EP0199706B1 - Method and device for preventing the denting of rails in the transition area between the end and the full section of the tongue - Google Patents

Method and device for preventing the denting of rails in the transition area between the end and the full section of the tongue Download PDFInfo

- Publication number

- EP0199706B1 EP0199706B1 EP86890076A EP86890076A EP0199706B1 EP 0199706 B1 EP0199706 B1 EP 0199706B1 EP 86890076 A EP86890076 A EP 86890076A EP 86890076 A EP86890076 A EP 86890076A EP 0199706 B1 EP0199706 B1 EP 0199706B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- rail

- heat treatment

- tongue

- temperature

- rails

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000000034 method Methods 0.000 title claims abstract description 23

- 230000007704 transition Effects 0.000 title description 9

- 238000010438 heat treatment Methods 0.000 claims abstract description 33

- 230000008569 process Effects 0.000 claims abstract description 15

- 230000008859 change Effects 0.000 claims abstract description 10

- 239000001301 oxygen Substances 0.000 claims description 5

- 229910052760 oxygen Inorganic materials 0.000 claims description 5

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 claims description 3

- 238000009529 body temperature measurement Methods 0.000 claims description 3

- 238000002156 mixing Methods 0.000 claims description 3

- 230000001105 regulatory effect Effects 0.000 claims description 3

- 239000002737 fuel gas Substances 0.000 claims description 2

- 239000007789 gas Substances 0.000 claims description 2

- 230000002441 reversible effect Effects 0.000 claims description 2

- 238000011282 treatment Methods 0.000 claims description 2

- 238000000137 annealing Methods 0.000 description 3

- 238000001816 cooling Methods 0.000 description 3

- 229910000831 Steel Inorganic materials 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 239000000463 material Substances 0.000 description 2

- 238000007493 shaping process Methods 0.000 description 2

- 239000010959 steel Substances 0.000 description 2

- 238000005054 agglomeration Methods 0.000 description 1

- 230000002776 aggregation Effects 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 238000002485 combustion reaction Methods 0.000 description 1

- 238000010924 continuous production Methods 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 238000006073 displacement reaction Methods 0.000 description 1

- 238000011065 in-situ storage Methods 0.000 description 1

- 239000007788 liquid Substances 0.000 description 1

- 238000013021 overheating Methods 0.000 description 1

- 230000035515 penetration Effects 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- 238000003303 reheating Methods 0.000 description 1

- 230000007480 spreading Effects 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D9/00—Heat treatment, e.g. annealing, hardening, quenching or tempering, adapted for particular articles; Furnaces therefor

- C21D9/04—Heat treatment, e.g. annealing, hardening, quenching or tempering, adapted for particular articles; Furnaces therefor for rails

Definitions

- the invention relates to a method for the heat treatment of rails in the transition region between the tongue end and standard rail profile, the rail being heated above the austenitizing temperature and subsequently cooled in still air, and to an apparatus for carrying out this method.

- the tongue rail end is usually bulged onto the Vignol rail profile by hot-forming in the die.

- the heating to the forming temperature required for this takes place in special annealing furnaces, the rails being inserted into the furnace to a corresponding length.

- the agglomeration process is usually divided into three work stages, between which reheating to the forming temperature is required.

- a temperature transition area is created in the profile towards the cold rail end, which results in a metallurgical change in the material structure.

- This structural change which occurs in particular in a temperature range of 750 to 760 ° C for pearlitic rail steel, has a kind of soft annealing effect. The longer the rail steel is in this temperature range, the greater this soft annealing effect and thus the decrease in strength.

- the length of the structural change zone is directly dependent on the forming temperature and the duration of the hot forming process.

- the drop in strength of the hardness trough reaches orders of magnitude of 150 to 200 N / mm 2 , and the wheel overflow results in a dent length which is in a range of approximately 120 mm. Dents can only be prevented if the length range in which a drop in hardness or a hardness trough is observed is limited to approximately 30 mm, since then plastic deformation due to Hertzian surface pressure depending on the wheel diameter and thus a dent formation is reliably prevented. If the structure change zone is limited to such lengths, the support of the edge zone structure is sufficient to avoid plastic deformation.

- DE-AS 25 41 978 already shows a process in which rails are heat-treated for the purpose of forming a fine pearlitic structure.

- the heating covers the entire length of the rail, using a continuous process.

- cooling is carried out in a controlled manner using compressed air or compressed air with a liquid medium.

- the method according to the invention essentially consists in that the heat treatment is carried out simultaneously with or immediately after the hot forming of the tongue rail end and that the transition region is heated to a depth of at least 7 mm and at most 25 mm and that the heat treatment is controlled so that the length of the structural change zone formed by reshaping the tongue is kept less than 30 mm in the longitudinal direction of the rail.

- This heat treatment restores the original state of the pearlitic structure, the selected depth of penetration being chosen with a view to the fact that the maximum stress is usually about 7 mm below the workpiece surface.

- An essential factor for heat treatment is the shortest possible heating time to the forming temperature in order to prevent the heat from spreading to the cold rail end.

- the workpieces are in a temperature range of approx. 400 to 450 ° C in the area of the structural change zone, which means that the heating-up time for the subsequent heat treatment can be shortened considerably by the fact that the heat treatment immediately after the hot shaping of the tongue rail end is made.

- the heat treatment can be limited to a short length.

- the control of the heat treatment is carried out in such a way that the length of the structural change zone created by reshaping the tongue is kept less than 30 mm in the longitudinal direction of the rail in order to effectively prevent dents from forming.

- the heating is advantageously carried out to a temperature above 860 ° C., the heat treatment preferably being limited to the rail head.

- the cooling then takes place in still air, as a result of which the original structural state is achieved before the forming.

- the procedure according to the invention is preferably such that a length range of at least 150 mm, preferably at least 300 mm, is subjected to the heat treatment at the transition zone between the standard rail profile and the tongue end.

- the maximum length range can generally be limited to less than 900 mm.

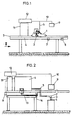

- This method for heat treatment of rails in the transition area between the tongue end and the control rail profile is essentially characterized in that, immediately after the last heat-forming step, a burner with a controllable flame temperature is movably supported over the surface of the rail, the travel of which is preferably limited by adjustable limit switches that the burner is mounted in a support with a reversible drive and that a temperature measuring device is provided for detecting the surface temperature of the rail.

- the design is such that the fuel gas and / or combustion air or oxygen supply and / or the linear travel speed of the burner along the rail is regulated as a function of temperature measurement values, preferably the temperature measurement device via control lines with a process computer is connected, which is connected to a controllable valve arrangement of a gas-oxygen mixing device for the burner.

- a process computer-controlled system has proven to be particularly advantageous.

- the burner bundles are mounted on a support and the heat treatment length can be optimally adjusted using limit switches.

- the introduction of heat can be monitored via a temperature measuring device, for example as a miliscope or pyrometer, whereby the hardness of the flame can be regulated by a process computer and in particular is operated with a hard flame in the heating process and is only operated with a soft flame in the holding stage. In this way, overheating of the areas that are already at the transition temperature can be ruled out.

- a temperature measuring device for example as a miliscope or pyrometer

- the burners 2 are water-cooled bundle burners, the flame direction of which is directed towards the head 3 of a rail 4.

- the burners are connected via gas lines 5 to a valve arrangement of a gas-oxygen mixing device which is shown schematically in FIG.

- limit switches 7 and 8 are arranged, which serve to limit the path of the support.

- Above the rail is a temperature measuring device 9, which is connected to a process computer 11 via signal lines 10.

- a display device for the measured temperature is designated by 12.

- the drive 13 for the support is arranged on the side next to the rail.

- the limit switches 7 and 8 for path limitation are also located in the area of the movable drive.

- the support can be moved on a table 14 and is supported on this table 14.

- the travel range of the support is usually limited to 600 to 900 mm, with the minimum travel path usually being selected at around 300 mm.

- the cooling in still air has proven to be sufficient to avoid undesired hardening and only to restore the state that prevailed before the heating to the hot forming temperature.

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Crystallography & Structural Chemistry (AREA)

- Mechanical Engineering (AREA)

- Materials Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Heat Treatment Of Articles (AREA)

- Laying Of Electric Cables Or Lines Outside (AREA)

- Heat Treatments In General, Especially Conveying And Cooling (AREA)

- Chutes (AREA)

- Furnace Charging Or Discharging (AREA)

- Seats For Vehicles (AREA)

- Manufacture And Refinement Of Metals (AREA)

- Screw Conveyors (AREA)

- Feeding, Discharge, Calcimining, Fusing, And Gas-Generation Devices (AREA)

- Electrical Discharge Machining, Electrochemical Machining, And Combined Machining (AREA)

- Excavating Of Shafts Or Tunnels (AREA)

- Underground Or Underwater Handling Of Building Materials (AREA)

- Machines For Laying And Maintaining Railways (AREA)

- Paper (AREA)

- Manufacturing Of Electrical Connectors (AREA)

- Railway Tracks (AREA)

Abstract

Description

Die Erfindung bezieht sich auf ein Verfahren zur Wärmebehandlung von Schienen im Übergangsbereich zwischen Zungenende und Regelschienenprofil, wobei die Schiene über die Austenitisierungstemperatur erwärmt wird und nachfolgend an ruhender Luft abgekühlt wird, sowie auf eine Vorrichtung zur Durchführung dieses Verfahrens.The invention relates to a method for the heat treatment of rails in the transition region between the tongue end and standard rail profile, the rail being heated above the austenitizing temperature and subsequently cooled in still air, and to an apparatus for carrying out this method.

Die Ausballung des Zungenschienenendes auf das Vignolschienenprofil erfolgt üblicherweise durch Warmformgebung im Gesenk. Die hiefür erforderliche Erhitzung auf die Umformungstemperatur erfolgt in besonderen Glühöfen, wobei die Schienen jeweils auf eine entsprechende Länge in den Ofen eingesteckt werden. Der Ausballungsprozeß ist zumeist in drei Arbeitsstufen unterteilt, zwischen welchen jeweils ein Nachwärmen auf Umformungstemperatur erforderlich ist. Zum kalten Schienenende hin entsteht im Profil ein Temperaturübergangsbereich, der eine metallurgische Veränderung des Werkstoffgefüges zur Folge hat. Diese Gefügeveränderung, welche im besonderen in einem Temperaturbereich von 750 bis 760°C bei perlitischem Schienenstahl auftritt, hat eine Art Weichglüheffekt zur Folge. Je länger sich der Schienenstahl in diesem Temperaturbereich befindet, desto größer wird dieser Weichglüheffekt und damit der Festigkeitsabfall. Die Länge der Gefügeänderungszone ist direkt abhängig von der Umformungstemperatur und von der Zeitdauer des Warmumformungsprozesses. Der Festigkeitsabfall der Härtemulde erreicht Größenordnungen von 150 bis 200 N/mm2, und beim Radüberlauf ergibt sich in der Folge eine Dellenlänge, welche sich in einem Bereich von etwa 120 mm bewegt. Eine Dellenbildung kann nur dann verhindert werden, wenn der Längenbereich, in welchem ein Härteabfall bzw. eine Härtemulde beobachtet wird, auf etwa 30 mm beschränkt wird, da dann eine plastische Verformung auf Grund der Hertz'schen Flächenpressung in Abhängigkeit vom Raddurchmesser und damit eine Dellenbildung zuverlässig verhindert wird. Bei einer Begrenzung der Gefügeänderungszone auf derartige Längen ist die Stützung des Randzonengefüges ausreichend, um eine plastische Verformung zu vermeiden.The tongue rail end is usually bulged onto the Vignol rail profile by hot-forming in the die. The heating to the forming temperature required for this takes place in special annealing furnaces, the rails being inserted into the furnace to a corresponding length. The agglomeration process is usually divided into three work stages, between which reheating to the forming temperature is required. A temperature transition area is created in the profile towards the cold rail end, which results in a metallurgical change in the material structure. This structural change, which occurs in particular in a temperature range of 750 to 760 ° C for pearlitic rail steel, has a kind of soft annealing effect. The longer the rail steel is in this temperature range, the greater this soft annealing effect and thus the decrease in strength. The length of the structural change zone is directly dependent on the forming temperature and the duration of the hot forming process. The drop in strength of the hardness trough reaches orders of magnitude of 150 to 200 N / mm 2 , and the wheel overflow results in a dent length which is in a range of approximately 120 mm. Dents can only be prevented if the length range in which a drop in hardness or a hardness trough is observed is limited to approximately 30 mm, since then plastic deformation due to Hertzian surface pressure depending on the wheel diameter and thus a dent formation is reliably prevented. If the structure change zone is limited to such lengths, the support of the edge zone structure is sufficient to avoid plastic deformation.

Aus der US-PS 2 484 897 und der GB-PS 448 416 sind Einrichtungen zur in situ Wärmebehandlung von bereits verlegten Schienen bekanntgeworden, bei welchen auf den Schienen verfahrbare Vorrichtungen mit Brennern ausgestattet sind, welche bei einem Verfahren eine Wärmebehandlung insbesondere im Bereich von Schienenstößen vornehmen. Eine derartige Wärmebehandlung von bereits verlegten Schienen im Gleisbett unterscheidet sich dabei wesentlich von Behandlungen, welche im Zusammenhang mit der Formgebung der Schienen im Gesenk vorgenommen werden, und es bestehen Übereinstimmungen allgemeiner Art lediglich darin, daß durch eine Wärmebehandlung gezielt das metallurgische Gefüge des Werkstoffes beeinflußt werden soll.From US Pat. No. 2,484,897 and GB Pat. No. 448,416, devices for in situ heat treatment of rails which have already been laid have become known, in which devices which can be moved on the rails are equipped with burners which, in the case of a method, heat treatment, in particular in the area of rail joints make. Such heat treatment of rails already laid in the track bed differs significantly from treatments which are carried out in connection with the shaping of the rails in the die, and there are general correspondences only in that the metallurgical structure of the material is specifically influenced by heat treatment should.

Aus der DE-AS 25 41 978 ist bereits ein Verfahren zu entnehmen, bei welchem eine Wärmebehandlung von Schienen zum Zwecke der Ausbildung eines feinperlitischen Gefüges vorgenommen wird. Die Erwärmung erfaßt, ausgehend von einer kalten Schiene, die gesamte Länge derselben, wobei ein Durchlaufverfahren eingesetzt wird. Nach dem Erwärmen auf Temperaturen über der Austenitisierungstemperatur wird gesteuert unter Verwendung von Preßluft bzw. Preßluft mit flüssigem Medium abgekühlt.DE-AS 25 41 978 already shows a process in which rails are heat-treated for the purpose of forming a fine pearlitic structure. Starting from a cold rail, the heating covers the entire length of the rail, using a continuous process. After heating to temperatures above the austenitizing temperature, cooling is carried out in a controlled manner using compressed air or compressed air with a liquid medium.

Die Erfindung zielt nun darauf ab, bei der Warmformgebung eine Absenkung der Festigkeit im Obergangsbereich zum kalten Schienenende zu vermeiden bzw. eine bereits erfolgte Gefügeänderung im Bereich der Umformung rückgängig zu machen. Zur Lösung dieser Aufgabe besteht das erfindungsgemäße Verfahren im wesentlichen darin, daß die Wärmebehandlung gleichzeitig mit der oder unmittelbar anschließend an die Warmumformung des Zungenschienenendes vorgenommen wird und daß der Übergangsbereich über eine Tiefe von wenigstens 7 mm und von höchstens 25 mm erwärmt wird und daß die Wärmebehandlung so gesteuert wird, daß die Länge der durch Umformen der Zunge entstandenen Gefügeänderungszone in Schienenlängsrichtung kleiner 30 mm gehalten wird. Durch diese Wärmebehandlung wird der Urzustand des perlitischen Gefüges wieder hergestellt, wobei die gewählte Eindringtiefe im Hinblick darauf gewählt wurde, daß sich das Spannungsmaximum üblicherweise etwa 7 mm unter der Werkstückoberfläche befindet. Ein wesentlicher Faktor für die Wärmebehandlung ist hiebei eine möglichst kurze Aufheizzeit auf Umformungstemperatur, um ein Ausbreiten der Wärme zum kalten Schienenende hin zu verhindern. Nach dem Ausballen der Zungenenden auf Vignolprofile befinden sich die Werkstücke in einem Temperaturbereich von ca. 400 bis 450°C im Bereich der Gefügeänderungszone, wodurch die Aufheizzeit für die nachfolgende Wärmebehandlung wesentlich dadurch verkürzt werden kann, daß die Wärmebehandlung unmittelbar anschließend an die Warmformgebung des Zungenschienenendes vorgenommen wird. Auf diese Weise kann die Wärmebehandlung auf eine kurze Länge beschränkt werden. Die Steuerung der Wärmebehandlung wird dabei so vorgenommen, daß die Länge der durch Umformen der Zunge entstandenen Gefügeänderungszone in Schienenlängsrichtung kleiner 30 mm gehalten wird, um eine Dellenbildung wirksam zu verhindern. In vorteilhafter Weise wird die Erwärmung auf eine Temperatur über 860°C vorgenommen, wobei bevorzugt die Wärmebehandlung auf den Schienenkopf beschränkt wird. Die Abkühlung erfolgt dann an ruhender Luft, wodurch der ursprüngliche Gefügezustand vor der Umformung erreicht wird.The invention is now aimed at avoiding a reduction in the strength in the transition area to the cold rail end during the hot forming or to undo an already made structural change in the area of the forming. To achieve this object, the method according to the invention essentially consists in that the heat treatment is carried out simultaneously with or immediately after the hot forming of the tongue rail end and that the transition region is heated to a depth of at least 7 mm and at most 25 mm and that the heat treatment is controlled so that the length of the structural change zone formed by reshaping the tongue is kept less than 30 mm in the longitudinal direction of the rail. This heat treatment restores the original state of the pearlitic structure, the selected depth of penetration being chosen with a view to the fact that the maximum stress is usually about 7 mm below the workpiece surface. An essential factor for heat treatment is the shortest possible heating time to the forming temperature in order to prevent the heat from spreading to the cold rail end. After bulging the tongue ends onto Vignol profiles, the workpieces are in a temperature range of approx. 400 to 450 ° C in the area of the structural change zone, which means that the heating-up time for the subsequent heat treatment can be shortened considerably by the fact that the heat treatment immediately after the hot shaping of the tongue rail end is made. In this way, the heat treatment can be limited to a short length. The control of the heat treatment is carried out in such a way that the length of the structural change zone created by reshaping the tongue is kept less than 30 mm in the longitudinal direction of the rail in order to effectively prevent dents from forming. The heating is advantageously carried out to a temperature above 860 ° C., the heat treatment preferably being limited to the rail head. The cooling then takes place in still air, as a result of which the original structural state is achieved before the forming.

In bevorzugter Weise wird erfindungsgemäß so vorgegangen, daß an der Übergangszone zwischen Regelschienenprofil und Zungenende ein Längenbereich von wenigstens 150 mm, vorzugsweise wenigstens 300 mm, der Wärmebehandlung unterworfen wird. Der maximale Längenbereich kann je nach Dauer des Warmumformungsprozesses in der Regel auf unter 900 mm begrenzt werden.The procedure according to the invention is preferably such that a length range of at least 150 mm, preferably at least 300 mm, is subjected to the heat treatment at the transition zone between the standard rail profile and the tongue end. Depending on the duration of the hot-forming process, the maximum length range can generally be limited to less than 900 mm.

Die erfindungsgemäße Vorrichtung zur Durchführung dieses Verfahrens zur Wärmebehandlung von Schienen im Übergangsbereich zwischen Zungenende und Regelschienenprofil ist im wesentlichen dadurch gekennzeichnet, daß unmittelbar anschließend an die letzte Wärmeumformungsstufe ein Brenner mit steuerbarer Flammtemperatur über die Oberfläche der Schiene verfahrbar gelagert ist, dessen Verfahrweg, vorzugsweise durch verstellbare Endschalter, begrenzt ist, daß der Brenner in einem Support mit reversierbarem Antrieb gelagert ist und daß ein Temperaturmeßgerät zur Erfassung der Oberflächentemperatur der Schiene vorgesehen ist. In besonders vorteilhafter Weise ist hiebei die Ausbildung so getroffen, daß die Brenngas- und/oder Verbrennungsluft- bzw. Sauerstoffzufuhr und/oder die lineare Fahrgeschwindigkeit des Brenners längs der Schiene in Abhängigkeit von Temperaturmeßwerten geregelt ist, wobei vorzugsweise das Temperaturmeßgerät über Steuerleitungen mit einem Prozeßrechner verbunden ist, welcher mit einer steuerbaren Ventilanordnung einer Gas-Sauerstoffmischeinrichtung für den Brenner verbunden ist. Um dem nichtlinearen Temperaturverlauf im Temperaturübergangsbereich Rechnung zu tragen, erweist sich eine prozeßrechnergesteuerte Anlage als besonders vorteilhaft. Die Brennerbündel sind hiebei auf einem Support montiert und die Wärmebehandlungslänge kann über Endschalter optimal eingestellt werden. Das Wärmeeinbringen kann über ein, beispielsweise als Miliskop bzw. Pyrometer, ausgebildetes Temperaturmeßgerät überwacht werden, wobei die Härte der Flamme durch einen Prozeßrechner geregelt werden kann und insbesondere im Aufheizvorgang mit harter Flamme gefahren wird und im Haltestadium nur mit weicher Flamme gefahren wird. Auf diese Weise kann ein Überhitzen der Bereiche, die sich bereits auf Umwandlungstemperatur befinden, ausgeschlossen werden. Die Erfindung wird nachfolgend anhand eines in der Zeichnung schematisch dargestellten Ausführungsbeispieles einer Vorrichtung zur Durchführung des erfindungsgemäßen Verfahrens näher erläutert. In dieser zeigen Fig.1 eine schematische Seitenansicht der erfindungsgemäßen Vorrichtung und Fig.2 eine Ansicht in Richtung des Pfeiles II der Fig.1. In Fig.1 ist ein verfahrbarer Support 1 ersichtlich, welcher Brenner 2 trägt. Bei den Brennern 2 handelt es sich um wassergekühlte Bündelbrenner, deren Flammrichtung auf den Kopf 3 einer Schiene 4 gerichtet ist. Die Brenner stehen über Gasleitungen 5 mit einer in Fig.2 ersichtlichen schematisch mit 6 angedeuteten Ventilanordnung einer Gas-Sauerstoffmischeinrichtung in Verbindung. Im Verschiebeweg des Supports 1 sind Endschalter 7 und 8 angeordnet, welche als Wegbegrenzung für den Verfahrweg des Supportes dienen. Oberhalb der Schiene befindet sich ein Temperaturmeßgerät 9, welches über Signalleitungen 10 mit einem Prozeßrechner 11 verbunden ist. Ein Anzeigegerät für die gemessene Temperatur ist mit 12 bezeichnet.The device according to the invention This method for heat treatment of rails in the transition area between the tongue end and the control rail profile is essentially characterized in that, immediately after the last heat-forming step, a burner with a controllable flame temperature is movably supported over the surface of the rail, the travel of which is preferably limited by adjustable limit switches that the burner is mounted in a support with a reversible drive and that a temperature measuring device is provided for detecting the surface temperature of the rail. In a particularly advantageous manner, the design is such that the fuel gas and / or combustion air or oxygen supply and / or the linear travel speed of the burner along the rail is regulated as a function of temperature measurement values, preferably the temperature measurement device via control lines with a process computer is connected, which is connected to a controllable valve arrangement of a gas-oxygen mixing device for the burner. In order to take account of the non-linear temperature profile in the temperature transition area, a process computer-controlled system has proven to be particularly advantageous. The burner bundles are mounted on a support and the heat treatment length can be optimally adjusted using limit switches. The introduction of heat can be monitored via a temperature measuring device, for example as a miliscope or pyrometer, whereby the hardness of the flame can be regulated by a process computer and in particular is operated with a hard flame in the heating process and is only operated with a soft flame in the holding stage. In this way, overheating of the areas that are already at the transition temperature can be ruled out. The invention is explained in more detail below with reference to an exemplary embodiment of a device for carrying out the method according to the invention, which is shown schematically in the drawing. 1 shows a schematic side view of the device according to the invention and FIG. 2 shows a view in the direction of arrow II of FIG. 1. 1 shows a movable support 1 which carries

Wie aus Fig.2 ersichtlich, ist der Antrieb 13 für den Support seitlich neben der Schiene angeordnet. Im Bereich des verfahrbaren Antriebes befinden sich auch die Endschalter 7 und 8 für die Wegbegrenzung. Der Support ist auf einem Tisch 14 verfahrbar und an diesem Tisch 14 abgestützt. Der Verfahrbereich des Supportes wird üblicherweise mit 600 bis 900 mm begrenzt, wobei der minimale Verfahrweg üblicherweise mit etwa 300 mm gewählt wird. Die Abkühlung an ruhender Luft hat sich als ausreichend erwiesen, um eine unerwünschte Aufhärtung zu vermeiden und lediglich den Zustand wiederum herzustellen, welcher vor der Aufheizung auf Warmumformungstemperatur vorherrschte.As can be seen from FIG. 2, the

Claims (7)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT0088785A AT391707B (en) | 1985-03-25 | 1985-03-25 | METHOD FOR PREVENTING ADJUSTMENT OF RAILS IN THE TRANSITIONAL AREA AND DEVICE FOR CARRYING OUT THIS METHOD |

| AT887/85 | 1985-03-25 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0199706A2 EP0199706A2 (en) | 1986-10-29 |

| EP0199706A3 EP0199706A3 (en) | 1987-05-13 |

| EP0199706B1 true EP0199706B1 (en) | 1990-03-14 |

Family

ID=3502117

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP86890076A Expired - Lifetime EP0199706B1 (en) | 1985-03-25 | 1986-03-24 | Method and device for preventing the denting of rails in the transition area between the end and the full section of the tongue |

Country Status (9)

| Country | Link |

|---|---|

| EP (1) | EP0199706B1 (en) |

| AT (2) | AT391707B (en) |

| CS (1) | CS266577B2 (en) |

| DD (1) | DD244990A5 (en) |

| DE (1) | DE3669538D1 (en) |

| HU (1) | HU195545B (en) |

| NO (1) | NO161632C (en) |

| PL (1) | PL145456B1 (en) |

| YU (2) | YU44545B (en) |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB448416A (en) * | 1933-09-06 | 1936-05-27 | Oxweld Railroad Service Compan | Improvements in or relating to the surface hardening of rails and to rails treated thereby |

| US2484897A (en) * | 1946-10-22 | 1949-10-18 | Linde Air Prod Co | Apparatus for heat-treating surfaces of rails |

| DE800867C (en) * | 1949-10-25 | 1950-12-11 | Deutsche Bundesbahn | Method and device for removing corrugations on rails |

| BE626486A (en) * | 1961-12-27 | |||

| DE2541978C3 (en) * | 1975-09-20 | 1978-08-24 | Butzbacher Weichenbau Gmbh, 6308 Butzbach | Process for the heat treatment of switch parts in a continuous process |

| DE2821227C2 (en) * | 1978-05-16 | 1982-12-23 | Krupp Stahl Ag, 4630 Bochum | Process for the production of rails with reduced corrugation |

-

1985

- 1985-03-25 AT AT0088785A patent/AT391707B/en not_active IP Right Cessation

-

1986

- 1986-03-12 YU YU365/86A patent/YU44545B/en unknown

- 1986-03-19 HU HU861158A patent/HU195545B/en not_active IP Right Cessation

- 1986-03-19 CS CS861937A patent/CS266577B2/en unknown

- 1986-03-21 NO NO861149A patent/NO161632C/en unknown

- 1986-03-24 DE DE8686890076T patent/DE3669538D1/en not_active Expired - Lifetime

- 1986-03-24 AT AT86890076T patent/ATE51036T1/en not_active IP Right Cessation

- 1986-03-24 DD DD86288247A patent/DD244990A5/en not_active IP Right Cessation

- 1986-03-24 EP EP86890076A patent/EP0199706B1/en not_active Expired - Lifetime

- 1986-03-24 PL PL1986258590A patent/PL145456B1/en unknown

-

1987

- 1987-09-04 YU YU1643/87A patent/YU44642B/en unknown

Non-Patent Citations (2)

| Title |

|---|

| Hüttentechnik, H. Grothe, S. 448-449 * |

| Technische Lieferbedingungen Juni 1979, Deutsche Bundesbahn TL 918142 * |

Also Published As

| Publication number | Publication date |

|---|---|

| ATE51036T1 (en) | 1990-03-15 |

| YU44545B (en) | 1990-08-31 |

| EP0199706A3 (en) | 1987-05-13 |

| YU36586A (en) | 1988-06-30 |

| NO161632B (en) | 1989-05-29 |

| YU164387A (en) | 1988-12-31 |

| YU44642B (en) | 1990-10-31 |

| DD244990A5 (en) | 1987-04-22 |

| CS193786A2 (en) | 1989-04-14 |

| PL145456B1 (en) | 1988-09-30 |

| DE3669538D1 (en) | 1990-04-19 |

| NO861149L (en) | 1986-09-26 |

| HUT43655A (en) | 1987-11-30 |

| ATA88785A (en) | 1990-05-15 |

| CS266577B2 (en) | 1990-01-12 |

| HU195545B (en) | 1988-05-30 |

| NO161632C (en) | 1989-09-06 |

| EP0199706A2 (en) | 1986-10-29 |

| AT391707B (en) | 1990-11-26 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE102006019395A1 (en) | Apparatus and method for forming blanks of higher and highest strength steels | |

| EP1412543B1 (en) | Method for cooling work pieces especially shape-rolled products from rail steel | |

| DE69324566T2 (en) | COOLING DEVICE AND METHOD FOR METAL STRIP | |

| EP2097544B1 (en) | Method and apparatus for the heat treatment of welds | |

| WO2008077537A1 (en) | Device for flame straightening | |

| DE3728498C2 (en) | Device for heat treatment of rails | |

| CH668728A5 (en) | Method and device for connecting werkstueckteilen. | |

| EP0199706B1 (en) | Method and device for preventing the denting of rails in the transition area between the end and the full section of the tongue | |

| DE3501522C1 (en) | Process for the production of steel rails with low residual stresses by means of roller straightening | |

| CH621364A5 (en) | Process and equipment for the heat treatment of switch components | |

| DE1496004B1 (en) | Method of tempering a sheet of glass | |

| EP0190448A1 (en) | Process for reducing residual stress of roller-straightened steel rails | |

| EP0416356A2 (en) | Device for producing steel strip | |

| DE3744044A1 (en) | METHOD FOR THE HEAT TREATMENT OF THE WELDING SEAM ON LONG-WELDED METAL TUBES AND DEVICE FOR CARRYING OUT THE METHOD | |

| DE4218099A1 (en) | METHOD FOR PRODUCING A SKI EDGE | |

| EP3862710B1 (en) | Furnace for partial heating of metal components | |

| DE3016259C2 (en) | Process for multi-layer arc welding of ferritic, tempered steels and for the subsequent heat treatment of the welding point and device for carrying out the process | |

| AT18135U1 (en) | Method and a device for welding passable components of a track using flash butt welding | |

| DE4421238A1 (en) | Process for the production of wear-resistant, rotatingly moving wire, rope and / or wire rope contact surfaces, in particular surfaces of wire drawing drums from wire drawing machines or similar transport rollers or drums | |

| DE662453C (en) | Annealing process to prepare hard-braked steel rail wheels for turning off the flattened wheel tread | |

| AT248202B (en) | Method and device for the heat treatment of rail connection and surfacing welds | |

| DE929971C (en) | Method for hardening rail ends | |

| DE655383C (en) | Device for the heat treatment of welding, flame cutting and the like. The like. Zones of workpieces that have changed in their structure or are partially subject to tension | |

| DE2940826A1 (en) | Deep hardening of workpieces, esp. railway rails - where brief surface quenching and controlled cooling produces fine sorbite structure with high wear resistance | |

| DE605738C (en) | Plant for the remuneration of chains |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH DE FR GB IT LI LU NL SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH DE FR GB IT LI LU NL SE |

|

| 17P | Request for examination filed |

Effective date: 19870813 |

|

| 17Q | First examination report despatched |

Effective date: 19880915 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE FR GB IT LI LU NL SE |

|

| REF | Corresponds to: |

Ref document number: 51036 Country of ref document: AT Date of ref document: 19900315 Kind code of ref document: T |

|

| ITF | It: translation for a ep patent filed | ||

| REF | Corresponds to: |

Ref document number: 3669538 Country of ref document: DE Date of ref document: 19900419 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) | ||

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| ITPR | It: changes in ownership of a european patent |

Owner name: CESSIONE;VOEST - ALPINE EISENBAHNSYSTEME GESELLSCH |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: 732 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PUE Owner name: VOEST-ALPINE EISENBAHNSYSTEME GESELLSCHAFT M.B.H. |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: TP |

|

| NLS | Nl: assignments of ep-patents |

Owner name: VOEST-ALPINE EISENBAHNSYSTEME GESELLSCHAFT M.B.H. |

|

| BECA | Be: change of holder's address |

Free format text: 920331 *VOEST-ALPINE EISENBAHNSYSTEME G.M.B.H.:FLORAGASSE 7, 1040 WIEN |

|

| ITTA | It: last paid annual fee | ||

| EPTA | Lu: last paid annual fee | ||

| EAL | Se: european patent in force in sweden |

Ref document number: 86890076.2 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 19960219 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19960222 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19960223 Year of fee payment: 11 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19970325 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19971001 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 19971001 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19971202 |

|

| EUG | Se: european patent has lapsed |

Ref document number: 86890076.2 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19980213 Year of fee payment: 13 Ref country code: FR Payment date: 19980213 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 19980223 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 19980224 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: LU Payment date: 19980303 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 19980320 Year of fee payment: 13 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19990324 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19990324 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19990324 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19990331 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19990331 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19990331 |

|

| BERE | Be: lapsed |

Owner name: VOEST-ALPINE EISENBAHNSYSTEME G.M.B.H. Effective date: 19990331 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19990324 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19991130 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20050324 |