EP0197449B1 - Piston à plusieurs parties pour une machine à combustion interne - Google Patents

Piston à plusieurs parties pour une machine à combustion interne Download PDFInfo

- Publication number

- EP0197449B1 EP0197449B1 EP86104232A EP86104232A EP0197449B1 EP 0197449 B1 EP0197449 B1 EP 0197449B1 EP 86104232 A EP86104232 A EP 86104232A EP 86104232 A EP86104232 A EP 86104232A EP 0197449 B1 EP0197449 B1 EP 0197449B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- piston

- head

- skirt

- centering

- end cover

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000002485 combustion reaction Methods 0.000 title claims abstract description 8

- 229910001092 metal group alloy Inorganic materials 0.000 claims abstract 3

- 239000002184 metal Substances 0.000 claims abstract 2

- 229910010293 ceramic material Inorganic materials 0.000 claims description 8

- 239000000463 material Substances 0.000 claims description 7

- 230000007704 transition Effects 0.000 claims description 3

- 229910000838 Al alloy Inorganic materials 0.000 claims 1

- 229910052751 metal Inorganic materials 0.000 claims 1

- 239000000919 ceramic Substances 0.000 abstract description 10

- 229910010271 silicon carbide Inorganic materials 0.000 description 6

- HBMJWWWQQXIZIP-UHFFFAOYSA-N silicon carbide Chemical compound [Si+]#[C-] HBMJWWWQQXIZIP-UHFFFAOYSA-N 0.000 description 5

- 238000010276 construction Methods 0.000 description 3

- 229910052581 Si3N4 Inorganic materials 0.000 description 2

- 239000007769 metal material Substances 0.000 description 2

- RVTZCBVAJQQJTK-UHFFFAOYSA-N oxygen(2-);zirconium(4+) Chemical compound [O-2].[O-2].[Zr+4] RVTZCBVAJQQJTK-UHFFFAOYSA-N 0.000 description 2

- HQVNEWCFYHHQES-UHFFFAOYSA-N silicon nitride Chemical compound N12[Si]34N5[Si]62N3[Si]51N64 HQVNEWCFYHHQES-UHFFFAOYSA-N 0.000 description 2

- 229910001928 zirconium oxide Inorganic materials 0.000 description 2

- 229910000505 Al2TiO5 Inorganic materials 0.000 description 1

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 1

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical compound [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 description 1

- 229910000831 Steel Inorganic materials 0.000 description 1

- 230000001133 acceleration Effects 0.000 description 1

- 238000005452 bending Methods 0.000 description 1

- 229910002804 graphite Inorganic materials 0.000 description 1

- 239000010439 graphite Substances 0.000 description 1

- 229910003474 graphite-silicon composite material Inorganic materials 0.000 description 1

- 238000000462 isostatic pressing Methods 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- AABBHSMFGKYLKE-SNAWJCMRSA-N propan-2-yl (e)-but-2-enoate Chemical compound C\C=C\C(=O)OC(C)C AABBHSMFGKYLKE-SNAWJCMRSA-N 0.000 description 1

- 229910052710 silicon Inorganic materials 0.000 description 1

- 239000010703 silicon Substances 0.000 description 1

- 230000003068 static effect Effects 0.000 description 1

- 239000010959 steel Substances 0.000 description 1

- 230000035882 stress Effects 0.000 description 1

- 230000001360 synchronised effect Effects 0.000 description 1

- 230000008646 thermal stress Effects 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02F—CYLINDERS, PISTONS OR CASINGS, FOR COMBUSTION ENGINES; ARRANGEMENTS OF SEALINGS IN COMBUSTION ENGINES

- F02F3/00—Pistons

- F02F3/0015—Multi-part pistons

- F02F3/0023—Multi-part pistons the parts being bolted or screwed together

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05C—INDEXING SCHEME RELATING TO MATERIALS, MATERIAL PROPERTIES OR MATERIAL CHARACTERISTICS FOR MACHINES, ENGINES OR PUMPS OTHER THAN NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES

- F05C2201/00—Metals

- F05C2201/02—Light metals

- F05C2201/021—Aluminium

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05C—INDEXING SCHEME RELATING TO MATERIALS, MATERIAL PROPERTIES OR MATERIAL CHARACTERISTICS FOR MACHINES, ENGINES OR PUMPS OTHER THAN NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES

- F05C2201/00—Metals

- F05C2201/04—Heavy metals

- F05C2201/0433—Iron group; Ferrous alloys, e.g. steel

- F05C2201/0448—Steel

Definitions

- the invention relates to a multi-part reciprocating piston for internal combustion engines as described and shown, for example, in DE-A-3218320.

- DE-A-3218320 describes a reciprocating piston with a piston ring which is connected to the associated piston rod by means of an expansion screw. Piston shirt, piston skirt, piston crown, top land are made in one piece.

- the reciprocating piston is used in internal combustion engines in which the translational movement of a piston is converted into a rotational movement by a crank-loop drive, in particular in which two pistons lie opposite one another.

- Reciprocating pistons of internal combustion engines composed of several individual parts are known in many embodiments in so-called large engine construction.

- the multi-part piston has been used there for a long time. The reasons lie in the various loads to which the motor piston is exposed.

- the piston crown with its top land is exposed to alternating thermal stresses and static pressures.

- the piston is generally subjected to high dynamic acceleration and deceleration forces.

- the piston shirt is subject to great bending forces due to the high normal pressures.

- the object of the invention is therefore to be seen in aligning the multiple parts of a reciprocating piston in such a way that the assembly or arrangement of a piston ring made of ceramic material in its intended annular groove in the top land of the piston crown, i.e. a piston ring, which is made of the material cannot be expanded without breaking, is easily possible.

- the designed multi-part design should meet the requirements placed on such a piston with regard to thermal and dynamic resilience and improve its running properties and service life.

- the construction of the reciprocating piston according to the invention allows the piston ring to be arranged in the annular groove provided in the top land of the piston crown without further ado before the assembly of its main parts.

- the piston shirt made of ceramic material and the piston head made of ceramic material with the top land result in good sliding properties and a long service life.

- the centering piece made of metallic material with the base plate and the upper end cover with the centering hub made of the same material not only center the reciprocating piston on the end of the piston rod but also guarantee a secure clamping of the main parts of the piston, since the elasticity of the metallic material can withstand the changing permanent loads that occur.

- the large amount of heat accumulating on the piston crown during the combustion process is rapidly dissipated to the piston rod by heat flow, so that heat build-up in the piston is avoided.

- the reciprocating piston according to the invention is particularly suitable for internal combustion engines in which the translational movement of two opposite, synchronous pistons is converted into rotation by a crank-loop drive, and both pistons are rigid with the associated piston rod, as described and illustrated, for example, in DE-C-920 758 .

- piston design according to the invention and the piston arrangement described can also be used in piston machines in which the normal pressures of the thrust crank mechanism are absorbed by a crosshead slide, as a result of which the piston skirt is relieved.

- piston engines have been proposed, for example, as so-called bio-gas engines.

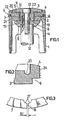

- the reciprocating piston consists essentially of a piston skirt 1 with a piston skirt 2, a piston skirt 3 with a top land 4, a centering sleeve 5 for radially fixing the two aforementioned main piston parts 1, and 3, 4, one in an annular groove 6 of the Top land 4 piston ring 7, a centering piece 8 with base plate 9 and from an end cover 10 with centering hub 11.

- a piston rod is designated, at each end of which there is a reciprocating piston (the second reciprocating piston is not shown), both of which are rigidly connected to the piston rod 12. This is done, for example, by a cap screw (13) which is screwed into the piston rod 12.

- the radial fixation of the reciprocating piston with respect to the piston rod 12 takes place by a snug fit 14 of the base plate 9 on the piston rod 12.

- the base plate 9 fixes with the help of their centering piece 8, the centering hub 11 of the end cover 10.

- the two parts 8, 9 and 10, 11 are secured against rotation by a dowel pin 15 which protrudes with its inner end into the piston rod 12.

- the dowel pin 15 also forms a fuse for the cap screw 13.

- the piston skirt 1 with the piston skirt 2, the piston skirt 3 with the top land 4, the resilient piston ring 7, which has an expansion slot 16, and the centering sleeve 5 are all made of a ceramic material which is thermally highly resilient and has good sliding properties .

- the piston ring 7 is provided with an arc-shaped rounded portion 17 for the arrangement of a torsion pin 18 which prevents the piston ring 7 from moving.

- a groove 19 is provided on the inner wall.

- a fillet 20 is incorporated on the piston crown 3 to avoid notch stresses.

- the top land 4 can be provided radially on the outside with a labyrinth seal in the form of rotational grooves 24 (FIG. 2).

- Piston shirt, piston ring and piston crown are made of ceramic.

- Shaped bodies made of silicon nitride and silicon carbide can be produced using the isostatic pressing process.

- the piston crown can also be made from aluminum titanate.

- piston skirt (1) and piston crown (3) are made of the same material, or if (1) (3), piston ring (7) and centering sleeve (5) are made of the same material.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Pistons, Piston Rings, And Cylinders (AREA)

Claims (7)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT86104232T ATE53893T1 (de) | 1985-04-04 | 1986-03-27 | Mehrteiliger hubkolben fuer brennkraftmaschinen. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE8510204U | 1985-04-04 | ||

| DE8510204U DE8510204U1 (de) | 1985-04-04 | 1985-04-04 | Mehrteiliger Hubkolben für Brennkraftmaschinen |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0197449A2 EP0197449A2 (fr) | 1986-10-15 |

| EP0197449A3 EP0197449A3 (en) | 1987-11-25 |

| EP0197449B1 true EP0197449B1 (fr) | 1990-05-02 |

Family

ID=6779583

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP86104232A Expired - Lifetime EP0197449B1 (fr) | 1985-04-04 | 1986-03-27 | Piston à plusieurs parties pour une machine à combustion interne |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US4751871A (fr) |

| EP (1) | EP0197449B1 (fr) |

| JP (1) | JPS61232366A (fr) |

| AT (1) | ATE53893T1 (fr) |

| CA (1) | CA1272645A (fr) |

| DE (2) | DE8510204U1 (fr) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102011009094A1 (de) | 2011-01-21 | 2012-07-26 | Bertwin Geist | Hubkolben für eine Hubkolbenmaschine sowie Hubkolbenmaschine, sowie Zylinder einer Hubkolbenmaschine |

Families Citing this family (18)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4833977A (en) * | 1986-05-07 | 1989-05-30 | Volkswagen Ag | Piston for internal combustion engine |

| US4955284A (en) * | 1989-02-27 | 1990-09-11 | Ingersoll-Rand Company | Piston having ceramic parts |

| US4920864A (en) * | 1989-04-14 | 1990-05-01 | Jpi Transportation Products, Inc. | Reinforced piston |

| US5076150A (en) * | 1990-05-04 | 1991-12-31 | Dresser-Rand Company | Piston assembly with wear resistant piston ring lands |

| GB2246833B (en) * | 1990-06-23 | 1994-05-25 | T & N Technology Ltd | Pistons for engines or motors |

| DE4301860A1 (de) * | 1993-01-25 | 1994-09-22 | Stefan Dipl Phys Stock | Spezialkolben für Kolbenmaschinen |

| US5375567A (en) * | 1993-08-27 | 1994-12-27 | Lowi, Jr.; Alvin | Adiabatic, two-stroke cycle engine |

| US6044819A (en) * | 1996-03-06 | 2000-04-04 | The United States Of America As Represented By The Administrator Of The National Aeronautics And Space Administration | Pistons and cylinders made of carbon-carbon composite materials |

| US5713333A (en) * | 1996-10-21 | 1998-02-03 | Cummins Engine Company, Inc. | Wear-resistant fuel distributor rotor |

| JPH10292868A (ja) * | 1997-04-18 | 1998-11-04 | Honda Motor Co Ltd | 液体ポンプの軸封機構 |

| US20080289488A1 (en) | 1999-04-01 | 2008-11-27 | Peter Robert Raffaele | Reciprocating fluid machines |

| US6076506A (en) * | 1998-05-20 | 2000-06-20 | Caterpillar Inc. | Piston for use in an engine |

| AUPR459501A0 (en) * | 2001-04-27 | 2001-05-24 | Raffaele, Michael John | Improvements in engines and components |

| DE102004018714B4 (de) * | 2004-04-17 | 2013-04-25 | Dr. Ing. H.C. F. Porsche Aktiengesellschaft | Verfahren zur Herstellung eines Kolbens |

| DE102004018712B4 (de) * | 2004-04-17 | 2013-04-25 | Dr. Ing. H.C. F. Porsche Aktiengesellschaft | Kolben für eine Brennkraftmaschine |

| EP1911952B1 (fr) * | 2006-10-11 | 2017-11-22 | Nissan Motor Co., Ltd. | Moteur à combustion interne |

| EP2111549A1 (fr) * | 2007-02-14 | 2009-10-28 | Agilent Technologies, Inc. | Appareil de pompage chlp ayant une chambre de piston et/ou de travail en carbure de silicium |

| JP7313505B1 (ja) * | 2022-03-28 | 2023-07-24 | Tpr株式会社 | ピストンユニット、トップランド部材、及びピストンユニット用部品の組合せ |

Family Cites Families (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE463748C (de) * | 1928-08-03 | Werke Kiel Akt Ges Deutsche | Mit Kuehleinsatz versehener Kolben fuer Brennkraftmaschinen | |

| GB119183A (en) * | 1918-02-11 | 1918-09-26 | Alphonse Soetens | Improvements in or relating to Pistons. |

| US1668672A (en) * | 1927-04-01 | 1928-05-08 | Charles W Darrah | Piston |

| US1956355A (en) * | 1931-02-18 | 1934-04-24 | Junkers Hugo | Internal combustion engine |

| US1963725A (en) * | 1933-09-08 | 1934-06-19 | Perfect Circle Co | Piston and piston ring |

| US2105950A (en) * | 1936-03-07 | 1938-01-18 | Ingersoll Rand Co | Piston |

| US2471477A (en) * | 1946-03-08 | 1949-05-31 | Air Liquide | Piston packing |

| US2657961A (en) * | 1950-03-15 | 1953-11-03 | Maschf Augsburg Nuernberg Ag | Piston for internal-combustion engines |

| DE920758C (de) * | 1951-12-21 | 1954-11-29 | Heinz Boerner | Zweitaktbrennkraftmaschine |

| US3136306A (en) * | 1961-04-20 | 1964-06-09 | Stevens Inst Technology | Piston for a high performance internal combustion engine |

| DE2212922B2 (de) * | 1972-03-17 | 1976-02-05 | Karl Schmidt Gmbh, 7107 Neckarsulm | Gebauter kolben fuer verbrennungskraftmaschinen |

| GB1439328A (en) * | 1972-07-28 | 1976-06-16 | Wellworthy Ltd | Pistons and piston rings |

| US4242948A (en) * | 1977-12-16 | 1981-01-06 | Cummins Engine Company, Inc. | Insulated composite piston |

| US4404935A (en) * | 1981-04-27 | 1983-09-20 | Kyocera International, Inc. | Ceramic capped piston |

| DE3363676D1 (en) * | 1982-03-05 | 1986-07-03 | Feldmuehle Ag | Positive displacement member of a piston pump |

| DE3218320A1 (de) * | 1982-05-14 | 1983-11-17 | Ficht GmbH, 8011 Kirchseeon | Vorrichtung zum loesbaren befestigen der kolben an den kolbenstangen einer brennkraftmaschine |

| DE3301913C2 (de) * | 1983-01-21 | 1985-05-09 | Feldmühle AG, 4000 Düsseldorf | Kolbenring für eine Brennkraftmaschine |

-

1985

- 1985-04-04 DE DE8510204U patent/DE8510204U1/de not_active Expired

-

1986

- 1986-03-19 US US06/841,307 patent/US4751871A/en not_active Expired - Fee Related

- 1986-03-27 AT AT86104232T patent/ATE53893T1/de not_active IP Right Cessation

- 1986-03-27 DE DE8686104232T patent/DE3670885D1/de not_active Expired - Fee Related

- 1986-03-27 EP EP86104232A patent/EP0197449B1/fr not_active Expired - Lifetime

- 1986-04-03 CA CA000505741A patent/CA1272645A/fr not_active Expired - Fee Related

- 1986-04-03 JP JP61075683A patent/JPS61232366A/ja active Granted

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102011009094A1 (de) | 2011-01-21 | 2012-07-26 | Bertwin Geist | Hubkolben für eine Hubkolbenmaschine sowie Hubkolbenmaschine, sowie Zylinder einer Hubkolbenmaschine |

| WO2012097893A1 (fr) | 2011-01-21 | 2012-07-26 | Geist, Bertwin | Piston alternatif pour moteur à piston alternatif, et moteur à piston alternatif, et cylindre d'un moteur à piston alternatif |

Also Published As

| Publication number | Publication date |

|---|---|

| US4751871A (en) | 1988-06-21 |

| ATE53893T1 (de) | 1990-06-15 |

| EP0197449A3 (en) | 1987-11-25 |

| DE8510204U1 (de) | 1985-07-11 |

| EP0197449A2 (fr) | 1986-10-15 |

| CA1272645A (fr) | 1990-08-14 |

| DE3670885D1 (de) | 1990-06-07 |

| JPH0587672B2 (fr) | 1993-12-17 |

| JPS61232366A (ja) | 1986-10-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0197449B1 (fr) | Piston à plusieurs parties pour une machine à combustion interne | |

| DE3506069C2 (fr) | ||

| DE68910934T2 (de) | Kolben. | |

| CA1222389A (fr) | Fixation d'un premier organe mecanique dans l'alesage d'un second | |

| DE68919074T2 (de) | Maschinenkolbenzusammenbau und dessen geschmiedeter kolben mit kühlraum. | |

| EP0222260B1 (fr) | Moteur à combustion interne | |

| EP0007661B1 (fr) | Assemblage de piston de moteur à combustion interne comportant des moyens de refroidissement liquide | |

| DE2307347A1 (de) | Mehrteiliger tauchkolben fuer viertaktbrennkraftmaschinen, insbesondere grossdieselmotoren | |

| DE3134768A1 (de) | "kolbenzylinderaggregat fuer brennkraftkolbenmaschinen, insbesondere fuer otto- und dieselmotoren" | |

| DE69319708T2 (de) | Mechanisch verbundenes verschleissfestes keramisches teil | |

| DE3611165C2 (fr) | ||

| EP0356457A1 (fr) | Piston plongeur en metal leger pour moteurs a combustion interne. | |

| EP1636474B1 (fr) | Procede de production d'un piston monobloc pour un moteur a combustion | |

| DE3249290T1 (de) | Zusammengesetzter kolben | |

| DE2644661A1 (de) | Kolben | |

| DE2522263C2 (de) | Kolbenringartige Segmentdichtung | |

| EP0166109B1 (fr) | Piston à plusieurs parties pour un moteur à combustion interne | |

| DE60006079T2 (de) | Freikolbenbrennkraftmaschine mit kolbenkopf und radial bewegbare kappe | |

| DE3101462C2 (de) | Mehrzylindrige Brennkraftmaschine, insbesondere Dieselmotor, mit einem Hubkolbentriebwerk | |

| EP1875977A1 (fr) | Liaison de canal de refroidissement à poutre ceinture | |

| DE3214093A1 (de) | Kolben fuer verbrennungskraftmaschinen mit einem seine brennraumnahen wandteile abdeckenden einsatz | |

| DE2410140A1 (de) | Leichtmetallkolben fuer brennkraftmaschinen | |

| DE2812416C2 (de) | Zylindertrommel für eine Axialkolbenmaschine | |

| DE3110292A1 (de) | "kolben fuer verbrennungsmotor" | |

| DE2107611A1 (de) | Brennkraftmaschine |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT DE FR GB IT |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT DE FR GB IT |

|

| 17P | Request for examination filed |

Effective date: 19880220 |

|

| 17Q | First examination report despatched |

Effective date: 19890210 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT DE FR GB IT |

|

| REF | Corresponds to: |

Ref document number: 53893 Country of ref document: AT Date of ref document: 19900615 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 3670885 Country of ref document: DE Date of ref document: 19900607 |

|

| ITF | It: translation for a ep patent filed | ||

| ET | Fr: translation filed | ||

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| ITTA | It: last paid annual fee | ||

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19940518 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19950210 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19950214 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 19950223 Year of fee payment: 10 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19951201 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19960327 Ref country code: AT Effective date: 19960327 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19960327 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19961129 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20050327 |