EP0766945B1 - Device for washing the ceiling of a dishwasher's tank - Google Patents

Device for washing the ceiling of a dishwasher's tank Download PDFInfo

- Publication number

- EP0766945B1 EP0766945B1 EP96830502A EP96830502A EP0766945B1 EP 0766945 B1 EP0766945 B1 EP 0766945B1 EP 96830502 A EP96830502 A EP 96830502A EP 96830502 A EP96830502 A EP 96830502A EP 0766945 B1 EP0766945 B1 EP 0766945B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- ceiling

- dishwasher

- rotor

- washing

- tank

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000005406 washing Methods 0.000 title claims description 14

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims description 13

- 230000008878 coupling Effects 0.000 claims description 2

- 238000010168 coupling process Methods 0.000 claims description 2

- 238000005859 coupling reaction Methods 0.000 claims description 2

- 230000000903 blocking effect Effects 0.000 claims 1

- 239000002245 particle Substances 0.000 description 2

- 230000015572 biosynthetic process Effects 0.000 description 1

- 239000011521 glass Substances 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 235000019645 odor Nutrition 0.000 description 1

Images

Classifications

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L15/00—Washing or rinsing machines for crockery or tableware

- A47L15/0018—Controlling processes, i.e. processes to control the operation of the machine characterised by the purpose or target of the control

- A47L15/0057—Cleaning of machines parts, e.g. removal of deposits like lime scale or proteins from piping or tub

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L15/00—Washing or rinsing machines for crockery or tableware

- A47L15/14—Washing or rinsing machines for crockery or tableware with stationary crockery baskets and spraying devices within the cleaning chamber

- A47L15/18—Washing or rinsing machines for crockery or tableware with stationary crockery baskets and spraying devices within the cleaning chamber with movably-mounted spraying devices

- A47L15/22—Rotary spraying devices

- A47L15/23—Rotary spraying devices moved by means of the sprays

Definitions

- the present invention relates to washing devices utilized in dishwashers and more in particular to a device for washing the ceiling of a dishwasher's tank.

- a further drawback of revolving sprinklers consists in that the washing nozzles are oriented in such a way as to hit always only certain portions of the ceiling, since they follow circular paths, whereby in some areas the dirt is not washed away.

- the object of the present invention is to provide a device for washing the tank ceiling suitable to overcome the above-mentioned drawbacks.

- a first fundamental advantage of the device according to the invention is that of generating a water film through which substantially the whole surface of the ceiling can be washed.

- a second advantage of the present device is that of being quite simple and cheap, and therefore easy to manufacture and to install inside a dishwasher.

- a third advantage of this device comes from its very small size, which allows a complete exploitation of the space existing between the top rack and the tank ceiling.

- Still another advantage of the device is that the same water flow provides both the rotation of the rotor and the washing jets that emanate from said rotor. Therefore, a smaller and more efficient water consumption is achieved in this way.

- the device according to the present invention is essentially made up of three members, namely a case 1, a coupling nut 2 that fixes the case 1 in its seat on the tank ceiling, and a rotor 3 that rotates about a vertical axis.

- the rotor 3 is composed of a plurality of vertical vanes 4 linked at their internal ends to a blind hollow cylindrical hub 5 provided with a horizontal nozzle 6 in correspondence to each vane 4.

- the hub 5 has a central vertical conduit 7 passing through nut 2 so as to project into case 1, and blocked therein by an O-ring 8 leaning on a slide ring 9.

- the tightness achieved by the O-ring 8 and the slide ring 9 allows the rotor 3 to freely rotate, while avoiding water leakage even under operating conditions of high pressure, and therefore providing more effectiveness if compared to traditional systems.

- Each vane is essentially S-shaped and it is provided with an intermediate deflector 10, located in correspondence to the first "curve” of the S, and an end deflector 11, also curved. These deflectors 10 and 11 have the twofold purpose of setting rotor 3 into rotation and of converting the horizontal jet coming out from the relevant nozzle 6 into a vertical water film.

- a gasket 12 is interposed between case 1 and nut 2 for the tightness between the washing device and its corresponding seat formed in the tank ceiling.

- the intermediate deflector 10 has a concavity which opposes that of the end deflector 11, so as to generate a rotational moment which is opposite to that given by the latter to rotor 3.

- the resulting rotating moment produces an anti-clockwise rotation, as indicated by arrow R.

- vanes 4 may come in a greater number, arranged along the perimeter of hub 5 in a way of obtaining a balanced rotation, typically in opposite angular positions.

- the end of vane 4 may be particularly shaped so as to favour the opening of the jet and consequently the formation of the water film.

- the end deflector 11 may be provided with a projecting lug 17 along the edge (fig.3), or with a series of grooves 18 arranged like a fan (fig.4).

- a portion of the jet may also be deviated downwards in order to wash the convex surface of cups and glasses which are usually placed in the top rack, as indicated in fig.5.

- rotor 3 might be made in other manners having different shapes, number and arrangement of vanes 4 and nozzles 6.

Landscapes

- Washing And Drying Of Tableware (AREA)

- Cleaning By Liquid Or Steam (AREA)

Description

- The present invention relates to washing devices utilized in dishwashers and more in particular to a device for washing the ceiling of a dishwasher's tank.

- It is well known that some particles of dirt removed from the dishes during the washing may adhere to the ceiling of the tank, especially when the upper sprinkler is placed underneath the top rack. Thus, it would be appropriate for the ceiling to be also washed during the washing cycle in order to avoid encrustations and bad odors.

- The devices that have been used so far may be divided into two categories, namely fixed nozzles and revolving sprinklers. Clearly, fixed nozzles possess a limited effectiveness because of their fixed position, even though they have the advantage of being very simple and cheap.

- On the other hand, revolving sprinklers are more effective but significantly more expensive, and they also have some drawbacks. In the given case that the dishwasher's upper sprinkler is mounted on the ceiling of the tank, such sprinkler should be provided with a series of nozzles also on the upper surface so as to wash the ceiling. However, these additional nozzles would reduce the effectiveness of the washing jets emanating from the lower nozzles, because the water flow would have to be shared among a greater number of nozzles. Such a device is disclosed in EP-A-524102.

- The case when a thorough washing of the ceiling is most necessary occurs with the upper sprinkler located underneath the top rack, because the dishes are hit by upward jets and hence dirt particles would tend to splash onto the ceiling. A dedicated revolving sprinkler for washing the ceiling and attached to the ceiling itself would imply additional costs, as well as a decrease in the height available to the dishes placed in the top rack.

- A further drawback of revolving sprinklers consists in that the washing nozzles are oriented in such a way as to hit always only certain portions of the ceiling, since they follow circular paths, whereby in some areas the dirt is not washed away.

- Therefore the object of the present invention is to provide a device for washing the tank ceiling suitable to overcome the above-mentioned drawbacks.

- This object is achieved by means of a device having the characteristics disclosed in claim 1.

- A first fundamental advantage of the device according to the invention is that of generating a water film through which substantially the whole surface of the ceiling can be washed.

- A second advantage of the present device is that of being quite simple and cheap, and therefore easy to manufacture and to install inside a dishwasher.

- A third advantage of this device comes from its very small size, which allows a complete exploitation of the space existing between the top rack and the tank ceiling.

- Still another advantage of the device is that the same water flow provides both the rotation of the rotor and the washing jets that emanate from said rotor. Therefore, a smaller and more efficient water consumption is achieved in this way.

- These and other advantages and characteristics of the device according to the present invention will be clear to those skilled in the art from the following detailed description of an embodiment thereof, with reference to the annexed drawings wherein:

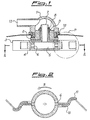

- Figure 1 is a partially sectional schematic front view showing the members that make up the device;

- Figure 2 is a cross-sectional view of the rotor along the line A-A of fig. 1;

- Figure 3 is an enlargement of the area P of fig.1, showing a first variant of the shape of the vanes;

- Figure 4 is a half view similarly to fig.1, showing a second variant of the shape of the vanes; and

- Figure 5 is a vertical cross-sectional schematic view of a dishwasher provided with the above-stated device.

-

- With reference to figs.1 and 2, it can be noticed that the device according to the present invention is essentially made up of three members, namely a case 1, a coupling nut 2 that fixes the case 1 in its seat on the tank ceiling, and a rotor 3 that rotates about a vertical axis. The rotor 3 is composed of a plurality of vertical vanes 4 linked at their internal ends to a blind hollow cylindrical hub 5 provided with a horizontal nozzle 6 in correspondence to each vane 4. The hub 5 has a central vertical conduit 7 passing through nut 2 so as to project into case 1, and blocked therein by an O-

ring 8 leaning on a slide ring 9. The tightness achieved by the O-ring 8 and the slide ring 9 allows the rotor 3 to freely rotate, while avoiding water leakage even under operating conditions of high pressure, and therefore providing more effectiveness if compared to traditional systems. - Each vane is essentially S-shaped and it is provided with an intermediate deflector 10, located in correspondence to the first "curve" of the S, and an

end deflector 11, also curved. Thesedeflectors 10 and 11 have the twofold purpose of setting rotor 3 into rotation and of converting the horizontal jet coming out from the relevant nozzle 6 into a vertical water film. Agasket 12 is interposed between case 1 and nut 2 for the tightness between the washing device and its corresponding seat formed in the tank ceiling. - It should be noted that the intermediate deflector 10 has a concavity which opposes that of the

end deflector 11, so as to generate a rotational moment which is opposite to that given by the latter to rotor 3. In this way it is feasible to operate at high pressures and/or use rather long vanes 4 while preventing the resulting rotating moment from causing an excessive revolving speed of rotor 3. In the case depicted in fig.2 the resulting moment produces an anti-clockwise rotation, as indicated by arrow R. - Of course, the vanes 4 may come in a greater number, arranged along the perimeter of hub 5 in a way of obtaining a balanced rotation, typically in opposite angular positions. By using shorter vanes and/or a lower water pressure it may as well be possible to eliminate the intermediate deflector 10 and thus shape vane 4 substantially as a J.

- Referring also to fig.5, the functioning of the device according to the present invention, which is in itself quite simple, is now explained. The water enters the washing device through an

upper connection 13 of case 1, incoming from abranch 14 of theconduit 15 which brings the water to theupper sprinkler 16. Passing through conduit 7, the water falls into the hollow hub 5 of rotor 3 and comes out from nozzles 6. Each jet that hits the corresponding vane 4 undergoes a first deviation and a first widening caused by the intermediate deflector 10, and is then again deviated and widened like a fan by theend deflector 11, thus setting rotor 3 into rotation. - As illustrated in figs.3 and 4, the end of vane 4 may be particularly shaped so as to favour the opening of the jet and consequently the formation of the water film. Besides having a trapezoidal shape rather than a straight one, the

end deflector 11 may be provided with a projectinglug 17 along the edge (fig.3), or with a series ofgrooves 18 arranged like a fan (fig.4). A portion of the jet may also be deviated downwards in order to wash the convex surface of cups and glasses which are usually placed in the top rack, as indicated in fig.5. - It is clear that the above-described and illustrated embodiment of the device according to the invention is just an example susceptible of various modifications. In particular, rotor 3 might be made in other manners having different shapes, number and arrangement of vanes 4 and nozzles 6.

Claims (5)

- A Dishwasher comprising a device for washing the ceiling of a dishwasher's tank, characterized in that said device includes a case (1) provided with a water connection (13), a coupling nut (2) for blocking said case (1) into its seat on the tank ceiling, and a rotor (3) that rotates about a vertical axis and consisting of a plurality of vertical vanes (4) linked at their internal ends to a blind hollow cylindrical hub (5) provided with a horizontal nozzle (6) in correspondence to each vane (4), the hub (5) being connected to the case (1) by way of a vertical conduit (7) passing through the nut (2) and rotatably blocked thereon, each vane (4) being shaped and provided with one or more deflectors capable of deviating the horizontal jet coming out from the relevant nozzle (6) and converting it into a vertical water film.

- A dishwasher according to claim 1, characterized in that the rotor (3) includes two essentially S-shaped opposite vanes (4) provided with an intermediate deflector (10) and an end deflector (11) placed respectively in correspondence to the first and to the second curve of the S, said deflectors (10,11) having opposed concavity.

- A dishwasher according to claim 1, characterized in that the rotor (3) includes two essentially J-shaped opposite vanes (4) provided with a single end deflector (11).

- A dishwasher according to one of the preceding claims, characterized in that the end deflector (11) has a projecting lug (17) along its edge.

- A dishwasher according to one of the claims 1 to 3, characterized in that the end deflector (11) has a series of grooves (18) arranged like a fan.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| ITMI952021 | 1995-10-03 | ||

| IT95MI002021A IT1275786B1 (en) | 1995-10-03 | 1995-10-03 | DEVICE FOR WASHING THE TOP OF THE TANK OF A DISHWASHER |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0766945A2 EP0766945A2 (en) | 1997-04-09 |

| EP0766945A3 EP0766945A3 (en) | 1998-07-01 |

| EP0766945B1 true EP0766945B1 (en) | 2002-01-09 |

Family

ID=11372307

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP96830502A Expired - Lifetime EP0766945B1 (en) | 1995-10-03 | 1996-10-01 | Device for washing the ceiling of a dishwasher's tank |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP0766945B1 (en) |

| DE (1) | DE69618409T2 (en) |

| ES (1) | ES2169789T3 (en) |

| IT (1) | IT1275786B1 (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US10959596B2 (en) | 2015-12-16 | 2021-03-30 | Whirlpool Corporation | Dishwasher with a spray arm system having a bearing assembly |

Families Citing this family (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2787007B1 (en) * | 1998-12-15 | 2001-02-23 | Esswein Sa | DISHWASHER EQUIPPED WITH ROTATING NOZZLES FOR HOMOGENEOUS WATERING |

| EP1046370A1 (en) * | 1999-04-19 | 2000-10-25 | CHEMISCHE FABRIK DR. WEIGERT (GMBH & CO.) | Conveyor dishwasher |

| KR20040023109A (en) * | 2002-09-10 | 2004-03-18 | 엘지전자 주식회사 | Upper water spray device for dishwasher |

| EP1929920B1 (en) * | 2006-12-06 | 2010-09-01 | Electrolux Home Products Corporation N.V. | Dishwasher |

| DE102009002147A1 (en) * | 2009-04-02 | 2010-10-14 | BSH Bosch und Siemens Hausgeräte GmbH | dishwasher |

| US9440266B2 (en) * | 2012-11-30 | 2016-09-13 | Steris Inc. | Washer / disinfector having a water inlet diffuser |

| WO2018113913A1 (en) * | 2016-12-20 | 2018-06-28 | Electrolux Appliances Aktiebolag | Washing liquid distrubution device for a dishwasher |

| USD885694S1 (en) | 2017-09-19 | 2020-05-26 | Electrolux Home Products, Inc. | Sprayer for dishwasher |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB633496A (en) * | 1947-04-28 | 1949-12-19 | Electrolux Ab | Improvements in or relating to dish washing machines |

| US2987260A (en) * | 1959-11-18 | 1961-06-06 | Gen Electric | Top spray dishwasher |

| DE1503866A1 (en) * | 1965-06-21 | 1969-06-12 | Rowenta Metallwarenfab Gmbh | Dishwasher |

| FR2679121B1 (en) * | 1991-07-16 | 1995-05-19 | Esswein Sa | IMPROVED DISHWASHER. |

-

1995

- 1995-10-03 IT IT95MI002021A patent/IT1275786B1/en active IP Right Grant

-

1996

- 1996-10-01 EP EP96830502A patent/EP0766945B1/en not_active Expired - Lifetime

- 1996-10-01 ES ES96830502T patent/ES2169789T3/en not_active Expired - Lifetime

- 1996-10-01 DE DE69618409T patent/DE69618409T2/en not_active Expired - Fee Related

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US10959596B2 (en) | 2015-12-16 | 2021-03-30 | Whirlpool Corporation | Dishwasher with a spray arm system having a bearing assembly |

Also Published As

| Publication number | Publication date |

|---|---|

| ITMI952021A0 (en) | 1995-10-03 |

| IT1275786B1 (en) | 1997-10-17 |

| DE69618409T2 (en) | 2002-08-29 |

| DE69618409D1 (en) | 2002-02-14 |

| EP0766945A3 (en) | 1998-07-01 |

| EP0766945A2 (en) | 1997-04-09 |

| ES2169789T3 (en) | 2002-07-16 |

| ITMI952021A1 (en) | 1997-04-03 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0766945B1 (en) | Device for washing the ceiling of a dishwasher's tank | |

| EP0786231B1 (en) | Hydraulic connection device for a dishwasher rack which can be positioned at two different heights | |

| EP1847207B1 (en) | Wash/rinse system for a drawer-type dishwasher | |

| US6869029B2 (en) | Water spray system for a dishwasher | |

| US3323529A (en) | Liquid distributing system for dishwashing machine | |

| JPH07250800A (en) | Spray arm normal/reverse rotating device for dish washer | |

| US4172463A (en) | Dishwasher upper spray and deflector disc | |

| CN104545748A (en) | Overflow protection device of water tank type cleaning machine | |

| CN109965804B (en) | Cleaning machine | |

| CN209899306U (en) | Spray system installed on cleaning machine and cleaning machine with spray system | |

| US5433228A (en) | Self-cleaning bearing flange for dishwasher spray arm | |

| CN216761698U (en) | Brush disc for cleaning equipment and cleaning equipment with brush disc | |

| CN209932633U (en) | Spraying system installed on cleaning machine and cleaning machine | |

| CN210241694U (en) | Cleaning nozzle structure and range hood applying same | |

| CN205514453U (en) | Dish washer spray arm device | |

| US3421525A (en) | Door for dishwasher | |

| CN209826617U (en) | Spraying system convenient to assemble and cleaning machine with spraying system | |

| CN216984830U (en) | Cleaning machine | |

| CN220124643U (en) | Spray head assembly and spray arm for dish washer | |

| CN220344353U (en) | Spraying structure for cleaning machine and cleaning machine | |

| CN218074906U (en) | Door body assembly for cleaning machine and cleaning machine | |

| US5546969A (en) | Dishwashing machine with integrated recycling system | |

| JP2005296181A (en) | Dishwasher | |

| CN216777013U (en) | A spray set for cleaning machine | |

| CN217645169U (en) | Cleaning machine with spray member |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): DE ES FR GB SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): DE ES FR GB SE |

|

| 17P | Request for examination filed |

Effective date: 19981217 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| 17Q | First examination report despatched |

Effective date: 20010412 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE ES FR GB SE |

|

| REF | Corresponds to: |

Ref document number: 69618409 Country of ref document: DE Date of ref document: 20020214 |

|

| ET | Fr: translation filed | ||

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2169789 Country of ref document: ES Kind code of ref document: T3 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 20020925 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20020926 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20021010 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20021031 Year of fee payment: 7 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20031001 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20031002 Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20031002 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20031031 Year of fee payment: 8 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20031001 |

|

| EUG | Se: european patent has lapsed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040630 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20031002 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050503 |