EP0494852A2 - Process for the production of cellulosic articles - Google Patents

Process for the production of cellulosic articles Download PDFInfo

- Publication number

- EP0494852A2 EP0494852A2 EP92890004A EP92890004A EP0494852A2 EP 0494852 A2 EP0494852 A2 EP 0494852A2 EP 92890004 A EP92890004 A EP 92890004A EP 92890004 A EP92890004 A EP 92890004A EP 0494852 A2 EP0494852 A2 EP 0494852A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- nozzle

- air gap

- channel

- length

- cellulosic

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Classifications

-

- D—TEXTILES; PAPER

- D01—NATURAL OR MAN-MADE THREADS OR FIBRES; SPINNING

- D01D—MECHANICAL METHODS OR APPARATUS IN THE MANUFACTURE OF ARTIFICIAL FILAMENTS, THREADS, FIBRES, BRISTLES OR RIBBONS

- D01D4/00—Spinnerette packs; Cleaning thereof

- D01D4/02—Spinnerettes

-

- D—TEXTILES; PAPER

- D01—NATURAL OR MAN-MADE THREADS OR FIBRES; SPINNING

- D01D—MECHANICAL METHODS OR APPARATUS IN THE MANUFACTURE OF ARTIFICIAL FILAMENTS, THREADS, FIBRES, BRISTLES OR RIBBONS

- D01D5/00—Formation of filaments, threads, or the like

- D01D5/06—Wet spinning methods

-

- D—TEXTILES; PAPER

- D01—NATURAL OR MAN-MADE THREADS OR FIBRES; SPINNING

- D01F—CHEMICAL FEATURES IN THE MANUFACTURE OF ARTIFICIAL FILAMENTS, THREADS, FIBRES, BRISTLES OR RIBBONS; APPARATUS SPECIALLY ADAPTED FOR THE MANUFACTURE OF CARBON FILAMENTS

- D01F2/00—Monocomponent artificial filaments or the like of cellulose or cellulose derivatives; Manufacture thereof

Abstract

Zur Herstellung eines cellulosischen Formkörpers wird eine cellulosische Aminoxidlösung durch eine Düse gepreßt, anschließend durch einen Luftspalt geführt, in diesem gegebenenfalls verstreckt und schließlich in einem Fällbad koaguliert. Erfindungsgemäß beträgt der minimale Lochdurchmesser der verwendeten Düse höchstens 150 µm, vorzugsweise höchstens 70 µm und beträgt die Länge des Düsenkanals mindestens 1000 µm, vorzugsweise etwa 1500 µm. Dadurch kann die Länge des Luftspaltes auf unter 35 mm oder sogar unter 10 mm reduziert werden, weil infolge einer Orientierung in der Langkanaldüse mit einem geringeren Verzug ausgekommen werden kann, ohne daß die textilen Eigenschaften der hergestellten Fasern leiden. Bei einer bevorzugten Ausführungsform des Düsenkanals ist dieser auf der Eintrittsseite kegelförmig und nur auf der Austrittsseite zylinderförmig.To produce a cellulosic shaped body, a cellulosic amine oxide solution is pressed through a nozzle, then passed through an air gap, optionally stretched therein and finally coagulated in a precipitation bath. According to the invention, the minimum hole diameter of the nozzle used is at most 150 μm, preferably at most 70 μm, and the length of the nozzle channel is at least 1000 μm, preferably about 1500 μm. As a result, the length of the air gap can be reduced to less than 35 mm or even less than 10 mm because, as a result of an orientation in the long-channel nozzle, less warpage can be achieved without the textile properties of the fibers produced suffering. In a preferred embodiment of the nozzle channel, it is conical on the inlet side and cylindrical only on the outlet side.

Description

Die vorliegende Erfindung betrifft ein Verfahren zur Herstellung eines cellulosischen Formkörpers, bei dem eine cellulosische Aminoxidlösung durch eine Düse gepreßt, anschließend durch einen Luftspalt geführt, in diesem gegebenenfalls verstreckt und schließlich in einem Fällbad koaguliert wird.The present invention relates to a process for the production of a cellulosic molding, in which a cellulosic amine oxide solution is pressed through a nozzle, then passed through an air gap, optionally stretched therein and finally coagulated in a precipitation bath.

Es ist bekannt, daß Fasern mit guten Gebrauchseigenschaften aus Hochpolymeren nur dann erhalten werden, wenn eine "Faserstruktur" erzielt werden kann (Ullmann, 5. Auflage Vol. A10, 456). Unter anderem ist es dazu nötig, mikroorientierte Bereiche im Polymeren, beispielsweise Fibride, in der Faser auszurichten. Diese Orientierung wird vom Herstellungsverfahren bestimmt und beruht auf physikalischen oder physikochemischen Vorgängen. In vielen Fällen bewirkt eine Verstreckung diese Orientierung.It is known that fibers with good performance properties can only be obtained from high polymers if a "fiber structure" can be achieved (Ullmann, 5th edition vol. A10, 456). Among other things, it is necessary to align micro-oriented areas in the polymer, for example fibrids, in the fiber. This orientation is determined by the manufacturing process and is based on physical or physicochemical processes. In many cases, stretching causes this orientation.

In welchem Verfahrensabschnitt und unter welchen Bedingungen diese Verstreckung erfolgt, ist ausschlaggebend für die erhaltenen Fasereigenschaften. Beim Schmelzspinnen werden die Fasern im warmen plastischen Zustand, während die Moleküle noch beweglich sind, verstreckt. Gelöste Polymere können trocken oder naß gesponnen werden. Beim Trockenspinnen erfolgt die Verstreckung, während das Lösungsmittel entweicht bzw. verdampft; die in ein Fällbad extrudierten Fäden werden während der Koagulierung verstreckt. Verfahren dieser Art sind bekannt und reichlich beschrieben. In all diesen Fällen ist es aber wichtig, daß der Übergang vom flüssigen Zustand (unabhängig, ob Schmelze oder Lösung) zum festen Zustand so erfolgt, daß während der Fadenbildung auch eine Orientierung der Polymerketten oder -kettenpakete (sprich Fibride, Fibrillen usw.) erzielt werden kann.The stage of the process and the conditions under which this stretching takes place are decisive for the fiber properties obtained. In melt spinning, the fibers are stretched in the warm, plastic state while the molecules are still mobile. Dissolved polymers can be spun dry or wet. In dry spinning, drawing takes place while the solvent escapes or evaporates; the threads extruded into a coagulation bath are drawn during the coagulation. Methods of this type are known and have been extensively described. In all these cases it is important that the transition from the liquid state (regardless of whether melt or solution) to the solid state takes place in such a way that the polymer chains or chain packages (i.e. fibrids, fibrils, etc.) are oriented during the formation of the thread can be.

Um das schlagartige Verdampfen eines Lösungsmittels aus einem Faden während des Trockenspinnens zu verhindern, gibt es mehrere Möglichkeiten.There are several ways to prevent the sudden evaporation of a solvent from a thread during dry spinning.

Die Problematik der sehr raschen Koagulation des Polymeren beim Naßspinnen (wie z. B. im Falle von cellulosischen Aminoxidlösungen) konnte jedoch bisher nur durch Kombination von Trockenund Naßspinnen gelöst werden.However, the problem of the very rapid coagulation of the polymer during wet spinning (such as in the case of cellulosic amine oxide solutions) has so far only been able to be solved by combining dry and wet spinning.

So ist bekannt, Lösungen von Polymeren über einen Luftspalt in das Koagulationsmedium einzubringen. In der EP-A-295 672 ist die Herstellung von Aramidfasern, die über einen Luftspalt in ein nicht-koagulierendes Medium eingebracht, verstreckt und anschließend koaguliert werden, beschrieben.It is known, for example, to introduce solutions of polymers into the coagulation medium via an air gap. EP-A-295 672 describes the production of aramid fibers, which are introduced and stretched through an air gap into a non-coagulating medium are then coagulated.

Die DD-PS 218 121 hat das Verspinnen von Cellulose in Aminoxiden über einen Luftspalt zum Gegenstand, wobei Vorkehrungen, die das Verkleben verhindern, vorgesehen sind.DD-PS 218 121 deals with the spinning of cellulose in amine oxides via an air gap, measures being taken to prevent sticking.

Gemäß der US-PS 4 501 886 wird eine Lösung von Cellulose-triacetat mittels eines Luftspaltes gesponnen.According to US Pat. No. 4,501,886, a solution of cellulose triacetate is spun using an air gap.

In der US-PS 3 414 645 ist ebenfalls die Herstellung von aromatischen Polyamiden aus Lösungen, in einem Trocken-Naß-Spinnverfahren beschrieben.US Pat. No. 3,414,645 also describes the preparation of aromatic polyamides from solutions in a dry-wet spinning process.

Bei all diesen Vërfahren wird im Luftspalt eine gewisse Orientierung erzielt, denn alleine das Ausfließenlassen einer zähflüssigen Lösung durch eine kleine Öffnung nach unten zwingt aufgrund der Schwerkraft den Lösungsteilchen eine Orientierung auf. Diese Orientierung durch die Schwerkraft kann noch erhöht werden, wenn die Extrudiergeschwindigkeit der Polymerlösung und die Abzugsgeschwindigkeit des Fadens so eingstellt sind, daß eine Verstreckung erzielt wird.With all of these methods, a certain orientation is achieved in the air gap, because just letting a viscous solution flow out through a small opening downward forces the solution particles to find their way due to gravity. This orientation by gravity can be increased if the rate of extrusion of the polymer solution and the rate of withdrawal of the thread are adjusted so that drawing is achieved.

Ein Verfahren dieser Art ist in der AT-PS 387 792 (bzw. den dazu äquivalenten US-PSen 4 246 221 und 4 416 698) beschrieben. Eine Lösung von Cellulose in NMMO (NMMO = N-Methylmorpholin-N-oxid) und Wasser wird geformt, im Luftspalt verstreckt und anschließend ausgefällt. Die Verstreckung wird bei einem Streckverhältnis von mindestens 3 vorgenommen. Dazu ist eine Luftspaltlänge von 5-70 cm notwendig.A method of this type is described in AT-PS 387 792 (or the equivalent US Pat. Nos. 4,246,221 and 4,416,698). A solution of cellulose in NMMO (NMMO = N-methylmorpholine-N-oxide) and water is formed, stretched in the air gap and then precipitated. The stretching is carried out at a stretch ratio of at least 3. This requires an air gap length of 5-70 cm.

Ein Nachteil dieses Verfahrens besteht darin, daß extrem hohe Abzugsgeschwindigkeiten erforderlich sind, um entsprechende textile Eigenschaften und Feinheit der Fäden zu erzielen. Weiters hat sich in der Praxis gezeigt, daß ein langer Luftspalt einerseits zu Faserverklebungen und anderseits bei hohen Verzügen auch zu Spinnunsicherheit und Fadenbruch führt. Es sind daher Vorkehrungen nötig, dies zu verhindern. Ein Verfahren dieser Art ist in der AT-PS 365 663 (bzw. in der äquivalenten US-PS 4 261 943) beschrieben. Für eine Großproduktion muß aber die Lochzahl in einer Spinndüse sehr hoch sein. In so einem Fall sind Vorkehrungen zur Verhinderung der Oberflächenklebrigkeit der frisch extrudierten Fäden, die durch einen Luftspalt in das Fällungsmittel gelangen, völlig unzureichend.A disadvantage of this process is that extremely high take-off speeds are required in order to achieve appropriate textile properties and fineness of the threads. Furthermore, it has been shown in practice that a long air gap on the one hand leads to fiber sticking and on the other hand leads to spinning insecurity and thread breakage in the case of high warpage. Precautions are therefore required to prevent this. A method of this type is described in AT-PS 365 663 (or in equivalent US-PS 4,261,943). For large-scale production, however, the number of holes in a spinneret must be very high. In such a case, precautions to prevent the surface stickiness of the freshly extruded threads which enter the precipitant through an air gap are completely inadequate.

Es ist Aufgabe der vorliegenden Erfindung, ein Spinnverfahren zu schaffen, mit dem trotz Verwendung eines kurzen Luftspaltes eine rasch koagulierende Lösung zu Fäden mit verbesserten Fasereigenschaften versponnen werden kann.It is an object of the present invention to provide a spinning process with which, despite the use of a short air gap, a rapidly coagulating solution can be spun into threads with improved fiber properties.

Diese Aufgabe wird durch ein Verfahren der eingangs genannten Art erfindungsgemä8 dadurch gelöst, daß der minimale Lochdurchmesser der verwendeten Düse höchstens 150 µm, vorzugsweise höchstens 70 µm, und die Länge des Düsenkanals mindestens 1000 µm, vorzugsweise etwa 1500 µm, beträgt.This object is achieved according to the invention by a method of the type mentioned at the outset in that the minimum hole diameter of the nozzle used is at most 150 μm, preferably at most 70 μm, and the length of the nozzle channel is at least 1000 μm, preferably about 1500 μm.

Durch Verwendung derartiger Langkanaldüsen mit geringem Durchmesser wird bereits in den Düsenkanälen durch Scherkräfte eine Orientierung des Polymeren erzielt. Dadurch kann der anschließende Luftspalt kurz gehalten werden: seine Länge beträgt zweckmäßigerweise höchstens 35, vorzugsweise höchstens 10mm. Dadurch wird die Störanfälligkeit stark reduziert; es gibt nur wesentlich geringere Titerschwankungen und damit keine Fadenrisse mehr; benachbarte Fäden können infolge des kürzeren Luftspaltes nicht mehr verkleben, sodaß die Lochdichte in der Spinndüse erhöht werden kann, wodurch die Produktivität steigt.By using such long-channel nozzles with a small diameter, an orientation of the polymer is achieved in the nozzle channels by shear forces. As a result, the subsequent air gap can be kept short: its length is expediently at most 35 mm, preferably at most 10 mm. This greatly reduces the susceptibility to faults; there are only significantly lower titre fluctuations and therefore no more thread breaks; Because of the shorter air gap, adjacent threads can no longer stick together, so that the hole density in the spinneret can be increased, which increases productivity.

Schließlich hat der gesponnene Faden auch gute textile Eigenschaften: Es wurde gefunden, daß insbesondere die Bruchdehnung verbessert werden kann. Das Arbeitsvermögen - d. h. das Produkt aus Dehnung und Festigkeit - verhält sich dabei umgekehrt proportional zum Lochdurchmesser. Weiters verbessert sich die Schlingenfestigkeit und die dazugehörende Bruchdehnung, was sich in einer verbesserten Scheuerbeständigkeit der aus diesen Fasern ersponnenen Gewebenäußert. Diese Eigenschaften verbessern sich ebenfalls bei sinkenden Lochdurchmessern.Finally, the spun thread also has good textile properties: it was found that the elongation at break in particular can be improved. Work capacity - d. H. the product of elongation and strength - behaves inversely proportional to the hole diameter. Furthermore, the loop strength and the associated elongation at break improve, which results in improved abrasion resistance of the fabrics spun from these fibers. These properties also improve with decreasing hole diameters.

Vorzugsweise ist der Düsenkanal auf der Eintrittsseite kegelförmig erweitert und auf der Austrittsseite zylinderförmig. Die Verwendung derartiger Düsen ist wegen der einfacheren Herstellbarkeit empfehlenswert; es ist schwierig, eine z. B. 1500 µm lange Düse durchgehend mit einem Durchmesser von nur z. B. 100 µm herzustellen. Eine Düse, bei der der minimale Durchmesser nur auf der Austrittsseite vorgesehen ist (z. B. auf 1/4 oder 1/3 der Länge) und die sich in Richtung Eintrittsseite kegelförmig erweitert, ist wesentlich leichter herstellbar und liefert auch gute Ergebnisse.The nozzle channel is preferably widened conically on the inlet side and cylindrical on the outlet side. The use of such nozzles is recommended because of the simpler manufacture; it is difficult to z. B. 1500 microns long nozzle with a diameter of only z. B. 100 microns. A nozzle in which the minimum diameter is only provided on the outlet side (e.g. to 1/4 or 1/3 of the length) and which widens conically towards the inlet side is much easier to manufacture and also delivers good results.

Anhand der folgenden Beispiele wird die Erfindung näher erläutert:The invention is explained in more detail using the following examples:

2276 g Zellstoff (Feststoff- oder Trockengehalt 94 %, DP=750 [DP = Durchschnittlicher Polymerisationsgrad]) und 0,02 % Rutin als Stabilisator werden in 26 139 g 60%iger wässeriger N-Metyhlmorpholinoxid-Lösung suspendiert. Während 2 Stunden wird bei 100°C und einem Vakuum bis zu 50 bis 300 mbar 9415 g Wasser abdestilliert. Die dabei entstandene Lösung wird anhand der Viskosität und unter dem Mikroskop beurteilt. 2276 g of pulp (solids or dry matter content 94%, DP = 750 [DP = average degree of polymerization]) and 0.02% rutin as a stabilizer are suspended in 26 139 g of 60% aqueous N-methylmorpholine oxide solution. 9415 g of water are distilled off at 100 ° C. and under a vacuum of up to 50 to 300 mbar for 2 hours. The resulting solution is assessed based on viscosity and under a microscope.

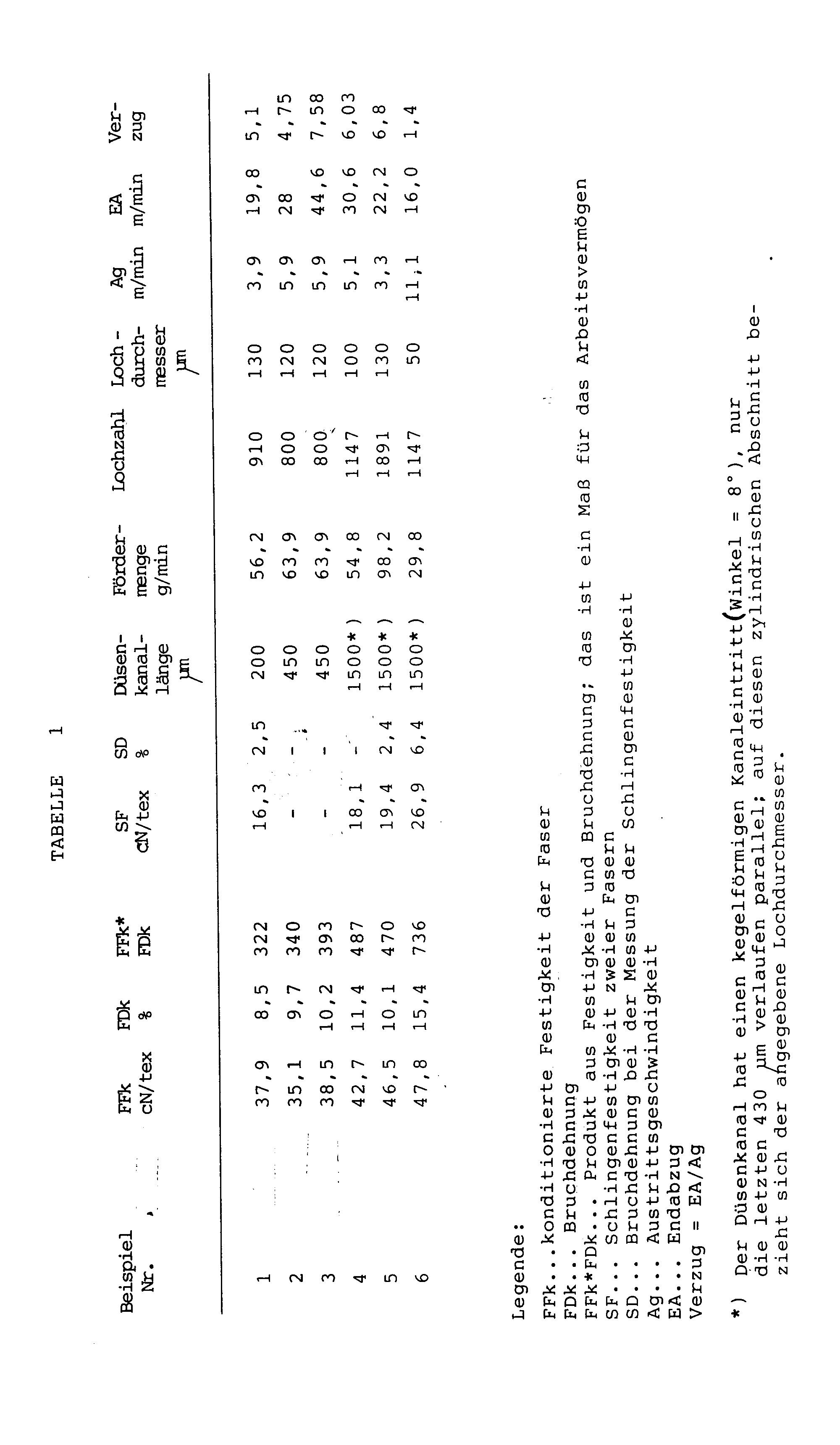

Anschließend wird diese Lösung bei einer Spinntemperatur von 75°C durch eine Spinndüse gepreßt, einen 9 mm langen Luftspalt geführt und schließlich in einem Fällbad, welches aus einer 20%igen wässerigen NMMO-Lösung besteht, koaguliert. Tabelle 1 enthält die bei diesem Versuch erzielten Eigenschaften der Fasern und die dazugehörenden Prozeßparameter.

Die Beispiele 1 bis 3 dienen nur zum Vergleich, die Beispiele 4 bis 6 sind erfindungsgemäße Beispiele. Besonders hervorgehoben werden soll der hervorragende Wert von 47,8 für die konditionierte Faserfestigkeit bei Beispiel 6 werden; ein derartiger Wert wird bei herkömmlichen Düsen erst bei einem Verzug von 100 erreicht!Examples 1 to 3 are only for comparison, Examples 4 to 6 are examples according to the invention. The outstanding value of 47.8 for the conditioned fiber strength in Example 6 should be particularly emphasized; Such a value is only reached with a delay of 100 with conventional nozzles!

Aus einem Vergleich der Beispiele 1 bis 3 mit den Beispielen 4 bis 6 ist unmittelbar ersichtlich, daß durch den Einsatz erfindungsgemäßer Düsen auch die Bruchdehnung verbessert wird. Weitens ist aus den.Beispielen 4 bis 6 ersichtlich, daß das Produkt aus Festigkeit und Bruchdehnung (FFk*FDk), die Schlingenfestigkeit sowie die Bruchdehnung bei der Messung der Schlingenfestigkeit mit sinkendem Lochdurchmesser steigen. Ein Vergleich von Beispiel 1 mit Beispiel 5 (bei diesen beiden Beispielen ist der Lochdurchmesser gleich) zeigt, daß diese Werte auch durch den Einsatz erfindungsgemäßer Langkanaldüsen gegenüber Düsen mit kurzem Kanal gleichen Durchmessers verbessert werden.A comparison of Examples 1 to 3 with Examples 4 to 6 shows immediately that the elongation at break is also improved by using nozzles according to the invention. Furthermore, it can be seen from Examples 4 to 6 that the product of strength and elongation at break (FFk * FDk), the loop strength and the elongation at break increase in the measurement of the loop strength with decreasing hole diameter. A comparison of Example 1 with Example 5 (in these two examples the hole diameter is the same) shows that these values can also be improved by using long-channel nozzles according to the invention compared to nozzles with a short channel of the same diameter.

Die Beispiele 2 und 3 zeigen, daß bei kleiner Düsenkanallänge die Fasereigenschaften vom Verzug im Luftspalt abhängen; sie werden mit steigendem Verzug besser. Die Beispiele 4 und 5 zeigen, daß bei vergleichbaren Verhältnissen (Verzug, Lochdurchmesser) durch eine erfindungsgemäße Langkanaldüse alle textilen Eigenschaften - ausgenommen die Bruchdehnung - wesentlich verbessert werden. Beispiel 6 zeigt, daß durch Anwendung eines kleinen Lochdurchmessers von 50 µm alle textilen Eigenschaften wesentlich verbessert werden.Examples 2 and 3 show that with a small nozzle channel length, the fiber properties depend on the distortion in the air gap; they get better as the default increases. Examples 4 and 5 show that, under comparable conditions (warpage, hole diameter), all textile properties - except the elongation at break - are significantly improved by a long-channel nozzle according to the invention. Example 6 shows that by using a small hole diameter of 50 microns, all textile properties are significantly improved.

Claims (3)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT0003291A AT395863B (en) | 1991-01-09 | 1991-01-09 | METHOD FOR PRODUCING A CELLULOSIC MOLDED BODY |

| AT32/91 | 1991-01-09 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0494852A2 true EP0494852A2 (en) | 1992-07-15 |

| EP0494852A3 EP0494852A3 (en) | 1993-03-17 |

| EP0494852B1 EP0494852B1 (en) | 1995-05-17 |

Family

ID=3479723

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP92890004A Expired - Lifetime EP0494852B1 (en) | 1991-01-09 | 1992-01-09 | Process for the production of cellulosic articles |

Country Status (24)

| Country | Link |

|---|---|

| US (1) | US5252284A (en) |

| EP (1) | EP0494852B1 (en) |

| JP (1) | JPH04308220A (en) |

| AT (1) | AT395863B (en) |

| BG (1) | BG60111A3 (en) |

| BR (1) | BR9200043A (en) |

| CA (1) | CA2059043A1 (en) |

| CZ (1) | CZ282528B6 (en) |

| DE (1) | DE59202175D1 (en) |

| DK (1) | DK0494852T3 (en) |

| ES (1) | ES2072746T3 (en) |

| FI (1) | FI97155C (en) |

| HU (1) | HU212340B (en) |

| MX (1) | MX9200080A (en) |

| NO (1) | NO303696B1 (en) |

| PH (1) | PH29990A (en) |

| PL (1) | PL169309B1 (en) |

| RO (1) | RO107701B1 (en) |

| RU (1) | RU2072006C1 (en) |

| SI (1) | SI9112009A (en) |

| SK (1) | SK279852B6 (en) |

| TR (1) | TR27259A (en) |

| YU (1) | YU47623B (en) |

| ZA (1) | ZA9110195B (en) |

Cited By (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO1993019230A1 (en) * | 1992-03-17 | 1993-09-30 | Lenzing Aktiengesellschaft | Process for manufacturing cellulose moulded bodies and a device for carrying it out |

| WO1994028210A1 (en) * | 1993-05-24 | 1994-12-08 | Courtaulds Fibres (Holdings) Limited | Spinnerette |

| WO1995002082A1 (en) * | 1993-07-08 | 1995-01-19 | Lenzing Aktiengesellschaft | Cellulose fibres |

| US5451364A (en) * | 1992-01-17 | 1995-09-19 | Viskase Corporation | Cellulose food casing manufacturing method |

| USH1592H (en) * | 1992-01-17 | 1996-09-03 | Viskase Corporation | Cellulosic food casing |

| US5603884A (en) * | 1994-11-18 | 1997-02-18 | Viskase Corporation | Reinforced cellulosic film |

| US5607639A (en) * | 1993-09-13 | 1997-03-04 | Lenzing Aktiengesellschaft | Process for the preparation of cellulose sheet |

| US5650112A (en) * | 1993-07-28 | 1997-07-22 | Lenzing Aktiengesellschaft | Process of making cellulose fibers |

| US5658525A (en) * | 1995-08-04 | 1997-08-19 | Viskase Corporation | Cellulose food casing manufacturing method |

| WO1997035054A1 (en) * | 1996-03-15 | 1997-09-25 | Courtaulds Plc | Manufacture of elongate members |

| WO1997041284A1 (en) * | 1996-04-29 | 1997-11-06 | Akzo Nobel N.V. | Process for producing a cellulose mould body |

| US5698151A (en) * | 1993-07-01 | 1997-12-16 | Lenzing Aktiengesellschaft | Process of making cellulose fibres |

| US5902532A (en) * | 1994-12-02 | 1999-05-11 | Akzo Nobel Nv | Process for manufacturing cellulose objects |

| US5939000A (en) * | 1993-05-24 | 1999-08-17 | Acordis Fibres (Holdings) Limited | Process of making cellulose filaments |

| EP1065301A1 (en) * | 1999-07-01 | 2001-01-03 | MELITTA HAUSHALTSPRODUKTE GmbH & Co. Kommanditgesellschaft | Reactive fibrous cellulosic coagulates |

| DE10043297B4 (en) * | 2000-09-02 | 2005-12-08 | Thüringisches Institut für Textil- und Kunststoff-Forschung e.V. | Process for the production of cellulose fibers and cellulose filament yarns |

| CN111270322A (en) * | 2020-02-15 | 2020-06-12 | 王金明 | Water bath drafting groove device for chemical fiber equipment |

Families Citing this family (36)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5658524A (en) * | 1992-01-17 | 1997-08-19 | Viskase Corporation | Cellulose article manufacturing method |

| US5417909A (en) * | 1992-06-16 | 1995-05-23 | Thuringisches Institut Fur Textil- Und Kunststoff-Forschung E.V. | Process for manufacturing molded articles of cellulose |

| WO1994019405A1 (en) * | 1993-02-16 | 1994-09-01 | Mitsubishi Rayon Co., Ltd. | Cellulose molding solution and process for molding therefrom |

| US5984655A (en) * | 1994-12-22 | 1999-11-16 | Lenzing Aktiengesellschaft | Spinning process and apparatus |

| US6235392B1 (en) * | 1996-08-23 | 2001-05-22 | Weyerhaeuser Company | Lyocell fibers and process for their preparation |

| US6221487B1 (en) | 1996-08-23 | 2001-04-24 | The Weyerhauser Company | Lyocell fibers having enhanced CV properties |

| US6773648B2 (en) | 1998-11-03 | 2004-08-10 | Weyerhaeuser Company | Meltblown process with mechanical attenuation |

| US6605648B1 (en) * | 1999-04-06 | 2003-08-12 | Phillips Plastics Corporation | Sinterable structures and method |

| US6368703B1 (en) | 1999-08-17 | 2002-04-09 | Phillips Plastics Corporation | Supported porous materials |

| US6869445B1 (en) | 2000-05-04 | 2005-03-22 | Phillips Plastics Corp. | Packable ceramic beads for bone repair |

| AT410319B (en) * | 2001-07-25 | 2003-03-25 | Chemiefaser Lenzing Ag | CELLULOSE SPONGE AND METHOD FOR THE PRODUCTION THEREOF |

| DE10200405A1 (en) * | 2002-01-08 | 2002-08-01 | Zimmer Ag | Cooling blowing spinning apparatus and process |

| DE10200406A1 (en) * | 2002-01-08 | 2003-07-24 | Zimmer Ag | Spinning device and process with turbulent cooling blowing |

| DE10204381A1 (en) * | 2002-01-28 | 2003-08-07 | Zimmer Ag | Ergonomic spinning system |

| DE10206089A1 (en) * | 2002-02-13 | 2002-08-14 | Zimmer Ag | bursting |

| DE10213007A1 (en) * | 2002-03-22 | 2003-10-09 | Zimmer Ag | Method and device for controlling the indoor climate in a spinning process |

| DE10223268B4 (en) * | 2002-05-24 | 2006-06-01 | Zimmer Ag | Wetting device and spinning system with wetting device |

| DE10314878A1 (en) * | 2003-04-01 | 2004-10-28 | Zimmer Ag | Method and device for producing post-stretched cellulose filaments |

| JP4234057B2 (en) * | 2003-06-30 | 2009-03-04 | ヒョスング コーポレーション | Cellulose dipcords and tires made from highly homogeneous cellulose solutions |

| AT6807U1 (en) * | 2004-01-13 | 2004-04-26 | Chemiefaser Lenzing Ag | CELLULOSIC FIBER OF THE LYOCELL GENERATION |

| DE102004024028B4 (en) * | 2004-05-13 | 2010-04-08 | Lenzing Ag | Lyocell method and apparatus with press water return |

| DE102004024029A1 (en) * | 2004-05-13 | 2005-12-08 | Zimmer Ag | Lyocell method and apparatus with metal ion content control |

| DE102004024030A1 (en) * | 2004-05-13 | 2005-12-08 | Zimmer Ag | Lyocell process with polymerization-degree-dependent adjustment of the processing time |

| KR100595751B1 (en) * | 2004-11-11 | 2006-07-03 | 주식회사 효성 | The Process for preparing a cellulose fiber |

| KR100966111B1 (en) | 2005-03-15 | 2010-06-28 | 주식회사 효성 | The Process for preparing a cellulose fiber |

| US8029260B2 (en) * | 2008-04-11 | 2011-10-04 | Reifenhauser Gmbh & Co. Kg Maschinenfabrik | Apparatus for extruding cellulose fibers |

| US8303888B2 (en) * | 2008-04-11 | 2012-11-06 | Reifenhauser Gmbh & Co. Kg | Process of forming a non-woven cellulose web and a web produced by said process |

| US8029259B2 (en) * | 2008-04-11 | 2011-10-04 | Reifenhauser Gmbh & Co. Kg Maschinenfabrik | Array of nozzles for extruding multiple cellulose fibers |

| EP2565304A1 (en) | 2011-09-02 | 2013-03-06 | Aurotec GmbH | Extrusion method and device |

| EP2565303A1 (en) | 2011-09-02 | 2013-03-06 | Aurotec GmbH | Extrusion method |

| EP2719801A1 (en) | 2012-10-10 | 2014-04-16 | Aurotec GmbH | Spinning bath and method for solidifying a moulded part |

| GB2511528A (en) | 2013-03-06 | 2014-09-10 | Speciality Fibres And Materials Ltd | Absorbent materials |

| WO2016163337A1 (en) | 2015-04-09 | 2016-10-13 | Spiber株式会社 | Polar solvent solution and production method thereof |

| CN107849100B (en) | 2015-04-09 | 2022-02-08 | 丝芭博株式会社 | Polar solvent solution and method for producing same |

| CN111194363B (en) * | 2017-10-06 | 2023-09-08 | 连津格股份公司 | Apparatus for extrusion of filaments and production of spunbonded fabrics |

| EP3674454A1 (en) * | 2018-12-28 | 2020-07-01 | Lenzing Aktiengesellschaft | Cellulose filament process |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2341555A (en) * | 1939-01-05 | 1944-02-15 | Baker & Co Inc | Extrusion device |

| US3767756A (en) * | 1972-06-30 | 1973-10-23 | Du Pont | Dry jet wet spinning process |

| US4416698A (en) * | 1977-07-26 | 1983-11-22 | Akzona Incorporated | Shaped cellulose article prepared from a solution containing cellulose dissolved in a tertiary amine N-oxide solvent and a process for making the article |

| JPS5930909A (en) * | 1982-08-09 | 1984-02-18 | Asahi Chem Ind Co Ltd | Spinneret for spinning |

| EP0299824A1 (en) * | 1987-07-01 | 1989-01-18 | Institut Textile De France | Process for the preparation of a cellulose spinning solution containing tertiary-amine oxide and an additive |

| EP0452610A2 (en) * | 1990-04-20 | 1991-10-23 | Lenzing Aktiengesellschaft | Process for the preparation of an aqueous N-methylmorpholine N-oxide solution of cellulose |

Family Cites Families (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3414645A (en) * | 1964-06-19 | 1968-12-03 | Monsanto Co | Process for spinning wholly aromatic polyamide fibers |

| US4246221A (en) * | 1979-03-02 | 1981-01-20 | Akzona Incorporated | Process for shaped cellulose article prepared from a solution containing cellulose dissolved in a tertiary amine N-oxide solvent |

| ZA785535B (en) * | 1977-10-31 | 1979-09-26 | Akzona Inc | Process for surface treating cellulose products |

| US4261943A (en) * | 1979-07-02 | 1981-04-14 | Akzona Incorporated | Process for surface treating cellulose products |

| US4501886A (en) * | 1982-08-09 | 1985-02-26 | E. I. Du Pont De Nemours And Company | Cellulosic fibers from anisotropic solutions |

| DD218124A1 (en) * | 1983-08-16 | 1985-01-30 | Waschgeraetewerk Veb | METHOD FOR CHARACTERIZING TENSIDE-BASED SOLUTIONS IN WASHING MACHINES |

| SU1224362A1 (en) * | 1984-06-29 | 1986-04-15 | Предприятие П/Я А-3844 | Method of producing cellulose fibres |

| JPS6414317A (en) * | 1987-06-18 | 1989-01-18 | Du Pont | Colored aramid fiber |

| DE4012479A1 (en) * | 1990-04-19 | 1991-10-24 | Degussa | Titanium dioxide pellets, process for their preparation and their use |

-

1991

- 1991-01-09 AT AT0003291A patent/AT395863B/en not_active IP Right Cessation

- 1991-12-30 ZA ZA9110195A patent/ZA9110195B/en unknown

- 1991-12-31 SI SI9112009A patent/SI9112009A/en unknown

- 1991-12-31 YU YU200991A patent/YU47623B/en unknown

-

1992

- 1992-01-06 CZ CS9222A patent/CZ282528B6/en not_active IP Right Cessation

- 1992-01-06 SK SK22-92A patent/SK279852B6/en unknown

- 1992-01-07 RO RO149074A patent/RO107701B1/en unknown

- 1992-01-07 PH PH43737A patent/PH29990A/en unknown

- 1992-01-08 CA CA002059043A patent/CA2059043A1/en not_active Abandoned

- 1992-01-08 BR BR929200043A patent/BR9200043A/en not_active IP Right Cessation

- 1992-01-08 PL PL92293115A patent/PL169309B1/en unknown

- 1992-01-08 RU SU925010647A patent/RU2072006C1/en active

- 1992-01-08 JP JP4001349A patent/JPH04308220A/en active Pending

- 1992-01-08 FI FI920072A patent/FI97155C/en active

- 1992-01-08 HU HU9200064A patent/HU212340B/en not_active IP Right Cessation

- 1992-01-08 NO NO920108A patent/NO303696B1/en unknown

- 1992-01-08 US US07/817,937 patent/US5252284A/en not_active Expired - Fee Related

- 1992-01-09 BG BG95746A patent/BG60111A3/en unknown

- 1992-01-09 TR TR00016/92A patent/TR27259A/en unknown

- 1992-01-09 MX MX9200080A patent/MX9200080A/en unknown

- 1992-01-09 ES ES92890004T patent/ES2072746T3/en not_active Expired - Lifetime

- 1992-01-09 DE DE59202175T patent/DE59202175D1/en not_active Expired - Fee Related

- 1992-01-09 EP EP92890004A patent/EP0494852B1/en not_active Expired - Lifetime

- 1992-01-09 DK DK92890004.2T patent/DK0494852T3/en active

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2341555A (en) * | 1939-01-05 | 1944-02-15 | Baker & Co Inc | Extrusion device |

| US3767756A (en) * | 1972-06-30 | 1973-10-23 | Du Pont | Dry jet wet spinning process |

| US4416698A (en) * | 1977-07-26 | 1983-11-22 | Akzona Incorporated | Shaped cellulose article prepared from a solution containing cellulose dissolved in a tertiary amine N-oxide solvent and a process for making the article |

| JPS5930909A (en) * | 1982-08-09 | 1984-02-18 | Asahi Chem Ind Co Ltd | Spinneret for spinning |

| EP0299824A1 (en) * | 1987-07-01 | 1989-01-18 | Institut Textile De France | Process for the preparation of a cellulose spinning solution containing tertiary-amine oxide and an additive |

| EP0452610A2 (en) * | 1990-04-20 | 1991-10-23 | Lenzing Aktiengesellschaft | Process for the preparation of an aqueous N-methylmorpholine N-oxide solution of cellulose |

Non-Patent Citations (1)

| Title |

|---|

| PATENT ABSTRACTS OF JAPAN vol. 8, no. 118 (C-226)31. Mai 1984 & JP-A-59 030 909 ( ASAHI KASEI KOGYO KK ) 18. Februar 1984 * |

Cited By (32)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| USH1592H (en) * | 1992-01-17 | 1996-09-03 | Viskase Corporation | Cellulosic food casing |

| US5451364A (en) * | 1992-01-17 | 1995-09-19 | Viskase Corporation | Cellulose food casing manufacturing method |

| US5798125A (en) * | 1992-03-17 | 1998-08-25 | Lenzing Aktiengesellschaft | Device for the preparation of cellulose mouldings |

| US5589125A (en) * | 1992-03-17 | 1996-12-31 | Lenzing Aktiengesellschaft | Process of and apparatus for making cellulose mouldings |

| US5968434A (en) * | 1992-03-17 | 1999-10-19 | Lenzing Aktiengesellschaft | Process of making cellulose moldings and fibers |

| EP0671492A1 (en) * | 1992-03-17 | 1995-09-13 | Lenzing Aktiengesellschaft | Process for manufacturing cellulose moulded bodies and a device for carrying it out |

| WO1993019230A1 (en) * | 1992-03-17 | 1993-09-30 | Lenzing Aktiengesellschaft | Process for manufacturing cellulose moulded bodies and a device for carrying it out |

| US5939000A (en) * | 1993-05-24 | 1999-08-17 | Acordis Fibres (Holdings) Limited | Process of making cellulose filaments |

| US5951932A (en) * | 1993-05-24 | 1999-09-14 | Acordis Fibres (Holdings) Limited | Process of making cellulose filaments |

| EP0756025A2 (en) * | 1993-05-24 | 1997-01-29 | Courtaulds Fibres (Holdings) Limited | Spinnerette |

| WO1994028210A1 (en) * | 1993-05-24 | 1994-12-08 | Courtaulds Fibres (Holdings) Limited | Spinnerette |

| AU689107B2 (en) * | 1993-05-24 | 1998-03-26 | Courtaulds Fibres (Holdings) Limited | Spinnerette |

| EP0756025A3 (en) * | 1993-05-24 | 1998-03-11 | Courtaulds Fibres (Holdings) Limited | Spinnerette |

| US5652001A (en) * | 1993-05-24 | 1997-07-29 | Courtaulds Fibres Limited | Spinnerette |

| US5698151A (en) * | 1993-07-01 | 1997-12-16 | Lenzing Aktiengesellschaft | Process of making cellulose fibres |

| US5543101A (en) * | 1993-07-08 | 1996-08-06 | Lenzing Aktiengesellschaft | Process of making cellulose fibres |

| GB2284383B (en) * | 1993-07-08 | 1997-04-09 | Chemiefaser Lenzing Ag | Cellulose fibres |

| GB2284383A (en) * | 1993-07-08 | 1995-06-07 | Chemiefaser Lenzing Ag | Cellulose fibres |

| WO1995002082A1 (en) * | 1993-07-08 | 1995-01-19 | Lenzing Aktiengesellschaft | Cellulose fibres |

| US5650112A (en) * | 1993-07-28 | 1997-07-22 | Lenzing Aktiengesellschaft | Process of making cellulose fibers |

| US5607639A (en) * | 1993-09-13 | 1997-03-04 | Lenzing Aktiengesellschaft | Process for the preparation of cellulose sheet |

| US5603884A (en) * | 1994-11-18 | 1997-02-18 | Viskase Corporation | Reinforced cellulosic film |

| US6042944A (en) * | 1994-12-02 | 2000-03-28 | Akzo Nobel Nv | Process for manufacturing cellulose formed objects and a yarn of cellulose filaments |

| US5902532A (en) * | 1994-12-02 | 1999-05-11 | Akzo Nobel Nv | Process for manufacturing cellulose objects |

| US5658525A (en) * | 1995-08-04 | 1997-08-19 | Viskase Corporation | Cellulose food casing manufacturing method |

| WO1997035054A1 (en) * | 1996-03-15 | 1997-09-25 | Courtaulds Plc | Manufacture of elongate members |

| GB2328397B (en) * | 1996-03-15 | 1999-08-11 | Courtaulds Plc | Manufacture of elongate members |

| GB2328397A (en) * | 1996-03-15 | 1999-02-24 | Courtaulds Plc | Manufacture of elongate members |

| WO1997041284A1 (en) * | 1996-04-29 | 1997-11-06 | Akzo Nobel N.V. | Process for producing a cellulose mould body |

| EP1065301A1 (en) * | 1999-07-01 | 2001-01-03 | MELITTA HAUSHALTSPRODUKTE GmbH & Co. Kommanditgesellschaft | Reactive fibrous cellulosic coagulates |

| DE10043297B4 (en) * | 2000-09-02 | 2005-12-08 | Thüringisches Institut für Textil- und Kunststoff-Forschung e.V. | Process for the production of cellulose fibers and cellulose filament yarns |

| CN111270322A (en) * | 2020-02-15 | 2020-06-12 | 王金明 | Water bath drafting groove device for chemical fiber equipment |

Also Published As

| Publication number | Publication date |

|---|---|

| HUT64110A (en) | 1993-11-29 |

| ZA9110195B (en) | 1992-10-28 |

| US5252284A (en) | 1993-10-12 |

| PL169309B1 (en) | 1996-06-28 |

| NO920108D0 (en) | 1992-01-08 |

| AT395863B (en) | 1993-03-25 |

| PL293115A1 (en) | 1992-08-24 |

| HU212340B (en) | 1996-05-28 |

| BR9200043A (en) | 1992-09-08 |

| FI97155B (en) | 1996-07-15 |

| ES2072746T3 (en) | 1995-07-16 |

| YU200991A (en) | 1994-01-20 |

| NO920108L (en) | 1992-07-10 |

| EP0494852B1 (en) | 1995-05-17 |

| TR27259A (en) | 1994-12-22 |

| HU9200064D0 (en) | 1992-04-28 |

| CS2292A3 (en) | 1992-08-12 |

| CZ282528B6 (en) | 1997-08-13 |

| FI920072A (en) | 1992-07-10 |

| CA2059043A1 (en) | 1992-07-10 |

| PH29990A (en) | 1996-10-29 |

| DE59202175D1 (en) | 1995-06-22 |

| MX9200080A (en) | 1992-07-01 |

| JPH04308220A (en) | 1992-10-30 |

| ATA3291A (en) | 1992-08-15 |

| FI97155C (en) | 1996-10-25 |

| YU47623B (en) | 1995-10-24 |

| NO303696B1 (en) | 1998-08-17 |

| DK0494852T3 (en) | 1995-07-10 |

| FI920072A0 (en) | 1992-01-08 |

| SI9112009A (en) | 1994-12-31 |

| BG60111A3 (en) | 1993-10-15 |

| SK279852B6 (en) | 1999-04-13 |

| RU2072006C1 (en) | 1997-01-20 |

| RO107701B1 (en) | 1993-12-30 |

| EP0494852A3 (en) | 1993-03-17 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0494852B1 (en) | Process for the production of cellulosic articles | |

| EP0574870B1 (en) | Process for producing cellulose moulded articles | |

| DE69030338T3 (en) | Process for the production of fibers, rovings and mats from liquid crystalline lyotropic polymers | |

| DE69723582T2 (en) | REGENERATED CELLULOSE FIBERS AND METHOD FOR THEIR PRODUCTION | |

| EP0659219B1 (en) | Cellulose fibres | |

| EP0494851B1 (en) | Process for the production of cellulosic articles | |

| EP0407901B1 (en) | Process for the fabrication of polyethylene fibres by the high speed spinning of ultra-high molecular weight polyethylene | |

| WO1996018760A1 (en) | Solvent-spun cellulosic filaments | |

| DE3541034C2 (en) | ||

| DE4219658C2 (en) | Process for the production of cellulose fiber filaments and foils by the dry-wet extrusion process | |

| EP0797696B1 (en) | Process for producing cellulose fibres | |

| DE60031138T2 (en) | SYNTHETIC FIBER OF ACRYLONITRILE AND MANUFACTURING METHOD | |

| EP0031078B2 (en) | Fine denier synthetic fibres and filaments and dry spinning process for their production | |

| AT405531B (en) | METHOD FOR PRODUCING CELLULOSIC FIBERS | |

| DE4409609A1 (en) | Process for spinning cellulose fibres and filament yarns | |

| EP1334223B1 (en) | Method for producing synthetic threads from polymer mixtures | |

| EP0051189B1 (en) | Method for producing of dry-spun polyacrylonitrile filaments and fibres with a shaped cross-section | |

| DE2736302C3 (en) | Process for the production of polypyrrolidone threads | |

| EP0944750B1 (en) | High-strength high-modulus polyacrylonitrile fibres, method for their production and use | |

| WO2002048435A1 (en) | Method for producing continuous moulded bodies consisting of cellulose | |

| WO2000000681A1 (en) | Elastane fiber and method of production | |

| DE2720087A1 (en) | PROCESS FOR MANUFACTURING VISCOSE FEMES AND FEMES PRODUCED BY THE PROCESS | |

| EP0645479A1 (en) | High strength and high modulus polyacrylonitrile fibers, process for their production and their use | |

| EP1299583B1 (en) | Method for producing cellulose fibres | |

| WO2013011133A1 (en) | Ultrathin carbon fibers |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): BE CH DE DK ES FR GB GR IT LI LU MC NL PT SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): BE CH DE DK ES FR GB GR IT LI LU MC NL PT SE |

|

| 17P | Request for examination filed |

Effective date: 19930908 |

|

| 17Q | First examination report despatched |

Effective date: 19940211 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): BE CH DE DK ES FR GB GR IT LI LU MC NL PT SE |

|

| REF | Corresponds to: |

Ref document number: 59202175 Country of ref document: DE Date of ref document: 19950622 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 19950605 |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: T3 |

|

| ET | Fr: translation filed | ||

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2072746 Country of ref document: ES Kind code of ref document: T3 |

|

| ITF | It: translation for a ep patent filed |

Owner name: STUDIO CONS. BREVETTUALE S.R.L. |

|

| ET1 | Fr: translation filed ** revision of the translation of the patent or the claims | ||

| REG | Reference to a national code |

Ref country code: GR Ref legal event code: FG4A Free format text: 3016498 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: LU Payment date: 19961201 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: MC Payment date: 19961217 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DK Payment date: 19961227 Year of fee payment: 6 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19980109 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19980202 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19980731 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19981211 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19981215 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19981217 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 19981223 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 19981229 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GR Payment date: 19981230 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19981231 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 19990111 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: PT Payment date: 19990118 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 19990122 Year of fee payment: 8 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000109 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000110 Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000110 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000131 Ref country code: GR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000131 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000131 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000131 |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: EBP |

|

| BERE | Be: lapsed |

Owner name: LENZING A.G. Effective date: 20000131 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000731 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000801 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20000109 |

|

| EUG | Se: european patent has lapsed |

Ref document number: 92890004.2 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000929 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 20000801 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20001101 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| REG | Reference to a national code |

Ref country code: PT Ref legal event code: MM4A Free format text: LAPSE DUE TO NON-PAYMENT OF FEES Effective date: 20000731 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20011010 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20050109 |