EP0238797A1 - Flat bed knitting machine provided with two needle beds and sinkers between the needles - Google Patents

Flat bed knitting machine provided with two needle beds and sinkers between the needles Download PDFInfo

- Publication number

- EP0238797A1 EP0238797A1 EP87100869A EP87100869A EP0238797A1 EP 0238797 A1 EP0238797 A1 EP 0238797A1 EP 87100869 A EP87100869 A EP 87100869A EP 87100869 A EP87100869 A EP 87100869A EP 0238797 A1 EP0238797 A1 EP 0238797A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- sinkers

- needles

- knitting machine

- stitch

- thread

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 238000009940 knitting Methods 0.000 title claims abstract description 41

- 239000004744 fabric Substances 0.000 claims description 12

- 238000004519 manufacturing process Methods 0.000 claims description 10

- 230000015572 biosynthetic process Effects 0.000 claims description 5

- 238000000034 method Methods 0.000 claims description 4

- 238000006073 displacement reaction Methods 0.000 description 2

- 230000014759 maintenance of location Effects 0.000 description 2

- 230000000717 retained effect Effects 0.000 description 2

- 230000001419 dependent effect Effects 0.000 description 1

- 238000013461 design Methods 0.000 description 1

- 238000003780 insertion Methods 0.000 description 1

- 230000037431 insertion Effects 0.000 description 1

- BASFCYQUMIYNBI-UHFFFAOYSA-N platinum Chemical compound [Pt] BASFCYQUMIYNBI-UHFFFAOYSA-N 0.000 description 1

- 238000012545 processing Methods 0.000 description 1

- 238000010079 rubber tapping Methods 0.000 description 1

- 238000012546 transfer Methods 0.000 description 1

- 230000007704 transition Effects 0.000 description 1

- 238000004804 winding Methods 0.000 description 1

Images

Classifications

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04B—KNITTING

- D04B15/00—Details of, or auxiliary devices incorporated in, weft knitting machines, restricted to machines of this kind

- D04B15/32—Cam systems or assemblies for operating knitting instruments

- D04B15/36—Cam systems or assemblies for operating knitting instruments for flat-bed knitting machines

- D04B15/362—Cam systems or assemblies for operating knitting instruments for flat-bed knitting machines with two needle beds in V-formation

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04B—KNITTING

- D04B15/00—Details of, or auxiliary devices incorporated in, weft knitting machines, restricted to machines of this kind

- D04B15/06—Sinkers

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04B—KNITTING

- D04B15/00—Details of, or auxiliary devices incorporated in, weft knitting machines, restricted to machines of this kind

- D04B15/10—Needle beds

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04B—KNITTING

- D04B15/00—Details of, or auxiliary devices incorporated in, weft knitting machines, restricted to machines of this kind

- D04B15/88—Take-up or draw-off devices for knitting products

- D04B15/90—Take-up or draw-off devices for knitting products for flat-bed knitting machines

Definitions

- the invention relates to a double-bed bottle knitting machine with needles which are longitudinally displaceable in its needle beds and between the needles about a common longitudinal axis between a rear and a front position and which are controlled by lock parts of the carriage and which are in the stitch formation region with a projection, a stitch-receiving throat formed below the projection and are provided with a curling edge.

- strikers have the disadvantage that they are direction-dependent and therefore have to be switched over when the carriage is reversed. Different types of stripes are also required for different types of knitting, so that the strippers have to be replaced frequently. Further disadvantages are that a stripper always affects several stitches lying next to each other at the same time and that the strippers, which are generally made of wire, can easily bend, which favors thread snagging. Strippers also make it difficult to see into the comb gap and often collide with tongue opener brushes on flat knitting machines. For some patterns that require needle bed displacement, the strikers must even be turned off so that they cannot operate there at all.

- the invention has for its object to design the sinkers of a two-bed flat knitting machine of the type mentioned so that a retention of the stitches from the area where the needles are driven out is reliably guaranteed without having to accept disabilities or restrictions in normal knitting operation.

- the wedge edge of the sinkers is formed in the knitting pull-off direction to and below the thread take-up throat and in that the sinkers of the two needle beds face each other and lie in their forward position with their projections spanning the ridge gap.

- the sinkers behind and somewhat below the wedge edge can have a short circular slot which has a closed edge and through which a wire which forms the stitch wiping edge of the needle bed in question is passed.

- the thread is placed over the sinkers below the projection of the sinkers which closes off the ridge gap. Slipped thread loops do not slip over the projections of the boards, which gives you a free hand when controlling the boards.

- the stitches formed are exposed and are not enclosed by the sinkers, so that needle bed displacement and a transfer of stitches can take place without hindrance. It is no problem to start knitting with empty needles.

- An adjustment movement of the sinkers in the direction of closing the comb gap during the last part of the withdrawal movement of the needles also makes it possible to compensate for a stitch length by means of the sinkers, as is the case when knitting with the needles of only one of the two needle beds, due to the wedge edge located underneath the sinker closure to maintain the same mesh length is desirable.

- the needle beds continue to have their own tapping edge in the familiar form of a wire.

- Interruption can be omitted.

- the machine is always operated with the same sinkers, regardless of whether single-surface or double-surface knitwear is manufactured.

- the holding down of the old stitches is fully secured, which reduces the dependency and thus the importance of the formation of a knitting device arranged below the comb gap.

- Even devices for keeping the knitted fabric wide are becoming less important.

- the stitch of each needle is individually retained by the associated board. An increase in The operating speed of a flat knitting machine designed according to the invention no longer poses any problems with regard to the retention of the knitted fabric.

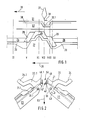

- the schematic representation of a knitting lock of the carriage, not shown, of the flat knitting machine in FIG. 1 shows a lock channel 20 for controlling the needles 21 of the front needle bed 22 or the needles 21.1 of the rear needle bed 23 (Fig. 2) of a flat knitting machine.

- the needle control curve 20 is limited in a known manner by fixed lock parts 24, 25, 26, 27 and two trigger lock parts 28 and 29 which are adjustable in a known manner.

- the knitted lock also has a lock channel 30 formed between lock parts 31 and 32 for the same-designed sinkers 33 of the front needle bed 22 or 33.1 of the rear needle bed 23, which protrude into the sinker track 30 with a control foot 34, 34.1.

- Fig. 1 shows the knitted lock in a lock setting for the carriage direction indicated by an arrow 35.

- the trigger lock parts 28, 29 are adjusted in opposite directions.

- the blank lock parts 31, 32 are adjusted en bloc in the direction of the arrow 36 shown in FIG. 1, so that the blank lock track area 30.1 reaches the height of the trigger lock part 28. 1 also shows a thread guide 37, which feeds a thread 38 to the needles 21 and / or 21.1 of the flat knitting machine in the area of the sinker web area 30.1.

- the sinkers 33 have an opening for a pivot axis 39 or 39.1 (FIG. 2) common to all sinkers 33 of a needle bed 22 or 23, on which the stitch pattern projections 40 shown individually in FIG. 4 are also lined up are each arranged between the plates 33 in the needle beds 22 and 23.

- the circuit board 33 also has a short circular-shaped slot 41 with a closed edge, through which a hole held by the mesh forming projections 40 and wire 42 forming the knitting edge of a needle bed is passed through.

- the arcuate slot 41 limits the pivoting movement of the boards around the common axis 39 from a rear position shown in FIG. 3 in the direction of the arrow 43 shown in FIG.

- the arcuate slot 41 is located behind a wedge edge 44 of the board, which adjoins a stitch-receiving throat 45, which in turn is formed in the knitting direction 53 indicated by an arrow below a projection 46 of the board 33.

- FIG. 1 different lock positions II, V, VI, VII, VIII, XI are marked with dash-dotted vertical lines. 2, 5, 6, 7, 8 and 9 show the position of the sinkers 33 and 33.1 and the position of the needles 21 and 21.1 of the two needle beds 22 and 23 at these points in the production of a single-surface knitted fabric, if only that Needles 21 of the front needle bed 22 process a thread 38.

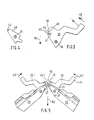

- Fig. 2 shows that at the lock point II, the plates 33 of the front needle bed 22 and the plates 33.1 of the rear needle bed 23 are in their rear position, in which they do not protrude into the comb gap 50 of the flat knitting machine. An old stitch 47 hangs in the head of the needle 21.

- Fig. 1 different lock positions II, V, VI, VII, VIII, XI are marked with dash-dotted vertical lines. 2, 5, 6, 7, 8 and 9 show the position of the sinkers 33 and 33.1 and the position of the needles 21 and 21.1 of the two needle beds 22 and 23 at these points in the production of a single-

- FIG. 5 shows the position of the knitting tools at point V of the lock representation of Fig. 1, before the start of the needle drive.

- the boards 33 and 33.1 of both needle beds 22 and 23 are simultaneously in the direction of the arrows 43 has been pivoted by the circuit board lock curve 30 into its front position, in which its projections 46 and 46.1 lie against one another.

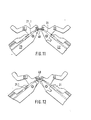

- the comb gap 50 is thus bridged by the plates 33 and 33.1, so that when the needles 21 of the front needle bed 22 are subsequently driven out into the position shown in FIG. 6, which they assume at position VI in FIG. 1, the old stitch 47 slips into the stitch receiving throat 45 of the associated board 33 and cannot slide up out of the comb gap 50. Only the boards 33.1 are controlled in the needle bed 23. The needles 21.1 remain at rest.

- the sinkers 33 and 33.1 of both needle beds 22 and 23 are pivoted back into their rear position by the sinker track 30 during the transition to the sinker track section 30.1, as shown in FIG. 7 from the lock point VII and as indicated by the arrows 43 there.

- the comb gap 50 of the flat knitting machine is free again and the thread 38 can be inserted by the thread guide 37 (FIG. 1) unhindered into the adjustment area of the needles 21 of the front needle bed 22.

- the old stitch 47 hangs on the shaft of the needle 21 and bears against the wire forming the stitch wiping edge 42 of the front needle bed 22.

- the boards 33 and 33.1 are held in their rear position by the board lock track section 30.1.

- the thread 38 gripped by the head of the needle 21 is drawn into the old stitch 47.

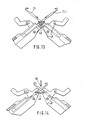

- the boards are selected rend further withdrawal of the needles 21 of the front needle bed 22 into the deepest withdrawal position shown in FIG. 9 at the point IX of the lock of FIG. 1 by the circuit board lock track 30 pivoted back to its front position, which in FIG. 9 by the arrows 43 is indicated.

- the wedge edge 44 (FIG.

- FIGS. 11 to 17 A detailed description of FIGS. 11 to 17 can be dispensed with.

- 11 and 12 show the connecting thread arch 49 between the old stitches held by the needles 21 and 21.1 of the two needle beds.

- 13 shows how, when the needles 21 and 21.1 are driven out, the old stitches on this connecting arch 49 are retained by the plates 33 and 33.1 in their forward position.

- FIG. 14 shows the inserted new thread 38, from which new stitches 51 and 52 on the two needle beds 22 and 23 are drawn in FIG. 16.

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Knitting Machines (AREA)

Abstract

Die bis zur Bildung einer geschlossenen Brücke über den Kammspalt (50) einer zweibettigen Flachstrickmaschine verschwenkbaren Platinen (33, 33.1) der beiden Nadelbetten (22, 23) weisen eine Kulierkante (44) auf, die in Gestrickabzugsrichtung (53) unterhalb der die Brücke bildenden Vorsprünge (46) der Platinen (33, 33.1) ausgebildet ist, wodurch ein sicheres Niederhalten der alten Maschen (47) in den Kammspalt (50) gewährleistet ist und mittels der Platinenen (33, 33.1) eine Ausgleichskulierbewegung durchführbar ist. The plates (33, 33.1) of the two needle beds (22, 23), which can be pivoted until a closed bridge over the comb gap (50) of a two-bed flat knitting machine, have a wedge edge (44) which, in the knitting pull-off direction (53), forms below the bridge Projections (46) of the sinkers (33, 33.1) is formed, which ensures that the old stitches (47) are held down securely in the comb gap (50) and a compensating-compensating movement can be carried out by means of the sinkers (33, 33.1).

Description

Die Erfindung betrifft eine zweibettige Flaschstrickmaschine mit in ihren Nadelbetten längsverschiebbaren Nadeln und zwischen den Nadeln um eine gemeinsame Längsachse zwischen einer hinteren und einer vorderen Stellung verstellbaren und von Schloßteilen des Schlittens gesteuerten Platinen, die im Maschenbildungsbereich mit einem Vorsprung, einer unterhalb des Vorsprunges ausgebildeten Maschenaufnahmekehle und mit einer Kulierkante versehen sind.The invention relates to a double-bed bottle knitting machine with needles which are longitudinally displaceable in its needle beds and between the needles about a common longitudinal axis between a rear and a front position and which are controlled by lock parts of the carriage and which are in the stitch formation region with a projection, a stitch-receiving throat formed below the projection and are provided with a curling edge.

Flachstrickmachinen mit den vorstehend genannten Merkmalen sind bekannt (CH-PS 73 088; DE-OS 15 85 083). Die verschwenkbaren Platinen sollen dabei eine Kulierkante an den Nadelbetten ersetzen und mit ihrer Maschenaufnahmekehle die auf den Nadeln hängenden Maschen beim Austreiben der Nadeln zurückhalten. Bei modernen und mit höheren Geschwindigkeiten laufenden Flachstrickmaschinen tritt das Problem des Niederhaltens der sogenannten alten Maschen aus dem Arbeitsbereich der Nadelköpfe bei der Erfassung des Fadens zur Bildung neuer Maschen oder Fanghenkel verstärkt in den Vordergrund. Man hat bislang versucht, mit Hilfe von mit dem Schlitten der Flachstrickmaschine mitbewegten Einstreifern, die in den Kammspalt der Flachstrickmaschine eintauchen, die alten Maschen nach unten in Richtung auf eine Gestrickabzugsvorrichtung zu drücken. Einstreifer haben aber den Nachteil, daß sie richtungsabhängig sind und daher bei der Schlittenumkehr umgeschaltet werden müssen. Auch sind für verschiedene Strickarten unterschiedliche Einstreiferformen erforderlich, so daß ein häufiges Auswechseln der Einstreifer stattfinden muß. Weitere Nachteile sind, daß ein Einstreifer immer mehrere nebeneinanderliegende Maschen gleichzeitig beeinflußt und daß sich die im allgemeinen aus Draht gefertigten Einstreifer leicht verbiegen können, was ein Hängenbleiben von Fäden begünstigt. Einstreifer erschweren auch den Einblick in den Kammspalt und kollidieren häufig mit Zungenöffnerbürsten der Flachstrickmaschinen. Bei einigen Mustern, die einen Nadelbettenversatz erforderlich machen, müssen die Einstreifer sogar ausgeschaltet werden, so daß sie dort überhaupt nicht wirksam werden können.Flat knitting machines with the features mentioned above are known (CH-PS 73 088; DE-OS 15 85 083). The pivotable sinkers are intended to replace a wedge edge on the needle beds and, with their stitch-receiving throat, hold back the stitches hanging on the needles when the needles are driven out. This happens with modern flat knitting machines running at higher speeds The problem of holding down the so-called old stitches from the working area of the needle heads when grasping the thread to form new stitches or tuck handles is increasingly emphasized. Attempts have so far been made to press the old stitches downward in the direction of a knitted fabric take-off device with the aid of scrapers which are moved along with the carriage of the flat knitting machine and which dip into the comb gap of the flat knitting machine. However, strikers have the disadvantage that they are direction-dependent and therefore have to be switched over when the carriage is reversed. Different types of stripes are also required for different types of knitting, so that the strippers have to be replaced frequently. Further disadvantages are that a stripper always affects several stitches lying next to each other at the same time and that the strippers, which are generally made of wire, can easily bend, which favors thread snagging. Strippers also make it difficult to see into the comb gap and often collide with tongue opener brushes on flat knitting machines. For some patterns that require needle bed displacement, the strikers must even be turned off so that they cannot operate there at all.

Die bisher bekannten und mit den Nadeln der beiden Nadelbetten der Flachstrickmaschine zusammenwirkenden Platinen erlauben keine optimale Lösung der anstehenden Probleme, weil bei ihnen das Kulieren des Fadens und die Verarbeitung des kulierten Fadens Schwierigkeiten macht. Bei den bekannten Platinen erfolgt das Kulieren der Fäden in Gestrickabzugsrichtung gesehen vor der Maschenaufnahmekehle, nämlich auf einem die Maschenaufnahmekehle begrenzenden Platinenvorsprung. Dadurch ist die Möglichkeit der Steuerung der Platinen eingeengt, weil der kulierte Faden jeweils über den die Maschenaufnahmekehle begrenzenden Platinenvorsprung nach unten abrutschen können muß. Zwischen miteinander zusammenwirkenden Platinen der beiden Nadelbetten muß ein Spalt verbleiben, der dem kulierten Faden das Nachrutschen auf den Platinen erlaubt. Damit bleibt aber trotz der Maschenaufnahmekehlen die bei schnellaufenden Maschinen nicht unerhebliche Gefahr, daß doch eine alte Masche von den im Austrieb befindlichen Nadeln aus dem Kammspalt nach oben gezogen wird.The previously known and interacting with the needles of the two needle beds of the flat knitting machine do not allow an optimal solution to the problems at hand, because with them the winding of the thread and the processing of the selected thread make it difficult. In the known sinkers, the threads are spliced in front of the stitch take-up groove, namely in the knitting pull-off direction, namely on a sinker projection delimiting the stitch take-up groove. This is the possibility of Control of the sinkers is restricted because the selected thread must be able to slide down over the sinker protrusion that delimits the stitch take-up throat. There must be a gap between the interacting sinkers of the two needle beds, which allows the selected thread to slide on the sinkers. However, despite the stitch-taking throats, there remains the not inconsiderable danger in high-speed machines that an old stitch is pulled upward from the comb gap by the needles that are in the process of being driven out.

Der Erfindung liegt die Aufgabe zugrunde, die Platinen einer zweibettigen Flachstrickmaschine der eingangs genannten Art so auszubilden, daß ein Zurückhalten der Maschen vom Austriebsbereich der Nadeln sicher gewährleistet ist, ohne daß Behinderungen oder Einschränkungen im normalen Strickbetrieb in Kauf genommen werden müssen.The invention has for its object to design the sinkers of a two-bed flat knitting machine of the type mentioned so that a retention of the stitches from the area where the needles are driven out is reliably guaranteed without having to accept disabilities or restrictions in normal knitting operation.

Die gestellte Aufgabe wird erfindungsgemäß dadurch gelöst, daß die Kulierkante der Platinen in Gestrickabzugsrichtung nach und unterhalb der Fadenaufnahmekehle ausgebildet ist und daß die Platinen der beiden Nadelbetten einander gegenüberstehen und in ihrer vorderen Stellung unter Bildung von den Kammspalt überspannenden Brücken mit ihren Vorsprüngen gegeneinanderliegen. Vorteilhafterweise können die Platinen hinter und etwas unterhalb der Kulierkante einen kurzen kreisbogenförmigen Schlitz aufweisen, der einen geschlossenen Rand hat und durch welchen ein die Maschenabschlagkante des betreffenden Nadelbettes bildender Draht hindurchgeführt ist.The object is achieved according to the invention in that the wedge edge of the sinkers is formed in the knitting pull-off direction to and below the thread take-up throat and in that the sinkers of the two needle beds face each other and lie in their forward position with their projections spanning the ridge gap. Advantageously, the sinkers behind and somewhat below the wedge edge can have a short circular slot which has a closed edge and through which a wire which forms the stitch wiping edge of the needle bed in question is passed.

Bei der erfindungsgemäß ausgebildeten Flachstrickmaschine wird der Faden unterhalb des den Kammspalt nach oben abschließenden Vorsprunges der Platinen über die Platinen gelegt. Ein Abrutschen von kulierten Fadenschleifen über die Vorsprünge der Platinen erfolgt nicht, wodurch man bei der Steuerung der Platinen freie Hand hat. Nach Abschluß des Kuliervorganges liegen die gebildeten Maschen frei und sind durch die Platinen nicht eingeschlossen, so daß ungehindert ein Nadelbettenversatz und ein Umhängen von Maschen erfolgen kann. Es bereitet kein Problem, einen Strickvorgang mit leeren Nadeln zu beginnen. Durch eine Verstellbewegung der Platinen in Richtung eines Schließens des Kammspaltes während des letzten Teils der Abzugsbewegung der Nadeln wird durch die unterhalb des den Kammspaltverschluß bewirkenden Platinenvorsprunges liegende Kulierkante auch ein Maschenlängenausgleich mittels der Platinen möglich, wie er beim Stricken mit den Nadeln nur eines der beiden Nadelbetten zur Einhaltung immer gleicher Maschenlängen wünschenswert ist. Die Nadelbetten behalten weiterhin eine eigene Abschlagkante in der bekannten Form eines Dahtes.In the flat knitting machine designed according to the invention, the thread is placed over the sinkers below the projection of the sinkers which closes off the ridge gap. Slipped thread loops do not slip over the projections of the boards, which gives you a free hand when controlling the boards. After completing the culvering process, the stitches formed are exposed and are not enclosed by the sinkers, so that needle bed displacement and a transfer of stitches can take place without hindrance. It is no problem to start knitting with empty needles. An adjustment movement of the sinkers in the direction of closing the comb gap during the last part of the withdrawal movement of the needles also makes it possible to compensate for a stitch length by means of the sinkers, as is the case when knitting with the needles of only one of the two needle beds, due to the wedge edge located underneath the sinker closure to maintain the same mesh length is desirable. The needle beds continue to have their own tapping edge in the familiar form of a wire.

Einstreifer können entfallen. Die Maschine wird immer mit den gleichen Platinen betrieben, unabhängig davon, ob einflächige oder doppelflächige Strickware hergestellt wird. Das Niederhalten der alten Maschen ist voll gesichert, wodurch sich die Abhängigkeit und damit Bedeutung der Ausbildung einer unterhalb des Kammspaltes angeordneten Gestrickabzugsvorrichtung verringert. Auch Einrichtungen zum Breithalten des gefertigten Gestrickes verlieren an Bedeutung. Die Masche einer jeden Nadel wird durch die zugehörige Platine einzeln zurückgehalten. Eine Erhöhung der Betriebsgeschwindigkeit einer erfindungsgemäß ausgebildeten Flachstrickmaschine ergibt bezüglich der Maschenrückhaltung des Gestrickabzuges keine Probleme mehr.Interruption can be omitted. The machine is always operated with the same sinkers, regardless of whether single-surface or double-surface knitwear is manufactured. The holding down of the old stitches is fully secured, which reduces the dependency and thus the importance of the formation of a knitting device arranged below the comb gap. Even devices for keeping the knitted fabric wide are becoming less important. The stitch of each needle is individually retained by the associated board. An increase in The operating speed of a flat knitting machine designed according to the invention no longer poses any problems with regard to the retention of the knitted fabric.

Nachfolgend wird ein Ausführungsbeispiel einer erfindungsgemäß ausgebildeten Flachstrickmaschine in bezug auf die erfindungswesentlichen Teile anhand der beiliegenden Zeichnung näher erläutert.An exemplary embodiment of a flat knitting machine designed according to the invention is explained in more detail below with reference to the parts essential to the invention with reference to the accompanying drawing.

Im einzelnen zeigen:

- Fig. 1 eine schematische Darstellung eines Strickschlosses der Flachstrickmaschine mit zugeordneten Platinensteuerschloßteilen;

- Fig. 2 einen Teilquerschnitt durch die beiden Nadelbetten im Bereich des Kammspaltes der Flachstrickmaschine an der Schloßstelle II in Fig. 1;

- Fig. 3 eine Einzeldarstellung einer Platine der Flachstrickmaschine;

- Fig. 4 eine Einzeldarstellung eines Maschenbildnervorsprunges der Nadelbetten;

- Fig. 5 eine der Fig. 2 entsprechende Darstellung an der Schloßstelle V in Fig. 1;

- Fig. 6 eine der Fig. 2 entsprechende Darstellung von der Schloßstelle VI in Fig. 1 bei der Herstellung eines einflächigen Gestrickes;

- Fig. 7 eine der Fig. 2 entsprechende Darstellung an der Schloßstelle VII in Fig. 1 bei der Herstellung eines einflächigen Gestricks,

- Fig. 8 eine der Fig. 2 entsprechende Darstellung an der Schloßstelle VIII in Fig. 1 bei der Herstellung einer einflächigen Strickware;

- Fig. 9 eine der Fig. 2 entsprechende Darstellung an der Schloßstelle IX in Fig. 1 bei der Herstellung einer einflächigen Strickware;

- Fig. 10 eine Teildraufsicht auf den Kammspaltbereich der Flachstrickmaschine an der Schloßstelle IX bei der Herstellung einer einflächigen Strickware;

- Fig. 11 - 16 den Fig. 2 und 5 - 9 entsprechende Darstellungen an den Schloßstellen II, V - IX in Fig. 1 bei der Herstellung eines doppelflächigen Gestrickes;

- Fig. 17 eine Teildraufsicht auf den Kammspaltbereich der Flachstrickmaschine an der Schloßstelle IX bei der Herstellung eines doppelflächigen Gestrickes.

- Figure 1 is a schematic representation of a knitting lock of the flat knitting machine with associated sinker control lock parts.

- 2 shows a partial cross section through the two needle beds in the area of the comb gap of the flat knitting machine at the lock point II in FIG. 1;

- 3 shows an individual illustration of a circuit board of the flat knitting machine;

- 4 shows an individual illustration of a mesh formation projection of the needle beds;

- FIG. 5 shows a representation corresponding to FIG. 2 at the lock point V in FIG. 1;

- 6 shows a representation corresponding to FIG. 2 of the lock point VI in FIG. 1 in the production of a single-surface knitted fabric;

- 7 a representation corresponding to FIG. 2 at the lock point VII in FIG. 1 in the production of a single-surface knitted fabric,

- 8 shows a representation corresponding to FIG. 2 at the lock point VIII in FIG. 1 in the production of a single-surface knitted fabric;

- 9 shows a representation corresponding to FIG. 2 at the lock point IX in FIG. 1 in the production of a single-surface knitted fabric;

- 10 shows a partial top view of the comb gap area of the flat knitting machine at the lock point IX during the production of a single-surface knitted fabric;

- 11 - 16 representations corresponding to FIGS. 2 and 5 - 9 at the lock points II, V - IX in FIG. 1 during the production of a double-layer knitted fabric;

- Fig. 17 is a partial plan view of the comb gap area of the flat knitting machine at the lock point IX in the manufacture of a double-faced knitted fabric.

Die schematische Darstellung eines Strickschlosses des nicht dargestellten Schlittens der Flachstrickmaschine in Fig. 1 zeigt einen Schloßkanal 20 zu Steuerung der Nadeln 21 des vorderen Nadelbettes 22 oder der Nadeln 21.1 des hinteren Nadelbettes 23 (Fig. 2) einer Flachstrickmaschine. Die Nadelsteuerkurve 20 wird in bekannter Weise durch feststehende Schloßteile 24, 25, 26, 27 und zwei in bekannter Weise verstellbare Abzugsschloßteile 28 und 29 begrenzt. Das Strickschloß weist außerdem eine zwischen Schloßteilen 31 und 32 ausgebildeten Schloßkanal 30 für die gleich ausgebildeten Platinen 33 des vorderen Nadelbettes 22 oder 33.1 des hinteren Nadelbettes 23 auf, die mit einem Steuerfuß 34, 34.1 in die Platinenschloßbahn 30 ragen. Die Nadeln 21, 21.1 und die Platinen 33, 33.1 der beiden Nadelbetten 22 und 23 sind jeweils aufeinander ausgerichtet. Fig. 1 zeigt das Strickschloß in einer Schloßeinstellung für die durch einen Pfeil 35 angedeutete Schlittenrichtung. Bei der Schlittenumkehr werden in bekannter Weise die Abzugsschloßteile 28, 29 gegenläufig verstellt. Außerdem werden die Platinenschloßteile 31, 32 en bloc in Richtung des in Fig. 1 eingetragenen Pfeiles 36 verstellt, so daß der Platinenschloßbahnbereich 30.1 auf die Höhe des Abzugsschloßteiles 28 gelangt. In Fig. 1 ist außerdem noch ein Fadenführer 37 dargestellt, der im Platinenschloßbahnbereich 30.1 einen Faden 38 den Nadeln 21 und/oder 21.1 der Flachstrickmaschine zuführt.The schematic representation of a knitting lock of the carriage, not shown, of the flat knitting machine in FIG. 1 shows a

Wie Fig. 3 zeigt, weisen die Platinen 33 eine Öffnung für eine allen Platinen 33 eines Nadelbettes 22 oder 23 gemeinsame Schwenkachse 39 oder 39.1 (Fig. 2) auf, auf welcher auch die in Fig. 4 einzeln dargestellten Maschenbildnervorsprünge 40 aufgereiht sind, die jeweils zwischen den Platinen 33 in den Nadelbetten 22 und 23 angeordnet sind. Die Platine 33 weist außerdem einen kurzen kreisbogenförmigen Schlitz 41 mit geschlossenem Rand auf, durch welchen ein von den Maschenbildnervorsprüngen 40 gehaltener und jeweils die Maschenabschlagkante eines Nadelbettes bildender Draht 42 hinduchgeführt ist. Der bogenförmige Schlitz 41 begrenzt die Schwenkbewegung der Platinen um die gemeinsame Achse 39 aus einer in Fig. 3 dargestellten hinteren Stellung in Richtung des in Fig. 3 eingetragenen Pfeiles 43 in eine vordere Stellung, die im Bereich des Platinenschloßbahnbereiches 30.1 erfolgt. Der bogenförmige Schlitz 41 befindet sich hinter einer Kulierkante 44 der Platine, die sich an eine Maschenaufnahmekehle 45 anschließt, die wiederum in der mit einem Pfeil angegebenen Gestrickabzugsrichtung 53 unterhalb eines Vorsprunges 46 der Platine 33 ausgebildet ist.As FIG. 3 shows, the

In Fig. 1 sind mit strichpunktierten Vertikallinien verschiedene Schloßstellen II, V, VI, VII, VIII, XI markiert. Die Fig. 2, 5, 6, 7, 8 und 9 zeigen die Stellung der Platinen 33 und 33.1 sowie die Stellung der Nadeln 21 und 21.1 der beiden Nadelbetten 22 und 23 an diesen Stellen bei der Herstellung einer einflächigen Gestrickware, wenn also nur die Nadeln 21 des vorderen Nadelbettes 22 einen Faden 38 verarbeiten.

Fig. 2 zeigt, daß an der Schloßstelle II die Platinen 33 des vorderen Nadelbettes 22 und die Platinen 33.1 des hinteren Nadelbettes 23 sich in ihrer hinteren Stellung befinden, in welcher sie nicht in den Kammspalt 50 der Flachstrickmaschine ragen. Im Kopf der Nadel 21 hängt eine alte Masche 47.

Fig. 5 zeigt die Stellung der Strickwerkzeuge an der Stelle V der Schloßdarstellung der Fig. 1, vor dem Beginn des Nadelaustriebs. Die Platinen 33 und 33.1 beider Nadelbetten 22 und 23 sind gleichzeitig in Richtung der Pfeile 43 durch die Platinenschloßkurve 30 in ihre vordere Stellung verschwenkt worden, in welcher ihre Vorsprünge 46 und 46.1 gegeneinanderliegen.In Fig. 1, different lock positions II, V, VI, VII, VIII, XI are marked with dash-dotted vertical lines. 2, 5, 6, 7, 8 and 9 show the position of the

Fig. 2 shows that at the lock point II, the

Fig. 5 shows the position of the knitting tools at point V of the lock representation of Fig. 1, before the start of the needle drive. The

Der Kammspalt 50 ist also durch die Platinen 33 und 33.1 überbrückt, so daß sich beim anschließenden Austreiben der Nadeln 21 des vorderen Nadelbettes 22 in die aus Fig. 6 ersichtliche Stellung, die sie an der Stelle VI der Fig. 1 einnehmen, die alte Masche 47 in die Maschenaufnehmekehle 45 der zugeordneten Platine 33 rutscht und nicht aus dem Kammspalt 50 hochrutschen kann. Im Nadelbett 23 werden nur die Platinen 33.1 gesteuert. Die Nadeln 21.1 bleiben in Ruhe.The

Vor Beginn des Fadeneinlegens werden die Platinen 33 und 33.1 beider Nadelbetten 22 und 23 durch die Platinenschloßbahn 30 beim Übergang in den Platinenschloßbahnabschnitt 30.1 in ihre hintere Stellung zurückverschwenkt, wie Fig. 7 von der Schloßstelle VII zeigt und wie dort durch die Pfeile 43 angedeutet ist. Der Kammspalt 50 der Flachstrickmaschine ist wieder frei und der Faden 38 kann vom Fadenführer 37 (Fig. 1) ungehindert in den Verstellbereich der Nadeln 21 des vorderen Nadelbettes 22 eingebracht werden. Die alte Masche 47 hängt auf dem Schaft der Nadel 21 und liegt gegen den die Maschenabschlagkante 42 des vorderen Nadelbettes 22 bildenden Draht an. Während des anschließenden Abzugs der Nadeln 21 bis in die aus Fig. 8 ersichtliche Stellung an der Schloßstelle VIII der Fig. 1 bleiben die Platinen 33 und 33.1 durch den Platinenschloßbahnabschnitt 30.1 in ihrer hinteren Stellung gehalten. An der Schloßstelle VIII wird der vom Kopf der Nadel 21 erfaßte Faden 38 in die alte Masche 47 eingezogen. Von dieser Abzugsstellung an werden die Platinen wäh rend des weiteren Abzugs der Nadeln 21 des vorderen Nadelbettes 22 bis in die aus Fig. 9 ersichtliche tiefste Abzugsstellung an der Stelle IX des Schlosses nach Fig. 1 durch die Platinenschloßbahn 30 wieder in ihre vordere Stellung zurückgeschwenkt, was in Fig. 9 durch die Pfeile 43 angedeutet ist. Bei dieser Verstellbewegung aus der hinteren in die vordere Stellung wird die Kulierkante 44 (Fig. 3) der Platinen 33 und 33.1, über welche der eingezogene Faden 38 der neu gebildeten Masche 48 zu liegen kommt, in den Kammspalt 50 hineinbewegt, wodurch eine Vergrößerung der Länge der neu gebildeten Masche 48 durch eine Hilfskulierung des Fadens 38 mittels der Platinen 33 erfolgt. Fig. 10 zeigt an dieser Stelle den Verlauf des zu neuen Maschen 48 gezogenen Fadens 38 über die Nadeln 21 und die Platinen 33 des Nadelbettes 22. Der Übersichtlichkeit wegen sind in Fig. 10 die alten Maschen 47 nicht mehr dargestellt.Before the thread insertion begins, the

Die Fig. 11 bis 17 zeigen das gleiche wie die Fig. 2 und 5 bis 10 bei der Herstellung einer zweiflächigen Strickware, wenn die Nadeln 21 des vorderen Nadelbettes 22 und die Nadeln 21.1 des hinteren Nadelbettes 23 zusammen mit den Platinen 33 und 33.1 in Tätigkeit sind.

- Fig. 11 entspricht der Fig. 2 und damit dem Steuerzustand an der Schloßstelle II in Fig. 1.

- Fig. 12 entspricht der Fig. 5 und damit den Steuerverhältnissen an der Schloßstelle V in Fig. 1.

- Fig. 13 entspricht der Fig. 6 und damit den Steuerverhältnissen an der Schloßstelle VI in Fig. 1.

- Fig. 14 entspricht Fig. VII und damit den Steuerverhältnissen an der Schloßstelle VII in Fig. 1.

- Fig. 15 entspricht Fig. 8 und damit den Steuerverhältnissen an der Schloßstelle VIII in Fig. 1.

- Fig. 16 entspricht Fig. 9 und damit den Steuerverhältnissen an der Schloßstelle X der Fig. 1.

- Fig. 17 schließlich entspricht der Fig. 10.

- 11 corresponds to FIG. 2 and thus the control state at the lock point II in FIG. 1st

- FIG. 12 corresponds to FIG. 5 and thus the control relationships at the lock point V in FIG. 1.

- Fig. 13 corresponds to Fig. 6 and thus the tax relationships at the lock point VI in Fig. 1st

- Fig. 14 corresponds to Fig. VII and thus the tax relationships at the lock point VII in Fig. 1st

- Fig. 15 corresponds to Fig. 8 and thus the tax relationships at the lock point VIII in Fig. 1st

- FIG. 16 corresponds to FIG. 9 and thus the tax relationships at the lock point X of FIG. 1.

- Finally, FIG. 17 corresponds to FIG. 10.

Auf eine ausführliche Beschreibung der Fig. 11 bis 17 kann verzichtet werden. Fig. 11 und 12 zeigen den Verbindungsfadenbogen 49 zwischen den von den Nadeln 21 und 21.1 der beiden Nadelbetten gehaltenen alten Maschen. Fig. 13 zeigt, wie beim Austrieb der Nadeln 21 und 21.1 die alten Maschen an diesem Verbindungsbogen 49 durch die in ihrer vorderen Stellung befindlichen Platinen 33 und 33.1 zurückgehalten sind. Fig. 14 zeigt den eingelegten neuen Faden 38, aus welchem in Fig. 16 neue Maschen 51 und 52 auf den beiden Nadelbetten 22 und 23 gezogen sind. Auch hier erfolgt eine Zusatzkulierung zum Längenausgleich der neuen Maschen 51 durch die in den Kammspalt 50 hineinbewegten Kulierkanten 47 der Platinen 33 und 33.1.A detailed description of FIGS. 11 to 17 can be dispensed with. 11 and 12 show the connecting

Claims (4)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19863609539 DE3609539A1 (en) | 1986-03-21 | 1986-03-21 | DOUBLE-BED FLAT-KNITTING MACHINE WITH PLATINES BETWEEN NEEDLES |

| DE3609539 | 1986-03-21 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0238797A1 true EP0238797A1 (en) | 1987-09-30 |

| EP0238797B1 EP0238797B1 (en) | 1989-10-04 |

Family

ID=6296928

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP87100869A Expired EP0238797B1 (en) | 1986-03-21 | 1987-01-22 | Flat bed knitting machine provided with two needle beds and sinkers between the needles |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US4713948A (en) |

| EP (1) | EP0238797B1 (en) |

| JP (1) | JPS62223348A (en) |

| DE (2) | DE3609539A1 (en) |

| ES (1) | ES2011022B3 (en) |

Cited By (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0325551A1 (en) * | 1988-01-13 | 1989-07-26 | Jumberca, S.A. | A device for positioning a yarn relative to a needle in a knitting machine |

| EP0441565A2 (en) * | 1990-02-07 | 1991-08-14 | Shima Seiki Mfg., Ltd. | Flat knitting machine having function for adjusting knock-over timing |

| EP0578458A1 (en) * | 1992-07-09 | 1994-01-12 | Shima Seiki Mfg., Ltd. | Sinker mechanism for flat knitting machines |

| EP0672770A1 (en) * | 1994-03-17 | 1995-09-20 | Shima Seiki Mfg., Ltd. | Flat knitting machine |

| EP0679747A1 (en) * | 1994-04-28 | 1995-11-02 | Shima Seiki Mfg., Ltd. | Yarn guiding method and apparatus for flat knitting machine |

| EP0681046A1 (en) * | 1994-05-06 | 1995-11-08 | PROTTI S.p.A. FABBRICA MACCHINE PER MAGLIERIA | Flat-bed knitting machine with means for facilitating the formation and casting off of stitches |

| EP0712951A1 (en) * | 1994-11-16 | 1996-05-22 | Tsudakoma Kogyo Kabushiki Kaisha | Sinker actuating apparatus |

| EP0897027A2 (en) * | 1997-08-11 | 1999-02-17 | Shima Seiki Manufacturing, Ltd. | A flat knitting machine with movable loop forming plates |

| EP1522618A1 (en) | 2003-10-07 | 2005-04-13 | H. Stoll GmbH & Co. | Sinker of a flat knitting machine |

Families Citing this family (18)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3629334A1 (en) * | 1986-08-28 | 1988-03-10 | Stoll & Co H | FLAT KNITTING MACHINE |

| DE3935763A1 (en) * | 1989-10-27 | 1991-05-02 | Stoll & Co H | FLAT KNITTING MACHINE |

| DE3937406C2 (en) * | 1989-11-10 | 1998-04-16 | Stoll & Co H | Process for producing a three-dimensional knitted fabric on a flat knitting machine |

| DE4102207A1 (en) * | 1991-01-25 | 1992-07-30 | Schieber Universal Maschf | FLAT KNITTING MACHINE |

| DE4128016A1 (en) * | 1991-08-23 | 1993-02-25 | Stoll & Co H | DOUBLE BED FLAT KNITTING MACHINE WITH NEEDLES AND BOARDS |

| US5355699A (en) * | 1992-04-16 | 1994-10-18 | Tsudakoma Kogyo Kabushiki Kaisha | Flat knitting machine and a method of operating the rocking sinkers of the flat knitting machine |

| DE4337776A1 (en) * | 1993-11-05 | 1995-05-11 | Stoll & Co H | Flat knitting machine with needles and sinkers |

| DE19704644B4 (en) * | 1997-02-07 | 2006-06-14 | H. Stoll Gmbh & Co. | Flat knitting machine and method of making a knit |

| DE19725073B4 (en) * | 1997-06-13 | 2004-11-25 | H. Stoll Gmbh & Co. | Knitting machine, in particular flat knitting machine |

| JP3044373B2 (en) * | 1997-09-12 | 2000-05-22 | 株式会社島精機製作所 | Flat knitting machine with loop presser and knitted fabric knitting method using loop presser |

| TW522186B (en) * | 1999-11-17 | 2003-03-01 | Shima Seiki Mfg | Sinker device of flat knitting machine |

| JP4519636B2 (en) * | 2004-12-28 | 2010-08-04 | 株式会社島精機製作所 | Flat knitting machine with movable sinker |

| EP2130960B1 (en) * | 2008-06-04 | 2010-12-01 | Groz-Beckert KG | Knitting system with a needle driven holding down sinker |

| CN101899741A (en) * | 2010-08-24 | 2010-12-01 | 宁波市裕人针织机械有限公司 | Sinker of flat machine |

| EP2570533A1 (en) * | 2011-09-16 | 2013-03-20 | Pai Lung Machinery Mill Co., Ltd. | Needle bed structure for flat knitting machines |

| US8381550B1 (en) * | 2011-09-19 | 2013-02-26 | Pai Lung Machinery Mill Co., Ltd. | Needle bed structure for flat knitting machines |

| US8397541B1 (en) * | 2011-09-19 | 2013-03-19 | Pai Lung Machinery Mill Co., Ltd. | Sinker control apparatus for flat knitting machines |

| JP6177263B2 (en) | 2015-02-03 | 2017-08-09 | 株式会社島精機製作所 | Flat knitting machine with movable sinker |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE342525C (en) * | ||||

| US2960854A (en) * | 1951-05-29 | 1960-11-22 | Eberl Franz | Knitting machine |

| DE1585281B1 (en) * | 1963-11-15 | 1970-06-04 | Paliz Ag | Double bed knitting machine |

| DE2061502A1 (en) * | 1969-12-23 | 1971-07-01 | Courtaulds Ltd , London | Trigger board |

Family Cites Families (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US616600A (en) * | 1898-12-27 | Knitting-machine | ||

| US616601A (en) * | 1898-12-27 | Knitting-machine | ||

| US570335A (en) * | 1896-10-27 | Half to edward powell | ||

| US1339708A (en) * | 1920-05-11 | Ments | ||

| DE233559C (en) * | ||||

| CH50515A (en) * | 1909-12-16 | 1911-06-16 | Schaffhauser Strickmaschinen F | Device on flat knitting machines for holding back and pressing the mesh pairs of 2 and 2 knitted fabrics |

| AT75346B (en) * | 1915-11-11 | 1919-01-25 | Moritz Barth | Device for automatically removing and hanging stitches on the flat knitting machine. |

| CH73088A (en) * | 1916-01-03 | 1916-08-16 | Moritz Barth | New on the flat knitting machine for stopping the needles within the work area |

| GB870260A (en) * | 1956-10-25 | 1961-06-14 | Karl Steinhof | Improvements in and relating to hand flat knitting machines |

| FR1207319A (en) * | 1957-11-11 | 1960-02-16 | Hand knitting machine | |

| CH485896A (en) * | 1963-11-15 | 1970-02-15 | Paliz Ag | Double bed knitting machine |

| US3362195A (en) * | 1964-07-28 | 1968-01-09 | Goisis Mario | Method of and apparatus for forming loops in flat knitting machines |

| DE1585083A1 (en) * | 1964-07-28 | 1970-05-21 | Mario Goisis | Method and device for loop formation on flat knitting machines |

| JPS458362Y1 (en) * | 1966-08-11 | 1970-04-20 | ||

| US3735812A (en) * | 1970-12-10 | 1973-05-29 | Courtaulds Ltd | Knitting machines |

| JPS521290Y2 (en) * | 1971-08-17 | 1977-01-13 |

-

1986

- 1986-03-21 DE DE19863609539 patent/DE3609539A1/en active Granted

-

1987

- 1987-01-22 DE DE8787100869T patent/DE3760678D1/en not_active Expired

- 1987-01-22 ES ES87100869T patent/ES2011022B3/en not_active Expired

- 1987-01-22 EP EP87100869A patent/EP0238797B1/en not_active Expired

- 1987-03-12 JP JP62055471A patent/JPS62223348A/en active Granted

- 1987-03-23 US US07/029,195 patent/US4713948A/en not_active Expired - Fee Related

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE342525C (en) * | ||||

| US2960854A (en) * | 1951-05-29 | 1960-11-22 | Eberl Franz | Knitting machine |

| DE1585281B1 (en) * | 1963-11-15 | 1970-06-04 | Paliz Ag | Double bed knitting machine |

| DE2061502A1 (en) * | 1969-12-23 | 1971-07-01 | Courtaulds Ltd , London | Trigger board |

Cited By (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0325551A1 (en) * | 1988-01-13 | 1989-07-26 | Jumberca, S.A. | A device for positioning a yarn relative to a needle in a knitting machine |

| EP0441565A2 (en) * | 1990-02-07 | 1991-08-14 | Shima Seiki Mfg., Ltd. | Flat knitting machine having function for adjusting knock-over timing |

| EP0441565A3 (en) * | 1990-02-07 | 1992-10-14 | Shima Seiki Mfg | Flat knitting machine having function for adjusting knock-over timing |

| EP0578458A1 (en) * | 1992-07-09 | 1994-01-12 | Shima Seiki Mfg., Ltd. | Sinker mechanism for flat knitting machines |

| EP0672770A1 (en) * | 1994-03-17 | 1995-09-20 | Shima Seiki Mfg., Ltd. | Flat knitting machine |

| EP0679747A1 (en) * | 1994-04-28 | 1995-11-02 | Shima Seiki Mfg., Ltd. | Yarn guiding method and apparatus for flat knitting machine |

| EP0681046A1 (en) * | 1994-05-06 | 1995-11-08 | PROTTI S.p.A. FABBRICA MACCHINE PER MAGLIERIA | Flat-bed knitting machine with means for facilitating the formation and casting off of stitches |

| EP0712951A1 (en) * | 1994-11-16 | 1996-05-22 | Tsudakoma Kogyo Kabushiki Kaisha | Sinker actuating apparatus |

| US5570592A (en) * | 1994-11-16 | 1996-11-05 | Tsudakoma Kogyo Kabushiki Kaisha | Sinker actuating apparatus having spring force advancing member |

| EP0897027A2 (en) * | 1997-08-11 | 1999-02-17 | Shima Seiki Manufacturing, Ltd. | A flat knitting machine with movable loop forming plates |

| EP0897027A3 (en) * | 1997-08-11 | 2000-03-15 | Shima Seiki Manufacturing, Ltd. | A flat knitting machine with movable loop forming plates |

| EP1522618A1 (en) | 2003-10-07 | 2005-04-13 | H. Stoll GmbH & Co. | Sinker of a flat knitting machine |

Also Published As

| Publication number | Publication date |

|---|---|

| JPH0210260B2 (en) | 1990-03-07 |

| ES2011022B3 (en) | 1989-12-16 |

| JPS62223348A (en) | 1987-10-01 |

| DE3760678D1 (en) | 1989-11-09 |

| DE3609539A1 (en) | 1987-10-01 |

| EP0238797B1 (en) | 1989-10-04 |

| US4713948A (en) | 1987-12-22 |

| DE3609539C2 (en) | 1987-12-23 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0238797B1 (en) | Flat bed knitting machine provided with two needle beds and sinkers between the needles | |

| DE19851403B4 (en) | Circular knitting machine for producing knitwear with combed fibers | |

| EP0424717B1 (en) | Flat knitting machine | |

| DE3311361C2 (en) | Knitting machine for the production of knitted fabrics | |

| DE60011707T2 (en) | A method for producing tubular goods, as well as hosiery and the like, which are closed at one axial end, using a single cylinder circular knitting machine | |

| DE3821213C2 (en) | ||

| EP0043135B1 (en) | Method of producing patterned plush articles and circular knitting machine for this method | |

| EP0259563B1 (en) | Flat bed knitting machine | |

| DE4129845A1 (en) | CIRCULAR KNITTING MACHINE FOR THE PRODUCTION OF PLUSH GOODS | |

| EP0857802B1 (en) | Flat bed knitting machine | |

| DE2730306C2 (en) | Method and flat knitting machine for the production of intarsia | |

| DE2617303C2 (en) | Plush circular knitting machine | |

| DE3540685C1 (en) | Knitting machine | |

| DE10018897A1 (en) | Latch needle for a knitting machine has at least one dividing edge at the inner side of the hook to give defined holding zones for different yarns at the same time for special effects in the fabric | |

| DE2531762C2 (en) | Knitting machine | |

| EP0532871B1 (en) | Two beds flat knitting machine with needles and sinkers | |

| DE2820724C2 (en) | Multi-system circular knitting machine | |

| DE19505646A1 (en) | Pile fabric knitting | |

| DE2245731A1 (en) | Latch needle for circular knitters - with slide held by friction in needle bed guide | |

| DE2847838A1 (en) | NEEDLE TONGUE GUIDE AND HIGH PILE CIRCULAR KNITTING MACHINE EQUIPPED WITH SUCH GUIDES | |

| DE2507815A1 (en) | DEVICE FOR FEEDING THE THREAD IN CIRCULAR KNITTING MACHINES WITH A FIXED NEEDLE CYLINDER AND ROTATING LOCKING SHEETS FOR THE MANUFACTURE OF OPEN KNITWEAR | |

| DE2531705A1 (en) | KNITTING MACHINE | |

| DE3507004C2 (en) | ||

| DE1585490B2 (en) | FLAT EDGE MOLDING MACHINE SYSTEM COTTON | |

| DE612276C (en) | Method of knitting two or more threads simultaneously and securely separated on flat weft knitting machines and device for carrying out the method |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): CH DE ES FR GB IT LI |

|

| 17P | Request for examination filed |

Effective date: 19871106 |

|

| 17Q | First examination report despatched |

Effective date: 19890228 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): CH DE ES FR GB IT LI |

|

| ET | Fr: translation filed | ||

| ITF | It: translation for a ep patent filed | ||

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) | ||

| REF | Corresponds to: |

Ref document number: 3760678 Country of ref document: DE Date of ref document: 19891109 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| ITTA | It: last paid annual fee | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 19950123 Year of fee payment: 9 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Effective date: 19960131 Ref country code: CH Effective date: 19960131 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19990121 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20000111 Year of fee payment: 14 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000122 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20000217 Year of fee payment: 14 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20000122 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20010928 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20011101 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20031218 Year of fee payment: 18 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20050122 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050124 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20050124 |