EP0730833B1 - Pneumatic membrane-type press - Google Patents

Pneumatic membrane-type press Download PDFInfo

- Publication number

- EP0730833B1 EP0730833B1 EP19960400465 EP96400465A EP0730833B1 EP 0730833 B1 EP0730833 B1 EP 0730833B1 EP 19960400465 EP19960400465 EP 19960400465 EP 96400465 A EP96400465 A EP 96400465A EP 0730833 B1 EP0730833 B1 EP 0730833B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- lid

- plate

- fact

- membrane

- shaft

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000012528 membrane Substances 0.000 claims description 37

- 238000006073 displacement reaction Methods 0.000 claims description 6

- 230000000295 complement effect Effects 0.000 claims description 2

- 239000000853 adhesive Substances 0.000 claims 1

- 230000001070 adhesive effect Effects 0.000 claims 1

- 238000007689 inspection Methods 0.000 claims 1

- 238000012550 audit Methods 0.000 description 3

- 238000000465 moulding Methods 0.000 description 2

- 230000000717 retained effect Effects 0.000 description 2

- 208000031968 Cadaver Diseases 0.000 description 1

- 240000008042 Zea mays Species 0.000 description 1

- 238000006243 chemical reaction Methods 0.000 description 1

- 238000004891 communication Methods 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 238000007747 plating Methods 0.000 description 1

- 230000001012 protector Effects 0.000 description 1

- 238000007789 sealing Methods 0.000 description 1

- 238000013022 venting Methods 0.000 description 1

Images

Classifications

-

- A—HUMAN NECESSITIES

- A43—FOOTWEAR

- A43D—MACHINES, TOOLS, EQUIPMENT OR METHODS FOR MANUFACTURING OR REPAIRING FOOTWEAR

- A43D25/00—Devices for gluing shoe parts

- A43D25/06—Devices for gluing soles on shoe bottoms

- A43D25/07—Devices for gluing soles on shoe bottoms using flexible diaphragm pressing devices

Definitions

- the present invention relates to membrane bells pneumatic suitable for a press intended in particular for bonding or analog of bands on a body like, for example but not exclusively, soles on shoes or the like.

- the object of the present invention is to produce a bell with pneumatic membrane adapted to a press intended in particular for bonding or the like of bands on bodies such as shoes, which has a greater operational safety than bells known in the art prior.

- the pneumatic diaphragm bell adapted to a press intended in particular when bonding or the like to strips on a body 7 such as a shoe, comprises a support 20 of the body 7, a plate 19 surrounding this support, a hollow cover 1 whose edge has a shape suitable for come into contact with the plate, a flexible membrane 2, and means 4 for secure the edge of the membrane with the cover to define, with the bottom of it, a closed volume 50.

- the means 4 for secure the edge of the membrane 2 with the cover have a clamp 3 to trap the edge of the membrane with a complementary part of the cover and means 51 for controlling the movement of the clamp 3 relative to the cover 1.

- These means 51 to control the movement of the clamp relative to the cover are chosen from the following: screws, cylinder.

- the control means 51 are constituted by a plurality of cylinders distributed around the cover 1 and actuated for example by a single command button. These cylinders can be of any type, electric, pneumatic, etc.

- the bell further comprises a conduit 52 opening through one 53 of its ends, in the closed volume 50 and able to be connected, by its other end 54, to a source of compressed gas (not shown), and means for mounting the cover 1 in displacement relative to the plate 19 so that it can take at least two positions, a first position in which the edge of the cover rests on the plate 19 and a second position in which the edge of the cover is distant from the plate 19.

- the bell further comprises controllable sealing means of the conduit 52 to close the conduit when the cover is substantially in its second position and open it when the cover is substantially in its first position.

- the means for mounting the cover 1 moving relative to the plate 19 are constituted by rotation means 14 comprising a fixed shaft relative to the plate 19 and a bearing secured to the cover 1 and mounted in rotation on the shaft by a friction surface.

- the conduit 52 then comprises a first blind breakthrough made along the axis 12 of the shaft, an orifice connecting this first breakthrough with the wall lateral of this tree and being produced along an axis substantially perpendicular to the axis 12 of the shaft, a second breakthrough 15 made in the bearing and emerging through a first end 53 in the closed volume 50 and by its other second end 16 on the friction surface of the bearing which is pivotally mounted on the shaft, and a pipe portion 57 including one end is connected to the opening of the first breakthrough and the other of which end constitutes the end 54 of the conduit 52 defined above.

- Controllable means for opening the conduit when the cover 1 is substantially in its first position and close it when it is substantially in its second position are constituted by the fact that the second breakthrough 15 is made in the bearing so that when the cover 1 is in its first position, its second end 16 is opposite the orifice and that, when the cover is in its second position, the second end 16 of the second breakthrough 15 is not opposite the orifice, the friction surface closing the outlet of the orifice.

- the bell further comprises controllable means for putting in communication volume 50 with the ambient environment, with the aim of deflate or at least partially empty this volume preferably before the cover 1 does not pass from its first position to the second.

- the means controllable to port volume 50 with the environment ambient are advantageously constituted by a valve or the like controlled manually, pneumatically, etc., for example a two-way pneumatic distributor 55 mounted in series on the duct 52, advantageously on the pipe portion 57.

- a first passing lane is defined from end 54 to end 53, the second is defined from the end 53 towards the outlet 56 which is a venting.

- the bell structure described above is advantageous because it prevents the conduit 52 supplying the volume 50 with compressed gas is moved at the same time as cover 1, as would be the case if the conduit led directly into the volume without passing through the shaft and the bearing. Indeed, as this cover is very heavy, it is necessary, as it will be mentioned below, that he is balanced during his movements of his first position to second and vice versa, and it's almost impossible to achieve such balancing with a floating conduit, itself very heavy to because of its reinforced structure, which leads directly into volume 50.

- This structure also has the following advantage: if the cover 1 is actuated from its first position to the second while, by error, the distributor 55 was not correctly positioned (having remained by example in its passageway "54 to 53"), volume 50 will only receive one small additional amount of compressed gas. Likewise, it will prevent the volume 50 does not receive compressed gas too soon before cover 1 has been locked on the tray 19.

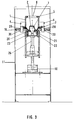

- the bell further comprises means for moving the support 20 of the body 7 in a direction substantially perpendicular to the plane of the plate 19 and a stop 9 integral with the cover 1 located in the closed volume 50, this stop being positioned on the path of movement of the support 20 when the cover is in its first position.

- the support 20 is provided with a removable plate 21 defining a light 22 intended to receive, by example as illustrated, a shoe 7, the removable plate being placed on a movable base 23 vertically adjustable by means for example of a bigorne 24 controlled by a motor 25.

- this support 20 can be constituted several auxiliary supports, for example two as illustrated on the figures.

- the two auxiliary supports are respectively controlled by two bigornes 24, 26 mounted in parallel and controlled respectively by two motors 25, 27 which, in the case where the body 7 is constituted by a shoe, respectively control the front of the shoe (the bighorn 24) and the heel (bighorn 26).

- the bell also includes means for lock the cover on the tray.

- These means can take different forms.

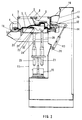

- One of their possible embodiments was schematically illustrated in Figures 1 and 3. They are in this case constituted by at least one hook 28 which hooks onto the plate 19 when the cover 1 is in its closed position.

- the bell further comprises one or more vision windows 6 made in the cover 1, which allow to see in inside the volume 50 after closing the cover 1 and checking, in particular, the positioning of the membrane 2 on the body 7.

- the cover must be able to pass from one of its positions to each other easily.

- the bell has means to control the rotation of the cover 1 relative to the plate.

- These means can be constituted, as illustrated in the figures, by a jack 13 of any type of which one end is connected to the cover 1. In the embodiment illustrated, its other end is connected to the frame 11 of the bell by a member turning 35.

- the bell also includes means for balance the cover in its rotation around the shaft.

- These means can be of any type, for example a spring, a counterweight, etc., and it is recalled that, as the structure described above avoids the presence of a conduit floating connected to the cover, balancing the cover is easier to achieve and remains constant whatever the position of the cover relative to the tray.

- the bell also includes, for example, screens protectors 17, 18 surrounding the shaft and the rotating bearing, these screens being advantageously secured to the frame 11 of the bell.

- Figure 2 shows the pneumatic diaphragm bell when the cover 1 is folded back in the closed position.

- Compressed air is supplied by the conduit 52 to volume 50, membrane 2 swells and hugs the entire surface of sole 29 of shoe 7, the pressure exerted by the membrane allowing the sole to adhere perfectly to the upper of the shoe 7.

- the pressure on the sole is reinforced by means of a fixed stop 9 advantageously on a metal cross member 8 on the upper part 5 of the cover 1.

- This stopper acts as a reaction to a booster 10 located at the bottom of the frame 11. It is of an appropriate shape corresponding to that of the sole 29 to stick on the upper of the shoe.

- FIG. 3 shows a transverse view in which the cover 1 is in the closed position, the membrane 2 applied to the sole 29 of the shoe 7.

- the cover 1 is locked by means of the hooks 28 coming from fit through the lights 30 made in the plate 19.

- FIG 4 is shown, in the clamped position, a cylinder clamping tire 51 adapted to cover 1, allowing tightening snapshot of the flange 3 energetically plating the edge of the membrane 2 on the edge of the cover 1 and the quick change of the membrane 2.

- FIG. 5 shows in detail a flat view of part of the clamping flange 3 of the membrane 2, provided with an oblong hole 31 facilitating, by simple movement of the clamp 3, the release of the means of fixing 32 of the jack 51 on the clamping flange 3, as well as a groove 34 of suitable shape cooperating with the lower part 36 of the bell for retain the edge of the membrane 2 in the form of a molding 33.

- FIG. 6 shows a detail of the pneumatic clamping cylinder 51 representing the fixing means 32 in the released position, the molding 33 of the membrane 2 which can then be released from the groove 34 of the clamping flange 3.

- Figure 7 are shown the different positions of the clamp 3 when changing the membrane 2.

- the pneumatic cylinder clamp 51 is in the released position and the clamp 3 has been moved, releasing the fixing means 32 through the oblong hole 31.

- Figure 8 shows a bottom view of the cover 1 making appear the membrane 2 retained by the clamp 3 with the holes oblong 31 allowing the release of the fixing means 32 of the flange tightening 3, during assembly or disassembly of the membrane 2, as well as the axis of articulation with a means 35 for fixing the bell on the frame 11 and the conduit 52 for the arrival of compressed air inside the closed volume 50 closed at 16 to ensure greater security, the air thus being unable to penetrate into the closed volume only when the cover 1 is locked on the plate 19 at by means of hooks 28.

Landscapes

- Footwear And Its Accessory, Manufacturing Method And Apparatuses (AREA)

- Actuator (AREA)

- Tents Or Canopies (AREA)

Description

La présente invention concerne les cloches à membrane pneumatique adaptée sur une presse destinée notamment au collage ou analogue de bandes sur un corps comme, par exemple mais non exclusivement, les semelles sur des chaussures ou analogues.The present invention relates to membrane bells pneumatic suitable for a press intended in particular for bonding or analog of bands on a body like, for example but not exclusively, soles on shoes or the like.

On connaít déjà de telles cloches, par exemple celles qui sont décrites et illustrées dans les GB-A-2 151 904, DE-A-35 16 577 et EP-A- 0 141 183.We already know such bells, for example those described and illustrated in GB-A-2 151 904, DE-A-35 16 577 and EP-A-0 141 183.

Cependant, la présente invention a pour but de réaliser une cloche à membrane pneumatique adaptée sur une presse destinée notamment au collage ou analogue de bandes sur des corps comme des chaussures, qui présente une plus grande sécurité de fonctionnement que les cloches connues de l'art antérieur.However, the object of the present invention is to produce a bell with pneumatic membrane adapted to a press intended in particular for bonding or the like of bands on bodies such as shoes, which has a greater operational safety than bells known in the art prior.

Plus précisément, la présente invention a pour objet une cloche à membrane pneumatique adaptée sur une presse destinée notamment au collage ou analogue de bandes sur un corps, comportant:

- un support dudit corps,

- un plateau entourant ledit support,

- un couvercle en creux dont le bord présente une forme adaptée pour venir au contact dudit plateau,

- une membrane souple,

- des moyens pour solidariser la bordure de ladite membrane avec ledit couvercle pour définir, avec le fond de celui-ci, un volume fermé,

- un conduit débouchant par une extrémité dans ledit volume fermé et apte à être connecté, par son autre extrémité, à une source de gaz comprimé,

- des moyens pour monter ledit couvercle en déplacement par rapport audit plateau de façon qu'il puisse prendre au moins deux positions, une première position dans laquelle le bord dudit couvercle repose sur ledit plateau et une seconde position dans laquelle le bord dudit couvercle est éloigné dudit plateau, ces moyens pour monter ledit couvercle en déplacement par rapport audit plateau étant constitués par des moyens de rotation, ces moyens de rotation comportant un arbre fixe par rapport audit plateau, un palier monté en rotation sur ledit arbre par une surface de friction, ledit palier étant solidaire dudit couvercle, et

- des moyens d'obturation commandables permettant d'obturer ledit conduit quand le couvercle est sensiblement dans sa seconde position et de l'ouvrir quand le couvercle est dans sa première position,

- une première percée borgne réalisée selon l'axe dudit arbre,

- un orifice reliant ladite première percée avec la paroi latérale dudit arbre et étant réalisé suivant un axe sensiblement perpendiculaire à l'axe dudit arbre, et

- une seconde percée réalisée dans le palier et débouchant par une première extrémité dans ledit volume et par son autre seconde extrémité sur la surface de friction dudit palier monté en pivotement sur ledit arbre, et que lesdits moyens d'obturation commandables dudit conduit sont constitués par le fait que ladite seconde percée est réalisée dans ledit palier de façon que, lorsque ledit couvercle est dans sa première position, la seconde extrémité de la seconde percée soit en regard dudit orifice et que, lorsque ledit couvercle est dans sa seconde position, la surface de friction obture la sortie dudit orifice.

- a support for said body,

- a tray surrounding said support,

- a hollow cover, the edge of which has a shape suitable for coming into contact with said tray,

- a flexible membrane,

- means for securing the edge of said membrane with said cover to define, with the bottom thereof, a closed volume,

- a conduit opening at one end into said closed volume and capable of being connected, at its other end, to a source of compressed gas,

- means for mounting said cover in displacement with respect to said tray so that it can take at least two positions, a first position in which the edge of said cover rests on said tray and a second position in which the edge of said cover is remote from said plate, these means for mounting said cover in displacement with respect to said plate being constituted by rotation means, these rotation means comprising a fixed shaft with respect to said plate, a bearing mounted for rotation on said shaft by a friction surface, said bearing being integral with said cover, and

- controllable closure means making it possible to seal said duct when the cover is substantially in its second position and to open it when the cover is in its first position,

- a first blind breakthrough made along the axis of said shaft,

- an orifice connecting said first breakthrough with the side wall of said shaft and being produced along an axis substantially perpendicular to the axis of said shaft, and

- a second breakthrough made in the bearing and opening by a first end in said volume and by its other second end on the friction surface of said bearing pivotally mounted on said shaft, and that said controllable closure means of said conduit are constituted by the causes said second breakthrough to be made in said bearing so that, when said cover is in its first position, the second end of the second breakout is opposite said orifice and that, when said cover is in its second position, the surface of friction closes the outlet of said orifice.

D'autres caractéristiques et avantages de la présente invention

apparaítront au cours de la description suivante donnée en regard des dessins

annexés à titre illustratif, mais nullement limitatif, dans lesquels:

Les huit figures représentent un même mode de réalisation d'une cloche à membrane pneumatique adaptée sur une presse, selon l'invention. En conséquence les mêmes références y désignent les mêmes éléments, quelle que soit la figure sur laquelle elles apparaissent.The eight figures represent the same embodiment of a bell with pneumatic membrane adapted to a press according to the invention. In consequence the same references designate the same elements there, whatever either the figure on which they appear.

La cloche à membrane pneumatique adaptée sur une presse destinée

notamment au collage ou analogue de bandes sur un corps 7 comme une

chaussure, comporte un support 20 du corps 7, un plateau 19 entourant ce

support, un couvercle en creux 1 dont le bord présente une forme adaptée pour

venir au contact du plateau, une membrane souple 2, et des moyens 4 pour

solidariser la bordure de la membrane avec le couvercle pour définir, avec le

fond de celui-ci, un volume fermé 50.The pneumatic diaphragm bell adapted to a press intended

in particular when bonding or the like to strips on a

Dans un mode de réalisation avantageux, les moyens 4 pour

solidariser la bordure de la membrane 2 avec le couvercle comportent une

bride de serrage 3 pour emprisonner la bordure de la membrane avec une

partie complémentaire du couvercle et des moyens 51 pour commander le

déplacement de la bride de serrage 3 par rapport au couvercle 1. Ces moyens 51

pour commander le déplacement de la bride de serrage par rapport au

couvercle sont choisis parmi les éléments suivants: vis, vérin. Dans le mode de

réalisation illustré, les moyens de commande 51 sont constitués par une

pluralité de vérins répartis autour du couvercle 1 et actionnés par exemple par

un bouton de commande unique. Ces vérins peuvent être de tout type,

électrique, pneumatique, etc.In an advantageous embodiment, the means 4 for

secure the edge of the

La cloche comporte en outre un conduit 52 débouchant, par l'une 53

de ses extrémités, dans le volume fermé 50 et apte à être connecté, par son

autre extrémité 54, à une source de gaz comprimé (non représentée), et des

moyens pour monter le couvercle 1 en déplacement par rapport au plateau 19

de façon qu'il puisse prendre au moins deux positions, une première position

dans laquelle le bord du couvercle repose sur le plateau 19 et une seconde

position dans laquelle le bord du couvercle est éloigné du plateau 19.The bell further comprises a

Selon une caractéristique importante de l'invention visant à

atteindre le but défini dans le préambule de la présente description, la cloche

comporte en outre des moyens d'obturation commandables du conduit 52

permettant d'obturer le conduit quand le couvercle est sensiblement dans sa

seconde position et de l'ouvrir lorsque le couvercle est sensiblement dans sa

première position.According to an important characteristic of the invention aimed at

achieve the goal defined in the preamble to this description, the bell

further comprises controllable sealing means of the

Dans un mode de réalisation avantageux, les moyens pour monter le

couvercle 1 en déplacement par rapport au plateau 19 sont constitués par des

moyens de rotation 14 comportant un arbre fixe par rapport au plateau 19 et

un palier solidaire du couvercle 1 et monté en rotation sur l'arbre par une

surface de friction.In an advantageous embodiment, the means for mounting the

cover 1 moving relative to the

Le conduit 52 comporte alors une première percée borgne réalisée

selon l'axe 12 de l'arbre, un orifice reliant cette première percée avec la paroi

latérale de cet arbre et étant réalisé suivant un axe sensiblement

perpendiculaire à l'axe 12 de l'arbre, une seconde percée 15 réalisée dans le

palier et débouchant par une première extrémité 53 dans le volume fermé 50 et

par son autre seconde extrémité 16 sur la surface de friction du palier qui est

monté en pivotement sur l'arbre, et une portion de conduite 57 dont une

extrémité est reliée à l'ouverture de la première percée et dont l'autre

extrémité constitue l'extrémité 54 du conduit 52 définie ci-avant.The

Les moyens commandables pour ouvrir le conduit quand le

couvercle 1 est sensiblement dans sa première position et l'obturer lorsqu'il est

sensiblement dans sa seconde position, sont constitués par le fait que la

seconde percée 15 est réalisée dans le palier de façon que, lorsque le couvercle

1 est dans sa première position, sa seconde extrémité 16 soit en regard de

l'orifice et que, lorsque le couvercle est dans sa seconde position, la seconde

extrémité 16 de la seconde percée 15 ne soit pas en regard de l'orifice, la

surface de friction obturant la sortie de l'orifice.Controllable means for opening the conduit when the

cover 1 is substantially in its first position and close it when it is

substantially in its second position, are constituted by the fact that the

La cloche comporte en outre des moyens commandables pour mettre

en communication le volume 50 avec le milieu ambiant, dans le but de

dégonfler ou vider au moins partiellement ce volume de préférence avant que

le couvercle 1 ne passe de sa première position à la seconde.The bell further comprises controllable means for putting

in

Dans le mode de réalisation illustré sur la figure 8, les moyens

commandables pour mettre en communication le volume 50 avec le milieu

ambiant sont avantageusement constitués par une vanne ou analogue

commandée manuellement, pneumatiquement, etc., par exemple un

distributeur pneumatique 55 à deux voies monté en série sur le conduit 52,

avantageusement sur la portion de conduite 57. Une première voie passante est

définie de l'extrémité 54 vers l'extrémité 53, la seconde est définie de

l'extrémité 53 vers la sortie 56 qui est une mise à l'atmosphère.In the embodiment illustrated in FIG. 8, the means

controllable to

La structure de cloche décrite ci-dessus est avantageuse car elle

permet d'éviter que le conduit 52 d'alimentation du volume 50 en gaz comprimé

ne soit déplacé en même temps que le couvercle 1, comme ce serait le cas si le

conduit débouchait directement dans le volume sans passer par l'arbre et le

palier. En effet, comme ce couvercle est très lourd, il faut, comme il sera

mentionné ci-après, qu'il soit équilibré pendant ses déplacements de sa

première position à la seconde et inversement, et il est presque impossible de

réaliser un tel équilibrage avec un conduit flottant, lui-même très lourd à

cause de sa structure renforcée, qui débouche directement dans le volume 50.The bell structure described above is advantageous because it

prevents the

Cette structure présente également l'avantage suivant: si le

couvercle 1 est actionné de sa première position à la seconde alors que, par

erreur, le distributeur 55 n'a pas bien été positionné (en étant resté par

exemple dans sa voie de passage "54 vers 53"), le volume 50 ne recevra qu'une

faible quantité supplémentaire de gaz comprimé. De même, elle évitera que le

volume 50 ne reçoive trop tôt du gaz comprimé avant que le couvercle 1 n'ait

été verrouillé sur le plateau 19.This structure also has the following advantage: if the

cover 1 is actuated from its first position to the second while, by

error, the

Dans une réalisation avantageuse, la cloche comporte en outre des

moyens pour déplacer le support 20 du corps 7 suivant une direction

sensiblement perpendiculaire au plan du plateau 19 et une butée 9 solidaire du

couvercle 1 située dans le volume fermé 50, cette butée étant positionnée sur le

trajet de déplacement du support 20 quand le couvercle est dans sa première

position. Dans le mode de réalisation illustré, le support 20 est muni d'une

plaque amovible 21 définissant une lumière 22 destinée à recevoir, par

exemple comme illustré, une chaussure 7, la plaque amovible étant posée sur

une embase mobile 23 réglable verticalement au moyen par exemple d'une

bigorne 24 commandée par un moteur 25. In an advantageous embodiment, the bell further comprises

means for moving the

Dans une réalisation avantageuse, ce support 20 peut être constitué

de plusieurs supports auxiliaires, par exemple deux comme illustré sur les

figures. Les deux supports auxiliaires sont respectivement commandés par

deux bigornes 24, 26 montées en parallèle et commandées respectivement par

deux moteurs 25, 27 qui, dans le cas où le corps 7 est constitué par une

chaussure, commandent respectivement l'avant de la chaussure (la bigorne

24) et le talon (la bigorne 26).In an advantageous embodiment, this

Dans le but principal annoncé dans le préambule de la présente

description, il est avantageux que la cloche comporte aussi des moyens pour

verrouiller le couvercle sur le plateau. Ces moyens peuvent prendre

différentes formes. L'un de leurs modes de réalisation possibles a été

schématiquement illustré sur les figures 1 et 3. Ils sont dans ce cas constitués

par au moins un crochet 28 qui vient s'accrocher sur le plateau 19 quand le

couvercle 1 est dans sa position fermée.For the main purpose announced in the preamble to this

description, it is advantageous that the bell also includes means for

lock the cover on the tray. These means can take

different forms. One of their possible embodiments was

schematically illustrated in Figures 1 and 3. They are in this case constituted

by at least one

De façon préférentielle, la cloche comporte en outre un ou plusieurs

hublots de vision 6 réalisés dans le couvercle 1, qui permettent de voir dans

l'intérieur du volume 50 après fermeture du couvercle 1 et de contrôler,

notamment, le positionnement de la membrane 2 sur le corps 7.Preferably, the bell further comprises one or more

vision windows 6 made in the cover 1, which allow to see in

inside the

Bien entendu, le couvercle doit pouvoir passer de l'une de ses

positions à l'autre de façon aisée. Dans ce but, la cloche comporte des moyens

pour commander la rotation du couvercle 1 par rapport au plateau. Ces moyens

peuvent être constitués, comme illustré sur les figures, par un vérin 13 de tout

type dont une extrémité est reliée au couvercle 1. Dans le mode de réalisation

illustré, son autre extrémité est reliée au bâti 11 de la cloche par un organe

tournant 35.Of course, the cover must be able to pass from one of its

positions to each other easily. For this purpose, the bell has means

to control the rotation of the cover 1 relative to the plate. These means

can be constituted, as illustrated in the figures, by a

De façon avantageuse, la cloche comporte aussi des moyens pour

équilibrer le couvercle dans sa rotation autour de l'arbre. Ces moyens peuvent

être de tout type, par exemple un ressort, un contrepoids, etc., et il est rappelé

que, comme la structure décrite ci-dessus évite la présence d'un conduit

flottant relié au couvercle, l'équilibrage du couvercle est plus facile à réaliser

et reste constant quelle que soit la position du couvercle par rapport au

plateau. Accessoirement, la cloche comporte aussi, par exemple, des écrans

protecteurs 17, 18 entourant l'arbre et le palier tournant, ces écrans étant

avantageusement solidarisés au bâti 11 de la cloche.Advantageously, the bell also includes means for

balance the cover in its rotation around the shaft. These means can

be of any type, for example a spring, a counterweight, etc., and it is recalled

that, as the structure described above avoids the presence of a conduit

floating connected to the cover, balancing the cover is easier to achieve

and remains constant whatever the position of the cover relative to the

tray. Incidentally, the bell also includes, for example, screens

La figure 2 représente la cloche à membrane pneumatique lorsque

le couvercle 1 est rabattu en position fermée. L'air comprimé est amené par le

conduit 52 jusqu'au volume 50, la membrane 2 se gonfle et épouse toute la

surface de la semelle 29 de la chaussure 7, la pression exercée par la membrane

permettant à la semelle d'adhérer parfaitement à l'empeigne de la chaussure 7.

La pression sur la semelle est renforcée au moyen d'une butée 9 fixée

avantageusement sur une traverse métallique 8 sur la partie supérieure 5 du

couvercle 1. Cette butée sert de réaction à un surpresseur 10 situé au bas du

bâti 11. Elle est d'une forme appropriée correspondant à celle de la semelle 29 à

coller sur l'empeigne de la chaussure.Figure 2 shows the pneumatic diaphragm bell when

the cover 1 is folded back in the closed position. Compressed air is supplied by the

La figure 3 montre une vue transversale dans laquelle le couvercle 1

est en position fermée, la membrane 2 appliquée sur la semelle 29 de la

chaussure 7. Le couvercle 1 est verrouillé au moyen des crochets 28 venant

s'adapter à travers les lumières 30 réalisées dans le plateau 19.FIG. 3 shows a transverse view in which the cover 1

is in the closed position, the

Sur la figure 4, est représenté, en position serrée, un vérin

pneumatique de bridage 51 adapté au couvercle 1, permettant le serrage

instantané de la bride 3 plaquant énergiquement la bordure de la membrane 2

sur le bord du couvercle 1 et le changement rapide de la membrane 2.In Figure 4, is shown, in the clamped position, a

La figure 5 représente en détail une vue à plat d'une partie de la

bride de serrage 3 de la membrane 2, munie d'un trou oblong 31 facilitant, par

simple déplacement de la bride de serrage 3, le dégagement du moyen de

fixation 32 du vérin 51 sur la bride de serrage 3, ainsi qu'une gorge 34 de

forme appropriée coopérant avec la partie inférieure 36 de la cloche pour

retenir la bordure de la membrane 2 en forme de moulure 33.FIG. 5 shows in detail a flat view of part of the

clamping

La figure 6 représente un détail du vérin pneumatique de bridage 51

représentant le moyen de fixation 32 en position desserrée, la moulure 33 de la

membrane 2 pouvant alors être dégagée de la gorge 34 de la bride de serrage 3.FIG. 6 shows a detail of the

Sur la figure 7 sont représentés les différents positionnements de la

bride de serrage 3 lors du changement de membrane 2. Le vérin pneumatique

de bridage 51 est en position desserrée et la bride de serrage 3 a été déplacée,

libérant le moyen de fixation 32 à travers le trou oblong 31.In Figure 7 are shown the different positions of the

La figure 8 représente une vue de dessous du couvercle 1 faisant

apparaítre la membrane 2 retenue par la bride de serrage 3 avec les trous

oblongs 31 permettant le dégagement des moyens de fixation 32 de la bride de

serrage 3, lors du montage ou du démontage de la membrane 2, ainsi que l'axe

d'articulation avec un moyen de fixation 35 de la cloche sur le bâti 11 et le

conduit 52 d'arrivée d'air comprimé à l'intérieur du volume fermé 50 obturé en

16 pour assurer une plus grande sécurité, l'air ne pouvant ainsi pénétrer dans

le volume fermé que lorsque le couvercle 1 est verrouillé sur le plateau 19 au

moyen des crochets 28.Figure 8 shows a bottom view of the cover 1 making

appear the

Claims (9)

- A pneumatic membrane bell fitted to a press intended in particular for applying strips to a body (7) by adhesive or the like, comprising:characterized by the facts that the duct (52) comprises at least:a support (20) for said body;a plate (19) surrounding said support;a hollow lid (1) whose edge is of a shape adapted to come into contact with said plate;a flexible membrane (2);means for securing the margin of said membrane to said lid so as to co-operate with the end wall of the lid to define a closed volume (50);a duct (52) having one end (53) opening out into said closed volume and suitable for having its other end (54) connected to a source of compressed gas;means for mounting said lid (1) movably relative to said plate (19) in such a manner as to enable it to take up at least two positions, a first position in which the edge of said lid rests on said plate (19), and a second position in which the edge of said lid is at a distance from said plate, said means for mounting said lid movably relative to said plate being constituted by rotary means (14), said rotary means comprising a shaft that is fixed relative to said plate, and a bearing mounted to rotate on said shaft via a friction surface, said bearing being secured to said lid; andcontrollable closure means enabling said duct (52) to be closed when the lid is substantially in its second position and to be opened when the lid is in its first position;and that said controllable means for closing said duct (52) are constituted by the fact that said second bore (15) is made in said bearing in such a manner that when said lid (1) is in its first position, the second end (16) of the second bore (15) is in register with said orifice and when said lid is in its second position, the friction surface closes the outlet of said orifice.a first blind bore made on the axis (12) of said shaft;an orifice connecting said first bore to the side wall of said shaft and made along an axis that is substantially perpendicular to the axis of said shaft; anda second bore (15) made through the bearing and opening out via a first end (53) in said volume (50) and via its other or second end (16) to the friction surface of said bearing pivotally mounted on said shaft;

- A bell according to claim 1, characterized by the fact that it further comprises means for moving said support (20) of said body (7) in a direction substantially perpendicular to the plane of said plate (19), and an abutment (9) secured to said lid, said abutment being situated in said closed volume (50) and being positioned on the displacement path of said support (20) when said lid (1) is in its first position.

- A bell according to claim 1 or 2, characterized by the fact that the means for securing the margin of said membrane (2) to said lid comprise a clamp (3) for holding said margin of the membrane captive with a complementary portion of said lid, and means (4) for controlling displacement of said clamp relative to said lid.

- A bell according to claim 3, characterized by the fact that the means (4) for controlling displacement of the clamp (3) relative to said lid (1) are selected from the following elements: screw; actuator.

- A bell according to any preceding claim, characterized by the fact that it further comprises means (28) for locking said lid (1) on said plate (19).

- A bell according to any preceding claim, characterized by the fact that said support (20) is constituted by a plurality of auxiliary supports and comprises means (20, 24, 25, 26, 27) for displacing said auxiliary support relative to said plate (19) in a direction that is substantially perpendicular to the plane of said plate.

- A bell according to any preceding claim, characterized by the fact that it includes at least one inspection porthole (6) formed in said lid (1).

- A bell according to any one of claims 1 to 7, characterized by the fact that it comprises means (13) for controlling rotation of said lid (1) relative to said plate (19).

- A bell according to any one of claims 1 to 8, characterized by the fact that it comprises means for balancing said lid (1) in its rotation about said shaft.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR9502801A FR2731327B1 (en) | 1995-03-10 | 1995-03-10 | PNEUMATIC MEMBRANE BELL ADAPTED TO A PRESS INTENDED IN PARTICULAR FOR BONDING SOLE ON SHOES |

| FR9502801 | 1995-03-10 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0730833A1 EP0730833A1 (en) | 1996-09-11 |

| EP0730833B1 true EP0730833B1 (en) | 2000-09-20 |

Family

ID=9476926

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP19960400465 Expired - Lifetime EP0730833B1 (en) | 1995-03-10 | 1996-03-05 | Pneumatic membrane-type press |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP0730833B1 (en) |

| DE (1) | DE69610344D1 (en) |

| ES (1) | ES2151134T3 (en) |

| FR (1) | FR2731327B1 (en) |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2754683B1 (en) * | 1996-10-18 | 1998-11-27 | Salomon Sa | PRESSING METHOD AND DEVICE FOR ASSEMBLING BY GLUING A SOLE WITH A SHOE SHOE |

| FR2839862B1 (en) | 2002-05-24 | 2005-08-19 | Tech Et Realisations Mecanique | MACHINE FOR FITTING A SOLE ON THE FOOT OF A FOOTWEAR |

| CN102293484A (en) * | 2011-08-31 | 2011-12-28 | 吴江源兴工艺鞋业有限公司 | Shoe edge pressing machine |

| CN114451638B (en) * | 2017-11-22 | 2024-08-23 | 耐克创新有限合伙公司 | Conformal film for shoemaking, press and method for manufacturing shoe article by using conformal film |

| IT202200023781A1 (en) * | 2022-11-17 | 2024-05-17 | Irocol S R L | MEMBRANE PRESS FOR FOOTWEAR BONDING. |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3338731C2 (en) * | 1983-10-25 | 1985-12-19 | Herbert Dr.-Ing. 8032 Gräfelfing Funck | Gluing press for gluing shoe soles to listed upper shoes |

| GB2151904B (en) * | 1983-12-01 | 1987-04-01 | Quiles D Pascual Sansano | Machine for attaching soles to footwear |

| DE3516577A1 (en) * | 1985-05-08 | 1986-11-13 | Herbert Dr.-Ing. 8032 Gräfelfing Funck | Bonding press for bonding shoe soles onto lasted-on upper shoes |

-

1995

- 1995-03-10 FR FR9502801A patent/FR2731327B1/en not_active Expired - Fee Related

-

1996

- 1996-03-05 ES ES96400465T patent/ES2151134T3/en not_active Expired - Lifetime

- 1996-03-05 EP EP19960400465 patent/EP0730833B1/en not_active Expired - Lifetime

- 1996-03-05 DE DE69610344T patent/DE69610344D1/en not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| DE69610344D1 (en) | 2000-10-26 |

| ES2151134T3 (en) | 2000-12-16 |

| EP0730833A1 (en) | 1996-09-11 |

| FR2731327A1 (en) | 1996-09-13 |

| FR2731327B1 (en) | 1997-05-23 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1165426B1 (en) | Device for filling receptacles fitted with an integrated cleaning device | |

| CA2428137A1 (en) | Flap hinge mechanism for an aircraft aerodynamic surface | |

| FR2849429A1 (en) | Flask opening and closing device, has closing shutter with controlled opening unit to assure complete tilting of shutter in opening, according to constant force value and movement applied to shutter | |

| CH407876A (en) | Mobile air knife transport | |

| EP0730833B1 (en) | Pneumatic membrane-type press | |

| EP3404176A1 (en) | Device for unlocking a door latch | |

| FR2480692A1 (en) | CONTROL DEVICE FOR THE VALVE MECHANISM OF A SERVOFREIN | |

| FR2943413A1 (en) | TRANSMISSION DEVICE FOR A POSITION SENSOR OF A TURBOCHARGER CONTROL BOX | |

| EP4255512A1 (en) | Diffuser attaching on a ventilation grill for the controlled dispensing of an air freshener | |

| FR3065438A1 (en) | MULTIPOSITION AIR INTAKE SYSTEM FOR AN AIRCRAFT | |

| EP0760306B1 (en) | Tank inlet cover | |

| FR2734770A1 (en) | LIGHTING SYSTEM EQUIPPED WITH THE FRONT PART OF A VEHICLE COMPRISING A LIGHT SOURCE AND A SIGNALING LIGHT | |

| FR2658060A1 (en) | FILTER HOLDER FOR A COFFEE MACHINE OR A TEAPER PROVIDED WITH A SAFETY DEVICE AGAINST AN UNDESIRED FLOW OF THE LIQUID. | |

| FR2528517A1 (en) | SHUTTER FOR MOUNTING INTO A BODY | |

| FR2794727A1 (en) | IMPROVED FLUID PRODUCT DISPENSING DEVICE | |

| EP0930412A1 (en) | Door hinge with check, especially for a vehicle | |

| EP0778111B1 (en) | Emergency stopping module for a robot | |

| EP1405796B1 (en) | Fluid dispensing apparatus | |

| EP0867570A1 (en) | Flushing cistern for recessed mounting operated at the top or at the front | |

| EP1134341B1 (en) | Articulated door system for vehicles, containers and similar | |

| EP1739248A1 (en) | Fume venting device with windshield | |

| FR2846108A1 (en) | Jack assembly for raising lid of building ventilation outlet, comprises support with lateral jack pivot, jack rod with tip to engage lid block and bolted plate on jack rod to align tip when retracted | |

| EP3301351A1 (en) | Integral mounting for luminous device with micro-mirror array | |

| FR2513577A1 (en) | SUNROOF THAT CAN RECEIVE A SUN VISOR FOR A MOTOR VEHICLE | |

| FR2739116A1 (en) | Cistern for w.c. flush |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): BE DE ES FR GB GR IT NL PT |

|

| 17P | Request for examination filed |

Effective date: 19970228 |

|

| 17Q | First examination report despatched |

Effective date: 19990305 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): BE DE ES FR GB GR IT NL PT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20000920 Ref country code: GR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000920 Ref country code: GB Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20000920 |

|

| REF | Corresponds to: |

Ref document number: 69610344 Country of ref document: DE Date of ref document: 20001026 |

|

| ITF | It: translation for a ep patent filed | ||

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2151134 Country of ref document: ES Kind code of ref document: T3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20001220 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20001221 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| GBV | Gb: ep patent (uk) treated as always having been void in accordance with gb section 77(7)/1977 [no translation filed] |

Effective date: 20000920 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20010331 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| BERE | Be: lapsed |

Owner name: SOC. D'ETUDES TECHNIQUES ET REALISATIONS MECANIQUE Effective date: 20010331 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20070315 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20070622 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20070326 Year of fee payment: 12 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20081125 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080331 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20080306 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080306 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080305 |