EP0246330A1 - Absorbierungsmittel für ein mutagenmittel des tabakrauches und dessen verwendung - Google Patents

Absorbierungsmittel für ein mutagenmittel des tabakrauches und dessen verwendung Download PDFInfo

- Publication number

- EP0246330A1 EP0246330A1 EP86906468A EP86906468A EP0246330A1 EP 0246330 A1 EP0246330 A1 EP 0246330A1 EP 86906468 A EP86906468 A EP 86906468A EP 86906468 A EP86906468 A EP 86906468A EP 0246330 A1 EP0246330 A1 EP 0246330A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- filter

- adsorbent

- tip

- polysaccharide

- powder

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A24—TOBACCO; CIGARS; CIGARETTES; SIMULATED SMOKING DEVICES; SMOKERS' REQUISITES

- A24D—CIGARS; CIGARETTES; TOBACCO SMOKE FILTERS; MOUTHPIECES FOR CIGARS OR CIGARETTES; MANUFACTURE OF TOBACCO SMOKE FILTERS OR MOUTHPIECES

- A24D3/00—Tobacco smoke filters, e.g. filter-tips, filtering inserts; Filters specially adapted for simulated smoking devices; Mouthpieces for cigars or cigarettes

- A24D3/06—Use of materials for tobacco smoke filters

- A24D3/12—Use of materials for tobacco smoke filters of ion exchange materials

-

- A—HUMAN NECESSITIES

- A24—TOBACCO; CIGARS; CIGARETTES; SIMULATED SMOKING DEVICES; SMOKERS' REQUISITES

- A24D—CIGARS; CIGARETTES; TOBACCO SMOKE FILTERS; MOUTHPIECES FOR CIGARS OR CIGARETTES; MANUFACTURE OF TOBACCO SMOKE FILTERS OR MOUTHPIECES

- A24D3/00—Tobacco smoke filters, e.g. filter-tips, filtering inserts; Filters specially adapted for simulated smoking devices; Mouthpieces for cigars or cigarettes

- A24D3/06—Use of materials for tobacco smoke filters

- A24D3/08—Use of materials for tobacco smoke filters of organic materials as carrier or major constituent

-

- A—HUMAN NECESSITIES

- A24—TOBACCO; CIGARS; CIGARETTES; SIMULATED SMOKING DEVICES; SMOKERS' REQUISITES

- A24D—CIGARS; CIGARETTES; TOBACCO SMOKE FILTERS; MOUTHPIECES FOR CIGARS OR CIGARETTES; MANUFACTURE OF TOBACCO SMOKE FILTERS OR MOUTHPIECES

- A24D3/00—Tobacco smoke filters, e.g. filter-tips, filtering inserts; Filters specially adapted for simulated smoking devices; Mouthpieces for cigars or cigarettes

- A24D3/06—Use of materials for tobacco smoke filters

- A24D3/16—Use of materials for tobacco smoke filters of inorganic materials

Definitions

- the present invention relates to an adsorbent for mutagenic compounds present in tobacco smoke upon inhalation, a process for using said adsorbent, and a filter-tip containing said adsorbent.

- tobacco smoke contains many carcinogens, for example, polycyclic aromatic hydrocarbons such as benz(a)pyrene or benz(a)anthracene, or nitrosoamines.

- carcinogens for example, polycyclic aromatic hydrocarbons such as benz(a)pyrene or benz(a)anthracene, or nitrosoamines.

- an object of the present invention is to provide an adsorbent for mutagenic compounds, which ,]s capable of remarkably reducing a total mutagenicity in tobacco smoke without impairing the inherent flavor thereof.

- Other objects of the present invention are to provide a process for removing mutagenic compounds present in tobacco smoke using the above adsorbent, and a filter-tip for tobacco containing the above adsorbent.

- the present invention relates to an adsorbent for mutagenic compounds present in tobacco smoke, comprising a polysaccharide or a modified substance thereof.

- the present invention relates to a process for removing mutagenic compounds from tobacco smoke, by adsorbing the mutagenic compounds present in tobacco smoke onto a polysaccharide or a modified substance thereof.

- the present invention relates to a filter-tip for tobacco, particularly a filter-tip for a cigarette, containing a polysaccharide or a modified substance thereof.

- polysaccharide used herein denotes a high-molecular weight compound formed by the condensation ,of about 7 or more monosaccharide molecules, and includes a simple polysaccharide obtained from identical monosaccharide molecules and a complex polysaccharide obtained from various monosaccharides or derivatives thereof.

- the polysaccharides used in the present invention are typically cellulose, agarose, amylose, chitin, chitosan, and derivatives thereof.

- the polysaccharide is preferably cellulose.

- the polysaccharide may be used as the adsorbent in any form, such as powders, granules or fibers, although powders are preferable.

- the particle size of the powder is not critical, but preferably powder having an average particle size of generally 0.1 - 200 ⁇ m, more preferably 0.1 - 40 pm, further preferably 1 - 10 ⁇ m, is employed.

- polysaccharide powders those prepared by a mechanical treatment (e.g., grinding or chopping) or a chemical-treatment (e.g., acid or alkali treatment) of animal or plant materials are employed.

- Such powders are, typically, cellulose powder such as cotton powder, pulp powder, flax powder or regenerated cellulosic fiber powder.

- these powders include crystalline cellulose powder prepared by an acid hydrolysis or cellulase treatment of pulp.

- the crystalline cellulose powder it is preferable to use fine powder having an average particle size of 0.1 - 200 um, more preferably 1 - 10 ⁇ m.

- agarose powder e.g., manufactured by Wako Junyaku Kogyo K.K.

- amylose powder e.g., manufactured by Nakai Kagaku Yakuhin K.K.

- chitin powder e.g., manufactured by Nakai Kagaku Yakuhin K.K.

- chitosan powder e.g., prepared by an alkali treatment of the above chitin powder

- modified substance of polysaccharide used herein denotes a material prepared by chemically modifying the above polysaccharide, particularly polysaccharide powder.

- modified substances include, for example, ion-exchange polysaccharide or hemin-dyed polysaccharide.

- the ion-exchange polysaccharide is a polysaccharide, particularly the powder thereof, formed by incorporating therein various dissociating substituents to exhibit the properties of an ion-exchange resin.

- a cellulosic anion exchanger such as aminoethyl (AE) -cellulose, diethylaminoethyl (DEAE) - cellulose, or triethylaminoethyl(TEAE)-cellulose

- a cellulosic cation exchanger such as carboxymethyl(CM)-cellulose, phosphate(P)-cellulose, or sulfoethyl(SE)-cellulose, or an agarose ion exchanger.

- the hemin-dyed polysaccharide is a polysaccharide, particularly the powder thereof, formed by subjecting the powder to a heat treatment in 2-chloroethyl amine and aqueous solution of NaOH, and thereafter, adding hemin to effect dyeing.

- These polysaccharides include, for example, hemin-dyed cellulose powder.

- the mutagenic compounds present in tobacco smoke can be adsorbed onto the adsorbent according to the present invention, merely by bringing tobacco smoke into contact with the adsorbent. Therefore, the adsorbent of the present invention may be employed in various ways.

- the adsorbent of the present invention may be employed in combination with a filter-tip for a cigarette.

- the adsorbent of the present invention can be incorporated in an expandable polymer such as polyvinyl alcohol (PVA) or polyvinyl formal (P VF ), followed by expansion molding to disperse the .adsorbent in the filter-tip.

- An average particle size of the adsorbent to be incorporated during filter-tip formation is preferably 0.1 - 200 ⁇ m, more preferably 1 - 10 um.

- the adsorbent can be employed in embodiments wherein the adsorbents are dispersed between cellulose acetate fibers for a filter-tip or units aggregating the adsorbents are inserted into spaces in cellulose acetates.

- an average particle size of the adsorbent powder is preferably 50 - 200 pm.

- the adsorbent may be dispersed in tobacco leaves. Even further, the adsorbent may be used as a component of a filter-tip for removing mutagenic compounds, which filter-tip is incorporated in a holder employed for smoking a cigarette.

- An amount of the adsorbent used of the present invention may vary with the conditions of application. When a single kind of the adsorbent is used, the amount is 1 - 500 mg/cigarette. When two or more adsorbents are used in combination, the amount of each adsorbent is 100 ug - 100 mg/cigarette and the total amount is 1 mg-1 g/cigarette.

- mutagenicity was determined according to the following procedure:

- a particle phase of cigarette smoke was trapped by a Whatman glass filter GF/C ( ⁇ 37 mm) using an automatic suction device.

- the filter was treated with dimethyl sulfoxide.

- the resultant eluted substance was designated as a cigarette smoke condensate (CSC) and used in experiments in the form of a DMSO solution.

- the suction was carried out at a rate of 650 ml/min for 2 seconds at intervals of 20 seconds. The suction was repeated twelve times for one cigarette.

- a mutagenicity of the resultant CSC was examined by the Yahagi preincubation method (Takie Yahagi, Tanpakushitsu, Kakusan, Koso (Protein, Nucleic Acid and Enzyme), 20, l178 (1975)) which is a modification of a method of Ames et al [B.N. Ames et al, Mutant Res. 31, 347 (1975)].

- As a strain cells of Salmonella typhimurium TA98 at a logarithmic growth middle phase were employed. When a liver microsome fraction (S9) is added to CSC, a stronger mutagenicity is observed.

- an S9 mixture solution of containing 100 ⁇ l of S9 (30 mg protein/ml), 100 ⁇ l of TA98 strain (1 x 10 8 ), and 100 ul of DMSO solution of CSC (0.3 mg) was used for a plate.

- the S9 was prepared from an enzyme- induced liver of an SD rat (having a weight of about 100 g) and treated with polychlorinated biphenyl.

- the amount of CSC was obtained as a weight (mg) per one cigarette by calculation from an absorbance at 260 mm measured by a spectrophotometer as well as by actual determination with an electronic load cell scale (Mettler AE163 ® ).

- T a total mutagenicity of a cigarette

- S represents the number of reverse colonies (excepting natural revertant colonies) per one plate

- CSC represents the weight (mg) of CSC per one cigarette.

- the mutagenicity of CSC increases linearly up to 400 - 500 pg/plate independently of the kind of cigarette and of the existence or absence of a filter-tip. Therefore, a total mutagenicity was shown on the basis of the numbers of reverse colonies at 300 pg/plate. A specific mutagenicity was shown on the same basis.

- This reference example illustrates that a tar content and mutagenicity of a certain cigarette are not correlated.

- Figure 1 illustrates a comparison between tar contents and specific mutagenicities in cigarettes.

- the specific mutagenicities were calculated from the numbers of revertant colonies at 300 ug/plate of the CSC according to the above-mentioned method, and marked with a spot in Figure 1 as the number of revertant colonies per 1 mg of CSC (an average of 20 cigarettes, in each brand).

- the data of the tar content (mg) of a cigarette was taken from that announced by The Japan Tobacco Inc., in a pamphlet.

- Figure 1 shows the results obtained from “Mild Seven” (1), “Seven Stars” (2), “Cabin '85 Mild” (3), “Hilite” (4), “Mild Seven Light” (5), “Hope” (6), “Echo” (7), “Peace” (8), and “Mild Seven Select” (9), the above cigarettes (1) to (9) being produced by The Japan Tobacco Inc., and “Lark Mild” by Liggett & Myers (10), _"Lark” by Liggett & Myers (11), “Parliament 100's” by Philip Morris (12), “Lark Mild 100's” by Liggett & Myers (13), “Lark 100's” by Ligett & Myers (14), “Salem Light” by R.J.

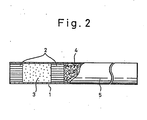

- the filter-tip body (1) comprises portions (2) of filter-tip of cellulose acetate and a space (3) therebetween for insertion of the adsorbent, and is attached to a cigarette body (5) containing tobacco leaves (4).

- Table 1 The values of Table 1 are an average + standard error of 10 runs.

- a material prepared by incorporating a crystalline cellulose powder (this powder was obtained by treating with diluted sulfuric acid a pulp available from Sanyo-Kokusaku Pulp Co., and had an average particle size of 0.4 ⁇ m, 4 um, 40 um or 100 um) into an expandable polyvinyl alcohol (PVA) during an expanding stage was molded into a cylinder 7 mm in diameter and 10 mm in length.

- the cylinder was inserted in a holding portion in a commercially available Heminphthalo-filter-tip (manufactured by Advance Co., Ltd.).

- the total mutagenicity of a cigarette (Mild Seven: Japan Tobacco Inc.) was calculated according to the above-mentioned method. A ratio of removing mutagenic compounds is shown in Figure 4 for each filter-tip.

- a ( ⁇ ) , B (o) C( ⁇ ) and D(x) represent crystalline cellulose powders having particle sizes of 0.4 pm, 4 ⁇ m, 40 ⁇ m, and 100 ⁇ m, respectively, and a relationship between an amount in weight (g) of crystalline cellulose powder incorporated in 1 liter of expandable polymer (PVA) and a rate of removing mutagenic compounds is shown.

- Triethylaminoethyl cellulose (TEAE-cellulose)-prepared by reacting crystalline cellulose powder (Avicel SF: Asahi Chemical Industry) having an average particle size of 6 ⁇ m with 2-chloroethylamine was dyed by hemin, and thereafter, unadsorbed hemin was thoroughly removed to obtain hemin-dyed cellulose powder. 2% by weight of hemin-dyed powder was blended with non-dyed crystalline cellulose powder to obtain an adsorbent. The efficiency of removing total mutagenic compounds and the specific mutagenicity were determined as in Examples 4 and 5.

- an efficiency of removing total mutagenic compounds in the case of no filter-tip is 0%, that in the case of the adsorbent consisting only of non-dyed cellulose powder was 45%, whereas that in the case of the adsorbent containing 2% by weight of hemin-dyed cellulose powder was 55%.

- the reduction rate of the specific mutagenicity is 0%, the rate was 15% with the adsorbent consisting of non-dyed cellulose, but was 30% with the adsorbent containing 2% by weight of hemin-dyed cellulose powder.

- the filter-tips were inserted in the holding part of Heminphthalo filter produced by Advance Co., Ltd., and then the panel tests were performed.

- the adsorbents inserted in Filter-tips Numbers. 1 to 6 are as follows:

- the adsorbent according to the present invention does not diminish the inherent flavor of tobacco, is able to efficiently and selectively adsorb mutagenic compounds present in tobacco smoke and remove the same from tobacco smoke, and greatly contributes to a decrease in the outbreak of diseases such as lung cancer by smoking.

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Inorganic Chemistry (AREA)

- Solid-Sorbent Or Filter-Aiding Compositions (AREA)

- Cigarettes, Filters, And Manufacturing Of Filters (AREA)

Applications Claiming Priority (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP252055/85 | 1985-11-12 | ||

| JP25205585A JPS62111679A (ja) | 1985-11-12 | 1985-11-12 | たばこ用フイルタ材 |

| JP21815886A JPS6374477A (ja) | 1986-09-18 | 1986-09-18 | たばこ用フイルタ材 |

| JP218158/86 | 1986-09-18 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0246330A1 true EP0246330A1 (de) | 1987-11-25 |

| EP0246330A4 EP0246330A4 (de) | 1988-04-26 |

Family

ID=26522426

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP19860906468 Withdrawn EP0246330A4 (de) | 1985-11-12 | 1986-11-11 | Absorbierungsmittel für ein mutagenmittel des tabakrauches und dessen verwendung. |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP0246330A4 (de) |

| WO (1) | WO1987002869A1 (de) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB2285908A (en) * | 1994-01-25 | 1995-08-02 | Gallaher Ltd | Filter material |

| LT4447B (lt) | 1995-11-09 | 1999-01-25 | Rhodia Acetow Ag | Cigaretė su filtru |

| CN103987284A (zh) * | 2011-12-06 | 2014-08-13 | 日本烟草产业株式会社 | 香烟过滤嘴及香烟 |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2739913A (en) * | 1953-07-02 | 1956-03-27 | Philip Morris And Co Ltd Inc | Tobacco product and method of making said product |

| GB996141A (en) * | 1964-06-04 | 1965-06-23 | British American Tobacco Co | Improvements in or relating to a filter assembly for a smoking tobacco product and method of making the same and smoking tobacco product including the filter assembly |

| DE2607208A1 (de) * | 1976-02-23 | 1977-08-25 | Hoechst Ag | Zigarettenfilter |

| JPS54110399A (en) * | 1978-02-15 | 1979-08-29 | Daicel Chem Ind Ltd | Powder-containing cigarette filter |

| JPS60110276A (ja) * | 1983-11-21 | 1985-06-15 | 東レ株式会社 | タバコフイルタ− |

| US5156730A (en) * | 1991-06-25 | 1992-10-20 | International Business Machines | Electrode array and use thereof |

-

1986

- 1986-11-11 WO PCT/JP1986/000571 patent/WO1987002869A1/ja not_active Ceased

- 1986-11-11 EP EP19860906468 patent/EP0246330A4/de not_active Withdrawn

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB2285908A (en) * | 1994-01-25 | 1995-08-02 | Gallaher Ltd | Filter material |

| LT4447B (lt) | 1995-11-09 | 1999-01-25 | Rhodia Acetow Ag | Cigaretė su filtru |

| RU2140758C1 (ru) * | 1995-11-09 | 1999-11-10 | Родиа Ацетов Аг | Сигарета с фильтром |

| CN103987284A (zh) * | 2011-12-06 | 2014-08-13 | 日本烟草产业株式会社 | 香烟过滤嘴及香烟 |

| CN103987284B (zh) * | 2011-12-06 | 2019-01-11 | 日本烟草产业株式会社 | 香烟过滤嘴及香烟 |

Also Published As

| Publication number | Publication date |

|---|---|

| EP0246330A4 (de) | 1988-04-26 |

| WO1987002869A1 (fr) | 1987-05-21 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CA1224106A (en) | Tobacco filter and fibrous ion exchange resin | |

| KR100265506B1 (ko) | 필터 담배 | |

| US4964426A (en) | Tobacco smoke filters and process for production thereof | |

| Iwata et al. | Utilization of DNA as functional materials: preparation of filters containing DNA insolubilized with alginic acid gel | |

| US20070295345A1 (en) | Selective Filtration of Cigarette Smoke using Chitosan Derivatives | |

| RU2631625C2 (ru) | Фильтр или элемент фильтра табачного дыма | |

| Carpita et al. | New features of plant-fructan structure revealed by methylation analysis and carbon-13 NMR spectroscopy | |

| EP0246330A1 (de) | Absorbierungsmittel für ein mutagenmittel des tabakrauches und dessen verwendung | |

| CN111227303A (zh) | 一种卷烟滤嘴添加材料及其制备方法与应用 | |

| GB2035041A (en) | Cigarette filters | |

| US3032445A (en) | Tobacco smoke filters | |

| GB1560418A (en) | Tobacco-smoke filter | |

| GB2166639A (en) | Process for producing granular algal adsorbents | |

| CN1897833B (zh) | 烟草烟雾过滤嘴 | |

| US5150723A (en) | Process for the production of tobacco smoke filters | |

| CN112841717A (zh) | 赋香凹凸棒石基卷烟滤嘴添加材料及其制备方法与应用 | |

| CA1138291A (en) | Tobacco-smoke filters | |

| US2920416A (en) | Treatment of tobacco smoke | |

| US3889691A (en) | Tobacco smoke filter | |

| US2920630A (en) | Tobacco smoke filter | |

| JP3012917B2 (ja) | 糖鎖分子量マーカーおよびその製造方法 | |

| US20050016555A1 (en) | Nucleic acid based filters | |

| WO2007092448A2 (en) | Filter compositions using highly refined cellulosic fiber ingredients | |

| JPS60168373A (ja) | タバコ用フイルタ− | |

| CN107594616A (zh) | 吸附组合物、其制备方法及应用 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19870803 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): DE FR GB |

|

| A4 | Supplementary search report drawn up and despatched |

Effective date: 19880426 |

|

| 17Q | First examination report despatched |

Effective date: 19900405 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 19900817 |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: KOBAYASHI, MIDORI Inventor name: YAGI, MICHIKO Inventor name: KUSUNOKI, SHINICHIRO Inventor name: NISHIKAWA, TAKUTO |