EP0231144B1 - Flexible under-layer - Google Patents

Flexible under-layer Download PDFInfo

- Publication number

- EP0231144B1 EP0231144B1 EP87730003A EP87730003A EP0231144B1 EP 0231144 B1 EP0231144 B1 EP 0231144B1 EP 87730003 A EP87730003 A EP 87730003A EP 87730003 A EP87730003 A EP 87730003A EP 0231144 B1 EP0231144 B1 EP 0231144B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- hollow bodies

- hollow

- filled

- bodies

- base

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000000463 material Substances 0.000 claims description 3

- 229920001084 poly(chloroprene) Polymers 0.000 claims description 3

- 239000004744 fabric Substances 0.000 claims description 2

- 239000006261 foam material Substances 0.000 claims 3

- 239000012530 fluid Substances 0.000 claims 2

- 230000009969 flowable effect Effects 0.000 abstract description 4

- 238000010276 construction Methods 0.000 abstract 1

- 239000007787 solid Substances 0.000 abstract 1

- 239000006260 foam Substances 0.000 description 5

- 239000011248 coating agent Substances 0.000 description 3

- 238000000576 coating method Methods 0.000 description 3

- 208000004210 Pressure Ulcer Diseases 0.000 description 2

- 208000027418 Wounds and injury Diseases 0.000 description 2

- 239000000853 adhesive Substances 0.000 description 2

- 230000001070 adhesive effect Effects 0.000 description 2

- 230000006378 damage Effects 0.000 description 2

- 238000011161 development Methods 0.000 description 2

- 230000018109 developmental process Effects 0.000 description 2

- 230000001771 impaired effect Effects 0.000 description 2

- 208000014674 injury Diseases 0.000 description 2

- 238000005192 partition Methods 0.000 description 2

- 206010011985 Decubitus ulcer Diseases 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 230000007423 decrease Effects 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 239000007788 liquid Substances 0.000 description 1

- 230000000737 periodic effect Effects 0.000 description 1

- 229920003023 plastic Polymers 0.000 description 1

Images

Classifications

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47C—CHAIRS; SOFAS; BEDS

- A47C27/00—Spring, stuffed or fluid mattresses or cushions specially adapted for chairs, beds or sofas

- A47C27/08—Fluid mattresses or cushions

- A47C27/081—Fluid mattresses or cushions of pneumatic type

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47C—CHAIRS; SOFAS; BEDS

- A47C27/00—Spring, stuffed or fluid mattresses or cushions specially adapted for chairs, beds or sofas

- A47C27/08—Fluid mattresses or cushions

- A47C27/10—Fluid mattresses or cushions with two or more independently-fillable chambers

Definitions

- the invention relates to a flexible base as a sitting or lying pillow for the human body according to the preamble of claim 1.

- Such a pad is known from DE-A-33 03 615, which relates to a bed, the bed surface of which is formed from approximately 200 individually inflatable elastic hollow bodies.

- a plastic base is divided into square fields which serve as hollow-body receiving compartments.

- the partitions necessary for the division have a height of about 15 cm and form compartments for the suitably usable hollow bodies, each of which is provided with a valve which allows air to be blown in or out.

- the intermediate walls extend over about a third of the height of the hollow bodies, so that these have a horizontal cross-sectional area of about 10 ⁇ 10 cm 2 about 30 cm the partitions protrude.

- the hollow bodies are therefore extremely unstable with respect to pressures acting obliquely from above, in particular if, as is indicated by way of example, they contain constrictions running horizontally in the middle to upper region.

- the hollow bodies must therefore support each other so as not to move sideways. This can also be seen in the fact that the lateral outer walls of the bed are pulled up to the upper edge of the hollow body.

- the position of the hollow bodies surrounding them can therefore no longer be controlled and the stability of the lying surface is considerably impaired.

- a pad which consists of individual inflatable hollow bodies.

- the hollow bodies In the non-inflated state, the hollow bodies are folded and are spaced from one another. When inflated, they unfold so that they lie against each other and support each other when inflated.

- the hollow bodies are arranged in rows on their Auflaaer in two mutually perpendicular directions and have a rectangular cross-section in the inflated state parallel to their support, so that they form a closed seat or lying surface. It is therefore necessary that all hollow bodies are inflated with approximately the same pressure, since here too, if the support effect ceases to exist only one hollow body can make the entire sitting or lying surface unstable. The function of the support is therefore considerably impaired if one of the hollow bodies cannot hold the required pressure due to a leak.

- the present invention is therefore based on the object of providing a flexible base which ensures a stable seating or lying surface even when individual hollow bodies or individual hollow body groups forming one areas compared to those of the rest Hollow bodies have different internal pressures.

- the invention is characterized in that the hollow bodies are spherical in the filled state and the respective surface of the support facing them is dome-shaped, that the shell of the hollow body consists of a foam with closed cavities, and that the foam on the outside of the hollow body with is coated with an inelastic material.

- the support therefore gives each hollow body a firm fit and, in conjunction with the inelastic coating, prevents the loaded hollow body from escaping, so that mutual support of the filled hollow body is not necessary. Therefore, the individual Any number of hollow bodies can be subjected to widely differing internal pressures.

- the hollow bodies are slightly deformed by the load of the human body, so that the contact surface, which is in itself only punctiform, is considerably enlarged.

- the hollow bodies are chosen to be sufficiently small to give the person in question the feeling of a closed seat or lying surface.

- the volume of the voids of the foam of the shell can be changed by the pressure of the flowable medium.

- the cavities represent air pockets that are highly heat-insulating. Depending on the pressure prevailing in the interior of the hollow body, these cavities are compressed to a greater or lesser extent so that the heat transfer resistance of the casing decreases when the pressure inside the hollow body rises. It is therefore possible to give the sitting or lying person a pleasant feeling of temperature by appropriately adjusting the internal pressure of the hollow body.

- a suitable foam for this purpose consists of neoprene

- This coating advantageously consists of a knitted fabric.

- the hollow body is preferably provided with a valve for the controllable entry and exit of the flowable medium.

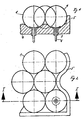

- FIG. 1 two adjacent hollow body 1 are shown, which are supported by a support 2.

- the hollow bodies 1 are pressurized from the inside by a gas or a liquid and take on a spherical shape.

- the support 2 has dome-shaped depressions at the locations provided for receiving the hollow body 1, which are adapted to the spherical shape of the hollow body 1.

- the hollow bodies 1 therefore lie firmly in the dome-shaped depressions on the surface of the support 2 and are thus secured against lateral deflection.

- the shell of the hollow body 1 is preferably made of coated neoprene.

- the hollow body 1 can be produced, for example, in such a way that two flat blanks made of foam or the like are connected to one another by an annular adhesive bond, the adhesive bond being additionally secured by a seam or a clip.

- a flowable medium preferably air

- a valve not shown

- a compressed air source At the other end of the hose 4 there is a compressed air source. It is also possible to control the compressed air source itself in a suitable manner. Since the base has a large number of hollow bodies 1, periodic pressurization can be carried out without this being perceived as uncomfortable by the person lying down. In this way, the development of pressure ulcers can be avoided in patients who are immobile for long periods.

- the arrangement of the hollow bodies 1 in adjacent rows is in one, i.e. 2 offset in the horizontal direction by half the distance between two adjacent hollow bodies 1 in order to obtain the largest possible number of hollow bodies 1 on a given surface.

- the support 2 is provided with a raised edge 5 which follows the mutually offset ends of the individual rows of hollow bodies.

Landscapes

- Mattresses And Other Support Structures For Chairs And Beds (AREA)

- Laminated Bodies (AREA)

- Invalid Beds And Related Equipment (AREA)

- Materials For Medical Uses (AREA)

Abstract

Description

Die Erfindung betrifft eine flexible Unterlage als Sitz- oder Liegekissen für den menschlichen Körper gemäß dem Oberbegriff des Anspruchs 1.The invention relates to a flexible base as a sitting or lying pillow for the human body according to the preamble of claim 1.

Eine derartige Unterlage ist aus der DE-A-33 03 615 bekannt, das sich auf eine Liege bezieht, deren Liegefläche aus etwa 200 einzeln aufblasbaren elastischen Hohlkörpern gebildet ist. Eine Kunststoffunterlage ist in als Hohlkörper-Aufnahmefächer dienende quadratische Felder unterteilt. Die für die Unterteilung notwendigen Zwischenwände besitzen eine Höhe von etwa 15 cm und bilden Aufnahmefächer für die passend einsetzbaren Hohlkörper, die jeweils mit einem Ventil versehen sind, welches ein Einblasen oder Ablassen von Luft ermöglicht. Die Zwischenwände erstrecken sich etwa über ein Drittel der Höhe der Hohlkörper, so daß diese bei einer horizontalen Querschnittsfläche von etwa 10 x 10 cm2 etwa 30 cm über die Zwischenwände hinausragen. Die Hohlkörper sind somit äußerst instabil gegenüber schräg von oben einwirkenden Drücken, insbesondere dann, wenn sie, wie beispielhaft angedeutet ist, im mittleren bis oberen Bereich horizontal verlaufende Einschnürungen enthalten. Die Hohlkörper müssen sich daher gegenseitig stützen, um nicht seitlich auszuweichen. Dies zeigt sich auch daran, daß die seitlichen Außenwände der Liege bis zur Oberkante der Hohlkörper hochgezogen sind. Bei einem - gesteuerten oder unbeabsichtigten - Entweichen von Luft aus einem oder mehreren der Hohlkörper kann daher die Stellung der diese umgebenden Hohlkörper nicht mehr kontrolliert werden und die Stabilität der Liegefläche wird erheblich beeinträchtigt.Such a pad is known from DE-A-33 03 615, which relates to a bed, the bed surface of which is formed from approximately 200 individually inflatable elastic hollow bodies. A plastic base is divided into square fields which serve as hollow-body receiving compartments. The partitions necessary for the division have a height of about 15 cm and form compartments for the suitably usable hollow bodies, each of which is provided with a valve which allows air to be blown in or out. The intermediate walls extend over about a third of the height of the hollow bodies, so that these have a horizontal cross-sectional area of about 10 × 10 cm 2 about 30 cm the partitions protrude. The hollow bodies are therefore extremely unstable with respect to pressures acting obliquely from above, in particular if, as is indicated by way of example, they contain constrictions running horizontally in the middle to upper region. The hollow bodies must therefore support each other so as not to move sideways. This can also be seen in the fact that the lateral outer walls of the bed are pulled up to the upper edge of the hollow body. In the event of a controlled or unintentional escape of air from one or more of the hollow bodies, the position of the hollow bodies surrounding them can therefore no longer be controlled and the stability of the lying surface is considerably impaired.

Aus der US-PS 4 005 236 ist eine Unterlage bekannt, die aus einzelnen aufblasbaren Hohlkörpern besteht. Im nicht aufgeblasenen Zustand sind die Hohlkörper gefaltet und weisen einen gegenseitigen Abstand auf. Beim Aufblasen entfalten sie sich, so daß sie im aufgeblasenen Zustand aneinander anliegen und sich gegenseitig stützen. Die Hohlkörper sind auf ihrem Auflaaer in zwei zueinander senkrechten Richtungen reihenförmig angeordnet und weisen im aufgeblasenen Zustand parallel zu ihrer Auflage einen rechteckigen Querschnitt auf, so daß sie eine geschlossene Sitz- oder Liegefläche bilden. Es ist somit erforderlich, daß sämtliche Hohlkörper mit etwa dem gleichen Druck aufgeblasen sind, da auch hier bei einem Wegfall der Stützwirkung auch nur eines Hohlkörpers die gesamte Sitz- bzw. Liegefläche instabil werden kann. Die Unterlage wird daher in ihrer Funktion erheblich beeinträchtigt, wenn bereits einer der Hohlkörper aufgrund einer Undichtigkeit den erforderlichen Druck nicht halten kann. Im Krankenhausbetrieb kommt es auch häufig vor, daß Patienten, die äußere Verletzungen aufweisen, im Bereich dieser Verletzungen nicht fest auf ihrer Unterlage aufliegen dürfen, so daß es vorteilhaft ist, diese Bereiche aus der Liegefläche auszusparen. Auch kann die Bildung von Druckgeschwüren an besonders gefährdeten Körperstellen bei längerem Liegen vermieden werden, wenn die Liegefläche im Bereich dieser Stellen zumindest zeitweise so verändert wird, daß sie hier keinen Druck auf den Körper des Patienten ausübt. Dies ist mit der aus der US-PS 4 005 236 bekannten Unterlage nicht möglich, da bei dieser alle Hohlkörper etwa den gleichen Innendruck besitzen müssen, so daß eine Liegefläche mit Bereichen unterschiedlicher Nachgiebigkeit nicht realisierbar ist.From US-PS 4 005 236 a pad is known which consists of individual inflatable hollow bodies. In the non-inflated state, the hollow bodies are folded and are spaced from one another. When inflated, they unfold so that they lie against each other and support each other when inflated. The hollow bodies are arranged in rows on their Auflaaer in two mutually perpendicular directions and have a rectangular cross-section in the inflated state parallel to their support, so that they form a closed seat or lying surface. It is therefore necessary that all hollow bodies are inflated with approximately the same pressure, since here too, if the support effect ceases to exist only one hollow body can make the entire sitting or lying surface unstable. The function of the support is therefore considerably impaired if one of the hollow bodies cannot hold the required pressure due to a leak. In hospital operation it also often happens that patients who have external injuries must not lie firmly on their surface in the area of these injuries, so that it is advantageous to leave these areas out of the lying surface. The formation of pressure sores on particularly vulnerable parts of the body when lying down for a long time can also be avoided if the lying surface in the area of these points is at least temporarily changed so that it does not exert any pressure on the patient's body here. This is not possible with the pad known from US Pat. No. 4,005,236, since in this case all hollow bodies must have approximately the same internal pressure, so that a lying surface with areas of different flexibility is not feasible.

Ausgehend vom Gegenstand der DE-A-33 03 615 liegt der vorliegenden Erfindung daher die Aufgabe zugrunde, eine flexible Unterlage zu schaffen, die eine stabile Sitz- oder Liegefläche auch dann gewährleistet, wenn einzelne Hohlkörper oder einzelne Bereiche bildende Hohlkörpergruppen einem gegenüber dem der übrigen Hohlkörper unterschiedlichen Innendruck besitzen.Based on the subject of DE-A-33 03 615, the present invention is therefore based on the object of providing a flexible base which ensures a stable seating or lying surface even when individual hollow bodies or individual hollow body groups forming one areas compared to those of the rest Hollow bodies have different internal pressures.

Diese Aufgabe wird erfindungsgemäß durch die im kennzeichnenden Teil des Anspruchs 1 angegebenen Merkmale gelöst. Vorteilhafte Ausbildungen der erfindungsgemäßen Unterlage ergeben sich aus den Unteransprüchen.This object is achieved by the features specified in the characterizing part of claim 1. Advantageous developments of the document according to the invention result from the subclaims.

Die Erfindung zeichnet sich dadurch aus, daß die Hohlkörper im gefüllten Zustand kugelförmig sind und die ihnen jeweils zugewandte Fläche des Auflagers kalottenförmig ausgebildet ist, daß die Hülle der Hohlkörper aus einem Schaumstoff mit geschlossenen Hohlräumen besteht, und daß der Schaumstoff auf der Außenseite der Hohlkörper mit einem unelastischen Material beschichtet ist. Das Auflager vermittelt daher jedem Hohlkörper einen festen Sitz und verhindert in Verbindung mit der unelastischen Beschichtung ein Ausweichen des belasteten Hohlkörpers, so daß eine gegenseitige Stützung der gefüllten Hohlkörper nicht erforderlich ist. Daher können die einzelnen Hohlkörper in beliebiger Auswahl stark unterschiedlichen Innendrücken unterworfen werden.The invention is characterized in that the hollow bodies are spherical in the filled state and the respective surface of the support facing them is dome-shaped, that the shell of the hollow body consists of a foam with closed cavities, and that the foam on the outside of the hollow body with is coated with an inelastic material. The support therefore gives each hollow body a firm fit and, in conjunction with the inelastic coating, prevents the loaded hollow body from escaping, so that mutual support of the filled hollow body is not necessary. Therefore, the individual Any number of hollow bodies can be subjected to widely differing internal pressures.

Die Hohlkörper werden durch die Last des menschlichen Körpers leicht deformiert, so daß die an sich nur punktförmige Berührungsfläche erheblich vergrößert wird. Außerdem werden die Hohlkörper hinreichend klein gewählt, um der jeweiligen Person das Gefühl einer geschlossenen Sitz- bzw. Liegefläche zu geben.The hollow bodies are slightly deformed by the load of the human body, so that the contact surface, which is in itself only punctiform, is considerably enlarged. In addition, the hollow bodies are chosen to be sufficiently small to give the person in question the feeling of a closed seat or lying surface.

Das Volumen der Hohlräume des Schaumstoffs der Hülle ist durch den Druck des fließfähigen Mediums veränderbar. Die Hohlräume stellen Lufteinschlüsse dar, die stark wärmeisolierend wirken. In Abhängigkeit von dem im Innern des Hohlkörpers herrschenden Druck werden diese Hohlräume mehr oder weniger stark komprimiert, so daß bei einem Druckanstieg im Innern des Hohlkörpers der Wärmeübergangswiderstand der Hülle abnimmt. Es ist daher möglich, durch entsprechende Einstellung des Innendruckes der Hohlkörper der sitzenden bzw. liegenden Person ein angenehmes Temperaturgefühl zu vermitteln. Ein geeigneter Schaumstoff für diesen Zweck besteht aus NeoprenThe volume of the voids of the foam of the shell can be changed by the pressure of the flowable medium. The cavities represent air pockets that are highly heat-insulating. Depending on the pressure prevailing in the interior of the hollow body, these cavities are compressed to a greater or lesser extent so that the heat transfer resistance of the casing decreases when the pressure inside the hollow body rises. It is therefore possible to give the sitting or lying person a pleasant feeling of temperature by appropriately adjusting the internal pressure of the hollow body. A suitable foam for this purpose consists of neoprene

Durch die unelastische Beschichtung ist die Gestalt des gefüllten Hohlkörpers unabhängig vom in seinem Innern herrschenden Druck Praktisch unverändert. Diese Beschichtung besteht vorteilhaft aus einem Gewirk.Due to the inelastic coating, the shape of the filled hollow body is practically unchanged regardless of the pressure inside. This coating advantageously consists of a knitted fabric.

Für den steuerbaren Ein- und Austritt des fließfähigen Mediums ist der Hohlkörper vorzugsweise mit einem Ventil versehen.The hollow body is preferably provided with a valve for the controllable entry and exit of the flowable medium.

Die Erfindung wird im folgenden anhand eines in den Figuren dargestellten Ausführungsbeispiels näher erläutert. Hierbei zeigen:

- Fig. 1

- einen senkrechten Schnitt durch einen Teil der Unterlage entlang der Linie I-I in Fig. 2 und

- Fig. 2

- die Draufsicht auf einen Teil der Unterlage.

- Fig. 1

- a vertical section through part of the pad along the line II in Fig. 2 and

- Fig. 2

- the top view of part of the document.

In Fig. 1 sind zwei nebeneinanderliegende Hohlkörper 1 dargestellt, die von einem Auflager 2 getragen werden. Die Hohlkörper 1 werden durch ein Gas oder eine Flüssigkeit von innen unter Druck gesetzt und nehmen dabei eine kugelförmige Gestalt an. Das Auflager 2 besitzt an den für die Aufnahme der Hohlkörper 1 vorgesehenen Stellen kalottenförmige Vertiefungen, die der kugelförmigen Gestalt der Hohlkörper 1 angepaßt sind. Die Hohlkörper 1 liegen daher in den kalottenförmigen Vertiefungen fest an der Oberfläche des Auflagers 2 an und werden so gegen seitliches Ausweichen gesichert gehalten. Die Hülle der Hohlkörper 1 besteht vorzugsweise aus beschichtetem Neopren.In Fig. 1 two adjacent hollow body 1 are shown, which are supported by a support 2. The hollow bodies 1 are pressurized from the inside by a gas or a liquid and take on a spherical shape. The support 2 has dome-shaped depressions at the locations provided for receiving the hollow body 1, which are adapted to the spherical shape of the hollow body 1. The hollow bodies 1 therefore lie firmly in the dome-shaped depressions on the surface of the support 2 and are thus secured against lateral deflection. The shell of the hollow body 1 is preferably made of coated neoprene.

Die Hohlkörper 1 können beispielsweise so hergestellt werden, daß zwei flache Zuschnitte aus Schaumstoff oder dergleichen durch eine ringförmige Verklebung miteinander verbunden werden, wobei die Verklebung zusätzlich durch eine Naht oder eine Klammer gesichert werden kann.The hollow body 1 can be produced, for example, in such a way that two flat blanks made of foam or the like are connected to one another by an annular adhesive bond, the adhesive bond being additionally secured by a seam or a clip.

In der Hülle der Hohlkörper 1 befindet sich eine Öffnung, in der mittels eines Befestigungsstutzens 3 das eine Ende eines Schlauches 4 befestigt ist. Der Ein- und Austritt eines Fließfähigen Mediums, vorzugsweise Luft, in die Hohlkörper 1 über jeweils den Schlauch 4 kann durch ein nicht dargestelltes Ventil gesteuert werden. Am anderen Ende des Schlauches 4 befindet sich eine Druckluftquelle. Es ist auch möqlich, die Druckluftquelle selbst in geeigneter Weise zu steuern. Da die Unterlage eine große Anzahl von Hohlkörpern 1 aufweist, kann eine periodische Druckbeaufschlagung durchgeführt werden, ohne daß dies von der liegenden Person als unangenehm empfunden wird. Hierdurch kann bei längere Zeit bewegungslos liegenden Patienten die Entstehung von Druckqeschwüren vermieden werden.In the shell of the hollow body 1 there is an opening in which one end of a hose 4 is fastened by means of a fastening piece 3. The entry and exit of a flowable medium, preferably air, into the hollow body 1 via the hose 4 in each case can be controlled by a valve (not shown). At the other end of the hose 4 there is a compressed air source. It is also possible to control the compressed air source itself in a suitable manner. Since the base has a large number of hollow bodies 1, periodic pressurization can be carried out without this being perceived as uncomfortable by the person lying down. In this way, the development of pressure ulcers can be avoided in patients who are immobile for long periods.

Die Anordnung der Hohlkörper 1 in einander benachbarten Reihen ist in einer, d.h. in Fig. 2 in der horizontalen Richtung um den halben Abstand zweier nebeneinanderliegender Hohlkörper 1 gegeneinender versetzt, um eine möglichst große Anzahl von Hohlkörpern 1 auf einer gegebenen Fläche zu erhalten. An den Kanten der Unterlage ist das Auflager 2 mit einem hochgezogenen Rand 5 versehen, der den gegeneinander versetzten Enden der einzelnen Hohlkörperreihen folgt.The arrangement of the hollow bodies 1 in adjacent rows is in one, i.e. 2 offset in the horizontal direction by half the distance between two adjacent hollow bodies 1 in order to obtain the largest possible number of hollow bodies 1 on a given surface. At the edges of the base, the support 2 is provided with a raised edge 5 which follows the mutually offset ends of the individual rows of hollow bodies.

Claims (4)

- Flexible underlayer for seating or mattress cushioning for the human body of a large number of hollow bodies arranged substantially in a plane and individually charged with a pressurised fluid medium and having flexible covers and a fixed base for the hollow bodies, in which the hollow bodies filled with the medium are arranged row-wise next to each other in two mutually orthogonal directions running parallel to the said plane, and in which the face of the base directed toward the hollow bodies is so shaped that it conforms to the lower parts of the filled hollow bodies and cradles them characterised in that the hollow bodies (1) in the filled state are spherical and the face of the base (2) which is towards each of them is formed as a cup-shaped cavity, that the cover of the hollow bodies comprises a foam material with closed cells, and that the foam material is coated on the outside of the hollow body (1) with an inelastic material.

- Underlayer according to claim 1, characterised in that the inelastic material is a knitted fabric.

- Underlayer according to claim 1 or 2, characterised in that the hollow bodies (1) are each provided with a controllable valve for the fluid medium.

- Underlayer according to any of claims 1 to 3, characterised in that the foam material is neoprene.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT87730003T ATE62812T1 (en) | 1986-01-23 | 1987-01-15 | FLEXIBLE UNDERLAY. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19863602173 DE3602173A1 (en) | 1986-01-23 | 1986-01-23 | FLEXIBLE DOCUMENT |

| DE3602173 | 1986-01-23 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0231144A2 EP0231144A2 (en) | 1987-08-05 |

| EP0231144A3 EP0231144A3 (en) | 1988-04-20 |

| EP0231144B1 true EP0231144B1 (en) | 1991-04-24 |

Family

ID=6292575

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP87730003A Expired - Lifetime EP0231144B1 (en) | 1986-01-23 | 1987-01-15 | Flexible under-layer |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US4750224A (en) |

| EP (1) | EP0231144B1 (en) |

| JP (1) | JPH0732734B2 (en) |

| AT (1) | ATE62812T1 (en) |

| DE (2) | DE3602173A1 (en) |

| ES (1) | ES2021748B3 (en) |

| GR (1) | GR3001998T3 (en) |

Families Citing this family (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3802607A1 (en) * | 1987-12-17 | 1989-06-29 | Adidas Sportschuhe | OUTSOLE FOR SPORTSHOES |

| AU7042691A (en) * | 1989-10-26 | 1991-05-31 | Tooling Promotion Ab | Mattress, cushion, and the like |

| US5873137A (en) * | 1996-06-17 | 1999-02-23 | Medogar Technologies | Pnuematic mattress systems |

| US6061928A (en) * | 1997-12-09 | 2000-05-16 | K-Swiss Inc. | Shoe having independent packed cushioning elements |

| US6327727B1 (en) * | 1998-09-08 | 2001-12-11 | Viktor Bocharnikov | Pheumatic cradle |

| US6493888B1 (en) * | 2000-04-18 | 2002-12-17 | Hill-Rom Services, Inc. | Pediatric mattress |

| US6401282B1 (en) | 2001-05-14 | 2002-06-11 | Hai Shum | Modular mattress system |

| US6502263B1 (en) * | 2001-07-26 | 2003-01-07 | Invacare Corporation | Seat cushion and positioning assembly including inflatable air cell pressure compensation insert |

| US6640367B2 (en) * | 2002-01-23 | 2003-11-04 | Chih-Yu Hsia | Pillows |

| US6966088B1 (en) | 2004-08-18 | 2005-11-22 | Hu Mary D | Cushion to support patient with bed sores |

| US8156939B1 (en) * | 2008-05-01 | 2012-04-17 | Rachael Joelle Maddalena | Therapeutic pressure pillow apparatus |

| GB201017183D0 (en) * | 2010-10-12 | 2010-11-24 | Katan Joseph M | Body support platform |

| US10485691B2 (en) * | 2011-07-22 | 2019-11-26 | Prs Medical Technologies, Inc. | Independently adjustable support system |

| US9308393B1 (en) | 2015-01-15 | 2016-04-12 | Dri-Em, Inc. | Bed drying device, UV lights for bedsores |

Family Cites Families (19)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE7216853U (en) * | 1972-08-10 | Kahl R | Mattress with spring elements | |

| GB122806A (en) * | 1918-11-29 | 1919-02-06 | Frederick William Brampton | A New or Improved Mattress for Beds. |

| US2491557A (en) * | 1946-03-12 | 1949-12-20 | Gordon L Goolsbee | Multiple air cell mattress |

| US2655369A (en) * | 1949-11-17 | 1953-10-13 | Louis C Musilli | Shock absorbing device |

| US3008465A (en) * | 1958-10-10 | 1961-11-14 | Ida Molner | Pulsating pneumatic body supporting device and pneumatic valve therefor |

| GB1299789A (en) * | 1970-05-22 | 1972-12-13 | Universal Oil Prod Co | Adjustable support cushion |

| GB1341325A (en) * | 1971-07-09 | 1973-12-19 | Scales J T | Inflatable support appliance |

| GB1380153A (en) * | 1972-04-04 | 1975-01-08 | Goodyear Tire & Rubber | Inflatable member particularly for use as a dunnage device |

| GB1442994A (en) * | 1972-07-21 | 1976-07-21 | Watkins Watson Ltd | Support appliances such as beds |

| US4005236A (en) * | 1973-05-16 | 1977-01-25 | Graebe Robert H | Expandable multicelled cushioning structure |

| US4279044A (en) * | 1979-11-16 | 1981-07-21 | Owen Douglas | Fluid support system for a medical patient |

| US4297755A (en) * | 1980-02-15 | 1981-11-03 | Mollura Carlos A | Non-planar waterbed |

| GB2070174A (en) * | 1980-02-26 | 1981-09-03 | Watkins & Watson Ltd | Conduit connector |

| JPS5778814A (en) * | 1980-11-01 | 1982-05-17 | Aisin Seiki | Matress apparatus |

| SE426545B (en) * | 1981-03-30 | 1983-01-31 | Jan Dranges | BODY SUPPORTING DEVICE IN THE FORM OF MOBILE OR SIMILAR AND PROCEDURE FOR MANUFACTURING ITS SAME |

| DE3303615A1 (en) * | 1983-02-03 | 1984-08-09 | Gerold 2900 Oldenburg Hobbensiefken | "Hobbibett" air bed (whose size is 100cm x 200 cm/15 cm high) consisting of 200 cavities which can be inflated individually and consist of rubber or plastic |

| DE8325103U1 (en) * | 1983-09-01 | 1984-01-19 | Hobbensiefken, Gerold, 2900 Oldenburg | LYING |

| JPS6045023U (en) * | 1983-09-05 | 1985-03-29 | 佐藤 久 | Air mattress type bed operated by computer |

| DE8601821U1 (en) * | 1986-01-23 | 1986-03-27 | Simon, Jochen, Dipl.-Ing. | Flexible base |

-

1986

- 1986-01-23 DE DE19863602173 patent/DE3602173A1/en active Granted

-

1987

- 1987-01-15 AT AT87730003T patent/ATE62812T1/en not_active IP Right Cessation

- 1987-01-15 ES ES87730003T patent/ES2021748B3/en not_active Expired - Lifetime

- 1987-01-15 EP EP87730003A patent/EP0231144B1/en not_active Expired - Lifetime

- 1987-01-15 DE DE8787730003T patent/DE3769483D1/en not_active Expired - Fee Related

- 1987-01-23 JP JP62015051A patent/JPH0732734B2/en not_active Expired - Lifetime

- 1987-01-23 US US07/006,456 patent/US4750224A/en not_active Expired - Fee Related

-

1991

- 1991-05-24 GR GR91400548T patent/GR3001998T3/en unknown

Also Published As

| Publication number | Publication date |

|---|---|

| US4750224A (en) | 1988-06-14 |

| ES2021748B3 (en) | 1991-11-16 |

| JPH0732734B2 (en) | 1995-04-12 |

| DE3602173C2 (en) | 1987-10-29 |

| EP0231144A3 (en) | 1988-04-20 |

| ATE62812T1 (en) | 1991-05-15 |

| DE3769483D1 (en) | 1991-05-29 |

| GR3001998T3 (en) | 1992-11-23 |

| DE3602173A1 (en) | 1987-07-30 |

| EP0231144A2 (en) | 1987-08-05 |

| JPS62217905A (en) | 1987-09-25 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE2816641C2 (en) | Cushions | |

| EP0231144B1 (en) | Flexible under-layer | |

| DE3876514T2 (en) | AIR MATTRESS AND METHOD FOR ADJUSTING IT. | |

| DE69129191T2 (en) | ZONED, CELL-SHAPED CUSHION WITH FLEXIBLE LATCHES CONTAINING AN INFLATING LINE | |

| EP0705549B1 (en) | Hollow object used as a seat support | |

| EP2029080B1 (en) | Cushion for supporting patients and for preventing pressure sores | |

| DE69212940T2 (en) | Maternity bed | |

| AT413014B (en) | SLEEP MATTRESS | |

| DE19516744A1 (en) | Prophylactic mattress built up from air pockets | |

| EP1785124A2 (en) | Padding element for a patient supporting surface on an operation table | |

| WO2006084393A2 (en) | Adjustable limb support | |

| DE20009249U1 (en) | Modular air mattress | |

| DE19827683C1 (en) | Self-inflating pad, especially a cushion, backrest or mattress | |

| DE2460181A1 (en) | DEVICE FOR SELECTIVE DISTRIBUTION OF A FLUID | |

| DE10007296A1 (en) | Rotaflex support element with bridge elements | |

| DE29707859U1 (en) | Waterbed | |

| EP0181591B1 (en) | Support for a lying or sitting person | |

| DE4302778A1 (en) | Lying area for beds, sofas and the like with air supply | |

| DE8601821U1 (en) | Flexible base | |

| DE2125514A1 (en) | Improvements to hospital beds | |

| DE102006037080B4 (en) | cushion layer | |

| DE2645052A1 (en) | Mattress for hospital bed - has slats set on fluid-filled support beams to adapt to body shape | |

| DE19647669C2 (en) | Orthopedic mattress or beach mat and support element therefor | |

| DE2642259C2 (en) | Inflatable pillow | |

| DE29618055U1 (en) | Impression and storage device |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH DE ES FR GB GR IT LI LU NL SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH DE ES FR GB GR IT LI LU NL SE |

|

| 17P | Request for examination filed |

Effective date: 19880901 |

|

| 17Q | First examination report despatched |

Effective date: 19891212 |

|

| ITF | It: translation for a ep patent filed | ||

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE ES FR GB GR IT LI LU NL SE |

|

| REF | Corresponds to: |

Ref document number: 62812 Country of ref document: AT Date of ref document: 19910515 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 3769483 Country of ref document: DE Date of ref document: 19910529 |

|

| ET | Fr: translation filed | ||

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| REG | Reference to a national code |

Ref country code: GR Ref legal event code: FG4A Free format text: 3001998 |

|

| EPTA | Lu: last paid annual fee | ||

| EAL | Se: european patent in force in sweden |

Ref document number: 87730003.8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: LU Payment date: 19970101 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19970108 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 19970117 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 19970122 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 19970127 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GR Payment date: 19970129 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19970131 Year of fee payment: 11 Ref country code: FR Payment date: 19970131 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 19970211 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19970325 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 19970407 Year of fee payment: 11 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19980115 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19980115 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19980115 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19980116 Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19980116 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19980131 Ref country code: GR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19980131 Ref country code: FR Free format text: THE PATENT HAS BEEN ANNULLED BY A DECISION OF A NATIONAL AUTHORITY Effective date: 19980131 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19980131 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19980131 |

|

| BERE | Be: lapsed |

Owner name: STRACKE HANS-JOACHIM Effective date: 19980131 Owner name: SIMON JOCHEN Effective date: 19980131 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19980801 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19980115 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 19980801 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19981001 |

|

| EUG | Se: european patent has lapsed |

Ref document number: 87730003.8 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20000503 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20050115 |