EP0244568B1 - Sheet conveyor for sheet-manipulating machines - Google Patents

Sheet conveyor for sheet-manipulating machines Download PDFInfo

- Publication number

- EP0244568B1 EP0244568B1 EP87101908A EP87101908A EP0244568B1 EP 0244568 B1 EP0244568 B1 EP 0244568B1 EP 87101908 A EP87101908 A EP 87101908A EP 87101908 A EP87101908 A EP 87101908A EP 0244568 B1 EP0244568 B1 EP 0244568B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- sheet

- gripper

- conveyor

- toothed belt

- support body

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H29/00—Delivering or advancing articles from machines; Advancing articles to or into piles

- B65H29/003—Delivering or advancing articles from machines; Advancing articles to or into piles by grippers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H29/00—Delivering or advancing articles from machines; Advancing articles to or into piles

- B65H29/02—Delivering or advancing articles from machines; Advancing articles to or into piles by mechanical grippers engaging the leading edge only of the articles

- B65H29/04—Delivering or advancing articles from machines; Advancing articles to or into piles by mechanical grippers engaging the leading edge only of the articles the grippers being carried by endless chains or bands

- B65H29/042—Intermediate conveyors, e.g. transferring devices

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H29/00—Delivering or advancing articles from machines; Advancing articles to or into piles

- B65H29/02—Delivering or advancing articles from machines; Advancing articles to or into piles by mechanical grippers engaging the leading edge only of the articles

- B65H29/04—Delivering or advancing articles from machines; Advancing articles to or into piles by mechanical grippers engaging the leading edge only of the articles the grippers being carried by endless chains or bands

- B65H29/045—Details of grippers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H5/00—Feeding articles separated from piles; Feeding articles to machines

- B65H5/08—Feeding articles separated from piles; Feeding articles to machines by grippers, e.g. suction grippers

- B65H5/085—Feeding articles separated from piles; Feeding articles to machines by grippers, e.g. suction grippers by combinations of endless conveyors and grippers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2404/00—Parts for transporting or guiding the handled material

- B65H2404/20—Belts

- B65H2404/23—Belts with auxiliary handling means

- B65H2404/231—Belts with auxiliary handling means pocket or gripper type

Definitions

- the present invention relates to a sheet conveyor for sheet-processing machines with a positively driven, rotating feed means, which runs at least over 2 end deflection wheels and possibly also between intermediate support wheels and carries at least one sheet transport gripper on its top, which opens or closes in the course of the circulation path becomes.

- Such sheet conveyors are known in various variations in the prior art. Such devices are usually designed as chain conveyors, which often feed a sheet to the front mark of a printing press or the like.

- a disadvantage of such chain conveyors is that their structure with the help of chains means that they are relatively complex and therefore cost-intensive. Often, the grippers are even switched into the chain on a special component in the form of a gripper carriage, which also requires a not inconsiderable design effort.

- chain conveyors run only with a considerable noise and have a considerable mass, so that they are not or only partially usable with high-speed machines.

- a transport device for flat objects is known according to the preamble of the claim, in which a gripping element actuated by a control cam and guide rails is inserted into a toothed belt.

- a sheet conveyor device is known from US Pat. No. 1,462,923, which is preferably provided for use in coating machines.

- grippers made of leaf springs which are also used in toothed belts. These run over deflection rollers, which are provided with circumferential recesses and thus act as a control cam for actuating the grippers.

- These devices are neither intended nor suitable for use in high-speed machines.

- High-speed offset printing machines can process up to 25,000 sheets per hour. It is important here that the sheets are gripped with great reliability and precision even in continuous operation.

- the invention achieves this in that the gripper is hook-shaped, has a cam lever-like extension and can be pivoted about an axis which is arranged at a distance from the toothed belt on its inside in the feed direction.

- the cam lever-like approach takes on two functions: First, it serves as an operating lever for the gripper when sliding over the cam track. Secondly, it supports a compression spring that closes the gripper in the non-activated position.

- the gripper mechanism of the sheet conveyor is actuated in a particularly advantageous manner in that the cam track for the actuating lever is part of the circumferential recesses of the gear or gears.

- the rotating grippers can be actuated particularly simply by running up or down one of the gearwheels, although it is not excluded that a separate (stationary) cam track is also provided for this purpose, in particular when opening and / or closing the grippers at a different location than is desired in the area of the support or deflection wheels of the sheet conveyor.

- the support body carrying the gripper passes through the toothed belt and rests with its support plate on the outside of the toothed belt, wherein it is clamped by at least two fastening pins which are located on the inside of the toothed belt and are inserted through the support body.

- the gripper mechanism can be replaced quickly and easily.

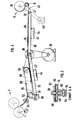

- two toothed belts (band 56) arranged parallel to the plane of the drawing are tensioned with the aid of two deflection rollers / gear wheels 52/54, of which, however, only one deflection roller 52 with one part in FIGS. 1 and 3 of the toothed belt 56 is shown.

- the belts 56 are designed as toothed belts and the associated deflection rollers 52/54 as corresponding toothed wheels. However, other forms of belts and pulleys are possible. As can be seen from FIGS. 1 and 2, the toothed belt 56 has a centrally arranged recess 55 at certain points along its longitudinal extent, into which the support body 60 with the gripper mechanism of the gripper 58 can be detachably inserted.

- the support body 60 has an approximately T-shaped shape which is provided with a central recess and which has a support plate 62 and which is arranged on the upper side of the toothed belt 56 has two central parts 64 which extend perpendicularly thereto and which accommodate between them the gripper 58 which is penetrated at some distance from the support plate 62 or the toothed belt 56 by a hinge pin 66 which is supported in the two central parts 64.

- the hook-shaped gripper 58 can thus be pivoted about the hinge pin 66 and the hook-shaped upper end of the gripper 58 which projects upwards over the support plate 62 above the top of the toothed belt 56 lies in the gripping position on the continuous part 63 of the support plate 62.

- a compression spring 68 is stretched between the support plate 62, 63 and a cam lever-like extension 70 of the hook-shaped gripper 58.

- the gripper 58 is normally pivoted into its clamping or gripping position, which it assumes in the entire course of the upper and lower run of the conveyor belt-like device and when it runs around the deflection roller 54. Only when the gripper mechanism runs around the deflection roller / gear 52 does the gripper, as shown in FIG. 1, assume the open position, specifically in that the cam-like extension 70 on the middle part 72 (which is larger than the deflection roller 54) (Cam track 61) runs up.

- both the deflecting roller 54 and the deflecting roller 52 have a groove-like recess 57 in their central planes which corresponds approximately to the width of the lower part of the gripper mechanism (FIG. 2), but the groove-shaped recess in the deflecting roller 52 is less deep than with the deflection roller 54, so that the gripper mechanism does not open in the latter.

- the depth of the recess of the deflection roller 54 is indicated by dashed lines at 53 in FIG. 1 and also in FIG.

- the gripper mechanism is easily detachably fastened to the toothed belt 56 by two locking pins 74 inserted through it. After removing these fastening pins 74, the gripper mechanism in FIG. 1 can simply be lifted out of the recess in the toothed belt 56. be lifted. These pins 75 are provided with a section of reduced diameter in the middle for better locking on the central parts 64 of the T-shaped support body 60, as can be clearly seen in FIG. 2.

- the mounting pins 74 are preferably arranged so that they just - as shown - fill two adjacent depressions of the toothed belt. Accordingly, the teeth must then be left out at the corresponding points on the gear wheels 52, 54, as is indicated in the lower left part of FIG. 1. Such an arrangement of the fastening pins then also requires that the grippers are arranged on the toothed belt 56 at a distance which corresponds to the pitch circle diameter of the gear wheels 52, 54 or a whole multiple thereof. However, it is conceivable to give these fastening pins 74 a cross section which corresponds to an elevation or a tooth of the toothed belt and then to arrange the fastening pins in place of such a tooth. In this case, the position of the grippers on the toothed belt can be chosen practically freely.

- a gripper mechanism is shown which is just beginning to leave the deflection roller 52 and thus initiates the closing process of the gripper 58.

- the path of a printing sheet emerging from a printing press is indicated by an arrow 59.

- the printing sheet hits the plate 62/63 on the upper run of the toothed belt 56 at an acute angle. This allows any undulations on the front edge of the printing sheet to be compensated for, since the sheet thus aligns itself on the plate 62/63.

- the sheet to be clamped is fed onto the toothed belt 56 or the support plate 62, 63 at such a speed that the differential speed is zero or approximately zero. Since the hinge pin 66 lies in the direction of movement of the toothed belt 56 in front of and below (in FIG. 1) the point of impact of the arch on the support plate 62, 63, the upper hook-shaped end of the gripper 58 protruding upward above the toothed belt 56 moves relative to the toothed belt when it is closed 56 backwards, ie against the direction of movement of the toothed belt, so that a secure grip and clamping of the front edge of the printing sheet arriving from the printing press is achieved.

- FIG. 4 shows a basic illustration of a specific application of the sheet conveyor according to the invention, namely as a turning device 50 of a sheet conveying and turning device between two printing machines 3, 5 connected in tandem, of which only one or two printing rollers and one toward the other and swinging suction roller for receiving and inserting a sheet to be printed are indicated by dash-dotted lines.

- an elongated belt conveyor 26 which consists of a number of endless elastic belts 28 with a high coefficient of friction arranged parallel to one another (and to the plane of the drawing). These belts 28 are guided over two deflection rollers 30 and 32 at the beginning and end of the elongated belt conveyor 26, further support rollers being distributed over the length of this conveyor as required.

- a support and drive roller is indicated in the middle at 38.

- the conveyor constructed in this way works in a very similar manner to a conventional conveyor belt, ie the printed sheets 36 deposited on its upper side by the turning device 50 and, if necessary, overlapping more or less are conveyed from the first printing press (left) to the second printing press (right) at a speed that depends on the circumstances of the individual case.

- the conveyor does not have to consist of individual endless belts 28 (approximately with a circular cross section) arranged parallel to one another, but it is readily conceivable that a coherent wide belt - for example with large holes in it or a network-like structure etc. - is used.

- the belt conveyor 26 being able to be driven either centrally at the central support and drive roller 38 via the main motor 39, which simultaneously drives the two printing presses 3, 5 synchronously , or alternatively - as shown - by a separate controllable drive motor 40 which, for example, acts on the deflection roller 32 at the end of the conveyor 26 and only drives the belt conveyor 26, while the main motor 39 drives the turning device 50 and the two printing presses 3, 5.

- suction chambers 41 are arranged just below the belt conveyor 26, which are subjected to a vacuum by suitable means.

- These suction chambers 42 have suction openings 44 pointing upwards, that is to say in the direction of the conveyor 26, so that there is a considerable air flow in the direction of the suction chambers, which then results in a more than over the large area of each printed sheet 36 deposited on the conveyor sufficient pressing force of the printed sheets against the conveyor having a significant coefficient of friction or its belts 28 leads.

- the printed sheets are thus fixed on the conveyor belt or belts of the conveyor and inevitably moved in the direction of the second printing press, where the front edge of each printing sheet finally abuts against a stop 46 serving as the front mark of the second printing press.

- the printed sheets are also aligned laterally, insofar as this is necessary at all.

- the fed sheet is fed from a reciprocating suction roll 14 in a known manner to the impression cylinder 18 of the second printing press.

- a test device for example in the form of a reflex head 47, is provided in the area of the abovementioned stop 46 (front mark of the second printing press). On the one hand, it checks the correct entry of the sheets into the machine 5 in terms of time and distance, and on the other hand it controls the activation of the offset cylinder 20 of the machine 5 if a sheet is available at the time of the query.

- the printing sheet running out of the first printing machine 3 is guided straight to the beginning of the upper run of the turning device 50, in such a way that the leading edge of the printing sheet is below the gripper 58 of the turning device which closes at this point is given.

- the turning device runs at a peripheral speed which corresponds exactly to the output speed of the printing sheet from the first printing machine 3, so that the entire sheet is pulled out of the printing machine and - without the gripper 58 opening - is guided around the deflection roller 54 of the turning device.

- the upper side of the printing sheet running out of the printing machine is turned downward, since the printed side of the printing sheet points downward, ie towards the conveyor 26, after reaching the lower run of the turning device.

- this gripper 58 attached to the toothed belt 56 of the turning device hits the deflection roller 52 at the end of the lower run (in the direction of rotation of the belt)

- this gripper opens and releases the front edge of the printing sheet, which now presses the previously generated print image onto the lower, i.e. the side facing the conveyor 26.

- the leading edge of the thus released, turned printing sheet then runs against a stop 51 at the end of the gap which is formed by the upper run of the belt conveyor 26 and the lower run of the turning device 50.

- the printed sheet is stopped and drawn against the belt conveyor 26 by the suction air generated by the suction chambers 42.

Abstract

Description

Die vorliegende Erfindung betrifft einen Bogenförderer für bogenverarbeitende Maschinen mit einem formschlüssig angetriebenen, umlaufenden Vorschubmittel, welches mindestens über 2 endständige Umlenkräder und ggf. auch über dazwischen angeordnete Stützräder läuft und an seiner Oberseite mindestens einen Bogentransportgreifer trägt, der im Verlaufe des Umlaufweges geöffnet bzw. geschlossen wird.The present invention relates to a sheet conveyor for sheet-processing machines with a positively driven, rotating feed means, which runs at least over 2 end deflection wheels and possibly also between intermediate support wheels and carries at least one sheet transport gripper on its top, which opens or closes in the course of the circulation path becomes.

Derartige Bogenförderer sind in verschiedenen Variationen im Stand der Technik bekannt. Gewöhnlich sind derartige Einrichtungen als Kettenförderer ausgebildet, die häufig einen Bogen an die Vordermarke einer Druckmaschine oder dergleichen heranführen. Ein Nachteil bei derartigen Kettenförderern besteht darin, daß sie durch ihren Aufbau mit Hilfe von Ketten relativ aufwendig und daher kostenintensiv sind. Häufig werden die Greifer sogar an einem besonderen Bauteil in Form eines Greiferwagens in die Kette eingeschaltet, was ebenfalls einen nicht unerheblichen konstruktiven Aufwand erfordert. Außerdem laufen Kettenförderer nur mit einer erheblichen Geräuschentwicklung und weisen eine beachtliche Masse auf, so daß sie schon vom Ansatz her bei schnellaufenden Maschinen nicht oder nur bedingt einsatzfähig sind.Such sheet conveyors are known in various variations in the prior art. Such devices are usually designed as chain conveyors, which often feed a sheet to the front mark of a printing press or the like. A disadvantage of such chain conveyors is that their structure with the help of chains means that they are relatively complex and therefore cost-intensive. Often, the grippers are even switched into the chain on a special component in the form of a gripper carriage, which also requires a not inconsiderable design effort. In addition, chain conveyors run only with a considerable noise and have a considerable mass, so that they are not or only partially usable with high-speed machines.

Aus der Deutschen Patentschrift 2 724 979 ist eine Transportvorrichtung für flache Gegenstände nach dem Oberbegriff des Patentanspruchs bekannt, bei der ein durch eine Steuerkurve und Führungsschienen betätigtes Greifelement in einen Zahnriemen eingesetzt ist. Ferner ist aus der US-Patentschrift 1 462 923 eine Bogenfördereinrichtung bekannt, die vorzugsweise für den Einsatz in Lackiermaschinen vorgesehen ist. Dort sind aus Blattfedern bestehende Greifer dargestellt, die ebenfalls in Zahnriemen eingesetzt sind. Diese laufen über Umlenkrollen, die mit Umfangsausnehmungen versehen sind und so als Steuerkurve für die Betätigung der Greifer wirken. Auch diese Vorrichtungen sind für den Einsatz in schnellaufenden Maschinen weder vorgesehen noch geeignet. Schnellaufende Offsetdruckmaschinen können bis zu 25 000 Bogen pro Stunde verarbeiten. Es kommt hier darauf an, daß die Bogen auch im Dauerbetrieb mit großer Zuverlässigkeit und Präzision ergriffen werden.From German patent specification 2 724 979 a transport device for flat objects is known according to the preamble of the claim, in which a gripping element actuated by a control cam and guide rails is inserted into a toothed belt. Furthermore, a sheet conveyor device is known from US Pat. No. 1,462,923, which is preferably provided for use in coating machines. There are shown grippers made of leaf springs, which are also used in toothed belts. These run over deflection rollers, which are provided with circumferential recesses and thus act as a control cam for actuating the grippers. These devices are neither intended nor suitable for use in high-speed machines. High-speed offset printing machines can process up to 25,000 sheets per hour. It is important here that the sheets are gripped with great reliability and precision even in continuous operation.

Es wird daher als die der vorliegenden Erfindung zugrundeliegende Aufgabe angesehen, die eingangs angesprochenen Fördervorrichtungen derart weiterzuentwickeln, daß sie vom Aufbau her besonders leicht und einfach und für schnellaufende Maschinen einsatzfähig sind und daß gleichzeitig die einzelnen Greifer bei Bedarf problemlos ausgewechselt werden können.It is therefore regarded as the object of the present invention to further develop the conveying devices mentioned at the outset in such a way that their construction is particularly light and simple and can be used for high-speed machines and that at the same time the individual grippers can be exchanged without any problems if required.

Diese Aufgabe wird durch eine Vorrichtung mit den Merkmalen des Patentanspruchs gelöst. Es hat sich gezeigt, daß die für den Einsatz in schnellaufenden Maschinen erforderliche Zuverlässigkeit und Präzision des Bogengreifens dadurch gewährleistet werden kann, daß der Greifer sich beim Schließen nach hinten, d.h. entgegen der Umlaufrichtung bewegt. Dies erreicht die Erfindung dadurch, daß der Greifer hakenförmig ausgestattet ist, einen nockenhebelartigen Ansatz aufweist und um eine Achse verschwenkbar ist, die mit Abstand vom Zahnriemen auf seiner Innenseite in Vorschubrichtung angeordnet ist. Der nockenhebelartige Ansatz übernimmt dabei zwei Funktionen: Erstens dient er als Betätigungshebel für den Greifer beim Gleiten über die Nockenbahn. Zweitens stützt er eine Druckfeder ab, die den Greifer in nicht aktivierter Position schließen läßt.This object is achieved by a device with the features of the patent claim. It has been shown that the reliability and precision of sheet gripping required for use in high-speed machines can be ensured by the gripper moving backwards when closing, i.e. moved against the direction of rotation. The invention achieves this in that the gripper is hook-shaped, has a cam lever-like extension and can be pivoted about an axis which is arranged at a distance from the toothed belt on its inside in the feed direction. The cam lever-like approach takes on two functions: First, it serves as an operating lever for the gripper when sliding over the cam track. Secondly, it supports a compression spring that closes the gripper in the non-activated position.

Der Greifermechanismus des Bogenförderers wird in besonders vorteilhafter Weise dadurch betätigt, daß die Nockenbahn für den Betätigungshebel Teil der Umfangsausnehmungen des oder der Zahnräder ist. Das bedeutet, daß die umlaufenden Greifer besonders einfach durch Auflaufen auf bzw. Ablaufen von einem der Zahnräder betätigt werden, wobei jedoch nicht ausgeschlossen ist, daß auch eine separate (stationäre) Nockenbahn zu diesem Zweck vorgesehen wird, und zwar insbesondere dann, wenn ein Öffnen und/oder Schließen der Greifer an einer anderen Stelle als im Bereich der Stütz- oder Umlenkräder des Bogenförderers gewünscht wird.The gripper mechanism of the sheet conveyor is actuated in a particularly advantageous manner in that the cam track for the actuating lever is part of the circumferential recesses of the gear or gears. This means that the rotating grippers can be actuated particularly simply by running up or down one of the gearwheels, although it is not excluded that a separate (stationary) cam track is also provided for this purpose, in particular when opening and / or closing the grippers at a different location than is desired in the area of the support or deflection wheels of the sheet conveyor.

Der den Greifer tragende Stützkörper durchsetzt den Zahnriemen und liegt mit seiner Auflageplatte auf der Zahnriemenaussenseite auf, wobei er durch mindestens zwei an der Zahnriemeninnenseite anliegende, durch den Stützkörper hindurchgesteckte Befestigungsstifte festgeklemmt wird. Durch eine solche Art der Befestigung läßt sich der Greifermechanismus schnell und problemlos auswechseln.The support body carrying the gripper passes through the toothed belt and rests with its support plate on the outside of the toothed belt, wherein it is clamped by at least two fastening pins which are located on the inside of the toothed belt and are inserted through the support body. With such a type of attachment, the gripper mechanism can be replaced quickly and easily.

Ein Ausführungsbeispiel der vorliegenden Erfindung wird unter Bezugnahme auf die beigefügten Zeichnungen beschrieben. Darin zeigen:

- Fig. 1 die konstruktive Ausbildung des einen Endes eines förderbandartigen Bogenförderers nach der vorliegenden Erfindung - das entgegengesetzte Ende ist im wesentlichen spiegelbildlich ausgebildet;

- Fig. 2 einen Schnitt längs Linie A-D in Figur 1;

- Fig. 3 eine Draufsicht auf Figur 1; und

- Fig. 4 die prinzipielle Darstellung einer Bogen-Förder- und Wendevorrichtung für in Tandemanordnung angeordnete Offset-Druckmaschinen, wobei der erfindungsgemäße Bogen-Förderer gemäß Figuren 1 -3 als

Wendeeinrichtung 50 dient.

- Fig. 1 shows the design of one end of a conveyor belt-type sheet conveyor according to the present invention - the opposite end is essentially a mirror image;

- 2 shows a section along line AD in FIG. 1;

- 3 shows a plan view of FIG. 1; and

- 4 shows the basic illustration of a sheet conveying and turning device for offset printing machines arranged in a tandem arrangement, the sheet conveyor according to the invention serving as a

turning device 50 according to FIGS. 1-3.

In dem nachfolgend beschriebenen bevorzugten Ausführungsbeispiel eines Bogenförderers sind zwei parallel zur Zeichenebene, nebeneinander angeordnete Zahnriemen (Band 56) mit Hilfe von jeweils zwei Umlenkrollen/Zahnrädern 52/54 aufgespannt, von denen jedoch in Figur 1 und 3 nur die eine Umlenkrolle 52 mit einem Teil des Zahnriemens 56 dargestellt ist.In the preferred exemplary embodiment of a sheet feeder described below, two toothed belts (band 56) arranged parallel to the plane of the drawing are tensioned with the aid of two deflection rollers /

Wie aus der Figur 1 ersichtlich ist, sind die Bänder 56 als Zahnriemen und die zugehörigen Umlenkrollen 52/54 als entsprechende Zahnräder ausgebildet. Allerdings sind andere Formen von Bändern und Umlenkrollen möglich. Wie aus den Figuren 1 und 2 entnehmbar ist, hat der Zahnriemen 56 an bestimmten Stellen seiner Längserstreckung eine mittig angeordnete Aussparung 55, in die der Stützkörper 60 mit dem Greifermechanismus des Greifers 58 lösbar eingesetzt werden kann. Der Stützkörper 60 weist eine mit einer mittigen Aussparung versehene, in etwa T-förmige Gestalt auf, die eine auf der Oberseite des Zahnriemens 56 angeordnete Auflageplatte 62 und zwei sich senkrecht dazu erstreckende Mittelteile 64 besitzt, die zwischen sich den Greifer 58 aufnehmen, der in einiger Entfernung von der Auflageplatte 62 bzw. dem Zahnriemen 56 von einem Scharnierstift 66 durchsetzt wird, der sich in den beiden Mittelteilen 64 abstützt. Der hakenförmig ausgebildete Greifer 58 ist also um den Scharnierstift 66 verschwenkbar und das über die Auflageplatte 62 nach oben über die Oberseite des Zahnriemens 56 aufragende hakenförmmige obere Ende des Greifers 58 liegt in der Greifstellung auf dem durchgehenden Teil 63 der Auflageplatte 62 auf. Eine Druckfeder 68 ist zwischen der Auflageplatte 62, 63 und einem nockenhebelartigen Ansatz 70 des hakenförmigen Greifers 58 gespannt. Durch diese Druckfeder 68 wird der Greifer 58 normalerweise in seine klemmende oder greifende Stellung verschwenkt, die er im ganzen Verlauf des oberen und unteren Trums der förderbandartigen Einrichtung und beim Herumlaufen um die Umlenkrolle 54 einnimmt. Ausschließlich beim Herumlaufen des Greifermechanismus um die Umlenkrolle/ das Zahnrad 52 nimmt der Greifer, wie in Figur 1 dargestellt, die geöffnete Stellung ein, und zwar dadurch, daß der nockenartige Ansatz 70 auf den (gegenüber der Umlenkrolle 54) einen größeren Durchmesser aufweisenden Mittelteil 72 (Nockenbahn 61) aufläuft. Dies bedeutet, daß sowohl die Umlenkrolle 54 als auch die Umlenkrolle 52 in ihren Mittelebenen eine nutenartige Aussparung 57 haben, die in etwa der Breite des unteren Teils des Greifermechanismus (Figur 2) entspricht, wobei jedoch die nutenförmige Aussparung bei der Umlenkrolle 52 weniger Tief ist als bei der Umlenkrolle 54, so daß der Greifermechanismus bei letzterer nicht öffnet. Die Tiefe der Aussparung der Umlenkrolle 54 ist bei 53 in Figur 1 und auch in Figur 4 strichliert angedeutet.As can be seen from FIG. 1, the

In vorteilhafter Weise ist der Greifermechanismus durch zwei hindurchgesteckte Sicherungsstifte 74 ohne weiteres lösbar an dem Zahnriemen 56 befestigt. Nach Entfernen dieser Befestigungsstifte 74 kann der Greifermechanismus in Figur 1 einfach nach oben aus der Aussparung im Zahnriemen 56 heraus-. gehoben werden. Diese Stifte 75 sind in der Mitte zur besseren Arretierung an den Mittelteilen 64 des T-förmigen Stützkörpers 60 mit einem Abschnitt verringerten Durchmessers versehen, wie dies in Figur 2 deutlich zu sehen ist.Advantageously, the gripper mechanism is easily detachably fastened to the

Die Befestigungsstifte 74 werden vorzugsweise so angeordnet, daß sie gerade - wie dargestellt - zwei benachbarte Vertiefungen des Zahnriemens ausfüllen. Demgemäß müssen dann an den entsprechenden Stellen der Zahnräder 52, 54 die Zähne fortgelassen sein, wie dies im unteren linken Teil der Figur 1 angedeutet ist. Eine solche Anordnung der Befestigungsstifte bedingt dann auch, daß die Greifer auf dem Zahnriemen 56 gerade mit einem Abstand angeordnet sind, der dem Teilkreisdurchmesser der Zahnräder 52, 54 oder einem ganzen Vielfachen davon entspricht. Allerdings ist es denkbar, diesen Befestigungsstiften 74 einen Querschnitt zu geben, der gerade einer Erhebung bzw. einem Zahn des Zahnriemens entspricht und die Befestigungsstifte dann gerade an Stelle eines solchen Zahnes anzuordnen. In diesem Fall kann die Position der Greifer auf dem Zahnriemen praktisch frei gewählt werden.The

Im oberen linken Teil der Figur 1 ist ein Greifermechanismus gezeigt, der gerade die Umlenkrolle 52 zu verlassen beginnt und damit den Schließvorgang des Greifers 58 einleitet. An der gleichen Stelle ist die Bahn eines beispielsweise aus einer Druckmaschine heraustretenden Druckbogens durch einen Pfeil 59 angedeutet. Der Druckbogen trifft unter einem spitzen Winkel auf die Platte 62/63 auf dem oberen Trum des Zahnriemens 56. Dadurch können eventuelle Welligkeiten an der Vorderkante des Druckbogens ausgeglichen werden, da sich der Bogen somit von selbst auf der Platte 62/63 ausrichtet. Da die Geschwindigkeit des Zahnriemens 56 und die Arbeitsgeschwindigkeit der Druckmaschine aufeinander abgestimmt sind, wird der einzuklemmende Bogen mit einer solchen Geschwindigkeit auf den Zahnriemen 56 bzw. die Auflageplatte 62, 63 gegeben, daß die Differenzgeschwindigkeit Null oder annähernd Null ist. Da der Scharnierstift 66 in Bewegungsrichtung des Zahnriemens 56 vor und unter (in Figur 1) dem Auftreffpunkt des Bogens auf die Auflageplatte 62, 63 liegt, bewegt sich das über den Zahnriemen 56 nach oben vorstehende obere hakenförmige Ende des Greifers 58 beim Schließen relativ zum Zahnriemen 56 nach hinten, d.h. entgegen der Bewegungsrichtung des Zahnriemens, so daß ein sicheres Ergreifen und Klemmen der Vorderkante des von der Druckmaschine einlaufenden Druckbogens erreicht wird.In the upper left part of FIG. 1, a gripper mechanism is shown which is just beginning to leave the

Die Figur 4 zeigt in prinzipieller Darstellung einen konkreten Anwendungsfall des erfindungsgemäßen Bogen-Förderers, und zwar als Wendeeinrichtung 50 einer Bogen-Förder- und Wendeeinrichtung zwischen zwei in Tandemanordnung hintereinandergeschaltete Druckmaschinen 3, 5, von denen nur ein bzw. zwei Druckwalzen und eine hin- und herpendelnde Saugwalze zum Aufnehmen und Einführen eines zu bedruckenden Bogens strichpunktiert angedeutet sind.FIG. 4 shows a basic illustration of a specific application of the sheet conveyor according to the invention, namely as a

Im Bereich unter und hinter dem Ausgabewalzenpaar 24 der ersten Druckmaschine - in Bewegungsrichtung der Druckbogen gesehen - befindet sich ein langgestreckter Bandförderer 26, der aus einer Anzahl von parallel zueinander (und zur Zeichenebene) angeordneten, endlosen elastischen Bändern 28 mit großem Reibungskoeffizienten besteht. Diese Bänder 28 werden über zwei Umlenkrollen 30 und 32 am Anfang und Ende des langgestreckten Bandförderers 26 geführt, wobei weitere Stützrollen je nach Bedarf über die Länge dieses Förderers verteilt angeordnet sind. Eine Stütz- und Antriebsrolle ist in der Mitte bei 38 angedeutet. Der in dieser Weise aufgebaute Förderer arbeitet ganz ähnlich wie ein übliches Förderband, d.h., die von der Wendeeinrichtung 50 auf seiner Oberseite abgelegten, bei Bedarf mehr oder weniger sich überlappenden Druckbogen 36 werden von der ersten Druckmaschine (links) zur zweiten Druckmaschine (rechts) befördert, und zwar mit einer Geschwindigkeit, die von den Umständen des Einzelfalles abhängt. Der Förderer muß nicht aus einzelnen, parallel zueinander angeordneten Endlosbändern 28 (etwa mit kreisförmigem Querschnitt) bestehen, sondern es ist ohne weiteres denkbar, daß auch ein in sich zusammenhängendes breites Band - beispielsweise mit großen Löchern darin oder eine netzwerkartige Struktur etc. - eingesetzt wird. Wesentlich ist hierbei natürlich, daß die einzelnen Bänder mit der gleichen Geschwindigkeit angetrieben werden, wobei der Antrieb des Bandförderers 26 entweder zentral bei der mittleren Stütz- und Antriebsrolle 38 über den Hauptmotor 39 erfolgen kann, der gleichzeitig auch die beiden Druckmaschinen 3, 5 synchron antreibt, oder alternativ - wie dargestellt - durch einen separaten regelbaren Antrisbsmotor 40, der beispielsweise auf die Umlenkrolle 32 am Ende des Förderers 26 einwirkt und nur den Bandförderer 26 antreibt, während der Hauptmotor 39 die Wendevorrichtung 50 und die beiden Druckmaschinen 3, 5 antreibt.In the area under and behind the

Damit die lose auf der Oberseite des Förderers abgelegten Druckbogen zwangsläufig vorwärts bewegt werden, sind dicht unterhalb des Bandförderers 26 mehrere große Saugkammern 41 angeordnet, die über geeignete Mittel mit Unterdruck beaufschlagt werden. Diese Saugkammern 42 haben nach oben, also in Richtung auf den Förderer 26 weisende Ansaugöffnungen 44, so daß sich eine erhebliche Luftströmung in Richtung auf die Saugkammern ergibt, was dann über die große Fläche eines jeden oben auf dem Förderer abgelegten Druckbogens 36 zu einer mehr als ausreichenden Andruckkraft der Druckbogen gegen den einen erheblichen Reibungskoeffizienten aufweisenden Förderer bzw. dessen Bänder 28 führt. Somit werden die Druckbogen auf dem Förderband bzw. den Bändern des Förderers fixiert und zwangsläufig in Richtung auf die zweite Druckmaschine bewegt, wo die Vorderkante eines jeden Druckbogens schließlich gegen einen als Vordermarke der zweiten Druckmaschine dienenden Anschlag 46 stößt. Im Verlauf des Förderers, vorzugsweise an seinem Ende, werden die Druckbogen auch seitlich ausgerichtet, soweit dies überhaupt notwendig ist. Im Bereich des erwähnten Anschlages 46 an der zweiten Druckmaschine, d.h. also an deren Vordermarke, wird der angeförderte Bogen von einer hin- und herpendelnden Saugwalze 14 in bekannter Weise dem Gegendruckzylinder 18 der zweiten Druckmaschine zugeführt.So that the loose printed sheets on the top of the conveyor are inevitably moved forward, several large suction chambers 41 are arranged just below the

Im Bereich des erwähnten Anschlages 46 (Vordermarke der zweiten Druckmaschine) ist eine Prüfvorrichtung, etwa in Form eines Reflexkopfes 47 vorgesehen. Einerseits überprüft sie den zeitlich und abstandsmäßig richtigen Einlauf der Bogen zur Maschine 5 und andererseits steuert sie die Zuschaltung des Offsetzylinders 20 der Maschine 5, wenn ein Bogen zum Abfragezeitpunkt vorhanden ist.A test device, for example in the form of a

Wie in Figur 4 dargestellt ist, wird der aus der ersten Druckmaschine 3 herauslaufende Druckbogen gerade auf den Anfang des oberen Trums der Wendeeinrichtung 50 geführt, und zwar in der Weise, daß die Vorderkante des Druckbogens unter den sich an dieser Stelle schließenden Greifer 58 der Wendeeinrichtung gegeben wird. Die Wendeeinrichtung läuft mit einer Umfangsgeschwindigkeit, die exakt der Ausgabegeschwindigkeit des Druckbogens aus der ersten Druckmaschine 3 entspricht, so daß der ganze Bogen aus der Druckmaschine abgezogen und - ohne daß der Greifer 58 sich öffnet - um die Umlenkrolle 54 der Wendeeinrichtung herumgeführt wird. Dadurch wird die Oberseite des aus der Druckmaschine herauslaufenden Druckbogens nach unten gewendet, da die bedruckte Seite des Druckbogens nach Erreichen des unteren Trums der Wendeeinrichtung nach unten, also zum Förderer 26 weist. Sobald der am Zahnriemen 56 der Wendeeinrichtung befestigte Greifer 58 am (in Umlaufrichtung des Bandes gelegenen) Ende des unteren Trums auf die Umlenkrolle 52 trifft, öffnet dieser Greifer und gibt die Vorderkante des Druckbogens frei, der das zuvor erzeugte Druckbild nunmehr auf der unteren, d.h. der dem Förderer 26 zugewandten Seite trägt. Die Vorderkante des somit freigegebenen, gewendeten Druckbogens läuft dann gegen einen Anschlag 51 am Ende des Spaltes, der von dem oberen Trum des Bandförderers 26 und dem unteren Trum der Wendeeinrichtung 50 gebildet wird. Dadurch wird der Druckbogen angehalten und von der von den Saugkammern 42 erzeugten Saugluft gegen den Bandförderer 26 gezogen.As shown in FIG. 4, the printing sheet running out of the

Claims (1)

- Sheet conveyor for sheet-manipulating machines having toothed belts (56) that are guided over at least two deflection rollers (52, 54) atthe ends of the conveyor and also if needed over intermediate support rollers, which toothed belts are provided on their outer sides with at least one sheet transport gripper with an activating lever, by means of which lever the gripper is opened or closed on meeting or leaving a cam track (58), which cam may be formed from recesses in the circumferences of the deflection rollers, said belts being provided at one or more points of the longitudinal extension with a recess (55) in which a support body (60) for the gripper mechanism is inserted, wherein the hook-shaped gripper (58) is pivotable towards the toothed belt about a hinge pin (66) which is disposed in front of the clamping point in the direction of motion of the toothed belt on the inside of the toothed belt at a clearance from it, wherein the gripper is activated by the cam track by means of a cam lever-like extension (70) serving as activating lever, which lever supports a compression spring (68) for the closing of the gripper, and wherein the support body is locked in securely by means of at least two securing pins (74) which are closely fitted to the inside of the toothed belt and which pass through the support body.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT87101908T ATE48267T1 (en) | 1986-02-20 | 1987-02-11 | SHEET FEEDERS FOR SHEET PROCESSING MACHINES. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19863605534 DE3605534A1 (en) | 1986-02-20 | 1986-02-20 | BOW CONVEYOR FOR BOW PROCESSING MACHINES |

| DE3605534 | 1986-02-20 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0244568A1 EP0244568A1 (en) | 1987-11-11 |

| EP0244568B1 true EP0244568B1 (en) | 1989-11-29 |

Family

ID=6294582

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP87101908A Expired EP0244568B1 (en) | 1986-02-20 | 1987-02-11 | Sheet conveyor for sheet-manipulating machines |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US4799664A (en) |

| EP (1) | EP0244568B1 (en) |

| JP (1) | JPS62255345A (en) |

| AT (1) | ATE48267T1 (en) |

| DE (2) | DE3605534A1 (en) |

| ES (1) | ES2012061B3 (en) |

Families Citing this family (29)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CH683913A5 (en) * | 1987-10-23 | 1994-06-15 | Ferag Ag | Feed for continuously accumulating fabrics, in particular printed products. |

| JPH01127537A (en) * | 1987-11-09 | 1989-05-19 | Sharp Corp | Feeding device for sheet material |

| US4972234A (en) * | 1989-02-17 | 1990-11-20 | Fujitsu Limited | Endless belt with recess for receiving sheet feeding grippers |

| US5054621A (en) * | 1989-12-18 | 1991-10-08 | Hybrid Systems, Inc. | Document sorting apparatus |

| US5265868A (en) * | 1990-05-03 | 1993-11-30 | Bell & Howell Phillipsburg | Sheet feeder |

| US5145161A (en) * | 1990-05-03 | 1992-09-08 | Bell & Howell Phillipsburg Co. | Sheet feeder |

| US5053826A (en) * | 1990-12-21 | 1991-10-01 | Xerox Corporation | Transfer loop synchronization in recirculating color printers |

| US5211392A (en) * | 1991-09-05 | 1993-05-18 | Xerox Corporation | Sheet transport apparatus for use in an electrophotographic printing machine |

| SE9103290L (en) * | 1991-11-07 | 1993-05-08 | Wamag Idab Ab | PROCEDURE AND DEVICE TO OPEN A SELF-CLOSED GRIPPING ON A GRIPPING TRANSPORT |

| US5244203A (en) * | 1992-04-24 | 1993-09-14 | Eastman Kodak Company | Sheet transporting apparatus with a transport belt to which sheets are selectively clamped |

| DE4223232A1 (en) * | 1992-07-15 | 1994-01-20 | Heidelberger Druckmasch Ag | Device for controlling opening time of gripper fingers in sheet delivery mechanism - has starting body displaceable along path matching curved or straight path of movement of grippers |

| DE4244343C2 (en) * | 1992-12-28 | 1996-08-29 | Wifag Maschf | Method and device for forming a shingled stream of folded printed copies |

| SE502958C2 (en) * | 1994-08-19 | 1996-02-26 | Sten Wallsten Ind Ab | Device for delivering selected specimens of objects from a conveyor belt |

| DE19519374C2 (en) * | 1995-05-26 | 1999-11-18 | Heidelberger Druckmasch Ag | Device for automatic sheet separation in the delivery of a sheet-fed rotary printing machine |

| US6336310B1 (en) * | 1998-09-08 | 2002-01-08 | Sanford Redmond | Method and apparatus for making compact packages for speadable product |

| DE19916668B4 (en) * | 1999-04-14 | 2010-06-24 | Michael Hörauf Maschinenfabrik GmbH & Co. KG | Device for transporting flat blanks |

| DE19949751A1 (en) * | 1999-10-15 | 2001-04-19 | Heidelberger Druckmasch Ag | Modular printing machine system for printing sheets |

| DE10047040A1 (en) * | 1999-10-15 | 2001-04-19 | Heidelberger Druckmasch Ag | Modular printing machine includes additional non-impact printer permitting individual markings, which is allocated to sheet transport system of printing machine |

| DE50005320D1 (en) * | 1999-12-07 | 2004-03-25 | Ferag Ag | Device and method for transporting supplementary products |

| US7017640B2 (en) * | 2001-02-09 | 2006-03-28 | Winter Steven B | Method and apparatus for manufacture of swatch-bearing sheets |

| AUPS061402A0 (en) * | 2002-02-19 | 2002-03-14 | Tna Australia Pty Limited | A device to aid packaging items |

| DE102004007599A1 (en) | 2003-03-27 | 2004-10-07 | Heidelberger Druckmaschinen Ag | Rotary printing press, has opener opening trailing edge grippers when sheets reach sheet decurler, and guide device aligning trailing edges of sheets leaving decurler for renewed guidance by grippers |

| WO2004091272A1 (en) * | 2003-04-03 | 2004-10-21 | Fuji Machine Mfg. Co., Ltd. | Electronic circuit component supplying device and electronic circuit component mounting machine |

| DE502005006128D1 (en) * | 2004-09-15 | 2009-01-15 | Ferag Ag | Method and device for separating flat objects from a horizontal stack |

| DE102006039987A1 (en) * | 2006-08-25 | 2008-02-28 | Koenig & Bauer Aktiengesellschaft | Stacking device for sheet processing machine, has clamping grippers which are formed, such that they bends sheet front edges in angle in delivery stack surface by taking over through gripper closure |

| DE102009016067A1 (en) | 2009-03-17 | 2010-09-23 | Steinemann Technology Ag | Device for conveying a bow |

| US8376356B2 (en) * | 2009-09-21 | 2013-02-19 | Goss International Americas, Inc. | Infinitely variable format signature collection apparatus and method of collecting signatures |

| CH703119A1 (en) | 2010-05-10 | 2011-11-15 | Ferag Ag | Apparatus and method for transporting flexible, sheet-like products. |

| CA2979915A1 (en) * | 2015-05-01 | 2016-11-10 | Curt G. Joa, Inc. | Apparatus and method for mechanically gripping and transporting webs of material |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1462923A (en) * | 1921-07-02 | 1923-07-24 | United Printing Machinery Comp | Sheet gripper |

| US3266796A (en) * | 1964-12-21 | 1966-08-16 | Ibm | Document handling apparatus |

| SE413007B (en) * | 1977-04-12 | 1980-03-31 | Wifag Maschf | DEVICE FOR CREATING A CURRENT OF OVERLAPPED FALSE PRINTED PRODUCTS |

| DE2724979C3 (en) * | 1977-06-02 | 1980-01-31 | Bielomatik Leuze Gmbh & Co, 7442 Neuffen | Transport device for flat objects |

| US4203590A (en) * | 1978-01-09 | 1980-05-20 | Levi Strauss & Co. | Gripper belt transfer |

-

1986

- 1986-02-20 DE DE19863605534 patent/DE3605534A1/en not_active Withdrawn

-

1987

- 1987-02-11 ES ES87101908T patent/ES2012061B3/en not_active Expired - Lifetime

- 1987-02-11 AT AT87101908T patent/ATE48267T1/en not_active IP Right Cessation

- 1987-02-11 DE DE8787101908T patent/DE3761044D1/en not_active Expired - Fee Related

- 1987-02-11 EP EP87101908A patent/EP0244568B1/en not_active Expired

- 1987-02-19 US US07/016,574 patent/US4799664A/en not_active Expired - Fee Related

- 1987-02-20 JP JP62035939A patent/JPS62255345A/en active Pending

Also Published As

| Publication number | Publication date |

|---|---|

| EP0244568A1 (en) | 1987-11-11 |

| ATE48267T1 (en) | 1989-12-15 |

| DE3605534A1 (en) | 1987-08-27 |

| DE3761044D1 (en) | 1990-01-04 |

| JPS62255345A (en) | 1987-11-07 |

| US4799664A (en) | 1989-01-24 |

| ES2012061B3 (en) | 1990-03-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0244568B1 (en) | Sheet conveyor for sheet-manipulating machines | |

| DE3637110C1 (en) | Device for cutting and dividing a continuous flow of printed products | |

| DE10005323A1 (en) | Device for handling printed products in rotary printing machines | |

| EP0303053B1 (en) | Sheet-transferring device | |

| DE2058606A1 (en) | Method and device for the lateral alignment of sheets, in particular in a printing press | |

| DD158883A5 (en) | TRANSPORT DEVICE FOR CARRYING OUT FRESH PRINTED BOW | |

| DE4424483C2 (en) | Boom of a sheet processing machine | |

| EP0241663B1 (en) | Apparatus for conveying and overturning sheets for sheet manipulating machines | |

| DE2638783A1 (en) | ARCH FEEDER | |

| DE3126808A1 (en) | GATHERING MACHINE | |

| DE3114581C2 (en) | Conveyor device for a sheet-fed rotary printing press | |

| DE2655098C3 (en) | Document feeder | |

| DE4424964C2 (en) | Sheet guiding device for turning sheets | |

| EP1072546B1 (en) | Conveyer for collating and processing printed sheets | |

| EP0014233B1 (en) | Device for conveying sheets to printing machines | |

| DE2624170C3 (en) | Side alignment device | |

| DE1102767B (en) | Sheet transport device on printing presses | |

| DE3428512C2 (en) | Device for the takeover and further transport of folded products | |

| DE2232610C2 (en) | Chain device to a conveyor system for paper processing companies | |

| CH686829A5 (en) | Device for transferring individual printed products of a stream of shingles. | |

| DE3034767C2 (en) | ||

| WO1998036385A1 (en) | Conveying device for individual sheets | |

| DE19540711C2 (en) | Device for releasing folded products | |

| DE2356570C3 (en) | Handling device for bottles or the like | |

| CH293137A (en) | Rotary printing machine for printing on sheets. |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH DE ES FR GB GR IT LI LU NL SE |

|

| 17P | Request for examination filed |

Effective date: 19870928 |

|

| 17Q | First examination report despatched |

Effective date: 19881118 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE ES FR GB GR IT LI LU NL SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19891129 Ref country code: NL Effective date: 19891129 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 19891129 |

|

| REF | Corresponds to: |

Ref document number: 48267 Country of ref document: AT Date of ref document: 19891215 Kind code of ref document: T |

|

| ITF | It: translation for a ep patent filed |

Owner name: BARZANO' E ZANARDO MILANO S.P.A. |

|

| ET | Fr: translation filed | ||

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) | ||

| REF | Corresponds to: |

Ref document number: 3761044 Country of ref document: DE Date of ref document: 19900104 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Effective date: 19900211 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19900212 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19900228 Ref country code: LI Effective date: 19900228 Ref country code: CH Effective date: 19900228 Ref country code: BE Effective date: 19900228 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| BERE | Be: lapsed |

Owner name: NEUE ROTAPRINT G.M.B.H. Effective date: 19900228 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19901031 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19901101 |

|

| 26N | No opposition filed | ||

| 26N | No opposition filed | ||

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19910211 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee | ||

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 19990301 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20050211 |