßen Wirbelschichttrockners.1 shows a conventional heat exchanger in a side view, FIG. 2 shows a heat exchanger according to the invention in a side view, FIG. 3 is a top view of the heat exchanger of FIG. 2, FIG. 4 is an enlarged illustration of a heat exchanger tube in an

Beim herkömmlichen Wärmetauscher der Fig. 1 ist an dessen Oberseite eine Sammelleitung 1 zur Zuführung von heißem Dampf als Wärmeträgerfluid vorgesehen. Mehrere gerade Verteilerleitungen 2 gehen seitlich von der Sammelleitung 1 ab und führen den heißen Dampf in im wesentlichen vertikale Wärmetauscherrohre 3. Der obere Teil des Wärmetauschers liegt im Bereich der Wirbelschicht W aus mittels einer Luftströmung von unten her (Pfeilrichtung) fluidisiertem, zu trocknendem Gut. Nachdem das Wärmeträgerfluid seine Wärmeenergie an diese Gut in der Wirbelschicht W abgegeben hat und dabei im wesentlichen vollständig kondensiert wurde, tritt das Wärmeträgerfluid aus mehreren nebeneinanderliegenden Rohren 3 als Kondensat in untere Abzugsleitungen 4. Mehrere Abzugsleitungen 4 münden in eine im unteren Bereich des Wärmetauschers liegende, gemeinsame Sammel-Abzugsleitung 5.In the conventional heat exchanger of FIG. 1, a

Beim erfindungsgemäßen Wärmetauscher gemäß der in Fig. 2 dargestellten Ausführungsform befindet sich die Sammelleitung 1' zur Zuführung des erwärmten Wärmeträgerfluids in dessen unterem Bereich. Auch von dieser Sammelleitung 1' gehen seitlich im wesentlichen horizontal liegende Verteilerleitungen 2' aus, die mehrere vertikal stehende Wärmetauscherrohre 3' versorgen. Diese Rohre 3' sind an ihrem oberen Ende 3'' frei und ragen bei der Verwendung in einem Wirbelschichttrockner mit diesem freien Ende 3'', vorzugsweise durch eine ebene Platte 6 abgeschlossen, in die Wirbelschicht W hinein.In the heat exchanger according to the invention in accordance with the embodiment shown in FIG. 2, the manifold 1 'for supplying the heated heat transfer fluid is located in its lower region. Also from this manifold 1 'are laterally essentially horizontal distribution lines 2' which supply several vertically standing heat exchanger tubes 3 '. These

Im Inneren des Wärmetauscherrohres 3' befindet sich konzentrisch ein zweites Rohr 7 mit gegenüber dem Wärmetauscherrohr 3' kleinerem Außendurchmesser. Nachdem das Wärmeträgerfluid im Rohr 3' hochgeströmt ist und dabei seine Wärmeenergie an das zu trocknende Gut in der Wirbelschicht W abgegeben hat, kondensiert es auch im Zwischenraum zwischen dem inneren Rohr 7 und der Innenseite des Wärmetauscherrohres 3'. Das Kondensat gelangt zurück in die Verteilerleitung 2' und die Sammelleitung 1', die beide hier auch als Kondensatableitungen fungieren. Schlupfdampf und/oder Luft tritt durch zumindest eine Öffnung 8 in das innere Rohr 7 ein und wird darin nach unten geführt. Am unteren Ende des Wärmetauscherrohres 3' ist das zweite, innere Rohr 7 mit einer Verlängerung 9 durch die Verteilerleitung 2' hindurchgeführt. Vorzugsweise sind zur baulichen und regeltechnischen Vereinfachung alle inneren Rohre 7 der an einer Verteilerleitung 2' angeschlossenen Wärmetauscherrohre 3' auch an eine gemeinsame untere Ableitung 10 angeschlossen, die vorzugsweise unterhalb aber parallel der Verteilerleitung 2' zu einer Sammel-Ableitung 11 für Luft und Schlupfdampf führt. Auch diese Sammel-Ableitung 11 verläuft vorzugsweise unterhalb der Sammelleitung 1', vorzugsweise parallel zu dieser.In the interior of the heat exchanger tube 3 'there is concentrically a

Bei Verwendung von nicht kondensierenden Wärmeträgerfluids treten diese nach dem Wärmetausch durch die Öffnung 8 in des innere Rohr 7 ein und strömen zum unteren Ende dieses Rohres 7, weiter durch die Verlängerung 9, in die Ableitung 10 und schließlich in die Sammel-Ableitung 11.If non-condensing heat transfer fluids are used, they enter the

Wie in der Draufsicht in Fig. 3 dargestellt ist, sind an eine Sammelleitung 1' - und auch eine Sammel-Ableitung 11 - vorzugsweise mehrere im wesentlichen gerade, im wesentlichen horizontal liegende und parallele Verteilerleitungen 2' angeschlossen. Jede dieser Verteilerleitungen 2' trägt mehrere senkrecht stehende Wärmetauscherrohre 3', deren obere Enden in die Wirbelschicht W ragen.As shown in the plan view in FIG. 3, a plurality of essentially straight, essentially horizontally lying and parallel distributor lines 2 'are connected to a collecting line 1' - and also a collecting line 11 '. Each of these distribution lines 2 'carries a plurality of vertical heat exchanger tubes 3', the upper ends of which protrude into the fluidized bed W.

Ein einzelnes erfindungsgemäßes Wärmetauscherrohr 3' ist in größerem Maßstab in Fig. 4 dargestellt. Dieses Rohr 3' ist stehend an die Verteilerleitung 2' angeschlossen, in einfachster Weise daran angeschweißt, allenfalls auch abnehmbar befestigt. Am oberen Ende befindet sich eine der Einfachheit halber ebene Endplatte 6, die meist in einfacher Weise ebenfalls angeschweißt ist. Die Eintrittsöffnung 8 für Luft oder Schlupfdampf liegt gegenüber der Achsrichtung schräg, wobei durch das Anliegen des inneren Rohres 7 an der Innenseite der Endplatte 6 eine Stabilisierung des inneren Rohres 7 im Wärmeträgerrohr 3' erzielt ist.A single heat exchanger tube 3 'according to the invention is shown on a larger scale in Fig. 4. This pipe 3 'is connected upright to the distribution line 2', welded to it in the simplest manner, and if necessary also attached removably. At the upper end there is a

Wenn ein nicht kondensierendes Wärmeträgerfluid, beispielsweise Warmwasser, verwendet wird, ist die Ableitung 10, 11 natürlich größer zu dimensionieren und dafür kann die Verteilerleitung 2', welche nun nicht mehr dem Rücktransport von Kondensat dienen muß, kleiner ausgeführt werden. An seinem unteren Ende ist das innere, zweite Rohr 7 durch die Verteilerleitung 2' hindurch verlängert und mündet mit dieser Verlängerung 9, die über die Unterseite dieser Leitung 2' hinaus noch ein Stück weiter nach unten reicht, in die vorzugsweise parallel der Leitung 2' verlaufende Ableitung 10 für Luft oder Schlupfdampf bzw. abgekühltes Wärmeträgerfluid.If a non-condensing heat transfer fluid, for example hot water, is used, the

Schließlich ist in Fig. 5 beispielhaft und schematisch ein Wirbelschichttrockner mit dem erfindungsgemäßen Wärmetauscher WT zur Trocknung des in der Wirbelschicht W fluidisierten Gutes dargestellt. Die Luft zur Fluidisierung wird in das turmförmige, sich vorzugsweise nach oben erweiternde Gehäuse 12 des Trockners mittels eines Zuluftventilators 13 eingeblasen. Es passiert den Wärmetauscher WT mit seinen vertikal stehenden Wärmetauscherrohren 3', denen über die Sammelleitung 1' Heißdampf als Wärmeträgerfluid zugeführt und das Kondensat abgeführt wird. Über die Leitung 10 und anschließend 11 wird Schlupfdampf und Luft abgeleitet.Finally, a fluidized bed dryer with the heat exchanger WT according to the invention for drying the material fluidized in the fluidized bed W is shown schematically by way of example and in FIG. The air for fluidization is blown into the tower-shaped, preferably upwardly widening

Claims (8)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT693/96 | 1996-04-17 | ||

| AT0069396A AT405685B (en) | 1996-04-17 | 1996-04-17 | HEAT EXCHANGER |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0802384A2 true EP0802384A2 (en) | 1997-10-22 |

| EP0802384A3 EP0802384A3 (en) | 1999-03-10 |

Family

ID=3497337

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP97103857A Withdrawn EP0802384A3 (en) | 1996-04-17 | 1997-03-07 | Heat exchanger |

Country Status (3)

| Country | Link |

|---|---|

| US (1) | US5940987A (en) |

| EP (1) | EP0802384A3 (en) |

| AT (1) | AT405685B (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP2505949A3 (en) * | 2011-04-01 | 2014-07-30 | H S Beratung GmbH & Co. KG | Dryer and method for drying wet raw materials |

| WO2023104401A1 (en) * | 2021-12-09 | 2023-06-15 | Andritz Technology And Asset Management Gmbh | Heat exchanger element and use thereof |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2003001334A2 (en) * | 2001-06-22 | 2003-01-03 | Wonderware Corporation | Remotely monitoring / diagnosing distributed components of a supervisory process control and manufacturing information application from a central location |

| JP5050241B2 (en) * | 2007-01-29 | 2012-10-17 | 株式会社Kelk | Fluid temperature controller |

| RU2484404C2 (en) * | 2010-03-29 | 2013-06-10 | Государственное образовательное учреждение высшего профессионального образования "Воронежский государственный технический университет" | Heat exchange method of gaseous media |

| RU2484403C2 (en) * | 2010-03-29 | 2013-06-10 | Государственное образовательное учреждение высшего профессионального образования "Воронежский государственный технический университет" | Regenerative heat exchanger |

| DE102011014131A1 (en) * | 2011-03-15 | 2012-09-20 | Thyssenkrupp Uhde Gmbh | Process for drying moist polymer powder and apparatus suitable therefor |

| US10094595B1 (en) * | 2012-05-10 | 2018-10-09 | Lockheed Martin Corporation | Solar heat collector |

| US11614287B2 (en) | 2021-06-24 | 2023-03-28 | Darby Renewable Energy Design Systems Inc. | Heat exchanger |

Family Cites Families (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE231602C (en) * | ||||

| GB1391430A (en) * | 1971-06-23 | 1975-04-23 | Ici Ltd | Tubular heat exchanger and use thereof in fluidised beds |

| GB1525222A (en) * | 1973-05-05 | 1978-09-20 | Pearce A | Fluidised beds |

| FR2308052A1 (en) * | 1975-04-18 | 1976-11-12 | Commissariat Energie Atomique | PLUNGE TUBE HEAT EXCHANGER |

| US3982901A (en) * | 1975-06-25 | 1976-09-28 | Dorr-Oliver Incorporated | Heat transfer element and tuyere for fluidized bed reactor |

| US4290387A (en) * | 1979-10-04 | 1981-09-22 | Curtiss-Wright Corporation | Fluidized bed combustor and tube construction therefor |

| JPS5677692A (en) * | 1979-11-27 | 1981-06-26 | Toyo Eng Corp | Heat exchanger |

| US4452233A (en) * | 1982-03-04 | 1984-06-05 | Goodman Jr Maurice | Solar energy collector |

| AU558049B2 (en) * | 1982-10-08 | 1987-01-15 | Asea Stal Aktiebolag | Collection of spent material and fly ash from a pressurised fluidised bed combustor |

| US4882283A (en) * | 1987-11-17 | 1989-11-21 | Phillips Petroleum Company | Heat exchange apparatus |

| SE464781B (en) * | 1989-06-21 | 1991-06-10 | Nonox Eng Ab | DEVICE FOR INDIRECT HEATING OF HIGH PRESSURE TO HIGH TEMPERATURE AND USE OF THE DEVICE |

| DE4008903A1 (en) * | 1990-03-20 | 1991-09-26 | Kloeckner Humboldt Deutz Ag | METHOD AND DEVICE FOR DRYING DAMP MATERIALS IN A FLUIDIZED BED |

| US5353864A (en) * | 1993-03-01 | 1994-10-11 | Fmc Corporation | Mass flow cooler |

-

1996

- 1996-04-17 AT AT0069396A patent/AT405685B/en not_active IP Right Cessation

-

1997

- 1997-03-07 EP EP97103857A patent/EP0802384A3/en not_active Withdrawn

- 1997-04-14 US US08/843,303 patent/US5940987A/en not_active Expired - Fee Related

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP2505949A3 (en) * | 2011-04-01 | 2014-07-30 | H S Beratung GmbH & Co. KG | Dryer and method for drying wet raw materials |

| WO2023104401A1 (en) * | 2021-12-09 | 2023-06-15 | Andritz Technology And Asset Management Gmbh | Heat exchanger element and use thereof |

Also Published As

| Publication number | Publication date |

|---|---|

| US5940987A (en) | 1999-08-24 |

| AT405685B (en) | 1999-10-25 |

| EP0802384A3 (en) | 1999-03-10 |

| ATA69396A (en) | 1999-02-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE3507981A1 (en) | HEAT EXCHANGER WITH ISOLATED EVAPORATION AND CONDENSATION ZONES | |

| DE19648128C2 (en) | Grate for a furnace | |

| EP0943435B1 (en) | Cooling cylinder | |

| EP0768424A2 (en) | Heated roll | |

| CH640631A5 (en) | HEAT EXCHANGER. | |

| AT405685B (en) | HEAT EXCHANGER | |

| DE1942157A1 (en) | Air-cooled condenser | |

| DE1958885B2 (en) | DEVICE FOR DRYING AND OVERHEATING OF WET STEAM IN STEAM POWER PLANTS | |

| EP0157920B1 (en) | Roll for a roller grate, for example for a refuse burning plant or the like | |

| DE2405999B2 (en) | NATURAL ZUG DRY COOLING TOWER | |

| DE19518323A1 (en) | Heat exchange between process and cooling fluids | |

| EP0123986A1 (en) | Feed-water heater | |

| DE2522070A1 (en) | ROLLED GOODS GUIDE FOR A ROLLING STAND | |

| DE2524080C3 (en) | Heat exchanger in which a vaporous medium condenses while giving off heat to another medium | |

| DE3016981C2 (en) | ||

| DE2712794C2 (en) | Horizontal axis steam superheater for supplying a high-performance turbine | |

| DE20010671U1 (en) | Heat exchangers for free-flowing solids | |

| CH662638A5 (en) | HEAT TRANSFER SYSTEM, PREFERRED FOR A PROCESS GAS. | |

| EP0097989B1 (en) | High pressure feedwater heater disposed upright in a header construction with a desuperheater and a steam-water separator | |

| DE102006053812B4 (en) | Pipe support with integrated cleaning device | |

| DE1078146B (en) | Heat exchanger with elements arranged in a row next to one another and connected via a common distribution or collecting channel provided with guide devices | |

| EP1191282A1 (en) | Cooled grate bar | |

| DE3908277A1 (en) | Erosion protection for heat exchangers | |

| DE3148132C2 (en) | Heat exchangers, especially upright feed water preheaters with steam separators | |

| DE2816293A1 (en) | COOLING TOWER |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): DE ES FR GB IT |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): DE ES FR GB IT |

|

| 17P | Request for examination filed |

Effective date: 19990719 |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: ANDRITZ AG |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 20011002 |