EP0787458A2 - Flüssigkeitsausgabevorrichtung - Google Patents

Flüssigkeitsausgabevorrichtung Download PDFInfo

- Publication number

- EP0787458A2 EP0787458A2 EP97107840A EP97107840A EP0787458A2 EP 0787458 A2 EP0787458 A2 EP 0787458A2 EP 97107840 A EP97107840 A EP 97107840A EP 97107840 A EP97107840 A EP 97107840A EP 0787458 A2 EP0787458 A2 EP 0787458A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- section

- actuating arm

- pouch

- check valve

- actuator

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47K—SANITARY EQUIPMENT NOT OTHERWISE PROVIDED FOR; TOILET ACCESSORIES

- A47K5/00—Holders or dispensers for soap, toothpaste, or the like

- A47K5/06—Dispensers for soap

- A47K5/12—Dispensers for soap for liquid or pasty soap

- A47K5/122—Dispensers for soap for liquid or pasty soap using squeeze bottles or the like

Definitions

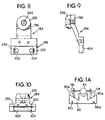

- the lower check valve actuator is mounted to the actuating arm which will cause a delay of the closing of the lower check valve, during retraction of the actuating arm, by restricting the action of the lever arms which stretch closed the discharge port.

- Tensioning pins are used as the lever arms.

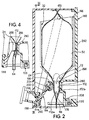

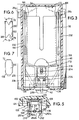

- the actuating arm 24 is pivotably connected to the front cover 14, near its top at pin connectors 28a, 28b (see Figure 6). Inside the dispenser 10 between the front cover 14 and the back plate 12 is located an elongated conical trough 32 having a wide open top end 34, generally straight sides 36, a cone section 38 and a bottom opening 40. The trough 32 is supported in the dispenser by clips 44 attached to the back plate 12.

- a film pouch 48 Placed within the trough 32 is a film pouch 48 having a sealed top end 50, a liquid containing volume or straight section 52, a generally conical section 58 below the straight section 52, and a cylindrical pathway 60 terminating in a narrow channel section 62 having an aperture 64 at its terminal end.

- a tube 70 Mounted within the cylindrical pathway 60 is a tube 70 having a sufficient thickness to retain a structural memory after collapsing. That is, the tube will spring back to its tubular shape after being compressed.

- Figure 2 illustrates another embodiment of the dispenser 10 described with regard to Figure 1, referred to as dispenser 160.

- the trough 32 is supported within the dispenser 160 by a plurality of clips 166.

- a film pouch 170 is similar to the film pouch 48 except for a substantially shorter polymeric tube 172 located therein.

- the tube 172 provides V-shaped notches 72 at a top end thereof and notches 178 at a bottom end thereof.

- a front portion of the tube 172 has a shorter length than a rear portion 172b.

- Figure 5 illustrates the functioning of the check valve 106.

- the pins 116, 118 are shown extended through the holes 136, 138 in the narrow channel section 62 of the pouch.

- the pins have annular slots 262a, 262b to hold the narrow channel section 62 thereon.

- the pins have distal ends 280, 282 with surfaces 280a, 282a tapered outwardly.

- FIGS 6 and 7 illustrate the tubular section 260 that is used in the present invention.

- V-shaped notches are formed both in the top section and the bottom section.

- an angle B is provided for the V-shaped notches.

- One actuator of the system of the present invention has several features which achieve these inventive advantages.

- the portion of the pump actuator arm at its upper end described as the upper check valve actuator tip portion, progressively engages and compresses the upstream end of the pump tube against a "pump anvil" projection on the dispenser back molding.

- the progressive engagement involves slidably engaging the contoured surfaces of the anvil and the tip in a manner which utilizes the physical properties of the polymer that is used to mold the actuator (high memory, low set retention) and the contoured shapes of the two parts in a rolling, wedging effect, rather than a knife effect. Because of the engagement, a reduced resistance to the closing of the pump sleeve is achieved by the unique notching at the point of engagement with the tip and anvil.

Landscapes

- Health & Medical Sciences (AREA)

- Public Health (AREA)

- Reciprocating Pumps (AREA)

- Beverage Vending Machines With Cups, And Gas Or Electricity Vending Machines (AREA)

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP93104544A EP0615717B1 (de) | 1992-01-27 | 1993-03-19 | Flüssigkeitsausgabevorrichtung |

Related Parent Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP93104544.7 Division | 1993-03-19 | ||

| EP93104544A Division EP0615717B1 (de) | 1992-01-27 | 1993-03-19 | Flüssigkeitsausgabevorrichtung |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0787458A2 true EP0787458A2 (de) | 1997-08-06 |

| EP0787458A3 EP0787458A3 (de) | 1997-08-13 |

Family

ID=8212718

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP97107839A Withdrawn EP0787457A3 (de) | 1993-03-19 | 1993-03-19 | Flüssigkeitsausgabevorrichtung |

| EP97107840A Withdrawn EP0787458A3 (de) | 1993-03-19 | 1993-03-19 | Flüssigkeitsausgabevorrichtung |

Family Applications Before (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP97107839A Withdrawn EP0787457A3 (de) | 1993-03-19 | 1993-03-19 | Flüssigkeitsausgabevorrichtung |

Country Status (2)

| Country | Link |

|---|---|

| EP (2) | EP0787457A3 (de) |

| DE (1) | DE69315552T2 (de) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US8387832B2 (en) | 2009-03-06 | 2013-03-05 | Gojo Industries, Inc. | Dispenser housing |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4349133A (en) * | 1979-09-12 | 1982-09-14 | Christine William C | Dispenser and refill package |

| FR2518505A1 (fr) * | 1981-12-17 | 1983-06-24 | Tellier Ets L | Appareil de distribution de portions de produits liquides epais |

| US4667854A (en) * | 1985-04-19 | 1987-05-26 | Ecolab Inc. | Liquid dispenser |

| US4932562A (en) * | 1988-04-29 | 1990-06-12 | Triparte, Ltd. | Liquid dispensing system |

| CH677092A5 (en) * | 1988-07-29 | 1991-04-15 | Essilor Int | Manual dispenser for small vol. of sterile liquids - includes flexible bag holding liq. which collapses as liq. is removed to prevent ingress of non-sterile ambient air |

-

1993

- 1993-03-19 EP EP97107839A patent/EP0787457A3/de not_active Withdrawn

- 1993-03-19 EP EP97107840A patent/EP0787458A3/de not_active Withdrawn

- 1993-03-19 DE DE1993615552 patent/DE69315552T2/de not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| DE69315552D1 (de) | 1998-01-15 |

| EP0787457A2 (de) | 1997-08-06 |

| DE69315552T2 (de) | 1998-07-02 |

| EP0787457A3 (de) | 1997-08-13 |

| EP0787458A3 (de) | 1997-08-13 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US5242083A (en) | Liquid dispensing system having a liquid reservoir | |

| US4130224A (en) | Viscous liquid dispenser | |

| US3881641A (en) | Dispensing device | |

| US4256242A (en) | Dispenser having a roller for squeezing amounts from a tube | |

| EP2731486B1 (de) | Absperrsystem für einen spender | |

| JPS6340093B2 (de) | ||

| US4235353A (en) | Trigger operated dispensing device with accumulating chamber | |

| US5016779A (en) | Apparatus for dispensing measured amounts of fluid from an open-ended pouch | |

| US4004717A (en) | Pressure fed liquid dispenser | |

| DE69410783T2 (de) | Flüssigkeitsspender | |

| US3758005A (en) | Dispensing system | |

| WO2000040131A1 (en) | Antiseptic soap dispenser with selectively variable dose | |

| JP2001113210A (ja) | 媒体を容器から任意選択的に噴霧して吐出するためのディスペンサ | |

| JPH1170357A (ja) | アプリケータ | |

| US4228926A (en) | Dispensing viscous fluids | |

| US4546904A (en) | Dispenser and package for liquid or granular materials | |

| EP1711094B1 (de) | Spender | |

| US4778085A (en) | Peristaltic fluid dispenser | |

| EP0787458A2 (de) | Flüssigkeitsausgabevorrichtung | |

| AU662044B2 (en) | Liquid dispensing system | |

| US5195660A (en) | Clamping type caulking gun | |

| US20020162855A1 (en) | Dispensing device for flowable material | |

| US10321791B2 (en) | Manually activated dispensers for squeezable bottles | |

| JPH06299969A (ja) | 液体分散システム | |

| US2556980A (en) | Housing enclosing paste container, having container-puncturing and destroying means, and paste extruder and outlet controller with common actuator |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AC | Divisional application: reference to earlier application |

Ref document number: 615717 Country of ref document: EP |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): BE CH DE DK FR GB IT LI NL SE |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): BE CH DE DK FR GB IT LI NL SE |

|

| 17P | Request for examination filed |

Effective date: 19980114 |

|

| 17Q | First examination report despatched |

Effective date: 20011102 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 20030108 |