EP0333003B1 - Rotary potentiometer - Google Patents

Rotary potentiometer Download PDFInfo

- Publication number

- EP0333003B1 EP0333003B1 EP19890104055 EP89104055A EP0333003B1 EP 0333003 B1 EP0333003 B1 EP 0333003B1 EP 19890104055 EP19890104055 EP 19890104055 EP 89104055 A EP89104055 A EP 89104055A EP 0333003 B1 EP0333003 B1 EP 0333003B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- insert

- rotary potentiometer

- rotor

- resistance track

- potentiometer according

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000010079 rubber tapping Methods 0.000 claims description 11

- 239000004020 conductor Substances 0.000 description 8

- 238000005452 bending Methods 0.000 description 2

- 230000037431 insertion Effects 0.000 description 2

- 238000003780 insertion Methods 0.000 description 2

- 230000004308 accommodation Effects 0.000 description 1

- 239000000853 adhesive Substances 0.000 description 1

- 230000001070 adhesive effect Effects 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 239000011888 foil Substances 0.000 description 1

- 238000007789 sealing Methods 0.000 description 1

- 238000004804 winding Methods 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01C—RESISTORS

- H01C10/00—Adjustable resistors

- H01C10/30—Adjustable resistors the contact sliding along resistive element

- H01C10/32—Adjustable resistors the contact sliding along resistive element the contact moving in an arcuate path

Definitions

- the invention relates to a rotary potentiometer, in which a resistance track is arranged on the inside of a cylindrical wall of a housing, in which a rotor is rotatably mounted about its cylinder axis, to which a wiper which is in contact with the resistance track is fastened.

- DE-AS 1 790 163 describes a small potentiometer, in the housing of which can be closed with a cover, a grinder spindle and a resistance winding are arranged axially parallel. This arrangement cannot be used for a rotary potentiometer of the type mentioned at the outset.

- the object of the invention is to propose a rotary potentiometer of the type mentioned, in which an axial insertion of the grinder into the housing is avoided during assembly.

- the above object is achieved with a rotary potentiometer of the type mentioned at the outset in that an opening is formed on the circumference of the wall through which the rotor can be inserted in the radial direction to the cylinder axis and which can be closed with an insert.

- the insert itself can carry functional elements of the rotary potentiometer. It is only attached after the rotor has been inserted.

- the resistance track is applied to a carrier film which is inserted through the opening in the housing. This makes it easier to arrange the resistance track in the correct position.

- the rotor is preferably rotatably mounted on the insert itself, the rotor axis of rotation lying in the cylinder axis when the insert is pushed into the opening. This makes assembly even easier. Because the rotor with the grinder and its electrical connection with the corresponding connection in use, e.g. by means of a spiral spring, can then be mounted on the insert outside the housing. After inserting the insert into the housing, the rotor is in the correct position and the insert closes the opening.

- a rotary potentiometer has a housing (1) which forms a cylindrical wall (2) extending over 180 ° and two wall legs (3, 4) which extend tangentially, as well as an upper (5) and a lower wall part (6).

- the cylinder axis of the wall (2) is designated (7).

- Edges (3 ', 4', 5 ', 6') of the wall legs (3, 4) or the wall parts (5, 6) enclose an opening (8).

- a flexible film (9) which carries a resistance track (10) is inserted into the housing (1). This runs partially cylindrical like the wall (2). It extends over a maximum of 180 °.

- the film (9) is shown unwound in Figure 2. It has conductor tracks (11, 12) which are connected to individual electrodes (14) via diodes (13). The individual electrodes (14) lie on the four edges of the resistance track (10).

- the conductor tracks (11, 12) can be connected to a flexible extension (9 ') of the film (9).

- the resistance track (10) can be laminated onto the film (9).

- the film can be glued into the housing (1). It is also possible to apply the resistance track (10) directly to the wall (2).

- the diodes (13) can also be applied to the film (9) after it has been inserted by means of a conductive adhesive. Your determination is then not burdened by mechanical stresses in the bending of the film (9). If the film (9) to be used is already equipped with diodes (13), its arrangement is advantageous on the parts of the film (9) which, after being inserted, rest on flat wall legs (3, 4); mechanical stresses due to the bending of the foil (9) are also avoided on the diodes (13).

- An insert (15) is provided, the cross section of which corresponds to the free cross section of the opening (8).

- a bearing journal (16) for a rotor (17) is formed on the insert (15) and carries a grinder (18).

- a partially cylindrical tapping surface (19) is formed on the insert (15), the size and radius of which corresponds to the resistance track (10).

- a stop web (20) is provided, to which stop lugs (21, 22) of the rotor (17) are assigned. These serve to limit the rotary movement of the rotor (17) to the extent of the resistance track (10) or the tapping surface (19).

- a plug (23) can be plugged in, which electrically connects the conductor tracks (11, 12) and the tapping surface (19).

- the rotor (17) is not only rotatable on the journal (16) about the axis of rotation (24) but also displaceable in its axial direction. It has a receptacle (25) for a drive rod (26).

- the receptacle (25) is provided with tangential slots (27) which make the receptacle (25) bendable in order to compensate for an axial offset between the drive rod (26) and the rotor (17).

- the drive rod (26) and the receptacle (25) are designed such that the drive rod (26) can be inserted into the receptacle (25) in a rotationally fixed and axially fixed manner.

- a bushing (28) for the drive rod (26) is formed on the wall part (5) of the housing (1).

- the assembly of the rotary potentiometer described is done as follows: After inserting the film (9) into the housing (1), the rotor (17) is placed on the bearing journal (16) so that the stop bar (20) stands between the two stop lugs (21, 22) and one end ( 18 ') of the grinder (18) on the tapping surface (19). The insert (15) is then inserted into the opening (8) and inserted between the wall legs (3, 4) and the wall parts (5, 6) into the housing (1), surfaces (15 ') of the insert (15) provide the appropriate guidance. In the inserted position, the insert (15) can be locked to the housing (1) by means of locking means (not shown). In this position, the cylinder axis (7) and the axis of rotation (24) are aligned. The end (18 '') of the grinder (18) resiliently rests on the resistance track (10).

- the drive rod (26) is then inserted through the bushing (28) into the receptacle (25) of the rotor (17) and the plug (23) is connected. If the drive rod (26) is now turned in the direction of arrow (D) or moved in the direction of arrow (H), then the grinder (18) picks up a corresponding voltage on the resistance track (10), which voltage is applied via the conductor tracks (11, 12), e.g. clocked with changing polarity, is brought up to the resistance track (10).

- pins (29) are provided on the inside of the wall legs (3, 4), to which corresponding free cuts (37) of the film (9) are assigned. This allows the film (9), which also extends along the wall legs (3, 4), Arrange in the correct position in the housing (1) in a simple manner. Due to its inherent elasticity, the film (9) is stretched flush against the cylindrical wall (2) by the pins (29).

- Contact springs (30) are provided on the insert (15) for contacting the conductor tracks (11, 12) (cf. FIGS. 3, 5).

- a contact spring (31) is further arranged on the insert (15), which contacts a conductor track (32) connected to the tapping surface (19) (cf. FIG. 4).

- the conductor track (32) is guided around a curve (33) of the insert (15). It ends in a recess (34). There the contact spring (31) lies against it.

- the contact springs (30, 31) are contacted by inserting the plug (23).

- a bellows (35) is provided to improve the sealing effect in the area of the passage of the drive rod (26).

- the bellows (35) is held at one end on the housing (1). Its other end abuts the rotor (17).

- FIG. 5 also shows a latching tongue (36) with which the drive rod (26) can be fixed axially to the rotor (17).

- the tapping surface (19) can also be arranged in the axial direction next to the resistance track.

Landscapes

- Engineering & Computer Science (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Adjustable Resistors (AREA)

Description

Die Erfindung betrifft ein Drehpotentiometer, bei dem eine Widerstandsbahn innen an einer zylindrischen Wandung eines Gehäuses angeordnet ist, in dem ein Rotor um dessen Zylinderachse drehbar gelagert ist, an weichem ein an der Widerstandsbahn anliegender Schleifer befestigt ist.The invention relates to a rotary potentiometer, in which a resistance track is arranged on the inside of a cylindrical wall of a housing, in which a rotor is rotatably mounted about its cylinder axis, to which a wiper which is in contact with the resistance track is fastened.

Ein derartiges Drehpotentiometer ist in der DE-OS 36 31 058 beschrieben. Bei diesem Potentiometer wird bei der Montage der Rotor in axialer Richtung der Zylinderachse in das Gehäuse eingeschoben. Der Schleifer muß dabei über den Rand der Widerstandsbahn gleiten. Dies ist dann ungünstig, wenn der Rand eine Stufe bildet. Denn der Schleifer kann an der Stufe beim Einschieben verbogen werden.Such a rotary potentiometer is described in DE-OS 36 31 058. With this potentiometer, the rotor is inserted into the housing in the axial direction of the cylinder axis during assembly. The grinder must slide over the edge of the resistance track. This is disadvantageous if the edge forms a step. Because the grinder can be bent at the step when inserting.

Sind neben der Widerstandsbahn in dem Gehäuse weitere Bauteile und/oder Anschlußleitungen angeordnet, dann ist ein axiales Einschieben des Rotors mit dem Schleifer besonders kritisch, da dabei nicht nur der Schleifer verbogen, sondern auch die Bauteile und Anschlußleitungen beschädigt werden können.If other components and / or connecting lines are arranged in the housing in addition to the resistance track, then an axial insertion of the rotor with the grinder is particularly critical since not only the grinder is bent, but also the components and connecting lines can be damaged.

In der EP 0 157 666 A1 ist ein ähnliches Drehpotentiometer beschrieben. Auch bei diesem wird der Rotor mit dem Schleifer in axialer Richtung in das Gehäuse eingeschoben. Ein V-förmiger Freiraum soll das Einschieben des Schleifers erleichtern. Dieser Freiraum steht für die Unterbringung von Funktionsteilen nicht zur Verfügung, so daß Bauraum verlorengeht.A similar rotary potentiometer is described in EP 0 157 666 A1. In this case too, the rotor with the grinder is pushed into the housing in the axial direction. A V-shaped free space should make it easier to insert the grinder. This free space is not available for the accommodation of functional parts, so that space is lost.

In der DE-AS 1 790 163 ist ein Kleinpotentiometer beschrieben, in dessen mit einem Deckel verschließbaren Gehäuse achsparallel eine Schleiferspindel und eine Widerstandswicklung angeordnet sind. Für ein Drehpotentiometer der eingangs genannten Art ist diese Anordnung nicht verwendbar.DE-AS 1 790 163 describes a small potentiometer, in the housing of which can be closed with a cover, a grinder spindle and a resistance winding are arranged axially parallel. This arrangement cannot be used for a rotary potentiometer of the type mentioned at the outset.

Aufgabe der Erfindung ist es, ein Drehpotentiometer der eingangs genannten Art vorzuschlagen, bei dem bei der Montage ein axiales Einschieben des Schleifers in das Gehäuse vermieden ist.The object of the invention is to propose a rotary potentiometer of the type mentioned, in which an axial insertion of the grinder into the housing is avoided during assembly.

Erfindungsgemäß ist obige Aufgabe bei einem Drehpotentiometer der eingangs genannten Art dadurch gelöst, daß am Umfang der Wandung eine Öffnung ausgebildet ist, durch die der Rotor in zur Zylinderachse radialer Richtung einführbar ist und die mit einem Einsatz verschließbar ist.According to the invention, the above object is achieved with a rotary potentiometer of the type mentioned at the outset in that an opening is formed on the circumference of the wall through which the rotor can be inserted in the radial direction to the cylinder axis and which can be closed with an insert.

Dadurch ist erreicht, daß der Schleifer bei der Montage nicht über Ränder der Widerstandsbahn und auch nicht über bei diesen angeordnete Leiterbahnen und Bauelemente gleitet. Gegenseitige Beschädigungen sind dadurch vermieden, ohne daß beim Einsetzen des Rotors eine besondere Sorgfalt notwendig ist.This ensures that the grinder does not slide over the edges of the resistance track during assembly and also not over conductor tracks and components arranged thereon. Mutual damage is avoided without special care being required when inserting the rotor.

Im Gehäuse braucht kein besonderer Freiraum vorgesehen zu sein. Der Einsatz selbst kann Funktionselemente des Drehpotentiometers tragen. Er wird erst nach dem Einsetzen des Rotors angebracht.No special free space needs to be provided in the housing. The insert itself can carry functional elements of the rotary potentiometer. It is only attached after the rotor has been inserted.

In bevorzugter Ausgestaltung der Erfindung ist die Widerstandsbahn auf eine Trägerfolie aufgebracht, die durch die Öffnung in das Gehäuse eingesetzt ist. Es ist damit eine lagerichtige Anordnung der Widerstandsbahn erleichtert.In a preferred embodiment of the invention, the resistance track is applied to a carrier film which is inserted through the opening in the housing. This makes it easier to arrange the resistance track in the correct position.

Vorzugsweise ist der Rotor an dem Einsatz selbst drehbar gelagert, wobei die Rotordrehachse bei in die Öffnung eingeschobenem Einsatz in der Zylindereachse liegt. Die Montage ist dadurch weiter erleichtert. Denn der Rotor mit dem Schleifer und dessen elektrische Verbindung mit dem entsprechenden Anschluß im Einsatz, z.B. durch eine Spiralfeder, kann dann außerhalb des Gehäuses an dem Einsatz montiert werden. Nach dem Einschieben des Einsatzes in das Gehäuse steht der Rotor in der richtigen Stellung und der Einsatz verschließt die Öffnung.The rotor is preferably rotatably mounted on the insert itself, the rotor axis of rotation lying in the cylinder axis when the insert is pushed into the opening. This makes assembly even easier. Because the rotor with the grinder and its electrical connection with the corresponding connection in use, e.g. by means of a spiral spring, can then be mounted on the insert outside the housing. After inserting the insert into the housing, the rotor is in the correct position and the insert closes the opening.

Weitere vorteilhafte Ausgestaltungen ergeben sich aus weiteren Unteransprüchen und der folgenden Beschreibung. In der Zeichnung zeigen:

- Figur 1

- eine Explosionsdarstellung eines Drehpotentiometers,

Figur 2- eine Widerstandsbahn des Drehpotentiometers in abgewickelter Lage,

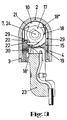

Figur 3- einen Schnitt eines Drehpotentiometers längs der Linie III nach

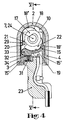

Figur 5, Figur 4- einen Schnitt längs der Linie IV

Figur 5- einen Längsschnitt längs der Linie V-V nach

Figur 4.

- Figure 1

- an exploded view of a rotary potentiometer,

- Figure 2

- a resistance path of the rotary potentiometer in a developed position,

- Figure 3

- 4 shows a section of a rotary potentiometer along the line III according to FIG. 5,

- Figure 4

- a section along the line IV

- Figure 5

- a longitudinal section along the line VV of Figure 4.

Ein Drehpotentiometer weist ein Gehäuse (1) auf, welches eine sich über 180° erstreckende zylindrische Wandung (2) und zwei diese tangential verlängernde Wandschenkel (3, 4) sowie ein oberes (5) und ein unteres Wandteil (6) bildet. Die Zylinderachse der Wandung (2) ist mit (7) bezeichnet. Ränder (3′, 4′, 5′, 6′) der Wandschenkel (3, 4) bzw. der Wandteile (5, 6) umschließen eine Öffnung (8).A rotary potentiometer has a housing (1) which forms a cylindrical wall (2) extending over 180 ° and two wall legs (3, 4) which extend tangentially, as well as an upper (5) and a lower wall part (6). The cylinder axis of the wall (2) is designated (7). Edges (3 ', 4', 5 ', 6') of the wall legs (3, 4) or the wall parts (5, 6) enclose an opening (8).

In das Gehäuse (1) ist eine flexible Folie (9) eingelegt, die eine Widerstandsbahn (10) trägt. Diese verläuft dabei teilzylindrisch wie die Wandung (2). Sie erstreckt sich höchstens über 180°. Die Folie (9) ist in Figur 2 abgewickelt dargestellt. Sie weist Leiterbahnen (11, 12) auf, welche über Dioden (13) an Einzelelektroden (14) angeschlossen sind. Die Einzelelektroden (14) liegen an den vier Rändern der Widerstandsbahn (10). An einem flexiblen Fortsatz (9′) der Folie (9) sind die Leiterbahnen (11, 12) anschließbar.A flexible film (9) which carries a resistance track (10) is inserted into the housing (1). This runs partially cylindrical like the wall (2). It extends over a maximum of 180 °. The film (9) is shown unwound in Figure 2. It has conductor tracks (11, 12) which are connected to individual electrodes (14) via diodes (13). The individual electrodes (14) lie on the four edges of the resistance track (10). The conductor tracks (11, 12) can be connected to a flexible extension (9 ') of the film (9).

Die Widerstandsbahn (10) kann auf die Folie (9) auflaminiert sein. Die Folie kann in das Gehäuse (1) geklebt sein. Es ist auch möglich die Widerstandsbahn (10) direkt auf die Wandung (2) aufzubringen. Die Dioden (13) können durch die vergleichsweise große Öffnung (8) auch nach dem Einsetzen der Folie (9) auf diese mittels eines Leitklebers aufgebracht werden. Ihre Festlegung ist dann nicht durch mechanische Spannungen der Biegung der Folie (9) belastet. Ist bereits die einzusetzende Folie (9) mit Dioden (13) bestückt, so ist deren Anordnung vorteilhaft auf den Teilen der Folie (9), die nach dem Einsetzen an ebenen Wandschenkeln (3, 4) anliegen; auch so sind an den Dioden (13) mechanische Spannungen durch die Biegung der Folie (9) vermieden.The resistance track (10) can be laminated onto the film (9). The film can be glued into the housing (1). It is also possible to apply the resistance track (10) directly to the wall (2). Through the comparatively large opening (8), the diodes (13) can also be applied to the film (9) after it has been inserted by means of a conductive adhesive. Your determination is then not burdened by mechanical stresses in the bending of the film (9). If the film (9) to be used is already equipped with diodes (13), its arrangement is advantageous on the parts of the film (9) which, after being inserted, rest on flat wall legs (3, 4); mechanical stresses due to the bending of the foil (9) are also avoided on the diodes (13).

Es ist ein Einsatz (15) vorgesehen, dessen Querschnitt dem freien Querschnitt der Öffnung (8) entspricht. Am Einsatz (15) ist ein Lagerzapfen (16) für einen Rotor (17) ausgebildet, welcher einen Schleifer (18) trägt.An insert (15) is provided, the cross section of which corresponds to the free cross section of the opening (8). A bearing journal (16) for a rotor (17) is formed on the insert (15) and carries a grinder (18).

Am Einsatz (15) ist eine teilzylindrische Abgriffsfläche (19) ausgebildet, deren Größe und Radius der Widerstandsbahn (10) entspricht. Neben der Abgriffsfläche (19) ist ein Anschlagsteg (20) vorgesehen, dem Anschlagnasen (21, 22) des Rotors (17) zugeordnet sind. Diese dienen der Begrenzung der Drehbewegung des Rotors (17) auf die Erstreckung der Widerstandsbahn (10) bzw. der Abgriffsfläche (19).A partially cylindrical tapping surface (19) is formed on the insert (15), the size and radius of which corresponds to the resistance track (10). In addition to the tapping surface (19), a stop web (20) is provided, to which stop lugs (21, 22) of the rotor (17) are assigned. These serve to limit the rotary movement of the rotor (17) to the extent of the resistance track (10) or the tapping surface (19).

Außen an den Einsatz (15) ist ein Stecker (23) ansteckbar, der die Leiterbahnen (11, 12) und die Abgriffsfläche (19) elektrisch anschließt.On the outside of the insert (15), a plug (23) can be plugged in, which electrically connects the conductor tracks (11, 12) and the tapping surface (19).

Der Rotor (17) ist auf dem Lagerzapfen (16) nicht nur um die Drehachse (24) drehbar, sondern auch in deren Axialrichtung verschieblich. Er weist eine Aufnahme (25) für eine Antriebsstange (26) auf. Die Aufnahme (25) ist mit tangentialen Schlitzen (27) versehen, die die Aufnahme (25) biegbar machen, um einen Achsversatz zwischen der Antriebsstange (26) und dem Rotor (17) auszugleichen. Die Antriebsstange (26) und die Aufnahme (25) sind so gestaltet, daß die Antriebsstange (26) drehfest und axial fest in die Aufnahme (25) einsteckbar ist. An dem Wandteil (5) des Gehäuses (1) ist eine Durchführung (28) für die Antriebsstange (26) ausgebildet.The rotor (17) is not only rotatable on the journal (16) about the axis of rotation (24) but also displaceable in its axial direction. It has a receptacle (25) for a drive rod (26). The receptacle (25) is provided with tangential slots (27) which make the receptacle (25) bendable in order to compensate for an axial offset between the drive rod (26) and the rotor (17). The drive rod (26) and the receptacle (25) are designed such that the drive rod (26) can be inserted into the receptacle (25) in a rotationally fixed and axially fixed manner. A bushing (28) for the drive rod (26) is formed on the wall part (5) of the housing (1).

Die Montage des beschriebenen Drehpotentiometers erfolgt etwa so:

Nach dem Einsetzen der Folie (9) in das Gehäuse (1) wird der Rotor (17) auf den Lagerzapfen (16) gesteckt, so daß der Anschlagsteg (20) zwischen den beiden Anschlagnasen (21, 22) steht und das eine Ende (18′) des Schleifers (18) an der Abgriffsfläche (19) anliegt. Anschließend wird der Einsatz (15) in die Öffnung (8) eingesetzt und zwischen den Wandschenkeln (3, 4) und den Wandteilen (5, 6) in das Gehäuse (1) eingeschoben, wobei Flächen (15′) des Einsatzes (15) die geeignete Führung bieten. In der eingeschobenen Stellung kann der Einsatz (15) mittels nicht näher dargestellter Rastmittel mit dem Gehäuse (1) verrastet sein. In dieser Stellung fluchten die Zylinderachse (7) und die Drehachse(24). Das Ende (18′′) des Schleifers (18) liegt federnd an der Widerstandsbahn (10) an.The assembly of the rotary potentiometer described is done as follows:

After inserting the film (9) into the housing (1), the rotor (17) is placed on the bearing journal (16) so that the stop bar (20) stands between the two stop lugs (21, 22) and one end ( 18 ') of the grinder (18) on the tapping surface (19). The insert (15) is then inserted into the opening (8) and inserted between the wall legs (3, 4) and the wall parts (5, 6) into the housing (1), surfaces (15 ') of the insert (15) provide the appropriate guidance. In the inserted position, the insert (15) can be locked to the housing (1) by means of locking means (not shown). In this position, the cylinder axis (7) and the axis of rotation (24) are aligned. The end (18 '') of the grinder (18) resiliently rests on the resistance track (10).

Anschließend wird die Antriebsstange (26) durch die Durchführung (28) in die Aufnahme (25) des Rotors (17) eingesteckt und der Stecker (23) angeschlossen. Wird nun die Antriebsstange (26) in Richtung des Pfeiles (D) gedreht oder in Richtung des Pfeiles (H) verschoben, dann greift der Schleifer (18) an der Widerstandsbahn (10) eine entsprechende Spannung ab, die über die Leiterbahnen (11, 12), z.B. mit wechselnder Polarität getaktet, an die Widerstandsbahn (10) herangeführt ist.The drive rod (26) is then inserted through the bushing (28) into the receptacle (25) of the rotor (17) and the plug (23) is connected. If the drive rod (26) is now turned in the direction of arrow (D) or moved in the direction of arrow (H), then the grinder (18) picks up a corresponding voltage on the resistance track (10), which voltage is applied via the conductor tracks (11, 12), e.g. clocked with changing polarity, is brought up to the resistance track (10).

Bei der Ausführung nach den Figuren 3 bis 5 sind innen an den Wandschenkeln (3, 4) Zapfen (29) vorgesehen, denen entsprechende Freischnitte (37) der Folie (9) zugeordnet sind. Dadurch läßt sich die Folie (9), die sich auch längs der Wandschenkel (3, 4) erstreckt, auf einfache Weise lagerichtig in dem Gehäuse (1) anordnen. Aufgrund ihrer Eigenelastizität ist die Folie (9) durch die Zapfen (29) bündig an die zylindrische Wandung (2) gespannt. Am Einsatz (15) sind Kontaktfedern (30) zur Kontaktierung der Leiterbahnen (11, 12) vorgesehen (vgl. Figur 3, 5). An dem Einsatz (15) ist weiterhin eine Kontaktfeder (31) angeordnet, welche eine mit der Abgriffsfläche (19) verbundene Leiterbahn (32) kontaktiert (vgl. Figur 4). Die Leiterbahn (32) ist um eine Rundung (33) des Einsatzes (15) geführt. Sie endet in einer Aussparung (34). Dort liegt die Kontaktfeder (31) an ihr an.In the embodiment according to FIGS. 3 to 5, pins (29) are provided on the inside of the wall legs (3, 4), to which corresponding free cuts (37) of the film (9) are assigned. This allows the film (9), which also extends along the wall legs (3, 4), Arrange in the correct position in the housing (1) in a simple manner. Due to its inherent elasticity, the film (9) is stretched flush against the cylindrical wall (2) by the pins (29). Contact springs (30) are provided on the insert (15) for contacting the conductor tracks (11, 12) (cf. FIGS. 3, 5). A contact spring (31) is further arranged on the insert (15), which contacts a conductor track (32) connected to the tapping surface (19) (cf. FIG. 4). The conductor track (32) is guided around a curve (33) of the insert (15). It ends in a recess (34). There the contact spring (31) lies against it.

Der Vergleich der Figuren 3 und 4 zeigt den Drehbereich des Rotors (17) und entsprechend die Umfangserstreckung der Widerstandsbahn (10) und der Abgriffsfläche (19).The comparison of Figures 3 and 4 shows the range of rotation of the rotor (17) and correspondingly the circumferential extent of the resistance track (10) and the tapping surface (19).

Die Kontaktfedern (30, 31) werden durch das Einstecken des Steckers (23) kontaktiert.The contact springs (30, 31) are contacted by inserting the plug (23).

Bei der Ausführung nach Figur 5 ist ein Faltenbalg (35) zur Verbesserung der Dichtwirkung im Bereich der Durchführung der Antriebsstange (26) vorgesehen. Der Faltenbalg (35) ist mit seinem einen Ende an dem Gehäuse (1) gehalten. Sein anderes Ende liegt an dem Rotor (17) an. In Figur 5 ist außerdem eine Rastzunge (36) gezeigt, mit der die Antriebsstange (26) axial fest an dem Rotor (17) fixierbar ist.In the embodiment according to FIG. 5, a bellows (35) is provided to improve the sealing effect in the area of the passage of the drive rod (26). The bellows (35) is held at one end on the housing (1). Its other end abuts the rotor (17). FIG. 5 also shows a latching tongue (36) with which the drive rod (26) can be fixed axially to the rotor (17).

Es ist auch möglich den Rotor (17) direkt zu kontaktieren. Es erübrigt sich dann die Abgriffsfläche (19). Die Abgriffsfläche (19) kann auch in Axialrichtung neben der Widerstandsbahn angeordnet sein.It is also possible to contact the rotor (17) directly. There is then no need for the tapping surface (19). The tapping surface (19) can also be arranged in the axial direction next to the resistance track.

Claims (10)

- Rotary potentiometer having a resistance track (10) disposed internally on one cylindrical wall (2) of a housing (1) in which a rotor (17) is mounted so as to rotate around its cylindrical axis (7), to which rotor is secured a slider (18) in contact with the resistance track (10), characterised in that an opening (8) is formed on the circumference of the wall (2), through which opening the rotor (17) can be introduced in a radial direction to the cylindrical axis (7), and which can be sealed with an insert (15).

- Rotary potentiometer according to claim 1, characterised in that the resistance track (10) is put onto a sheet (9), which is inserted into the housing (1) through the opening (8).

- Rotary potentiometer according to claim 1 or 2, characterised in that the rotor (17) is mounted on the insert (15) so as to rotate thereon, the rotational axis (24) of the rotor lying on the cylindrical axis (7) once the insert (15) has been pushed into the opening (8).

- Rotary potentiometer according to any of the preceding claims, characterised in that the resistance track (10) extends through not more than 180° and formed on the insert (15) is a tapping surface (19), cylindrical like the resistance track (10), and against which the slider (18) bears.

- Rotary potentiometer according to any of the preceding claims, characterised in that on the housing (1) the cylindrical wall (2) incorporates tangentially extending side pieces (3, 4) which delimit the opening (8).

- Rotary potentiometer according to claim 5, characterised in that the sheet (9) in addition to the resistance track (10) contains electrical components (13) whose configuration on the sheet (9) is associated with the planar side pieces (3, 4).

- Rotary potentiometer according to any of the preceding claims, characterised in that provided on the insert (15) is a stop segment (20) for limiting the rotation of the rotor (17).

- Rotary potentiometer according to any of the preceding claims, characterised in that the rotor (17) is mounted on the insert (15) so as to be longitudinally displaceable along the rotational axis (24).

- Rotary potentiometer according to any of the preceding claims, characterised in that a locator (25) for a drive shaft (26) which projects beyond the housing (1) is provided on the insert (15).

- Rotary potentiometer according to any of the preceding claims, characterised in that provided on the insert (15) is a plug connector (23) for electrically connecting the resistance track (10) and the tapping surface (19).

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3808583 | 1988-03-15 | ||

| DE19883808583 DE3808583C1 (en) | 1988-03-15 | 1988-03-15 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0333003A2 EP0333003A2 (en) | 1989-09-20 |

| EP0333003A3 EP0333003A3 (en) | 1990-04-18 |

| EP0333003B1 true EP0333003B1 (en) | 1993-10-20 |

Family

ID=6349755

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP19890104055 Expired - Lifetime EP0333003B1 (en) | 1988-03-15 | 1989-03-08 | Rotary potentiometer |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP0333003B1 (en) |

| DE (1) | DE3808583C1 (en) |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1790163C3 (en) * | 1968-09-20 | 1973-12-06 | Dale Electronics, Inc., Columbus, Nebr. (V.St.A.) | Small potentiometer with an elongated cuboid housing that can be closed by a housing cover |

| US4355293A (en) * | 1979-10-22 | 1982-10-19 | The Bendix Corporation | Electrical resistance apparatus having integral shorting protection |

| FR2560428B1 (en) * | 1984-02-28 | 1987-02-27 | Renix Electronique Sa | ROTARY POTENTIOMETER IN PARTICULAR FOR ANGULAR POSITION MEASUREMENT |

| DE3631058A1 (en) * | 1986-09-12 | 1988-03-24 | Preh Elektro Feinmechanik | METHOD FOR PRODUCING GUIDANCE AND / OR RESISTANCE TRACKS ON A SUBSTRATE AND POTENTIOMETER PRODUCED BY THIS METHOD |

-

1988

- 1988-03-15 DE DE19883808583 patent/DE3808583C1/de not_active Expired

-

1989

- 1989-03-08 EP EP19890104055 patent/EP0333003B1/en not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| EP0333003A3 (en) | 1990-04-18 |

| DE3808583C1 (en) | 1989-05-11 |

| EP0333003A2 (en) | 1989-09-20 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE2749028C2 (en) | High voltage connector | |

| DE60008058T2 (en) | rotary connector | |

| DE69501873T2 (en) | Waterproof electrical connector | |

| DE2912413C2 (en) | ||

| DE1961846B2 (en) | Speed sensor for determining the speed or change in speed of vehicle wheels, in particular for brake slip control systems of motor vehicles | |

| DE4028892A1 (en) | DRIVING DEVICE, IN PARTICULAR FOR WINDOW WIPERS ON MOTOR VEHICLES | |

| EP0387585A1 (en) | Flat cable spirals | |

| EP0333003B1 (en) | Rotary potentiometer | |

| DE2710129A1 (en) | CABLE REEL | |

| DE2155457B2 (en) | Power tool with an axially displaceable stator | |

| DE2742749A1 (en) | LIMIT SWITCH | |

| DE2548131A1 (en) | CABLE REEL | |

| DE112006003971T5 (en) | Rotary terminal mechanism | |

| DE1440751B2 (en) | COIL POTENTIOMETER | |

| EP0344628B1 (en) | Explosionproof lampholder for twopin-fluorescent tubes | |

| DE19547959A1 (en) | Device for electrically connecting parts to the steering wheel and the steering column of a motor vehicle | |

| DE1763883C3 (en) | Brush holder | |

| DE3727199C1 (en) | Coaxial cable plug connector | |

| DE2805509A1 (en) | PIPE CONNECTOR | |

| DE69501284T2 (en) | Rotatable electrical connector with a flexible cable limited in length | |

| DE10162127A1 (en) | Electrical connector between two end points | |

| DE2607075A1 (en) | Cable reeling arrangement with unlimited rotation - uses coaxial contacts with annular contact spring permitting rotation only when current switched off | |

| DE8812072U1 (en) | Radio-suppressed commutator motor, in particular motor vehicle on-board motor | |

| DE3838666C2 (en) | ||

| DE202025105284U1 (en) | Slip ring assembly and contact element carrier for this |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): FR GB IT |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): FR GB IT |

|

| 17P | Request for examination filed |

Effective date: 19900911 |

|

| 17Q | First examination report despatched |

Effective date: 19930326 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): FR GB IT |

|

| ET | Fr: translation filed | ||

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 19931102 |

|

| ITF | It: translation for a ep patent filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19970213 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19970214 Year of fee payment: 9 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19980308 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: THE PATENT HAS BEEN ANNULLED BY A DECISION OF A NATIONAL AUTHORITY Effective date: 19980331 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19980308 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20050308 |