EP0457750B1 - Internal combustion engine with cooling liquid - Google Patents

Internal combustion engine with cooling liquid Download PDFInfo

- Publication number

- EP0457750B1 EP0457750B1 EP91890092A EP91890092A EP0457750B1 EP 0457750 B1 EP0457750 B1 EP 0457750B1 EP 91890092 A EP91890092 A EP 91890092A EP 91890092 A EP91890092 A EP 91890092A EP 0457750 B1 EP0457750 B1 EP 0457750B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- dynamo

- cap

- internal combustion

- combustion engine

- cover

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02B—INTERNAL-COMBUSTION PISTON ENGINES; COMBUSTION ENGINES IN GENERAL

- F02B77/00—Component parts, details or accessories, not otherwise provided for

- F02B77/11—Thermal or acoustic insulation

- F02B77/13—Acoustic insulation

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02B—INTERNAL-COMBUSTION PISTON ENGINES; COMBUSTION ENGINES IN GENERAL

- F02B67/00—Engines characterised by the arrangement of auxiliary apparatus not being otherwise provided for, e.g. the apparatus having different functions; Driving auxiliary apparatus from engines, not otherwise provided for

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02B—INTERNAL-COMBUSTION PISTON ENGINES; COMBUSTION ENGINES IN GENERAL

- F02B75/00—Other engines

- F02B75/02—Engines characterised by their cycles, e.g. six-stroke

- F02B2075/022—Engines characterised by their cycles, e.g. six-stroke having less than six strokes per cycle

- F02B2075/025—Engines characterised by their cycles, e.g. six-stroke having less than six strokes per cycle two

Definitions

- the invention relates to a liquid-cooled internal combustion engine with a piston-controlled outlet, in particular a two-stroke internal combustion engine, which is equipped with an alternator or an alternator and a lubricating oil pump and in which the cylinder head has a cap which seals against it and forms the coolant space, avoiding metallic contact the cylinder extends approximately to the outlet and has a crank-side cap sealing surface.

- the invention is therefore based on the object of eliminating these deficiencies and reducing the vibration excitation by the frequency spectrum of the internal combustion engine to a minimum or largely preventing the transmission of structure-borne noise.

- the invention solves this problem in that both the lubricating oil pump and the alternator are provided with lids which, like the cap, are interposed with soft seals and avoid metallic contact on the crank or machine housing, the Have the cap and the cover for the lubricating oil pump tightened collar screws for their attachment, between whose head and the cap or the cover a washer with a vulcanized rubber layer is inserted.

- the cap and the cover for the lubricating oil pump are fastened with collar screws tightened to the stop, between the screw head and the cap or the cover the washers are inserted with a vulcanized rubber layer, so that on the one hand a reliable attachment of the cap or the achieved a lid and on the other hand metallic contact is avoided. Since these are collar screws, they can only be tightened to a certain extent, which prevents the soft seals from being pressed together too strongly. However, there is no metallic contact, because between the screw head and the cap or the cover, the washer is arranged. When adjusting the rubber hardness, care must of course be taken to ensure that the sealing function remains guaranteed.

- the cylinder 1 of a two-stroke internal combustion engine has overflow channels 2 for the fuel-air mixture and an outlet channel 3, the slots of these channels being controlled by the piston 4.

- the upper part of the cylinder 1 or the cylinder head 5 are water-cooled, the cylinder head 5 being a coolant chamber which is sealed off from it has forming cap 6, which extends approximately over the cylinder 1 to the outlet 3 and has a crank-side cap sealing surface 7.

- a soft seal 9 is provided between the cap sealing surface 7 and the engine or crankcase 8.

- collar screws 10 for fastening the cap 6 to the housing 8 are collar screws 10 (Fig.

- a washer 12 is inserted with vulcanized rubber layer 13, so that any metallic Contact between the cap 6 and the housing 8 or the fastening screw 10 is avoided.

- a thermostat is designated, which has no inventive significance.

- a cover 16 is also provided for the lubricating oil pump 15, which rests on the crankcase 8 via a soft seal 9 and has a maintenance opening 18 which can be closed by a further cover 17.

- the cover 16 is attached to the crankcase 8 in the manner shown in FIG. 2.

- the oil pump 15 is not attached to the cover 16, but on a support 20 held by arms 19 of the crankcase 8, so that the required distance of the oil pump drive gear 21 from the crankshaft 22 remains constant.

- the cover 23 for the alternator 24 terminates in a connection piece 25 with which the cover 23 in the cylindrical housing part 8a of the crankcase 8 for the alternator 24 with the interposition of O-rings 26 is inserted without screws.

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Acoustics & Sound (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Cylinder Crankcases Of Internal Combustion Engines (AREA)

- Lubrication Details And Ventilation Of Internal Combustion Engines (AREA)

- Lubrication Of Internal Combustion Engines (AREA)

- Gasket Seals (AREA)

Description

Die Erfindung betrifft eine flüssigkeitsgekühlte Brennkraftmaschine mit kolbengesteuertem Auslaß, insbesondere Zweitakt-Brennkraftmaschine, die mit einer Licht- bzw. Zündlichtmaschine sowie einer Schmierölpumpe ausgestattet ist und bei der der Zylinderkopf unter Vermeidung metallischer Berührung eine gegen ihn abgedichtete, den Kühlflüssigkeitsraum bildende Kappe besitzt, die über den Zylinder etwa bis zum Auslaß reicht und eine kurbelseitige Kappendichtfläche aufweist.The invention relates to a liquid-cooled internal combustion engine with a piston-controlled outlet, in particular a two-stroke internal combustion engine, which is equipped with an alternator or an alternator and a lubricating oil pump and in which the cylinder head has a cap which seals against it and forms the coolant space, avoiding metallic contact the cylinder extends approximately to the outlet and has a crank-side cap sealing surface.

Brennkraftmaschinen dieser Art sind bereits bekannt. Nach der DE-A-36 37 890 erübrigen sich nur teilweise Befestigungsschrauben für die Kappe am Zylinder, da ja die Kappe unter Überdruck stehendes Kühlmittel enthalt und dementsprechend gegen dieses Kühlmittel abdichten muß. Wesentlich ist aber, daß jegliche Maßnahmen zur Verhinderung der Schallabstrahlung von der Licht- bzw. Zuglichtmaschine und der Schmierölpumpe, die ja an der Brennkraftmaschine in der Regel unmittelbar angeordnet sind, fehlen, so daß die Schallabstrahlung von diesen Maschinenteilen überhaupt ungehindert erfolgt.Internal combustion engines of this type are already known. According to DE-A-36 37 890 there are only partially unnecessary fastening screws for the cap on the cylinder, since the cap contains coolant which is under pressure and must accordingly seal against this coolant. It is essential, however, that any measures to prevent the sound radiation from the alternator or alternator and the lubricating oil pump, which are usually arranged directly on the internal combustion engine, are missing, so that the sound radiation from these machine parts takes place unhindered.

Es ist zwar auch schon bekannt, Nebenaggregate, die benachbart an der Kurbelwelle vorgesehen sind, mit einem geräuschmindernden Deckel zu versehen (EP-A-304 553), der an dem Kurbelwellengehäuse oder dem Maschinengehäuse befestigt ist, jedoch erfolgt hier die Befestigung dieser Deckel mit Hilfe von einfachen Schrauben, so daß doch eine merkliche Schallabstrahlung durch die metallische Berührung der Schrauben und der sonstigen Teile erfolgt.Although it is also known to provide auxiliary units which are provided adjacent to the crankshaft with a noise-reducing cover (EP-A-304 553) which is fastened to the crankshaft housing or the machine housing, these covers are also fastened here With the help of simple screws, so that there is a noticeable sound radiation through the metallic contact of the screws and the other parts.

Der Erfindung liegt daher die Aufgabe zugrunde, diese Mängel zu beseitigen und die Schwingungsanregung durch das Frequenzsektrum der Brennkraftmaschine auf ein Mindestmaß herabzusetzen bzw. die Körperschallübertragung weitgehend zu unterbinden.The invention is therefore based on the object of eliminating these deficiencies and reducing the vibration excitation by the frequency spectrum of the internal combustion engine to a minimum or largely preventing the transmission of structure-borne noise.

Die Erfindung löst die gestellte Aufgabe dadurch, daß sowohl die Schmierölpumpe als auch die Licht- bzw. Zündlichtmaschine mit Deckeln versehen sind, die ebenso wie die Kappe unter Zwischenlage von Weichdichtungen und unter Vermeidung metallischer Berührung am Kurbel- bzw. Maschinengehäuse gehalten sind, wobei die Kappe und die Deckel für die Schmierölpumpe zu ihrer Befestigung auf Anschlag angezogene Bundschrauben besitzen, zwischen deren Kopf und der Kappe bzw. dem Deckel eine Beilagscheibe mit anvulkanisierter Gummischicht eingelegt ist.The invention solves this problem in that both the lubricating oil pump and the alternator are provided with lids which, like the cap, are interposed with soft seals and avoid metallic contact on the crank or machine housing, the Have the cap and the cover for the lubricating oil pump tightened collar screws for their attachment, between whose head and the cap or the cover a washer with a vulcanized rubber layer is inserted.

Es sind also nicht nur die Kappe, sondern auch die beiden Gehäusedeckel vom Kurbel- bzw. Maschinengehäuse akkustisch entkoppelt, so daß keine Körperschallübertragung vom Gehäuse auf die Kappe bzw. die Deckel erfolgen kann und von diesen Kapselteilen auch keine Schallabstrahlung zu befürchten ist. Dazu kommt noch, daß die Kappe und der Deckel für die Schmierölpumpe mit auf Anschlag angezogenen Bundschrauben befestigt sind, zwischen deren Schraubenkopf und der Kappe bzw. dem Deckel die Beilagscheiben mit anvulkanisierter Gummischicht eingelegt sind, so daß einerseits eine verläßliche Befestigung der Kappe bzw. des einen Deckels erzielt und anderseits auch eine metallische Berührung vermieden wird. Da es sich um Bundschrauben handelt, können diese nur bis zu einem gewissen Maß angezogen werden, wodurch ein zu starkes Zusammenpressen der Weichdichtungen vermieden wird. Dennoch tritt keine metallische Berührung auf, weil jeweils zwischen dem Schraubenkopf und der Kappe bzw. dem Deckel die Beilagscheibe angeordnet ist. Bei der Abstimmung der Gummihärte muß selbstverständlich darauf geachtet werden, daß die Dichtfunktion gewährleistet bleibt.So it is not only the cap, but also the two housing covers that are acoustically decoupled from the crank or machine housing, so that structure-borne noise cannot be transmitted from the housing to the cap or cover, and no noise radiation is to be feared from these capsule parts. In addition, the cap and the cover for the lubricating oil pump are fastened with collar screws tightened to the stop, between the screw head and the cap or the cover the washers are inserted with a vulcanized rubber layer, so that on the one hand a reliable attachment of the cap or the achieved a lid and on the other hand metallic contact is avoided. Since these are collar screws, they can only be tightened to a certain extent, which prevents the soft seals from being pressed together too strongly. However, there is no metallic contact, because between the screw head and the cap or the cover, the washer is arranged. When adjusting the rubber hardness, care must of course be taken to ensure that the sealing function remains guaranteed.

Für die Halterung der Licht- bzw. Zündlichtmaschine wird eine besonders günstige Konstruktion dadurch erreicht, daß der Deckel für diese Maschine in einen Stutzen ausläuft, mit dem er in dem zylindrischen Gehäuseteilen für die Licht- bzw. Zündlichtmaschine unter Zwischenlage von O-Ringen schraubenlos eingesteckt ist. Diese Ausbildung verbindet einen festen Sitz, eine einwandfreie akkustische Entkoppelung und güsntige Herstellungskosten miteinander.For the mounting of the alternator or alternator, a particularly favorable construction is achieved in that the cover for this machine ends in a socket with which it is inserted without screws in the cylindrical housing parts for the alternator or alternator with the interposition of O-rings is. This training combines a tight fit, a perfect acoustic decoupling and reasonable production costs.

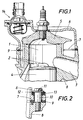

In der Zeichnung ist der Erfindungsgegenstand beispielsweise dargestellt, und zwar zeigen

- Fig. 1 den Oberteil einer flüssigkeitsgekühlten Brennkraftmaschine im Schnitt durch die Zylinderachse,

- Fig. 2 eine Schraubbefestigung als Einzelheit im größeren Maßstab,

- Fig. 3 die Kapselung der Ölpumpe im Schnitt durch die Kurbelwellenachse im größeren Maßstab und

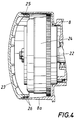

- Fig. 4 die Abdeckung der Licht- bzw. Zündlichtmaschine im Teilschnitt.

- 1 shows the upper part of a liquid-cooled internal combustion engine in section through the cylinder axis,

- 2 a screw fastening as a detail on a larger scale,

- Fig. 3 shows the encapsulation of the oil pump in section through the crankshaft axis on a larger scale and

- Fig. 4 shows the cover of the alternator or pilot light in partial section.

Der Zylinder 1 einer Zweitakt-Brennkraftmaschine weist Überströmkanäle 2 für das Kraftstoff-Luftgemisch und einen Auslaßkanal 3 auf, wobei die Schlitze dieser Kanäle durch den Kolben 4 gesteuert werden. Der obere Teil des Zylinders 1 bzw. der Zylinderkopf 5 sind wassergekühlt, wobei der Zylinderkopf 5 eine gegen ihn abgedichtete, den Kühlflüssigkeitsraum bildende Kappe 6 besitzt, die über den Zylinder 1 etwa bis zum Auslaß 3 reicht und eine kurbelseitige Kappendichtfläche 7 aufweist. Zwischen der Kappendichtfläche 7 und dem Maschinen- bzw. Kurbelgehäuse 8 ist eine Weichdichtung 9 vorgesehen. Zur Befestigung der Kappe 6 am Gehäuse 8 dienen Bundschrauben 10 (Fig. 2), die auf Anschlag angezogen sind und zwischen deren Kopf 11 und der Kappe 6 bzw. dem Kappenflansch jeweils eine Beilagscheibe 12 mit anvulkanisierter Gummischicht 13 eingelegt ist, so daß jegliche metallische Berührung zwischen der Kappe 6 und dem Gehäuse 8 bzw. der Befestigungsschraube 10 vermieden ist. Mit 14 ist ein Thermostat bezeichnet, der keinerlei erfinderische Bedeutung hat.The

Aus Fig. 3 ergibt sich, daß für die Schmierölpumpe 15 ebenfalls ein Deckel 16 vorgesehen ist, der am Kurbelgehäuse 8 über eine Weichdichtung 9 anliegt und eine durch einen weiteren Deckel 17 verschließbare Wartungsöffnung 18 aufweist. Die Befestigung des Deckels 16 am Kurbelgehäuse 8 erfolgt in der in Fig. 2 dargestellten Weise. Die Ölpumpe 15 ist nicht am Deckel 16 befestigt, sondern auf einem von Auslegern 19 des Kurbelgehäuses 8 gehaltenen Träger 20, so daß der erforderliche Abstand des Ölpumpen-Antriebszahnrades 21 von der Kurbelwelle 22 konstant bleibt.From Fig. 3 it follows that a

Gemäß Fig. 4 läuft der Deckel 23 für die Licht- bzw. Zündlichtmaschine 24 in einen Stutzen 25 aus, mit dem der Deckel 23 in dem zylindrischen Gehäuseteil 8a des Kurbelgehäuses 8 für die Licht- bzw.Zündlichtmaschine 24 unter Zwischenlage von O-Ringen 26 schraubenlos eingesteckt ist.4, the

Claims (2)

- A liquid-cooled internal combustion engine having a piston-controlled exhaust, more particularly a two-stroke internal combustion engine equipped with a dynamo or magneto dynamo (24) and a lubricating oil pump (15) and in which the cylinder head (5) has without metal contact a cap (6) which is sealed off from the cylinder head, forms the cooling liquid chamber, extends over the cylinder (1) approximately as far as the exhaust (3) and has a cap sealing surface (7) on the crank side, characterised in that both the lubricating oil pump (15) and the dynamo or magneto dynamo (24) are provided with covers (16, 17; 23) which, like the cap (6) at its sealing surface (7), are held on the crank case or engine housing (8; 8a) with the interposition of soft gaskets (9; 26) and with the avoidance of metal contact, the cap (6) and the cover (16, 17) for the lubricating oil pump (15) having, for their fixing, collar screws (10) which are tightened to abutment and between whose head (11) and the cap (6) and cover (16) respectively there is inserted a washer (12) having a rubber layer (13) vulcanised thereon.

- An internal combustion engine according to claim 1, characterised in that the cover (23) for the dynamo or magneto dynamo (24) terminates in a flange (25) by means of which it is inserted without screws and with the interposition of O-rings (26) into the cylindrical housing part (8a) for the dynamo or magneto dynamo (24).

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT0108690A ATA108690A (en) | 1990-05-16 | 1990-05-16 | LIQUID-COOLED INTERNAL COMBUSTION ENGINE |

| AT1086/90 | 1990-05-16 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0457750A1 EP0457750A1 (en) | 1991-11-21 |

| EP0457750B1 true EP0457750B1 (en) | 1993-12-15 |

Family

ID=3506285

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP91890092A Expired - Lifetime EP0457750B1 (en) | 1990-05-16 | 1991-04-29 | Internal combustion engine with cooling liquid |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US5241934A (en) |

| EP (1) | EP0457750B1 (en) |

| JP (1) | JPH04228862A (en) |

| AT (1) | ATA108690A (en) |

| DE (1) | DE59100715D1 (en) |

| ES (1) | ES2048005T3 (en) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6491014B1 (en) * | 2000-08-30 | 2002-12-10 | Keith Eickert | Valve cover assembly for internal combustion engine |

| JP3943972B2 (en) * | 2002-03-19 | 2007-07-11 | 本田技研工業株式会社 | Engine casing |

| JP6055505B2 (en) * | 2015-03-31 | 2016-12-27 | 富士重工業株式会社 | engine |

Family Cites Families (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| AT121814B (en) * | 1928-11-06 | 1931-03-10 | Climax Motorenwerke Und Schiff | Multi-cylinder internal combustion engine. |

| US3926157A (en) * | 1973-10-12 | 1975-12-16 | Bombardier Ltd | Two-cycle engine with inlet porting by rotary valve |

| GB1582148A (en) * | 1976-05-12 | 1980-12-31 | Deere & Co | Vibration isolation assembly |

| US4066058A (en) * | 1976-05-12 | 1978-01-03 | Deere & Company | Vibration isolation system |

| AT387624B (en) * | 1981-03-31 | 1989-02-27 | Steyr Daimler Puch Ag | PISTON PISTON ENGINE |

| DE3519205A1 (en) * | 1985-05-29 | 1986-12-04 | Dr.Ing.H.C. F. Porsche Ag, 7000 Stuttgart | ATTACHING A COVER TO A CYLINDER HEAD |

| DE3637890A1 (en) * | 1985-11-06 | 1987-05-14 | Steyr Daimler Puch Ag | Liquid-cooled internal combustion engine with piston-controlled exhaust, especially two-stroke internal combustion engine |

| US4667628A (en) * | 1986-03-06 | 1987-05-26 | General Motors Corporation | Oil pan isolation mounting and seal |

| US4719892A (en) * | 1986-06-26 | 1988-01-19 | General Motors Corporation | Cavity closure with isolator seal and method |

-

1990

- 1990-05-16 AT AT0108690A patent/ATA108690A/en not_active IP Right Cessation

-

1991

- 1991-04-29 ES ES91890092T patent/ES2048005T3/en not_active Expired - Lifetime

- 1991-04-29 DE DE91890092T patent/DE59100715D1/en not_active Expired - Fee Related

- 1991-04-29 EP EP91890092A patent/EP0457750B1/en not_active Expired - Lifetime

- 1991-05-10 JP JP3199767A patent/JPH04228862A/en active Pending

- 1991-05-10 US US07/698,459 patent/US5241934A/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| DE59100715D1 (en) | 1994-01-27 |

| ATA108690A (en) | 1994-12-15 |

| ES2048005T3 (en) | 1994-03-01 |

| EP0457750A1 (en) | 1991-11-21 |

| US5241934A (en) | 1993-09-07 |

| JPH04228862A (en) | 1992-08-18 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE1914162C3 (en) | Air-cooled single cylinder internal combustion engine | |

| DE1301655C2 (en) | Internal combustion engine with fluid-cooled cylinder liners | |

| DE1220202B (en) | Arrangement of cylinder liners, in particular wet cylinder liners in internal combustion engines | |

| EP0695866A1 (en) | Cylinder block for an internal combustion engine with a water jacket made of aluminium | |

| DE2801431A1 (en) | Piston engine fitter in outer trough - has centring damper rings at ends of cylinder block coaxial to crankshaft | |

| EP0457750B1 (en) | Internal combustion engine with cooling liquid | |

| DE2920081A1 (en) | INTERNAL COMBUSTION ENGINE | |

| DE2143734B2 (en) | Internal combustion engine with an intermediate pipe inserted into the passage for the cooling water between the cylinder head and the crankcase | |

| DE4242265C1 (en) | Valve cover | |

| EP0062030A1 (en) | Reciprocating piston internal-combustion engine | |

| DE7534073U (en) | CYLINDER HEAD FOR A COMBUSTION MACHINE WITH COMPRESSION IGNITION | |

| DE3439534C2 (en) | Vibrating rammer | |

| DE2917339A1 (en) | STEERING WHEEL BOX FOR INTERNAL COMBUSTION ENGINES | |

| DE19732422C2 (en) | Chain cover for an internal combustion engine | |

| DE720953C (en) | Crankshaft seal for internal combustion engines | |

| AT347185B (en) | WHEEL BOX FOR COMBUSTION MACHINERY | |

| DE3335983C2 (en) | Internal combustion engine | |

| AT393541B (en) | INJECTION ENGINE | |

| DE3229561A1 (en) | INTERNAL COMBUSTION ENGINE | |

| DE3637890A1 (en) | Liquid-cooled internal combustion engine with piston-controlled exhaust, especially two-stroke internal combustion engine | |

| DE2908735A1 (en) | Liquid-cooled engine cylinder block - has housings or sheet metal sections forming part of external walls | |

| DE4039190C1 (en) | Crankcase gasket for vehicle IC engine - has shaped seal to fit around flanges on cylinder block and bump | |

| DE4401486A1 (en) | Housing cover | |

| AT394759B (en) | INTERNAL COMBUSTION ENGINE WITH LIQUID COOLING | |

| DE3105738A1 (en) | "DEVICE FOR SETTING THE DELIVERY START OF AN INJECTION PUMP FOR INTERNAL COMBUSTION ENGINES" |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): CH DE ES FR GB IT LI SE |

|

| 17P | Request for examination filed |

Effective date: 19911021 |

|

| 17Q | First examination report despatched |

Effective date: 19930115 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): CH DE ES FR GB IT LI SE |

|

| REF | Corresponds to: |

Ref document number: 59100715 Country of ref document: DE Date of ref document: 19940127 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 19940222 Year of fee payment: 4 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 19940126 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2048005 Country of ref document: ES Kind code of ref document: T3 |

|

| ITF | It: translation for a ep patent filed |

Owner name: UFFICIO TECNICO ING. A. MANNUCCI |

|

| ET | Fr: translation filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 19940321 Year of fee payment: 4 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19940324 Year of fee payment: 4 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19940330 Year of fee payment: 4 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 19940422 Year of fee payment: 4 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| EAL | Se: european patent in force in sweden |

Ref document number: 91890092.9 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19950429 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19950430 Ref country code: LI Effective date: 19950430 Ref country code: CH Effective date: 19950430 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19950503 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19951229 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19950429 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19960103 |

|

| EUG | Se: european patent has lapsed |

Ref document number: 91890092.9 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20010503 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050429 |