EP0486135A2 - Hair treatment composition - Google Patents

Hair treatment composition Download PDFInfo

- Publication number

- EP0486135A2 EP0486135A2 EP19910308065 EP91308065A EP0486135A2 EP 0486135 A2 EP0486135 A2 EP 0486135A2 EP 19910308065 EP19910308065 EP 19910308065 EP 91308065 A EP91308065 A EP 91308065A EP 0486135 A2 EP0486135 A2 EP 0486135A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- hair

- treatment composition

- weight

- hair treatment

- perfluoropolyether

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 239000000203 mixture Substances 0.000 title claims abstract description 79

- 239000010702 perfluoropolyether Substances 0.000 claims abstract description 37

- 239000000463 material Substances 0.000 claims abstract description 31

- 239000000178 monomer Substances 0.000 claims description 15

- 239000002453 shampoo Substances 0.000 claims description 14

- 239000003093 cationic surfactant Substances 0.000 claims description 11

- 229920000642 polymer Polymers 0.000 claims description 11

- 239000004094 surface-active agent Substances 0.000 claims description 7

- 239000000654 additive Substances 0.000 claims 1

- 230000000996 additive effect Effects 0.000 claims 1

- 238000009472 formulation Methods 0.000 description 17

- -1 alkyl sulphates Chemical class 0.000 description 16

- 230000003750 conditioning effect Effects 0.000 description 13

- 125000000217 alkyl group Chemical group 0.000 description 10

- 239000004615 ingredient Substances 0.000 description 9

- 239000003795 chemical substances by application Substances 0.000 description 6

- 150000002191 fatty alcohols Chemical class 0.000 description 6

- 238000000034 method Methods 0.000 description 6

- 229920001296 polysiloxane Polymers 0.000 description 6

- DGAQECJNVWCQMB-PUAWFVPOSA-M Ilexoside XXIX Chemical compound C[C@@H]1CC[C@@]2(CC[C@@]3(C(=CC[C@H]4[C@]3(CC[C@@H]5[C@@]4(CC[C@@H](C5(C)C)OS(=O)(=O)[O-])C)C)[C@@H]2[C@]1(C)O)C)C(=O)O[C@H]6[C@@H]([C@H]([C@@H]([C@H](O6)CO)O)O)O.[Na+] DGAQECJNVWCQMB-PUAWFVPOSA-M 0.000 description 4

- 239000003945 anionic surfactant Substances 0.000 description 4

- 239000000047 product Substances 0.000 description 4

- 239000011734 sodium Substances 0.000 description 4

- 229910052708 sodium Inorganic materials 0.000 description 4

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 4

- VEXZGXHMUGYJMC-UHFFFAOYSA-M Chloride anion Chemical compound [Cl-] VEXZGXHMUGYJMC-UHFFFAOYSA-M 0.000 description 3

- IAYPIBMASNFSPL-UHFFFAOYSA-N Ethylene oxide Chemical compound C1CO1 IAYPIBMASNFSPL-UHFFFAOYSA-N 0.000 description 3

- PEDCQBHIVMGVHV-UHFFFAOYSA-N Glycerine Chemical compound OCC(O)CO PEDCQBHIVMGVHV-UHFFFAOYSA-N 0.000 description 3

- 229910019142 PO4 Inorganic materials 0.000 description 3

- 125000004432 carbon atom Chemical group C* 0.000 description 3

- 239000003921 oil Substances 0.000 description 3

- 235000021317 phosphate Nutrition 0.000 description 3

- 238000002360 preparation method Methods 0.000 description 3

- QTDIEDOANJISNP-UHFFFAOYSA-N 2-dodecoxyethyl hydrogen sulfate Chemical compound CCCCCCCCCCCCOCCOS(O)(=O)=O QTDIEDOANJISNP-UHFFFAOYSA-N 0.000 description 2

- QGZKDVFQNNGYKY-UHFFFAOYSA-O Ammonium Chemical compound [NH4+] QGZKDVFQNNGYKY-UHFFFAOYSA-O 0.000 description 2

- 108010009736 Protein Hydrolysates Proteins 0.000 description 2

- 125000002252 acyl group Chemical group 0.000 description 2

- BTBJBAZGXNKLQC-UHFFFAOYSA-N ammonium lauryl sulfate Chemical compound [NH4+].CCCCCCCCCCCCOS([O-])(=O)=O BTBJBAZGXNKLQC-UHFFFAOYSA-N 0.000 description 2

- 239000002280 amphoteric surfactant Substances 0.000 description 2

- 229920006317 cationic polymer Polymers 0.000 description 2

- 229920001577 copolymer Polymers 0.000 description 2

- 239000006260 foam Substances 0.000 description 2

- BXWNKGSJHAJOGX-UHFFFAOYSA-N hexadecan-1-ol Chemical compound CCCCCCCCCCCCCCCCO BXWNKGSJHAJOGX-UHFFFAOYSA-N 0.000 description 2

- 238000000338 in vitro Methods 0.000 description 2

- 239000002736 nonionic surfactant Substances 0.000 description 2

- GLDOVTGHNKAZLK-UHFFFAOYSA-N octadecan-1-ol Chemical compound CCCCCCCCCCCCCCCCCCO GLDOVTGHNKAZLK-UHFFFAOYSA-N 0.000 description 2

- 239000002245 particle Substances 0.000 description 2

- 239000002304 perfume Substances 0.000 description 2

- 239000003755 preservative agent Substances 0.000 description 2

- 239000003531 protein hydrolysate Substances 0.000 description 2

- 235000018102 proteins Nutrition 0.000 description 2

- 108090000623 proteins and genes Proteins 0.000 description 2

- 102000004169 proteins and genes Human genes 0.000 description 2

- 238000003756 stirring Methods 0.000 description 2

- XTPPAVHDUJMWEX-UHFFFAOYSA-M 1-ethenylpyridin-1-ium;chloride Chemical compound [Cl-].C=C[N+]1=CC=CC=C1 XTPPAVHDUJMWEX-UHFFFAOYSA-M 0.000 description 1

- JKNCOURZONDCGV-UHFFFAOYSA-N 2-(dimethylamino)ethyl 2-methylprop-2-enoate Chemical compound CN(C)CCOC(=O)C(C)=C JKNCOURZONDCGV-UHFFFAOYSA-N 0.000 description 1

- DUMAFWZFOOOEPH-UHFFFAOYSA-N 2-[bis(2-hydroxyethyl)amino]ethanol;dodecyl benzenesulfonate Chemical compound OCCN(CCO)CCO.CCCCCCCCCCCCOS(=O)(=O)C1=CC=CC=C1 DUMAFWZFOOOEPH-UHFFFAOYSA-N 0.000 description 1

- BIHQJMSIEXRWPS-UHFFFAOYSA-N 2-[bis(2-hydroxyethyl)amino]ethanol;dodecyl dihydrogen phosphate Chemical compound OCCN(CCO)CCO.CCCCCCCCCCCCOP(O)(O)=O BIHQJMSIEXRWPS-UHFFFAOYSA-N 0.000 description 1

- OYINQIKIQCNQOX-UHFFFAOYSA-M 2-hydroxybutyl(trimethyl)azanium;chloride Chemical compound [Cl-].CCC(O)C[N+](C)(C)C OYINQIKIQCNQOX-UHFFFAOYSA-M 0.000 description 1

- KWIUHFFTVRNATP-UHFFFAOYSA-N Betaine Natural products C[N+](C)(C)CC([O-])=O KWIUHFFTVRNATP-UHFFFAOYSA-N 0.000 description 1

- 244000303965 Cyamopsis psoralioides Species 0.000 description 1

- XMSXQFUHVRWGNA-UHFFFAOYSA-N Decamethylcyclopentasiloxane Chemical compound C[Si]1(C)O[Si](C)(C)O[Si](C)(C)O[Si](C)(C)O[Si](C)(C)O1 XMSXQFUHVRWGNA-UHFFFAOYSA-N 0.000 description 1

- ZAFNJMIOTHYJRJ-UHFFFAOYSA-N Diisopropyl ether Chemical group CC(C)OC(C)C ZAFNJMIOTHYJRJ-UHFFFAOYSA-N 0.000 description 1

- LCGLNKUTAGEVQW-UHFFFAOYSA-N Dimethyl ether Chemical group COC LCGLNKUTAGEVQW-UHFFFAOYSA-N 0.000 description 1

- 239000004150 EU approved colour Substances 0.000 description 1

- 206010019049 Hair texture abnormal Diseases 0.000 description 1

- 102000011782 Keratins Human genes 0.000 description 1

- 108010076876 Keratins Proteins 0.000 description 1

- FYYHWMGAXLPEAU-UHFFFAOYSA-N Magnesium Chemical compound [Mg] FYYHWMGAXLPEAU-UHFFFAOYSA-N 0.000 description 1

- 241000772415 Neovison vison Species 0.000 description 1

- GOOHAUXETOMSMM-UHFFFAOYSA-N Propylene oxide Chemical group CC1CO1 GOOHAUXETOMSMM-UHFFFAOYSA-N 0.000 description 1

- 206010039792 Seborrhoea Diseases 0.000 description 1

- DBMJMQXJHONAFJ-UHFFFAOYSA-M Sodium laurylsulphate Chemical compound [Na+].CCCCCCCCCCCCOS([O-])(=O)=O DBMJMQXJHONAFJ-UHFFFAOYSA-M 0.000 description 1

- 239000004141 Sodium laurylsulphate Substances 0.000 description 1

- NINIDFKCEFEMDL-UHFFFAOYSA-N Sulfur Chemical group [S] NINIDFKCEFEMDL-UHFFFAOYSA-N 0.000 description 1

- 239000005864 Sulphur Substances 0.000 description 1

- GSEJCLTVZPLZKY-UHFFFAOYSA-N Triethanolamine Chemical class OCCN(CCO)CCO GSEJCLTVZPLZKY-UHFFFAOYSA-N 0.000 description 1

- 150000001298 alcohols Chemical class 0.000 description 1

- 125000001931 aliphatic group Chemical group 0.000 description 1

- 150000003973 alkyl amines Chemical class 0.000 description 1

- 125000002947 alkylene group Chemical group 0.000 description 1

- 150000001413 amino acids Chemical class 0.000 description 1

- 235000021120 animal protein Nutrition 0.000 description 1

- 125000000129 anionic group Chemical group 0.000 description 1

- 239000003242 anti bacterial agent Substances 0.000 description 1

- ZWXYEWJNBYQXLK-UHFFFAOYSA-N azanium;4-dodecoxy-4-oxo-3-sulfobutanoate Chemical compound [NH4+].CCCCCCCCCCCCOC(=O)C(S(O)(=O)=O)CC([O-])=O ZWXYEWJNBYQXLK-UHFFFAOYSA-N 0.000 description 1

- 229960003237 betaine Drugs 0.000 description 1

- 239000006172 buffering agent Substances 0.000 description 1

- 229960000541 cetyl alcohol Drugs 0.000 description 1

- 229960001927 cetylpyridinium chloride Drugs 0.000 description 1

- YMKDRGPMQRFJGP-UHFFFAOYSA-M cetylpyridinium chloride Chemical compound [Cl-].CCCCCCCCCCCCCCCC[N+]1=CC=CC=C1 YMKDRGPMQRFJGP-UHFFFAOYSA-M 0.000 description 1

- WOWHHFRSBJGXCM-UHFFFAOYSA-M cetyltrimethylammonium chloride Chemical compound [Cl-].CCCCCCCCCCCCCCCC[N+](C)(C)C WOWHHFRSBJGXCM-UHFFFAOYSA-M 0.000 description 1

- 230000003749 cleanliness Effects 0.000 description 1

- MRUAUOIMASANKQ-UHFFFAOYSA-N cocamidopropyl betaine Chemical compound CCCCCCCCCCCC(=O)NCCC[N+](C)(C)CC([O-])=O MRUAUOIMASANKQ-UHFFFAOYSA-N 0.000 description 1

- 229940073507 cocamidopropyl betaine Drugs 0.000 description 1

- 229940018562 coco monoisopropanolamide Drugs 0.000 description 1

- 239000007859 condensation product Substances 0.000 description 1

- 239000002537 cosmetic Substances 0.000 description 1

- 229940086555 cyclomethicone Drugs 0.000 description 1

- GQOKIYDTHHZSCJ-UHFFFAOYSA-M dimethyl-bis(prop-2-enyl)azanium;chloride Chemical compound [Cl-].C=CC[N+](C)(C)CC=C GQOKIYDTHHZSCJ-UHFFFAOYSA-M 0.000 description 1

- REZZEXDLIUJMMS-UHFFFAOYSA-M dimethyldioctadecylammonium chloride Chemical compound [Cl-].CCCCCCCCCCCCCCCCCC[N+](C)(C)CCCCCCCCCCCCCCCCCC REZZEXDLIUJMMS-UHFFFAOYSA-M 0.000 description 1

- 238000009826 distribution Methods 0.000 description 1

- 125000003438 dodecyl group Chemical group [H]C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])* 0.000 description 1

- JZKFHQMONDVVNF-UHFFFAOYSA-N dodecyl sulfate;tris(2-hydroxyethyl)azanium Chemical compound OCCN(CCO)CCO.CCCCCCCCCCCCOS(O)(=O)=O JZKFHQMONDVVNF-UHFFFAOYSA-N 0.000 description 1

- SYELZBGXAIXKHU-UHFFFAOYSA-N dodecyldimethylamine N-oxide Chemical compound CCCCCCCCCCCC[N+](C)(C)[O-] SYELZBGXAIXKHU-UHFFFAOYSA-N 0.000 description 1

- 239000000975 dye Substances 0.000 description 1

- 239000003792 electrolyte Substances 0.000 description 1

- 238000011156 evaluation Methods 0.000 description 1

- 239000000284 extract Substances 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- 229920001519 homopolymer Polymers 0.000 description 1

- 235000012907 honey Nutrition 0.000 description 1

- 229940094506 lauryl betaine Drugs 0.000 description 1

- 239000007788 liquid Substances 0.000 description 1

- 239000011777 magnesium Substances 0.000 description 1

- 229910052749 magnesium Inorganic materials 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 235000013336 milk Nutrition 0.000 description 1

- 210000004080 milk Anatomy 0.000 description 1

- 238000002156 mixing Methods 0.000 description 1

- DVEKCXOJTLDBFE-UHFFFAOYSA-N n-dodecyl-n,n-dimethylglycinate Chemical compound CCCCCCCCCCCC[N+](C)(C)CC([O-])=O DVEKCXOJTLDBFE-UHFFFAOYSA-N 0.000 description 1

- GOQYKNQRPGWPLP-UHFFFAOYSA-N n-heptadecyl alcohol Natural products CCCCCCCCCCCCCCCCCO GOQYKNQRPGWPLP-UHFFFAOYSA-N 0.000 description 1

- 125000001117 oleyl group Chemical group [H]C([*])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])/C([H])=C([H])\C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])[H] 0.000 description 1

- 229940006093 opthalmologic coloring agent diagnostic Drugs 0.000 description 1

- 125000005010 perfluoroalkyl group Chemical group 0.000 description 1

- 150000002989 phenols Chemical class 0.000 description 1

- 229950001046 piroctone Drugs 0.000 description 1

- BTSZTGGZJQFALU-UHFFFAOYSA-N piroctone olamine Chemical compound NCCO.CC(C)(C)CC(C)CC1=CC(C)=CC(=O)N1O BTSZTGGZJQFALU-UHFFFAOYSA-N 0.000 description 1

- 229920005862 polyol Polymers 0.000 description 1

- 150000003077 polyols Chemical class 0.000 description 1

- 229920002451 polyvinyl alcohol Polymers 0.000 description 1

- 230000000717 retained effect Effects 0.000 description 1

- 108700004121 sarkosyl Proteins 0.000 description 1

- 208000008742 seborrheic dermatitis Diseases 0.000 description 1

- 229920002545 silicone oil Polymers 0.000 description 1

- 239000000344 soap Substances 0.000 description 1

- 229940083542 sodium Drugs 0.000 description 1

- 235000019333 sodium laurylsulphate Nutrition 0.000 description 1

- ADWNFGORSPBALY-UHFFFAOYSA-M sodium;2-[dodecyl(methyl)amino]acetate Chemical compound [Na+].CCCCCCCCCCCCN(C)CC([O-])=O ADWNFGORSPBALY-UHFFFAOYSA-M 0.000 description 1

- HFQQZARZPUDIFP-UHFFFAOYSA-M sodium;2-dodecylbenzenesulfonate Chemical compound [Na+].CCCCCCCCCCCCC1=CC=CC=C1S([O-])(=O)=O HFQQZARZPUDIFP-UHFFFAOYSA-M 0.000 description 1

- SFVFIFLLYFPGHH-UHFFFAOYSA-M stearalkonium chloride Chemical compound [Cl-].CCCCCCCCCCCCCCCCCC[N+](C)(C)CC1=CC=CC=C1 SFVFIFLLYFPGHH-UHFFFAOYSA-M 0.000 description 1

- KDYFGRWQOYBRFD-UHFFFAOYSA-L succinate(2-) Chemical compound [O-]C(=O)CCC([O-])=O KDYFGRWQOYBRFD-UHFFFAOYSA-L 0.000 description 1

- 239000000375 suspending agent Substances 0.000 description 1

- 230000008719 thickening Effects 0.000 description 1

- HHLJUSLZGFYWKW-UHFFFAOYSA-N triethanolamine hydrochloride Chemical compound Cl.OCCN(CCO)CCO HHLJUSLZGFYWKW-UHFFFAOYSA-N 0.000 description 1

- 239000004034 viscosity adjusting agent Substances 0.000 description 1

- 238000005406 washing Methods 0.000 description 1

- 238000009736 wetting Methods 0.000 description 1

- PICXIOQBANWBIZ-UHFFFAOYSA-N zinc;1-oxidopyridine-2-thione Chemical compound [Zn+2].[O-]N1C=CC=CC1=S.[O-]N1C=CC=CC1=S PICXIOQBANWBIZ-UHFFFAOYSA-N 0.000 description 1

Classifications

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K8/00—Cosmetics or similar toiletry preparations

- A61K8/18—Cosmetics or similar toiletry preparations characterised by the composition

- A61K8/30—Cosmetics or similar toiletry preparations characterised by the composition containing organic compounds

- A61K8/69—Cosmetics or similar toiletry preparations characterised by the composition containing organic compounds containing fluorine

- A61K8/70—Cosmetics or similar toiletry preparations characterised by the composition containing organic compounds containing fluorine containing perfluoro groups, e.g. perfluoroethers

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61Q—SPECIFIC USE OF COSMETICS OR SIMILAR TOILETRY PREPARATIONS

- A61Q5/00—Preparations for care of the hair

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61Q—SPECIFIC USE OF COSMETICS OR SIMILAR TOILETRY PREPARATIONS

- A61Q5/00—Preparations for care of the hair

- A61Q5/02—Preparations for cleaning the hair

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61Q—SPECIFIC USE OF COSMETICS OR SIMILAR TOILETRY PREPARATIONS

- A61Q5/00—Preparations for care of the hair

- A61Q5/12—Preparations containing hair conditioners

Definitions

- the present invention relates to hair-treatment compositions, and more particularly to shampoos or conditioning compositions which comprise a perfluoropolyether material.

- oils can provide conditioning benefits such as ease of combing of wet or dry hair, soft feel and improved shine. Generally, however, these materials are only effective at high levels.

- EP 360 292 (AUSIMONT) relates to the use of 0.01 to 20 % by weight of perfluoropolyethers having perfluoroalkyl end groups in foam baths, cleansing milks, bath oils and liquid soaps for the treatment of seborrhea.

- condition of hair can be improved by using a hair-treatment composition which contains only low levels of a perfluoro polyether material.

- conditioning benefits to hair can be provided by using a hair-treatment composition which comprises from 0.00001 to 0.01 % by weight of a perfluoropolyether material.

- the invention provides a hair treatment composition comprising from 0.00001 to 0.01 % by weight of a perfluoropolyether material.

- the hair treatment composition according to the invention is a shampoo or a hair-conditioner.

- the hair-treatment composition of the invention comprises a perfluoropolyether material.

- Suitable perfluoropolyethers and their method of preparation are described in GB 1,104,482, US 3,242,218, US 3,665,041, US 3,715378, US 4,523,039, EP 148,482 and EP 191,490.

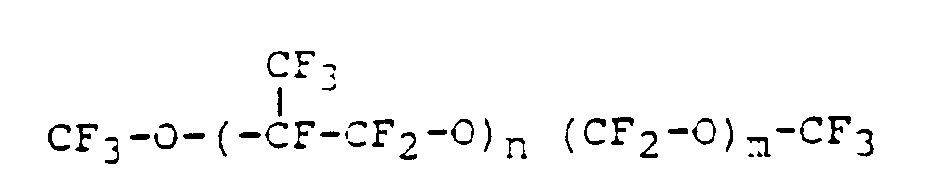

- Preferred perfluoropolyether materials are homo- or copolymers of the following formula: wherein

- polymers of the invention may be homopolymers (iffor each monomer y is the same) or copolymers (if at least two values of y are chosen for different monomers).

- n is selected such that the molecular weight of the polymer is from 100-100,000, more preferably 500-50,000, most preferably 1,000 to 10,000.

- Particularly preferred end-groups of the perfluoro polyether (PFPE) material are those wherein z is 1 or 2.

- Suitable monomer units for use in polymers of the invention are for example disclosed in EP 360 292.

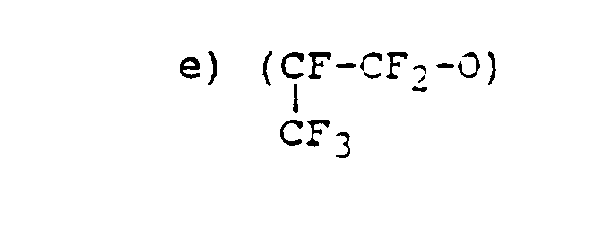

- Particularly preferred polymer backbone monomers are of the group consisting of :

- Particularly preferred polymers comprise a combination of branched polymer unit, for example monomers d) and/ore), with linear monomers, for example a)-c), f) org).

- Particular suitable are polymers comprising mixtures of isopropylether groups and methyl ether groups.

- PFPE materials are those having the formula : wherein the ratio of n to m is from 20 to 40, and wherein preferably the backbone monomers are randomly distributed along the PFPE chain.

- Preferred PFPE materials of this formula are those sold underthe trade name FOMBLIN HC by Montefluos.

- FOMBLIN HC/04 average molecular weight 1500

- FOMBLIN HC/25 average molecular weight 3200

- FOMBLIN HC/R average molecular weight 6600.

- Demnam S-20 having a molecular weight of 2,500

- Demnam S-65 having a molecular weight of 4,500

- Demnam S-100 having a molecular weight of 5,600

- Demnam S-200 having a molecular weight of 8,400.

- the level of PFPE materials in hair treatment compositions of the invention is from 0.00001 to 0.01 % by weight of the composition, more preferably 0.0001 to 0.008%, most preferably 0.0001 to 0.005 %.

- PFPE perfluoropolyether

- Preferred hair treatment composition of the invention comprise one or more surfactant materials and/or one or more conditioning agents.

- Shampoo compositions in accordance to the present invention preferably comprise one or more surfactant materials selected from anionic, nonionic, amphoteric or cationic surfactants or mixtures thereof.

- Hair conditioning products preferably comprise one or more cantionic surfactants.

- the use of cationic surfactants is especially preferred, because thes ingredients are capable of providing conditioning benefits to hair.

- Suitable anionic surfactants are the alkyl sulphates, alkyl ether sulphates, alkaryl sulphonates, alkyl succinates, alkyl sulphosuccinates, N-alkoyl sarcosinates, alkyl phosphates, alkyl ether phosphates, alkyl ether carboxylates, and a-olefin sulphonates, especially their sodium, magnesium, ammonium and mono-, di- and tri-ethanolamine salts.

- the alkyl groups generally contain from 8 to 18 carbon atoms and may be unsaturated.

- the alkyl ether sulphates, alkyl ether phosphates and alkyl ether carboxylates may contain from 1 to 10 ethylene oxide or propylene oxide units per molecules, and preferably contain 2 to 3 ethylene oxide units per molecule.

- anionic surfactants include sodium oleyl succinate, ammonium lauryl sulphosuccinate, ammonium lauryl sulphate, sodium dodecylbenzene sulphonate, triethanolamine dodecylbenzene sulphonate and sodium N-lauryl sarcosinate.

- the most preferred anionic surfactants are sodium lauryl sulphate, triethanolamine lauryl sulphate, triethanolamine monolauryl phosphate, sodium lauryl ether sulphate 1 EO, 2EO and 3EO, ammonium lauryl sulphate and ammonium lauryl ether sulphate 1 EO, 2EO and 3EO.

- the nonionic surfactants suitable for use in the composition of the invention may include condensation products of aliphatic (C 8 -C l8 ) primary or secondary linear or branched-chain alcohols or phenols with alkylene oxides, usually ethylene oxide and generally 6-30 EO.

- Nonionics includes mono- or di alkyl alkanolamides or alkyl polyglucosides. Examples include coco mono- or di-ethanolamide, coco mono- isopropanolamide, and coco di-glucoside.

- amphoteric surfactants suitable for use in the composition of the invention may include alkyl amine oxides, alkyl betaines, alkyl amidopropyl betaines, alkyl sulphobetaines, alkyl glycinates, alkyl carboxyglycinates, alkyl amphopropionates, alkyl amidopropyl hydroxysultaines, acyl taurates and acyl glutamates wherein the alkyl and acyl groups have from 8 to 18 carbon atoms.

- Examples include lauryl amine oxide, cocodimethyl sulphopropyl betaine and preferably lauryl betaine, cocamidopropyl betaine and sodium cocamphopropionate.

- cationic surfactants include: cetyl trimethylammonium chloride, stearyl dimethylbenzyl ammonium chloride, cetylpyridinium chloride, quaternium-5, -31, -18 and mixtures thereof.

- the level of surfactant materials in shampoo compositions of the invention is preferably more than 1 %, more preferably 2-35 % and most preferably from 5 to 30% by weight of the composition.

- the level of cationic surfactants is preferably from 0.01 to 10 %, more preferably 0.05 to 5 %, most preferably 0.1 to 2 % by weight of the composition.

- the hair-treatment composition of the invention comprises in addition to the perfluoropolyether materials and the cationic surfactant -if any- an additional conditioning agent, this material is preferably chosen from cationic polymers, volatile and non-volatile silicones, protein hydrolysates orquaternised protein hydrolysates.

- Suitable cationic polymers include Guar Hydroxypropyltrimonium chloride, Quaternium-19, -23 -40, -57, poly (dimethyldiallylammonium chloride), poly (dimethyl butenyl ammonium chloride)-,w- bis (triethanolammonium chloride), Poly (dipropyldiallylammonium chloride), Poly (methyl-beta-propaniodiallylammonium chloride), Poly (diallylpiperidinium chloride), poly (vinyl pyridinium chloride), quaternised poly (vinyl alcohol), quaternised poly (dimethylaminoethylmethacrylate) and mixtures thereof.

- suitable volatile silicone materials include cyclomethicone, available commercially as Dow Corning DC 345, and volatile Silicone 7158, available form Union Carbide.

- Suitable protein derivatives include lauryl dimonium hydroxy propylamino hydrolysed animal protein, available commercially under the tradename LAMEQUAT L, and hydrolysed keratin containing sulphur-bearing amino acids, available commercially under the tradename CROQUAT WKP.

- Conditioning agents which are especially suitable for use in shampoos or conditioners according to the invention include volatile and non-volatile silicone oils, such as for example polyalkylsiloxanes, polyalkylaryl siloxanes, silicone gums, cyclomethicones and aminofunctional silicones.

- volatile and non-volatile silicone oils such as for example polyalkylsiloxanes, polyalkylaryl siloxanes, silicone gums, cyclomethicones and aminofunctional silicones.

- silicone materials are incorporated in the shampoo conditioner as small particles, preferably of particle size 0.01 to 1 um.

- the preferred level of conditioning agents other than perfluoropolyethers and cationic surfactants in compositions of the invention is from 0 to 20 %, for example from 0.01 to 10 % or from 0.1 to 5 % by weight.

- a fatty alcohol material Another ingredient that may advantageously be incroporated into products of the invention is a fatty alcohol material.

- the use of these materials is especially preferred in conditioning compositions of the invention, in particular conditioning compositions which comprise one or more cationic surfactant materials.

- conditioning compositions which comprise one or more cationic surfactant materials.

- the combined use of fatty alcohol materials and cationic surfactants in conditioning compositions is believed to be especially advantageous, because this leads to the forming of a lamellar phase, wherein the cationic surfactant is dispersed.

- Preferred fatty alcohols comprises from 8 to 22 carbon atoms, more preferably 16 to 20.

- Examples of preferred fatty alcohols are cetyl alcohol and stearyl alcohol. The use of these materials is also advantageous in that they contribute to the overall conditioning properties of compositions of the invention.

- the level of fatty alcohol materials is conveniently from 0 to 10 %, more preferred from 0.1 to 5 % by weight of the product.

- the weight ratio of cationic surfactant to fatty alcohol is preferably from 10 : 1 to 1 : 10, more preferably from 4 : 1 to 1 : 8, most preferably from 1 : 1 to 1 : 4.

- the hair-treatment composition of the invention may also include minor amounts of other ingredients commonly found in hair-treatment compositions, such as antibacterial agents, antidandruff agents such as zinc pyri- dinethione or Octopirox, foam boosters, pearlescers, perfumes, dyes, colouring agents, preservatives, viscosity modifiers, proteins, polymers, buffering agents, polyols and other moisturising agents, herb extracts, mink oil or honey.

- other ingredients commonly found in hair-treatment compositions such as antibacterial agents, antidandruff agents such as zinc pyri- dinethione or Octopirox, foam boosters, pearlescers, perfumes, dyes, colouring agents, preservatives, viscosity modifiers, proteins, polymers, buffering agents, polyols and other moisturising agents, herb extracts, mink oil or honey.

- compositions of the invention preferably comprise from 20-99.5 % of water, more preferably 60-98%, most preferably 80-96 % by weight.

- hair treatment compositions according to the invention are preferably packed.

- Any suitable container can be used for this purpose, but generally compositions of the invention will be packed in closed containers like bottles, sachets and the like.

- Hair treatment compositions of the invention are generally applied in an amount of from 1 to 50 mls.

- Preferred amounts for shampoos are 3 to 5 mls to wet hair.

- the wet hair is worked to create a lather.

- the lather may be retained on the head for a short time before rinsing, e.g. from 1 to 4 minutes, or may immediately be rinsed.

- the treatment may be repeated, if required.

- the preferred dosage is from 8 to 20 mls which is applied to hair after washing or rinsing, whereafter the wet hair is worked and rinsed.

- PFPE ingredient in preparing hair-treatment compositions of the invention, preferably conventional hot or cold mixing processes are used.

- Preferred methods for adding the PFPE ingredient to the compositions are the forming of a predispersion of PFPE with small amounts of surfactants in combination with a thickening amount of electrolyte, or a predispersion can be formed of PFPE with polymer ingredients, or a predispersion of PFPE with low levels of surfactant in combination with glycerol. This predispersion is than used in the preparation of the final hair-treatment composition.

- the following conditioner compositions can be made by heating the water to 80°C. The first five ingredients are added with stirring. The mixture is cooled to 40 °C with stirring. Preservatives, perfume and colour are added. The resulting mixture is cooled.

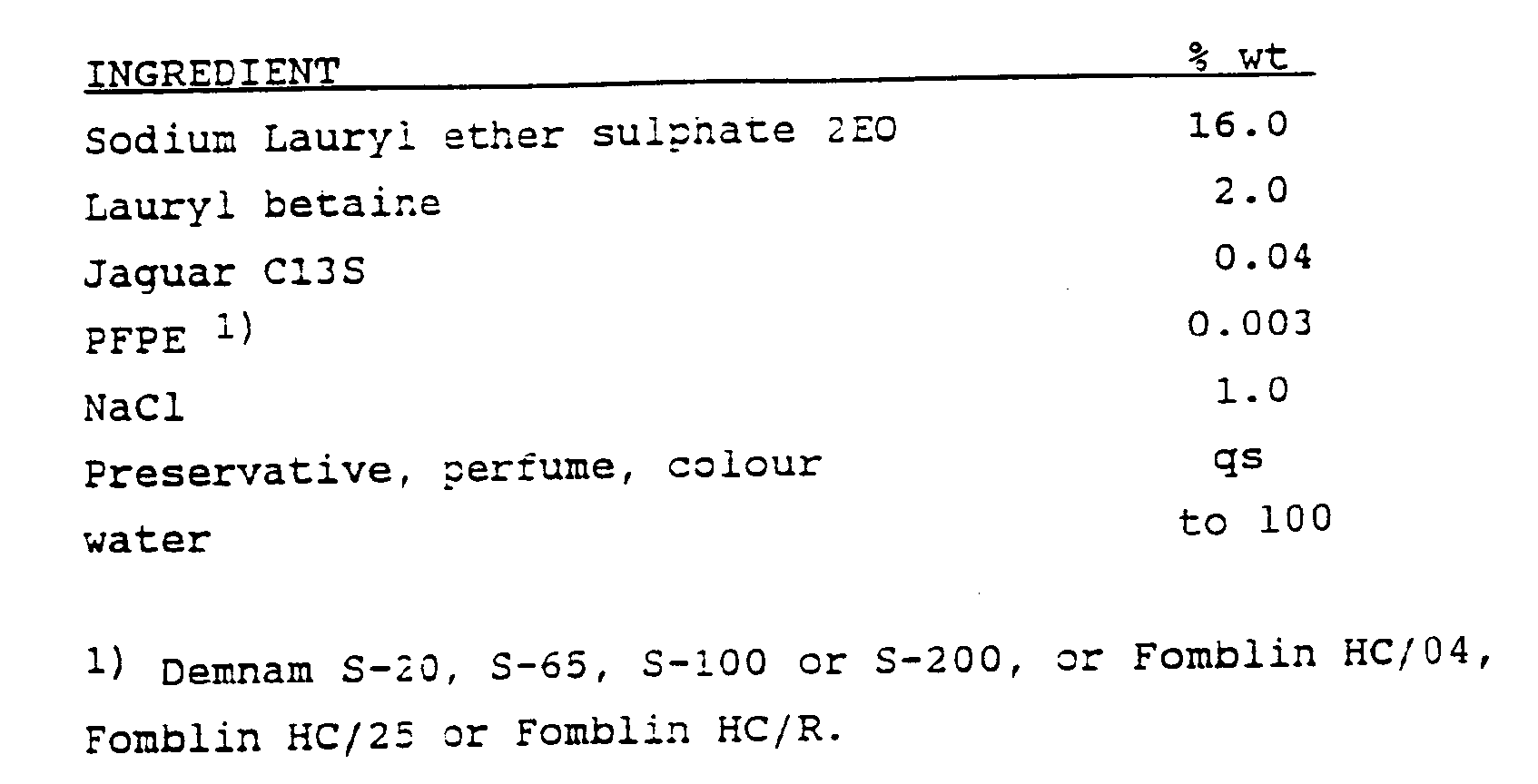

- a shampoo of the following forumulation can be made by using a simple cold process, whereby all the ingredients are mixed using a paddle stirrer.

- the composition containing Fomblin HC/04 was tested in vitro on hair by wetting 8 g of hair, lathering it for 30 s with 0.5 ml of shampoo, leaving it for another 20 s and rinsing with water; the procedure was repeated but using 0.4 g of the shampoo, the hair was dried. As a comparison the hair was treated with the above composition in the absence of PFPE.

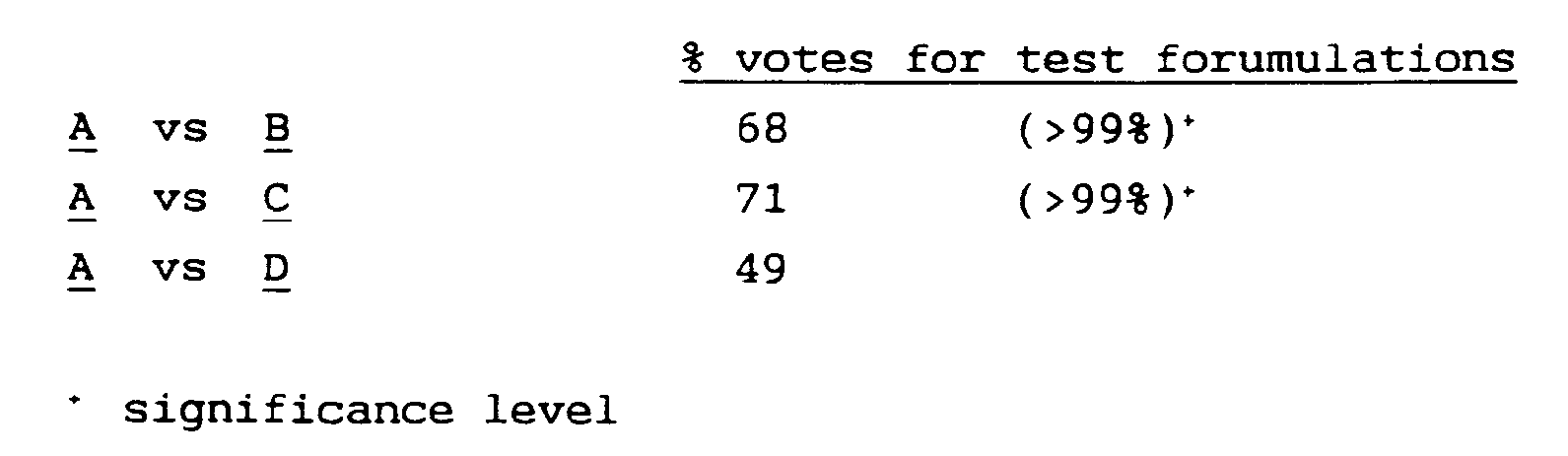

- the evaluation was carried out by twelve trained assessors in the from of paired comparison test. The results were interpreted statistically at 0.01 and 0.05 confidence levels. Softness was assessed by feel. Shine was assessed by viewing the hair switches mounted over a curved surface undera spotlight to create a highlight which was then visually assessed for its light intensity.

- the hair treated with the composition according to the invention had a significantly better condition, especially as far as dry-combing and shine is concerned. Similar results may be obtained by using the other PFPE materials as indicated above.

- the composition containing Fomblin HC/R was tested in vitro on hair by a method as described in example II. As a comparison the hair was treated with the above composition in the absence of PFPE. The hair treated with the composition according to the invention had a significantly better condition, especially as far as dry-combing and shine is concerned. Similar results may be obtained by using the other PFPE materials as indicated above.

- Formulation A was a control

- Formulations B and C were in accordance with the present invention

- Formulation D was not in accordance with the invention. All amounts are in % wt, unless otherwise stated.

- Formulation E was a control

- Formulation F was in accordance with the present invention

- Formulation G was not in accordance with the invention. Amounts are in % wt, unless otherwise stated.

Landscapes

- Health & Medical Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Animal Behavior & Ethology (AREA)

- General Health & Medical Sciences (AREA)

- Public Health (AREA)

- Veterinary Medicine (AREA)

- Birds (AREA)

- Epidemiology (AREA)

- Dermatology (AREA)

- Cosmetics (AREA)

- Compositions Of Macromolecular Compounds (AREA)

Abstract

Description

- The present invention relates to hair-treatment compositions, and more particularly to shampoos or conditioning compositions which comprise a perfluoropolyether material.

- It is known that oils can provide conditioning benefits such as ease of combing of wet or dry hair, soft feel and improved shine. Generally, however, these materials are only effective at high levels.

-

- EP 360 292 (AUSIMONT) relates to the use of 0.01 to 20 % by weight of perfluoropolyethers having perfluoroalkyl end groups in foam baths, cleansing milks, bath oils and liquid soaps for the treatment of seborrhea.

- Surprisingly, we have found that the condition of hair can be improved by using a hair-treatment composition which contains only low levels of a perfluoro polyether material. In particular it has been found that conditioning benefits to hair can be provided by using a hair-treatment composition which comprises from 0.00001 to 0.01 % by weight of a perfluoropolyether material.

- Other possible advantages obtained by using low levels of perfluoropolyether materials in hair treatment compositions are: low-risk of over-conditioning, improved cleanliness and interference with sebaceous distribution.

- Accordingly, the invention provides a hair treatment composition comprising from 0.00001 to 0.01 % by weight of a perfluoropolyether material.

- Preferably the hair treatment composition according to the invention is a shampoo or a hair-conditioner.

- The invention will now be described in detail.

- The hair-treatment composition of the invention comprises a perfluoropolyether material. Suitable perfluoropolyethers and their method of preparation are described in GB 1,104,482, US 3,242,218, US 3,665,041, US 3,715378, US 4,523,039, EP 148,482 and EP 191,490.

-

- z is an integer from 1 to 6, more preferably 1-3, most preferably 1 or 2;

- for each monomer, y is independantly selected from the integer-range from 1 to 6, more preferably 1-5, most preferably 1-3;

- n indicates the total number of monomers in the polymer backbone and is at least 1, more preferably at least 5, most preferably at least 10

- Since y is independently selected for each monomer unit, polymers of the invention may be homopolymers (iffor each monomer y is the same) or copolymers (if at least two values of y are chosen for different monomers).

- Most preferably n is selected such that the molecular weight of the polymer is from 100-100,000, more preferably 500-50,000, most preferably 1,000 to 10,000.

- Particularly preferred end-groups of the perfluoro polyether (PFPE) material are those wherein z is 1 or 2.

- Suitable monomer units for use in polymers of the invention are for example disclosed in EP 360 292. Particularly preferred polymer backbone monomers are of the group consisting of :

- a) (CF2-CF2-O)

- b) (CF2-O)

- c) (CaFs-O)

- f) (CF2-O-CF2-O)

- g) (CF2-O-C2F4-O);

- Particularly preferred polymers comprise a combination of branched polymer unit, for example monomers

d) and/ore), with linear monomers, for example a)-c), f) org). Especially suitable are polymers comprising mixtures of isopropylether groups and methyl ether groups. -

- Preferred PFPE materials of this formula are those sold underthe trade name FOMBLIN HC by Montefluos. For example, FOMBLIN HC/04 (average molecular weight 1500), FOMBLIN HC/25 (average molecular weight 3200) and FOMBLIN HC/R (average molecular weight 6600).

- Other suitable materials are sold under the Demnam trade name ex Daikin Industries Ltd, for example Demnam S-20 having a molecular weight of 2,500, Demnam S-65 having a molecular weight of 4,500 Demnam S-100 having a molecular weight of 5,600 and Demnam S-200 having a molecular weight of 8,400.

- If mixtures of backbone monomers are used, preferably the different types of monomers are randomly distributed along the PFPE chain.

- The level of PFPE materials in hair treatment compositions of the invention is from 0.00001 to 0.01 % by weight of the composition, more preferably 0.0001 to 0.008%, most preferably 0.0001 to 0.005 %.

- If less than 0.00001 % by weight of PFPE is used in the composition, no appreciable improvement in condition will be observed. The use of PFPE levels over 0.01 % by weight of the composition provides cost disadvantages, also this may lead to problem in manufacturing and the hair may appear oily or dull, also the use of levels of perfluoropolyethers at higher levels will generally generate the need for suspending agents.

- Preferred hair treatment composition of the invention comprise one or more surfactant materials and/or one or more conditioning agents.

- Shampoo compositions in accordance to the present invention preferably comprise one or more surfactant materials selected from anionic, nonionic, amphoteric or cationic surfactants or mixtures thereof.

- Hair conditioning products preferably comprise one or more cantionic surfactants. The use of cationic surfactants is especially preferred, because thes ingredients are capable of providing conditioning benefits to hair.

- Suitable anionic surfactants are the alkyl sulphates, alkyl ether sulphates, alkaryl sulphonates, alkyl succinates, alkyl sulphosuccinates, N-alkoyl sarcosinates, alkyl phosphates, alkyl ether phosphates, alkyl ether carboxylates, and a-olefin sulphonates, especially their sodium, magnesium, ammonium and mono-, di- and tri-ethanolamine salts. The alkyl groups generally contain from 8 to 18 carbon atoms and may be unsaturated. The alkyl ether sulphates, alkyl ether phosphates and alkyl ether carboxylates may contain from 1 to 10 ethylene oxide or propylene oxide units per molecules, and preferably contain 2 to 3 ethylene oxide units per molecule.

- Examples of suitable anionic surfactants include sodium oleyl succinate, ammonium lauryl sulphosuccinate, ammonium lauryl sulphate, sodium dodecylbenzene sulphonate, triethanolamine dodecylbenzene sulphonate and sodium N-lauryl sarcosinate. The most preferred anionic surfactants are sodium lauryl sulphate, triethanolamine lauryl sulphate, triethanolamine monolauryl phosphate, sodium lauryl ether sulphate 1 EO, 2EO and 3EO, ammonium lauryl sulphate and ammonium lauryl ether sulphate 1 EO, 2EO and 3EO.

- The nonionic surfactants suitable for use in the composition of the invention may include condensation products of aliphatic (C8-Cl8) primary or secondary linear or branched-chain alcohols or phenols with alkylene oxides, usually ethylene oxide and generally 6-30 EO.

- Other suitable nonionics includes mono- or di alkyl alkanolamides or alkyl polyglucosides. Examples include coco mono- or di-ethanolamide, coco mono- isopropanolamide, and coco di-glucoside.

- The amphoteric surfactants suitable for use in the composition of the invention may include alkyl amine oxides, alkyl betaines, alkyl amidopropyl betaines, alkyl sulphobetaines, alkyl glycinates, alkyl carboxyglycinates, alkyl amphopropionates, alkyl amidopropyl hydroxysultaines, acyl taurates and acyl glutamates wherein the alkyl and acyl groups have from 8 to 18 carbon atoms. Examples include lauryl amine oxide, cocodimethyl sulphopropyl betaine and preferably lauryl betaine, cocamidopropyl betaine and sodium cocamphopropionate.

- Examples cationic surfactants include: cetyl trimethylammonium chloride, stearyl dimethylbenzyl ammonium chloride, cetylpyridinium chloride, quaternium-5, -31, -18 and mixtures thereof.

- The level of surfactant materials in shampoo compositions of the invention is preferably more than 1 %, more preferably 2-35 % and most preferably from 5 to 30% by weight of the composition. In hair-conditioner products according to the invention the level of cationic surfactants is preferably from 0.01 to 10 %, more preferably 0.05 to 5 %, most preferably 0.1 to 2 % by weight of the composition.

- If the hair-treatment composition of the invention comprises in addition to the perfluoropolyether materials and the cationic surfactant -if any- an additional conditioning agent, this material is preferably chosen from cationic polymers, volatile and non-volatile silicones, protein hydrolysates orquaternised protein hydrolysates.

- Suitable cationic polymers include Guar Hydroxypropyltrimonium chloride, Quaternium-19, -23 -40, -57, poly (dimethyldiallylammonium chloride), poly (dimethyl butenyl ammonium chloride)-,w- bis (triethanolammonium chloride), Poly (dipropyldiallylammonium chloride), Poly (methyl-beta-propaniodiallylammonium chloride), Poly (diallylpiperidinium chloride), poly (vinyl pyridinium chloride), quaternised poly (vinyl alcohol), quaternised poly (dimethylaminoethylmethacrylate) and mixtures thereof.

- Examples of suitable volatile silicone materials include cyclomethicone, available commercially as Dow Corning DC 345, and volatile Silicone 7158, available form Union Carbide.

- Suitable protein derivatives include lauryl dimonium hydroxy propylamino hydrolysed animal protein, available commercially under the tradename LAMEQUAT L, and hydrolysed keratin containing sulphur-bearing amino acids, available commercially under the tradename CROQUAT WKP.

- Conditioning agents which are especially suitable for use in shampoos or conditioners according to the invention include volatile and non-volatile silicone oils, such as for example polyalkylsiloxanes, polyalkylaryl siloxanes, silicone gums, cyclomethicones and aminofunctional silicones. Preferably these silicone materials are incorporated in the shampoo conditioner as small particles, preferably of particle size 0.01 to 1 um.

- The preferred level of conditioning agents other than perfluoropolyethers and cationic surfactants in compositions of the invention is from 0 to 20 %, for example from 0.01 to 10 % or from 0.1 to 5 % by weight.

- Another ingredient that may advantageously be incroporated into products of the invention is a fatty alcohol material. The use of these materials is especially preferred in conditioning compositions of the invention, in particular conditioning compositions which comprise one or more cationic surfactant materials. The combined use of fatty alcohol materials and cationic surfactants in conditioning compositions is believed to be especially advantageous, because this leads to the forming of a lamellar phase, wherein the cationic surfactant is dispersed.

- Preferred fatty alcohols comprises from 8 to 22 carbon atoms, more preferably 16 to 20. Examples of preferred fatty alcohols are cetyl alcohol and stearyl alcohol. The use of these materials is also advantageous in that they contribute to the overall conditioning properties of compositions of the invention.

- The level of fatty alcohol materials is conveniently from 0 to 10 %, more preferred from 0.1 to 5 % by weight of the product. The weight ratio of cationic surfactant to fatty alcohol is preferably from 10 : 1 to 1 : 10, more preferably from 4 : 1 to 1 : 8, most preferably from 1 : 1 to 1 : 4.

- The hair-treatment composition of the invention may also include minor amounts of other ingredients commonly found in hair-treatment compositions, such as antibacterial agents, antidandruff agents such as zinc pyri- dinethione or Octopirox, foam boosters, pearlescers, perfumes, dyes, colouring agents, preservatives, viscosity modifiers, proteins, polymers, buffering agents, polyols and other moisturising agents, herb extracts, mink oil or honey.

- Compositions of the invention preferably comprise from 20-99.5 % of water, more preferably 60-98%, most preferably 80-96 % by weight.

- After preparation, hair treatment compositions according to the invention are preferably packed. Any suitable container can be used for this purpose, but generally compositions of the invention will be packed in closed containers like bottles, sachets and the like.

- Hair treatment compositions of the invention are generally applied in an amount of from 1 to 50 mls. Preferred amounts for shampoos are 3 to 5 mls to wet hair. After applying the shampoo the wet hair is worked to create a lather. The lather may be retained on the head for a short time before rinsing, e.g. from 1 to 4 minutes, or may immediately be rinsed. The treatment may be repeated, if required. For conditioners the preferred dosage is from 8 to 20 mls which is applied to hair after washing or rinsing, whereafter the wet hair is worked and rinsed.

- In preparing hair-treatment compositions of the invention, preferably conventional hot or cold mixing processes are used. Preferred methods for adding the PFPE ingredient to the compositions are the forming of a predispersion of PFPE with small amounts of surfactants in combination with a thickening amount of electrolyte, or a predispersion can be formed of PFPE with polymer ingredients, or a predispersion of PFPE with low levels of surfactant in combination with glycerol. This predispersion is than used in the preparation of the final hair-treatment composition.

- The invention is further illustrated by the following Examples:

-

-

- The composition containing Fomblin HC/04 was tested in vitro on hair by wetting 8 g of hair, lathering it for 30 s with 0.5 ml of shampoo, leaving it for another 20 s and rinsing with water; the procedure was repeated but using 0.4 g of the shampoo, the hair was dried. As a comparison the hair was treated with the above composition in the absence of PFPE.

- The evaluation was carried out by twelve trained assessors in the from of paired comparison test. The results were interpreted statistically at 0.01 and 0.05 confidence levels. Softness was assessed by feel. Shine was assessed by viewing the hair switches mounted over a curved surface undera spotlight to create a highlight which was then visually assessed for its light intensity.

- The hair treated with the composition according to the invention had a significantly better condition, especially as far as dry-combing and shine is concerned. Similar results may be obtained by using the other PFPE materials as indicated above.

-

- The composition containing Fomblin HC/R was tested in vitro on hair by a method as described in example II. As a comparison the hair was treated with the above composition in the absence of PFPE. The hair treated with the composition according to the invention had a significantly better condition, especially as far as dry-combing and shine is concerned. Similar results may be obtained by using the other PFPE materials as indicated above.

-

-

-

-

-

-

-

-

and mixture of these monomers.

Claims (8)

wherein

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP90309623 | 1990-09-03 | ||

| EP90309623 | 1990-09-03 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0486135A2 true EP0486135A2 (en) | 1992-05-20 |

| EP0486135A3 EP0486135A3 (en) | 1992-09-30 |

| EP0486135B1 EP0486135B1 (en) | 1995-04-12 |

Family

ID=8205534

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP91308065A Expired - Lifetime EP0486135B1 (en) | 1990-09-03 | 1991-09-03 | Hair treatment composition |

Country Status (11)

| Country | Link |

|---|---|

| US (2) | US5275808A (en) |

| EP (1) | EP0486135B1 (en) |

| JP (1) | JPH04247014A (en) |

| KR (1) | KR970001641B1 (en) |

| AT (1) | ATE120950T1 (en) |

| AU (1) | AU648100B2 (en) |

| BR (1) | BR9103784A (en) |

| CA (1) | CA2050212C (en) |

| DE (1) | DE69108854T2 (en) |

| ES (1) | ES2071230T3 (en) |

| ZA (1) | ZA916976B (en) |

Cited By (69)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0512744A2 (en) * | 1991-05-03 | 1992-11-11 | Unilever Plc | Hair treatment composition containing a perfluoropolyether compound and a pearlescing agent |

| EP0560516A1 (en) * | 1992-03-02 | 1993-09-15 | Unilever Plc | Hair care composition |

| US5451395A (en) * | 1990-09-03 | 1995-09-19 | Chesebrough-Pond's Usa Co., Division Of Conopco, Inc. | Hair treatment composition |

| US6589519B1 (en) | 1997-08-25 | 2003-07-08 | L'oreal S.A. | Cosmetic compositions containing a polyoxyalkylenated aminosilicone block copolymer and a conditioner, and uses thereof |

| US6626962B1 (en) | 1998-01-13 | 2003-09-30 | L'oreal S.A. | Mixture for the oxidation tinting of keratin fibers containing a laccase and tinting method using said mixture |

| US6635262B2 (en) | 2000-03-14 | 2003-10-21 | L'oreal S.A. | Roll-on applicator comprising a hair composition |

| EP1688127A1 (en) | 2005-01-18 | 2006-08-09 | L'oreal | Hair treatment composition containing an aromatic alcohol, an aromatic carboxylic acid a protecting agent |

| EP1997473A2 (en) | 2007-04-30 | 2008-12-03 | L'Oreal | Use of a multi-carbosite, multi-group coupling agent for protecting the colour of artificially dyed keratin fibres with respect to washing; dyeing processes |

| WO2010063954A2 (en) | 2008-12-02 | 2010-06-10 | L'oreal | Cosmetic method using a composition containing siloxane resins and a powder dye |

| US7759296B2 (en) | 2003-06-19 | 2010-07-20 | Lubrizol Advanced Materials, Inc. | Cationic polymers and fixative application therefor |

| WO2010124994A2 (en) | 2009-04-28 | 2010-11-04 | L'oreal | Coloured composition |

| EP2248508A2 (en) | 2009-04-30 | 2010-11-10 | L'Oréal | Wax-in-water emulsion including the combination of a glutamic acid derivative and an alkyl polyglycoside. |

| WO2011030308A1 (en) | 2009-09-11 | 2011-03-17 | L'oreal | Make-up and/or care method for keratinous material |

| US7914775B2 (en) | 2000-11-20 | 2011-03-29 | L'oreal S.A. | Composition for treating keratinous materials comprising a cationic associative polyurethane polymer and a protecting or conditioning agent |

| WO2011051323A2 (en) | 2009-10-29 | 2011-05-05 | L'oreal | Makeup and/or care composition containing pigments coated with a fluoro compound and a vinyl polymer containing a carbosiloxane dendrimer-based unit |

| WO2011062805A1 (en) | 2009-11-23 | 2011-05-26 | Lubrizol Advanced Materials, Inc. | Surfactant-polymer blends |

| WO2011068820A1 (en) | 2009-12-01 | 2011-06-09 | Lubrizol Advanced Materials, Inc. | Hydrolytically stable multi-purpose polymers |

| WO2011081907A1 (en) | 2009-12-14 | 2011-07-07 | Lubrizol Advanced Materials, Inc. | Cassia derivatives |

| EP2363110A1 (en) | 2009-09-15 | 2011-09-07 | L'Oréal | Use of drying oils for protecting the color of artificially colored keratin fibers against washing; method for coloring hair |

| WO2011130460A1 (en) | 2010-04-14 | 2011-10-20 | Lubrizol Advanced Materials, Inc. | Thickened amino acid surfactant compositions and methods therefor |

| WO2011137218A1 (en) | 2010-04-29 | 2011-11-03 | Lubrizol Advanced Materials, Inc. | Cassia derivatives |

| WO2012006402A1 (en) | 2010-07-09 | 2012-01-12 | Lubrizol Advanced Materials, Inc. | Structured acrylate copolymer thickeners |

| WO2012030750A2 (en) | 2010-09-02 | 2012-03-08 | Lubrizol Advanced Materials, Inc. | Polymers and compositions |

| WO2012044929A2 (en) | 2010-09-30 | 2012-04-05 | Lubrizol Advanced Materials, Inc. | Structured acrylate copolymer for use in multi-phase systems |

| WO2012047957A1 (en) | 2010-10-05 | 2012-04-12 | Lubrizol Advanced Materials, Inc. | Acrylate copolymer thickeners |

| WO2012054107A1 (en) | 2010-07-09 | 2012-04-26 | Lubrizol Advanced Materials, Inc. | Blends of acrylic copolymer thickeners |

| WO2012170171A1 (en) | 2011-06-10 | 2012-12-13 | Lubrizol Advanced Materials, Inc. | Cassia derivatives |

| WO2013144871A1 (en) | 2012-03-27 | 2013-10-03 | L'oreal | Cosmetic process for caring for and/or making up keratin materials |

| WO2014167543A1 (en) | 2013-04-12 | 2014-10-16 | L'oreal | Gel-type cosmetic composition |

| US8895040B2 (en) | 2008-06-06 | 2014-11-25 | Lubrizol Advanced Materials, Inc. | Ester compounds for use in personal care products |

| WO2014204959A2 (en) | 2013-06-18 | 2014-12-24 | Lubrizol Advanced Materials, Inc. | Colloidally stable dispersions based on modified galactomannans |

| WO2015042013A1 (en) | 2013-09-18 | 2015-03-26 | Lubrizol Advanced Materials, Inc. | Stable linear polymers |

| WO2015069823A1 (en) | 2013-11-08 | 2015-05-14 | Lubrizol Advanced Materials, Inc. | Semi-permanent hair straightening composition and method |

| WO2015100122A1 (en) | 2013-12-23 | 2015-07-02 | Lubrizol Advanced Materials, Inc. | Suspension and stability agent for antidandruff hair care compositions |

| WO2016100466A1 (en) | 2014-12-18 | 2016-06-23 | Lubrizol Advanced Materials, Inc. | Amphiphilic suspension and stability agent for antidandruff hair care compositions |

| WO2016110475A1 (en) | 2015-01-05 | 2016-07-14 | L'oreal | Composition, in particular a cosmetic makeup and/or care composition, comprising a lipophilic clay, from 1% to 10% by weight of mica and at least one non-cyclic silicone oil |

| WO2017102507A1 (en) | 2015-12-17 | 2017-06-22 | L'oreal | Water-in-oil emulsion with moisturizing effect containing hydrophobic coated pigments and an aqueous phase at high content |

| WO2017112586A1 (en) | 2015-12-23 | 2017-06-29 | Lubrizol Advanced Materials, Inc. | Hydrophobically modified alkali-swellable emulsion polymers |

| WO2017112584A2 (en) | 2015-12-23 | 2017-06-29 | Lubrizol Advanced Materials, Inc. | Alkali-swellable emulsion polymers |

| WO2017220742A1 (en) | 2016-06-23 | 2017-12-28 | L'oreal | Composition comprising stabilized polymer particles, a hydrophobic film-forming polymer, an aqueous phase and a surfactant |

| WO2018114214A1 (en) | 2016-12-21 | 2018-06-28 | L'oreal | Water-in-oil emulsion comprising a particular emulsifying system, a lipophilic clay, and an organopolysiloxane elastomer powder coated with a silicone resin |

| WO2018114213A1 (en) | 2016-12-21 | 2018-06-28 | L'oreal | Water-in-oil emulsion containing baicalin, a xanthine base, a vitamin b3, and a polyvalent metal cation salt |

| WO2018228783A1 (en) | 2017-06-15 | 2018-12-20 | L'oreal | Water-in-oil emulsion based on non-thickening, non-interference fillers, on a nonvolatile oil, on a hydrophobic film-forming polymer, on and emulsifying silicone elastomer and on pigments |

| WO2019115289A1 (en) | 2017-12-15 | 2019-06-20 | L'oreal | Composition of gel/gel type based on pigments, at least one saturated linear c3-c8 dihydroxyalkane and salicylic acid in free form |

| WO2019200027A1 (en) | 2018-04-12 | 2019-10-17 | Lubrizol Advanced Materials, Inc. | Hair modification composition and method therefor |

| EP3578160A1 (en) | 2015-12-17 | 2019-12-11 | L'oreal | Composition of gel/gel type based on hydrophobic coated pigments and a glycol compound |

| FR3083116A1 (en) | 2018-07-02 | 2020-01-03 | L'oreal | COMPOSITION COMPRISING AN ESTER-TERMINATED POLYMER (ESTER-AMIDE), A VOLATILE ALKANE, A TACKIFYING RESIN AND AT LEAST ONE PIGMENT |

| WO2020007686A1 (en) | 2018-07-02 | 2020-01-09 | L'oreal | Fluid composition comprising an ester-terminated poly(ester-amide) polymer, a volatile alkane, a monoalcohol and at least one pigment |

| WO2020011540A1 (en) | 2018-07-12 | 2020-01-16 | L'oreal | Composition comprising a silicone/polyurea or silicone/polyurethane copolymer or silicone/polyurea/polyurethane copolymer, a silicone resin, a volatile alkane and a c2-c8 monoalcohol |

| FR3085272A1 (en) | 2018-09-03 | 2020-03-06 | L'oreal | POLYOL ANHYDROUS EMULSION IN SILICONE COMPRISING AT LEAST ONE HYDROPHOBIC COATED PIGMENT WITHOUT ALKYL DIMETHICONE COPOLYOL AND WITHOUT EMULSIFIER |

| FR3085273A1 (en) | 2018-09-03 | 2020-03-06 | L'oreal | POLYOL ANHYDROUS EMULSION IN SILICONE WITHOUT ALKYL DIMETHICONE COPOLYOL COMPRISING AN EMULSIZING SILICONE ELASTOMER AND AT LEAST ONE HYDROPHOBIC MODIFIED PIGMENT |

| FR3088201A1 (en) | 2018-11-13 | 2020-05-15 | L'oreal | COMPOSITION COMPRISING POLYMER PARTICLES, A VOLATILE HYDROCARBON OIL, A FILM-FORMING SILICONE VINYL POLYMER, A PHENYLATED SILICONE NON-VOLATILE OIL |

| FR3088205A1 (en) | 2018-11-13 | 2020-05-15 | L'oreal | KIT FOR MAKING EYEBROWS AND THEIR CONTOUR WITH TWO COMPOSITIONS; TWO-STEP MAKEUP PROCESS |

| FR3088207A1 (en) | 2018-11-13 | 2020-05-15 | L'oreal | KIT FOR MAKING EYEBROWS AND THEIR CONTOUR WITH TWO COMPOSITIONS; TWO-STEP MAKEUP PROCESS |

| FR3088208A1 (en) | 2018-11-13 | 2020-05-15 | L'oreal | KIT FOR MAKING EYEBROWS AND THEIR CONTOUR WITH TWO COMPOSITIONS; TWO-STEP COLORING PROCESS |

| FR3088206A1 (en) | 2018-11-13 | 2020-05-15 | L'oreal | KIT FOR MAKING EYEBROWS AND THEIR CONTOUR WITH TWO COMPOSITIONS; TWO-STEP MAKEUP PROCESS |

| FR3095758A1 (en) | 2019-05-06 | 2020-11-13 | L'oreal | Oil-in-oil emulsion with at least one hydrophobic coated metal oxide and at least two immiscible oils comprising a non-volatile polar hydrocarbon oil and a non-volatile silicone oil |

| FR3111556A1 (en) | 2020-06-18 | 2021-12-24 | L'oreal | Composition comprising polymer particles, a volatile hydrocarbon-based oil, a film-forming silicone vinyl polymer, a coconut oil |

| WO2022199974A1 (en) | 2021-03-26 | 2022-09-29 | L'oreal | Emulsion with neutralized water-soluble screening agent, nonvolatile nonphenylated silicone oil, film-forming polymer and linear polyoxyalkylenated polydimethylmethylsiloxane emulsifier |

| WO2022245758A1 (en) | 2021-05-17 | 2022-11-24 | Lubrizol Advanced Materials, Inc. | Hair color compositions for mitigating color loss |

| FR3126877A1 (en) | 2021-09-15 | 2023-03-17 | L'oreal | Care and/or makeup composition comprising a silicone elastomer containing carboxylic acid functions and a copolymer based on silicone resin and silicone of the dimethiconol type. |

| WO2023059784A1 (en) | 2021-10-06 | 2023-04-13 | Lubrizol Advanced Materials, Inc. | Stabilized rheology modifier emulsions |

| WO2023094277A1 (en) | 2021-11-26 | 2023-06-01 | L'oreal | Cosmetic water-in-oil emulsion comprising a specific water-soluble uv screening agent, a base, a volatile oil, a hydrophobic film-forming polymer, a polyoxyalkylenated linear polydimethylmethylsiloxane and a vitamin b3 |

| WO2023118430A1 (en) | 2021-12-23 | 2023-06-29 | L'oreal | Cosmetic composition comprising a natural resin |

| FR3135206A1 (en) | 2022-05-05 | 2023-11-10 | L'oreal | Cosmetic process using microneedle sheet |

| WO2024008772A1 (en) | 2022-07-05 | 2024-01-11 | L'oreal | Cosmetic composition comprising a natural resin |

| WO2024008771A1 (en) | 2022-07-05 | 2024-01-11 | L'oreal | Cosmetic composition comprising a natural resin |

| WO2024008769A1 (en) | 2022-07-05 | 2024-01-11 | L'oreal | Cosmetic composition comprising a natural resin |

| FR3139007A1 (en) | 2022-08-23 | 2024-03-01 | L'oreal | COMPOSITION SUITABLE FOR COSMETIC TREATMENTS OF KERATINOUS SUBSTANCE |

Families Citing this family (20)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB9216854D0 (en) * | 1992-08-07 | 1992-09-23 | Unilever Plc | Detergent composition |

| US5667772A (en) * | 1992-10-29 | 1997-09-16 | Lancaster Group Ag | Preparation containing a fluorocarbon emulsion and usable as cosmetics or dermatics |

| US5851544A (en) * | 1997-12-18 | 1998-12-22 | Chesebrough-Pond's Usa Co., Division Of Conopco, Inc. | Cosmetic skin or hair care compositions containing fluorocarbons infused with carbon dioxide |

| KR20040007097A (en) * | 2002-07-16 | 2004-01-24 | 주식회사 엘지생활건강 | Hair dye and post treatment composition |

| US7261744B2 (en) * | 2002-12-24 | 2007-08-28 | L'oreal S.A. | Method for dyeing or coloring human keratin materials with lightening effect using a composition comprising at least one fluorescent compound and at least one optical brightener |

| US7192454B2 (en) * | 2003-04-01 | 2007-03-20 | L'oreal S.A. | Composition for dyeing human keratin materials, comprising a fluorescent dye and a particular sequestering agent, process therefor and use thereof |

| US7208018B2 (en) * | 2003-04-01 | 2007-04-24 | L'oreal | Composition for dyeing human keratin materials, comprising at least one fluorescent dye and at least one associative polymer, process therefor and use thereof |

| US7303589B2 (en) | 2003-04-01 | 2007-12-04 | L'oreal S.A. | Process for dyeing human keratin fibers, having a lightening effect, comprising at least one fluorescent compound and compositions of the same |

| US7195650B2 (en) * | 2003-04-01 | 2007-03-27 | L'oreal S.A. | Process for dyeing, with a lightening effect, human keratin fibers that have been permanently reshaped, using at least one composition comprising at least one fluorescent dye |

| US7150764B2 (en) * | 2003-04-01 | 2006-12-19 | L'oreal S.A. | Composition for dyeing a human keratin material, comprising at least one fluorescent dye and at least one insoluble conditioning agent, process thereof, use thereof, and devices thereof |

| US7186278B2 (en) * | 2003-04-01 | 2007-03-06 | L'oreal S.A. | Composition for dyeing human keratin materials, comprising at least one fluorescent dye and at least one compound comprising an acid functional group and processes therefor |

| US7736631B2 (en) | 2003-04-01 | 2010-06-15 | L'oreal S.A. | Cosmetic dye composition with a lightening effect for human keratin materials, comprising at least one fluorescent dye and at least one aminosilicone, and process of dyeing |

| US7195651B2 (en) * | 2003-04-01 | 2007-03-27 | L'oreal S.A. | Cosmetic composition for dyeing human keratin materials, comprising at least one fluorescent dye and at least one cationic polymer, and a dyeing process therefor |

| US7204860B2 (en) * | 2003-04-01 | 2007-04-17 | L'oreal | Composition for dyeing human keratin materials, comprising at least one fluorescent dye and at least one polyol, process therefor and use thereof |

| US7147673B2 (en) | 2003-04-01 | 2006-12-12 | L'oreal S.A. | Composition for dyeing human keratin materials, comprising at least one fluorescent dye and at least one insoluble polyorganosiloxane conditioning polymer, process therefor and use thereof |

| US7250064B2 (en) * | 2003-04-01 | 2007-07-31 | L'oreal S.A. | Dye composition comprising at least one fluorescent dye and a non-associative thickening polymer for human keratin materials, process therefor, and method thereof |

| US8790623B2 (en) | 2005-01-18 | 2014-07-29 | Il'Oreal | Composition for treating keratin fibers, comprising at least one aromatic alcohol, at least one aromatic carboxylic acid, and at least one protecting agent |

| JP4819377B2 (en) * | 2005-03-10 | 2011-11-24 | 中野製薬株式会社 | Three-component hair cosmetic and hair treatment method |

| US7998464B2 (en) * | 2005-09-29 | 2011-08-16 | L'oreal S.A. | Process for the photoprotective treatment of artificially dyed keratin fibers by application of a liquid water/steam mixture |

| KR20210038437A (en) * | 2018-07-27 | 2021-04-07 | 가부시키가이샤 모레스코 | Hair protection agent, hair treatment agent and hair treatment method |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0360292A2 (en) * | 1988-09-23 | 1990-03-28 | AUSIMONT S.p.A. | Process for preparing cleansing emulsions for beauty treatment and cosmetic products obtained thereby |

Family Cites Families (21)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| NL6801885A (en) * | 1968-02-09 | 1968-04-25 | ||

| US3972998A (en) * | 1969-10-24 | 1976-08-03 | Lever Brothers Company | Hair preparation containing a fluoropolymer |

| US4184973A (en) * | 1973-06-25 | 1980-01-22 | The Harshaw Chemical Company | Hair grooming aid containing fibrillatable polytetrafluoroethylene resin |

| US4062939A (en) * | 1974-01-04 | 1977-12-13 | Widner College | Perfluorocarbon resins in a hair and scalp conditioning and cleansing composition |

| US4176176A (en) * | 1974-05-31 | 1979-11-27 | Alberto-Culver Company | Hair shampoo and cleanser compositions |

| US4013786A (en) * | 1974-05-31 | 1977-03-22 | Alberto Culver Company | Hair creme rinses and hair conditioners containing hydrophobic-lipophobic perfluorinated compounds |

| US4183367A (en) * | 1976-06-17 | 1980-01-15 | American Cyanamid Company | Enhancing the drying of hair by the use of fluorinated catonic and amphoteric surfactants |

| JPS55100308A (en) * | 1979-01-24 | 1980-07-31 | Daikin Ind Ltd | Hairdressing agent |

| FR2458564A1 (en) * | 1979-06-07 | 1981-01-02 | Oreal | NOVEL PERFLUOROUS SURFACTANT OLIGOMERS, PROCESS FOR THEIR PREPARATION AND COMPOSITIONS CONTAINING SAME |

| JPS6034730A (en) * | 1983-08-05 | 1985-02-22 | Nippon Mektron Ltd | Polyperfluoroether emulsion |

| EP0415462B1 (en) * | 1983-12-26 | 1996-05-08 | Daikin Industries, Limited | Halogen-containing polyether |

| IT1200385B (en) * | 1985-02-13 | 1989-01-18 | Montefluos Spa | OXETANIC STRUCTURE FLUIDS HAVING IMPROVED CHARACTERISTICS FOR SPECIAL APPLICATIONS |

| FR2579211B1 (en) * | 1985-03-20 | 1987-09-18 | Atochem | FLUORINATED COPOLYMERS AND THEIR APPLICATION TO HYDROPHOBIC AND OLEOPHOBIC TREATMENT OF VARIOUS SUBSTRATES |

| IT1183530B (en) * | 1985-03-29 | 1987-10-22 | Monteluos S P A | COMPOSITIONS FOR COSMETICS INCLUDING PERFLUOROPOLYETERS |

| US4765975A (en) * | 1986-03-04 | 1988-08-23 | The Gillette Company | Hair conditioning |

| JPH0747530B2 (en) * | 1986-10-27 | 1995-05-24 | 株式会社資生堂 | Hair cosmetics |

| US4895876A (en) * | 1987-03-20 | 1990-01-23 | Air Products And Chemicals, Inc. | Concentrated stable fluorochemical aqueous emulsions containing triglycerides |

| IT1229483B (en) * | 1988-08-26 | 1991-09-03 | Ausimont Spa | SYNDET SOAPS WITH IMPROVED PROPERTIES. |

| AU648100B2 (en) * | 1990-09-03 | 1994-04-14 | Unilever Plc | Hair treatment composition |

| US5160733A (en) * | 1991-05-06 | 1992-11-03 | Clairol Inc. | Conditioning compositions with perfluoropolymethylisopropylethers |

| DE4207589C1 (en) | 1992-03-10 | 1993-04-01 | Siemens Nixdorf Informationssysteme Ag, 4790 Paderborn, De |

-

1991

- 1991-08-29 AU AU83433/91A patent/AU648100B2/en not_active Expired

- 1991-08-29 CA CA002050212A patent/CA2050212C/en not_active Expired - Lifetime

- 1991-09-02 BR BR919103784A patent/BR9103784A/en not_active IP Right Cessation

- 1991-09-02 KR KR1019910015234A patent/KR970001641B1/en not_active IP Right Cessation

- 1991-09-03 US US07/753,510 patent/US5275808A/en not_active Expired - Lifetime

- 1991-09-03 EP EP91308065A patent/EP0486135B1/en not_active Expired - Lifetime

- 1991-09-03 ZA ZA916976A patent/ZA916976B/en unknown

- 1991-09-03 AT AT91308065T patent/ATE120950T1/en not_active IP Right Cessation

- 1991-09-03 DE DE69108854T patent/DE69108854T2/en not_active Expired - Lifetime

- 1991-09-03 JP JP3222933A patent/JPH04247014A/en active Pending

- 1991-09-03 ES ES91308065T patent/ES2071230T3/en not_active Expired - Lifetime

-

1993

- 1993-09-21 US US08/125,049 patent/US5451395A/en not_active Expired - Fee Related

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0360292A2 (en) * | 1988-09-23 | 1990-03-28 | AUSIMONT S.p.A. | Process for preparing cleansing emulsions for beauty treatment and cosmetic products obtained thereby |

Cited By (90)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5451395A (en) * | 1990-09-03 | 1995-09-19 | Chesebrough-Pond's Usa Co., Division Of Conopco, Inc. | Hair treatment composition |

| EP0512744A2 (en) * | 1991-05-03 | 1992-11-11 | Unilever Plc | Hair treatment composition containing a perfluoropolyether compound and a pearlescing agent |

| EP0512744A3 (en) * | 1991-05-03 | 1993-05-12 | Unilever Plc | Hair treatment composition containing a perfluoropolyether compound and a pearlescing agent |

| EP0560516A1 (en) * | 1992-03-02 | 1993-09-15 | Unilever Plc | Hair care composition |

| US5439673A (en) * | 1992-03-02 | 1995-08-08 | Chesebrough-Pond's Usa Co., Division Of Conopco, Inc. | Hair care composition |

| US6589519B1 (en) | 1997-08-25 | 2003-07-08 | L'oreal S.A. | Cosmetic compositions containing a polyoxyalkylenated aminosilicone block copolymer and a conditioner, and uses thereof |

| US6626962B1 (en) | 1998-01-13 | 2003-09-30 | L'oreal S.A. | Mixture for the oxidation tinting of keratin fibers containing a laccase and tinting method using said mixture |

| US6635262B2 (en) | 2000-03-14 | 2003-10-21 | L'oreal S.A. | Roll-on applicator comprising a hair composition |

| US7914775B2 (en) | 2000-11-20 | 2011-03-29 | L'oreal S.A. | Composition for treating keratinous materials comprising a cationic associative polyurethane polymer and a protecting or conditioning agent |

| US7759296B2 (en) | 2003-06-19 | 2010-07-20 | Lubrizol Advanced Materials, Inc. | Cationic polymers and fixative application therefor |

| EP1688127A1 (en) | 2005-01-18 | 2006-08-09 | L'oreal | Hair treatment composition containing an aromatic alcohol, an aromatic carboxylic acid a protecting agent |

| EP1997473A2 (en) | 2007-04-30 | 2008-12-03 | L'Oreal | Use of a multi-carbosite, multi-group coupling agent for protecting the colour of artificially dyed keratin fibres with respect to washing; dyeing processes |

| US8895040B2 (en) | 2008-06-06 | 2014-11-25 | Lubrizol Advanced Materials, Inc. | Ester compounds for use in personal care products |

| WO2010063954A2 (en) | 2008-12-02 | 2010-06-10 | L'oreal | Cosmetic method using a composition containing siloxane resins and a powder dye |

| WO2010063960A2 (en) | 2008-12-02 | 2010-06-10 | L'oreal | Cosmetic method using a composition containing siloxane resins and fillers |

| WO2010063964A2 (en) | 2008-12-02 | 2010-06-10 | L'oreal | Cosmetic composition for making-up and/or caring for keratin materials and make-up method |

| WO2010063962A2 (en) | 2008-12-02 | 2010-06-10 | L'oreal | Cosmetic method using a composition containing siloxane resins and a specific non-ionic silicone surfactant |

| WO2010063958A2 (en) | 2008-12-02 | 2010-06-10 | L'oreal | Cosmetic method using a composition containing siloxane resins and a volatile solvent |

| WO2010063955A2 (en) | 2008-12-02 | 2010-06-10 | L'oreal | Cosmetic method using a composition containing siloxane resins and a non-volatile oil |

| WO2010063965A2 (en) | 2008-12-02 | 2010-06-10 | L'oreal | Cosmetic composition for making-up and/or caring for keratin material and make-up method |

| WO2010124994A2 (en) | 2009-04-28 | 2010-11-04 | L'oreal | Coloured composition |

| EP2248508A2 (en) | 2009-04-30 | 2010-11-10 | L'Oréal | Wax-in-water emulsion including the combination of a glutamic acid derivative and an alkyl polyglycoside. |

| US9320920B2 (en) | 2009-04-30 | 2016-04-26 | L'oreal | Wax-in-water emulsion comprising a combination of a glutamic acid derivative and an alkylpolyglycoside |

| WO2011030308A1 (en) | 2009-09-11 | 2011-03-17 | L'oreal | Make-up and/or care method for keratinous material |

| EP2363110A1 (en) | 2009-09-15 | 2011-09-07 | L'Oréal | Use of drying oils for protecting the color of artificially colored keratin fibers against washing; method for coloring hair |

| WO2011051323A2 (en) | 2009-10-29 | 2011-05-05 | L'oreal | Makeup and/or care composition containing pigments coated with a fluoro compound and a vinyl polymer containing a carbosiloxane dendrimer-based unit |

| WO2011062805A1 (en) | 2009-11-23 | 2011-05-26 | Lubrizol Advanced Materials, Inc. | Surfactant-polymer blends |

| WO2011068820A1 (en) | 2009-12-01 | 2011-06-09 | Lubrizol Advanced Materials, Inc. | Hydrolytically stable multi-purpose polymers |

| WO2011081907A1 (en) | 2009-12-14 | 2011-07-07 | Lubrizol Advanced Materials, Inc. | Cassia derivatives |

| WO2011130460A1 (en) | 2010-04-14 | 2011-10-20 | Lubrizol Advanced Materials, Inc. | Thickened amino acid surfactant compositions and methods therefor |

| WO2011137218A1 (en) | 2010-04-29 | 2011-11-03 | Lubrizol Advanced Materials, Inc. | Cassia derivatives |

| WO2012006402A1 (en) | 2010-07-09 | 2012-01-12 | Lubrizol Advanced Materials, Inc. | Structured acrylate copolymer thickeners |

| WO2012054107A1 (en) | 2010-07-09 | 2012-04-26 | Lubrizol Advanced Materials, Inc. | Blends of acrylic copolymer thickeners |

| WO2012030750A2 (en) | 2010-09-02 | 2012-03-08 | Lubrizol Advanced Materials, Inc. | Polymers and compositions |

| WO2012031113A2 (en) | 2010-09-02 | 2012-03-08 | Lubrizol Advanced Materials, Inc. | Polymers and compositions |

| WO2012044929A2 (en) | 2010-09-30 | 2012-04-05 | Lubrizol Advanced Materials, Inc. | Structured acrylate copolymer for use in multi-phase systems |

| WO2012047957A1 (en) | 2010-10-05 | 2012-04-12 | Lubrizol Advanced Materials, Inc. | Acrylate copolymer thickeners |

| WO2012170171A1 (en) | 2011-06-10 | 2012-12-13 | Lubrizol Advanced Materials, Inc. | Cassia derivatives |

| WO2013144871A1 (en) | 2012-03-27 | 2013-10-03 | L'oreal | Cosmetic process for caring for and/or making up keratin materials |

| WO2014167543A1 (en) | 2013-04-12 | 2014-10-16 | L'oreal | Gel-type cosmetic composition |

| WO2014204959A2 (en) | 2013-06-18 | 2014-12-24 | Lubrizol Advanced Materials, Inc. | Colloidally stable dispersions based on modified galactomannans |

| WO2015042013A1 (en) | 2013-09-18 | 2015-03-26 | Lubrizol Advanced Materials, Inc. | Stable linear polymers |

| WO2015069823A1 (en) | 2013-11-08 | 2015-05-14 | Lubrizol Advanced Materials, Inc. | Semi-permanent hair straightening composition and method |

| WO2015100122A1 (en) | 2013-12-23 | 2015-07-02 | Lubrizol Advanced Materials, Inc. | Suspension and stability agent for antidandruff hair care compositions |

| WO2016100466A1 (en) | 2014-12-18 | 2016-06-23 | Lubrizol Advanced Materials, Inc. | Amphiphilic suspension and stability agent for antidandruff hair care compositions |

| WO2016110475A1 (en) | 2015-01-05 | 2016-07-14 | L'oreal | Composition, in particular a cosmetic makeup and/or care composition, comprising a lipophilic clay, from 1% to 10% by weight of mica and at least one non-cyclic silicone oil |

| EP3578160A1 (en) | 2015-12-17 | 2019-12-11 | L'oreal | Composition of gel/gel type based on hydrophobic coated pigments and a glycol compound |

| WO2017102507A1 (en) | 2015-12-17 | 2017-06-22 | L'oreal | Water-in-oil emulsion with moisturizing effect containing hydrophobic coated pigments and an aqueous phase at high content |

| WO2017112586A1 (en) | 2015-12-23 | 2017-06-29 | Lubrizol Advanced Materials, Inc. | Hydrophobically modified alkali-swellable emulsion polymers |

| WO2017112584A2 (en) | 2015-12-23 | 2017-06-29 | Lubrizol Advanced Materials, Inc. | Alkali-swellable emulsion polymers |

| WO2017220742A1 (en) | 2016-06-23 | 2017-12-28 | L'oreal | Composition comprising stabilized polymer particles, a hydrophobic film-forming polymer, an aqueous phase and a surfactant |

| WO2018114214A1 (en) | 2016-12-21 | 2018-06-28 | L'oreal | Water-in-oil emulsion comprising a particular emulsifying system, a lipophilic clay, and an organopolysiloxane elastomer powder coated with a silicone resin |

| WO2018114213A1 (en) | 2016-12-21 | 2018-06-28 | L'oreal | Water-in-oil emulsion containing baicalin, a xanthine base, a vitamin b3, and a polyvalent metal cation salt |

| WO2018228783A1 (en) | 2017-06-15 | 2018-12-20 | L'oreal | Water-in-oil emulsion based on non-thickening, non-interference fillers, on a nonvolatile oil, on a hydrophobic film-forming polymer, on and emulsifying silicone elastomer and on pigments |

| WO2019115289A1 (en) | 2017-12-15 | 2019-06-20 | L'oreal | Composition of gel/gel type based on pigments, at least one saturated linear c3-c8 dihydroxyalkane and salicylic acid in free form |

| WO2019200027A1 (en) | 2018-04-12 | 2019-10-17 | Lubrizol Advanced Materials, Inc. | Hair modification composition and method therefor |

| US11478412B2 (en) | 2018-04-12 | 2022-10-25 | Lubrizol Advanced Materials, Inc. | Hair modification composition and method therefor |

| FR3083116A1 (en) | 2018-07-02 | 2020-01-03 | L'oreal | COMPOSITION COMPRISING AN ESTER-TERMINATED POLYMER (ESTER-AMIDE), A VOLATILE ALKANE, A TACKIFYING RESIN AND AT LEAST ONE PIGMENT |

| WO2020007686A1 (en) | 2018-07-02 | 2020-01-09 | L'oreal | Fluid composition comprising an ester-terminated poly(ester-amide) polymer, a volatile alkane, a monoalcohol and at least one pigment |

| WO2020007687A1 (en) | 2018-07-02 | 2020-01-09 | L'oreal | Composition comprising an ester-terminated poly(ester-amide) polymer, a volatile alkane, a tackifying resin and at least one pigment |

| WO2020011540A1 (en) | 2018-07-12 | 2020-01-16 | L'oreal | Composition comprising a silicone/polyurea or silicone/polyurethane copolymer or silicone/polyurea/polyurethane copolymer, a silicone resin, a volatile alkane and a c2-c8 monoalcohol |

| FR3085272A1 (en) | 2018-09-03 | 2020-03-06 | L'oreal | POLYOL ANHYDROUS EMULSION IN SILICONE COMPRISING AT LEAST ONE HYDROPHOBIC COATED PIGMENT WITHOUT ALKYL DIMETHICONE COPOLYOL AND WITHOUT EMULSIFIER |

| FR3085273A1 (en) | 2018-09-03 | 2020-03-06 | L'oreal | POLYOL ANHYDROUS EMULSION IN SILICONE WITHOUT ALKYL DIMETHICONE COPOLYOL COMPRISING AN EMULSIZING SILICONE ELASTOMER AND AT LEAST ONE HYDROPHOBIC MODIFIED PIGMENT |

| WO2020099099A1 (en) | 2018-11-13 | 2020-05-22 | L'oreal | Two-composition kit for making up the eyebrows and their contour; two-step makeup process |

| FR3088207A1 (en) | 2018-11-13 | 2020-05-15 | L'oreal | KIT FOR MAKING EYEBROWS AND THEIR CONTOUR WITH TWO COMPOSITIONS; TWO-STEP MAKEUP PROCESS |

| FR3088208A1 (en) | 2018-11-13 | 2020-05-15 | L'oreal | KIT FOR MAKING EYEBROWS AND THEIR CONTOUR WITH TWO COMPOSITIONS; TWO-STEP COLORING PROCESS |

| FR3088206A1 (en) | 2018-11-13 | 2020-05-15 | L'oreal | KIT FOR MAKING EYEBROWS AND THEIR CONTOUR WITH TWO COMPOSITIONS; TWO-STEP MAKEUP PROCESS |

| FR3088205A1 (en) | 2018-11-13 | 2020-05-15 | L'oreal | KIT FOR MAKING EYEBROWS AND THEIR CONTOUR WITH TWO COMPOSITIONS; TWO-STEP MAKEUP PROCESS |

| WO2020099109A1 (en) | 2018-11-13 | 2020-05-22 | L'oreal | Two-composition kit for making up the eyebrows and their contour; two-step makeup process |

| FR3088201A1 (en) | 2018-11-13 | 2020-05-15 | L'oreal | COMPOSITION COMPRISING POLYMER PARTICLES, A VOLATILE HYDROCARBON OIL, A FILM-FORMING SILICONE VINYL POLYMER, A PHENYLATED SILICONE NON-VOLATILE OIL |

| FR3095758A1 (en) | 2019-05-06 | 2020-11-13 | L'oreal | Oil-in-oil emulsion with at least one hydrophobic coated metal oxide and at least two immiscible oils comprising a non-volatile polar hydrocarbon oil and a non-volatile silicone oil |

| FR3111556A1 (en) | 2020-06-18 | 2021-12-24 | L'oreal | Composition comprising polymer particles, a volatile hydrocarbon-based oil, a film-forming silicone vinyl polymer, a coconut oil |

| WO2022199974A1 (en) | 2021-03-26 | 2022-09-29 | L'oreal | Emulsion with neutralized water-soluble screening agent, nonvolatile nonphenylated silicone oil, film-forming polymer and linear polyoxyalkylenated polydimethylmethylsiloxane emulsifier |