EP0515371B1 - Hand-held machine tool - Google Patents

Hand-held machine tool Download PDFInfo

- Publication number

- EP0515371B1 EP0515371B1 EP90916263A EP90916263A EP0515371B1 EP 0515371 B1 EP0515371 B1 EP 0515371B1 EP 90916263 A EP90916263 A EP 90916263A EP 90916263 A EP90916263 A EP 90916263A EP 0515371 B1 EP0515371 B1 EP 0515371B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- machine tool

- working shaft

- shaft

- tool according

- coupling

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B25—HAND TOOLS; PORTABLE POWER-DRIVEN TOOLS; MANIPULATORS

- B25F—COMBINATION OR MULTI-PURPOSE TOOLS NOT OTHERWISE PROVIDED FOR; DETAILS OR COMPONENTS OF PORTABLE POWER-DRIVEN TOOLS NOT PARTICULARLY RELATED TO THE OPERATIONS PERFORMED AND NOT OTHERWISE PROVIDED FOR

- B25F3/00—Associations of tools for different working operations with one portable power-drive means; Adapters therefor

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B25—HAND TOOLS; PORTABLE POWER-DRIVEN TOOLS; MANIPULATORS

- B25D—PERCUSSIVE TOOLS

- B25D16/00—Portable percussive machines with superimposed rotation, the rotational movement of the output shaft of a motor being modified to generate axial impacts on the tool bit

- B25D16/003—Clutches specially adapted therefor

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B25—HAND TOOLS; PORTABLE POWER-DRIVEN TOOLS; MANIPULATORS

- B25F—COMBINATION OR MULTI-PURPOSE TOOLS NOT OTHERWISE PROVIDED FOR; DETAILS OR COMPONENTS OF PORTABLE POWER-DRIVEN TOOLS NOT PARTICULARLY RELATED TO THE OPERATIONS PERFORMED AND NOT OTHERWISE PROVIDED FOR

- B25F5/00—Details or components of portable power-driven tools not particularly related to the operations performed and not otherwise provided for

- B25F5/001—Gearings, speed selectors, clutches or the like specially adapted for rotary tools

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B25—HAND TOOLS; PORTABLE POWER-DRIVEN TOOLS; MANIPULATORS

- B25D—PERCUSSIVE TOOLS

- B25D2211/00—Details of portable percussive tools with electromotor or other motor drive

- B25D2211/006—Parallel drill and motor spindles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B25—HAND TOOLS; PORTABLE POWER-DRIVEN TOOLS; MANIPULATORS

- B25D—PERCUSSIVE TOOLS

- B25D2211/00—Details of portable percussive tools with electromotor or other motor drive

- B25D2211/06—Means for driving the impulse member

- B25D2211/068—Crank-actuated impulse-driving mechanisms

Definitions

- the hand machine tool can be used wherever work and machining is carried out using tools of all kinds.

- the area of manual workmanship by non-specialists should be taken into account, as well as the area of professional handicraft and industrial processing.

- the invention relates to a hand machine tool according to the preamble of claim 1, in particular for drilling, punching, sawing, chiseling, filing, grinding, screwing, drilling saws, rasps, drilling files, circular saws, rasps, planing with a working shaft and with a, preferably electric, drive motor.

- a generic hand machine tool is known from WO-A-89/11955.

- Such machines are for certain functions, e.g. known as a saw-file rasp or as a drilling and impact drilling machine.

- a machine tool for stone processing in which the striking tool can be set either in a striking movement or in a striking and at the same time rotating (drilling) movement (DE-U-19 03 434).

- a rotary hammer has also been proposed in which an automatic switchover to the most varied of operating modes is possible, the technical solution being that a contour is scanned on the tool used is and the resulting information is converted into switching signals, for example for a certain speed and for a certain number of strokes (DE-A-37 20 512).

- a hand-held tool in which a tool can be set either into a rotation or into a rotation and a striking movement or into a pure striking movement, the special solution being that there is a very specific association between the speed and the striking movements, to make holes in a perforated base in a very specific way (EP-A-143 086).

- a very special embodiment shows an externally driven saw, the special idea being to use a drill known per se as the drive, which is connected to the actual saw via a flexible shaft. The rotary movement is then set into a translational movement in the housing of the saw (US Pat. No. 4,841,643).

- Another known drill shows a gear design with which the number of blows per revolution of the output shaft can be adapted to the material of a workpiece to be machined when the speed of the output shaft is set.

- the proposed option for this consists in a gear on the output shaft which can be displaced on a spline, which can be assigned to different pinions of the drive (DE-C-27 34 965).

- a generic machine tool with a working shaft provided with a tool holder and a drive device in which the rotary movement continuously transmitted from a drive motor to a tool holder can be switched off and locked as desired, a rotatable intermediate shaft, which is axially displaceable and has a toothing in which one or the other axially different position can be brought with an externally operable switching device such that the toothing either for switching the rotary movement on or off or for non-rotatably locking the working shaft of a tool - Or disengageable, the working shaft of the tool can, if required, be simultaneously set in a reciprocating movement with a swash plate gear which can be driven via a clutch which can be switched by axial displacement of the intermediate shaft.

- the invention has for its object to provide a hand machine tool of the generic type for a larger number of different machining functions, in particular for drilling, filing, rasps, drilling files, circular saws, grinding, planing, impact drilling, screws, saws, saws, rasps and chisels. Furthermore, it should, preferably possible when the work shaft is at a standstill, another work machine, e.g. to drive a circular saw.

- Another tool e.g. a circular saw or a flexible shaft, connectable. It is advantageous if the sixth clutch is arranged on the side of the drive motor facing away from the tool holder on the working shaft.

- a coupling of the first and a coupling of the second group can be made separately selectable, enables a number of different functions to be achieved. If the shaft is rotated via the first clutch, a round rasp can be set in rotating and simultaneously reciprocating motion when the third clutch engages, or hammer drilling can be carried out when the fourth clutch engages, or it can be done when the fifth clutch engages Coupling the working shaft must be locked in the longitudinal direction and so normal drilling or screwing can be carried out.

- a sawing movement can be achieved via the third coupling or a striking movement for a chisel via the fourth coupling or complete locking via the fifth coupling, so that the machine tool as a whole can be used like a screwdriver with increased leverage.

- the machine tool can also form the drive for another machine tool as a motor.

- the embodiment of the hand machine tool according to the invention is characterized in that the motor rotates a first bevel gear with an axis parallel to the working shaft, which drives a second bevel gear with an axis approximately perpendicular to the working shaft and that a push rod gear for generating the oscillating movement parallel to the working shaft, and that a third bevel gear with an axis parallel to the working shaft is axially displaceable such that it either engages with the second bevel gear in the form of the first clutch or is locked in the form of the second clutch, whereby a fixedly connected to the third bevel gear first spur gear is in engagement with a second spur gear attached to the working shaft and that the working shaft is mounted displaceably in the axial direction and that on the working shaft one over a certain, such as the stroke of the oscillation corresponding movement distance, e.g.

- an inner stop on the the drive, e.g. a drill chuck, side facing away

- an adjustable, e.g. ring-shaped, external stop arranged on the working shaft is arranged in the axial direction on the working shaft freely movable block to which the oscillating movement is fed with a certain stroke and that the block is held in a first position of the outer stop, for example clamping, in such a way that the working shaft follows the oscillating movement supplied to the block in the axial direction or that the outer stop is in a second position which is less than the stroke of the oscillating movement and is less than the stroke of the oscillating movement Position is fixed so that with each movement an (outward) blow is applied to the working shaft, or that the outer blow is arranged in a third position which is more than the stroke of the oscillating movement away from the first position, so that the working wave from the oscillating motion ni is not influenced and stands still in the axial direction.

- the oscillating movement is thus produced by means of a bevel gear, which at the same time serves to transmit the rotary movement or to lock the working shaft.

- the movement in the longitudinal direction can be adjusted in a simple manner by means of the adjustable outer stop, which then acts like separate (third, fourth, fifth) couplings.

- the block can be freely rotated on the working shaft so that it can rotate with the oscillating drive can be connected.

- the working shaft is expediently returned to a certain rest position by means of a tension or compression spring on an adjustable carriage, so that an adjustment of the outer stop is possible without difficulty and the required distance for the block remains free during the oscillating movement.

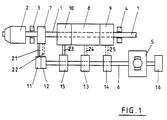

- a working shaft 1 carries a tool holder 2, e.g. a drill chuck.

- the shaft 1 is supported in bearings 3 and 4 in such a way that it is longitudinally extended by a stroke of e.g. 15 mm is displaceable.

- a drive shaft 6 can be set in rotation by a motor 5.

- a first and a second clutch 11 and 12 Arranged on the shaft 6 are a first and a second clutch 11 and 12, which can set or block the working shaft 1 in rotary motion via transmission members 21 and 22 and a gear arrangement 7.

- the third clutch 13, the fourth clutch 14 and the fifth clutch 15 are also arranged on the shaft 6 and are connected to the working shaft 1 via transmission elements 23, 24, 25 and gear arrangements 8, 9, 10.

- An oscillating movement or a striking movement can be supplied in the longitudinal direction by means of the third coupling 13 or via the fourth coupling 14 of the working shaft 1.

- the working shaft 1 can also be locked by means of the fifth clutch 15.

- the working shaft 1 rotates, but cannot be moved in the longitudinal direction.

- the effect of a drilling machine is thus obtained.

- the clutch 13 is closed, the working shaft 1 reciprocates in the longitudinal direction and rotates in the process; it can thus be used in the chuck 2, for example, a round rasp with which openings in a wooden plate can be created and enlarged.

- the clutches 12 and 13 closed, the working shaft 1 does not rotate, but moves back and forth in the longitudinal direction. A normal saw blade can thus be brought into effect in the tool holder 2.

- the clutches 12 and 14 are closed, the shaft does not rotate, does not move appreciably in the longitudinal direction, but only exerts impacts.

- a chisel attached to a tool holder 2 can thus do its job.

- the shaft 1 rotates and strikes; a hammer drill can therefore be brought into effect.

- the clutches 12 and 15 are closed, the working shaft 1 is immovably fixed.

- a tool inserted into the holder 2 can thus be used in the intended manner, the hand machine tool as a whole being able to be used as a larger handle with increased force and leverage.

- screws also Allen screws or screws, can be actuated by hand using a socket wrench, whereby after overcoming a greater resistance, the rotary movement can be started by switching from 12 to 11, thus further loosening the screw in question can be effected.

- a sixth coupling 16 to drive another tool, for example a circular saw, flexible shaft or the like.

- another tool for example a circular saw, flexible shaft or the like.

- the hand-held machine tool is also used as such, and its motor and the control circuits for speed and force, which are provided in a manner known per se can be operated together.

- the working shaft 1 in the bearings 3 and 4 carries a drill chuck 2 or another tool holder.

- a second bevel gear 33 in engagement with the first bevel gear 31 is mounted on an axis 32, indicated only by dashed lines and perpendicular to the working shaft 1.

- the axis 32 is fixed in a bearing block 34.

- a third bevel gear 35 with an axis 36 is arranged on a bearing block 37.

- a spring-loaded pin 73 which engages with a corresponding axial displacement of the spur gear 38 in a bore 74, not shown, in the gear 38 and fixes it.

- the third bevel gear 35 is structurally connected to a first spur gear 38 which is in engagement with a second spur gear 39 on the working shaft 1.

- the second spur gear 39 has a considerable length such that the shaft 1 can be displaced in the longitudinal direction in accordance with the intended stroke, without the rotation of the working shaft 1 being impaired.

- the shaft 1 is on the far right and touches with the flank of the spur gear 39 the bearing block 4, which is optionally provided with a slide bearing or also with a ball bearing 40 on the end face.

- an adjustable fixed stop ring 41 is attached, with which, as will be described later, the oscillating movement can be adapted if necessary.

- An axle bearing 42 which is connected to a push rod 43, is eccentrically attached to the second bevel gear 33.

- This push rod which can optionally be divided and additionally supported, actuates a movement rod 44.

- the other end is fastened to a block 45 which is moved back and forth on the axis 1 in the longitudinal direction in accordance with the stroke represented by a double arrow 51 when the bevel gear 33 rotates in a circle.

- a driver 46 is attached to the working shaft 1, which can snap into a first, second or third groove 47, 48 or 49 in a manner shown in more detail in FIG. 3, wherein it has an adjustable outer stop for the movement of the block 45 the shaft 1 forms.

- the driver 46 If the driver 46 is engaged in the groove 47 shown on the right, it practically rests with its lateral surface on the side surface of the block 45; the side surfaces of which can carry damping elements and / or ball bearings 50 in order to prevent mechanical interference during the reciprocating movement of the block 45 and during the rotation of parts attached to the shaft To avoid stress.

- the block 45 In this position, the block 45 is thus enclosed between the stop 41 and the driver 46; during the lateral movement of the block 45, the shaft 1 is thus taken along with the parts attached to it and carries out the oscillating movement predetermined by the bevel gear 33 from the eccentric arrangement, which is transmitted via the movement rod 44 from the push rod 43 to the block 45.

- This setting is therefore suitable, for example, to put either a fixed saw or a rotating circular rasp into operation, depending on whether or not a rotary movement is transmitted to the second spur gear 39 from the first spur gear 38.

- a tension spring 52 can be arranged over the end of the shaft so that it pulls the shaft 1 into the position shown in the drawing, in which the second spur gear 39 is pulled against the bearing 4. If the spur gear 39 is now supplied with rotation, the machine tool according to the invention can work as a drilling machine.

- the block 45 can initially move freely over approximately half of the stroke 51 and does not move the shaft 1. Then the block 45 hits the Carrier 46 and moves it forward a little. In this way, a blow can be exerted on the tool mounted in the tool holder 2, for example a simple chisel or a stone drill, which can then also be rotated.

- a housing holding the parts together with a holder 53b in the manner of a drill handle is shown in a manner known per se.

- this housing can also be provided with an additional handle 53c in the region of the bearing 3 in order to facilitate guiding the tool at work.

- a switch is indicated, which can also bring about electronic speed control in a known manner, depending on how hard the finger is pressed on it.

- the end of the working shaft 1 on the inside of the housing is provided with an axial bore 78a, into which a swivel 78 is inserted.

- two grub screws 79 are countersunk, which are arranged extending into the axial bore 78a.

- the tip of the grub screws 79 engage in a circumferential groove 47a in the swivel 78, so that rotation of the working shaft 1 is possible without hindrance.

- the swivel 78 is supported on a screw connection 78b at one end of a tension spring 52, so that an axial movement of the working shaft 1 is only possible under the influence of the spring force of the tension spring 52.

- the tension spring is connected at its other end to an adjusting slide 55 which is adjustable via an adjusting clamping screw 55a.

- Fig. 3 shows a hand machine tool according to the invention cut approximately along the line B-B in Fig. 2 in the view from above.

- the same parts are provided with the same reference numbers.

- 3 shows in particular the mechanism for adjusting the position of the driver 46.

- This driver which encircles the shaft 1 in the area of the groove 48, is formed by two half rings which are pressed against the shaft 1 by means of springs 57 and 58, respectively.

- the springs 57 and 58 are supported against the front part of the housing 53 or the like via washers. 59 and 60.

- Rods 61 and 62 are guided through slots 53a in the housing 53 and carry button plates 63 and 64 at their upper ends.

- buttons 65 and 66 are located in the protective box under protective covers 65 and 66, which can be opened forward about pivot axes 67 and 68.

- the protective covers touch protective switches 65a, 66a which interrupt the power supply as soon as the covers are opened, the covers 65, 66 being held in their closed position by the springs 67a, 68a.

- the button plates 63 and 64 can then be gripped and pulled outwards, so that the parts of the driver 46 are lifted out of the groove 48 and the driver 46 can be moved into the groove 47 or into the groove 49.

- either the third or the fourth or the fifth coupling is then effective in such a way that either, as described above, the shaft 1 is set in oscillating motion or makes striking movements or is locked in the longitudinal direction.

- the driver 46 consisting of two semi-ring-shaped elements with the springs 57 and 58 and the rods 61 and 62 in a schematic semi-oblique representation. It can be clearly seen how the two half-part drivers 46 can be pulled out of the shaft 1 from the groove by means of the button plates 63 and 64, while they are normally held in the groove 48 by means of the two springs 57, 58.

- FIG. 4 shows a representation corresponding to the section AA in FIG. 2, that is to say at the level of the engagement area of the first and second spur gearwheels 38 and 39.

- the bearing journal 36 of the first gearwheel is slidably mounted in the bearing block 37 , wherein the displacement takes place by means of a spring-loaded raster adjusting lever 71, the movement of which is transmitted via a lever 72 to a groove 75 in the axle piece 36, so that the third bevel gear 35 is either engaged or not with the second bevel gear 33.

- the work wave 1 then stands still, but it can still perform back and forth movements.

- the locking element 71 is connected via a bolt slot connection 76 under the action of a spring 77, not shown, to the lever 72 so that the locking element 71 can be pulled up to carry out the adjustment.

- Protection covers 80, 81 are provided in the area of the front tip of the working shaft 1. These are the Part of the working shaft 1 projecting from the front of the housing and arranged to overlap the tool holder 2, wherein they can each be pivoted about a pivot axis 67b, 68b and are held under the force of a spring 67c, 68c in a closed position in which they form a cylindrical cover cap (80.81) add.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Percussive Tools And Related Accessories (AREA)

- Portable Power Tools In General (AREA)

- Medicines Containing Material From Animals Or Micro-Organisms (AREA)

- Gripping On Spindles (AREA)

- Manipulator (AREA)

- Sawing (AREA)

- Walking Sticks, Umbrellas, And Fans (AREA)

- Adornments (AREA)

Abstract

Description

Die Hand-Werkzeugmaschine ist überall dort einsetzbar, wo Arbeiten und Bearbeitungen unter Verwendung von Werkzeugen jeder Art durchgeführt werden. Der Bereich der handwerklichen Eigenbearbeitung durch Nichtfachleute ist dabei ebenso in Betracht zu ziehen wie der Bereich des professionellen Handwerks und der industriellen Bearbeitung.The hand machine tool can be used wherever work and machining is carried out using tools of all kinds. The area of manual workmanship by non-specialists should be taken into account, as well as the area of professional handicraft and industrial processing.

Die Erfindung bezieht sich auf eine Hand-Werkzeugmaschine nach dem Oberbegriff des Anspruchs 1, insbesondere zum Bohren, Schlagboren, Sägen, Meißeln, Feilen, Schleifen, Schrauben, Bohrsägen, Bohrraspeln, Bohrfeilen, Kreissägen, Raspeln, Hobeln mit einer Arbeitswelle und mit einem, vorzugsweise elektrischen, Antriebsmotor. Eine gattungsgemäße Hand-Werkzeugmaschine ist aus der WO-A-89/11955 bekannt.The invention relates to a hand machine tool according to the preamble of

Derartige Maschinen sind für bestimmte Funktionen, z.B. als Säge-Feile-Raspel oder als Bohr- und Schlagbohr-Maschine bekannt.Such machines are for certain functions, e.g. known as a saw-file rasp or as a drilling and impact drilling machine.

So ist eine Werkzeugmaschine zur Steinbearbeitung bekannt, bei der das Schlagwerkzeug wahlweise in eine schlagende Bewegung oder in eine schlagende und zugleich drehende (bohrende) Bewegung versetzbar ist (DE-U-19 03 434).For example, a machine tool for stone processing is known in which the striking tool can be set either in a striking movement or in a striking and at the same time rotating (drilling) movement (DE-U-19 03 434).

Auch ist ein Bohrhammer vorgeschlagen worden, bei dem ein automatisches Umschalten auf unterschiedlichste Betriebsarten möglich ist, wobei die technische Lösung darin besteht, daß eine Kontur am eingesetzten Werkzeug abgetastet wird und die sich hieraus ergebenden Informationen in Schaltsignale, beispielsweise für eine bestimmte Drehzahl und für eine bestimmte Schlagzahl, umgewandelt werden (DE-A-37 20 512).A rotary hammer has also been proposed in which an automatic switchover to the most varied of operating modes is possible, the technical solution being that a contour is scanned on the tool used is and the resulting information is converted into switching signals, for example for a certain speed and for a certain number of strokes (DE-A-37 20 512).

Weiterhin ist ein Handarbeitsgerät bekannt, bei dem ein Werkzeug entweder in eine Drehung oder in eine Drehung und eine Schlagbewegung oder in eine reine Schlagbewegung versetzbar ist, wobei die spezielle Lösung darin besteht, daß eine ganz bestimmte Zuordnung zwischen der Drehzahl und den Schlagbewegungen gegeben ist, um in ganz bestimmter Weise Löcher in einen Lochboden einzubringen (EP-A-143 086).Furthermore, a hand-held tool is known in which a tool can be set either into a rotation or into a rotation and a striking movement or into a pure striking movement, the special solution being that there is a very specific association between the speed and the striking movements, to make holes in a perforated base in a very specific way (EP-A-143 086).

Eine ganz spezielle Ausgestaltung zeigt eine fremdangetriebene Säge, wobei die spezielle Idee darin besteht, als Antrieb eine an sich bekannte Bohrmaschine zu verwenden, die über eine flexible Welle mit der eigentlichen Säge verbunden wird. Im Gehäuse der Säge wird dann die Drehbewegung in eine Translationsbewegung ungesetzt (US-A-4,841,643).A very special embodiment shows an externally driven saw, the special idea being to use a drill known per se as the drive, which is connected to the actual saw via a flexible shaft. The rotary movement is then set into a translational movement in the housing of the saw (US Pat. No. 4,841,643).

Eine weitere bekannte Bohrmaschine zeigt eine Getriebeausgestaltung, mit der bei eingestellter Drehzahl der Abgabewelle die Anzahl der Schläge pro Umdrehung der Abgabewelle an das Material eines zu bearbeitenden Werkstücks anpaßbar ist. Die hierzu vorgeschlagene Möglichkeit besteht in einem auf einem Keilprofil versetzbaren Zahnrad auf der Abgabewelle, das unterschiedlichen Ritzeln des Antriebes zugeordnet werden kann (DE-C-27 34 965).Another known drill shows a gear design with which the number of blows per revolution of the output shaft can be adapted to the material of a workpiece to be machined when the speed of the output shaft is set. The proposed option for this consists in a gear on the output shaft which can be displaced on a spline, which can be assigned to different pinions of the drive (DE-C-27 34 965).

Aus der WO-A-89/11955 ist eine gattungsgemäße Werkzeugmaschine mit einer mit einem Werkzeughalter versehenen Arbeitswelle und einer Antriebseinrichtung bekannt, bei der die vom Antriebsmotor über ein Getriebe ständig auf einen Werkzeughalter übertragene Drehbewegung sich beliebig abschalten und arretieren läßt, eine drehbare Zwischenwelle, die axial verschiebbar gelagert ist und eine Verzahnung aufweist, in die eine oder andere axial unterschiedliche Position mit einer von außen bedienbaren Schalteinrichtung gebracht werden kann derart, daß die Verzahnung entweder zum Ein- oder Ausschalten der Drehbewegung bzw. zur drehfesten Verriegelung der Arbeitswelle eines Werkzeugs ein- oder auskuppelbar ist, die Arbeitswelle des Werkzeugs bei Bedarf gleichzeitig in eine hin- und hergehende Bewegung mit einem Taumelscheibengetriebe versetzt werden kann, das über eine durch axiale Verschiebung der Zwischenwelle schaltbare Kupplung antreibbar ist.From WO-A-89/11955 a generic machine tool with a working shaft provided with a tool holder and a drive device is known, in which the rotary movement continuously transmitted from a drive motor to a tool holder can be switched off and locked as desired, a rotatable intermediate shaft, which is axially displaceable and has a toothing in which one or the other axially different position can be brought with an externally operable switching device such that the toothing either for switching the rotary movement on or off or for non-rotatably locking the working shaft of a tool - Or disengageable, the working shaft of the tool can, if required, be simultaneously set in a reciprocating movement with a swash plate gear which can be driven via a clutch which can be switched by axial displacement of the intermediate shaft.

Der Erfindung liegt die Aufgabe zugrunde, eine Hand-Werkzeugmaschine der gattungsgemäßen Art für eine größere Anzahl unterschiedlicher Bearbeitungsfunktionen auszubilden, insbesondere für Bohren, Feilen, Bohrraspeln, Bohrfeilen, Kreissägen, Schleifen, Hobeln, Schlagbohren, Schrauben, Sägen, Bohrsägen, Raspeln und Meißeln. Weiter soll es, vorzugsweise bei Stillstand der Arbeitswelle möglich, eine weitere Arbeitsmaschine, z.B. eine Kreissäge anzutreiben.The invention has for its object to provide a hand machine tool of the generic type for a larger number of different machining functions, in particular for drilling, filing, rasps, drilling files, circular saws, grinding, planing, impact drilling, screws, saws, saws, rasps and chisels. Furthermore, it should, preferably possible when the work shaft is at a standstill, another work machine, e.g. to drive a circular saw.

Diese Aufgabe wird durch die im Patentanspruch 1 gekennzeichneten Merkmale gelöst.This object is achieved by the features characterized in

Zweckmäßig ist über eine sechste Kupplung ein weiteres Werkzeug, z.B. eine Kreissäge oder eine biegsame Welle, anschließbar. Es ist vorteilhaft, wenn die sechste Kupplung an der dem Werkzeughalter an der Arbeitswelle abgewandten Seite des Antriebsmotors angeordnet ist.Another tool, e.g. a circular saw or a flexible shaft, connectable. It is advantageous if the sixth clutch is arranged on the side of the drive motor facing away from the tool holder on the working shaft.

Dadurch, daß je eine Kupplung der ersten und je eine Kupplung der zweiten Gruppe getrennt wählbar wirksam gemacht werden können, läßt sich eine Mehrzahl verschiedener Funktionen erzielen. Wenn die Welle über die erste Kupplung in Drehung versetzt ist, kann bei eingreifender dritter Kupplung eine Rund-Raspel in drehende und gleichzeitig in hin- und hergehende Bewegung versetzt werden oder es kann bei eingreifender vierter Kupplung ein Schlagbohren ausgeführt werden oder es kann bei eingreifender fünfter Kupplung die Arbeitswelle in Längsrichtung arretiert sein und so normales Bohren oder Schrauben vorgenommen werden. Wenn über die zweite Kupplung eine Blockierung der Arbeitswelle in Drehrichtung bewirkt ist, kann über die dritte Kupplung eine Sägebewegung erzielt werden oder über die vierte Kupplung eine Schlagbewegung für einen Meißel oder über die fünfte Kupplung eine vollständige Arretierung, so daß die Werkzeugmaschine im Ganzen nach Art eines Schraubenziehers mit vergrößerter Hebelwirkung benutzt werden kann.The fact that a coupling of the first and a coupling of the second group can be made separately selectable, enables a number of different functions to be achieved. If the shaft is rotated via the first clutch, a round rasp can be set in rotating and simultaneously reciprocating motion when the third clutch engages, or hammer drilling can be carried out when the fourth clutch engages, or it can be done when the fifth clutch engages Coupling the working shaft must be locked in the longitudinal direction and so normal drilling or screwing can be carried out. If the working shaft is blocked in the direction of rotation via the second coupling, a sawing movement can be achieved via the third coupling or a striking movement for a chisel via the fourth coupling or complete locking via the fifth coupling, so that the machine tool as a whole can be used like a screwdriver with increased leverage.

Mittels der sechsten Kupplung kann die Werkzeugmaschine auch als Motor den Antrieb für eine andere Werkzeugmaschine bilden.By means of the sixth coupling, the machine tool can also form the drive for another machine tool as a motor.

Da die durch die einzelnen Kupplungen bewirkten Bewegungen sich gegenseitig ausschließen, soll immer nur eine dieser Kupplungen in jeder Gruppe wirksam sein.Since the movements caused by the individual clutches are mutually exclusive, only one of these clutches should be effective in each group.

Die erfindungsgemäße Ausführungsform der Hand-Werkzeugmaschine nach der Erfindung ist dadurch gekennzeichnet, daß der Motor ein erstes Kegelzahnrad mit einer zur Arbeitswelle parallelen Achse in Drehung versetzt, das ein zweites Kegelzahnrad mit einer zur Arbeitswelle etwa senkrecht stehenden Achse antreibt und das ein Schubstangengetriebe zum Erzeugen der zur Arbeitswelle parallel gerichteten oszillierenden Bewegung trägt, und daß ein drittes Kegelzahnrad mit einer zur Arbeitswelle parallelen Achse in Achsrichtung verschiebbar ist derart, daß es entweder in Form der ersten Kupplung mit dem zweiten Kegelzahnrad in Eingriff steht oder in Form der zweiten Kupplung arretiert ist, wobei ein mit dem dritten Kegelzahnrad fest verbundenes erstes Stirnzahnrad in Eingriff steht mit einem an der Arbeitswelle angebrachten zweiten Stirnzahnrad und daß die Arbeitswelle in Achsrichtung verschiebbar gelagert ist und daß auf der Arbeitswelle ein über eine bestimmte, etwa dem Hub der oszillierenden Bewegung entsprechende Wegstrecke, z.B. 15 mm, zwischen einem inneren Anschlag (auf der dem Antrieb, z.B. einem Bohrfutter, abgewandten Seite) und einem verstellbaren, z.B. ringförmigen, auf der Arbeitswelle angeordneten, äußeren Anschlag in achsialer Richtung auf der Arbeitswelle frei beweglicher Klotz angeordnet ist, dem die mit einem bestimmten Hub oszillierende Bewegung zugeführt wird und daß der Klotz in einer ersten Position des äußeren Anschlages, z.B. klemmend, so festgehalten wird, daß die Arbeitswelle in achsialer Richtung der dem Klotz zugeführten oszillierenden Bewegung folgt oder daß der äußere Anschlag in einer, gegenüber der ersten Position um weniger als den Hub der oszillierenden Bewegung entfernten zweiten Position befestigt ist, so daß bei jeder Bewegung ein (nach außen gerichteter) Schlag auf die Arbeitswelle ausgeübt wird, oder daß der äußere Schlag in einer, gegenüber der ersten Position um mehr als den Hub der oszillierenden Bewegung entfernten dritten Position angeordnet ist, so daß die Arbeitswelle von der oszillierenden Bewegung nicht beeinflußt wird und in achsialer Richtung stillsteht.The embodiment of the hand machine tool according to the invention is characterized in that the motor rotates a first bevel gear with an axis parallel to the working shaft, which drives a second bevel gear with an axis approximately perpendicular to the working shaft and that a push rod gear for generating the oscillating movement parallel to the working shaft, and that a third bevel gear with an axis parallel to the working shaft is axially displaceable such that it either engages with the second bevel gear in the form of the first clutch or is locked in the form of the second clutch, whereby a fixedly connected to the third bevel gear first spur gear is in engagement with a second spur gear attached to the working shaft and that the working shaft is mounted displaceably in the axial direction and that on the working shaft one over a certain, such as the stroke of the oscillation corresponding movement distance, e.g. 15 mm, between an inner stop (on the the drive, e.g. a drill chuck, side facing away) and an adjustable, e.g. ring-shaped, external stop arranged on the working shaft, is arranged in the axial direction on the working shaft freely movable block to which the oscillating movement is fed with a certain stroke and that the block is held in a first position of the outer stop, for example clamping, in such a way that the working shaft follows the oscillating movement supplied to the block in the axial direction or that the outer stop is in a second position which is less than the stroke of the oscillating movement and is less than the stroke of the oscillating movement Position is fixed so that with each movement an (outward) blow is applied to the working shaft, or that the outer blow is arranged in a third position which is more than the stroke of the oscillating movement away from the first position, so that the working wave from the oscillating motion ni is not influenced and stands still in the axial direction.

Bei dieser Maschine wird also die oszillierende Bewegung mittels eines Kegelradgetriebes hergestellt, das gleichzeitig zur Übertragung der Drehbewegung oder zum Arretieren der Arbeitswelle dient. Die Bewegung in Längsrichtung kann dabei mittels des verstellbaren äußeren Anschlages in einfacher Weise eingestellt werden, der dann wie getrennte (dritte, vierte, fünfte) Kupplungen wirkt.In this machine, the oscillating movement is thus produced by means of a bevel gear, which at the same time serves to transmit the rotary movement or to lock the working shaft. The movement in the longitudinal direction can be adjusted in a simple manner by means of the adjustable outer stop, which then acts like separate (third, fourth, fifth) couplings.

Der Klotz kann auf der Arbeitswelle frei drehbar sein, so daß er mit dem oszillierenden Antrieb drehungsfrei verbunden sein kann.The block can be freely rotated on the working shaft so that it can rotate with the oscillating drive can be connected.

Die Arbeitswelle wird zweckmäßig mittels einer Zug- oder Druck-Feder auf einen verstellbaren Schlitten in eine bestimmte Ruhelage zurückgeführt, damit ein Einstellen des äußeren Anschlages ohne Schwierigkeit möglich ist und bei der oszillierenden Bewegung die erforderliche Wegstrecke für den Klotz frei bleibt.The working shaft is expediently returned to a certain rest position by means of a tension or compression spring on an adjustable carriage, so that an adjustment of the outer stop is possible without difficulty and the required distance for the block remains free during the oscillating movement.

Die Erfindung wird nachstehend anhand der Zeichnung beispielsweise näher erläutert. Es zeigen

- Fig.1

- in einer Prinzipdarstellung eine Hand-Werkzeugmaschine nach der Erfindung,

- Fig.2

- in Seitenansicht eine Ausführungsform der Erfindung nach Art einer Handbohrmaschine,

- Fig.3

- in Aufsicht die gleiche Maschine,

- Fig.4

- in Aufsicht entsprechend der Schnittlinie A das unter der Arbeitswelle liegende Getriebe, jeweils teilweise im Schnitt, und

- Fig.5

- in einer Ausschnittsdarstellung einen Teil der Maschine gem. Fig. 3 in einer schaubildlichen, vergrößerten Ansicht.

- Fig. 1

- a schematic representation of a hand machine tool according to the invention,

- Fig. 2

- a side view of an embodiment of the invention in the manner of a hand drill,

- Fig. 3

- the same machine under supervision,

- Fig. 4

- in supervision according to section line A, the gearbox lying under the working shaft, partly in section, and

- Fig. 5

- in a detail of a part of the machine acc. Fig. 3 in a diagrammatic, enlarged view.

In Fig. 1 trägt eine Arbeitswelle 1 einen Werkzeughalter 2, z.B. ein Bohrfutter. Die Welle 1 ist in Lagern 3 und 4 gehaltert, und zwar derart, daß sie in Längsrichtung um einen Hub von z.B. 15 mm verschiebbar ist. Von einem Motor 5 kann eine Antriebswelle 6 in Rotation versetzt werden. Auf der Welle 6 sind eine erste und eine zweite Kupplung 11 bzw. 12 angeordnet, die über übertragungsglieder 21 bzw. 22 und eine Getriebeanordnung 7 die Arbeitswelle 1 in Drehbewegung versetzen oder blockieren können.In Fig. 1, a working

Auf der Welle 6 sind weiterhin die dritte Kupplung 13, die vierte Kupplung 14 und fünfte Kupplung 15 angeordnet, die über übertragungsglieder 23, 24, 25 und Getriebeanordnungen 8, 9, 10 mit der Arbeitswelle 1 verbunden sind. Dabei kann mittels der dritten Kupplung 13 oder über die vierte Kupplung 14 der Arbeitswelle 1 in Längsrichtung eine oszillierende Bewegung oder eine Schlagbewegung zugeführt werden. Mittels der fünften Kupplung 15 kann die Arbeitswelle 1 alternativ auch arretiert werden.The

Wenn z.B. die Kupplungen 11 und 15 wirksam sind, rotiert die Arbeitswelle 1, ist aber in Längsrichtung nicht verschiebbar. Es wird somit die Wirkung einer Bohrmaschine erhalten. Wenn statt der Kupplung 15 die Kupplung 13 geschlossen ist, bewegt sich die Arbeitswelle 1 in Längsrichtung hin und her und dreht sich dabei; es kann somit in das Bohrfutter 2 z.B. eine Rundraspel eingesetzt werden, mit der Öffnungen in einer Holzplatte erzeugt und vergrößert werden können. Sind dagegen die Kupplungen 12 und 13 geschlossen, so dreht sich die Arbeitswelle 1 nicht, bewegt sich jedoch in Längsrichtung hin und her. Im Werkzeughalter 2 kann somit ein normales Sägeblatt zur Wirkung gebracht werden. Sind die Kupplungen 12 und 14 geschlossen, so dreht sich die Welle nicht, bewegt sich auch nicht nenneswert in Längsrichtung, sondern übt lediglich Schläge aus. Ein an einem Werkzeughalter 2 angebrachter Meißel kann somit sein Werk verrichten. Entsprechend ist bei geschlossenen Kupplungen 11 und 14 die Welle 1 in Rotation und führt Schläge aus; es kann also ein Schlagbohrer zur Wirkung gebracht werden. Sind die Kupplungen 12 und 15 geschlossen, so steht die Arbeitswelle 1 unverrückbar fest. Ein in den Halter 2 eingesetztes Werkzeug kann somit in der vorgesehenen Weise benutzt werden, wobei die Hand-Werkzeugmaschine insgesamt als größerer Handgriff mit verstärkter Kraft- und Hebelwirkung benutzt werden kann. So lassen sich z.B. Schrauben, auch Imbusschrauben oder Schrauben mittels eines Steckschlüssels, mit der Hand betätigen, wobei nach Überwindung eines größeren Widerstandes durch Umkuppeln von 12 auf 11 die Drehbewegung in Gang gesetzt und somit das weitere schnellere Lösen der betreffenden Schraube bewirkt werden kann.If, for example, the

Es ist auch möglich, mittels einer sechsten Kupplung 16 ein anderes antreibbares Werkzeug, z.B. eine Kreissäge, biegsame Welle od.dgl. anzuschließen, wobei dann die Hand-Werkzeugmaschine auch als solche benutzt wird, und ihr Motor und die ggf. in an sich bekannter Weise vorgesehenen Steuerschaltungen für Geschwindigkeit und Kraft betätigt gemeinsam werden können.It is also possible to use a

Die Arbeitswelle 1 in den Lagern 3 und 4 trägt ein Bohrfutter 2 oder einen anderen Werkzeughalter. Ein Motor 5, der nur schematisch angedeutet ist, treibt über eine Achse 30, die in einem Lagerblock 30a gelagert ist, ein erstes Kegelzahnrad 31, dessen Achse somit der Achse der Arbeitswelle 1 parallel ist. Auf einer nur gestrichelt angedeuteten, senkrecht zur Arbeitswelle 1 stehenden Achse 32 ist ein zweites Kegelzahnrad 33 im Eingriff mit dem ersten Kegelzahnrad 31 angebracht. Die Achse 32 ist in einem Lagerblock 34 befestigt.The working

In Flucht mit der Achse 30 des ersten Kegelzahnrades 31 ist ein drittes Kegelzahnrad 35 mit einer Achse 36 an einem Lagerblock 37 angeordnet. An dem Lagerblock 37 ist ein federbelasteter Stift 73, der bei entsprechender axialer Verschiebung des Stirn-Zahnrades 38 in eine nicht dargestellte Bohrung 74 im Zahnrad 38 eingreift und dieses festsetzt. Das dritte Kegelzahnrad 35 ist konstruktiv verbunden mit einem ersten Stirn-Zahnrad 38, das im Eingriff steht mit einem zweiten Stirn-Zahnrad 39 auf der Arbeitswelle 1.In alignment with the

In der dargestellten Lage wird die Rotation des Motors 5 über die Zahnräder auf die Arbeitswelle 1 übertragen, so daß die Welle 1 ebenfalls rotiert. Das zweite Stirnzahnrad 39 hat eine beträchtliche Länge derart, daß die Welle 1 entsprechend dem vorgesehenen Hub in Längsrichtung verschoben werden kann, ohne daß dabei die Rotation der Arbeitswelle 1 beeinträchtigt wird.In the position shown, the rotation of the

In der dargestellten Position steht die Welle 1 ganz rechts und berührt mit der Flanke des Stirnzahnrades 39 den Lagerbock 4, der ggf. mit einem Gleitlager oder auch mit einem Kugellager 40 an der Stirnseite versehen ist. An der anderen Seite des Stirnzahnrades 39 ist ein einstellbarer fester Anschlagring 41 angebracht, mit dem, wie noch zu beschreiben sein wird, die oszillierende Bewegung ggf. angepaßt werden kann.In the position shown, the

An dem zweiten Kegelzahnrad 33 ist exzentrisch ein Achslager 42 angebracht, das mit einer Schubstange 43 verbunden ist. Diese Schubstange, die ggf. unterteilt und noch zusätzlich gelagert sein kann, betätigt eine Bewegungsstange 44. Deren anderes Ende ist an einem Klotz 45 befestigt, der auf der Achse 1 in Längsrichtung entsprechend dem durch einen doppelten Pfeil 51 dargestellten Hub hin- und herbewegt wird, wenn sich das Kegelzahnrad 33 im Kreise dreht.An axle bearing 42, which is connected to a

Auf der Arbeitswelle 1 ist ein Mitnehmer 46 angebracht, der auf eine, in Fig. 3 näher dargestellte Weise in eine erste, zweite oder dritte Nut 47, 48 oder 49 einrasten kann, wobei er einen verstellbaren äußeren Anschlag für die Bewegung des Klotzes 45 auf der Welle 1 bildet.A

Ist der Mitnehmer 46 in der am weitesten rechts dargestellten Nut 47 eingerastet, so liegt er mit seiner seitlichen Oberfläche praktisch an der Seitenfläche des Klotzes 45 an; dessen Seitenflächen können Dämpfungselemente und/oder Kugellager 50 tragen, um bei der Hin- und Herbewegung des Klotzes 45 und bei der Drehung von an der Welle angebrachten Teilen störende mechanische Beanspruchungen zu vermeiden. In dieser Position ist somit der Klotz 45 zwischen dem Anschlag 41 und dem Mitnehmer 46 eingeschlossen; bei der seitlichen Bewegung des Klotzes 45 wird somit die Welle 1 mit den auf ihr befestigten Teilen mitgenommen und führt die von der Exzenteranordnung von dem Kegelzahnrad 33 vorgegebene oszillierende Bewegung aus, die über die Bewegungsstange 44 von der Schubstange 43 auf den Klotz 45 übertragen wird. Diese Einstellung ist somit geeignet, z.B. entweder eine feststehende Säge oder eine sich drehende Rundraspel in Tätigkeit zu setzen, je nach dem, ob auf das zweite Stirnzahnrad 39 vom ersten Stirnzahnrad 38 her eine Drehbewegung übertragen wird oder nicht.If the

Befindet sich der Mitnehmer 46 eingerastet in der Nut 49, so befindet sich der dadurch gebildete Anschlag außerhalb des Hub-Bereiches des Klotzes 45, und die Welle 1 wird von der Längsbewegung des Klotzes 45 nicht beeinflußt Damit in dieser Lage die Welle 1 eine definierte Position hat, kann über dem Ende der Welle eine Zug-Feder 52 so angeordnet sein, daß es die Welle 1 jeweils in die in der Zeichnung dargestellte Position zieht, in der das zweite Stirnzahnrad 39 gegen das Lager 4 gezogen ist. Wenn dem Stirnzahnrad 39 nun eine Rotation zugeführt wird, kann die Werkzeugmaschine nach der Erfindung als Bohrmaschine arbeiten.If the

Befindet sich dagegen der Mitnehmer 46 in der in der Zeichnung dargestellten Lage, in der er in der Nut 48 eingerastet ist, kann sich der Klotz 45 zunächst über etwa die Hälfte des Hubes 51 frei bewegen und verschiebt die Welle 1 nicht. Danach schlägt der Klotz 45 auf den Mitnehmer 46 und bewegt ihn ein Stück nach vorn. Auf diese Weise kann ein Schlag auf das im Werkzeughalter 2 angebrachte Werkzeug ausgeübt werden, z.B. einen einfachen Meißel oder einen Steinbohrer, der dann zusätzlich in Rotation versetzt werden kann.If, on the other hand, the

Um die bisher beschriebenen Teile herum ist in an sich bekannter Weise ein die Teile zusammenhaltendes Gehäuse mit einer Halterung 53b nach Art eines Bohrmaschinengriffes dargestellt. Dieses Gehäuse kann, wie ebenfalls bekannt ist, im Bereich des Lagers 3 weiter mit einem zusätzlichen Handgriff 53c versehen sein, um die Führung des Werkzeuges bei der Arbeit zu erleichtern. Bei 54 ist ein Schalter angedeutet, der in ebenfalls bekannter Weise auch eine elektronische Drehzahlregelung bewirken kann, je nach dem, wie stark mit dem Finger darauf gedrückt wird.Around the parts described so far, a housing holding the parts together with a

Das gehäuseinnenseitige Ende der Arbeitswelle 1 ist mit einer Axialbohrung 78a versehen, in die ein Drehwirbel 78 eingesteckt ist. Im Endbereich der Arbeitswelle 1 sind zwei Madenschrauben 79 versenkt, die sich bis in die Axialbohrung 78a erstreckend angeordnet sind. Die Spitze der Madenschrauben 79 greifen in eine umlaufende Nut 47a im Drehwirbel 78 ein, so daß eine Drehung der Arbeitswelle 1 unbehindert möglich ist. Der Drehwirbel 78 stützt sich über eine Schraubenverbindung 78b an einem Ende einer Zugfeder 52 ab, so daß eine Axialbewegung der Arbeitswelle 1 nur unter Einfluß der Federkraft der Zugfeder 52 möglich ist. Die Zugfeder ist mit ihrem anderen Ende mit einem Stellschlitten 55 verbunden, der über eine Stellspannschraube 55a verstellbar ist.The end of the working

Fig. 3 zeigt eine Hand-Werkzeugmaschine nach der Erfindung etwa entsprechend der Linie B-B in Fig. 2 aufgeschnitten in der Ansicht von oben. Gleiche Teile sind mit gleichen Bezugsziffern versehen. Fig. 3 zeigt insbesondere den Mechanismus zum Einstellen der Lage des Mitnehmers 46. Dieser Mitnehmer, der die Welle 1 im Bereich der Nut 48 ringförmig umgreift, wird von zwei Halbringen gebildet, die mittels Federn 57 bzw. 58 gegen die Welle 1 gedrückt werden. Die Federn 57 und 58 stützen sich dabei gegen den vorderen Teil des Gehäuses 53 ab über Unterleggleitscheiben od.dgl. 59 und 60. Durch Schlitze 53a im Gehäuse 53 sind weiter Stäbe 61 und 62 geführt, die an ihren oberen Enden Knopfplatten 63 und 64 tragen. Diese Knopfplatten liegen im Schutzkasten unter Schutzdeckeln 65 und 66, die um Schwenkachsen 67 und 68 nach vorn aufgeklappt werden können. Die Schutzdeckel berühren in geschlossenem Zustand Schutzschalter 65a,66a, die die Stromzufuhr unterbrechen, sobald die Deckel aufgeklappt werden, wobei die Deckel 65,66 durch die Federn 67a,68a in ihrer geschlossenen Stellung gehalten werden. In einem solchen aufgeklappten Zustand können dann die Knopfplatten 63 und 64 angefaßt und nach außen gezogen werden, so daß die Teile des Mitnehmers 46 aus der Nut 48 herausgehoben werden und der Mitnehmer 46 in die Nut 47 oder in die Nut 49 verschoben werden kann.Fig. 3 shows a hand machine tool according to the invention cut approximately along the line B-B in Fig. 2 in the view from above. The same parts are provided with the same reference numbers. 3 shows in particular the mechanism for adjusting the position of the

Durch Umsetzen des Mitnehmers 46 wird dann entweder die dritte oder die vierte oder die fünfte Kupplung derart wirksam, daß entweder, wie obenstehend beschrieben, die Welle 1 in oszillierende Bewegung versetzt wird oder Schlagbewegungen ausführt oder in Längsrichtung arretiert wird. In Fig. 5 sind der aus zwei halbringförmigen Elementen bestehende Mitnehmer 46 mit den Federn 57 und 58 und die Stäbe 61 und 62 in einer schematischen Halb-Schrägdarstellung wiedergegeben. Es ist deutlich erkennbar, wie mittels der Knopfplatte 63 und 64 die zwei halbteiligen Mitnehmers 46 von der Welle 1 aus der Nut herausgezogen werden können, während sie normalerweise mittels der zwei Federn 57,58 in der Nut 48 gehalten werden.By moving the

Fig. 4 zeigt eine Darstellung entsprechend dem Schnitt A-A in Fig. 2, also in Höhe des Eingriffsbereiches des ersten und des zweiten Stirn-Zahnrades 38 bzw. 39. Hier ist dargestellt, wie der Lagerzapfen 36 des ersten Zahnrades im Lagerblock 37 verschiebbar gehaltert ist, wobei die Verschiebung mittels eines federbelasteten Rasterstellhebels 71 erfolgt, dessen Bewegung über einen Hebel 72 auf eine Nut 75 in dem Achsstück 36 übertragen wird, so daß das dritte Kegelzahnrad 35 mit dem zweiten Kegelzahnrad 33 entweder im Eingriff ist oder nicht. Im letztgenannten Fall greift weiter ein in einer Bohrung des Lagerblockes 37 federnd gelagerter Arretierungsstift 73 in eine entsprechende Bohrung 74 im ersten Stirnzahnrad 38 ein und blockiert dessen Drehung und damit auch die Drehung des damit im Eingriff befindlichen zweiten Stirn-Zahnrades 39 auf der Welle 1. Die Arbeitswelle 1 steht dann still, sie kann aber noch Hin- und Herbewegungen ausführen. Das Rastelement 71 ist über eine Bolzen-Langlochverbindung 76 unter Einwirkung einer nicht dargestellten Feder 77 mit dem Hebel 72 so verbunden, daß ein Hochziehen des Rastelementes 71 zur Durchführung der Verstellung möglich ist.FIG. 4 shows a representation corresponding to the section AA in FIG. 2, that is to say at the level of the engagement area of the first and second spur gearwheels 38 and 39. Here it is shown how the bearing

Im Bereich der vorderen Spitze der Arbeitswelle 1 sind Eingriffschutzdeckel 80,81 vorgesehen. Diese sind den vorne aus dem Gehäuse auskragenden Teil der Arbeitswelle 1 und den Werkzeughalter 2 überdeckend angeordnet, wobei sie jeweils um eine Schwenkachse 67b,68b schwenkbar sind und unter der Kraft einer Feder 67c,68c in einer Schließstellung gehalten sind, in der sie sich zu einer zylindrischen Deckelkappe (80,81) ergänzen.Protection covers 80, 81 are provided in the area of the front tip of the working

Claims (18)

- Hand-held machine tool, more particularly for drilling, percussion drilling, sawing or chiseling, with a working shaft (1) provided with a tool holder and a drive means with a preferably electic driving motor (5), in which the drive means is constructed so as to provide a rotational movement and a reciprocating (oscillating) movement, and in which the working shaft (1) is selectably movable in the longitudinal direction either so as to be stoppable or so as to be set into an oscillating movement (translation) and, in the process, so as to be either blockable or rotatable in the direction of the rotation,

characterized in that

the working shaft (1) can be selectably set set into a rotational movement by means of a first coupling (11) or, by means of a second coupling (12), so as to be blockable without rotation and in that, moreover, the working shaft (1) can, in the longitudinal direction, be set into an oscillating movement by means of a third coupling (13) or, by means of a fourth coupling (14), be caused to execute percussive movements or, by means of a fifth coupling (15), can be stopped, and in that the driving motor (5) serving as drive means, is capable of setting into rotation a first bevel gear (31) having an axis (30) parallel to the working shaft (1), which drives a second bevel gear (33) having a shaft (32) located approximately vertically to the working shaft (1) and which drives a connecting rod gearing (43,44) for producing the oscillating movement directed parallel to the operating shaft (1), and in that a third bevel gear (35) having an axis (36) parallel to the working shaft (1), is displaceable in the axial direction in such a way that it is either, in the form of the first coupling (11), in engagement with the second bevel gear or, in the form of the second coupling (12), is locked (at 37), in which case a first spur gear (38) rigidly connected to the third bevel gear (35) is in engagement with a second spur gear (39) mounted on the working shaft (1) and in that the working shaft (1) is supported in such a way that it is displaceable in the axial direction (3,4) and in that, on the working shaft (1), across a certain stretch corresponding approximately to the travel of the oscillating movement, e.g. 15 mm, between an internal stop (41) (on the side facing away from the drive means, e.g. a tool locking chuck (2))and an adjustable, e.g. annular external stop of the driver (46), a block (45) is disposed on the working shaft (1) which is freely displaceable in the axial direction which is disposed so as to, with a certain travel (51), be able to execute the oscillating movement, and in that the block (45), in a first position (47) of the external stop (46), is retained, e.g. clampingly, in such a way that the working shaft (1) follows in the axial direction the oscillating movement imparted to the block (45), or in that the external stop of the driver (46) is secured, compared with the first position (47), in a second position (48) removed by less than the length of travel (51) of the oscillating movement so that, with each movement, an (outwardly directed) blow is dealt to the working shaft (1), or in that the external stop of the driver (46) is, compared with the first position (47), is disposed removed by more than the length of travel (51) of the oscillating movement so that the working shaft (1) is unaffected by the oscillating movement and is inoperative in the axial direction. - Machine tool according to Claim 1, characterized in that a sixth coupling (16) is provided, with the aid of which a further tool, e.g. a circular saw or a flexible shaft can be connected.

- Machine tool according to Claim 2, characterized in that the sixth coupling (16) is disposed on the side of the driving motor (5) which faces away from the working shaft (1).

- Machine tool according to Claims 1 to 3, characterized in that the third, the fourth and the fifth coupling (13, 14, 15) can be actuated by means of an operating member in such a way that, in each case, solely one coupling is effective.

- Machine tool according to any of Claims 1 to 4, characterized in that the axis (50) of the bevel gear (31) of the motor (5) is supported in a bearing block (30a) and the axis (32) of the bevel gear (33) in a bearing block (34) and the axis (36) of the spur gear (38,35) is supported in a bearing block (37).

- Machine tool according to any of Claims 1 to 5, characterized in that, on the working shaft (1), a second spur gear (39) is mounted which is in engagement with the first spur gear (38) the length corresponds to the travel (51), whose double length corresponds to the length of travel (51) of the oscillating movement in such a way that it remains in engagement also during the oscillating movement transmitted to the working shaft (1)

- Machine tool according to any of Claims 1 to 7, characterized in that the adjustable stop (63,64) is formed by a circular driver (46) comprised of two halves which can be brought into engagement with one of the grooves (47, 48,49) corresponding to one of the three positions on the working shaft (1).

- Machine tool according to Claim 7, characterized in that the adjustable stop (63,64) comprised of two driver portions (46) is retained by means of springs (57,58), sliding disks (59,60) in the groove.

- Machine tool according to any of Claims 6, 7 or 8, characterized in that the third bevel gear (35) with the first spur gear (38) with its axle (36), wherein a slotted groove (75) is provided, opposite the second bevel gear (33), with the aid of a spring-loaded snap-in type setting lever (71) fitted with a swivelable setting spindle (72) guided in the groove (75), is disconnectable so that the first coupling (11) is disengaged and the working shaft (1) no longer executes a rotational movement.

- Machine tool according to Claim 9, characterized in that the third bevel gear (35) which is connected with the first spur gear (38), in the disconnected state, by means of a spring-loaded pin (73) acting as a second coupling (37) provided with several drilled holes and engaging laterally into the spur gear (38), is locked into the oppositely located first spur gear (38).

- Machine tool according to any of Claims 1 to 10, characterized in that the block (45), on its lateral surfaces, is provided with one or several cushioning elements (50) and/or ball bearings (50).

- Machine tool according to any of Claims 1 to 11, characterized in that the bearing block (3) and/or the bearing bracket (4), on its lateral surfaces, is provided with one or several cushioning elements and or with ball bearings (40,40a).

- Machine tool according to any of Claims 1 to 12, characterized in that, on the bevel gear (33), a shaft bearing (42) is mounted, whose end facing away from the shaft bearing (42) engages into a shaft bearing which is disposed on the motion rod (44) on the end of the same which faces away from the block (45).

- Machine tool according to any of Claims 1 to 13, characterized in that, on the housing (53), next to the handle (53b), a further handle (53c) is disposed possibly so as to be swivelable, within the area of the bearing (3).

- Machine tool according to any of Claims 1 to 14, characterized in that, for the adjustment and the setting of the driver (46), which is comprised of two half-rings that are pressed against the shaft (1) by means of springs (57,58), in which case the springs (57,58) are supported on the housing (53) with the aid of supporting sliding disks (58,59), and in that rods (61,62) are passed through slots (53a) in the housing (53), which are connected with the driver (46), which bear knurled knob-like plates (63, 64), which are disposed underneath a guard or protective cover ((65,66) which is swivelable about a swivel axis (67,68).

- Machine tool according to Claim 15, characterized in that, within the contact area of the guard (65,66) located opposite the swivel axis (67,68), one protective circuit breaker each (65a,66a) is disposed on/in the housing (53) which, when the guard (65,66) ceases to act upon the protective circuit breaker, interrupts the energy supply (current supply) to the driving motor (5), and/or in that each guard (65,66), while subjected to the action of a spring (67a,68a), is locked in its closed position.

- Machine tool according to any of Claims 1 to 16, characterized in that, in the shaft (1), on the terminal area of the latter located opposite the tool holder (2), a groove (47a) is provided wherein at least two grub screws (79) are countersunk and extend into an axial bore (78a) in the shaft (1), where the points of the grub screws (79) engage into a circumferential groove of a swivel (78), the swivel (78) being connected with the aid of a screw connection (78b) to a tension spring (52) which, with its other end, engages at one end into the setting carriage (55), which is adjustable by means of a tigthening set-screw (55a).

- Machine tool according to any of Claims 1 to 17, characterized in that the portion of the working shaft (1) which projects from the front of the housing and the tool holder (2) are disposed underneath the two guards (80,81) which are in each case swivelable about a swivel axis (67b,68b) and complement each other so as to form a cylindrical covering cap which, due to the action of pertinently disposed springs (67c,68c), are retained in a closing position.

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE9001665 | 1990-02-13 | ||

| DE9001665U | 1990-02-13 | ||

| PCT/EP1990/001863 WO1991012116A1 (en) | 1990-02-13 | 1990-11-08 | Hand-held machine tool |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0515371A1 EP0515371A1 (en) | 1992-12-02 |

| EP0515371B1 true EP0515371B1 (en) | 1994-08-10 |

Family

ID=6850977

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP90916263A Expired - Lifetime EP0515371B1 (en) | 1990-02-13 | 1990-11-08 | Hand-held machine tool |

Country Status (5)

| Country | Link |

|---|---|

| EP (1) | EP0515371B1 (en) |

| AT (1) | ATE109712T1 (en) |

| AU (1) | AU6639090A (en) |

| DE (3) | DE9015285U1 (en) |

| WO (1) | WO1991012116A1 (en) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102005043124A1 (en) * | 2005-09-10 | 2007-03-15 | ThyssenKrupp Präzisionsschmiede GmbH | Bevel gear with connecting teeth |

| US7645101B2 (en) | 2005-09-16 | 2010-01-12 | Black & Decker Inc. | Chuck with internally threaded jaw in a PTO application |

| US7690658B2 (en) | 2004-09-20 | 2010-04-06 | Black & Decker Inc. | Tool chuck with power take off feature |

Families Citing this family (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5664634A (en) * | 1995-10-23 | 1997-09-09 | Waxing Corporation Of America, Inc. | Power tool |

| DE19540396A1 (en) * | 1995-10-30 | 1997-05-07 | Hilti Ag | Drilling and / or chiseling device |

| RO111555B1 (en) * | 1995-12-12 | 2002-05-30 | Dumitru Panu-Misăilescu | Portable hand machine |

| DE19619428B4 (en) * | 1996-05-14 | 2005-11-10 | Eduard Gasinski | Hand-operated combination machine tool with drill and jigsaw function |

| CN108161075A (en) * | 2017-12-30 | 2018-06-15 | 天津市九方煤矿机械制造有限公司 | A kind of stand supports Pneumatic hand drilling machine |

| WO2022216964A1 (en) | 2021-04-07 | 2022-10-13 | Milwaukee Electric Tool Corporation | Impact power tool |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO1989011955A1 (en) * | 1988-06-04 | 1989-12-14 | Robert Bosch Gmbh | Drilling hammer |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3286776A (en) * | 1964-06-23 | 1966-11-22 | Kenneth Conklin | Combination power hand tool |

| US3841416A (en) * | 1972-08-15 | 1974-10-15 | Black & Decker Mfg Co | Portable jig-saw and spindle sander |

| US4031622A (en) * | 1975-10-28 | 1977-06-28 | Wells Manufacturing Corporation | Portable power driven implement |

| US4467896A (en) * | 1983-06-17 | 1984-08-28 | Black & Decker Inc. | Locking mechanism for a rotary power machine |

| US4841643A (en) * | 1988-04-22 | 1989-06-27 | Colella Vincent J | Drill powered saber saw |

-

1990

- 1990-11-07 DE DE9015285U patent/DE9015285U1/en not_active Expired - Lifetime

- 1990-11-08 WO PCT/EP1990/001863 patent/WO1991012116A1/en active IP Right Grant

- 1990-11-08 AU AU66390/90A patent/AU6639090A/en not_active Abandoned

- 1990-11-08 DE DE90EP9001863A patent/DE4092497D2/en not_active Expired - Fee Related

- 1990-11-08 AT AT90916263T patent/ATE109712T1/en not_active IP Right Cessation

- 1990-11-08 DE DE59006798T patent/DE59006798D1/en not_active Expired - Fee Related

- 1990-11-08 EP EP90916263A patent/EP0515371B1/en not_active Expired - Lifetime

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO1989011955A1 (en) * | 1988-06-04 | 1989-12-14 | Robert Bosch Gmbh | Drilling hammer |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7690658B2 (en) | 2004-09-20 | 2010-04-06 | Black & Decker Inc. | Tool chuck with power take off feature |

| DE102005043124A1 (en) * | 2005-09-10 | 2007-03-15 | ThyssenKrupp Präzisionsschmiede GmbH | Bevel gear with connecting teeth |

| US7645101B2 (en) | 2005-09-16 | 2010-01-12 | Black & Decker Inc. | Chuck with internally threaded jaw in a PTO application |

Also Published As

| Publication number | Publication date |

|---|---|

| EP0515371A1 (en) | 1992-12-02 |

| WO1991012116A1 (en) | 1991-08-22 |

| DE4092497A1 (en) | 1993-01-28 |

| DE59006798D1 (en) | 1994-09-15 |

| DE4092497D2 (en) | 1993-01-28 |

| ATE109712T1 (en) | 1994-08-15 |

| AU6639090A (en) | 1991-09-03 |

| DE9015285U1 (en) | 1991-06-06 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE2728961C2 (en) | Rotary hammer with lockable tool holder | |

| DE60127471T2 (en) | Mechanism for cam drive | |

| DE19605156B4 (en) | Tool head for use in machine tools and machine tool with such a tool head | |

| DE3328886C2 (en) | Electric hammer drill | |

| DE102006029363A1 (en) | Electric hand tool | |

| DE1964083A1 (en) | Machine tool for stone processing | |

| EP3056317A1 (en) | Handheld machine tool | |

| EP0515371B1 (en) | Hand-held machine tool | |

| DE102006059633A1 (en) | impact drill | |

| DE19845024C2 (en) | Power driven screwdriver | |

| EP2364817A2 (en) | Hammer drill device | |

| DE2511469A1 (en) | Hand operated two speed power drill - has two part change over with opposing springs and two gears on common shaft | |

| DE3841515A1 (en) | HAND TOOL WITH MANUAL GEARBOX | |

| EP0884138A2 (en) | Hammer drill | |

| DE3310145C2 (en) | Electropneumatic hammer drill with replaceable hammer mechanism | |

| EP0297041A2 (en) | Hand tool | |

| DE4205840A1 (en) | Spindle lock for hammer drill with chisel function - is effected by bringing sliding gear cluster of spindle drive transmission into mesh with teeth of locking segment fixed to housing | |

| DE1957505A1 (en) | Portable impact drill | |

| DE3637354C2 (en) | ||

| DE69803817T2 (en) | Rotary Hammer | |

| CH356396A (en) | Device on an electric hand drill to optionally change the latter for rotary drilling and percussion drilling | |

| DE3031075C2 (en) | ||

| DE4341753A1 (en) | Electric tool | |

| DE3322963C2 (en) | Hammer drill | |

| DE4113116A1 (en) | DRILL GRINDING MACHINE |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19920828 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH DE DK ES FR GB GR IT LI LU NL SE |

|

| 17Q | First examination report despatched |

Effective date: 19930111 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE DK ES FR GB GR IT LI LU NL SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRE;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED.SCRIBED TIME-LIMIT Effective date: 19940810 Ref country code: ES Free format text: THE PATENT HAS BEEN ANNULLED BY A DECISION OF A NATIONAL AUTHORITY Effective date: 19940810 Ref country code: BE Effective date: 19940810 Ref country code: DK Effective date: 19940810 Ref country code: FR Effective date: 19940810 Ref country code: GB Effective date: 19940810 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 19940810 Ref country code: NL Effective date: 19940810 |

|

| REF | Corresponds to: |

Ref document number: 109712 Country of ref document: AT Date of ref document: 19940815 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 59006798 Country of ref document: DE Date of ref document: 19940915 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Effective date: 19941108 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19941110 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Effective date: 19941130 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19941130 Ref country code: LI Effective date: 19941130 |

|

| EN | Fr: translation not filed | ||

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| GBV | Gb: ep patent (uk) treated as always having been void in accordance with gb section 77(7)/1977 [no translation filed] |

Effective date: 19940810 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19950801 |

|

| 26N | No opposition filed |