EP0502373A2 - Heating apparatus - Google Patents

Heating apparatus Download PDFInfo

- Publication number

- EP0502373A2 EP0502373A2 EP92102905A EP92102905A EP0502373A2 EP 0502373 A2 EP0502373 A2 EP 0502373A2 EP 92102905 A EP92102905 A EP 92102905A EP 92102905 A EP92102905 A EP 92102905A EP 0502373 A2 EP0502373 A2 EP 0502373A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- flanges

- casing

- heat exchanger

- double

- jacket

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24H—FLUID HEATERS, e.g. WATER OR AIR HEATERS, HAVING HEAT-GENERATING MEANS, e.g. HEAT PUMPS, IN GENERAL

- F24H1/00—Water heaters, e.g. boilers, continuous-flow heaters or water-storage heaters

- F24H1/22—Water heaters other than continuous-flow or water-storage heaters, e.g. water heaters for central heating

- F24H1/40—Water heaters other than continuous-flow or water-storage heaters, e.g. water heaters for central heating with water tube or tubes

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24H—FLUID HEATERS, e.g. WATER OR AIR HEATERS, HAVING HEAT-GENERATING MEANS, e.g. HEAT PUMPS, IN GENERAL

- F24H1/00—Water heaters, e.g. boilers, continuous-flow heaters or water-storage heaters

- F24H1/22—Water heaters other than continuous-flow or water-storage heaters, e.g. water heaters for central heating

- F24H1/24—Water heaters other than continuous-flow or water-storage heaters, e.g. water heaters for central heating with water mantle surrounding the combustion chamber or chambers

- F24H1/26—Water heaters other than continuous-flow or water-storage heaters, e.g. water heaters for central heating with water mantle surrounding the combustion chamber or chambers the water mantle forming an integral body

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24H—FLUID HEATERS, e.g. WATER OR AIR HEATERS, HAVING HEAT-GENERATING MEANS, e.g. HEAT PUMPS, IN GENERAL

- F24H1/00—Water heaters, e.g. boilers, continuous-flow heaters or water-storage heaters

- F24H1/22—Water heaters other than continuous-flow or water-storage heaters, e.g. water heaters for central heating

- F24H1/44—Water heaters other than continuous-flow or water-storage heaters, e.g. water heaters for central heating with combinations of two or more of the types covered by groups F24H1/24 - F24H1/40 , e.g. boilers having a combination of features covered by F24H1/24 - F24H1/40

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24H—FLUID HEATERS, e.g. WATER OR AIR HEATERS, HAVING HEAT-GENERATING MEANS, e.g. HEAT PUMPS, IN GENERAL

- F24H9/00—Details

- F24H9/14—Arrangements for connecting different sections, e.g. in water heaters

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24H—FLUID HEATERS, e.g. WATER OR AIR HEATERS, HAVING HEAT-GENERATING MEANS, e.g. HEAT PUMPS, IN GENERAL

- F24H9/00—Details

- F24H9/14—Arrangements for connecting different sections, e.g. in water heaters

- F24H9/146—Connecting elements of a heat exchanger

Definitions

- the invention relates to a heating device with a burner arranged in a combustion chamber having a double jacket and provided with a flue gas discharge and a lamella heat exchanger, the double jacket of the combustion chamber having an outwardly directed flange and the lamella heat exchanger in a rotating, congruent with the inner wall or the inner walls of the double jacket is held, which is provided with flanges with which the jacket is connected to the double jacket and the flue gas outlet.

- EP-OS 315 577 it is also known to provide a double-walled combustion chamber with a circumferential flange on which a heat exchanger bracket, which also has a flange, is mounted.

- the two flanges lie snugly on top of one another and are connected to one another in a conventional manner by means of an elaborate weld seam or conventional fastening bolts.

- the main disadvantage here is a remaining residual uncertainty with regard to the tightness of the connection despite considerable installation effort.

- the aim of the invention is to avoid these disadvantages and to propose a heating device of the type mentioned at the outset, which is distinguished by a simple structure in which there are no problems with the mounting of the fin heat exchanger.

- this is achieved in that the flanges of the jacket are connected to the flanges of the double jacket by squeezing tooth-like sections of the flanges which are separated from one another by cuts in the outer edge regions, the tooth-like sections being bent out of the parting plane of the flanges.

- bushings through the double jacket of the combustion chamber for holding the fin heat exchanger are unnecessary.

- the bushings can be designed and manufactured much easier in the jacket of the finned heat exchanger than in the double jacket of the combustion chamber, as was the case with a previous solution.

- there is a very easy to manufacture connection of the double jacket to the finned heat exchanger which can be produced with little manufacturing effort.

- the mutually adjacent sections of the flanges which are poisoned with one another are bent out of the parting plane of the flanges in opposite directions.

- a metal seal is interposed between the flanges of the combustion chamber and the jacket of the finned heat exchanger.

- a circumferential groove is used in the contact surface of the flange of the flue gas outlet, which groove is used to receive a seal.

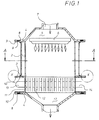

- the heating device according to FIG. 1 has a combustion chamber 1, which is surrounded by a double jacket 2, through which a medium to be heated, mostly water, flows. At its end faces, the double jacket 2 is provided with flanges 3 which protrude outwards.

- a hood 5 which also has a flange 4 and in which a burner 6 is held.

- This hood is provided on one end face with a nozzle 7, which serves to supply a combustible mixture.

- a circumferential groove 8 is incorporated in the flange 4, in which an elastically deformable seal 9 is inserted.

- the flanges 4 and 3 of the hood 5 or the double jacket 2 can be connected in the usual way by means of screws and nuts passing through the flanges or produced by clamping.

- the double jacket 2 also has a flange 3 against which a flange 10 of a jacket 11 abuts, in which is held a fin heat exchanger 12.

- This sheath has a clear cross section corresponding to the clear cross section of the double casing 2.

- the feed and discharge lines 13, 14 penetrate opposite walls of the jacket 11.

- a metallic seal (not shown) is interposed between the flanges 3 and 10, the service life of which is essentially designed for the service life of the entire heating device.

- the connection of the two flanges 3 and 10 is designed to be operationally inseparable. This connection takes place in such a way that congruent cuts 18 are arranged in the edges of the flanges 3 and 10, which separate different sections 15, 16 from one another.

- the individual sections 15, 16 of the flanges 3, 10 are potted together, at least one of these sections 15, 16 being bent out of the parting plane of the flanges 3, 10, as can be seen from FIG. 3. In principle, it is also possible to bend the sections 15, 16 in opposite directions from the parting plane of the flanges 3, 10.

- a flange 4 of a flue gas outlet 17 On the lower flange 10 of the casing 11, there is a flange 4 of a flue gas outlet 17. It is in the flange 4 of the flue gas 17 as well as in the flange 4 of the hood 5, a groove 8 for receiving a seal 9 is provided, wherein the connection of the flanges 10 and 4 can also be made by means of screws and nuts.

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Heat-Exchange Devices With Radiators And Conduit Assemblies (AREA)

- Yarns And Mechanical Finishing Of Yarns Or Ropes (AREA)

- Instantaneous Water Boilers, Portable Hot-Water Supply Apparatuses, And Control Of Portable Hot-Water Supply Apparatuses (AREA)

- Control And Other Processes For Unpacking Of Materials (AREA)

- Heat-Pump Type And Storage Water Heaters (AREA)

- Gas Burners (AREA)

- Resistance Heating (AREA)

- Baking, Grill, Roasting (AREA)

- General Preparation And Processing Of Foods (AREA)

Abstract

Description

Die Erfindung bezieht sich auf eine Heizeinrichtung mit einem in einer einen Doppelmantel aufweisenden, mit einem Rauchgasabzug versehenen Brennkammer angeordneten Brenner und einem Lamellen-Wärmetauscher, wobei der Doppelmantel der Brennkammer einen nach außen gerichteten Flansch aufweist und der Lamellen-Wärmetauscher in einem umlaufenden, kongruent mit der Innenwand beziehungsweise den Innenwänden des Doppelmantels ausgebildeten Mantel gehalten ist, der mit Flanschen versehen ist, mit denen der Mantel mit dem Doppelmantel und dem Rauchgasabzug verbunden ist.The invention relates to a heating device with a burner arranged in a combustion chamber having a double jacket and provided with a flue gas discharge and a lamella heat exchanger, the double jacket of the combustion chamber having an outwardly directed flange and the lamella heat exchanger in a rotating, congruent with the inner wall or the inner walls of the double jacket is held, which is provided with flanges with which the jacket is connected to the double jacket and the flue gas outlet.

Bei solchen Heizeinrichtungen ergibt sich stets das Problem der Anbringung des Wärmetauschers.With such heating devices, there is always the problem of attaching the heat exchanger.

Bei einer bekannten Lösung durchsetzen die Zu- und Ableitungen des Lamellen-Wärmetauschers den Doppelmantel der Brennkammer. Dabei ergeben sich jedoch erhebliche Probleme im Hinblick auf die Beständigkeit der Durchführungen, da sich in diesen Bereichen erhebliche Spannungen aufgrund von größeren Temperaturunterschieden ergeben, die zu Rissen führen können.In a known solution, the feed and discharge lines of the finned heat exchanger enforce the double jacket of the combustion chamber. However, there are considerable problems with regard to the durability of the bushings, since considerable stresses arise in these areas due to larger temperature differences, which can lead to cracks.

Aus der EP-OS 315 577 ist es weiterhin bekannt, eine doppelwandige Brennkammer mit einem umlaufenden Flansch zu versehen, auf dem eine Wärmetauscherhalterung, die ebenfalls einen Flansch aufweist, montiert wird. Die beiden Flansche liegen dabei satt aufeinander und werden in herkömmlicher Weise mittels einer aufwendigen Schweißnaht oder üblicher Befestigungsbolzen miteinander verbunden. Nachteilig hierbei ist vor allem eine verbleibende Restunsicherheit in bezug auf die Dichtigkeit der Verbindung trotz eines erheblichen Montageaufwandes.From EP-OS 315 577 it is also known to provide a double-walled combustion chamber with a circumferential flange on which a heat exchanger bracket, which also has a flange, is mounted. The two flanges lie snugly on top of one another and are connected to one another in a conventional manner by means of an elaborate weld seam or conventional fastening bolts. The main disadvantage here is a remaining residual uncertainty with regard to the tightness of the connection despite considerable installation effort.

Ziel der Erfindung ist es, diese Nachteile zu vermeiden und eine Heizeinrichtung der eingangs erwähnten Art vorzuschlagen, die sich durch einen einfachen Aufbau auszeichnet, bei dem sich keine Probleme bei der Halterung des Lamellen-Wärmetauschers ergeben.The aim of the invention is to avoid these disadvantages and to propose a heating device of the type mentioned at the outset, which is distinguished by a simple structure in which there are no problems with the mounting of the fin heat exchanger.

Erfindungsgemäß wird dies dadurch erreicht, daß die Flansche des Mantels mit den Flanschen des Doppelmantels durch Verquetschen von in den äußeren Randbereichen durch Schnitte voneinander getrennten zahnartigen Abschnitten der aneinander anliegenden Flansche verbunden sind, wobei die zahnartigen Abschnitte aus der Trennebene der Flansche ausgebogen sind.According to the invention, this is achieved in that the flanges of the jacket are connected to the flanges of the double jacket by squeezing tooth-like sections of the flanges which are separated from one another by cuts in the outer edge regions, the tooth-like sections being bent out of the parting plane of the flanges.

Auf diese Weise werden Durchführungen durch den Doppelmantel der Brennkammer zur Halterung des Lamellen-Wärmetauschers überflüssig. Die Durchführungen lassen sich im Mantel des Lamellen-Wärmetauschers wesentlich einfacher gestalten und herstellen als im Doppelmantel der Brennkammer, wie dies bei einer bisherigen Lösung vorgesehen war. Außerdem ergibt sich eine sehr einfach herstellbare Verbindung des Doppelmantels mit dem Lamellen-Wärmetauscher, die sich mit geringem fertigungstechnischen Aufwand herstellen läßt.In this way, bushings through the double jacket of the combustion chamber for holding the fin heat exchanger are unnecessary. The bushings can be designed and manufactured much easier in the jacket of the finned heat exchanger than in the double jacket of the combustion chamber, as was the case with a previous solution. In addition, there is a very easy to manufacture connection of the double jacket to the finned heat exchanger, which can be produced with little manufacturing effort.

Dabei kann nach einem weiteren Merkmal der Erfindung vorgesehen sein, daß die aneinander angrenzenden miteinander verguetschten Abschnitte der Flansche in einander entgegengesetzten Richtungen aus der Trennebene der Flansche ausgebogen sind.According to a further feature of the invention, it can be provided that the mutually adjacent sections of the flanges which are poisoned with one another are bent out of the parting plane of the flanges in opposite directions.

Dadurch ergibt sich eine besonders sichere Verbindung der Brennkammer mit dem den Lamellen-Wärmetauscher haltenden Mantel.This results in a particularly secure connection of the combustion chamber with the jacket holding the finned heat exchanger.

Nach einem weiteren Merkmal der Erfindung kann vorgesehen sein, daß zwischen den Flanschen der Brennkammer und dem Mantel des Lamellen-Wärmetauschers eine Metalldichtung zwischengelegt ist.According to a further feature of the invention it can be provided that a metal seal is interposed between the flanges of the combustion chamber and the jacket of the finned heat exchanger.

Auf diese Weise läßt sich sehr einfach ein hohes Maß an Dichtheit erreichen, wobei die Dichtung selbst sehr beständig ist und den in diesem Bereich herrschenden Temperaturen widersteht.In this way it is very easy to achieve a high degree of tightness, the seal itself being very stable and withstanding the temperatures prevailing in this area.

Nach einem weiteren Merkmal der Erfindung kann vorgesehen sein, daß in der Anlagefläche des Flansches des Rauchgasabzuges eine umlaufende Rille eingearbeitet ist, die zur Aufnahme einer Dichtung dient.According to a further feature of the invention it can be provided that a circumferential groove is used in the contact surface of the flange of the flue gas outlet, which groove is used to receive a seal.

Auf diese Weise ergibt sich eine in konstruktiver Hinsicht sehr einfache Verbindung des Mantels mit dem Rauchgasabzug.In this way, there is a constructionally very simple connection of the jacket to the flue gas outlet.

Die Erfindung wird nun anhand der Zeichnung näher erläutert.The invention will now be explained in more detail with reference to the drawing.

Dabei zeigen:

Figur 1 schematisch einen Schnitt durch eine erfindungsgemäße Heizeinrichtung,Figur 2 einen Schnitt entlang der Linie A-A,Figur 3 ein Detail des Verbindungsbereiches der Brennkammer mit dem Mantel.

- FIG. 1 shows schematically a section through a heating device according to the invention,

- FIG. 2 shows a section along the line AA,

- Figure 3 shows a detail of the connection area of the combustion chamber with the jacket.

Die Heizeinrichtung nach der Figur 1 weist eine Brennkammer 1 auf, die von einem Doppelmantel 2 umgeben ist, der von einem zu erwärmenden Medium, zumeist Wasser, durchströmt ist. An seinen Stirnseiten ist der Doppelmantel 2 mit Flanschen 3 versehen, die nach außen vorkragen.The heating device according to FIG. 1 has a

An dem oberen Ende der Brennkammer 1 sitzt eine ebenfalls einen Flansch 4 aufweisende Haube 5, in der ein Brenner 6 gehalten ist. Diese Haube ist an ihrer einen Stirnseite mit einem Stutzen 7 versehen, der zur Zufuhr eines brennbaren Gemisches dient.At the upper end of the

Dabei ist in dem Flansch 4 eine umlaufende Nut 8 eingearbeitet, in der eine elastisch verformbare Dichtung 9 eingelegt ist.A

Die Verbindung der Flansche 4 und 3 der Haube 5 beziehungsweise des Doppelmantels 2 kann in üblicher Weise mittels die Flansche durchsetzender Schrauben und Muttern erfolgen oder durch Verklammern hergestellt werden.The

An seinem unteren Ende weist der Doppelmantel 2 ebenfalls einen Flansch 3 auf, an dem ein Flansch 10 eines Mantels 11 anliegt, in dem ein Lamellen-Wärmetauscher 12 gehalten ist. Dieser Mantel weist einen dem lichten Querschnitt des Doppelmantels 2 entsprechenden lichten Querschnitt auf. Dabei durchsetzen die Zu- und Ableitungen 13, 14 einander gegenüberliegende Wände des Mantels 11.At its lower end, the

Zwischen die Flansche 3 und 10 ist eine metallische Dichtung (nicht dargestellt) zwischengelegt, deren Lebensdauer im wesentlichen auf die Lebensdauer der gesamten Heizeinrichtung ausgelegt ist. Die Verbindung der beiden Flansche 3 und 10 ist dabei betriebsmäßig unlösbar gestaltet. Diese Verbindung erfolgt dabei in der Weise, daß in den Rändern der Flansche 3 und 10 kongruente Schnitte 18 angeordnet sind, die verschiedene Abschnitte 15, 16 voneinander trennen.A metallic seal (not shown) is interposed between the

Die einzelnen Abschnitte 15, 16 der Flansche 3, 10 sind miteinander verguetscht, wobei zumindest einer dieser Abschnitte 15, 16 aus der Trennebene der Flansche 3, 10 ausgebogen ist, wie dies aus der Figur 3 zu ersehen ist. Dabei ist es grundsätzlich auch möglich, die Abschnitte 15, 16 in zueinander entgegengesetzten Richtungen aus der Trennebene der Flansche 3, 10 auszubiegen.The

Bei der Herstellung der Verbindung der Flansche 3 und 10 ist es zweckmäßig, die einzelnen Abschnitte 15 beziehungsweise 16 der Flansche 3, 10 gemeinsam aus der Trennebene der Flansche auszubiegen und im ausgebogenen Zustand miteinander zu verquetschen. Dies kann in einem Arbeitsgang erfolgen.When establishing the connection of the

An dem unteren Flansch 10 des Mantels 11 liegt ein Flansch 4 eines Rauchgasabzuges 17 an. Dabei ist in dem Flansch 4 des Rauchgasabzuges 17 ebenso wie in dem Flansch 4 der Haube 5 eine Nut 8 zur Aufnahme einer Dichtung 9 versehen, wobei die Verbindung der Flansche 10 und 4 ebenfalls mittels Schrauben und Muttern erfolgen kann.On the

Claims (4)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT380/91 | 1991-02-25 | ||

| AT0038091A AT395209B (en) | 1991-02-25 | 1991-02-25 | HEATING DEVICE |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0502373A2 true EP0502373A2 (en) | 1992-09-09 |

| EP0502373A3 EP0502373A3 (en) | 1993-03-24 |

| EP0502373B1 EP0502373B1 (en) | 1994-10-12 |

Family

ID=3489054

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP92102905A Expired - Lifetime EP0502373B1 (en) | 1991-02-25 | 1992-02-21 | Heating apparatus |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP0502373B1 (en) |

| AT (2) | AT395209B (en) |

| DE (2) | DE9202440U1 (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| AT407791B (en) * | 1998-02-17 | 2001-06-25 | Vaillant Gmbh | HEATER |

| AT410483B (en) * | 1999-01-21 | 2003-05-26 | Vaillant Gmbh | COOLED COMBUSTION CHAMBER |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2540614A1 (en) * | 1983-02-07 | 1984-08-10 | Piemontese Radiatori | Motor vehicle radiator construction |

| US4718484A (en) * | 1980-08-15 | 1988-01-12 | Snydergeneral Corporation | Heat exchanger unit |

| EP0315577A2 (en) * | 1987-11-03 | 1989-05-10 | Joh. Vaillant GmbH u. Co. | Burner heated apparatus, especiallly water heater |

-

1991

- 1991-02-25 AT AT0038091A patent/AT395209B/en not_active IP Right Cessation

-

1992

- 1992-02-21 DE DE9202440U patent/DE9202440U1/en not_active Expired - Lifetime

- 1992-02-21 AT AT92102905T patent/ATE112842T1/en not_active IP Right Cessation

- 1992-02-21 DE DE59200608T patent/DE59200608D1/en not_active Expired - Fee Related

- 1992-02-21 EP EP92102905A patent/EP0502373B1/en not_active Expired - Lifetime

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4718484A (en) * | 1980-08-15 | 1988-01-12 | Snydergeneral Corporation | Heat exchanger unit |

| FR2540614A1 (en) * | 1983-02-07 | 1984-08-10 | Piemontese Radiatori | Motor vehicle radiator construction |

| EP0315577A2 (en) * | 1987-11-03 | 1989-05-10 | Joh. Vaillant GmbH u. Co. | Burner heated apparatus, especiallly water heater |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| AT407791B (en) * | 1998-02-17 | 2001-06-25 | Vaillant Gmbh | HEATER |

| AT410483B (en) * | 1999-01-21 | 2003-05-26 | Vaillant Gmbh | COOLED COMBUSTION CHAMBER |

Also Published As

| Publication number | Publication date |

|---|---|

| DE9202440U1 (en) | 1992-04-02 |

| DE59200608D1 (en) | 1994-11-17 |

| ATA38091A (en) | 1992-02-15 |

| EP0502373B1 (en) | 1994-10-12 |

| ATE112842T1 (en) | 1994-10-15 |

| EP0502373A3 (en) | 1993-03-24 |

| AT395209B (en) | 1992-10-27 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE4116692A1 (en) | HEAT EXCHANGER INSERT FOR AIR HEATERS | |

| EP0502373B1 (en) | Heating apparatus | |

| DE3601000A1 (en) | Water-heating boiler | |

| DE2126226C3 (en) | Heat exchanger | |

| DE2930577A1 (en) | Heat exchanger for heat recovery from exhaust gas - using bundle of glass tubes supported in tube plate and sealed with O=rings | |

| DE2123697A1 (en) | Glass tube heat exchanger - with spring loaded seal between tube and plate | |

| EP0209703B1 (en) | Glow insert for furnaces, in particular for boilers, and furnace equipped with such a glow insert | |

| EP0711954B1 (en) | Air/flue gas stack | |

| DE4116383C2 (en) | ||

| DE69001197T2 (en) | BOILER SECTION FOR LOW TEMPERATURE BOILERS. | |

| DE1551431A1 (en) | Heater | |

| DE1291496B (en) | Boiler for firing with flowing fuel | |

| AT395473B (en) | ARRANGEMENT FOR GUIDING FRESH AIR AND EXHAUST GAS | |

| DE9110224U1 (en) | Flue gas exhaust pipe | |

| EP0331141B1 (en) | Boiler | |

| DE4216649C2 (en) | Sealing cord | |

| EP0430061B1 (en) | Boiler | |

| AT400889B (en) | Air supply and waste gas discharge system | |

| DE3108452C2 (en) | Oil / gas boilers | |

| DE7136314U (en) | Heating boiler | |

| CH425140A (en) | Sectional boilers for liquid and gaseous fuels | |

| DE1802196C (en) | Heater with a closed, heat-emitting housing | |

| DE9207530U1 (en) | Double-walled heating shaft | |

| DE9209416U1 (en) | Boilers for burner firing | |

| DE8412113U1 (en) | BOILER |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH DE DK ES FR GB GR IT LI LU NL PT SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH DE DK ES FR GB GR IT LI LU NL PT SE |

|

| 17P | Request for examination filed |

Effective date: 19930904 |

|

| 17Q | First examination report despatched |

Effective date: 19931208 |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: VAILLANT GES.M.B.H Owner name: JOH. VAILLANT GMBH U. CO. Owner name: N.V. VAILLANT S.A. Owner name: VAILLANT GMBH Owner name: VAILLANT B.V. Owner name: VAILLANT LTD. Owner name: VAILLANT S.A.R.L |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE DK ES FR GB GR IT LI LU NL PT SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRE;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED.SCRIBED TIME-LIMIT Effective date: 19941012 Ref country code: ES Free format text: THE PATENT HAS BEEN ANNULLED BY A DECISION OF A NATIONAL AUTHORITY Effective date: 19941012 Ref country code: BE Effective date: 19941012 Ref country code: NL Effective date: 19941012 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 19941012 Ref country code: DK Effective date: 19941012 Ref country code: GB Effective date: 19941012 |

|

| REF | Corresponds to: |

Ref document number: 112842 Country of ref document: AT Date of ref document: 19941015 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 59200608 Country of ref document: DE Date of ref document: 19941117 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19950112 Ref country code: PT Effective date: 19950112 |

|

| ET | Fr: translation filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19950228 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| GBV | Gb: ep patent (uk) treated as always having been void in accordance with gb section 77(7)/1977 [no translation filed] |

Effective date: 19941012 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 19960220 Year of fee payment: 5 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 19960229 Year of fee payment: 5 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19960319 Year of fee payment: 5 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19960322 Year of fee payment: 5 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Effective date: 19970221 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Effective date: 19970228 Ref country code: LI Effective date: 19970228 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19971030 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19971101 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |