EP0510323B1 - Dispositif de brasage au laser - Google Patents

Dispositif de brasage au laser Download PDFInfo

- Publication number

- EP0510323B1 EP0510323B1 EP92102723A EP92102723A EP0510323B1 EP 0510323 B1 EP0510323 B1 EP 0510323B1 EP 92102723 A EP92102723 A EP 92102723A EP 92102723 A EP92102723 A EP 92102723A EP 0510323 B1 EP0510323 B1 EP 0510323B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- frame

- down device

- hold

- laser

- shaped

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L24/00—Arrangements for connecting or disconnecting semiconductor or solid-state bodies; Methods or apparatus related thereto

- H01L24/80—Methods for connecting semiconductor or other solid state bodies using means for bonding being attached to, or being formed on, the surface to be connected

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K1/00—Soldering, e.g. brazing, or unsoldering

- B23K1/005—Soldering by means of radiant energy

- B23K1/0056—Soldering by means of radiant energy soldering by means of beams, e.g. lasers, E.B.

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K13/00—Apparatus or processes specially adapted for manufacturing or adjusting assemblages of electric components

- H05K13/04—Mounting of components, e.g. of leadless components

- H05K13/0404—Pick-and-place heads or apparatus, e.g. with jaws

- H05K13/0408—Incorporating a pick-up tool

- H05K13/0409—Sucking devices

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K13/00—Apparatus or processes specially adapted for manufacturing or adjusting assemblages of electric components

- H05K13/04—Mounting of components, e.g. of leadless components

- H05K13/046—Surface mounting

- H05K13/0465—Surface mounting by soldering

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/01—Chemical elements

- H01L2924/01068—Erbium [Er]

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/01—Chemical elements

- H01L2924/01076—Osmium [Os]

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/013—Alloys

- H01L2924/014—Solder alloys

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/10—Details of semiconductor or other solid state devices to be connected

- H01L2924/11—Device type

- H01L2924/12—Passive devices, e.g. 2 terminal devices

- H01L2924/1204—Optical Diode

- H01L2924/12042—LASER

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K3/00—Apparatus or processes for manufacturing printed circuits

- H05K3/30—Assembling printed circuits with electric components, e.g. with resistor

- H05K3/32—Assembling printed circuits with electric components, e.g. with resistor electrically connecting electric components or wires to printed circuits

- H05K3/34—Assembling printed circuits with electric components, e.g. with resistor electrically connecting electric components or wires to printed circuits by soldering

- H05K3/341—Surface mounted components

- H05K3/3421—Leaded components

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K3/00—Apparatus or processes for manufacturing printed circuits

- H05K3/30—Assembling printed circuits with electric components, e.g. with resistor

- H05K3/32—Assembling printed circuits with electric components, e.g. with resistor electrically connecting electric components or wires to printed circuits

- H05K3/34—Assembling printed circuits with electric components, e.g. with resistor electrically connecting electric components or wires to printed circuits by soldering

- H05K3/3494—Heating methods for reflowing of solder

Definitions

- the invention relates to a device for laser soldering fine contacts of pre-soldered microelectronic components according to the preamble of claim 1.

- Such a device is known from JP-A-2232999.

- the present invention has for its object to provide a device of the type mentioned, which eliminates the aforementioned disadvantage in a simple and reliable manner and creates a precisely positionable hold-down device for micro-contacts, the fast and highly accurate given contact or component dimensions can be adjusted in a confined space.

- FIG. 1 shows a schematic representation of an assembly system for laser soldering fine contacts of microelectronic components which are not glued to one another using either flux or solder paste, but are pre-soldered using an XY table 140, a Z-axis adjustment device 30 and a laser head 100 as outlined in FIG. 2.

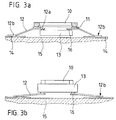

- FIG. 3a and 3b now illustrate in a schematic representation how pre-tinned microelectronic components 13 - hereinafter referred to as chip - with numerous, very thin and parallel contacts (leads) 12 at very short intervals according to the TAB soldering method (tape automated bonding) be connected to each other.

- the Z-axis adjustment device 30 shown in FIG. 1 is equipped with a frame-shaped hold-down device 10, which according to FIG. 3a, a so-called "Kapton frame" 11 can be assigned.

- This hold-down device 10 now presses through the Kapton frame 11 or directly onto the contact ends 12a of the numerous contact clips 12 of the chip 13 to be soldered. These contact ends 12a of the chip 13 are now preformed in such a way that a mechanical contact 12b of all contact clips 12 is applied to the contact pin 12 by a defined pressure load Conductor connections 14 take place and the laser bonding takes place at these contact points 12b.

- connection legs A variant is outlined in FIG. 3b, in which the hold-down device 10 presses on the rear side (compared to FIG. 3a) of the chip 13 and the contacts 12 are therefore on the “underside” of the chip 13.

- connection elements of the contact bracket are referred to, which are sometimes referred to as "connection legs”.

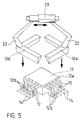

- the function of the laser soldering device sketched in FIGS. 1 to 3b can be described as follows: The multi-axis robot or XY table equipped with a vision system, its automatic control as well as the placement and laser bonding head are activated. This is followed by the calibration, the rough positioning of the placement head 100 over the component (chip) 13, the repositioning and fine positioning by means of the vision system (see FIG. 6) in accordance with the specified component dimensioning.

- the assembly head 100 moves onto the chip 13, which is picked up by means of a suction nozzle 21 and transported to the circuit position — for example a printed circuit board or hybrid 15 — and is positioned precisely by means of the vision system.

- the height of the proboscis 21 is adjustable. After this positioning, the suction button or plunger 20 is vented and the frame-shaped hold-down device 10 is lowered.

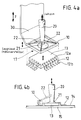

- FIG. 4a and 4b illustrate an embodiment of the frame-shaped hold-down device 10, which has a height-adjustable suction nozzle 21 on a stamp 20 for the simultaneous loading and fixing of the or the chip 13 is provided, the frame-shaped hold-down device 10 being connected to the stamp by means of length-adjustable frame holder 22.

- the frame-shaped hold-down device 10 is divided into two halves 10a, 10b (FIG. 5) and can be adapted diagonally to the different contact geometries by means of an adjusting device 23. This can be done mechanically via a double thread etc. but also pneumatically using the existing pneumatics, because after the chip has been positioned and the suction button 20 has been vented, the placement head 100 is pneumatically decoupled and brought into the zero position or the laser position.

- the frame-shaped hold-down device 10 is brought to the exact position via an XY table 140 (FIG. 6) assigned to it and an image recognition system 120 and a correction control system 130.

- the hold-down device 10 is designed to be very flat.

- a grid-shaped Teflon insulation layer 17 on the underside also has an advantageous effect.

- the frame-shaped hold-down device 10 is thus raised pneumatically in the Z direction before and after the soldering, is pressed lightly onto the contact ends 12a and 12b in a defined manner immediately before and during the soldering process.

- the hold-down device 100 is only extended except for a constant spring pressure, but not dimensionally controlled.

- the XY table 140 arranged for its adjustment is supplied by the same controller that is assigned to the XY table of the laser head 100. Of course, this only applies to systems with such tables.

- FIG. 7a to 7c illustrate a variant for economical laser bonding with a multi-axis robot, that is to say without an XY table 110.

- the multi-axis robot with vision system, the automatic control and the placement and laser bonding head 100 are activated, as a result of which the calibration, rough positioning of the placement head over the component 13, the repositioning and fine positioning by means of the vision system.

- the laser and mounting head 100 works in principle the same, only the "connection legs" 16 are not pressed on the inside of the component (chip) 13, but on the outer ends of the contact bracket 12 in front of the hold-down device 10. Here the decoupling from the hold-down device 10 and the laser placement head 100 takes place electromagnetically.

- CIM Computer Integrated Manufacturing

- the measure proves to be advantageous in the case of the multi-axis robot to additionally design or mount the laser mounting head 100 in such a way that it can be deflected in two directions at a certain angle ⁇ .

Landscapes

- Engineering & Computer Science (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Manufacturing & Machinery (AREA)

- Computer Hardware Design (AREA)

- Power Engineering (AREA)

- Physics & Mathematics (AREA)

- Optics & Photonics (AREA)

- Mechanical Engineering (AREA)

- Electric Connection Of Electric Components To Printed Circuits (AREA)

Claims (6)

- Dispositif pour le soudage par laser de contacts fins de composants (13) de micro-électronique pré-enrobés de métal d'apport au moyen d'une tête de montage de composants à laser (100) qui peut être déplacée en hauteur le long de l'axe Z au moyen d'un dispositif de positionnement (30), est supportée et guidée avec commande par programme ou par ordinateur par un robot multiaxe ou une table XY (110) et est pourvue d'un dispositif presseur (10) en forme de cadre qui exerce une pression déterminée sur le composant TAB (Tape Automated Bonding Chip) (13) à souder, caractérisé par le fait que le dispositif presseur (10) en forme de cadre est divisé en deux parties (10a, 10b) et peut être adapté aux diiférentes formes de contacts grâce à un dispositif de réglage (23), le dispositif presseur (10) pressant les éléments de connexion (16) entre le composant TAB (13) et les pattes de contact (12) au niveau de leurs extrémités sur le substrat (film d'adhésif) 15.

- Dispositif selon la revendication 1, caractérisé par le fait que le dispositif presseur (10) en forme de cave est lié à la tige (20) ou à la buse d'aspiration (21) par l'intermédiaire d'un porte cadre (22) réglable en longueur.

- Dispositif selon la revendication 1 ou 2, caractérisé par le fait que le dispositif presseur (10) en forme de cadre est plat et que sa face inférieure est isolée au moyen d'une couche de téflon (17) agencée en réseau .

- Dispositif selon l'une des revendications 1 à 3, caractérisé par le fait qu'aux fins d'assurer un positionnement précis, une table XY (140), un système de prise de vue (120) et un système de correction (130) sont associés au dispositif Presseur (10) en forme de cadre.

- Dispositif selon l'une des revendications 1 à 4, caractérisé par le fait que la table XY (140) du dispositif presseur (10) en forme de cadre est dépIacée par le même dispositif de commande que la table XY (110) disposée au-dessus de la tête à laser (100).

- Dispositif selon l'une des revendications 1 à 5, caractérisé par le fait que la séparation des éléments de connexion (16) des pattes de contact (12) du dispositif presseur (10) en forme de cadre et de la tête à laser (100) est opérée au moyen d'un dispositif électro-magnétique.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE4105875 | 1991-02-25 | ||

| DE4105875A DE4105875C1 (fr) | 1991-02-25 | 1991-02-25 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0510323A1 EP0510323A1 (fr) | 1992-10-28 |

| EP0510323B1 true EP0510323B1 (fr) | 1994-08-31 |

Family

ID=6425839

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP92102723A Expired - Lifetime EP0510323B1 (fr) | 1991-02-25 | 1992-02-19 | Dispositif de brasage au laser |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP0510323B1 (fr) |

| DE (1) | DE4105875C1 (fr) |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE4137232C1 (fr) * | 1991-11-13 | 1993-05-06 | Deutsche Aerospace Ag, 8000 Muenchen, De | |

| DE4304912C2 (de) * | 1993-02-18 | 2003-03-06 | Klaus Siebert | Verfahren und Vorrichtung zur durchgehend automatischen Chipherstellung unter Vakuum |

| DE4337513C2 (de) * | 1993-11-03 | 1998-07-02 | Siemens Ag | Anordnung zum Erwärmen einer Bondstelle beim Goldraht-Thermosonic-Wirebonden |

| DE19831033C2 (de) * | 1998-07-11 | 2002-06-13 | Dual M Tech Ag | Rüstsatzfreie Vorrichtung zum zielgerichteten Bewegen von elektronischen Bauteilen |

| JP4147923B2 (ja) * | 2002-12-03 | 2008-09-10 | 松下電器産業株式会社 | 電子部品実装装置および電子部品実装方法 |

| CN103420135B (zh) * | 2013-08-15 | 2016-03-30 | 深圳市华星光电技术有限公司 | 卡匣的校正装置及校正方法 |

| CN112207433A (zh) * | 2020-12-07 | 2021-01-12 | 华工法利莱切焊系统工程有限公司 | 一种用于连续激光焊接的气体保护装置及方法 |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2931857A1 (de) * | 1979-08-06 | 1981-04-16 | Siemens AG, 1000 Berlin und 8000 München | Loetbuegel fuer mikroloetstellen |

| DE3606764A1 (de) * | 1986-03-01 | 1987-09-03 | Messerschmitt Boelkow Blohm | Verfahren und vorrichtung zum mikroloeten |

| DD250677A1 (de) * | 1986-07-01 | 1987-10-21 | Erfurt Mikroelektronik | Verfahren und vorrichtung zum kontaktieren aufsetzbarer elektronischer bauelemente |

| DE3701013A1 (de) * | 1987-01-15 | 1988-07-28 | Messerschmitt Boelkow Blohm | Verfahren zum mikroloeten |

| US4845335A (en) * | 1988-01-28 | 1989-07-04 | Microelectronics And Computer Technology Corporation | Laser Bonding apparatus and method |

| DE3939812C2 (de) * | 1989-12-01 | 1993-11-11 | Deutsche Aerospace | Laserlötsystem für SMD-Elemente |

-

1991

- 1991-02-25 DE DE4105875A patent/DE4105875C1/de not_active Expired - Lifetime

-

1992

- 1992-02-19 EP EP92102723A patent/EP0510323B1/fr not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| EP0510323A1 (fr) | 1992-10-28 |

| DE4105875C1 (fr) | 1992-08-13 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE69511609T2 (de) | Verbinden von einem Halbleiter mit einem Substrat | |

| DE102015112518B3 (de) | Bestückmaschine und Verfahren zum Bestücken eines Trägers mit ungehäusten Chips | |

| DE3939812C2 (de) | Laserlötsystem für SMD-Elemente | |

| DE3616494C2 (fr) | ||

| DE69431828T2 (de) | Verfahren zur Herstellung von gedruckten Schaltungskarten | |

| DE3686693T2 (de) | Ausrichtungsvorrichtung eines halbleiterplaettchentraegers und verfahren zum ausrichten. | |

| DE102008024928A1 (de) | Elektronikbauelement-Montagesytem und Elektronikbauelement-Montageverfahren | |

| DE102005017849A1 (de) | Elektronisches Bauteil und Verfahren zur Herstellung einer elektrischen Verbindung | |

| EP0510323B1 (fr) | Dispositif de brasage au laser | |

| EP1326730A1 (fr) | Dispositif pour positionner un outil par rapport a une piece d'usinage | |

| DE69112164T2 (de) | Aufbringen einer Lötpaste. | |

| DE2640613C2 (de) | Verfahren und Vorrichtung zum Kontaktieren von Schaltungsbausteinen in eine Schichtschaltung | |

| DE4105874C1 (fr) | ||

| EP1719156A1 (fr) | Dispositif pour isoler et souder des plaquettes semi-conductrices et procede d'isolement et de soudage | |

| DE10121578C2 (de) | Verfahren und Bestückungssystem zum Bestücken eines Substrats mit elektronischen Bauteilen | |

| EP2983458A1 (fr) | Procede de fixation d'une source lumineuse semi-conductrice smd sur une carte de circuits imprimes d'un phare de vehicule automobile | |

| EP0305696B1 (fr) | Procédé de désoudage de composants SMD montés en surface et collés | |

| DE10228152A1 (de) | Selbsthaftende flexible Reparaturschaltung | |

| JPS6156880B2 (fr) | ||

| EP0305698A2 (fr) | Dispositif de dosage pour couvrir une plaque à circuits imprimés d'une pâte à souder pour le soudage de composants à montage sur une surface | |

| DE102016223710B4 (de) | Verfahren und Vorrichtung zur Herstellung einer Beleuchtungseinrichtung | |

| EP0305697B1 (fr) | Procédé de soudure d'éléments montés en surface et maintenus par une tête de soudure pouvant être temporairement mise sous vide | |

| DE102018129805B3 (de) | Aufnahme eines zu bestückenden Trägers mit Träger-Aufnahmevorrichtung aufweisend einen Grundkörper und ein Adapterelement sowie System und Bestückmaschine diese aufweisend und Verfahren zum Bestücken eines Trägers | |

| EP0305695B1 (fr) | Tête à souder pour le logement et pour ajuster des éléments pendant le soudage et le dessoudage, en particulier pour éléments montés sur surface | |

| DE4438449A1 (de) | Verfahren zur direkten Kontaktierung elektronischer Bauelemente mit einem Träger und direkt kontaktierbare Bauelemente hierzu |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19920821 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): DE FR GB IT NL |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: DEUTSCHE AEROSPACE AKTIENGESELLSCHAFT |

|

| 17Q | First examination report despatched |

Effective date: 19930604 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: TEMIC TELEFUNKEN MICROELECTRONIC GMBH |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): FR NL |

|

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19960202 Year of fee payment: 5 Ref country code: FR Payment date: 19960202 Year of fee payment: 5 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19970901 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19971030 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 19970901 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |