EP0342464A1 - Aseptische Behälterausgiessvorrichtung - Google Patents

Aseptische Behälterausgiessvorrichtung Download PDFInfo

- Publication number

- EP0342464A1 EP0342464A1 EP89108231A EP89108231A EP0342464A1 EP 0342464 A1 EP0342464 A1 EP 0342464A1 EP 89108231 A EP89108231 A EP 89108231A EP 89108231 A EP89108231 A EP 89108231A EP 0342464 A1 EP0342464 A1 EP 0342464A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- package

- tap

- platform

- platen

- tip

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 239000007788 liquid Substances 0.000 claims abstract description 16

- 230000000149 penetrating effect Effects 0.000 claims abstract description 12

- 239000012530 fluid Substances 0.000 claims abstract description 8

- 239000012858 resilient material Substances 0.000 claims abstract description 4

- 238000004806 packaging method and process Methods 0.000 abstract description 7

- 230000035515 penetration Effects 0.000 abstract description 2

- 239000000243 solution Substances 0.000 description 11

- 230000006835 compression Effects 0.000 description 7

- 238000007906 compression Methods 0.000 description 7

- 238000009455 aseptic packaging Methods 0.000 description 4

- 238000004891 communication Methods 0.000 description 3

- 235000013305 food Nutrition 0.000 description 3

- 238000004026 adhesive bonding Methods 0.000 description 2

- 235000015097 nutrients Nutrition 0.000 description 2

- 238000009825 accumulation Methods 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 238000013461 design Methods 0.000 description 1

- 238000007599 discharging Methods 0.000 description 1

- 229940079593 drug Drugs 0.000 description 1

- 239000003814 drug Substances 0.000 description 1

- 235000011389 fruit/vegetable juice Nutrition 0.000 description 1

- 238000003780 insertion Methods 0.000 description 1

- 230000037431 insertion Effects 0.000 description 1

- 239000008155 medical solution Substances 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 235000013336 milk Nutrition 0.000 description 1

- 239000008267 milk Substances 0.000 description 1

- 210000004080 milk Anatomy 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000012544 monitoring process Methods 0.000 description 1

- 238000003825 pressing Methods 0.000 description 1

- 238000007789 sealing Methods 0.000 description 1

- 239000010902 straw Substances 0.000 description 1

Images

Classifications

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61J—CONTAINERS SPECIALLY ADAPTED FOR MEDICAL OR PHARMACEUTICAL PURPOSES; DEVICES OR METHODS SPECIALLY ADAPTED FOR BRINGING PHARMACEUTICAL PRODUCTS INTO PARTICULAR PHYSICAL OR ADMINISTERING FORMS; DEVICES FOR ADMINISTERING FOOD OR MEDICINES ORALLY; BABY COMFORTERS; DEVICES FOR RECEIVING SPITTLE

- A61J1/00—Containers specially adapted for medical or pharmaceutical purposes

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B67—OPENING, CLOSING OR CLEANING BOTTLES, JARS OR SIMILAR CONTAINERS; LIQUID HANDLING

- B67B—APPLYING CLOSURE MEMBERS TO BOTTLES JARS, OR SIMILAR CONTAINERS; OPENING CLOSED CONTAINERS

- B67B7/00—Hand- or power-operated devices for opening closed containers

- B67B7/24—Hole-piercing devices

- B67B7/26—Hole-piercing devices combined with spouts

Definitions

- the present invention relates to a system for the delivery of a solution from an aseptic package and, in particular, to a tap for such a package containing solutions for medical applications such as enteral feeding, as by nasal gauge.

- the term "aseptic packaging” is intended to embrace the packaging of various liquids within a carton, the carton being of the type that is punctured to obtain access to the packaged liquid.

- the packaged liquid is a food product, such as juices or milk products

- puncture the packaging at a preselected location (which is often weakened) and to withdraw the liquid through a straw.

- aseptic packaging render their use desirable in many medical applications. For example, it is often desirable, or necessary, to deliver liquids to a person by a nasal tube for such purposes as enteral feeding, the delivery of nutrients, the delivery of medication, etc. Aseptic packaging is often suitable for such liquids. However, while aseptic packaging has been employed for certain medical solutions, it has often been the practice to open the packages and empty their contents into a more traditional container for delivery. In part, this has resulted from limitations on package size. However, more recent packaging techniques allow the packaging of liquid in greater quantities. Also, the tap described above in the context of food products, has the drawback of not discharging the liquid in an even flow but, instead, discharges the contents of the package intermittedly as air enters the container through the tap.

- the Rautsola tap provides, inter alia, a fitting having a projecting/penetrating tip to form an orifice through the carton/package sidewall.

- a liquid passage through the fitting allows a dispensing of the packaged solution, while provision is made for make-up air to the interior of the package.

- the fitting is maintained and positioned in the package sidewall by threads which cooperate with the orifice through the package sidewall.

- the Rautsola tap is dependent upon the cooperation of the threads of the tap with the package sidewall and also requires a significant relative rotation between the package and fitting for securement and sealing.

- French patent 857,465 to Herve refers to a tap for metallic packages, the walls of which have a relatively high rigidity.

- this tap has a resilient disc which is pressed into an opening in the metallic wall which has been previously provided with an aperture by means of a penetrating tip shown in Fig. 4.

- this hole or aperture in the wall forms an inwardly extending ring flange which presses against the portion of said resilient disc which has been pressed into the package.

- this means the resilient material of disc does not expand within the passage but is compressed by said ring flange in order to secure and seal the known tap at the wall.

- Such a type of tap is however not suitable for use with aseptic packages.

- the resilient disc comprises a radial dimension which is much broader that the radial dimension of the stem portion being joined with the penetrating tip. Therefore, said resilient disc cannot be introduced through the aperture in the wall without axially pressing on it as, for example, by the screw of Figs. 5 to 7 of the French patent.

- the present invention provides a system for the enteral delivery of a solution contained within an aseptic package without the intervening step of emptying the package into a traditional container.

- the solution may be dispensed through a giving set and metering system of known design and, typically, via a tube as by nasal gauge.

- a tap having a body, a package penetrating tip extending from the body, a liquid passageway extending from the tip and through the body for dispensing liquid from the package and a fluid passageway extending from the tip through the body for admitting make-up air to the package.

- the package wall is also engaged to secure the tap within the package wall.

- the tap of the present invention employs a cylindrical member of a resilient material positioned between the body and the penetrating tip, the cylindrical member being insertable through the package wall in trailing relation to the tip. The resilient cylindrical member is selectively compressed, along its cylindrical axis, causing it to expand within the package against the package wall.

- the package wall is engaged without the requirement of a thread-type cooperation between the tap and package wall and without a significant relative rotation between the tap and package.

- a rotation of approximately 90° (one quarter turn) of a portion of the tap of the present invention is required for full engagement of the package wall.

- the present invention employs a circular platform, the platform having cams extending from its surface toward the package penetrating tip of the tap.

- a cap having a platen defining an endwall thereof is positioned with the platen generally parallel to the platform and with a sidewall of the cap surrounding a portion of the body.

- a resilient, cylindrical member is positioned between the cap and pentrating tip for selective compression along its cylindrical axis (and expansion within the package against the package wall) on movement of the cap away from the platform.

- the platform of the disclosed preferred embodiment is provided with a plurality of cams while the platen carries multiple cam followers, each cooperating with a different one of the platform cams.

- the cams and cam followers On rotation of one or both of the platform and cap relative to the other, the cams and cam followers selectively establish the distance between the cap platen and platform and, accordingly, the state of compression of the resilient member. That is, the relative angular or rotational orientation of the platen and platforms establishes the distance between the platen and platform and the state of compression of the cylindrical, resilient member.

- the cam followers may be formed as ramps with each ramp being provided with a plateau to provide a stable, compressed state of the cylindrical, resilient member.

- securement of the tap of the present invention to a package is accomplished by compression of the cylindrical resilient member within the package, said member being in its generally cylindrical configuration during entry. Only after the cylindrical member has been introduced into the package is it compressed along its cylindrical axis to expand within the package and engage the side wall of the package to seal the orifice formed by tip and also to secure the tap to the package.

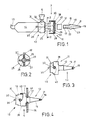

- Figure 1 is an exploded view of a tap in accordance with the present invention, including a body designated generally at 10, a cap designated generally at 11, a cylindrical, resilient member 12 and a penetrating tip member designated generally at 13.

- the body 10 is secured to a reservoir 14 in any desired manner, the reservoir being connected to an elongated tubing 15 which extends to a "giving set" and any desired metering system.

- the reservoir 14 may be secured to the body 10 as by gluing it to a collar thereof. Accumulation of solution dispensed from an aseptic package will occur within the reservoir 14, allowing a monitoring of the dispensing.

- the penetrating tip 13 includes a generally conical portion 16 and an extending stem 17, the conical portion 16 and stem 17 being joined to each other at a shoulder 18.

- the conical portion 16 is obliquely truncuated at a surface 19, the surface 19, in cooperation with the conical portion 16, providing a cutting edge to facilitate penetration of an aseptic package.

- a fluid passageway for make-up air is represented by dashed line 21 and extends from the surface 19 through the tip 13 to exit through the sidewall of the stem 17.

- a second passageway for solution to be dispensed is represented by a dashed line 22 and extends from an opening 23 in the conical portion 16 of tip 13 and through the stem portion 17. Passageways 21 and 22 cooperate with passageways within the body portion 10 in a matter to be described more fully below.

- a generally cylindrical, resilient member 12 is configured to fit over the stem portion 17 of tip 13 to abut against the shoulder 18. On insertion of the tip 13 through the wall of a package, the orifice made by the tip 13 will allow the member 12 to extend through the package wall and into the interior of the package. As will be apparent from the discussion below, the cylindrical, resilient member 12 will be compressed along its cylindrical axis such that it will expand within the packaging to engage the package wall and seal the orifice in that wall formed by the tip 13 as well as secure the tap to the package. The solution within the package will be dispensed through the passageway 22, entering the tip 13 at the opening 23, while make-up air to the interior of the package will enter the package via the passageway 21.

- the body 10 is provided with a platform 25, the platform 25 having a central hub 26 and extending cam members 27.

- the hub 26 has a central opening 28 (See Figure 2) for accepting the stem 17 of tip 13.

- the stem 17 may be secured within the opening 28 of hub 26 in any desired manner, as by gluing, for example.

- a first passageway 29 extends from the opening 28 through the body 10 and into the reservoir 14 via a stub 30.

- the passageway 29 is represented by a dashed line in Figure 1.

- a second fluid passageway 31 extends through a stub 32 in a sidewall of the body 10 and is also represented by a dashed line.

- the passageway 31 will, on proper orientation of stem 17 within body 10, establish fluid communication with the passageway 21 of tip 13 when the stem 17 of the tip 13 is within the opening 28 of hub 26. Similarily, fluid communication between the passageway 29 of body 10 and the passageway 22 of tip 13 is established when the stem 17 is inserted within the opening 28 and hub 26 of body 10. Thus, a passageway for solution is established through the opening 23, passageway 22 and passageway 29 and into the reservoir 14 for a solution to be dispensed while make-up air for the package interior is provided through the passageway 31 of body 10 and passageway 21 of tip 13.

- assembly of the tip 13 and body 10, with their respective passageways 21/31 and 22/29 in communication establishes a tap by which solution within an aseptic package may be dispensed, with a provision for make-up air.

- the tap as described to this point, is not securable to a package.

- the member 12 Securement of the tap to a package is accomplished by compression of the cylindrical resilient member 12 within the package.

- the member 12 is positioned over the stem 17 and enters the package by an orifice formed by the tip 13.

- the member 12 is in its generally cylindrical configuration. This configuration is illustrated in Figure 3 which may be termed the package penetrating configuration.

- the member 12 is compressed along its cylindrical axis to expand within the package and engage the sidewall of the package to seal the orifice formed by the tip 13 and also to secure the tap to the package.

- This configuration of the member 12 is illustrated in Figure 4 with the cut-away element 35 representing the package wall.

- Compression of the member 12 is accomplished by a camming cooperation between the cams 26 on the platform 25 and cam surfaces 36 within a cap 38.

- the cap 38 includes an endwall 39, the inner surface of which serves as a platen carrying the camming surfaces 36.

- the platform 25 is generally circular, while the sidewall of the cap 38 is cylindrical and extends over the body 10 with the platen surface of endwall 38 being generally parallel to the platform 25.

- the cam surfaces 36 each cooperate with a different one of the cams 27 and are formed as ramps such that the relative rotation or orientation of the cap 38 and body member 10 establishes the distance between the platen surface of endwall 39 and the platform 25.

- the sidewall of the cap 38 facilitates manipulation of that cap during relative rotational movement with the body 10, and its platform 25.

- This cutout is illustrated at 40 in Figures 3 and 4.

- Such a cap is illustrated at 41 in Figure 1.

- the cap 41 will also assist in manipulation of the body 10 during establishment of its relative angular orientation with the cap 38.

- the cap 41 is not illustrated in Figures 2-4.

- the camming surfaces 36 may be provided with plateaus in the regions indicated at 44, the plateaus being either ramps of reduced angle or "flat" portions.

Landscapes

- Health & Medical Sciences (AREA)

- Veterinary Medicine (AREA)

- Public Health (AREA)

- Pharmacology & Pharmacy (AREA)

- Life Sciences & Earth Sciences (AREA)

- Animal Behavior & Ethology (AREA)

- General Health & Medical Sciences (AREA)

- Mechanical Engineering (AREA)

- Engineering & Computer Science (AREA)

- Packages (AREA)

- Infusion, Injection, And Reservoir Apparatuses (AREA)

- Closures For Containers (AREA)

- Transition And Organic Metals Composition Catalysts For Addition Polymerization (AREA)

- Closing Of Containers (AREA)

- Artificial Filaments (AREA)

- Medical Preparation Storing Or Oral Administration Devices (AREA)

- Packaging Of Special Articles (AREA)

- Nozzles (AREA)

- Containers And Plastic Fillers For Packaging (AREA)

- Containers And Packaging Bodies Having A Special Means To Remove Contents (AREA)

- Materials For Medical Uses (AREA)

- Liquid Developers In Electrophotography (AREA)

- Diaphragms For Electromechanical Transducers (AREA)

- Coupling Device And Connection With Printed Circuit (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT89108231T ATE80591T1 (de) | 1988-05-17 | 1989-05-08 | Aseptische behaelterausgiessvorrichtung. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US19496388A | 1988-05-17 | 1988-05-17 | |

| US194963 | 1988-05-17 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0342464A1 true EP0342464A1 (de) | 1989-11-23 |

| EP0342464B1 EP0342464B1 (de) | 1992-09-16 |

Family

ID=22719538

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP89108231A Expired - Lifetime EP0342464B1 (de) | 1988-05-17 | 1989-05-08 | Aseptische Behälterausgiessvorrichtung |

Country Status (16)

| Country | Link |

|---|---|

| EP (1) | EP0342464B1 (de) |

| JP (1) | JPH0236879A (de) |

| KR (1) | KR890016958A (de) |

| AT (1) | ATE80591T1 (de) |

| AU (1) | AU609987B2 (de) |

| BR (1) | BR8902290A (de) |

| CA (1) | CA1319343C (de) |

| DE (1) | DE68902868T2 (de) |

| DK (1) | DK236289A (de) |

| ES (1) | ES2035418T3 (de) |

| FI (1) | FI88698C (de) |

| GR (1) | GR3005811T3 (de) |

| NO (1) | NO170458C (de) |

| NZ (1) | NZ228954A (de) |

| PH (1) | PH26174A (de) |

| PT (1) | PT90566B (de) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FI98804C (fi) * | 1994-06-14 | 1997-08-25 | Tuomo Halonen Oy | Tyhjennysventtiili nestepakkausten, kuten nestepussien, tyhjentämistä varten |

| KR101874937B1 (ko) * | 2016-11-28 | 2018-07-06 | 주식회사 시공테크 | 모터 원리를 이용한 회전 가능한 디스플레이 소자 |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB433679A (en) * | 1933-03-17 | 1935-08-19 | Alberto Louis Maggenti | Improvements relating to devices for tapping containers |

| DE3531644A1 (de) * | 1985-09-05 | 1987-03-05 | Arnold Zimmer | Ausgussvorrichtung fuer in papiertueten verpackte getraenke |

-

1989

- 1989-05-02 NZ NZ228954A patent/NZ228954A/xx unknown

- 1989-05-08 EP EP89108231A patent/EP0342464B1/de not_active Expired - Lifetime

- 1989-05-08 AT AT89108231T patent/ATE80591T1/de active

- 1989-05-08 ES ES198989108231T patent/ES2035418T3/es not_active Expired - Lifetime

- 1989-05-08 DE DE8989108231T patent/DE68902868T2/de not_active Expired - Fee Related

- 1989-05-15 FI FI892326A patent/FI88698C/fi not_active IP Right Cessation

- 1989-05-15 AU AU34818/89A patent/AU609987B2/en not_active Ceased

- 1989-05-16 CA CA000599804A patent/CA1319343C/en not_active Expired - Fee Related

- 1989-05-16 PT PT90566A patent/PT90566B/pt not_active IP Right Cessation

- 1989-05-16 PH PH38656A patent/PH26174A/en unknown

- 1989-05-16 NO NO891957A patent/NO170458C/no unknown

- 1989-05-16 DK DK236289A patent/DK236289A/da not_active Application Discontinuation

- 1989-05-16 JP JP1120632A patent/JPH0236879A/ja active Granted

- 1989-05-17 BR BR898902290A patent/BR8902290A/pt unknown

- 1989-05-17 KR KR1019890006585A patent/KR890016958A/ko not_active Withdrawn

-

1992

- 1992-09-25 GR GR920402136T patent/GR3005811T3/el unknown

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB433679A (en) * | 1933-03-17 | 1935-08-19 | Alberto Louis Maggenti | Improvements relating to devices for tapping containers |

| DE3531644A1 (de) * | 1985-09-05 | 1987-03-05 | Arnold Zimmer | Ausgussvorrichtung fuer in papiertueten verpackte getraenke |

Also Published As

| Publication number | Publication date |

|---|---|

| PT90566B (pt) | 1994-04-29 |

| CA1319343C (en) | 1993-06-22 |

| BR8902290A (pt) | 1990-01-09 |

| NZ228954A (en) | 1990-08-28 |

| GR3005811T3 (de) | 1993-06-07 |

| KR890016958A (ko) | 1989-12-14 |

| DK236289D0 (da) | 1989-05-16 |

| FI88698C (fi) | 1993-06-28 |

| DE68902868D1 (de) | 1992-10-22 |

| NO891957L (no) | 1989-11-20 |

| NO170458B (no) | 1992-07-13 |

| AU3481889A (en) | 1989-11-23 |

| PH26174A (en) | 1992-03-18 |

| JPH0587258B2 (de) | 1993-12-16 |

| DE68902868T2 (de) | 1993-01-07 |

| EP0342464B1 (de) | 1992-09-16 |

| NO891957D0 (no) | 1989-05-16 |

| ATE80591T1 (de) | 1992-10-15 |

| PT90566A (pt) | 1989-11-30 |

| NO170458C (no) | 1992-10-21 |

| AU609987B2 (en) | 1991-05-09 |

| FI88698B (fi) | 1993-03-15 |

| DK236289A (da) | 1989-11-18 |

| FI892326A0 (fi) | 1989-05-15 |

| FI892326L (fi) | 1989-11-18 |

| ES2035418T3 (es) | 1993-04-16 |

| JPH0236879A (ja) | 1990-02-06 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US4826500A (en) | Enteral nutrient delivery system | |

| CN103492276B (zh) | 具有适配器的密封装置 | |

| US8118802B2 (en) | Connector for packaging containing medical fluids and packaging for medical fluids | |

| US6454088B2 (en) | Two-compartment package | |

| US3788524A (en) | Additive container | |

| JP3228496B2 (ja) | 無菌状態で低圧によって第1の液体成分と第2の固体または液体成分を混合する装置 | |

| US5876372A (en) | Syringe system accomodating seperate prefilled barrels for two constituents | |

| US6524295B2 (en) | Container cap assembly having an enclosed penetrator | |

| EP0740633B1 (de) | Kindergesicherte behälterverschlussanordnung | |

| US6056135A (en) | Liquid transfer device to facilitate removal of liquid from a container by a syringe | |

| EP1052180B1 (de) | Verpackung für sofort haftende Klebstoffe | |

| US4519513A (en) | Container having pierceable insert | |

| US4976379A (en) | Dispensing container with integral funnel | |

| JP2010509141A (ja) | 蓋及び分注システム | |

| JPH0431946B2 (de) | ||

| US5407099A (en) | Device for withdrawing filling material from bags | |

| US8528783B2 (en) | Sterile dispensing package with coupling insert for receipt of piercing member and method of using the same | |

| IE822473L (en) | Opening disposable syrup containers | |

| US5000349A (en) | Aseptic package tap | |

| EP0342464A1 (de) | Aseptische Behälterausgiessvorrichtung | |

| EP0537281B1 (de) | Füllstutzen für einen sack | |

| US5007565A (en) | Integral vent tube | |

| TWI734281B (zh) | 連接器 | |

| US7584870B2 (en) | Connecting device | |

| US20230301870A1 (en) | Container With Threaded Connector |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH DE ES FR GB GR IT LI LU NL SE |

|

| 17P | Request for examination filed |

Effective date: 19900501 |

|

| 17Q | First examination report despatched |

Effective date: 19911029 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE ES FR GB GR IT LI LU NL SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 19920916 |

|

| REF | Corresponds to: |

Ref document number: 80591 Country of ref document: AT Date of ref document: 19921015 Kind code of ref document: T |

|

| ITF | It: translation for a ep patent filed | ||

| REF | Corresponds to: |

Ref document number: 68902868 Country of ref document: DE Date of ref document: 19921022 |

|

| ET | Fr: translation filed | ||

| REG | Reference to a national code |

Ref country code: GR Ref legal event code: FG4A Free format text: 3005811 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2035418 Country of ref document: ES Kind code of ref document: T3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19930508 Ref country code: AT Effective date: 19930508 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19930509 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19930510 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19930531 Ref country code: LI Effective date: 19930531 Ref country code: CH Effective date: 19930531 Ref country code: BE Effective date: 19930531 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| BERE | Be: lapsed |

Owner name: FRESENIUS A.G. Effective date: 19930531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19931201 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19930508 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19940131 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19940201 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| REG | Reference to a national code |

Ref country code: GR Ref legal event code: MM2A Free format text: 3005811 |

|

| EUG | Se: european patent has lapsed |

Ref document number: 89108231.5 Effective date: 19931210 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 19990405 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20050508 |