EP0403813B1 - Method and apparatus for the dosed filling of liquid and pasty products, especially of foodstuffs or the like - Google Patents

Method and apparatus for the dosed filling of liquid and pasty products, especially of foodstuffs or the like Download PDFInfo

- Publication number

- EP0403813B1 EP0403813B1 EP90109756A EP90109756A EP0403813B1 EP 0403813 B1 EP0403813 B1 EP 0403813B1 EP 90109756 A EP90109756 A EP 90109756A EP 90109756 A EP90109756 A EP 90109756A EP 0403813 B1 EP0403813 B1 EP 0403813B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- metering

- piston

- product

- metering piston

- suction

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01F—MEASURING VOLUME, VOLUME FLOW, MASS FLOW OR LIQUID LEVEL; METERING BY VOLUME

- G01F11/00—Apparatus requiring external operation adapted at each repeated and identical operation to measure and separate a predetermined volume of fluid or fluent solid material from a supply or container, without regard to weight, and to deliver it

- G01F11/02—Apparatus requiring external operation adapted at each repeated and identical operation to measure and separate a predetermined volume of fluid or fluent solid material from a supply or container, without regard to weight, and to deliver it with measuring chambers which expand or contract during measurement

- G01F11/021—Apparatus requiring external operation adapted at each repeated and identical operation to measure and separate a predetermined volume of fluid or fluent solid material from a supply or container, without regard to weight, and to deliver it with measuring chambers which expand or contract during measurement of the piston type

- G01F11/023—Apparatus requiring external operation adapted at each repeated and identical operation to measure and separate a predetermined volume of fluid or fluent solid material from a supply or container, without regard to weight, and to deliver it with measuring chambers which expand or contract during measurement of the piston type with provision for varying the stroke of the piston

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B3/00—Packaging plastic material, semiliquids, liquids or mixed solids and liquids, in individual containers or receptacles, e.g. bags, sacks, boxes, cartons, cans, or jars

- B65B3/26—Methods or devices for controlling the quantity of the material fed or filled

- B65B3/30—Methods or devices for controlling the quantity of the material fed or filled by volumetric measurement

- B65B3/32—Methods or devices for controlling the quantity of the material fed or filled by volumetric measurement by pistons co-operating with measuring chambers

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01F—MEASURING VOLUME, VOLUME FLOW, MASS FLOW OR LIQUID LEVEL; METERING BY VOLUME

- G01F11/00—Apparatus requiring external operation adapted at each repeated and identical operation to measure and separate a predetermined volume of fluid or fluent solid material from a supply or container, without regard to weight, and to deliver it

- G01F11/02—Apparatus requiring external operation adapted at each repeated and identical operation to measure and separate a predetermined volume of fluid or fluent solid material from a supply or container, without regard to weight, and to deliver it with measuring chambers which expand or contract during measurement

- G01F11/021—Apparatus requiring external operation adapted at each repeated and identical operation to measure and separate a predetermined volume of fluid or fluent solid material from a supply or container, without regard to weight, and to deliver it with measuring chambers which expand or contract during measurement of the piston type

Definitions

- the invention relates first of all to a method for the metered filling of liquid and pasty products, in particular foodstuffs or the like, with an adjustable shut-off device which controls the product inlet and outlet and a metering piston which is mounted to move back and forth between a suction position and ejection position in a metering housing, a dose chamber located on the front side of the metering piston being constantly connected to the product inlet during suction via the shut-off device and a dose chamber lying on the rear side of the metering piston.

- the device shown there is intended for volumetric metering of pasty substances.

- the known device works in such a way that the paste to be filled is sucked on the piston side, ie with its larger piston surface, through the metering chamber, which is connected to the product inlet via the shut-off device, by the metering piston during its upward stroke.

- the shut-off element separates the product inlet from the aforementioned dosing chamber and connects the latter to the product outlet by correspondingly adjusting the control piston of the shut-off element.

- the metering piston When the metering piston moves downwards, it pushes the quantity of product to be filled into the filling container via the product outlet. As soon as the dosing piston has reached its bottom dead center position, the shut-off element is adjusted via the control piston connected to it in such a way that the product outlet is separated from the dosing chamber and the latter is in turn connected to the product inlet. The metering piston then moves upward again in order to suck in product from the product feed.

- the invention has for its object to propose a method suitable for the metered filling of liquid and pasty products, in particular foods or the like.

- a secure exchange of the product is ensured in all can spaces, so that no outdated or segregated and possibly reinfected product is discharged in an uncontrolled manner.

- the invention is also based on the object of creating a suitable device for carrying out the method, which is characterized by a particularly simple construction.

- the object on which the invention is based is initially achieved in that the stroke range or the lower and upper dead center of the metering piston is shifted without changing the metering stroke during the suction of the product.

- the idea on which the invention is based is therefore that of moving the bottom and top dead center while the product is being sucked in without the metering stroke being changed.

- the displacement of the stroke range or the bottom and top dead center of the metering piston can be carried out step by step or step by step or also continuously.

- a device suitable for carrying out the method according to the invention for the metered filling of liquid and pasty products, in particular foodstuffs, with an adjustable shut-off device which controls the product inlet and outlet and a metering piston which is mounted so as to be movable back and forth between a suction position and ejection position in a metering housing, is characterized by an adjusting device axial displacement of the unchanged stroke distance of the dosing piston during the suction phase of the dosing device.

- any drive or adjustment device is conceivable that is capable of shifting the stroke range of the stroke range according to the desired time or continuously Dosing piston.

- commercially available electromotively driven, time-controlled push spindle drives are suitable as the adjustment device.

- the drive for the adjustment device can also be tapped from the dosing drive or by other separate drives, such as. B. hydraulic and pneumatic cylinder-piston units. It is also conceivable that the adjustment bearing according to the invention of the stroke range of the metering piston z. B. to run fully automatically by means of a programmed memory controller.

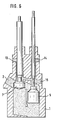

- the metering device has a metering housing 1 with a product inlet 2 and a product outlet 3.

- the product inlet 2 and the product outlet 3 are controlled by a shut-off device 4, which in the exemplary embodiment shown consists of a rotatable valve body 5 and a valve rod 6 , which can be rotated by a drive, not shown, so that the valve body 5 can be brought into a position that closes the product outlet 3, as shown in FIG. 1, and on the other hand can be moved into an open position, as is shown in FIGS 4 and 5 is shown.

- a metering piston 7 is slidably mounted, which is shown schematically by means of a piston rod 8 in FIG adjusting device 9 is connected.

- a front dose chamber 11 and a rear dose chamber 12 are formed by the metering piston 7 in the metering cylinder 6. While the front dose space 11 is only connected to the product inlet when the valve body 5 is in the appropriate position (FIG. 1), the rear dose space 12 is in constant communication with the product inlet 2.

- metering piston 7 is shown in its lowest position with solid lines.

- the normal stroke range of the metering piston 7 in the metering cylinder 6 is designated by I, the top dead center position of the metering piston 7 being indicated in dash-dotted lines.

- the metering piston 7 can be displaced in its entire stroke range during the product suction, e.g. B. in the stroke range designated II.

- the new dead center positions of the metering piston 7 are drawn with dashed lines.

- the metering piston 7 can move between the normal stroke range I and the new stroke range II either stepwise or step by step or also continuously during the suction phase, with the result that the dose spaces 11 and 12 with the metering piston 7 so that the product is exchanged well. In this way, in particular in the rear dose space 12, it is avoided that outdated or segregated product can arise.

- the displacement of the stroke range of the metering piston after certain intervals, for. B. be performed after every third suction stroke.

- the shift can take place continuously, for. B. in such a way that starting from the normal bottom dead center, the metering piston is shifted to the new top dead center. The dosing piston is then adjusted from this position to the new bottom dead center. Then the dosing piston is sucked up to the old upper one Dead center and finally the ejection movement to the old bottom dead center.

- the metering piston can also be moved continuously between the above-mentioned extreme dead centers, but the stroke range always remains the same. Regardless of this, as is known, top dead center can of course be shifted in order to change the output volume as required.

- the dosing device works as follows:

- the metering piston 7 is in its lowest position.

- the shut-off element 4 is in its position with its valve body 5 such that the product outlet 3 is closed, whereas the product inlet 2 is connected to the front dose space 11 via the shut-off element 4.

- the metering piston 7 is then, starting from FIG. 2, moved into the position according to FIG. 3, which shows the end of the suction stroke.

- valve body 5 is rotated via the valve rod 6 so that the connection between the product inlet and the front dose space 11 is blocked by the valve body 5 and at the same time the latter comes into connection with the product outlet 3, as shown in FIG. 4.

- the metering piston 7 is now at the beginning of the ejection position. As can be seen from FIG. 5, the metering piston 7 is moved downward and the product is expelled from the outlet opening 3 into a container (not shown).

- the metering device can be brought into the cleaning position shown in FIG. 6, in which both the metering piston 7 and the valve body 5 have been moved upwards.

- Cleaning liquid can be introduced into the dosing device via the product inlet 2 and additional inlet openings 13, 14 and 15, so that all parts of the metering device are thoroughly washed.

- a push spindle drive does not necessarily have to be provided as the adjusting device, but the adjustment or displacement of the stroke range of the metering piston can also be achieved by an adjusting device, the drive of which is tapped off directly by the dosing drive or by other separate drives, such as, for. B. hydraulic or pneumatic cylinders with a suitable control valve device. It is only important that the stroke range of the metering piston during the suction of the product at certain intervals, for. B. after every fifth suction process or continuously, i.e. is shifted in the dosing cylinder with every suction stroke, so that a secure exchange of the product is achieved in all dosing rooms.

Description

Die Erfindung bezieht sich zunächst auf ein Verfahren zum dosierten Abfüllen von flüssigen und pastösen Produkten, insbesondere Nahrungsmitteln oder dgl., mit einem den Produktzulauf und Produktablauf steuernden, verstellbaren Absperrorgan und einem zwischen einer Ansaugstellung und Ausstoßstellung in einem Dosiergehäuse hin- und herbeweglich gelagerten Dosierkolben, wobei ein auf der Vorderseite des Dosierkolbens liegender Doseurraum während des Ansaugens über das Absperrorgan und ein auf der Rückseite des Dosierkolbens liegender Doseurraum ständig mit dem Produktzulauf in Verbindung steht.The invention relates first of all to a method for the metered filling of liquid and pasty products, in particular foodstuffs or the like, with an adjustable shut-off device which controls the product inlet and outlet and a metering piston which is mounted to move back and forth between a suction position and ejection position in a metering housing, a dose chamber located on the front side of the metering piston being constantly connected to the product inlet during suction via the shut-off device and a dose chamber lying on the rear side of the metering piston.

Ein Verfahren der eingangs genannten Art geht aus der deutschen Patentschrift 29 00 851 hervor. Die dort dargestellte Vorrichtung ist zur volumetrischen Dosierung pastöser Stoffe vorgesehen. Die bekannte Vorrichtung arbeitet in der Weise, daß durch den Dosierkolben bei seinem Aufwärtshub die abzufüllende Paste kolbenseitig, d.h. mit seiner größeren Kolbenfläche über den Doseurraum angesaugt wird, der über das Absperrorgan mit dem Produktzulauf verbunden ist. Sobald der Dosierkolben seinen oberen Totpunkt erreicht hat, wird durch das Absperrorgan der Produktzulauf vom vorgenannten Doseurraum getrennt und letzterer durch entsprechende Verstellung des Steuerkolbens des Absperrorgans mit dem Produktablauf verbunden. Bei dem nun folgenden Abwärtsbewegen des Dosierkolbens stößt dieser die abzufüllende Produktmenge über den Produktablauf in den Abfüllbehälter. Sobald der Dosierkolben seine untere Totpunktstellung erreicht hat, wird das Absperrorgan über den damit verbundenen Steuerkolben derart verstellt, daß der Produktablauf vom Doseurraum getrennt wird und letzterer wiederum mit dem Produktzulauf in Verbindung gebracht wird. Daraufhin erfolgt ein erneuter Aufwärtsgang des Dosierkolbens, um wiederum Produkt aus dem Produktzulauf anzusaugen.A method of the type mentioned at the outset is evident from the German patent specification 29 00 851. The device shown there is intended for volumetric metering of pasty substances. The known device works in such a way that the paste to be filled is sucked on the piston side, ie with its larger piston surface, through the metering chamber, which is connected to the product inlet via the shut-off device, by the metering piston during its upward stroke. As soon as the dosing piston is has reached top dead center, the shut-off element separates the product inlet from the aforementioned dosing chamber and connects the latter to the product outlet by correspondingly adjusting the control piston of the shut-off element. When the metering piston moves downwards, it pushes the quantity of product to be filled into the filling container via the product outlet. As soon as the dosing piston has reached its bottom dead center position, the shut-off element is adjusted via the control piston connected to it in such a way that the product outlet is separated from the dosing chamber and the latter is in turn connected to the product inlet. The metering piston then moves upward again in order to suck in product from the product feed.

Obwohl sich Vorrichtungen der vorgenannten Art bzw. nach dem eingangs erläuterten Verfahren betriebene Doseure an sich in der Praxis gut bewährt haben, gibt es dann Probleme, wenn keimarme Produkte abgefüllt werden sollen. Das ist deshalb der Fall, weil der auf der rückwärtigen Seite des Dosierkolbens liegende Doseurraum ständig mit Produkt gefüllt ist und es hier durchaus zu einer Reinfektion aus dem Produktionsprozeß kommen kann, sofern nicht ein ständiger gesicherter Austausch des Produktes gewährleistet ist. Auch beim Abfüllen von Produkten, die entweder zur Entmischung oder zum Festsetzen in den Zuleitungen neigen, kann es Schwierigkeiten geben, die insbesondere aufgrund der diskontinuierlichen Betriebsweise der bekannten Vorrichtung auftreten, wenn der Dosierkolben während seiner Abwärtsbewegung das Produkt ausstößt.Although devices of the aforementioned type or doses operated according to the method explained at the beginning have proven themselves in practice, there are problems when low-germ products are to be filled. This is because the dosing space on the rear side of the dosing piston is constantly filled with product and reinfection from the production process can certainly occur, unless a constant, secure replacement of the product is guaranteed. Even when filling products which tend to either separate or become stuck in the feed lines, there can be difficulties which arise in particular due to the discontinuous operation of the known device when the metering piston expels the product during its downward movement.

Der Erfindung liegt die Aufgabe zugrunde, ein zum dosierten Abfüllen von flüssigen und pastösen Produkten, insbesondere Nahrungsmitteln oder dgl. geeignetes Verfahren vorzuschlagen, durch das mit besonders einfachen Mitteln ein gesicherter Austausch des Produktes in allen Doseurräumen gewährleistet ist, so daß kein überaltertes bzw. entmischtes und gegebenenfalls reinfektioniertes Produkt unkontrolliert ausgestoßen wird. Gleichfalls liegt der Erfindung die Aufgabe zugrunde, zur Durchführung des Verfahrens eine geeignete Vorrichtung zu schaffen, die sich durch einen besonders einfachen Aufbau auszeichnet.The invention has for its object to propose a method suitable for the metered filling of liquid and pasty products, in particular foods or the like. By means of particularly simple means, a secure exchange of the product is ensured in all can spaces, so that no outdated or segregated and possibly reinfected product is discharged in an uncontrolled manner. The invention is also based on the object of creating a suitable device for carrying out the method, which is characterized by a particularly simple construction.

Die der Erfindung zugrundeliegende Aufgabe wird in verfahrensmäßiger Hinsicht zunächst dadurch gelöst, daß der Hubbereich bzw. der untere und obere Totpunkt des Dosierkolbens während der Ansaugung des Produktes ohne Veränderung des Dosierhubs verlagert wird. Die der Erfindung zugrundeliegende Idee ist also die, den unteren und oberen Totpunkt während des Ansaugens des Produktes wandern zu lassen, ohne daß der Dosierhub verändert wird. Die Verlagerung des Hubbereiches bzw. des unteren und oberen Totpunktes des Dosierkolbens kann stufenweise bzw. schrittweise oder aber auch stufenlos erfolgen. Das bedeutet, daß je nach abzufüllendem Produkt, insbesondere dessen Viskosität jeweils der untere und obere Totpunkt, ohne daß dabei der Dosierhub verändert wird, in bestimmten Zeitintervallen oder fortlaufend verlagert werden, so daß das Produkt, insbesondere im Hinterkolbenraum ständig in Bewegung ist und ausgetauscht wird. Somit wird kein überaltertes bzw. entmischtes Produkt unkontrolliert ausgestoßen. Auch ist dadurch ein Reinfektion aus dem Produktionsprozeß ausgeschlossen, d.h. es kann keine Vermehrung der Keime des keimarmen Produktes stattfinden.In terms of the method, the object on which the invention is based is initially achieved in that the stroke range or the lower and upper dead center of the metering piston is shifted without changing the metering stroke during the suction of the product. The idea on which the invention is based is therefore that of moving the bottom and top dead center while the product is being sucked in without the metering stroke being changed. The displacement of the stroke range or the bottom and top dead center of the metering piston can be carried out step by step or step by step or also continuously. This means that depending on the product to be filled, in particular its viscosity, the bottom and top dead centers, without changing the metering stroke, are shifted at certain time intervals or continuously, so that the product, especially in the rear piston chamber, is constantly in motion and is exchanged . This means that no outdated or segregated product is ejected in an uncontrolled manner. This also prevents reinfection from the production process, i.e. the germs of the low-germ product cannot multiply.

Eine zum Durchführen des erfindungsgemäßen Verfahrens geeignete Vorrichtung zum dosierten Abfüllen von flüssigen und pastösen Produkten, insbesondere Nahrungsmitteln mit einem den Produktzulauf und Produktablauf steuernden verstellbaren Absperrorgan und einem zwischen einer Ansaugstellung und Ausstoßstellung in einem Dosiergehäuse hin- und herbeweglich gelagerten Dosierkolben zeichnet sich durch eine Verstelleinrichtung zur axialen Verlagerung der unveränderten Hubstrecke des Dosierkolbens während der Ansaugphase des Doseurs aus. An sich ist jede beliebige Antriebs- bzw. Verstelleinrichtung denkbar, die in der Lage ist, jeweils nach gewünschter Zeit oder ständig eine im vorgegebenen Rahmen bestimmte Verlagerung des Hubbereichs des Dosierkolbens vorzunehmen. So eignen sich als Verstellvorrichtung durchaus handelsübliche elektromotorisch angetriebene, zeitgesteuerte Schubspindelantriebe. Der Antrieb für die Verstelleinrichtung kann auch vom Doseurantrieb abgezapft werden oder durch sonstige separate Antriebe, wie z. B. hydraulische und pneumatische Zylinder-Kolben-Einheiten ausgebildet sein. Auch ist es denkbar, die erfindungsgemäße Verstellagerung des Hubbereichs des Dosierkolbens z. B. mittels einer programmierten Speichersteuerung vollautomatisch ablaufen zu lassen.A device suitable for carrying out the method according to the invention for the metered filling of liquid and pasty products, in particular foodstuffs, with an adjustable shut-off device which controls the product inlet and outlet and a metering piston which is mounted so as to be movable back and forth between a suction position and ejection position in a metering housing, is characterized by an adjusting device axial displacement of the unchanged stroke distance of the dosing piston during the suction phase of the dosing device. In itself, any drive or adjustment device is conceivable that is capable of shifting the stroke range of the stroke range according to the desired time or continuously Dosing piston. For example, commercially available electromotively driven, time-controlled push spindle drives are suitable as the adjustment device. The drive for the adjustment device can also be tapped from the dosing drive or by other separate drives, such as. B. hydraulic and pneumatic cylinder-piston units. It is also conceivable that the adjustment bearing according to the invention of the stroke range of the metering piston z. B. to run fully automatically by means of a programmed memory controller.

Ein bevorzugtes Ausführungsbeispiel der Erfindung ist in der Zeichnung dargestellt und wird im folgenden näher erläutert:A preferred embodiment of the invention is shown in the drawing and is explained in more detail below:

Es zeigen in jeweils schematischer Darstellung:

- Fig. 1 Die nach der Erfindung ausgebildete Dosiervorrichtung mit der Verstell-Lagerung des Dosierkolbens in einer senkrechten Schnittdarstellung,

- Fig. 2 die Dosiervorrichtung zu Beginn des Ansaughubes,

- Fig. 3 die Vorrichtung am Ende des Ansaughubes,

- Fig. 4 den Beginn des Auspressens,

- Fig. 5 das Ende des Auspressens und

- Fig. 6 die Dosiervorrichtung in der Reinigungsstellung.

- 1 shows the metering device designed according to the invention with the adjustable mounting of the metering piston in a vertical sectional view,

- 2 the dosing device at the beginning of the suction stroke,

- 3 shows the device at the end of the suction stroke,

- 4 the beginning of the squeezing,

- Fig. 5 shows the end of squeezing and

- Fig. 6 shows the dosing device in the cleaning position.

Wie aus Fig. 1 hervorgeht, besitzt die Dosiervorrichtung ein Dosiergehäuse 1 mit einem Produktzulauf 2 und einem Produktablauf 3. Der Produktzulauf 2 und der Produktablauf 3 sind durch ein Absperrorgan 4 gesteuert, welches im dargestellten Ausführungsbeispiel aus einem drehbaren Ventilkörper 5 und einer Ventilstange 6 besteht, die von einem nicht dargestellten Antrieb verdreht werden kann, so daß der Ventilkörper 5 einmal in eine den Produktablauf 3 verschließende Stellung gebracht werden kann, so wie in Fig. 1 dargestellt und zum anderen in eine Offenstellung bewegt werden kann, so wie dies in den Fig. 4 und 5 gezeigt ist.As can be seen from FIG. 1, the metering device has a metering housing 1 with a product inlet 2 and a product outlet 3. The product inlet 2 and the product outlet 3 are controlled by a shut-off

In einem im wesentlichen parallel zum Absperrorgan verlaufenden Dosierzylinder 6 ist ein Dosierkolben 7 gleitbeweglich gelagert, der über eine Kolbenstange 8 mit einer in Fig. 1 schematisch dargestellten Verstelleinrichtung 9 verbunden ist. Durch den Dosierkolben 7 wird im Dosierzylinder 6 ein vorderer Doseurraum 11 und ein hinterer Doseurraum 12 gebildet. Während der vordere Doseurraum 11 nur bei entsprechender Stellung (Fig. 1) des Ventilkörpers 5 mit dem Produktzulauf verbunden ist steht der hintere Doseurraum 12 mit dem Produktzulauf 2 ständig in Verbindung.In a metering cylinder 6 which runs essentially parallel to the shut-off element, a

In Fig. 1 ist der Dosierkolben 7 mit ausgezogenen Linien in seiner untersten Stellung gezeigt. Der normale Hubbereich des Dosierkolbens 7 im Dosierzylinder 6 ist mit I bezeichnet, wobei die obere Totpunktlage des Dosierkolbens 7 in strichpunktierten Linien angedeutet ist. Durch die Verstelleinrichtung 9, beispielsweise einen handelsüblichen, elektromotorisch und zeitabhängig gesteuerten Schubspindelantrieb mit Endanschlägen kann der Dosierkolben 7 während der Produktansaugung in seinem gesamten Hubbereich verlagert werden, z. B. in den mit II bezeichneten Hubbereich. Die neuen Totpunktlagen des Dosierkolbens 7 sind mit gestrichelten Linien gezeichnet. Das bedeutet, daß aufgrund einer entsprechenden Steuerung, die auch programmgespeichert sein kann, der Dosierkolben 7 während der Ansaugphase zwischen dem normalen Hubbereich I und dem neuen Hubbereich II entweder stufenweise bzw. schrittweise oder aber auch stufenlos wandern kann, mit der Folge, daß die Doseurräume 11 und 12 mit dem Dosierkolben 7 so beaufschlagt werden, daß das Produkt gut ausgetauscht wird. Hierdurch wird insbesondere im hinteren Doseurraum 12 vermieden, daß überaltertes bzw. entmischtes Produkt entstehen kann.In Fig. 1, the

In konkreter Ausführung der Erfindung kann die Verlagerung des Hubbereichs des Dosierkolbens nach bestimmten Intervallen, z. B. nach jedem dritten Ansaughub durchgeführt werden. Ebenso kann die Verlagerung stetig erfolgen, z. B. in der Weise, daß ausgehend vom normalen unteren Totpunkt der Dosierkolben bis zum neuen oberen Totpunkt verlagert wird. Von dieser Position aus wird dann der Dosierkolben bis zum neuen unteren Totpunkt verstellt. Danach erfolgt eine Ansaugbewegung des Dosierkolbens bis zum alten oberen Totpunkt und schließlich die Ausstoßbewegung bis zum alten unteren Totpunkt. Selbstverständlich kann man bei entsprechender Steuerung den Dosierkolben auch stufenlos zwischen den vorstehend genannten Extremtotpunkten wandern lassen, wobei der Hubbereich jedoch stets gleich bleibt. Unabhängig davon kann natürlich - wie bekannt - der obere Totpunkt verlagert werden, um das Ausstoßvolumen je nach Bedarf zu verändern.In a concrete embodiment of the invention, the displacement of the stroke range of the metering piston after certain intervals, for. B. be performed after every third suction stroke. Likewise, the shift can take place continuously, for. B. in such a way that starting from the normal bottom dead center, the metering piston is shifted to the new top dead center. The dosing piston is then adjusted from this position to the new bottom dead center. Then the dosing piston is sucked up to the old upper one Dead center and finally the ejection movement to the old bottom dead center. Of course, with appropriate control, the metering piston can also be moved continuously between the above-mentioned extreme dead centers, but the stroke range always remains the same. Regardless of this, as is known, top dead center can of course be shifted in order to change the output volume as required.

Die Wirkungsweise der Dosiervorrichtung ist wie folgt:The dosing device works as follows:

Ausgehend von der in Fig. 1 dargestellten Stellung, d.h. bei Beginn des Ansaugens steht der Dosierkolben 7 in seiner untersten Stellung. Das Absperrorgan 4 ist mit seinem Ventilkörper 5 in einer solchen Stellung, daß der Produktauslauf 3 abgeschlossen ist, hingegen der Produktzulauf 2 über das Absperrorgan 4 mit dem vorderen Doseurraum 11 in Verbindung steht. Der Dosierkolben 7 wird dann, ausgehend von der Fig. 2, in die Stellung nach Fig. 3 bewegt, welche das Ende des Ansaughubes zeigt.Starting from the position shown in Fig. 1, i.e. at the start of suction, the

Daraufhin wird der Ventilkörper 5 über die Ventilstange 6 so verdreht, daß durch den Ventilkörper 5 die Verbindung zwischen dem Produktzulauf und dem vorderen Doseurraum 11 abgesperrt wird und gleichzeitig letzterer mit dem Produktablauf 3 in Verbindung gelangt, so wir das in Fig. 4 gezeigt ist. Der Dosierkolben 7 befindet sich nun zu Beginn der Ausstoßstellung. Wie aus Fig. 5 hervorgeht, wird der Dosierkolben 7 nach unten bewegt und dabei das Produkt aus der Auslauföffnung 3 in einen nicht dargestellten Behälter ausgestoßen.Then the

Zu Reinigungszwecken kann die Dosiervorrichtung in die in Fig. 6 gezeigte Reinigungsstellung gebracht werden, in welcher sowohl der Dosierkolben 7 als auch der Ventilkörper 5 nach oben bewegt worden sind. Über den Produktzulauf 2 und zusätzliche Einlauföffnungen 13, 14 und 15 kann Reinigungsflüssigkeit in den Doseur eingebracht werden, so daß alle Teile der Dosiervorrichtung gut umspült werden.For cleaning purposes, the metering device can be brought into the cleaning position shown in FIG. 6, in which both the

Es versteht sich, daß die Erfindung nicht nur auf das dargestellten Ausführungsbeispiel beschränkt ist, sondern im Rahmen der Ansprüche auch Änderungen zulässig sind. So braucht als Verstelleinrichtung nicht unbedingt ein Schubspindelantrieb vorgesehen sein, sondern die Verstellung bzw. Verlagerung des Hubbereichs des Dosierkolbens kann auch von einer Verstelleinrichtung erzielt werden, deren Antrieb direkt vom Doseurantrieb abgezapft wird oder aber durch sonstige separate Antriebe, wie z. B. hydraulische oder pneumatische Zylinder mit geeigneter Steuerventileinrichtung. Wesentlich ist nur, daß der Hubbereich des Dosierkolbens während des Ansaugens des Produktes in bestimmten Intervallen, z. B. nach jedem fünften Ansaugvorgang oder aber ständig, d.h. bei jedem Ansaughub im Dosierzylinder verlagert wird, so daß ein gesicherter Austausch des Produktes in allen Doseurräumen erreicht wird.It is understood that the invention is not limited to the exemplary embodiment shown, but that changes are also permitted within the scope of the claims. Thus, a push spindle drive does not necessarily have to be provided as the adjusting device, but the adjustment or displacement of the stroke range of the metering piston can also be achieved by an adjusting device, the drive of which is tapped off directly by the dosing drive or by other separate drives, such as, for. B. hydraulic or pneumatic cylinders with a suitable control valve device. It is only important that the stroke range of the metering piston during the suction of the product at certain intervals, for. B. after every fifth suction process or continuously, i.e. is shifted in the dosing cylinder with every suction stroke, so that a secure exchange of the product is achieved in all dosing rooms.

Claims (6)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3919913 | 1989-06-19 | ||

| DE3919913A DE3919913C1 (en) | 1989-06-19 | 1989-06-19 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0403813A1 EP0403813A1 (en) | 1990-12-27 |

| EP0403813B1 true EP0403813B1 (en) | 1992-08-12 |

Family

ID=6383003

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP90109756A Expired - Lifetime EP0403813B1 (en) | 1989-06-19 | 1990-05-22 | Method and apparatus for the dosed filling of liquid and pasty products, especially of foodstuffs or the like |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US5019127A (en) |

| EP (1) | EP0403813B1 (en) |

| DE (2) | DE3919913C1 (en) |

| DK (1) | DK0403813T3 (en) |

Families Citing this family (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE4226566C2 (en) * | 1992-08-12 | 1996-04-18 | Jagenberg Ag | Device for dosing and filling liquid or pasty products |

| ATE200453T1 (en) * | 1997-08-18 | 2001-04-15 | Benhil Gasti Verpackungsmaschi | DEVICE AND METHOD FOR DOSAGED FILLING OF LIQUID TO PASTY PRODUCTS |

| EP0994333A1 (en) * | 1998-10-16 | 2000-04-19 | Comas S.p.a. | Volumetric metering device for fluid products in particular of the alimentary type |

| AU4686600A (en) * | 1999-04-27 | 2000-11-10 | Michael C. Johnson | Dispensing machine with portion control |

| US6814109B2 (en) * | 2003-01-03 | 2004-11-09 | Packaging Technologies, Inc. | Zero clearance rotor valve for product filling |

| ITTO20070680A1 (en) * | 2007-09-27 | 2009-03-28 | Francesco Bonato | "DOSING DEVICE FOR LIQUID OR PASTOSE SUBSTANCES" |

| DE102008028772A1 (en) * | 2008-06-17 | 2009-12-24 | Hansen, Bernd, Dipl.-Ing. | Device for filling containers |

| CA2831681C (en) * | 2011-03-31 | 2021-01-19 | Fishman Corporation | System and method for accurately delivering controlled amounts of viscous fluid to a fluid delivery device |

| DE102011119455A1 (en) * | 2011-11-28 | 2013-05-29 | Robert Bosch Gmbh | Apparatus for simultaneously filling at least two foodstuffs of different nature into a container |

| DE102013109969A1 (en) * | 2013-09-11 | 2015-03-12 | Krones Ag | Device for dosing a filling product in a container to be filled |

| CA2955551A1 (en) * | 2014-07-18 | 2016-01-21 | Pi-Design Ag | Kitchen appliance for processing foodstuff |

| DE102018113421A1 (en) * | 2018-06-06 | 2019-12-12 | Prominent Gmbh | Dosing pump with linear motor |

Family Cites Families (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR1278869A (en) * | 1961-01-13 | 1961-12-15 | Mec Carlo Migliavacca & C Soc | Device for the automatic feeding and dosing of powder, granular or liquid products, in particular jam |

| US3168225A (en) * | 1961-03-06 | 1965-02-02 | Chemetron Corp | Valve arrangement for receptacle filling machines |

| US3865281A (en) * | 1970-05-18 | 1975-02-11 | Owens Illinois Inc | Apparatus for filling containers |

| DE2308689A1 (en) * | 1973-02-22 | 1974-09-05 | Breitner Abfuellanlagen Kg Mas | FILLING DEVICE FOR LIQUID MEDIA |

| US3833155A (en) * | 1973-09-07 | 1974-09-03 | Phillips Petroleum Co | Positive displacement liquid dispensing mechanism |

| US3850345A (en) * | 1973-11-28 | 1974-11-26 | Fmc Corp | Filling valve |

| US4076482A (en) * | 1976-03-04 | 1978-02-28 | Whetstone Henry M | Charge forming and depositing machine |

| DE2658147A1 (en) * | 1976-12-22 | 1978-07-06 | Bosch Gmbh Robert | DOSING DEVICE FOR SEEDLESS MEASURING AND FILLING OF LIQUID |

| DE2900851C2 (en) * | 1979-01-11 | 1984-09-20 | Bayer Ag, 5090 Leverkusen | Device for volumetric dosing of pasty substances |

| US4399932A (en) * | 1981-06-02 | 1983-08-23 | Guenter Zimmermann | Volumetric metering valve |

| US4437498A (en) * | 1981-11-09 | 1984-03-20 | Liquipak International, Inc. | Carton filling apparatus |

| DE3443557A1 (en) * | 1984-11-29 | 1986-05-28 | Lieder Maschinenbau GmbH & Co KG, 3033 Schwarmstedt | METHOD AND DEVICE FOR MEASURING A FLOWABLE PRODUCT |

| NL8501983A (en) * | 1985-07-10 | 1987-02-02 | Stork Bepak Bv | PLUNDER DOSER. |

| DE3636804C1 (en) * | 1986-10-29 | 1988-05-26 | Benz & Hilgers Gmbh | Device for the metered filling of flowable or pasty filling material in containers |

-

1989

- 1989-06-19 DE DE3919913A patent/DE3919913C1/de not_active Expired - Fee Related

-

1990

- 1990-05-22 EP EP90109756A patent/EP0403813B1/en not_active Expired - Lifetime

- 1990-05-22 DK DK90109756.8T patent/DK0403813T3/en active

- 1990-05-22 DE DE9090109756T patent/DE59000250D1/en not_active Expired - Fee Related

- 1990-05-23 US US07/528,127 patent/US5019127A/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| EP0403813A1 (en) | 1990-12-27 |

| DE59000250D1 (en) | 1992-09-17 |

| DK0403813T3 (en) | 1992-12-07 |

| DE3919913C1 (en) | 1990-04-26 |

| US5019127A (en) | 1991-05-28 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE2303436C2 (en) | Molding machine | |

| EP0061472B1 (en) | Coffee machine | |

| DE3309964C2 (en) | Device for dosing and mixing two or more flowable plastic reaction components | |

| EP0403813B1 (en) | Method and apparatus for the dosed filling of liquid and pasty products, especially of foodstuffs or the like | |

| EP1602579B1 (en) | Apparatus for filling food product cups | |

| DD241189A5 (en) | METHOD FOR INJECTING VISCOUS LIQUID IN BREAD OR CONFECTIONERY | |

| DE3402136A1 (en) | FILLING DEVICE | |

| DE3636804C1 (en) | Device for the metered filling of flowable or pasty filling material in containers | |

| EP1515611B1 (en) | Method and device for dosing and introducing ingredients into a kneading machine | |

| DE102008055813B3 (en) | Device and method for dosing confectionery masses | |

| EP0793566B1 (en) | Device for the metered feed of the individual components of fluid multi-component plastics to a mixing head | |

| DE3943436C2 (en) | ||

| DE2415237C3 (en) | Device for the metered filling of liquid substances that solidify in the idle state, such as margarine or the like | |

| EP0131904A2 (en) | Dipping filling device | |

| EP1494920B1 (en) | Metering device for flowable products | |

| DE1966542C3 (en) | Plant for processing cast resin | |

| DE3630077A1 (en) | DEVICE FOR SIMULTANEOUSLY DOSED FILLING OF LIQUID OR SOFT PLASTIC SUBSTANCES LIKE BUTTER, MARGARINE, PASTE OR THE LIKE CONTAINERS CONTAINED ABOVE Mouthpieces | |

| DE2461892A1 (en) | Piston feeder for supply of dough - giving portions of consistant weight and volume | |

| EP0287968A2 (en) | Method and device for rationing and mixing multi-component plastic materials, especially polyurethane | |

| AT351480B (en) | MACHINE FOR CUTTING DOWN DOUGH PIECES | |

| DE2262254A1 (en) | Foundry sand liquid bonding agent dispenser - consists of adjustable piston travel cylinder | |

| DE3227616C2 (en) | ||

| DE60312278T2 (en) | Device for producing silicone from two components | |

| DE2248235C2 (en) | Device for discharging foam masses and similar sensitive masses in partial quantities | |

| DE2824680A1 (en) | Viscous foodstuff metering equipment - has plunger type outlet valve actuated by stem guided in metering piston rod |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): CH DE DK FR GB LI |

|

| 17P | Request for examination filed |

Effective date: 19910126 |

|

| 17Q | First examination report despatched |

Effective date: 19911212 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): CH DE DK FR GB LI |

|

| REF | Corresponds to: |

Ref document number: 59000250 Country of ref document: DE Date of ref document: 19920917 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) | ||

| ET | Fr: translation filed | ||

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: T3 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19940419 Year of fee payment: 5 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19940420 Year of fee payment: 5 Ref country code: CH Payment date: 19940420 Year of fee payment: 5 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19940421 Year of fee payment: 5 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DK Payment date: 19940630 Year of fee payment: 5 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19950522 Ref country code: DK Effective date: 19950522 |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: EBP |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Effective date: 19950531 Ref country code: CH Effective date: 19950531 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19950522 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19960201 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19960229 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |