EP0253184B1 - Device for weft insertion in a gripper loom - Google Patents

Device for weft insertion in a gripper loom Download PDFInfo

- Publication number

- EP0253184B1 EP0253184B1 EP87109282A EP87109282A EP0253184B1 EP 0253184 B1 EP0253184 B1 EP 0253184B1 EP 87109282 A EP87109282 A EP 87109282A EP 87109282 A EP87109282 A EP 87109282A EP 0253184 B1 EP0253184 B1 EP 0253184B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- tape

- wheel

- recess

- belt

- picking

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000003780 insertion Methods 0.000 title description 18

- 230000037431 insertion Effects 0.000 title description 18

- 230000002093 peripheral effect Effects 0.000 claims description 18

- 230000007704 transition Effects 0.000 claims description 5

- 235000004879 dioscorea Nutrition 0.000 claims 1

- 239000012858 resilient material Substances 0.000 claims 1

- 239000000463 material Substances 0.000 description 8

- 238000004804 winding Methods 0.000 description 8

- 238000009941 weaving Methods 0.000 description 7

- 235000014676 Phragmites communis Nutrition 0.000 description 2

- 238000010276 construction Methods 0.000 description 2

- 239000013013 elastic material Substances 0.000 description 2

- 238000000034 method Methods 0.000 description 2

- 235000004443 Ricinus communis Nutrition 0.000 description 1

- 240000000528 Ricinus communis Species 0.000 description 1

- 230000007423 decrease Effects 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 230000000630 rising effect Effects 0.000 description 1

- 238000007665 sagging Methods 0.000 description 1

Images

Classifications

-

- D—TEXTILES; PAPER

- D03—WEAVING

- D03D—WOVEN FABRICS; METHODS OF WEAVING; LOOMS

- D03D47/00—Looms in which bulk supply of weft does not pass through shed, e.g. shuttleless looms, gripper shuttle looms, dummy shuttle looms

- D03D47/27—Drive or guide mechanisms for weft inserting

- D03D47/275—Drive mechanisms

- D03D47/276—Details or arrangement of sprocket wheels

-

- D—TEXTILES; PAPER

- D03—WEAVING

- D03D—WOVEN FABRICS; METHODS OF WEAVING; LOOMS

- D03D47/00—Looms in which bulk supply of weft does not pass through shed, e.g. shuttleless looms, gripper shuttle looms, dummy shuttle looms

- D03D47/27—Drive or guide mechanisms for weft inserting

- D03D47/271—Rapiers

- D03D47/272—Rapier bands

-

- D—TEXTILES; PAPER

- D03—WEAVING

- D03D—WOVEN FABRICS; METHODS OF WEAVING; LOOMS

- D03D47/00—Looms in which bulk supply of weft does not pass through shed, e.g. shuttleless looms, gripper shuttle looms, dummy shuttle looms

- D03D47/27—Drive or guide mechanisms for weft inserting

- D03D47/277—Guide mechanisms

Definitions

- the invention relates to a device for weft insertion on a belt rapier weaving machine, with a belt wheel driven in an alternating direction of rotation and a flexible entry belt carrying an insertion member for a weft thread, which is attached at one end to the belt wheel and which with winding and unwinding in a more is issued as a 360 ° circumferential wrapping area of the belt wheel of an oscillating movement transversely to the warp threads from or into the shed, as well as with a flexible guide element, which wraps around the part of the entry belt located on the belt wheel and a first section at a distance has a second section running from the entry belt and guided over two deflection rollers arranged at a distance from one another.

- the guide element is formed by a rope, the two ends of which are each guided through a recess provided in the circumferential area of the band wheel against the axis of the band wheel and fastened to a tab arranged inside the band wheel body .

- a screw In the circumferential area of the band wheel adjoining the cutout in the unwinding direction of the entry band, one end of the entry band is fastened by a screw.

- a support section is formed on the circumference of the belt wheel, which has a thickness that is approximately constant over 100 ° of the circumference of the belt wheel and a thickness that is essentially spiral-like over the remaining circumference section and that increases continuously in the unwinding direction, this circumference section in the region of the recess ends with a gradation, the height of which corresponds to the sum of the thicknesses of the rope and the entry tape.

- kinks can occur in the part of the entry belt that wraps around the clamping end, which lead to permanent deformation of the entry belt and thus the service life and can affect the leadership of the entry belt.

- the guide element deflected in the area of the recess with a correspondingly small radius is also subjected to particularly high stress.

- the invention has for its object to provide a particularly improved in this respect device of the type mentioned, which - with a simplified design of the tape wheel - a kink-free guidance of the entry belt when winding the tape wheel through an angle of more than 360 ° and a corresponding gentle guidance of the guide element also permitted in connection with belt wheels in a compact design.

- At least one trough-like recess is provided on the circumference of the belt wheel for receiving one end section of the entry belt and / or one end section of the guide element, and that at least one can be fastened in the recess against the relevant end section of the entry belt and / or the guide element clampable clamping piece is provided, which is adapted to the course of the adjoining the depression in both circumferential sections of the surfaces to be wrapped and continuously curved over the depression in the circumferential direction of the support surface for the portion of the entry belt or the guide passed over the depression . of the guide element.

- the device designed according to the invention permits particularly gentle guidance of the entry belt in a guideway which, from the clamping point arranged in the recess, runs flatly curved against the peripheral surface of the belt wheel. At the same time, when the clamping point is wound over, a secure guidance of the portion of the entry belt extending over the recess and the portion of the guide element which lies against it is ensured.

- a kink-free run-up of the relevant section of the entry belt onto the transition point between the end section located in the depression and the part of the guide element already wrapping around the entry wheel or during the unwinding process is corresponding kink-free running of the relevant section of the entry belt can be achieved from the area of the said transition point, since the clamping piece designed and arranged according to the invention, with its arched support surface, prevents "sagging" of the sections of the entry belt and the guide element lying against the recess. Accordingly, additional stresses on the material, which is already highly stressed, in particular in connection with the large working widths and high weft insertion rates of today's weaving machines, are avoided.

- a particularly compact design can be achieved with a tape wheel that can be rewound several times.

- the entangled arrangement of Um Steering castors are known per se in connection with a lateral deflection of a rope-like, cut-off guide element; a lateral deflection of a band-like guide element has so far been avoided in the case of weft insertion devices of the type mentioned at the outset.

- the design according to claim 2 ensures trouble-free lateral deflection and thus reliable guiding of the cut-off band-like guide element in two adjacent wrap areas of the band wheel.

- the embodiment according to claim 2 leads, in particular, to a relatively low load on both the feed belt and the belt wheel, which is evenly distributed over the width of the guide belt, since high local loads, such as can occur when using a rope-like guide element, are eliminated.

- the belt wheel which has to be stopped and accelerated again each time the direction of rotation changes, can therefore be of a correspondingly light construction, for example made of a plastic, and have a correspondingly low mass.

- the band-shaped guide element can neither "dig" into the entry belt nor via this into the peripheral surface of the band wheel and can have a much smaller thickness than a rope-like design, so that even with multiple winding of the Band wheel results in a relatively small, alternately accelerating and decelerating moving mass.

- a tight fit of the generally relatively dimensionally stable entry belt can already be ensured at the transition point between the clamping point and the peripheral region of the belt wheel.

- the machine frame I contains on the left side and on the right side a carrier 3 with a holding plate 4, on which a belt wheel 5 is rotatably arranged.

- I only shows the left side of the machine frame I with the left carrier 3, which is mirror-image to the right carrier, and the band wheel 5, which is mirror-image to the right band wheel.

- a reed 6 is attached for guiding warp threads, not shown.

- a first end section 7a of a flexible entry belt 7 is fastened to the circumference of the left band wheel 5, the second end section 7b of which bears a gripper head 8 intended for gripping one end of a weft thread, not shown.

- a corresponding entry belt, also provided with a gripper head, is attached to the right belt wheel.

- the two belt wheels are each driven in an oscillating and counter-rotating manner, with the winding and unwinding of the two entry belts 7 giving the gripper heads 8 fastened thereon an oscillating movement transversely to the warp threads out of or into the shed, not shown, formed by them.

- the rapier heads 8 are constantly moved along the sley 2 to the middle of the shed and then pulled out of the shed again.

- One end of a weft thread is transferred from a weft thread supply arranged on the right-hand side of the weaving machine, not shown, outside the shed to the rapier head arranged on the right entry belt.

- the weft thread is inserted into the first half of the shed and in the middle of the shed is transferred to the rapier head 8 arranged on the left entry belt 7, through which the weft thread is then inserted into the second half of the shed.

- the weft thread is cast in a known manner by the reed 6 in the tip of the shed, not shown.

- the weft insertion device can also have a single belt wheel 5 and a single entry belt 7, which can be guided from one side of the loom over the entire weaving width and back, the gripper head of which carries out a complete weft insertion.

- the rapier head 8 passes through the left edge of the shed.

- the gripper head 8 is guided against the center of the shed by the entry band 7 moved when unwinding from the band wheel 5 according to arrow 10, after taking over the weft thread entered by the right gripper head - by winding up the entry band 7 according to arrow 10a - from the shed and after that Subject change for a new weft entry against the center of the shed and returned.

- the entry belt 7 is wound with a wrap angle of more than 360 °, corresponding to the representation according to FIG. I, for example approx. 460 ° with the rapier head 8 located outside the shed, on the circumference of the belt wheel 5 and from the outlet point on the belt wheel 5 via a guide rail II guided against a guide track provided on the sley 2.

- a belt-like, lengthened guide belt 12 is provided, which can have a smaller width than the entry belt 7.

- the guide belt 12 wraps around the part of the entry belt 7 located on the belt wheel 5 and presses it - under the action of a spring arrangement 31 which can be braced against the guide belt 12 - against the circumference of the belt wheel 5.

- a first end section 12a of the guide belt 12 is together with the corresponding one End section 7a of the entry belt 7 in a provided on the circumference of the belt wheel 5, flat domed trough-like recess 13 by a recessed insert 14 into this, which is clamped by a screw 15 via the two end sections 7a and 12a against the bottom of the recess 13. 4 and 5, the recess 13 can be delimited by flat convexly curved surface parts 13d and 13e which merge into the cylindrical peripheral surface of the belt wheel 5.

- the deflection roller 16 is arranged on an axis 32 parallel to the axis of the belt wheel 5, which is attached to a support 33 connected to the machine frame I.

- the deflection roller 17 is arranged on an axis 34 which is inclined with respect to the axis 32 and which is movably guided by a holder 35.

- the holder 35 is fastened to a support part 36 connected to the machine frame I and contains the spring arrangement 31, shown in simplified form in FIG. I as a tension spring, by means of which the guide band 12 is held tensioned over the deflection roller 17.

- the deflection roller 16 can also be guided in a movable manner and cooperate with a corresponding spring arrangement.

- the guide belt 12 is - with the entry belt 7 wound up - with a looping angle of over 360 ° , corresponding to the illustration according to FIG. I, for example approximately 620 °, against which the recess 13 also extends over the second looping area 5b which the second end section 12b of the guide belt 12 is fastened by a second clamping piece 18 which can be inserted into the recess 13.

- a second clamping piece 18 which can be inserted into the recess 13.

- the deflection rollers 16, 17 are designed with cambered circumferential surfaces and are arranged so that they are interlocked so that the circumferential regions of the deflection rollers 16 and 17 facing the circumference of the belt wheel 5 are offset from one another in the axial direction of the belt wheel 5 and each against the first looping region 5a and the second wrap area 5b of the belt wheel 5 are oriented.

- cooperating guide means of known type can be provided.

- the depression 13 can be designed essentially symmetrically to a radial plane 20 running through the axis of rotation of the band wheel 5.

- the clamping pieces 14 and 18 each have a cross section adapted to the shape of the recess 13 and each contain a support surface 14a or 18a adapted to the course of the portions of the surfaces to be wrapped around the recesses 13 in both circumferential directions of the belt wheel 5 for the relevant clamping piece 14 or 18 overwrapping portion of the entry belt 7 or the guide belt 12.

- the clamping pieces 14 and 18 can each be designed asymmetrically with respect to the radial plane 20 by the support surfaces 14a and 18a, depending on the one or the other circumferential direction of the Band wheel 5 continuously rising, curved like a spiral over the "length" of the relevant clamping piece 14 or 18.

- the clamping piece 14 can be designed such that it is in the position placed on the end sections 7a and 12a of the entry belt 7 and the guide belt 12 with an edge portion 14b which continues from the recess 13 against the peripheral surface of the belt wheel 5 Parts of the end portions 7a and 12 overlap, for example by an amount which corresponds at least approximately to the sum of the thicknesses of the clamped end portions 7a and 12a, over the circumferential surface of the band wheel 5, while one pointing in the opposite circumferential direction, the En the edge section 14c covering the end sections 7a and 12 lies in the region of the peripheral surface.

- These support surfaces 14a and 18a allow a kink-free transition from the cylindrical circumferential surface of the belt wheel 5 to the thickness increased by the thickness of the entry belt 7 and the guide belt 12 (FIG. 4) or by the thickness of the guide belt 12 (FIG. 5) Surface of the corresponding part of the guide band 12 formed winding surface.

- kink-free guidance of these belts can also be achieved by clamping pieces 14 and 18, each of which has the same dimension, e.g. are increased on one side in accordance with the thickness of the entry belt 7 and accordingly have identical cross sections.

- the edge parts 14c and 18c of the clamping pieces 14 and 18 assigned to the ends of the end sections 7a and 12a and 12b can each be provided with a guide pin 21 which projects above the clamping surface of the respective clamping piece 14 and 18 and which is guided by a respective end section 7a, 12a or 12b provided opening 19 can be inserted into a guide opening 22 provided on the belt wheel 5 in the region of the recess 13.

- a faulty insertion of the clamping pieces 14 and 18 is prevented by these guide pins 21 arranged asymmetrically on the clamping pieces 14 and 18.

- the guide openings 22, e.g. can each be designed in the form of an elongated hole, which permits positioning of the relevant clamping piece 14 or 18, which can be set in the circumferential direction of the band wheel 5.

- the entry belt 7 can have a zone 25 of less rigidity than in its remaining longitudinal extent. 6, with a constant strip thickness T, the entry strip 7 can have a layer 26 made of the relatively rigid base material of the entry strip 7 and continuing over the length A with a reduced strip thickness T i , and a layer 27, for example glued, connected to this layer 26 contain soft elastic material, the thickness S of which can correspond to the thickness Ti of the layer 26 as shown in FIG. 6.

- the layer 26, which continues over the length section A and consists of the base material of the entry belt 7, can be arranged between two layers 27 made of flexible material and connected to them.

- the thicknesses T i and S of these layers 26, 27 can correspond, for example, to one third each of the thickness T of the entry belt 7.

- the layer 26 consisting of the base material of the entry belt 7 can have a graded thickness Ti which decreases towards the end of the belt, and the layers 27 made of flexible material can each be designed with a correspondingly increasing thickness S.

- the portion of the entry belt 7 extending over the length section A can be designed with a thickness Ti that tapers conically towards the end of the tape and can be connected to the layer 27 of soft elastic material that has a correspondingly conically increasing thickness.

- the entry belt 7 can have a thickness T 1 that tapers conically towards the end of the belt and can be connected to two layers 27 attached on both sides with correspondingly increasing thicknesses S.

- two separate recesses 13 ′ and 13 ′′ can also be formed on the band wheel 5, which are arranged in mirror image offset with respect to one another in the circumferential direction of the band wheel 5 and which, viewed in the axial direction of the band wheel 5, each can have an asymmetrical, approximately wedge-shaped cross-section with respect to their greatest depth dimension .

- the support surfaces 14a and 18a which rise in the opposite circumferential direction from the area of the circumferential surface of the band wheel 5, are formed, the over the Peripheral surface projecting edge portions 14b and 18b are each arranged in the converging cross-sectional area of the respective clamping piece 14 'and 18'.

- the distinctive design of the recesses 13 'and 13 "prevents incorrect insertion of the clamping pieces 14' and 18 ', whereby the arrangement one specifically s guide part is unnecessary.

- the support surfaces for the entry belt 7 and for the part of the guide belt 12 which is to be wound up and unwound next to it can be formed on a common clamping piece running over the two looping regions 5a and 5b.

- the end sections 7a and 12a of the entry belt 7 and the guide belt 12 arranged in the same looping area 5a can also each be fastened by their own clamping piece in depressions of the belt wheel 5 offset in the circumferential direction.

- another, e.g. rope-like guide element can be provided.

- the arrangement according to the invention of a clamping piece, which is countersunk in a trough-like recess of the belt wheel and is designed according to the invention, can also be advantageous in connection with a guide element embodied approximately in the form of an endless belt, which only wraps around the outermost winding position of the portion of the entry belt located on the belt wheel .

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Looms (AREA)

Description

Die Erfindung betrifft eine Vorrichtung für den Schusseintrag an einer Bandgreiferwebmaschine, mit einem in wechselndem Drehsinn angetriebenen Bandrad und einem ein Eintragsorgan für einen Schussfaden tragenden, biegsamen Eintragsband, welches mit einem Ende am Bandrad befestigt ist und welchem unter Auf- und Abwickeln in einem über mehr als 360° des Umfanges überwickelbaren Umschlingungsbereich des Bandrades eines oszillierende Bewegung quer zu den Kettfäden aus dem bzw. in das Webfach erteilt wird, sowie mit einem biegsamen Führungselement, welches einen die jeweils auf dem Bandrad befindliche Partie des Eintragsbandes umschlingenden ersten Abschnitt und einen im Abstand vom Eintragsband verlaufenden, über zwei im Abstand voneinander angeordnete Umlenkrollen geführten zweiten Abschnitt aufweist.The invention relates to a device for weft insertion on a belt rapier weaving machine, with a belt wheel driven in an alternating direction of rotation and a flexible entry belt carrying an insertion member for a weft thread, which is attached at one end to the belt wheel and which with winding and unwinding in a more is issued as a 360 ° circumferential wrapping area of the belt wheel of an oscillating movement transversely to the warp threads from or into the shed, as well as with a flexible guide element, which wraps around the part of the entry belt located on the belt wheel and a first section at a distance has a second section running from the entry belt and guided over two deflection rollers arranged at a distance from one another.

Bei einer aus der CH-Patentschrift 652 764 bekannten Vorrichtung der genannten Art ist das Führungselement durch ein Seil gebildet, dessen beide Enden je durch eine im Umfangsbereich des Bandrades vorgesehene Aussparung gegen die Achse des Bandrades geführt und an einer innerhalb des Bandradkörpers angeordneten Lasche befestigt sind. In dem an die Aussparung in Abwickelrichtung des Eintragsbandes anschliessenden Umfangsbereich des Bandrades ist das eine Ende des Eintragsbandes durch eine Schraube befestigt. Zur Führung des Eintragsbandes ist am Umfang des Bandrades eine Auflagepartie ausgebildet, welche eine etwa über 100° des Umfanges des Bandrades konstante Dicke und eine über die restliche Umfangspartie im wesentlichen spiralartig verlaufende, in Abwickelrichtung kontinuierlich zunehmende Dicke aufweist, wobei diese Umfangspartie im Bereich der Aussparung mit einer Abstufung endet, deren Höhe der Summe der Dicken des Seiles und des Eintragsbandes entspricht. Durch diese Ausführung wird bei einer Ueberwicklung des Bandrades mit einem Umschlingungswinkel von mehr als 360° in vielen Fällen, insbesondere bei der Verwendung eines relativ harten Eintragsbandes, eine schonende, knickfreie Führung des Eintragsbandes und des Führungselementes erzielt. Bei der Verwendung eines aus einem weicheren Material, z.B. Kunststoff, bestehenden Eintragsbandes, insbesondere im Zusammenhang mit einem Bandrad mit relativ kleinem Durchmesser, können in der das Einspannende überwickelnden Partie des Eintragsbandes Knickstellen auftreten, welche zu einer bleibenden Deformation des Eintragsbandes führen und damit die Lebensdauer und die Führung des Eintragsbandes beeinträchtigen können. Bei Ausführungen mit einem kleinen Durchmesser des Bandrades wird zudem das im Bereich der Aussparung mit entsprechend kleinem Radius umgelenkte Führungselement besonders stark beansprucht.In a device of the type mentioned known from CH patent specification 652 764, the guide element is formed by a rope, the two ends of which are each guided through a recess provided in the circumferential area of the band wheel against the axis of the band wheel and fastened to a tab arranged inside the band wheel body . In the circumferential area of the band wheel adjoining the cutout in the unwinding direction of the entry band, one end of the entry band is fastened by a screw. To guide the entry belt, a support section is formed on the circumference of the belt wheel, which has a thickness that is approximately constant over 100 ° of the circumference of the belt wheel and a thickness that is essentially spiral-like over the remaining circumference section and that increases continuously in the unwinding direction, this circumference section in the region of the recess ends with a gradation, the height of which corresponds to the sum of the thicknesses of the rope and the entry tape. With this design, a gentle, kink-free guidance of the entry belt and the guide element is achieved in many cases when the belt wheel is wound with a wrap angle of more than 360 ° , especially when using a relatively hard entry belt. When using an entry belt made of a softer material, e.g. plastic, in particular in connection with a band wheel with a relatively small diameter, kinks can occur in the part of the entry belt that wraps around the clamping end, which lead to permanent deformation of the entry belt and thus the service life and can affect the leadership of the entry belt. In the case of designs with a small diameter of the band wheel, the guide element deflected in the area of the recess with a correspondingly small radius is also subjected to particularly high stress.

Der Erfindung liegt die Aufgabe zugrunde, eine insbesondere in dieser Hinsicht verbesserte Vorrichtung der eingangs genannten Art zu schaffen, welche - bei vereinfachter Ausführung des Bandrades - eine knickfreie Führung des Eintragsbandes bei der Ueberwicklung des Bandrades um einen Winkel von mehr als 360° und eine entsprechend schonende Führung des Führungselementes auch im Zusammenhang mit Bandrädern in kompakter Ausführung gestattet.The invention has for its object to provide a particularly improved in this respect device of the type mentioned, which - with a simplified design of the tape wheel - a kink-free guidance of the entry belt when winding the tape wheel through an angle of more than 360 ° and a corresponding gentle guidance of the guide element also permitted in connection with belt wheels in a compact design.

Diese Aufgabe wird gemäss der Erfindung dadurch gelöst, dass am Umfang des Bandrades mindestens eine muldenartige Vertiefung zur Aufnahme des einen Endabschnitts des Eintragsbandes und/oder eines Endabschnitts des Führungselementes vorgesehen ist, und dass mindestens ein in der Vertiefung befestigbares, gegen den betreffenden Endabschnitt des Eintragsbandes und/oder des Führungselementes verspannbares Klemmstück vorgesehen ist, welches eine an den Verlauf der an die Vertiefung in beiden Umfangsrichtungen anschliessenden Abschnitte der zu überwickelnden Flächen angepasste, über die Vertiefung in Umfangsrichtung kontinuierlich gewölbt verlaufende Stützfläche für die jeweils über die Vertiefung geführte Partie des Eintragsbandes bzw. des Führungselementes aufweist.This object is achieved according to the invention in that at least one trough-like recess is provided on the circumference of the belt wheel for receiving one end section of the entry belt and / or one end section of the guide element, and that at least one can be fastened in the recess against the relevant end section of the entry belt and / or the guide element clampable clamping piece is provided, which is adapted to the course of the adjoining the depression in both circumferential sections of the surfaces to be wrapped and continuously curved over the depression in the circumferential direction of the support surface for the portion of the entry belt or the guide passed over the depression . of the guide element.

Die erfindungsgemäss ausgebildete Vorrichtung gestattet eine besonders schonende Führung des Eintragsbandes in einer Führungsbahn, die von der in der Vertiefung angeordneten Klemmstelle flach gekrümmt gegen die Umfangsfläche des Bandrades verläuft. Zugleich wird beim Ueberwickeln der Einspannstelle eine sichere Führung der über die Vertiefung verlaufenden Partie des Eintragsbandes und der an dieses anliegenden Partie des Führungselementes gewährleistet. Entsprechend ist bei einem Umschlingungswinkel von über 360° beim Aufwickelvorgang ein knickfreies Auflaufen der betreffenden Partie des Eintragsbandes auf die Uebergangsstelle zwischen dem in der Vertiefung befindlichen Endabschnitt und der bereits auf dem Umfang des Bandrades befindlichen Partie des das Eintragsband umschlingenden Führungselementes bzw. beim Abwickelvorgang ein entsprechend knickfreies Ablaufen der betreffenden Partie des Eintragsbandes aus dem Bereich der genannten Uebergangsstelle erzielbar, da das erfindungsgemäss ausgebildete und angeordnete Klemmstück mit seiner gewölbten Stützfläche ein "Durchhängen" der über die Vertiefung verlaufenden Partien des Eintragsbandes und des daran anliegenden Führungselementes verhindert. Entsprechend werden zusätzliche Beanspruchungen des insbesondere im Zusammenhang mit den grossen Arbeitsbreiten und hohen Schusseintragsleistungen heutiger Webmaschinen bereits sehr hoch beanspruchten Materials vermieden.The device designed according to the invention permits particularly gentle guidance of the entry belt in a guideway which, from the clamping point arranged in the recess, runs flatly curved against the peripheral surface of the belt wheel. At the same time, when the clamping point is wound over, a secure guidance of the portion of the entry belt extending over the recess and the portion of the guide element which lies against it is ensured. Correspondingly, at a wrap angle of more than 360 ° during the winding-up process, a kink-free run-up of the relevant section of the entry belt onto the transition point between the end section located in the depression and the part of the guide element already wrapping around the entry wheel or during the unwinding process is corresponding kink-free running of the relevant section of the entry belt can be achieved from the area of the said transition point, since the clamping piece designed and arranged according to the invention, with its arched support surface, prevents "sagging" of the sections of the entry belt and the guide element lying against the recess. Accordingly, additional stresses on the material, which is already highly stressed, in particular in connection with the large working widths and high weft insertion rates of today's weaving machines, are avoided.

Ausgestaltungen der Erfindung sind in den abhängigen Patentansprüchen angegeben.Embodiments of the invention are specified in the dependent claims.

Nach der im Anspruch 2 hervorgehobenen Ausführungsform mit einem in Form eines flachen Bandes ausgebildeten abgelängten Führungselement und mit gegeneinander verschränkt angeordneten, bombierten Umlenkrollen, die eine Führung dieses flachen Bandes in zwei gegeneinander in axialer Richtung des Bandrades versetzten Abschnitten gestatten, kann eine besonders kompakte Bauweise mit einem mehrfach überwickelbaren Bandrad erzielt werden. Die verschränkte Anordnung von Umlenkrollen ist zwar im Zusammenhang mit einer seitlichen Auslenkung eines seilartigen, abgelängten Führungselement an sich bekannt; von einer seitlichen Auslenkung einer bandartigen Führungselementes wurde jedoch bei Schusseintragsvorrichtungen der eingangs genannten Art bisher abgesehen. Durch die Ausführung nach Anspruch 2 wird eine störungsfreie seitliche Auslenkung und damit eine betriebssichere Führung des abgelängten bandartigen Führungselementes in zwei nebeneinanderliegenden Umschlingungsbereichen des Bandrades gewährleistet. Die Ausführung nach Anspruch 2 führt insbesondere zu einer über die Breite des das Eintragsband umschlingenden Führungsbandes gleichmässig verteilten, relativ geringen Beanspruchung sowohl des Eintragsbandes als auch des Bandrades, da hohe örtliche Beanspruchungen, wie sie etwa bei der Verwendung eines seilartigen Führungselementes auftreten können, entfallen. Das Bandrad, welches bei jedem Wechsel der Drehrichtung angehalten und wieder beschleunigt werden muss, kann daher in entsprechend leichter Bauweise, z.B. aus einem Kunststoff, ausgeführt werden und eine entsprechend geringe Masse aufweisen. Das bandförmige Führungselement kann sich femer -im Gegensatz zu einem seilartigen Führungselement - weder in das Eintragsband noch über dieses in die Umfangsfläche des Bandrades "eingraben" und kann eine wesentlich geringere Dicke als eine seilartige Ausführung aufweisen, so dass sich auch bei einer mehrfachen Ueberwicklung des Bandrades eine relativ kleine, jeweils abwechselnd zu beschleunigende und zu verzögernde bewegliche Masse ergibt.According to the embodiment highlighted in

Nach der im Anspruch 5 hervorgehobenen Ausführungsform der Erfindung kann bereits an der Uebergangsstelle zwischen der Einspannstelle und dem Umfangsbereich des Bandrades ein sattes Anliegen des in der Regel relativ formsteifen Eintragsbandes gewährleistet werden.According to the embodiment of the invention emphasized in

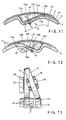

Weitere Merkmale ergeben sich aus der folgenden Beschreibung eines in der Zeichnung schematisch dargestellten Ausführungsbeispiels der Erfindung. Es zeigen:

- Fig. I Teile einer Schusseintragsvorrichtung einer Bandgreiferwebmaschine in einer perspektivischen Teilansicht,

- Fig. 2 eine Einzelheit der Schusseintragsvorrichtung in einem Teilschnitt entsprechend der Linie 11 - 11 in Fig. I in einer grösseren Darstellung,

- Fig. 3 die Einzelheit nach Fig. 2 in einem entsprechenden Teilschnitt in einem anderen Betriebszustand,

- Fig. 4 einen Teilschnitt der Schusseintragsvorrichtung entsprechend der Linie IV - IV in Fig. 2,

- Fig. 5 eine Teilansicht der Schusseintragsvorrichtung entsprechend dem Pfeil V in Fig. 3,

- Fig. 6, 7, 8, 9 und 10 je eine weitere Einzelheit der Schusseintragsvorrichtung in einer Teil-Seitenansicht mit Teilschnitt, je in einer anderen Ausführungsform,

- Fig. 11 einen der Fig. 4 entsprechenden Teilschnitt einer Schusseintragsvorrichtung in einer anderen Ausführungsform,

- Fig. 12 eine der Fig. 5 entsprechende Teilansicht der Schusseintragsvorrichtung nach Fig. 11, und

- Fig. 13 einen Teilschnitt entsprechend der Linie XIII - XIII in Fig. I.

- I parts of a weft insertion device of a belt rapier weaving machine in a perspective partial view,

- 2 shows a detail of the weft insertion device in a partial section along the line 11-11 in FIG. I in a larger representation,

- 3 shows the detail according to FIG. 2 in a corresponding partial section in a different operating state,

- 4 shows a partial section of the weft insertion device along the line IV-IV in FIG. 2,

- 5 is a partial view of the weft insertion device according to arrow V in FIG. 3,

- 6, 7, 8, 9 and 10 each a further detail of the weft insertion device in a partial side view with partial section, each in a different embodiment,

- 11 shows a partial section corresponding to FIG. 4 of a weft insertion device in another embodiment,

- FIG. 12 is a partial view corresponding to FIG. 5 of the weft insertion device according to FIG. 11, and

- 13 is a partial section along the line XIII - XIII in Fig. I.

In der Fig. sind Teile eines Maschinengestelles I und einer Weblade 2 einer Bandgreiferwebmaschine bekannter Bauweise dargestellt. Das Maschinengestell I enthält an der linken Seite und an der rechten Seite je einen Träger 3 mit einer Halteplatte 4, an der ein Bandrad 5 drehbar angeordnet ist. In der Fig. I ist lediglich die linke Seite des Maschinengestells I mit dem zum rechten Träger spiegelbildlichen linken Träger 3 und dem zum rechten Bandrad spiegelbildlichen Bandrad 5 dargestellt. Auf der Weblade 2 ist ein Webeblatt 6 zur Führung von nicht dargestellten Kettfäden befestigt. Am Umfang des linken Bandrades 5 ist ein erster Endabschnitt 7a eines flexiblen Eintragsbandes 7 befestigt, dessen zweiter Endabschnitt 7b einen zum Erfassen eines Endes eines nicht dargestellten Schussfadens bestimmten Greiferkopf 8 trägt. Ein entsprechendes, ebenfalls mit einem Greiferkopf versehenes Eintragsband ist auf dem rechten Bandrad befestigt.Parts of a machine frame I and a

Die beiden Bandräder werden jeweils oszillierend und gegenläufig angetrieben, wobei unter Auf- und Abwickeln der beiden Eintragsbänder 7 den auf diesen befestigten Greiferköpfen 8 jeweils eine oszillierende Bewegung quer zu den Kettfäden aus dem bzw. in das durch diese gebildete, nicht dargestellte Webfach erteilt wird. Dabei werden die Greiferköpfe 8 ständig entlang der Weblade 2 bis in die Mitte des Webfaches bewegt und anschliessend wieder aus dem Webfach herausgezogen. Von einem an der nicht dargestellten rechten Seite der Webmaschine, ausserhalb des Webfaches angeordneten Schussfadenvorrat wird jeweils ein Ende eines Schussfadens dem auf dem rechten Eintragsband angeordneten Greiferkopf übergeben. Von diesem wird der Schussfaden in die erste Hälfte des Webfaches eingetragen und in der Mitte des Webfaches dem auf dem linken Eintragsband 7 angeordneten Greiferkopf 8 übergeben, durch den der Schussfaden anschliessend in die zweite Hälfte des Webfaches eingetragen wird. Nach beendetem Schusseintrag wird der Schussfaden in bekannter Weise durch das Webeblatt 6 in der Spitze des nicht dargestellten Webfaches angeschlagen.The two belt wheels are each driven in an oscillating and counter-rotating manner, with the winding and unwinding of the two

Bei Bandgreiferwebmaschinen anderer Bauart kann die Schusseintragsvorrichtung auch jeweils ein einziges Bandrad 5 und ein einziges von der einen Seite der Webmaschine über die ganze Webbreite und zurück führbares Eintragsband 7 aufweisen, dessen Greiferkopf jeweils einen vollständigen Schusseintrag ausführt.In the case of belt rapier weaving machines of a different type, the weft insertion device can also have a

In der in Fig. I dargestellten Betriebsstellung durchläuft der Greiferkopf 8 den linken Rand des Webfaches. Der Greiferkopf 8 wird durch das beim Abwickeln vom Bandrad 5 gemäss Pfeil 10 bewegte Eintragsband 7 gegen die Mitte des Webfaches geführt, nach Uebernahme des vom rechten Greiferkopf eingetragenen Schussfadens - durch Aufwickeln des Eintragsbandes 7 gemäss Pfeil 10a - aus dem Webfach herausgezogen und nach dem Fachwechsel jeweils für einen erneuten Schusseintrag gegen die Mitte des Webfaches und zurückgeführt.In the operating position shown in Fig. I, the

Das Eintragsband 7 ist mit einem Umschlingungswinkel von mehr als 360°, entsprechend der Darstellung nach Fig. I z.B. ca. 460° bei ausserhalb des Webfaches befindlichem Greiferkopf 8, auf dem Umfang des Bandrades 5 aufgewickelt und von der Ablaufstelle am Bandrad 5 über eine Führungsschiene II gegen eine an der Weblade 2 vorgesehene Führungsbahn geführt. Um ein Abheben des Eintragsbandes 7 vom Umfang des Bandrades 5 zu verhindern, ist ein riemenartiges, abgelängtes Führungsband 12 vorgesehen, welches eine geringere Breite als das Eintragsband 7 aufweisen kann. Das Führungsband 12 umschlingt die jeweils auf dem Bandrad 5 befindliche Partie des Eintragsbandes 7 und drückt dieses - unter der Wirkung einer gegen das Führungsband 12 verspannbaren Federanordnung 31 - gegen den Umfang des Bandrades 5. Ein erster Endabschnitt 12a des Führungsbandes 12 ist zusammen mit dem entsprechenden Endabschnitt 7a des Eintragsbandes 7 in einer am Umfang des Bandrades 5 vorgesehenen, flach gewölbten muldenartigen Vertiefung 13 durch ein in diese versenkt einsetzbares Klemmstück 14 befestigt, welches durch eine Schraube 15 über die beiden Endabschnitte 7a und 12a gegen den Grund der Vertiefung 13 verspannbar ist. Entsprechend der Darstellung nach den Fig. 4 und 5, kann die Vertiefung 13 durch flach konvex gewölbte Flächenpartien 13d und 13e begrenzt sein, die in die zylindrische Umfangsfläche des Bandrades 5 übergehen.The

Das Führungsband 12, welches in einem ersten Umschlingungsbereich 5a zusammen mit dem Eintragsband 7 über den Umfang des Bandrades 5 verläuft, ist nahe der Ablaufstelle des Eintragsbandes 7 vom Bandrad 5 über eine im Bereich der Führungsschiene 11 angeordnete erste Umlenkrolle 16 vom Eintragsband 7 weggeführt und über eine im Abstand vom Bandrad 5 angeordnete zweite Umlenkrolle 17 in einer relativ langen Schlaufe gegen einen am Umfang des Bandrades 5 neben dem ersten Umschlingungsbereich 5a vorgesehenen zweiten Umschlingungsbereich 5b geführt.The

Die Umlenkrolle 16 ist auf einer zur Achse des Bandrades 5 parallelen Achse 32 angeordnet, die an einem mit dem Maschinengestell I verbundenen Träger 33 angebracht ist. Die Umlenkrolle 17 ist auf einer gegenüber der Achse 32 schräggestellten Achse 34 angeordnet, die durch eine Halterung 35 beweglich geführt ist. Die Halterung 35 ist an einem mit dem Maschinengestell I verbundenen Tragteil 36 befestigt und enthält die in Fig. I vereinfacht als Zugfeder dargestellte Federanordnung 31, durch welche das Führungsband 12 über die Umlenkrolle 17 gespannt gehalten wird. Zudem werden bei jedem Schusseintrag Distanzunterschiede zwischen den Achsen 32 und 34 ausgeglichen, die sich jeweils beim Auf- und Abwickeln des Eintragsbandes 7 und des Führungsbandes 12 ergeben können. Es kann auch die Umlenkrolle 16 beweglich geführt sein und mit einer entsprechenden Federanordnung zusammenwirken.The

Im zweiten Umschlingungsbereich 5b ist das Führungsband 12 - bei aufgewickeltem Eintragsband 7 - mit einem Umschlingungswinkel von über 360°, entsprechend der Darstellung nach Fig. I z.B. ca. 620°, gegen die auch über den zweiten Umschlingungsbereich 5b sich erstreckende Vertiefung 13 geführt, in welcher der zweite Endabschnitt 12b des Führungsbandes 12 durch ein in die Vertiefung 13 versenkt einsetzbares zweites Klemmstück 18 befestigt ist. Beim Abwickeln des Eintragsbandes 7 wird die damit aus dem ersten Umschlingungsbereich 5a ablaufende Partie des Führungsbandes 12 im zweiten Umschlingungsbereich 5b des Bandrades 5 aufgewickelt. Die bei aufgewickeltem Eintragsband 7 im Bereich der Klemmstücke 14 und 18 bestehenden Verhältnisse sind in den Fig. I, 2 und 4 dargestellt. Die entsprechenden Verhältnisse bei abgewickeltem Eintragsband 7 - mit z.B. zweifach überwickeltem Klemmstück 18 - sind aus den Fig. 3 und 5 ersichtlich.In the

Entsprechend den Fig. und 13 sind die Umlenkrollen 16, 17 mit bombierten Umfangsflächen ausgeführt und so gegeneinander verschränkt angeordnet, dass die dem Umfang des Bandrades 5 zugekehrten Umfangsbereiche der Umlenkrollen 16 und 17 in axialer Richtung des Bandrades 5 gegeneinander versetzt und je gegen den ersten Umschlingungsbereich 5a bzw. den zweiten Umschlingungsbereich 5b des Bandrades 5 orientiert sind. Zur Fixierung der Winkelstellung der Umlenkrolle 17 können nicht dargestellte, z.B. mit der Halterung 35 zusammenwirkende Führungsmittel bekannter Art vorgesehen sein.13 and 13, the

Wie insbesondere aus den Fig. 4 und 5 hervorgeht, kann die Vertiefung 13 im wesentlichen symmetrisch zu einer durch die Drehachse des Bandrades 5 verlaufenden Radialebene 20 ausgebildet sein. Die Klemmstücke 14 und 18 weisen je einen an die Form der Vertiefung 13 angepassten Querschnitt auf und enthalten je eine an den Verlauf der an die Vertiefung 13 in beiden Umfangsrichtungen des Bandrades 5 anschliessenden Partien der zu umschlingenden Flächen angepasste Stützfläche 14a bzw. 18a für die das betreffende Klemmstück 14 bzw. 18 überwickelnde Partie des Eintragsbandes 7 bzw. des Führungsbandes 12. Darstellungsgemäss können die Klemmstücke 14 und 18 je bezüglich der Radialebene 20 unsymmetrisch ausgeführt sein, indem die Stützflächen 14a und 18a, je nach der einen bzw. der anderen Umfangsrichtung des Bandrades 5 kontinuierlich ansteigend, spiralartig gewölbt über die "Länge" des betreffenden Klemmstücks 14 bzw. 18 verlaufen.As can be seen in particular from FIGS. 4 and 5, the

Gemäss Fig. 4 kann das Klemmstück 14 so ausgebildet sein, dass es in der auf die Endabschnitte 7a und 12a des Eintragsbandes 7 und des Führungsbandes 12 aufgesetzten Stellung mit einer Randpartie 14b, welche die aus der Vertiefung 13 gegen die Umfangsfläche des Bandrades 5 sich fortsetzenden Partien der Endabschnitte 7a und 12 überdeckt, etwa um ein Mass, welches der Summe der Dicken der eingespannten Endabschnitte 7a und 12a zumindest annähernd entspricht, über die Umfangsfläche des Bandrades 5 vorsteht, während eine in die entgegengesetzte Umfangsrichtung weisende, die Enden der Endabschnitte 7a und 12 überdeckende Randpartie 14c im Bereich der Umfangsfläche liegt. Entsprechend kann gemäss Fig. 5 eine Randpartie 18b des Klemmstücks 18, welche die aus der Vertiefung 13 gegen die Umfangsfläche des Bandrades 5 sich fortsetzende Partie des eingespannten Endabschnitts 12b des Führungsbandes 12 überdeckt, etwa um die Dicke dieses Führungsbandes 12 über die Umfangsfläche des Bandrades 5 vorstehen, während eine das Ende des Endabschnitts 12b überdeckende Randpartie 18c des Klemmstücks 18 im Bereich der Umfangsfläche liegt.4, the clamping

Diese Stützflächen 14a und 18a gestatten einen knickfreien Uebergang von der zylindrischen Umfangsfläche des Bandrades 5 auf die um die Dicken des Eintragsbandes 7 und des Führungsbandes 12 (Fig. 4) bzw. um die Dicke des Führungsbandes 12 (Fig. 5) erhöhte, durch die Oberfläche der entsprechenden Partie des Führungsbandes 12 gebildete Wickelfläche. Je nach Material und Ausführung des Eintragsbandes 12, kann eine knickfreie Führung dieser Bänder auch durch Klemmstücke 14 und 18 erzielt werden, die je um ein gleiches Mass, z.B. entsprechend der Dicke des Eintragsbandes 7, einseitig erhöht sind und dementsprechend identische Querschnitte aufweisen. Die den Enden der Endabschnitte 7a und 12a bzw. 12b zugeordneten Randpartien 14c und 18c der Klemmstücke 14 und 18 können je mit einem über die Klemmfläche des betreffenden Klemmstücks 14 bzw. 18 vorstehenden Führungsstift 21 versehen sein, der durch eine im betreffenden Endabschnitt 7a, 12a bzw. 12b vorgesehene Oeffnung 19 in eine am Bandrad 5 im Bereich der Vertiefung 13 vorgesehene Führungsöffnung 22 einführbar ist. Durch diese an den Klemmstücken 14 und 18 unsymmetrisch angeordneten Führungsstifte 21 wird ein fehlerhaftes Einsetzen der Klemmstücke 14 und 18 verhindert. Wie in den Fig. 4 und 5 angedeutet, können die Führungsöffnungen 22, z.B. je in Form eines Langlochs ausgebildet sein, welches eine in Umfangsrichtung des Bandrades 5 einstellbare Positionierung des betreffenden Klemmstücks 14 bzw. 18 gestattet.These support surfaces 14a and 18a allow a kink-free transition from the cylindrical circumferential surface of the

Das Eintragsband 7 kann in einem Längenabschnitt A, der sich gemäss Fig. 4 über den vom Klemmstück 14 überdeckten Teil der Vertiefung 13 und einen daran anschliessenden Teil der Umfangsfläche des Bandrades 5 erstreckt, eine Zone 25 geringerer Steifigkeit als in seiner übrigen Längserstreckung aufweisen. Gemäss Fig. 6 kann das Eintragsband 7 - bei konstanter Banddicke T - eine über den Längenabschnitt A mit reduzierter Banddicke Ti sich fortsetzende Schicht 26 aus dem relativ steifen Grundmaterial des Eintragsbandes 7 und eine mit dieser Schicht 26 verbundene, z.B. verklebte Schicht 27 aus einem weichelastischem Material enthalten, deren Dicke S entsprechend der Darstellung nach Fig. 6 der Dicke Ti der Schicht 26 entsprechen kann.In a length section A, which extends according to FIG. 4 over the part of the

Gemäss Fig. 7 kann die über den Längenabschnitt A sich fortsetzende, aus dem Grundmaterial des Eintragsbandes 7 bestehende Schicht 26 zwischen zwei Schichten 27 aus weichelastischem Material angeordnet und mit diesen verbunden sein. Darstellungsgemäss können die Dicken Ti und S dieser Schichten 26, 27, z.B. je einem Drittel der Dicke T des Eintragsbandes 7 entsprechen.According to FIG. 7, the

Gemäss Fig. 8 kann die aus dem Grundmaterial des Eintragsbandes 7 bestehende Schicht 26 eine abgestufte, gegen das Bandende hin abnehmende Dicke Ti aufweisen, und die aus weichelastischem Material bestehenden Schichten 27 können je mit einer entsprechend stufenartig zunehmenden Dicke S ausgeführt sein.According to FIG. 8, the

Wie in der Fig. 9 dargestellt, kann die über den Längenabschnitt A verlaufende Partie des Eintragsbandes 7 mit gegen das Bandende hin konisch abnehmender Dicke Ti ausgeführt sein und mit der eine entsprechend konisch zunehmende Dicke aufweisenden Schicht 27 aus weichelastischem Material verbunden sein.As shown in FIG. 9, the portion of the

Gemäss Fig. 10 kann das Eintragsband 7 mit gegen das Bandende konisch abnehmender Dicke T1 ausgeführt und mit zwei beidseitig angesetzten Schichten 27 mit entsprechend zunehmenden Dicken S verbunden sein.According to FIG. 10, the

Entsprechend der Darstellung nach den Fig. 11 und 12 können am Bandrad 5 auch zwei voneinander getrennte Vertiefungen 13' und 13" ausgebildet sein, die gegeneinander in Umfangsrichtung des Bandrades 5 spiegelbildlich versetzt angeordnet sind und die, in axialer Richtung des Bandrades 5 gesehen, je einen bezüglich ihrer grössten Tiefenabmessung unsymmetrischen, annähernd keilförmigen Querschnitt aufweisen können. An entsprechend keilförmigen Klemmstücken 14' und 18' sind die aus dem Bereich der Umfangsfläche des Bandrades 5 je in die entgegengesetzte Umfangsrichtung spiralartig ansteigenden Stützflächen 14a bzw. 18a ausgebildet, wobei die über die Umfangsfläche vorstehenden Randpartien 14b und 18b je im konvergierenden Querschnittsbereich des betreffenden Klemmstücks 14' bzw. 18' angeordnet sind. Durch die unverwechselbare Ausbildung der Vertiefungen 13' und 13" wird ein fehlerhaftes Einsetzen der Klemmstücke 14' und 18' verhindert, wobei sich die Anordnung eines speziellen Führungsteils erübrigt.11 and 12, two

Es sind noch verschiedene andere Ausführungsformen der Erfindung möglich. So können etwa die Stützflächen für das Eintragsband 7 und für die neben diesem auf- und abzuwickelnde Partie des Führungsbandes 12 an einem über die beiden Umschlingungsbereiche 5a und 5b verlaufenden, gemeinsamen Klemmstück ausgebildet sein. Die im gleichen Umschlingungsbereich 5a angeordneten Endabschnitte 7a und 12a des Eintragsbandes 7 und des Führungsbandes 12 können auch je durch ein eigenes Klemmstück in gegeneinander in Umfangsrichtung versetzten Vertiefungen des Bandrades 5 befestigt sein. Anstelle eines Führungsbandes 12 kann auch ein anderes, z.B. seilartiges Führungselement vorgesehen sein. Die erfindungsgemässe Anordnung eines in einer muldenartigen Vertiefung des Bandrades versenkt angebrachten und erfindungsgemäss ausgebildeten Klemmstücks kann ferner auch im Zusammenhang mit einem etwa in Form eines endlosen Bandes ausgeführten Führungselement von Vorteil sein, welches lediglich die jeweils äusserste Wickellage der auf dem Bandrad befindlichen Partie des Eintragsbandes umschlingt.Various other embodiments of the invention are possible. For example, the support surfaces for the

Claims (7)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CH282486 | 1986-07-15 | ||

| CH2824/86 | 1986-07-15 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0253184A1 EP0253184A1 (en) | 1988-01-20 |

| EP0253184B1 true EP0253184B1 (en) | 1990-09-19 |

Family

ID=4242429

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP87109282A Expired - Lifetime EP0253184B1 (en) | 1986-07-15 | 1987-06-27 | Device for weft insertion in a gripper loom |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US4771815A (en) |

| EP (1) | EP0253184B1 (en) |

| JP (1) | JPS6328943A (en) |

| BR (1) | BR8703659A (en) |

| DE (1) | DE3765039D1 (en) |

| SU (1) | SU1748654A3 (en) |

Families Citing this family (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0331801A1 (en) * | 1988-03-09 | 1989-09-13 | Contraves Ag | Band wheel for the weft insertion in a loom |

| DE58903434D1 (en) * | 1988-07-22 | 1993-03-18 | Sulzer Ag | WIFE ENTRY DEVICE OF A GRIPPER WEAVING MACHINE. |

| IT1236649B (en) * | 1989-11-03 | 1993-03-25 | Nuovo Pignone Spa | PERFECTED BELT DRIVE SYSTEM OF THE PLATE HOLDER FOR A TEXTILE FRAME WITHOUT SHUTTLE. |

| CH679937A5 (en) * | 1989-11-29 | 1992-05-15 | Sulzer Ag | Weft insertion strip oscillating drive wheel - has single wall section with corrugated profile near rim for lightweight and rigidity |

| JPH08209494A (en) * | 1995-02-08 | 1996-08-13 | Toyota Autom Loom Works Ltd | Picking apparatus in rapier loom |

| JP5180668B2 (en) * | 2008-05-07 | 2013-04-10 | 三工機器株式会社 | Coil winding device |

| DE102011009765B3 (en) * | 2011-01-28 | 2011-11-10 | Lindauer Dornier Gmbh | Weaving machine for manufacturing fabric, has shedding unit for variable lifting and lowering wrap material for forming weaving shed |

| DE102012212169A1 (en) * | 2012-07-11 | 2014-01-16 | Lindauer Dornier Gesellschaft Mit Beschränkter Haftung | Apparatus for temporarily storing ribbon-like weft material for a loom and weaving machine with such a device |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3682204A (en) * | 1969-06-02 | 1972-08-08 | Raymond Dewas | Weaving looms with external weft reserve |

| FR2427409A1 (en) * | 1978-05-31 | 1979-12-28 | Rueti Ag Maschf | RIBBON GUIDANCE FOR A CLAW Loom |

| GB2077699B (en) * | 1980-06-16 | 1984-09-05 | Loewy Robertson Eng Co Ltd | Coiler drum with gripper mechanism |

| CH652764A5 (en) * | 1981-10-14 | 1985-11-29 | Rueti Ag Maschf | DEVICE FOR THE SHOT ENTRY ON A TAPE GRIPPER WEAVING MACHINE. |

| EP0080191A1 (en) * | 1981-11-20 | 1983-06-01 | Helmut Meinunger | Winding device for a projection screen |

| IT1210932B (en) * | 1982-09-03 | 1989-09-29 | Omv Off Mecc Vilminore | COMMAND TAPE OF PLATE HOLDER PLIERS IN WEAVING FRAMES WITH VARIABLE RIGIDITY. |

| JPS59187645A (en) * | 1983-04-01 | 1984-10-24 | 株式会社石川製作所 | Flexible band pressing apparatus of rapier loom |

-

1987

- 1987-05-12 JP JP62115699A patent/JPS6328943A/en active Pending

- 1987-06-26 SU SU874202817A patent/SU1748654A3/en active

- 1987-06-27 EP EP87109282A patent/EP0253184B1/en not_active Expired - Lifetime

- 1987-06-27 DE DE8787109282T patent/DE3765039D1/en not_active Expired - Fee Related

- 1987-06-30 US US07/068,894 patent/US4771815A/en not_active Expired - Fee Related

- 1987-07-14 BR BR8703659A patent/BR8703659A/en unknown

Also Published As

| Publication number | Publication date |

|---|---|

| SU1748654A3 (en) | 1992-07-15 |

| BR8703659A (en) | 1988-03-22 |

| US4771815A (en) | 1988-09-20 |

| DE3765039D1 (en) | 1990-10-25 |

| EP0253184A1 (en) | 1988-01-20 |

| JPS6328943A (en) | 1988-02-06 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DD269408A5 (en) | GUIDE FOR MOVING A GRIPPER SHOULDERS WITHIN THE WEBFACHES OF A WEBSTUHLES | |

| CH636386A5 (en) | TAPE FABRIC, METHOD FOR THE PRODUCTION THEREOF, AND TAPE WEAVING MACHINE FOR CARRYING OUT THE METHOD. | |

| DE2856552C2 (en) | Zipper with a woven strap | |

| EP0253184B1 (en) | Device for weft insertion in a gripper loom | |

| EP0146663B1 (en) | Weft inserting device for a needle loom | |

| EP0352223B1 (en) | Weft insertion device for a gripper loom | |

| DE68916602T2 (en) | Device for controlling the movement of the weft insertion grippers in the compartment of defenseless weaving machines. | |

| CH654183A5 (en) | WOVEN ZIPPER STRIP AND DEVICE FOR THEIR PRODUCTION. | |

| DE2114006B2 (en) | Reinforcement insert for belts or belts, in particular conveyor belts | |

| DE2921848C2 (en) | Tape guide for tape rapier weaving machine | |

| EP0576854A1 (en) | Gripper loom | |

| EP0906461A1 (en) | Transfer gripper for a rapier loom | |

| DE2855420C2 (en) | Zipper with a woven strap | |

| DE2855606C2 (en) | Thread guide on a creel for warping and warping systems or the like. | |

| DE3237835C2 (en) | Device for weft insertion on a tape rapier loom | |

| DE3148086A1 (en) | EDGE PROTECTING DEVICE AND LINKED BELT WITH IT | |

| DE3020596C2 (en) | ||

| CH639440A5 (en) | Weft insertion device for weaving machines with removal of the weft from stationary bobbins. | |

| CH674446A5 (en) | ||

| DE69518113T2 (en) | Improved guiding system for the looper entry belt in a defenseless weaving machine | |

| DE69509036T2 (en) | Guideway for rapier bands in weaving machines | |

| EP1586683A2 (en) | Gripper tape for a rapier loom and rapier loom | |

| EP0811712B1 (en) | Thread clamp for a feeding gripper and feeding gripper with such a clamp | |

| EP0776390B1 (en) | Gripper weaving machine | |

| DE2030433A1 (en) | Weft lance - with bowed steel spring stiffners |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): BE DE FR IT |

|

| 17P | Request for examination filed |

Effective date: 19880711 |

|

| 17Q | First examination report despatched |

Effective date: 19891205 |

|

| ITF | It: translation for a ep patent filed | ||

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): BE DE FR IT |

|

| REF | Corresponds to: |

Ref document number: 3765039 Country of ref document: DE Date of ref document: 19901025 |

|

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| ITTA | It: last paid annual fee | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19930519 Year of fee payment: 7 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19950228 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19950518 Year of fee payment: 9 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19970301 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20020612 Year of fee payment: 16 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20030630 |

|

| BERE | Be: lapsed |

Owner name: *GEBRUDER SULZER A.G. Effective date: 20030630 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20050627 |