EP0524122A1 - Container made from flexible material for transporting perishable produce - Google Patents

Container made from flexible material for transporting perishable produce Download PDFInfo

- Publication number

- EP0524122A1 EP0524122A1 EP92460017A EP92460017A EP0524122A1 EP 0524122 A1 EP0524122 A1 EP 0524122A1 EP 92460017 A EP92460017 A EP 92460017A EP 92460017 A EP92460017 A EP 92460017A EP 0524122 A1 EP0524122 A1 EP 0524122A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- volume

- packaging according

- flaps

- packaging

- bellows

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D5/00—Rigid or semi-rigid containers of polygonal cross-section, e.g. boxes, cartons or trays, formed by folding or erecting one or more blanks made of paper

- B65D5/20—Rigid or semi-rigid containers of polygonal cross-section, e.g. boxes, cartons or trays, formed by folding or erecting one or more blanks made of paper by folding-up portions connected to a central panel from all sides to form a container body, e.g. of tray-like form

- B65D5/24—Rigid or semi-rigid containers of polygonal cross-section, e.g. boxes, cartons or trays, formed by folding or erecting one or more blanks made of paper by folding-up portions connected to a central panel from all sides to form a container body, e.g. of tray-like form with adjacent sides interconnected by gusset folds

- B65D5/248—Rigid or semi-rigid containers of polygonal cross-section, e.g. boxes, cartons or trays, formed by folding or erecting one or more blanks made of paper by folding-up portions connected to a central panel from all sides to form a container body, e.g. of tray-like form with adjacent sides interconnected by gusset folds and at least one side being extended and doubled-over to enclose the adjacent gusset flaps

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D5/00—Rigid or semi-rigid containers of polygonal cross-section, e.g. boxes, cartons or trays, formed by folding or erecting one or more blanks made of paper

- B65D5/20—Rigid or semi-rigid containers of polygonal cross-section, e.g. boxes, cartons or trays, formed by folding or erecting one or more blanks made of paper by folding-up portions connected to a central panel from all sides to form a container body, e.g. of tray-like form

- B65D5/2038—Rigid or semi-rigid containers of polygonal cross-section, e.g. boxes, cartons or trays, formed by folding or erecting one or more blanks made of paper by folding-up portions connected to a central panel from all sides to form a container body, e.g. of tray-like form at least two opposed folded-up portions having a non-rectangular shape

- B65D5/2047—Rigid or semi-rigid containers of polygonal cross-section, e.g. boxes, cartons or trays, formed by folding or erecting one or more blanks made of paper by folding-up portions connected to a central panel from all sides to form a container body, e.g. of tray-like form at least two opposed folded-up portions having a non-rectangular shape trapezoidal, e.g. to form a body with diverging side walls

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D5/00—Rigid or semi-rigid containers of polygonal cross-section, e.g. boxes, cartons or trays, formed by folding or erecting one or more blanks made of paper

- B65D5/42—Details of containers or of foldable or erectable container blanks

- B65D5/44—Integral, inserted or attached portions forming internal or external fittings

- B65D5/46—Handles

- B65D5/46072—Handles integral with the container

- B65D5/4612—Handles integral with the container formed by extensions of side flaps or by side flaps of a container formed by folding-up portions connected to a central panel from all sides

- B65D5/46128—Handles integral with the container formed by extensions of side flaps or by side flaps of a container formed by folding-up portions connected to a central panel from all sides two opposite closure flaps being provided with handle elements which are in contact with each other

- B65D5/46144—Handles integral with the container formed by extensions of side flaps or by side flaps of a container formed by folding-up portions connected to a central panel from all sides two opposite closure flaps being provided with handle elements which are in contact with each other either the handle elements being formed with lugs which engage with the other side walls or closure flaps, or the other closure flaps folding over a part of the handle to maintain the handle in position

Definitions

- the invention relates to a packaging made of flexible material intended to allow the transport of perishable products.

- the packaging according to the invention is thus particularly suitable for the transport of seafood and freshwater products.

- the transport of perishable foodstuffs is subordinated in its efficiency to the maintenance over time of the bacteriological, chemical and physical qualities of the transported product.

- the term maintenance over time of these qualities means conservation in the strict sense of the product as well as any minimal modification not perceptible by the consumer even the most demanding and not likely to present any danger to his health.

- crustaceans and molluscs are frequently accompanied, during transport, by seaweed and / or seawater which promote the increase in their shelf life, on the one hand by reducing the increase in temperature during the operation and, on the other hand, by creating a pseudobiological environment favorable to the maintenance of the life of the transported organisms.

- Transport can then be complicated by the leakage of water through the walls of the container used for transport, a leak which causes various soiling, in particular inside vehicles (cars, coaches, etc.) in which the means serving to transport these perishable goods are placed.

- the object of the present invention is to provide a packaging made of flexible material for the transport of perishable foodstuffs, having qualities enabling it to respond to the various problems developed above and showing other advantages.

- the packaging according to the invention also makes it possible to transport perishable goods, such as seafood and freshwater products, without any leakage. water or any other material. It also allows, in a preferred embodiment, to ensure better conservation of the transported product by defining an interior volume generally sealed against radiation and, in particular, in daylight and heat.

- the packaging according to the invention is an optimal packaging usable by the consumer for transport from the place of sale to the place of consumption.

- the volume delimited by the packaging meets criteria of darkness and maintenance of temperature and humidity creating a pseudobiological environment allowing to keep crustaceans alive and instinctively calm. , which facilitates the transport operation.

- the packaging according to the invention also has, in an interesting embodiment, an internal volume delimited by smooth walls making it impossible to cut or cut these walls by the tongs or the shell of crustaceans.

- Another particularly advantageous advantage of the packaging according to the present invention is that it is produced by the volume of a single flat blank according to a simple manipulation accessible to any user.

- the packaging made of flexible material for the transport of perishable products consists of a single piece of a container part surmounted by a part of obturation forming a cover and is achieved by the volume of a single flat cutout. It is characterized in that it has intrinsic means making it possible to ensure the total tightness with liquids of the container forming part and the overall sealing of the packaging to radiation and in that the internal volume formed by the forming part lid closed on the container part does not have any roughness.

- the flexible material constituting the packaging is chosen from the materials making it possible to maintain the humidity in the interior volume.

- the packaging according to the present invention is produced by setting up a flat blank comprising a bottom and four lateral faces, these lateral faces being connected together in pairs by bellows. Each of these bellows is formed by two angular sectors separated by a central fold line.

- the central fold lines allow the angular sectors to be brought together during the volume setting.

- two of the opposite lateral faces are extended by flaps which can be brought back onto the bellows when the latter are folded during the operation of setting up the blank.

- the flaps can be provided with lateral lugs capable of cooperating with notches located at the level of the closing flaps.

- two of the opposite lateral faces are each extended by a closing flap, these two closing flaps being able to be joined in a single plane during the setting in volume of the cutout.

- these closing flaps can each be extended by a tab, these two tabs being pierced with an opening, the two openings being able to be placed facing each other during the setting in volume in order to form a handle.

- a locking tongue is cut out in each of the flaps and each of these locking tongues is pierced with a slot capable of cooperating, during the setting in volume, with notches cut out on the legs.

- At least one of the closing flaps is preferably provided with a closable window.

- the material constituting the packaging is a cardboard coated on its internal face, that is to say the face intended to delimit the internal volume once the cut is set in volume, of a hot-melt food resin .

- this hot-melt food resin may be made up polyurethane foam.

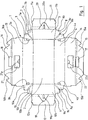

- a cutout 1 has a bottom 2 and four side faces 3, 4, 5, 6 having an identical height. Two of these side faces 3, 4 have a length greater than the other two side faces 5, 6.

- the side faces 3, 4, 5, 6 are connected by four bellows 7, 8, 9, 10, each of these bellows being constituted of two angular sectors 7a, 7b, 8a, 8b, 9a, 9b, 10a, 10b. For each bellows, the angular sectors are separated by a central fold line 7c, 8c, 9c, 10c, making it possible to confer their function on the bellows.

- the side faces 5, 6 are extended by flaps 11, 12 each provided with a locking tongue 19, 20 having a slot 19a, 20a.

- the flaps 11, 12 are moreover provided on their lateral edges with lugs 11a, 11b, 12a, 12b capable of cooperating with notches 3a, 3b, 4a, 4b situated at the ends of the lateral faces 3, 4.

- These lateral faces 3 , 4 are each extended by a closing flap 13, 14, each of these closing flaps being provided with a closable window 21, 22 constituted by a cut in the material forming the cut, cut delimiting a leaf provided with 'a small notch 21a, 22a for opening and closing the window.

- the closing flaps 13, 14 are themselves extended by lugs 15, 16 pierced with openings 17, 18 and provided at their ends with recesses 15a, 15b, 16a, 16b.

- the packaging obtained by setting up the cutout shown in FIG. 1 has a part forming a container 24 and a closing part forming a cover 25.

- Cut-out 1 is made of cardboard coated, on its internal face intended to delimit the interior volume of the packaging, with a polyurethane foam which makes it possible both to ensure the sealed transport of perishable foodstuffs while also ensuring thermal sealing. conducive to the conservation of the bacteriological, physical and chemical qualities of the product transported.

- the packaging Due to its conformation, the packaging also makes it possible to maintain the relative humidity in the interior volume approximately constant for a longer time than the other types of packaging, and therefore to further improve the conditions of transport.

- the interior volume has no roughness, which makes it all particularly suitable for transporting crustaceans.

- the handle 23 facilitates the gripping of the packaging and the closing system organized by the locking tongues 19, 20 on the recesses 15a, 15b, 16a, 16b secure the closing of the packaging.

Abstract

Description

L'invention concerne un emballage en matériau flexible ayant pour objet de permettre le transport de produits périssables. L'emballage selon l'invention est ainsi particulièrement adapté au transport des produits de la mer et d'eau douce.The invention relates to a packaging made of flexible material intended to allow the transport of perishable products. The packaging according to the invention is thus particularly suitable for the transport of seafood and freshwater products.

Le transport des denrées périssables est subordonné dans son efficacité au maintien dans le temps des qualités bactériologiques, chimiques et physiques du produit transporté. On entend par maintien dans le temps de ces qualités, la conservation au sens strict du produit ainsi que toute modification minime non perceptible par le consommateur même le plus exigeant et non susceptible de présenter un quelconque danger pour sa santé.The transport of perishable foodstuffs is subordinated in its efficiency to the maintenance over time of the bacteriological, chemical and physical qualities of the transported product. The term maintenance over time of these qualities means conservation in the strict sense of the product as well as any minimal modification not perceptible by the consumer even the most demanding and not likely to present any danger to his health.

Le maintien des différentes qualités des produits transportés est évidemment nécessaire pour permettre la vente des produits en question puisqu'un manque à ce maintien entraîne inéluctablement une dégradation des qualités organoleptiques, et en particulier des qualités gustatives, visuelles, olfactives et éventuellement tactiles du produit et conséquemment une désaffection de la part du consommateur.The maintenance of the different qualities of the products transported is obviously necessary to allow the sale of the products in question since a lack of this maintenance inevitably leads to a degradation of the organoleptic qualities, and in particular of the taste, visual, olfactory and possibly tactile qualities of the product and consequently a disaffection on the part of the consumer.

Un autre problème posé par le transport des denrées périssables apparaît suivant la nature environnementielle du produit transporté, celui-ci pouvant être accompagné dans son transport par d'autres éléments dont la nature peut provoquer des exigences quant aux moyens utilisés pour effectuer le transport.Another problem posed by the transport of perishable foodstuffs appears according to the environmental nature of the product transported, this product being able to be accompanied in its transport by other elements whose nature can cause requirements as for the means used to carry out the transport.

Ainsi, à titre d'exemple, les crustacés et les mollusques sont fréquemment accompagnés, lors du transport, de goémon et/ou d'eau de mer qui favorisent l'augmentation de leur durée de conservation, d'une part en diminuant l'augmentation de la température au cours de l'opération et, d'autre part, en créant un environnement pseudobiologique favorable au maintien de la vie des organismes transportés. Le transport peut alors être compliqué par la fuite de l'eau à travers les parois du contenant servant au transport, fuite qui occasionne diverses salissures, notamment à l'intérieur des véhicules (automobiles, autocars, ...) dans lesquels les moyens servant au transport de ces denrées périssables sont placés. Ce problème est accru lorsque ces denrées périssables sont constituées d'organismes vivants munis de systèmes de défense piquants, pinçants ou coupants tels que de nombreux crustacés (crabes, écrevisses, homards, langoustes, langoustines, araignées de mer ...) ou les oursins. En effet, l'actionnement de ces systèmes de défense permet à l'animal de couper les contenants qui sont classiquement utilisés pour son transport, tels que les sacs en matière plastique, et ainsi d'autoriser sa propre fuite ou celle de l'eau ou du goémon qui l'accompagnent. De surcroît, et dans le cadre de l'utilisation de nombreux contenants, le transport des crustacés à pinces est rendu difficile par la présence, à l'intérieur de ces contenants, d'aspérités constituant autant de prises permettant auxdits crustacés de sortir du contenant ou de le sectionner plus facilement.Thus, by way of example, crustaceans and molluscs are frequently accompanied, during transport, by seaweed and / or seawater which promote the increase in their shelf life, on the one hand by reducing the increase in temperature during the operation and, on the other hand, by creating a pseudobiological environment favorable to the maintenance of the life of the transported organisms. Transport can then be complicated by the leakage of water through the walls of the container used for transport, a leak which causes various soiling, in particular inside vehicles (cars, coaches, etc.) in which the means serving to transport these perishable goods are placed. This problem is increased when these perishable goods are made up of living organisms provided with pungent, pinching or cutting defense systems such as many crustaceans (crabs, crayfish, lobsters, lobsters, langoustines, spider crabs ...) or sea urchins. Actually, the activation of these defense systems allows the animal to cut the containers which are conventionally used for its transport, such as plastic bags, and thus to authorize its own leak or that of water. or the seaweed accompanying it. In addition, and in the context of the use of numerous containers, the transportation of pincer crustaceans is made difficult by the presence, inside these containers, of roughness constituting as many catches allowing said crustaceans to exit from the container. or to section it more easily.

Ces différents problèmes interviennent fréquemment lors du transport effectué par le consommateur du lieu de vente vers le lieu de consommation.These various problems occur frequently during the transport carried out by the consumer from the point of sale to the place of consumption.

Ainsi, les produits de la mer et d'eau douce sont vendus aux consommateurs en poissonnerie. Pour transporter les produits achetés, les consommateurs utilisent de façon empirique toutes sortes de contenants tels que des sacs en matière plastique, des filets, des paniers, etc ... puisqu'il n'existe pas actuellement d'emballages dédiés à ce genre de transport. Il en résulte différents incidents dûs aux problèmes cités ci-dessus et un mécontentement notamment des autocaristes transportant les touristes acheteurs de ce type de produits.Thus, seafood and freshwater products are sold to consumers in fishmongers. To transport the products purchased, consumers empirically use all kinds of containers such as plastic bags, nets, baskets, etc ... since there is currently no packaging dedicated to this kind of transport. This results in various incidents due to the problems cited above and dissatisfaction, in particular of the coach operators transporting tourists who buy this type of product.

Au moment de la vente au consommateur, les produits pêchés sont exposés à la vente sans emballage. Il y a donc rupture de la chaîne du froid, rupture susceptible de favoriser le développement rapide des microorganismes et provoquant une accélération des processus de dégradation cellulaire et induisant par conséquent un risque éventuel pour le consommateur.At the time of sale to the consumer, the caught products are displayed for sale without packaging. There is therefore a break in the cold chain, a break capable of promoting the rapid development of microorganisms and causing an acceleration of the cellular degradation processes and consequently inducing a possible risk for the consumer.

L'objet de la présente invention est de proposer un emballage en matériau flexible pour le transport des denrées périssables, présentant des qualités lui permettant de répondre aux différents problèmes développés ci-dessus et montrant d'autes avantages.The object of the present invention is to provide a packaging made of flexible material for the transport of perishable foodstuffs, having qualities enabling it to respond to the various problems developed above and showing other advantages.

L'emballage selon l'invention permet en outre de transporter des denrées périssables, tels que des produits de la mer et d'eau douce, sans fuite quelconque d'eau ou de toute autre matière. Il permet également, dans une variante préférentielle de réalisation, d'assurer une meilleure conservation du produit transporté en délimitant un volume intérieur globalement étanche aux rayonnements et, en particulier, à la lumière du jour et à la chaleur.The packaging according to the invention also makes it possible to transport perishable goods, such as seafood and freshwater products, without any leakage. water or any other material. It also allows, in a preferred embodiment, to ensure better conservation of the transported product by defining an interior volume generally sealed against radiation and, in particular, in daylight and heat.

L'emballage selon l'invention, d'un coût de production minime, est un conditionnement optimal utilisable par le consommateur pour le transport du lieu de vente au lieu de consommation. De plus, en ce qui concerne le transport des crustacés, le volume délimité par l'emballage répond à des critères d'obscurité et de maintien de la température et de l'humidité créant un environnement pseudobiologique permettant de maintenir les crustacés vivants et instinctivement tranquilles, ce qui facilite l'opération de transport.The packaging according to the invention, with a minimal production cost, is an optimal packaging usable by the consumer for transport from the place of sale to the place of consumption. In addition, with regard to the transport of crustaceans, the volume delimited by the packaging meets criteria of darkness and maintenance of temperature and humidity creating a pseudobiological environment allowing to keep crustaceans alive and instinctively calm. , which facilitates the transport operation.

L'emballage selon l'invention présente par ailleurs, dans un mode de réalisation intéressant, un volume intérieur délimité par des parois lisses rendant impossible la coupure ou le sectionnement de ces parois par les pinces ou la carapace des crustacés.The packaging according to the invention also has, in an interesting embodiment, an internal volume delimited by smooth walls making it impossible to cut or cut these walls by the tongs or the shell of crustaceans.

Un autre avantage particulièrement intéressant de l'emballage selon la présente invention est qu'il est réalisé par la mise en volume d'une unique découpe plane selon une manipulation simple accessible à tout utilisateur.Another particularly advantageous advantage of the packaging according to the present invention is that it is produced by the volume of a single flat blank according to a simple manipulation accessible to any user.

Selon l'invention, l'emballage en matériau flexible pour le transport de produits périssables, tels que les produits de la mer et d'eau douce est constitué d'un seul tenant d'une partie formant contenant surmontée d'une partie d'obturation formant couvercle et est réalisé par la mise en volume d'une découpe unique plane. Il est caractérisé en ce qu'il présente des moyens intrinsèques permettant d'assurer l'étanchéité totale aux liquides de la partie formant contenant et l'étanchéité globale de l'emballage aux rayonnements et en ce que le volume intérieur formé par la partie formant couvercle rabattu sur la partie formant contenant ne présente pas d'aspérité.According to the invention, the packaging made of flexible material for the transport of perishable products, such as seafood and freshwater products, consists of a single piece of a container part surmounted by a part of obturation forming a cover and is achieved by the volume of a single flat cutout. It is characterized in that it has intrinsic means making it possible to ensure the total tightness with liquids of the container forming part and the overall sealing of the packaging to radiation and in that the internal volume formed by the forming part lid closed on the container part does not have any roughness.

Egalement préférentiellement, le matériau flexible constituant l'emballage est choisi parmi les matériaux permettant d'assurer le maintient de l'hygrométrie dans le volume intérieur.Also preferably, the flexible material constituting the packaging is chosen from the materials making it possible to maintain the humidity in the interior volume.

Selon un mode de réalisation particulièrement avantageux, l'emballage selon la présente invention est réalisé par la mise en volume d'une découpe plane comprenant un fond et quatre faces latérales, ces faces latérales étant reliées entre elles deux à deux par des soufflets. Chacun de ces soufflets est formé par deux secteurs angulaires séparés par une ligne de pliage centrale.According to a particularly advantageous embodiment, the packaging according to the present invention is produced by setting up a flat blank comprising a bottom and four lateral faces, these lateral faces being connected together in pairs by bellows. Each of these bellows is formed by two angular sectors separated by a central fold line.

Les lignes de pliage centrales permettent le rapprochement des secteurs angulaires lors de la mise en volume.The central fold lines allow the angular sectors to be brought together during the volume setting.

Avantageusement, deux des faces latérales opposées sont prolongées par des rabats pouvant être ramenés sur les soufflets lorsque ceux-ci sont pliés lors de l'opération de la mise en volume de la découpe.Advantageously, two of the opposite lateral faces are extended by flaps which can be brought back onto the bellows when the latter are folded during the operation of setting up the blank.

Selon une disposition intéressante, les rabats peuvent être munis d'ergots latéraux aptes à coopérer avec des encoches situées au niveau des volets de fermeture.According to an advantageous arrangement, the flaps can be provided with lateral lugs capable of cooperating with notches located at the level of the closing flaps.

Préférentiellement, deux des faces latérales opposées sont chacune prolongées par un volet de fermeture, ces deux volets de fermeture pouvant être joints dans un plan unique lors de la mise en volume de la découpe.Preferably, two of the opposite lateral faces are each extended by a closing flap, these two closing flaps being able to be joined in a single plane during the setting in volume of the cutout.

Additionnellement, ces volets de fermeture peuvent être prolongés chacun par une patte, ces deux pattes étant percées d'une ouverture, les deux ouvertures pouvant être mises en regard lors de la mise en volume afin de former une poignée.Additionally, these closing flaps can each be extended by a tab, these two tabs being pierced with an opening, the two openings being able to be placed facing each other during the setting in volume in order to form a handle.

Avantageusement, une langue de verrouillage est découpée dans chacun des rabats et chacune des ces langues de verrouillage est percée d'une fente apte à coopérer, lors de la mise en volume, avec des décrochements découpés sur les pattes.Advantageously, a locking tongue is cut out in each of the flaps and each of these locking tongues is pierced with a slot capable of cooperating, during the setting in volume, with notches cut out on the legs.

Dans le but de pouvoir observer le produit contenu à l'intérieur de l'emballage, au moins un des volets de fermeture est préférentiellement muni d'une fenêtre obturable.In order to be able to observe the product contained inside the packaging, at least one of the closing flaps is preferably provided with a closable window.

D'une façon intéressante, le matériau constituant l'emballage est un carton revêtu sur sa face intérieure, c'est-à-dire la face destinée à délimiter le volume intérieur une fois la découpe mise en volume, d'une résine alimentaire thermofusible. Avantageusement, cette résine alimentaire thermofusible pourra être constituée d'une mousse de polyuréthane.Interestingly, the material constituting the packaging is a cardboard coated on its internal face, that is to say the face intended to delimit the internal volume once the cut is set in volume, of a hot-melt food resin . Advantageously, this hot-melt food resin may be made up polyurethane foam.

L'invention ainsi que les multiples avantages qu'elle présente seront plus facilement compris grâce à la description qui va suivre d'un exemple non limitatif de réalisation de l'invention, en référence aux dessins dans lesquels :

- la figure 1 représente une vue de face d'une découpe dont la mise en volume permet d'obtenir un emballage selon l'invention ;

- la figure 2 représente l'emballage obtenu par la mise en volume de la découpe représentée à la figure 1.

- FIG. 1 represents a front view of a blank whose volume setting makes it possible to obtain a packaging according to the invention;

- FIG. 2 represents the packaging obtained by the volume of the blank shown in FIG. 1.

Selon la figure 1, une découpe 1 présente un fond 2 et quatre faces latérales 3, 4, 5, 6 possédant une hauteur identique. Deux de ces faces latérales 3, 4 présentent une longueur supérieure aux deux autres faces latérales 5, 6. Les faces latérales 3, 4, 5, 6 sont reliées par quatre soufflets 7, 8, 9, 10, chacun de ces soufflets étant constitué de deux secteurs angulaires 7a, 7b, 8a, 8b, 9a, 9b, 10a, 10b. Pour chaque soufflet, les secteurs angulaires sont séparés par une ligne de pliage centrale 7c, 8c, 9c, 10c, permettant de conférer leur fonction aux soufflets. Les faces latérales 5, 6 sont prolongées par des rabats 11, 12 munis chacun d'une langue de verrouillage 19, 20 présentant une fente 19a, 20a. Les rabats 11, 12 sont par ailleurs munis sur leurs bords latéraux d'ergots 11a, 11b, 12a, 12b aptes à coopérer avec des encoches 3a, 3b, 4a, 4b situées aux extrémités des faces latérales 3, 4. Ces faces latérales 3, 4 sont quant à elles prolongées chacune par un volet de fermeture 13, 14, chacun de ces volets de fermeture étant muni d'une fenêtre obturable 21, 22 constituée par une coupe dans le matériau formant la découpe, coupe délimitant un battant muni d'une petite entaille 21a, 22a permettant d'ouvrir et de fermer la fenêtre.According to Figure 1, a

Les volets de fermeture 13, 14 sont eux-mêmes prolongés par des pattes 15, 16 percées d'ouvertures 17, 18 et pourvues en leurs extrémités de décrochements 15a, 15b, 16a, 16b.The

Selon la figure 2, l'emballage obtenu par la mise en volume de la découpe représentée à la figure 1 présente une partie formant contenant 24 et une partie d'obturation formant couvercle 25.According to FIG. 2, the packaging obtained by setting up the cutout shown in FIG. 1 has a part forming a

En référence aux deux figures, la mise en volume est effectuée selon les étapes suivantes :

- les faces latérales 3, 4, 5, 6 sont amenées en position sensiblement verticale, les lignes de pliage centrales 7c, 8c, 9c, 10c permettant le pliage des

soufflets - les

soufflets 7 et 8 d'une part et 9 et 10 d'autre part sont plaqués respectivement contre les faces latérales 5 et 6 ; - les

rabats - les

ergots encoches rabats - les langues de

verrouillage rabats - les volets de

fermeture - les

pattes ouvertures 17 et 18 afin de constituer unepoignée 23 ; - enfin, les langues de

verrouillage 19 et 20 sont accrochées de façon à faire coopérer lesfentes 19a, 20a respectivement avec lesdécrochements décrochements

- the lateral faces 3, 4, 5, 6 are brought into a substantially vertical position, the

central fold lines bellows - the

bellows - the

flaps - the

pins notches flaps - the locking

tongues flaps - the closing flaps 13, 14 are brought back to the part now formed forming the container, in a horizontal plane;

- the

tabs openings handle 23; - finally, the locking

tongues slots 19a, 20a cooperate respectively with therecesses recesses

La découpe 1 est réalisée en carton revêtu, sur sa face interne destinée à délimiter le volume intérieur de l'emballage, d'une mousse de polyuréthane qui permet à la fois d'assurer le transport étanche des denrées périssables en assurant également une étanchéité thermique propice à la conservation des qualités bactériologiques, physiques et chimiques du produit transporté.Cut-

De par sa conformation, l'emballage permet également de maintenir environ constante l'hygrométrie dans le volume intérieur pendant un temps plus long que les autres types d'emballages, et donc d'améliorer encore les conditions du transport.Due to its conformation, the packaging also makes it possible to maintain the relative humidity in the interior volume approximately constant for a longer time than the other types of packaging, and therefore to further improve the conditions of transport.

Le volume intérieur ne présente pas d'aspérité, ce qui le rend tout particulièrement adapté au transport des crustacés. La poignée 23 facilite la préhension de l'emballage et le système de fermeture organisé par les langues de verrouillage 19, 20 sur les décrochements 15a, 15b, 16a, 16b sécurisent la fermeture de l'emballage.The interior volume has no roughness, which makes it all particularly suitable for transporting crustaceans. The

Claims (10)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR9107915 | 1991-06-24 | ||

| FR9107915A FR2677962A1 (en) | 1991-06-24 | 1991-06-24 | PACKAGING IN FLEXIBLE MATERIAL FOR THE TRANSPORT OF PERISHABLE PRODUCTS. |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| EP0524122A1 true EP0524122A1 (en) | 1993-01-20 |

Family

ID=9414341

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP92460017A Withdrawn EP0524122A1 (en) | 1991-06-24 | 1992-06-24 | Container made from flexible material for transporting perishable produce |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP0524122A1 (en) |

| FR (1) | FR2677962A1 (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2791951A1 (en) * | 1999-04-08 | 2000-10-13 | Mermonde | Container and procedure for packaging perishable foodstuffs such as shellfish has relatively rigid transparent panel between contents and top seal |

| IT202000012202A1 (en) * | 2020-05-25 | 2021-11-25 | Artecarta Italia S R L | NON-SPILL FOOD BOX |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| ITMI942357A1 (en) * | 1994-11-21 | 1996-05-21 | Luigi Fraccaro | SINGLE-PIECE CARDBOARD PACKAGE FOR SWEETS |

| IT201700035574A1 (en) * | 2017-03-31 | 2018-10-01 | Novagraphica Bags Srl | BOX FOR FOODS FROM EXPECTED REMOVAL |

| CN109028693B (en) * | 2018-04-23 | 2020-10-09 | 汕头市深投科技有限公司 | Improved aquatic product fresh-keeping device |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR940449A (en) * | 1945-07-12 | 1948-12-13 | Unfolding packaging | |

| FR1032151A (en) * | 1951-02-07 | 1953-06-30 | Service Professionnel D Achat | Waterproof box obtained by folding |

| FR1065819A (en) * | 1952-11-03 | 1954-05-31 | Leak-proof packaging for pasty or other fluid products | |

| US4391405A (en) * | 1981-10-23 | 1983-07-05 | Weyerhaeuser Company | Container |

| US4687130A (en) * | 1986-11-17 | 1987-08-18 | Beeler Mfg. Co. | Disposable ice and beverage container |

-

1991

- 1991-06-24 FR FR9107915A patent/FR2677962A1/en active Granted

-

1992

- 1992-06-24 EP EP92460017A patent/EP0524122A1/en not_active Withdrawn

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR940449A (en) * | 1945-07-12 | 1948-12-13 | Unfolding packaging | |

| FR1032151A (en) * | 1951-02-07 | 1953-06-30 | Service Professionnel D Achat | Waterproof box obtained by folding |

| FR1065819A (en) * | 1952-11-03 | 1954-05-31 | Leak-proof packaging for pasty or other fluid products | |

| US4391405A (en) * | 1981-10-23 | 1983-07-05 | Weyerhaeuser Company | Container |

| US4687130A (en) * | 1986-11-17 | 1987-08-18 | Beeler Mfg. Co. | Disposable ice and beverage container |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2791951A1 (en) * | 1999-04-08 | 2000-10-13 | Mermonde | Container and procedure for packaging perishable foodstuffs such as shellfish has relatively rigid transparent panel between contents and top seal |

| IT202000012202A1 (en) * | 2020-05-25 | 2021-11-25 | Artecarta Italia S R L | NON-SPILL FOOD BOX |

Also Published As

| Publication number | Publication date |

|---|---|

| FR2677962B1 (en) | 1995-02-03 |

| FR2677962A1 (en) | 1992-12-24 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US20110038564A1 (en) | Reusable silicone bag | |

| US9179750B2 (en) | Combination beverage and sandwich container | |

| US20150197388A1 (en) | Watermelon Pouch | |

| EP0524122A1 (en) | Container made from flexible material for transporting perishable produce | |

| WO2002055403A1 (en) | Easy-to-open packaging shell | |

| EP2011742A1 (en) | Vertical stand-up pouch for steam cooking and steam cooking method | |

| FR2682935A1 (en) | Tamper indicator for packaging trays, trays including such an indicator and applications | |

| FR2962111A1 (en) | Sealed reusable package for shipping and storage department e.g. postal department, has hermetic inviolable closing device whose access faces are formed by consisting male and female rivets provided with incipient fracture part | |

| CA2860518A1 (en) | Compostable box for recycling food residue | |

| CH688089A5 (en) | isothermal packaging. | |

| CN212465750U (en) | Barbecue bag and lunch box | |

| EP2354031B1 (en) | Lidded container | |

| FR2914284A1 (en) | Semi rigid envelope shaped package for storing e.g. wine, has valve type distribution device comprising neck passing via recesses formed in tab and surface of outer case, where tab is moved in translation and folds neck in closed position | |

| EP1186549A1 (en) | Disposable container for mixable foodstuffs | |

| FR2915468A3 (en) | Oblong type recyclable food e.g. bread, package, e.g. bag, for e.g. bakery, has transparent area/window made of material such as copy paper and gelatin paper type transparent or translucent paper, fixed at rest of package structure | |

| FR2784662A1 (en) | Package for pasty food product comprises two complementary parts with overlaping edges that form lid and linked by temporary seal ruptured by pull tab formed from film element. | |

| US20150344208A1 (en) | Pack for consumable products, in particular foodstuffs | |

| FR2576881A1 (en) | Package for portions of food products | |

| CA2145741A1 (en) | Adjustable volume reusable container | |

| CH372240A (en) | Packaging | |

| EP4066708A1 (en) | Portable and reusable packaging, in particular for packaging foodstuffs | |

| EP0865995B1 (en) | Thermoplastic packaging item, manufacture and use thereof | |

| FR2505141A1 (en) | Plastics mouse-trap with lid and base - has partition dividing bait and entry compartments, preventing access by domestic animals | |

| FR2864826A1 (en) | Liquid, solid or pasty food`s control sample preserving tray for use in e.g. school, has cells, each having independent cover, where each cell is surrounded by projecting groove fitted in groove on circumference of cover associated to cell | |

| WO2002059009A1 (en) | Cap with special hollow space |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): ES GB IT NL PT |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 19930721 |