EP0342335A2 - Process for engobing or glazing roofing tiles - Google Patents

Process for engobing or glazing roofing tiles Download PDFInfo

- Publication number

- EP0342335A2 EP0342335A2 EP89105195A EP89105195A EP0342335A2 EP 0342335 A2 EP0342335 A2 EP 0342335A2 EP 89105195 A EP89105195 A EP 89105195A EP 89105195 A EP89105195 A EP 89105195A EP 0342335 A2 EP0342335 A2 EP 0342335A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- glazing

- engobing

- roof tiles

- roof

- base

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B28—WORKING CEMENT, CLAY, OR STONE

- B28B—SHAPING CLAY OR OTHER CERAMIC COMPOSITIONS; SHAPING SLAG; SHAPING MIXTURES CONTAINING CEMENTITIOUS MATERIAL, e.g. PLASTER

- B28B11/00—Apparatus or processes for treating or working the shaped or preshaped articles

- B28B11/04—Apparatus or processes for treating or working the shaped or preshaped articles for coating or applying engobing layers

- B28B11/044—Apparatus or processes for treating or working the shaped or preshaped articles for coating or applying engobing layers with glaze or engobe or enamel or varnish

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B28—WORKING CEMENT, CLAY, OR STONE

- B28B—SHAPING CLAY OR OTHER CERAMIC COMPOSITIONS; SHAPING SLAG; SHAPING MIXTURES CONTAINING CEMENTITIOUS MATERIAL, e.g. PLASTER

- B28B11/00—Apparatus or processes for treating or working the shaped or preshaped articles

- B28B11/04—Apparatus or processes for treating or working the shaped or preshaped articles for coating or applying engobing layers

- B28B11/048—Apparatus or processes for treating or working the shaped or preshaped articles for coating or applying engobing layers by spraying or projecting

Definitions

- the invention relates to a method for engobing or glazing roof tiles which, lying on a ceramic base, are dried and fired.

- roof tiles have not been engobed or glazed in a dry state on a ceramic base because the engobe or glaze jet would wet the base.

- the glaze or engobe would build up over time and lead to soiling of the roof tiles and sticking of the underlay. But all of this means an undesirable reduction in quality.

- Roof tiles that are dried and fired on ceramic substrates are therefore usually wet-engobed or glazed, which is associated with a considerable reduction in quality.

- the invention is therefore based on the object of demonstrating a method with which roof tiles dried and fired on ceramic substrates are engobed between drying and firing or can be glazed without having to remove them from the base.

- the claim 2 indicates an additional protective measure for the base against jet wetting.

- the advantage of the method according to the invention is that the drying, engobing or glazing and firing of the roof tiles can be carried out quickly as a result of the roof tiles remaining on their base and the operating and cost expenditure is kept low.

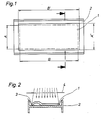

- a roof tile 1 lies on a ceramic base 2, which is designed here as a cassette and serves as support for drying or firing the roof tile 1.

- the roof tile 1 has the dimensions A ', B' and is covered by a screen 4 during glazing or engobing, which has a section A, B.

- This section A, B is slightly smaller than the area of the brick determined by the dimensions A ', B', and so much smaller that the ceramic base is shielded from the glaze or engobes, but the roof tile is glazed or engobed clean .

- the roof tile 1 can be placed on paper 3 additionally laid on the ceramic base 2 and prepared with quartz sand and / or kaolin.

- the paper pad prevents glaze or engobes from sticking to the ceramic surface if the method of working is not quite correct.

Abstract

Description

Die Erfindung betrifft ein Verfahren zum Engobieren oder Glasieren von Dachziegeln, die, auf einer keramischen Unterlage liegend, getrocknet und gebrannt werden.The invention relates to a method for engobing or glazing roof tiles which, lying on a ceramic base, are dried and fired.

Dachziegel werden bislang nicht in trockenem Zustand auf einer keramischen Unterlage engobiert oder glasiert, weil der Engobe- oder Glasurstrahl die Unterlage benetzen würde. Die Glasur oder Engobe würde mit der Zeit aufbauen zur Verschmutzung der Dachziegel und zum Kleben der Unterlage führen. Dies alles bedeutet aber eine nicht erwünschte Qualitätsminderung.Until now, roof tiles have not been engobed or glazed in a dry state on a ceramic base because the engobe or glaze jet would wet the base. The glaze or engobe would build up over time and lead to soiling of the roof tiles and sticking of the underlay. But all of this means an undesirable reduction in quality.

Das Engobieren oder Glasieren von Dachziegeln nach dem Trocknen und vor dem Brennen ohne die unterstützende Unterlage hat sich aber nicht durchgesetzt, weil dann eine Vielzahl von Handhabungen erforderlich ist, nämlich das Trocknen der Dachziegel auf der Unterlage, das Abnehmen der Dachziegel von der Unterlage vor dem Engobieren oder Glasieren und das Wiederumsetzen der Dachziegel auf die Unterlage vor dem Brennen.However, the engobing or glazing of roof tiles after drying and before firing without the supporting base did not prevail because a large number of manipulations are then required, namely drying the roof tiles on the base, removing the roof tiles from the base in front of the Engob or glaze and reposition the roof tiles on the surface before firing.

Auf keramischen Unterlagen getrocknete und gebrannte Dachziegel werden deshalb in der Regel naß engobiert oder glasiert, was mit erheblicher Qualitätsminderung verbinden ist.Roof tiles that are dried and fired on ceramic substrates are therefore usually wet-engobed or glazed, which is associated with a considerable reduction in quality.

Der Erfindung liegt daher die Aufgabe zugrunde, ein Verfahren aufzuzeigen, mit dem auf keramischen Unterlagen getrocknete und gebrannte Dachziegel zwischen dem Trocknen und Brennen engobiert oder glasiert werden können, ohne daß sie dazu von der Unterlage abgenommen werden müssen.The invention is therefore based on the object of demonstrating a method with which roof tiles dried and fired on ceramic substrates are engobed between drying and firing or can be glazed without having to remove them from the base.

Diese Aufgabe wird mit den im kennzeichnenden Teil des Anspruchs 1 aufgeführten Maßnahmen gelöst.This object is achieved with the measures listed in the characterizing part of

Der Anspruch 2 kennzeichnet eine zusätzliche Schutzmaßnahme für die Unterlage gegen Strahlbenetzung.The

Der Vorteil des erfindungsgemäßen Verfahrens besteht darin, daß das Trocknen, Engobieren oder Glasieren und Brennen der Dachziegel infolge des Verbleibens der Dachziegel auf ihrer Unterlage zügig durchführbar ist und der Betriebs- sowie Kostenaufwand niedrig gehalten wird.The advantage of the method according to the invention is that the drying, engobing or glazing and firing of the roof tiles can be carried out quickly as a result of the roof tiles remaining on their base and the operating and cost expenditure is kept low.

Ein Ausführungsbeispiel des Verfahrens ist in der Zeichnung dargestellt und nachstehend naher erläutert. Es zeigen:

- Fig .1 eine Draufsicht einer keramischen Unterlage mit einem daraufliegenden Dachziegel

- Fig. 2 einen Schnitt durch die keramische Unterlage während des Glasier- oder Engobiervorganges.

- Fig .1 is a plan view of a ceramic base with a roof tile thereon

- Fig. 2 shows a section through the ceramic base during the glazing or engobing process.

Ein Dachziegel 1 liegt auf einer keramischen Unterlage 2, die hier als Kassette ausgebildet ist und als Unterstützung beim Trocknen bzw. Brennen das Dachziegels 1 dient. Der Dachziegel 1 hat die Abmessungen A′, B′ und wird während des Glasierens oder Engobierens von einer Blende 4 überdeckt, die einen Ausschnitt A, B aufweist. Dieser Ausschnitt A, B ist etwas kleiner als die durch die Abmessungen A′, B′ bestimmte Fläche des Ziegels, und zwar um so viel kleiner, daß die keramische Unterlage gegen den Glasur- oder Engobestrahl abgeschirmt, der Dachziegel aber kantenrein glasiert oder engobiert wird.A

Der Dachziegel 1 kann auf ein auf der keramischen Unterlage 2 zusätzlich aufgelegtes, mit Quarzsand und/oder Kaolin präpariertes Papier 3 abgelegt werden. Die Papierauflage verhindert, daß bei nicht ganz sachgemäßer Arbeitsweise Glasur- oder Engobespritzer auf der keramischen Unterlage kleben bleiben.The

Claims (2)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT89105195T ATE80338T1 (en) | 1988-05-20 | 1989-03-23 | PROCESS FOR ENGOBING OR GLAZING ROOF TILES. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3817231A DE3817231C1 (en) | 1988-05-20 | 1988-05-20 | |

| DE3817231 | 1988-05-20 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0342335A2 true EP0342335A2 (en) | 1989-11-23 |

| EP0342335A3 EP0342335A3 (en) | 1990-08-29 |

| EP0342335B1 EP0342335B1 (en) | 1992-09-09 |

Family

ID=6354789

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP89105195A Expired - Lifetime EP0342335B1 (en) | 1988-05-20 | 1989-03-23 | Process for engobing or glazing roofing tiles |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP0342335B1 (en) |

| AT (1) | ATE80338T1 (en) |

| DE (2) | DE3817231C1 (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0878679A3 (en) * | 1997-05-14 | 2000-12-06 | EISENMANN MASCHINENBAU KG (Komplementär: EISENMANN-Stiftung) | Process for drying tiles, in particular roof tiles |

| CN110078522A (en) * | 2019-04-22 | 2019-08-02 | 景德镇欧神诺陶瓷有限公司 | A kind of ceramic tile production process |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE4023290C1 (en) * | 1990-07-21 | 1991-09-05 | Hans Lingl Anlagenbau Und Verfahrenstechnik Gmbh & Co Kg, 7910 Neu-Ulm, De | |

| DE19638297C1 (en) * | 1996-08-16 | 1997-12-11 | Bayerische Dachziegelwerke Bog | Producing clay roof tiles |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE740469C (en) * | 1938-11-04 | 1943-10-21 | Hans Lingl | Device for engobing a clay strand or moldings |

| US3560236A (en) * | 1968-12-30 | 1971-02-02 | Scm Corp | Method and composition for preferentially glazing ceramic bodies |

-

1988

- 1988-05-20 DE DE3817231A patent/DE3817231C1/de not_active Expired

-

1989

- 1989-03-23 DE DE8989105195T patent/DE58902232D1/en not_active Expired - Fee Related

- 1989-03-23 AT AT89105195T patent/ATE80338T1/en not_active IP Right Cessation

- 1989-03-23 EP EP89105195A patent/EP0342335B1/en not_active Expired - Lifetime

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE740469C (en) * | 1938-11-04 | 1943-10-21 | Hans Lingl | Device for engobing a clay strand or moldings |

| US3560236A (en) * | 1968-12-30 | 1971-02-02 | Scm Corp | Method and composition for preferentially glazing ceramic bodies |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0878679A3 (en) * | 1997-05-14 | 2000-12-06 | EISENMANN MASCHINENBAU KG (Komplementär: EISENMANN-Stiftung) | Process for drying tiles, in particular roof tiles |

| CN110078522A (en) * | 2019-04-22 | 2019-08-02 | 景德镇欧神诺陶瓷有限公司 | A kind of ceramic tile production process |

Also Published As

| Publication number | Publication date |

|---|---|

| DE58902232D1 (en) | 1992-10-15 |

| ATE80338T1 (en) | 1992-09-15 |

| EP0342335B1 (en) | 1992-09-09 |

| DE3817231C1 (en) | 1989-01-05 |

| EP0342335A3 (en) | 1990-08-29 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE3861641D1 (en) | CERAMIC FLOOR TILE, ASSORTMENT OF VARIOUS FLOOR TILES, METHOD AND DEVICE FOR PRODUCING A TILE ASSORTMENT. | |

| ATE128058T1 (en) | METHOD AND DEVICE FOR PREPARING GLASS PANELS FOR MULTIPLE GLAZING WITH AT LEAST ONE COATED GLASS PANE. | |

| DE3817231C1 (en) | ||

| DE4023290C1 (en) | ||

| DE2364801C3 (en) | Process for drying, in particular, hygroscopic substances with independent control of the climate in the drying system | |

| EP0186143A3 (en) | Apparatus for applying covering sheets to plate-like elements | |

| ATE80195T1 (en) | METHOD OF REALIZING A CONCRETE STRUCTURE LIKE BRIDGE SHEETS AND DEVICE FOR APPLICATION. | |

| DE517706C (en) | Process for the production of sample plaques from colored mortars | |

| DE3632085A1 (en) | METHOD AND DEVICE FOR CERAMIZING GLASS CERAMIC WINDOWS | |

| EP0881342A3 (en) | Apparatus and method for demolishing a building | |

| EP0101860B1 (en) | Device for adjusting ceramic plates in a stacking rack | |

| EP0183018A2 (en) | Method of renovating a brick wall of a building covered with plaster and damaged by damp | |

| EP0519212B1 (en) | Roofing tiles and process for their production | |

| DE684263C (en) | Equipment on veneer joint gluing machines for applying glue or binding agent to the veneer edges to be glued using glue discs | |

| EP0943592A1 (en) | Process for the production of flat ceramic products, in particular roof tiles | |

| DD148322A1 (en) | METHOD AND DEVICE FOR APPLYING FACADE ELEMENTS | |

| DE3306351C2 (en) | Self-propelled device for moving heavy concrete parts | |

| AT16689B (en) | Method and device for inserting glazed roof tiles into the kiln. | |

| DE514928C (en) | Method for fixing the glass panes on the workbenches of the grinding and polishing machines | |

| DE1584426C (en) | Device for lifting and lowering still plastic aerated concrete blocks | |

| DE1544182A1 (en) | Process for the production of flat semiconductor plates provided with epitaxially grown layers | |

| DE3617458A1 (en) | Kiln shuttle | |

| DE1937331A1 (en) | Ready-to-lay tile panels on glass fibre - backing | |

| DE1765774A1 (en) | Process for applying thick film resistance layers to a substrate | |

| DE2149561A1 (en) | METHOD AND DEVICE FOR THE AUTOMATIC PRODUCTION OF WALL PARTS FROM BRICK, IN PARTICULAR. BLOCK BRICKS, FOR FINISHED CONSTRUCTION |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH DE FR GB IT LI NL |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH DE FR GB IT LI NL |

|

| RHK1 | Main classification (correction) |

Ipc: B28B 11/04 |

|

| 17P | Request for examination filed |

Effective date: 19900720 |

|

| 17Q | First examination report despatched |

Effective date: 19910327 |

|

| ITF | It: translation for a ep patent filed |

Owner name: STUDIO MASSARI S.R.L. |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE FR GB IT LI NL |

|

| REF | Corresponds to: |

Ref document number: 80338 Country of ref document: AT Date of ref document: 19920915 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 58902232 Country of ref document: DE Date of ref document: 19921015 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) | ||

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19931201 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 19940310 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19940315 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19940328 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 19940330 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19940331 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 19940413 Year of fee payment: 6 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19950323 Ref country code: AT Effective date: 19950323 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Effective date: 19950331 Ref country code: CH Effective date: 19950331 Ref country code: BE Effective date: 19950331 |

|

| BERE | Be: lapsed |

Owner name: HANS LINGL ANLAGENBAU UND VERFAHRENSTECHNIK G.M.B Effective date: 19950331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19951001 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19950323 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19951130 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 19951001 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20050323 |