EP0191908B1 - Supporting wall - Google Patents

Supporting wall Download PDFInfo

- Publication number

- EP0191908B1 EP0191908B1 EP85114011A EP85114011A EP0191908B1 EP 0191908 B1 EP0191908 B1 EP 0191908B1 EP 85114011 A EP85114011 A EP 85114011A EP 85114011 A EP85114011 A EP 85114011A EP 0191908 B1 EP0191908 B1 EP 0191908B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- retaining wall

- shaped blocks

- shaped

- another

- wall according

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 230000003068 static effect Effects 0.000 claims description 14

- 230000001154 acute effect Effects 0.000 claims description 3

- 230000015572 biosynthetic process Effects 0.000 claims description 2

- 239000004575 stone Substances 0.000 description 30

- 239000002689 soil Substances 0.000 description 8

- 238000010276 construction Methods 0.000 description 5

- 238000006073 displacement reaction Methods 0.000 description 3

- 230000007704 transition Effects 0.000 description 3

- 230000000694 effects Effects 0.000 description 2

- 230000002349 favourable effect Effects 0.000 description 2

- 230000005484 gravity Effects 0.000 description 2

- 238000010521 absorption reaction Methods 0.000 description 1

- 239000011449 brick Substances 0.000 description 1

- 238000005034 decoration Methods 0.000 description 1

- 238000001035 drying Methods 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 230000002787 reinforcement Effects 0.000 description 1

- 230000000630 rising effect Effects 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E02—HYDRAULIC ENGINEERING; FOUNDATIONS; SOIL SHIFTING

- E02D—FOUNDATIONS; EXCAVATIONS; EMBANKMENTS; UNDERGROUND OR UNDERWATER STRUCTURES

- E02D29/00—Independent underground or underwater structures; Retaining walls

- E02D29/02—Retaining or protecting walls

- E02D29/025—Retaining or protecting walls made up of similar modular elements stacked without mortar

Definitions

- the invention relates to a retaining wall which is inclined relative to the vertical against a backfill of the soil and is made of shaped blocks of concrete arranged one above the other, the upper and lower sides of which are in positive engagement with each other and each have a projection or projection formed by step-like mutually offset bearing surfaces extending in parallel planes. have a correspondingly formed depression.

- Such a retaining wall is known from the publication "STOTTMURER AV BETONPRODUK-TER", Norges Betonindustriforbund, April 1981, p. 5 below. There, however, only one projection or only one reinforcement is provided on each top and bottom of a shaped block. From the same publication, but p. 6 above, a retaining wall is known with shaped stones, in which not all of the support surfaces extend parallel to one another, but whose support surfaces increase in distance from the imaginary central transverse planes of each shaped stone on its top side on the earth side and on its underside on the earth side lose weight.

- the object of the present invention is to create a retaining wall with large construction heights with the same size of the shaped blocks with great centering accuracy.

- the retaining wall according to the invention consists of shaped stones with three support surfaces which are staggered with respect to one another on the top and bottom, all of which run parallel to one another.

- shaped blocks arranged one above the other are centered twice within the retaining wall. Angling the stones when building the retaining wall is almost impossible. This is particularly due to the fact that the middle bearing surfaces are larger than the other bearing surfaces and the shoulders formed consequently have a certain minimum distance from one another.

- the further provided relative arrangement of the support surfaces to each other and to a central transverse plane of the shaped brick makes it possible to build the retaining wall in such a way that, in layers lying one above the other, several stones are arranged adjacent to one another transversely to the longitudinal extension of the retaining wall, the stones of the upper layer being opposite the stones of the lower layer are offset transversely to the longitudinal direction of the retaining wall and are still in positive engagement.

- the mutually offset bearing surfaces of the shaped blocks are connected to one another by an obliquely directed stop surface which drops towards the air side.

- this results in an enlargement of the statically effective bearing surface and is also maintained with slight relative displacements of the shaped blocks with respect to one another.

- Such slight relative displacements are often unavoidable in practice when installing the shaped blocks, i.e. when the retaining wall is put on.

- the support surfaces run right up to the front and back of the molded blocks, there is a statically effective support width that is only slightly smaller than the length of the molded block (dimension transverse to the longitudinal extension of the supporting wall).

- the static axis of a shaped stone or the retaining wall formed from it runs through the center of the support width.

- the support surfaces of the shaped stones are arranged at an oblique angle to the static axis, an obtuse angle being formed on the earth side and an acute angle on the air side relative to the static axis.

- the shaped blocks can be installed in the heavyweight retaining wall according to the invention in layers reversed with respect to the earth and air side.

- the formation of retaining walls with a graduated width or depth by arranging two or more shaped blocks in the direction transverse to the longitudinal extension of the retaining walls next to one another is particularly advantageous.

- the form stones that are adjacent in height are offset from one another and with mutual positive engagement with one another (toothing).

- the shaped blocks of the retaining wall are provided on the earth side and on the air side with head parts adjoining a support part formed by the support surfaces, which can be designed in a corresponding (different) manner for decoration, for better sound absorption or for interlocking with the ground.

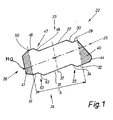

- the exemplary embodiments of shaped blocks shown in the drawings are used to manufacture retaining walls, namely heavy-weight drying retaining walls 20 with one-sided soil backfill 21.

- the retaining wall 20 is inclined towards the soil backfill Level arranged.

- the angle of the retaining wall 20 with respect to the horizontal is preferably between 60 ° and 70 °.

- shaped blocks 22 shown in the drawings form an upper side 23, an underside 24, an air-side end face 25 and a rear side 26 facing the soil backfill 21.

- Upper side 23 and underside 24 are designed to correspond to one another in all embodiments, in such a way that a appropriate, form-fitting superimposition of the shaped blocks 22 is ensured within the retaining wall 20.

- the top 23 and bottom 24 each consist of at least three bearing surfaces 27, 28 and 46 or 31, 32 and 51, which extend in mutually offset planes and always run parallel to one another.

- the bearing surface 28 facing the air side is offset from the ground-side bearing surface 27 downward - in the case of a horizontally lying molded block - to form a shoulder 29 with an inclined bearing surface 30 in the present case. This is sloping towards the air side, for example at an angle of approximately 45 ° to the two support surfaces 27 and 28.

- an earth-side support surface 31 and an air-side support surface 32 are also formed on the underside 24, which are also directed parallel to one another and parallel to the upper support surfaces 27, 28.

- the air-side bearing surface 32 is offset downwards in the same way, forming a shoulder 33, which is formed by an oblique stop surface 34.

- the shoulders with abutment surfaces on the top 23 and underside 24 give rise to depressions and recesses in the area of the superimposed surfaces of the shaped blocks 22, which interlock in a form-fitting and self-centering manner.

- the bearing surfaces 27, 28 and 46, as well as the stop surfaces 30 and 48 rest against the associated bearing surfaces 31, 32 and 51 or the stop surfaces 34 and 52 of the adjacent shaped stone.

- the support width b is decisive for the load capacity or permissible construction height of the retaining wall 20.

- a static axis 37 of the shaped block or the retaining wall extends in the middle of the support width b.

- the shaped blocks 22 are designed such that the static axis 37 is directed at an oblique angle to the upper and lower bearing surfaces 27 and 31, respectively, in such a way that an acute angle on the upper side of the shaped block 22 faces the air side is.

- the retaining wall 20 is preferably arranged inclined to the soil backfill 21 in an angular range of 60 ° to 70 ° of the static axis 37. The result of this is that the bearing surfaces 27, 28 and 46 and 31, 32 and 51 always slope downward to the soil backfill 21, while the stop surfaces 30, 34 and 48, 52 also extend downwards towards the air side. As a result, the aforementioned surfaces have a self-centering effect for the shaped stones 22 arranged one above the other.

- the support width b of the shaped blocks 22 or the retaining wall 20 as a whole is of particular importance statically.

- a force-resultant R resulting from the dead weight of the retaining wall 20 and the earth pressure due to the soil backfill 21 must run due to static regulations within a core cross section 38 or 39 de retaining wall 20, in each case in the area of the lower shaped stones 22.

- This static relevant core cross-section 38, 39 is 1/6 of the support width B. It extends centrally, that is to say with the same dimensions, on both sides of the static axis 37.

- a large support width b results in a correspondingly large core cross-section 38 or 39.

- the retaining wall 20 can have a correspondingly larger construction height.

- the shaped blocks 22 have more than two bearing surfaces and shoulders on the top 23 and bottom 24.

- a third bearing surface 46 is formed on the ground side, which extends according to the design principle of the shaped blocks in a horizontal position of the same at a higher level than the adjacent (larger) bearing surface 27.

- a shoulder 47 is formed with an obliquely directed stop surface 48

- an extension 41 which is trapezoidal in cross section, so that the bearing surface 46 is part of an edge-side projection 50 which is trapezoidal in cross section.

- a corresponding support surface 51 with stop surface 52 is formed on the underside, that is to say also with a shoulder 53.

- the top and bottom are correspondingly cascaded, rising on the top 23 toward the earth side.

- the middle bearing surface 27, 31 is large in relation to the approximately equally large bearing surfaces 28 and 46 or 32 and 51.

- the end face 25 consists of a head 40 with a triangular cross section with a lower round edge 44.

- the lower plane of the head 40 extends in extension of the support surface 32, but is not an effective component of the same, since the head 40 is outside the support width b lies.

- the cross-sectional areas of head 40 and shoulder 41 are of equal size, so that the statically interesting center of gravity S lies in the area of the static axis 37.

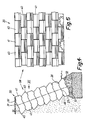

- Fig. 2 shows a shaped block 22 with mirror-symmetrical design such that the shaped blocks laid regardless of the front and back can be, since both sides are designed to match, in the present case arched, that is crowned.

- the shaped block is provided with three bearing surfaces 27, 28, 31, 32 and 46 and 51 on the top and bottom.

- the bearing surfaces 46 and 51 facing the soil backfill 21 have the same size as the air-side bearing surfaces 28 and 32.

- the height of the shoulders 29, 33, 47, 53 is also the same, so that a twisted laying of the shaped blocks by 180 ° within the Retaining wall 20 is possible.

- the center of gravity S lies on the static axis 37 in this same-sided design.

- the arrangement of always parallel support surfaces and, as in the exemplary embodiment shown, of stop surfaces arranged parallel to one another has the effect that even with slight relative displacements of the shaped blocks with respect to one another, as cannot be completely ruled out in practice when the retaining wall is erected, the effective support width b does not is changed in a noticeable way. There is only a gap of one or a few millimeters in the area of the heel 29 or 33. The stable, structurally perfect storage of the shaped stone is still preserved.

- FIG. 3 shows a shaped block 22 which corresponds in principle to the design according to FIG. 2.

- the front side and / or the rear side - in the exemplary embodiment shown the rear side 26 - are provided with a structured surface. These are grooves 64 which run in the longitudinal direction or horizontally and have an essentially trapezoidal cross section. These are separated from one another by appropriately designed ribs 65.

- Retaining walls of different external appearance can be formed from a shaped block 22 designed in this way, using only one type of shaped blocks (FIG. 3), and in fact by alternately laying the shaped blocks with the structured surfaces on the air side or on the earth side.

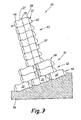

- Fig. 6 shows a retaining wall 20 with a variable effective cross section.

- a wall base 61 consists of a plurality of layers 43 of shaped stones 22 lying next to one another transversely to the longitudinal extension of the retaining wall 20, specifically in the embodiment with a third bearing surface 46 on the upper side, as in the exemplary embodiment in FIG. 1 or FIG. 2 and 3.

- the (smooth) backsides 26 face each other within the layers 43. This results in the area of the wall base 61 or a lower foundation layer 62, a support width b 2 , which results from the support surfaces of the two adjacent form stones 22 of the foundation layer 62.

- the stacked shaped blocks 22 are also in a mutual, positive engagement by the projections 50 on the one hand and by the shoulder 53 arranged opposite.

- the arrangement is such that the molded blocks on the opposite side are each reversed with respect to the top 23 and bottom 24. This results in a meandering interlocking of the stacked and adjacent stones in the area of a vertical central plane.

- Two adjacent shaped blocks of a layer 58 or 62 form a depression into which a projection 50 fits.

- the wall base 61 there is an upper wall part 63 made of layers 58, each with a shaped stone in the direction perpendicular to the level of the retaining wall 20.

- a statically favorable namely relatively wide core cross section 38 or 39 given.

- the lower molded block 22 of the upper wall part 63 is supported with the lower stop surface 34 on the upper stop surface 48 of the front molded block of the wall base 61. As a result, there is also a self-centering relative position of the shaped stones in this area.

- the number of layers 58 and 62 in the area of the wall base 61 is selected such that the lower core cross-section 39 is used on the basis of the specifications of the upper core cross-section 38 and the direction of the resultant R.

- the base layer 62 in this embodiment consists of three shaped stones 22 adjoining one another in the direction perpendicular to the plane of the retaining wall 20.

- the shaped stones in the sense of the embodiment of FIG Fig. 1 and the relative arrangement of the same also creates a self-centering support in the region of the transition from the upper wall part 63 to the wall base 61 and the layer 58 consisting of two shaped stones to the foundation layer 62.

- this retaining wall 20 made of shaped stones of the preferred embodiment of FIG. 1, there is an optimal interlocking interlocking of shaped stones in the area of the respective cross-sectional widening of the retaining wall, i.e. in the area of the lower layer 58 to the upper layer 43 and from the lower layer 43 to the foundation layer 62.

- Two shaped stones of one layer (here layer 43) are covered by a staggered shaped stone of an adjacent layer (here: layer 58 on the one hand and foundation layer 62 on the other hand), with engagement of the shoulders and depressions as a result of the cascade-shaped design.

- Such a wall is highly resilient or can be constructed with a large construction height.

- the shaped blocks can have any suitable or meaningful dimension.

- the total length of the shaped stone from the end face 25 to the rear side 26 is approximately 30 cm.

- the height of such a shaped block that is to say the distance between the support surfaces 27 and 31 from one another, is approximately 15 cm, for example.

- the shoulders, that is to say the distance between the parallel support surfaces, is 2.5 cm in one exemplary embodiment.

- the width of the small support surfaces 28, 32 ... is favorable at about 3.5 cm.

- the central transverse plane parallel to the larger bearing surfaces is referred to as the MQ (see e.g. Figures 1 and 2).

Landscapes

- Engineering & Computer Science (AREA)

- Environmental & Geological Engineering (AREA)

- Life Sciences & Earth Sciences (AREA)

- General Life Sciences & Earth Sciences (AREA)

- Mining & Mineral Resources (AREA)

- Paleontology (AREA)

- Civil Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Structural Engineering (AREA)

- Retaining Walls (AREA)

- Revetment (AREA)

- Materials For Medical Uses (AREA)

Description

Die Erfindung betrifft eine genenüber der Lotrechten gegen eine Erdreich-Hinterfüllung geneigte Stützmauer aus lagenweise übereinander angeordneten Formsteinen aus Beton, deren Ober- und Unterseiten miteinander in formschlüssigem Eingriff stehen und jeweils einen durch stufenartig gegeneinander versetzte, in parallelen Ebenen sich erstreckende Auflagerflächen gebildeten Vorsprung bzw. eine entsprechend gebildete Vertiefung aufweisen.The invention relates to a retaining wall which is inclined relative to the vertical against a backfill of the soil and is made of shaped blocks of concrete arranged one above the other, the upper and lower sides of which are in positive engagement with each other and each have a projection or projection formed by step-like mutually offset bearing surfaces extending in parallel planes. have a correspondingly formed depression.

Eine derartige Stützmauer ist bekannt aus der Druckschrift "STOTTMURER AV BETONPRODUK-TER", Norges Betonindustriforbund, April 1981, S. 5 unten. Dort ist jedoch an jeder Ober- bzw. Unterseite eines Formsteins nur ein Vorsprung bzw. nur eine Vertifung vorgesehen. Aus derselben Druckschrift, jedoch S. 6 oben, ist eine Stützmauer bekannt mit Formsteinen, bei denen sich zwar nicht alle Auflagerflächen parallel zueinander erstrecken, deren Auflagerflächen aber in ihrem Abstand zu gedachten mittleren Querebenen eines jeden Formsteins an seiner Oberseite erdseitig zunehmen und seiner Unterseite erdseitig abnehmen.Such a retaining wall is known from the publication "STOTTMURER AV BETONPRODUK-TER", Norges Betonindustriforbund, April 1981, p. 5 below. There, however, only one projection or only one reinforcement is provided on each top and bottom of a shaped block. From the same publication, but p. 6 above, a retaining wall is known with shaped stones, in which not all of the support surfaces extend parallel to one another, but whose support surfaces increase in distance from the imaginary central transverse planes of each shaped stone on its top side on the earth side and on its underside on the earth side lose weight.

Aufgabe der vorliergenden Erfindung ist es, eine Stützmauer mit großen konstruktionshöhen bei gleicher Größe der Formsteine mit großer Zentriergenauigkeit zu schaffen.The object of the present invention is to create a retaining wall with large construction heights with the same size of the shaped blocks with great centering accuracy.

Erfindungsgemäß wird die Aufgabe durch die ke.nnzeichenden Merkmale des Anspruchs 1 gelöst. Die erfindungsgemäße Stützmauer besteht aus Formsteinen mit an Ober- und Unterseite jeweils drei stufenartig gegeneinander versetzten Auflagerflächen, die alle parallel zueinander verlaufen. Durch diese Maßnahme werden innerhalb der Stützmauer übereinander angeordnete Formsteine zweifach zentriert. Ein Verwinkeln der Steine beim Aufbau der Stützmauer wird so geradezu unmöglich. Dazu trägt besonders bei, daß die mittleren Auflagerflächen größer sind als die anderen Auflagerflächen und die gebildeten Absätze demzufolge einen gewissen Mindestabstand voneinander aufweisen. Die weiterhin vorgesehene relative Anordnung der Auflagerflächen zueinander sowie zu einer mittleren Querebene des Formsteins ermöglicht es, die Stützmauer so aufzubauen, daß in übereinanderliegenden Lagen mehrere Steine quer zur Längserstreckung der Stützmauer benachbart angeordnet sind, wobei die Steine der oberen Lage gegenüber den Steinen der unteren Lage quer zur längsrichtung der Stützmauer versetzt sind und trotzdem in formschlüssigem Eingriff stehen.According to the invention the object is achieved by the characterizing features of claim 1. The retaining wall according to the invention consists of shaped stones with three support surfaces which are staggered with respect to one another on the top and bottom, all of which run parallel to one another. As a result of this measure, shaped blocks arranged one above the other are centered twice within the retaining wall. Angling the stones when building the retaining wall is almost impossible. This is particularly due to the fact that the middle bearing surfaces are larger than the other bearing surfaces and the shoulders formed consequently have a certain minimum distance from one another. The further provided relative arrangement of the support surfaces to each other and to a central transverse plane of the shaped brick makes it possible to build the retaining wall in such a way that, in layers lying one above the other, several stones are arranged adjacent to one another transversely to the longitudinal extension of the retaining wall, the stones of the upper layer being opposite the stones of the lower layer are offset transversely to the longitudinal direction of the retaining wall and are still in positive engagement.

Vorteilhafterweise sind die gegeneinander versetzten Auflagerflächen der Formsteine durch eine schräggerichtete, nämlich in Richtung zur Luftseite abfallende Anschlagfläche miteinander verbunden. Dadurch wird überraschenderweise eine Vergrößerung der statisch wirksamen Auflagerfläche erzielt und bei geringfügigen Relativverschiebungen der Formsteine zueinander auch aufrecht erhalten. Derartige geringfügige Relativverschiebungen sind beim Verbauen der Formsteine, also beim Aufsetzen der Stützmauer in der Praxis häufig nicht zu vermeiden.Advantageously, the mutually offset bearing surfaces of the shaped blocks are connected to one another by an obliquely directed stop surface which drops towards the air side. Surprisingly, this results in an enlargement of the statically effective bearing surface and is also maintained with slight relative displacements of the shaped blocks with respect to one another. Such slight relative displacements are often unavoidable in practice when installing the shaped blocks, i.e. when the retaining wall is put on.

Da die Auflagerflächen bis unmittlebar an die Stirnseite sowie an die Rückseite der Formsteine verlaufen, ergibt sich eine statisch wirksame Auflagerbreite, die nur geringfügig kleiner ist als die Länge des Formsteins (Abmessung quer zur Längserstreckung der Stützwand). Die statische Achse eines Formsteins bzw. der daraus gebildeten Stützmauer verläuft durch die Mitte der Auflagerbreite. Erfindungsgemäß sind die Auflagerflächen der Formsteine unter einem schiefen Winkel zur statischen Achse angeordnet, wobei ein stumpfer Winkel auf der Erdseite und ein spitzer Winkel auf der Luftseite gegenüber der statischen Achse gebildet sind.Since the support surfaces run right up to the front and back of the molded blocks, there is a statically effective support width that is only slightly smaller than the length of the molded block (dimension transverse to the longitudinal extension of the supporting wall). The static axis of a shaped stone or the retaining wall formed from it runs through the center of the support width. According to the invention, the support surfaces of the shaped stones are arranged at an oblique angle to the static axis, an obtuse angle being formed on the earth side and an acute angle on the air side relative to the static axis.

Die Formsteine können in der erfindungsgemäßen Schwergewichts-Stützmauer lagenweise seitenverkehrt in bezug auf Erd- und Luftseite miteinander verbaut werden. Besonders vorteilhaft ist aber die Bildung von Stützmauern mit abgestufter Breite bzw. Tiefe durch Anordnung von zwei oder mehreren Formsteinen in Richtung quer zur Längerstreckung der Stützmauern nebeneinander. Es werden dadurch im Querschnitt stufenartig ausgebildete untere Mauersokkel gebildet, die die Konstruktionshöhe bzw. die Belastbarkeit der Stützmauer beträchtlich erhöhen. Im Bereich des Übergangs von einer Abstufung der Stützmauer zur anderen liegen die in der Höhe benachbarten Formsteine versetzt zueinander und mit wechselseitigem formschlüssigem Eingriff miteinander (Verzahnung).The shaped blocks can be installed in the heavyweight retaining wall according to the invention in layers reversed with respect to the earth and air side. However, the formation of retaining walls with a graduated width or depth by arranging two or more shaped blocks in the direction transverse to the longitudinal extension of the retaining walls next to one another is particularly advantageous. As a result, lower wall blocks formed in a step-like manner in cross section, which considerably increase the construction height and the load-bearing capacity of the retaining wall. In the area of the transition from one gradation of the retaining wall to the other, the form stones that are adjacent in height are offset from one another and with mutual positive engagement with one another (toothing).

Nach einem weiteren Merkmal der Erfindung sind die Formsteine der Stützmauer erdseitig und luftseitig mit an einen durch die Auflagerflächen gebildeten Tragteil anschließenden Kopfteilen versehen, die zur Dekoration, zur besseren Schallabsorption oder zur Verzahnung mit dem Erdreich in entsprechender Weise (unterschiedlich) gestaltet sein können.According to a further feature of the invention, the shaped blocks of the retaining wall are provided on the earth side and on the air side with head parts adjoining a support part formed by the support surfaces, which can be designed in a corresponding (different) manner for decoration, for better sound absorption or for interlocking with the ground.

Weitere Einzelheiten der erfindungsgemäßen Stützmauer werden nachfolgend anhand der Zeichnungen näher erläutert, es zeigen:

- Fig. 1 ein bevorzugtes Ausführungsbeispiel eines Formsteins in Seitenansicht,

- Fig. 2 ein weiteres Ausführungsbeispiel eines Formsteins in Seitenansicht,

- Fig. 3 eine universell einsetzbare Ausführungsform eines Formsteins in Seitenansicht,

- Fig. 4 einen Ausschnitt einer Stützmauer im Vertikalschnitt aus Formsteinen gem. Fig. 1,

- Fig. 5 einen Abschnitt einer Stutzmauer gem. Fig. 4 on Vorderansicht,

- Fig. 6 eine stufenförmig ausgebildete Stützmauer in Seitenansicht bzw. in Vertikalschnitt,

- Fig. 7 ein anderes Ausführungsbeispiel einer stufenförmig ausgebildeten Stützmauer aus Formsteinen gem. Fig. 1.

- 1 shows a preferred embodiment of a shaped block in side view,

- 2 shows another embodiment of a shaped block in side view,

- 3 shows a universally applicable embodiment of a shaped block in a side view,

- Fig. 4 shows a detail of a retaining wall in vertical section from shaped stones. Fig. 1,

- Fig. 5 shows a section of a retaining wall. 4 on front view,

- 6 a step-shaped retaining wall in side view or in vertical section,

- Fig. 7 shows another embodiment of a step-shaped retaining wall made of shaped stones. Fig. 1.

Die in den Zeichnungen dargestellten Ausführungsbeispiele von Formsteinen dienen zur Herstellung von Stützmauern, nämlich Schwergewichts-Trocknen- Stützmauern 20 mit einseitiger Erdreich-Hinterfüllung 21. Die Stützmauer 20 ist in einer gegen die Erdreich-Hinterfüllung geneigten Ebene angeordnet. Der Winkel der Stützmauer 20 gegenüber der Horizontalen beträgt vorzugsweise zwischen 60° und 70°.The exemplary embodiments of shaped blocks shown in the drawings are used to manufacture retaining walls, namely heavy-weight

die in den Zeichnungen dargestellten Ausführungsbeispiele von Formsteinen 22 bilden eine Oberseite 23, eine Unterseite 24, eine luftseitige Stirnseitige 25 und eine der Erdreich-Hinterfüllung 21 zugekehrte Rückseite 26. Oberseite 23 und Unterseite 24 sind bei allen Ausführungsformen korrespondierend zueinander gestaltet, derart, daß ein passendes, formschlüssiges Übereinanderlegen der Formsteine 22 innerhalb der Stützmauer 20 gewährleistet ist.The exemplary embodiments of

Zur Erzielung optimaler statischer Verhältnisse bestehen Oberseite 23 und Unterseite 24 aus je mindestens drei Auflagerflächen 27, 28 und 46 bzw. 31, 32 und 51, die sich in der Höhe nach gegeneinander versetzen Ebenen erstrecken und stets parallel zueinander verlaufen. Die der Luftseite zugekehrte Auflagerfläche 28 ist gegenüber der erdseitigen Auflagerfläche 27 nach unten abgesetzt - bei horizontal liegendem Formstein - unter Bildung eines Absatzes 29 mit einer im vorliegenden Falle schrägen Auflagerfläche 30. Diese ist zur Luftseite hin abfallend angeordnet, beispielsweise mit einem Winkel von etwa 45° zu den beiden Auflagerflächen 27 und 28.To achieve optimal static conditions, the

Korrespondierend hierzu sind auch an der Unterseite 24 eine erdseitige Auflagerfläche 31 une eine luftseitige Auflagerfläche 32 gebildet, die ebenfalls parallel zueinander sowie parallel zu den oberen Auflagerflächen 27, 28 gerichtet sind. Für den formschlüssigen wechselseitigen Eingriff mit einem benachbarten unteren Formstein ist die luftseitige Auflagerfläche 32 in gleicher Weise unter Bildung eines Absatzes 33 nach unten versetzt, der durch eine schräge Anschlagfläche 34 gebildet ist.Corresponding to this, an earth-

Durch die Absätze mit Anschlagflächen auf Oberseite 23 und Unterseite 24 entstehen passend zueinander ausgebildete Erhöhungen und Vertiefungen im Bereich der aufeinander liegenden Flächen der Formsteine 22, die formschlüssig und selbstzentrierend ineinandergreifen.The shoulders with abutment surfaces on the

Bei ordnungsgemäß übereinander verlegten Formsteinen 22 liegen die Auflagerflächen 27, 28 und 46, sowie die Anschlagflächen 30 und 48 vollflächig an den zugeordneten Auflagerflächen 31,32 und 51 bzw. der Anschlagflächen 34 und 52 des benachbarten Formsteins an. Dadurch kommt statisch eine Auflagerbreite b zur Wirkung, die der Summe der Auflager- und Anschlagflächen entspricht (s. z.B. Fig. 2). Die Auflagerbreite b ist für die Belastbarkeit bzw. zulässige Konstruktionshöhe der Stützmauer 20 maßgebend. Eine statische Achse 37 des Formsteins bzw. der Stützmauer erstreckt sich in der Mitte der Auflagerbreite b. Bei den gezeigten Ausführungsbeispielen sind die Formsteine 22 so ausgebildet, daß die statische Achse 37 unte einem schiefen Winkel zu den oberen und unteren Auflagerflächen 27 bzw. 31 gerichtet ist, und zwar derart, daß ein spitzer Winkel auf der Oberseite des Formsteins 22 der Luftseite zugekehrt ist. Die Stützmauer 20 ist vorzugsweise zur Erdreich-Hinterfüllung 21 in einem Winkelbereich von 60° bis 70° der statischen Achse 37 geneigt angeordnet. Daraus ergibt sich, daß die Auflagerflächen 27, 28 und 46 sowie 31, 32 und 51 stets zur Erdreich-Hinterfüllung 21 abfallend verlaufen, während die Anschlagflächen 30, 34 bzw. 48, 52 zur Luftseite hin ebenfalls abfallend sich erstrecken. Die vorgenannten Flächen haben dadurch eine selbstzentrierende Wirkung für die übereinander angeordneten Formsteine 22.When the

Die Auflagerbreite b der Formsteine 22 bzw. der Stützmauer 20 insgesamt ist statisch von besonderer Bedeutung. Eine sich aus dem Eigengewicht der Stützmauer 20 sowie dem Erddruck aufgrund der Erdreich-Hinterfüllung 21 ergebende Kraft-Resultierende R muß aufgrund statischer Vorschriften innerhalb eines Kernquerschnitts 38 bzw. 39 de Stützmauer 20 verlaufen, und zwar jeweils im Bereich der unteren Formsteine 22. Dieser statisch relevante Kernquerschnitt 38, 39 betragt 1/6 der Auflagerbreite B. Sie erstreckt sich mittig, also mit gleichen Abmessungen, zu beiden Seiten der statischen Achse 37. Eine große Auflagerbreite b hat einen entsprechend großen Kernquerschnitt 38 bzw. 39 zur Folge. Die Stützmauer 20 kann eine entsprechend größere Konstruktionshöhe aufweisen.The support width b of the

Die Formsteine 22 haben an Oberseite 23 und Unterseite 24 mehr als zwei Auflagerflächen und Absätzen. Bei dem Ausführungsbeispiel der Fig. 1 ist erdseitig eine dritte Auflagerfläche 46 gebildet, die nach dem Konstruktionsprinzip der Formsteine bei horizontaler Lage desselben auf höherer Ebene sich erstreckt als die benachbarte (größere) Auflagerfläche 27. Zwischen beiden wird ein Absatz 47 gebildet mit schräggerichteter Anschlagfläche 48. Auf der Erdseite schließt im vorliegenden Fall ein im Querschnitt trapezförmiger Ansatz 41 an, so daß die Auflagerfläche 46 Teil eines randseitigen, im Querschnitt trapezförmigen Vorsprungs 50 ist.The shaped blocks 22 have more than two bearing surfaces and shoulders on the top 23 and bottom 24. In the embodiment of FIG. 1, a

Eine korrespondierende Auflagerfläche 51 mit Anschlagfläche 52 ist an der Unterseite gebildet, also ebenfalls mit einem Absatz 53. Oberseite und Unterseite sind auf diese Weise korrespondierend kaskadenförmig ausgebildet, auf der Oberseite 23 in Richtung zur Erdseite hin ansteigend. Die mittlere Auflagerfläche 27, 31 ist groß im Verhältnis zu den etwa gleich großen Auflagerflächen 28 und 46 bzw. 32 und 51.A

Die Stirnseite 25 besteht bei diesem besonders vorteilhaften Formstein 22 aus einem im Querschnitt dreieckförmigem Kopf 40 mit unterer Rundkante 44. Die untere Ebene des Kopfes 40 erstreckt sich in Verlängerung der Auflagerfläche 32, ist jedoch nicht wirksamer Bestandteil derselben, da der Kopf 40 außerhalb der Auflagerbreite b liegt. Die Querschnittsflächen von Kopf 40 und Ansatz 41 sind gleich groß, so daß der Statisch interessaute Schwerpunkt S im Bereich der statischen Achse 37 liegt.In this particularly advantageous shaped

Fig. 2 zeigt einen Formstein 22 mit spiegelsymmetrischer Ausbildung derart, daß die Formsteine ohne Rücksicht auf Stirn- und Rückseite verlegt werden können, da beide Seiten übereinstimmend ausgebildet sind, im vorliegenden Falle bogenförmig, also ballig. Der Formstein ist mit jeweils drei Auflagerflächen 27, 28, 31, 32 sowie 46 und 51 an Oberseite und Unterseite versehen. Die der Erdreich-Hinterfüllung 21 zugekehrten Auflagerflächen 46 und 51 haben die gleiche Größe wie die luftseitigen Auflagerflächen 28 und 32. Auch die Höhe der Absätze 29, 33, 47, 53 ist übereinstimmend, so daß eine seitenverdrehte Verlegung der Formsteine um 180° innherhalb der Stützmauer 20 möglich ist. Der Schwerpunkt S liegt bei dieser seitengleichen Ausbildung auf der statischen Achse 37.Fig. 2 shows a

Die Anordnung von stets parallelen Auflagerflächen und, wie bei dem dargestellten Ausführungsbeispiel, von paralell zueinander angeordneten Anschlagflächen bewirkt, daß auch bei geringfügigen Relativverschiebungen der Formsteine zueinander, wie sie in der Praxis beim Errichten der Stützmauer nicht vollständig ausgeschlossen werden können, die wirksame Auflagerbreite b nicht in merkbarer Weise verändert wird. Es entsteht lediglich im Bereich des Absatzes 29 bzw. 33 ein Spalt von einem oder wenigen Millimetern. Die stabile, statisch einwandfreie Lagerung der Formsteins bleibt gleichwohl erhalten.The arrangement of always parallel support surfaces and, as in the exemplary embodiment shown, of stop surfaces arranged parallel to one another has the effect that even with slight relative displacements of the shaped blocks with respect to one another, as cannot be completely ruled out in practice when the retaining wall is erected, the effective support width b does not is changed in a noticeable way. There is only a gap of one or a few millimeters in the area of the

Fig. 3 zeigt einen Formstein 22, der im Prinzip der Gestaltung gemäß Fig. 2 entspricht. Dies bedeutet, daß Kopf 40 und Ansatz 41 im wesentlichen übereinstimmend ausgebildet sind, so daß dieser Formstein seitenverkehrt einbaubar ist. Die Stirnseite und/oder die Rückseite - bei dem gezeigten Ausführungsbeispiel die Rückseite 26 - sind mit einer strukturierten Oberfläche versehen. Es handelt sich hier um in Längsrichtung bzw. horizontal verlaufende Nuten 64 von im wesentlichen trapezförmigem Querschnitt. Diese werden durch entsprechend gestaltete Rippen 65 voneinander getrennt.FIG. 3 shows a

Aus einem so gestalteten Formstein 22 können Stützmauern unterschiedlicher äußerer Erscheinung gebildet werden, und zwar unter Verwendung nur eines Typs von Formsteinen (Fig. 3), und zwar durch abwechselndes Verlegen der Formsteine mit den strukturierten Flächen zur Luftseite bzw. zur Erdseite.Retaining walls of different external appearance can be formed from a shaped

Fig. 6 zeigt eine Stützmauer 20 mit veränderlichem wirksamen Querschnitt. Im unteren Bereich besteht ein Mauersockel 61 aus mehreren Lagen 43 von quer zur Längserstreckung der Stützmauer 20 nebeneinanderliegenden Formsteinen 22, und zwar in der Ausführung mit einer dritten Auflagerfläche 46 an der Oberseite, wie bei dem Ausführungsbeispiel der Fig. 1 bzw. der Fig. 2 und 3. Die (glatten) Rückseiten 26 sind innerhalb der Lagen 43 einander zugekehrt. Dadurch ergibt sich im Bereich des Mauersockels 61 bzw. einer unteren Fundamentlage 62 eine Auflagerbreite b2, die sich aus den Auflagerflächen der beiden jeweils nebeneinanderliegenden Formsteine 22 der Fundamentlage 62 ergibt. Die übereinander angeordneten Formsteine 22 stehen darüber hinaus in einem wechselseitigen, formschlüssigen Eingriff durch die Vorsprünge 50 einerseits und durch den gegenüberliegen angeordneten Absatz 53 andererseits. Die Anordnung ist so getroffen, daß die erseitigen Formsteine jeweils seitenverkehrt in bezug auf Oberseite 23 und Unterseite 24 angeordnet sind. Dadurch ergibt sich im Bereich einer vertikalen Mittelebene eine mäanderförmige Verzahnung der übereinander sowie nebeneinanderliegenden Formsteine. Jeweils zwei benachbarte Formsteine einer Lage 58 bzw. 62 bilden ein Vertiefung, in die ein Vorsprung 50 passen eintritt.Fig. 6 shows a retaining

Oberhalb des Mauersockels 61 besteht ein Maueroberteil 63 aus Lagen 58 mit jeweils einem Formstein in der Richtung senkrecht zur Ebene der Stützmauer 20. Im Bereich der Fundamentlage 62 sowie des Übergangs von Maueroberteil 63 zum Mauersockel 61 ist ein statisch günstiger, nämlich verhältnismäßig breiter Kernquerschnitt 38 bzw. 39 gegeben.Above the

Der untere Formstein 22 des Maueroberteils 63 stützt sich mit der unteren Anschlagfläche 34 an der oberen Anschlagfläche 48 des vorderen Formsteins des Mauersockels 61 ab. Dadurch ist auch in diesem Bereich eine selbstzentrierende Relativlage der Formsteine gegeben. Die Anzahl der Lagen 58 bzw. 62 im Bereich des Mauersockels 61 ist so gewählt, daß der untere Kernquerschnitt 39 aufgrund der Vorgaben des oberen Kernquerschnitts 38 und der Richtung der Resultierenden R ausgenutzt wird.The lower molded

Die Stützmauer gemäß Fig. 7 ist ähnlich aufgebaut, nämlich mit Mauersockel 61 und Maueroberteil 63. Die Sockellage 62 besteht bei diesem Ausführungsbeispiel aus drei in Richtung senkrecht zur Ebene der Stützmauer 20 aneinander anschließenden Formsteinen 22. Durch die Gestaltung der Formsteine im Sinne des Ausführungsbeispiels der Fig. 1 und die Relativanordnung derselben wird auch hier eine selbstzentrierende Abstützung im Bereich des Übergangs von Maueroberteil 63 zu Mauersockel 61 sowie der aus zwei Formsteinen bestehenden Lage 58 zur Fundamentlage 62 geschaffen.7 is constructed similarly, namely with

Bei dieser Stützmauer 20 aus Formsteinen der bevorzugten Ausführung der Fig. 1 ist eine optimale formschlüssige Verzahnung von Formsteinen im Bereich der jeweiligen Querschnittsverbreiterung der Stützmauer gegeben, also im Bereich der unteren Lage 58 zur oberen Lage 43 und von der unteren Lage 43 zur Fundamentlage 62. Zwei Formsteine einer Lage (hier Lage 43) werden durch einen versetzt liegenden Formstein einer benachbarten Lage (hier: Lage 58 einerseits und Fundamentlage 62 andererseits) überdeckt, und zwar unter Eingriff der Absätze und Vertiefungen in Folge der kaskadenförmigen Gestaltung ineinander. Eine derartige Mauer ist hoch belastbar bzw. mit großer Konstruktionshöhe ausführbar.With this retaining

Die Formsteine können jede geeignete bzw. sinnvolle Abmessung aufweisen. Bei einer vorteilhaften Ausführung im sinne von Fig. 1 beträgt die Gesamtlänge des Formsteins von der Stirnseite 25 zur Rückseite 26 etwa 30 cm. Die Höhe eines derartigen Formsteins, also der Abstand der Stütsflächen 27 und 31 voneinander, beträgt beispielsweise ca. 15 cm. Die Absätze, also der Abstand der parallelen Auflagerflächen voneinander, beträgrt bei einem Ausführungsbeispiel 2,5 cm. Die Breite der kleinen Auflagerflächen 28, 32 ... ist mit etwa 3,5 cm günstig.The shaped blocks can have any suitable or meaningful dimension. In an advantageous embodiment in the sense of FIG. 1, the total length of the shaped stone from the

Die zu den größeren Auflagerflächen parallele mittlere Querebene wird als MQ bezeichnet (vgl. z.B. Figuren 1 und 2).The central transverse plane parallel to the larger bearing surfaces is referred to as the MQ (see e.g. Figures 1 and 2).

Claims (15)

Priority Applications (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT85114011T ATE54694T1 (en) | 1985-02-18 | 1985-11-04 | RETAINING WALL. |

| FI860273A FI85529C (en) | 1985-02-18 | 1986-01-21 | MOT BAKOMLIGGANDE MARKFYLLNING LUTAD STOEDMUR. |

| AU52765/86A AU587599B2 (en) | 1985-02-18 | 1986-01-28 | Shaped (concrete) block for retaining walls and also a retaining wall |

| JP61028065A JPH0745732B2 (en) | 1985-02-18 | 1986-02-13 | Retaining concrete block and retaining wall |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19853505530 DE3505530A1 (en) | 1985-02-18 | 1985-02-18 | (CONCRETE) MOLDED STONE FOR SUPPORT WALLS AND SUPPORT WALL |

| DE3505530 | 1985-02-18 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0191908A1 EP0191908A1 (en) | 1986-08-27 |

| EP0191908B1 true EP0191908B1 (en) | 1990-07-18 |

Family

ID=6262821

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP85114011A Expired - Lifetime EP0191908B1 (en) | 1985-02-18 | 1985-11-04 | Supporting wall |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US4711606A (en) |

| EP (1) | EP0191908B1 (en) |

| CA (1) | CA1245870A (en) |

| DE (2) | DE3505530A1 (en) |

| DK (1) | DK518485A (en) |

| IT (1) | IT1188391B (en) |

| NO (1) | NO174752C (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2005113911A1 (en) | 2004-05-17 | 2005-12-01 | Sf-Kooperation Gmbh Beton-Konzepte | Supporting wall and moulded blocks of concrete for building a supporting wall |

| DE102004047823A1 (en) * | 2004-09-29 | 2006-03-30 | Sf-Kooperation Gmbh Beton-Konzepte | Wall, especially against the vertical against a soil backfill inclined retaining wall |

Families Citing this family (49)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CA1298982C (en) * | 1988-02-25 | 1992-04-21 | Eugene M. Bender | Retaining wall construction and blocks therefore |

| DE3810934A1 (en) * | 1988-03-31 | 1989-10-12 | Rudolf Peter Gmbh & Co Kg Kies | Process for using returned residual concrete from ready-mixed concrete |

| US4993206A (en) * | 1989-02-03 | 1991-02-19 | National Concrete Masonry Association | Interlocking building units and walls constructed thereby |

| CA62573S (en) | 1989-02-20 | 1989-02-28 | Raymond Rodenburgh | Double unit for retaining wall |

| DE3917500A1 (en) * | 1989-05-30 | 1990-12-06 | Sf Vollverbundstein | (CONCRETE) MOLDED STONE FOR SUPPORT WALLS, MOLD FOR THE PRODUCTION AND SUPPORT WALL |

| US5294216A (en) | 1989-09-28 | 1994-03-15 | Anchor Wall Systems, Inc. | Composite masonry block |

| US5062610A (en) * | 1989-09-28 | 1991-11-05 | Block Systems Inc. | Composite masonry block mold for use in block molding machines |

| US5017049A (en) * | 1990-03-15 | 1991-05-21 | Block Systems Inc. | Composite masonry block |

| US5044833A (en) * | 1990-04-11 | 1991-09-03 | Wilfiker William K | Reinforced soil retaining wall and connector therefor |

| US5120164A (en) * | 1991-05-24 | 1992-06-09 | Tony Iacocca | Retaining wall and block for constructing the same |

| USD344349S (en) | 1992-06-16 | 1994-02-15 | Masako Ohta | Wave energy dissipation block |

| US5704183A (en) | 1992-10-06 | 1998-01-06 | Anchor Wall Systems, Inc. | Composite masonry block |

| ES2135493T3 (en) | 1992-10-06 | 1999-11-01 | Anchor Wall Syst | A COMPOSITE MASONRY BLOCK. |

| US5490363A (en) | 1992-10-06 | 1996-02-13 | Anchor Wall Sytems, Inc. | Composite masonry block |

| US5484236A (en) * | 1993-10-25 | 1996-01-16 | Allan Block Corporation | Method of forming concrete retaining wall block |

| US5425600A (en) * | 1994-01-21 | 1995-06-20 | Gordon; Bradford C. | Drainage block feedthrough for assembly of walls constructed of specialized retaining blocks |

| CA2143278A1 (en) * | 1994-04-14 | 1995-10-15 | Louis Arvai | Concrete gabions |

| ES2205041T3 (en) * | 1995-06-02 | 2004-05-01 | Novabrick International Inc. | BLOCK FOR THE CONSTRUCTION OF A WALL WITHOUT MORTAR. |

| US5913790A (en) * | 1995-06-07 | 1999-06-22 | Keystone Retaining Wall Systems, Inc. | Plantable retaining wall block |

| US5601384A (en) * | 1995-06-07 | 1997-02-11 | Keystone Retaining Wall Systems, Inc. | Plantable retaining wall |

| USD387434S (en) * | 1996-01-03 | 1997-12-09 | Keystone Retaining Wall Systems, Inc. | Front face of a plantable retaining wall block |

| US5765970A (en) * | 1996-06-17 | 1998-06-16 | Fox; James C. | Plastic retaining wall construction |

| USD458693S1 (en) | 1996-11-08 | 2002-06-11 | Anchor Wall Systems, Inc. | Retaining wall block |

| US6029943A (en) | 1996-11-08 | 2000-02-29 | Anchor Wall Systems, Inc. | Splitting technique |

| US6082057A (en) | 1996-11-08 | 2000-07-04 | Anchor Wall Systems, Inc. | Splitting technique |

| US5879603A (en) | 1996-11-08 | 1999-03-09 | Anchor Wall Systems, Inc. | Process for producing masonry block with roughened surface |

| USD409312S (en) * | 1997-02-11 | 1999-05-04 | Staten Bobby L | Decorative landscape stone |

| USD415845S (en) * | 1997-02-11 | 1999-10-26 | Staten Bobby L | Decorative edging stone |

| USD397451S (en) | 1997-06-10 | 1998-08-25 | Keystone Retaining Wall Systems, Inc. | Section of a retaining wall with plantable blocks |

| USD445512S1 (en) | 1997-10-27 | 2001-07-24 | Anchor Wall Systems, Inc. | Retaining wall block |

| USD430680S (en) * | 1999-01-15 | 2000-09-05 | Handy-Stone Corporation | Concrete block |

| DE19905842A1 (en) | 1999-02-12 | 2000-08-17 | Karl Weber Betonwerk Gmbh & Co | palisade |

| EP1153173A1 (en) * | 1999-02-12 | 2001-11-14 | Shaw Technologies Inc. | Interlocking segmental retaining wall |

| DE29902467U1 (en) * | 1999-02-12 | 2000-06-29 | Karl Weber Betonwerk GmbH & Co. KG, 32457 Porta Westfalica | palisade |

| USD438640S1 (en) | 1999-08-17 | 2001-03-06 | Anchor Wall Systems, Inc. | Face of a retaining wall block |

| USD437422S1 (en) | 1999-08-17 | 2001-02-06 | Anchor Wall Systems, Inc. | Face of a retaining wall block |

| US6267533B1 (en) * | 1999-08-18 | 2001-07-31 | George S. Bourg | Erosion control system |

| US6250850B1 (en) | 1999-08-19 | 2001-06-26 | Rockwood Retaining Walls, Inc. | Block with multifaceted bottom surface |

| DE10002390A1 (en) * | 2000-01-20 | 2001-07-26 | Sf Koop Gmbh Beton Konzepte | Molded concrete block for inclined retaining wall with soil back fill has projecting front part of different material and/or shape and/or color on visible front face |

| EP1493869A1 (en) * | 2003-06-30 | 2005-01-05 | Martin Mannhart | Blockwall and building element for its construction |

| MX2007006123A (en) | 2004-11-24 | 2007-10-04 | Contech Technologies Llc | Retaining wall block with face connection. |

| DE102005050456A1 (en) | 2005-10-19 | 2007-04-26 | Sf-Kooperation Gmbh Beton-Konzepte | retaining wall |

| US20100031592A1 (en) * | 2007-02-12 | 2010-02-11 | James Carolan | Composite panel |

| US7849656B2 (en) * | 2008-04-18 | 2010-12-14 | Anchor Wall Systems, Inc. | Dry cast block arrangement and methods |

| PT2319048E (en) * | 2008-08-22 | 2015-11-25 | Veritas Medical Solutions Llc | Masonry block with continuously curved surfaces |

| PT105009A (en) | 2010-03-09 | 2011-09-09 | Antonio Jose Vieira Da Cunha | BLOCK FOR BUILDING FOUNDATION SYSTEMS AND METHOD FOR BUILDING WALLS WITH THE PURPOSE BLOCK |

| US9677271B2 (en) | 2015-10-08 | 2017-06-13 | Anchor Wall Systems, Inc. | Concrete unit and methods |

| PL422755A1 (en) * | 2017-09-05 | 2019-03-11 | Przedsiębiorstwo Realizacyjne Inora - Inorganic Activities Spółka Z Ograniczoną Odpowiedzialnością | Building masonry unit |

| US20190368152A1 (en) * | 2018-05-30 | 2019-12-05 | Earth Wall Products, Llc | Method for making modular retaining wall block with lever extension using cmu block machine |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0181230A2 (en) * | 1984-11-08 | 1986-05-14 | John Watson Crighton | Improvements in or relating to building blocks |

Family Cites Families (18)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US789730A (en) * | 1903-01-30 | 1905-05-16 | Henry L Hinton | Tile building-block and method of forming same. |

| FR376718A (en) * | 1907-04-12 | 1907-08-19 | Eugene Fichefet | Coating of embankments and banks |

| CA744126A (en) * | 1961-11-13 | 1966-10-11 | R. Svee Hallbjorn | Block for making protecting covers on slopes of moles and breakwaters |

| US3488964A (en) * | 1967-11-27 | 1970-01-13 | Giken Kogyo Kk | Concrete block |

| DE1912155A1 (en) * | 1969-03-11 | 1970-11-05 | Fischer Karl | Composite stone |

| JPS5056004A (en) * | 1973-09-14 | 1975-05-16 | ||

| DE7520030U (en) * | 1975-06-24 | 1977-06-16 | Sf-Vollverbundstein-Kooperation Gmbh, 2820 Bremen | COMPONENT SET FOR CREATING SUPPORT WALLS |

| DE2731228C2 (en) * | 1977-07-11 | 1983-02-03 | Sf-Vollverbundstein-Kooperation Gmbh, 2820 Bremen | Concrete shaped stone for the production of a retaining wall and retaining wall made of such shaped stones |

| DE3068345D1 (en) * | 1979-06-29 | 1984-08-02 | Quadie Bausysteme Gmbh | Construction such as a retaining wall or the like |

| DE3017064C2 (en) * | 1980-05-03 | 1984-04-05 | Gimmler, Luise Maria, 6618 Wadern-Bardenbach | Embankment block |

| DE8012113U1 (en) * | 1980-05-03 | 1980-07-31 | Gimmler, Helmut, 6618 Wadern-Bardenbach | SHEEP FORM STONE |

| DE3163580D1 (en) * | 1981-03-10 | 1984-06-20 | Rolf Scheiwiller | Assembly of blocks for constructing walls |

| US4512685A (en) * | 1981-09-08 | 1985-04-23 | Ameron, Inc. | Mortarless retaining-wall system and components thereof |

| CA1182295A (en) * | 1982-08-16 | 1985-02-12 | Angelo Risi | Retaining wall system |

| AT391507B (en) * | 1983-01-24 | 1990-10-25 | Rausch Peter | BLOCK |

| FR2544764B1 (en) * | 1983-04-19 | 1985-12-06 | Rech Ste Civile Et | SUPPORT ELEMENT FOR THE PREPARATION OF RETENTION TALUS AND THE LIKE |

| US4601148A (en) * | 1983-06-24 | 1986-07-22 | Angelo Risi | Module for walls and free standing structure |

| CH663437A5 (en) * | 1984-06-21 | 1987-12-15 | Carl Schiffer | Slope block |

-

1985

- 1985-02-18 DE DE19853505530 patent/DE3505530A1/en not_active Withdrawn

- 1985-11-04 EP EP85114011A patent/EP0191908B1/en not_active Expired - Lifetime

- 1985-11-04 DE DE8585114011T patent/DE3578765D1/en not_active Expired - Fee Related

- 1985-11-11 DK DK518485A patent/DK518485A/en not_active Application Discontinuation

- 1985-11-11 NO NO854476A patent/NO174752C/en not_active IP Right Cessation

-

1986

- 1986-01-24 CA CA000500289A patent/CA1245870A/en not_active Expired

- 1986-01-31 US US06/824,804 patent/US4711606A/en not_active Expired - Lifetime

- 1986-02-14 IT IT19422/86A patent/IT1188391B/en active

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0181230A2 (en) * | 1984-11-08 | 1986-05-14 | John Watson Crighton | Improvements in or relating to building blocks |

Non-Patent Citations (1)

| Title |

|---|

| "Stottemurer AV Betonprodukter", Norges Betonindustriforbund, April 1981 * |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2005113911A1 (en) | 2004-05-17 | 2005-12-01 | Sf-Kooperation Gmbh Beton-Konzepte | Supporting wall and moulded blocks of concrete for building a supporting wall |

| DE102004047823A1 (en) * | 2004-09-29 | 2006-03-30 | Sf-Kooperation Gmbh Beton-Konzepte | Wall, especially against the vertical against a soil backfill inclined retaining wall |

Also Published As

| Publication number | Publication date |

|---|---|

| DE3505530A1 (en) | 1986-08-21 |

| IT1188391B (en) | 1988-01-07 |

| CA1245870A (en) | 1988-12-06 |

| NO174752B (en) | 1994-03-21 |

| DK518485A (en) | 1986-08-19 |

| NO854476L (en) | 1986-08-19 |

| DK518485D0 (en) | 1985-11-11 |

| DE3578765D1 (en) | 1990-08-23 |

| NO174752C (en) | 1994-06-29 |

| US4711606A (en) | 1987-12-08 |

| IT8619422A0 (en) | 1986-02-14 |

| IT8619422A1 (en) | 1987-08-14 |

| EP0191908A1 (en) | 1986-08-27 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0191908B1 (en) | Supporting wall | |

| DE2731228C2 (en) | Concrete shaped stone for the production of a retaining wall and retaining wall made of such shaped stones | |

| AT391507B (en) | BLOCK | |

| EP0428762B1 (en) | Slab-shaped paving element | |

| EP0058925A1 (en) | Construction set for a cribbing for use in retaining walls, noise protecting walls or the like | |

| DE3538124A1 (en) | Shaped block | |

| EP0517117B1 (en) | Wooden plant container | |

| EP0039448A2 (en) | Wall made of concrete elements | |

| DE3320034A1 (en) | COMPONENT FOR PRODUCING A CARRIER OR THE LIKE | |

| WO2002025033A1 (en) | Step stone for a stairway and a stairway assembled therefrom | |

| DE2532520B2 (en) | PROTECTION DEVICE, IN PARTICULAR SOUND PROTECTION DEVICE AND MOUNTING FASTENING FOR ROADS, COMPOSING OF PREFABRICATED COMPONENTS MADE OF ARTIFICIAL STONE, CONCRETE OR THE LIKE. | |

| DE19960320A1 (en) | Paving stone system | |

| DE3510914A1 (en) | Double block | |

| DE9404446U1 (en) | Molded concrete block | |

| EP3967827B1 (en) | Prefabricated concrete step | |

| DE29619957U1 (en) | Pavement element for building an open, coherent floor covering | |

| DE8504505U1 (en) | Concrete moulded block | |

| EP2331752A1 (en) | Ground covering made from moulded blocks | |

| EP1835077A1 (en) | Stone for building gravity walls | |

| DE3517337A1 (en) | Shaped stones for a stair-like embankment wall as well as method for making such an embankment wall | |

| DE3144888A1 (en) | Insulating sheet for heat insulation and impact-sound insulation | |

| DE102021121703A1 (en) | Drainage device, drainage system, method for assembling the drainage system and method for manufacturing the drainage device | |

| DE3033650A1 (en) | Tiered concrete noise screen wall box blocks - are tapered, of decreasing depth upwards and offset by half length | |

| DE19817879A1 (en) | Concrete stone | |

| DE29812506U1 (en) | Machine foundation made of concrete |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH DE FR GB IT LI NL SE |

|

| 17P | Request for examination filed |

Effective date: 19870203 |

|

| 17Q | First examination report despatched |

Effective date: 19880316 |

|

| 17Q | First examination report despatched |

Effective date: 19881118 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE FR GB IT LI NL SE |

|

| REF | Corresponds to: |

Ref document number: 54694 Country of ref document: AT Date of ref document: 19900815 Kind code of ref document: T |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) | ||

| REF | Corresponds to: |

Ref document number: 3578765 Country of ref document: DE Date of ref document: 19900823 |

|

| ITF | It: translation for a ep patent filed | ||

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| ITTA | It: last paid annual fee | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19941130 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 19950104 Year of fee payment: 10 |

|

| EAL | Se: european patent in force in sweden |

Ref document number: 85114011.1 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Effective date: 19951130 |

|

| BERE | Be: lapsed |

Owner name: SF-VOLLVERBUNDSTEIN-KOOPERATION G.M.B.H. Effective date: 19951130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19960601 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 19960601 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 20001106 Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20001110 Year of fee payment: 16 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20011105 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| EUG | Se: european patent has lapsed |

Ref document number: 85114011.1 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20020730 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20021113 Year of fee payment: 18 Ref country code: AT Payment date: 20021113 Year of fee payment: 18 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20031104 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040602 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20041104 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20041117 Year of fee payment: 20 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20051103 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: PE20 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |