EP0184635A1 - Roof edge cover - Google Patents

Roof edge cover Download PDFInfo

- Publication number

- EP0184635A1 EP0184635A1 EP85113057A EP85113057A EP0184635A1 EP 0184635 A1 EP0184635 A1 EP 0184635A1 EP 85113057 A EP85113057 A EP 85113057A EP 85113057 A EP85113057 A EP 85113057A EP 0184635 A1 EP0184635 A1 EP 0184635A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- web

- clamping piece

- cladding

- profile

- roof edge

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 238000005253 cladding Methods 0.000 claims description 51

- 238000007789 sealing Methods 0.000 claims description 5

- 238000004519 manufacturing process Methods 0.000 description 3

- 238000010276 construction Methods 0.000 description 1

- 230000001066 destructive effect Effects 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04D—ROOF COVERINGS; SKY-LIGHTS; GUTTERS; ROOF-WORKING TOOLS

- E04D13/00—Special arrangements or devices in connection with roof coverings; Protection against birds; Roof drainage ; Sky-lights

- E04D13/15—Trimming strips; Edge strips; Fascias; Expansion joints for roofs

- E04D13/155—Trimming strips; Edge strips; Fascias; Expansion joints for roofs retaining the roof sheathing

Definitions

- the innovation relates to a roof edge cladding which consists of a cladding profile and an angularly designed clamping piece which can be locked therewith, by means of which the roof skin can be clamped to the cladding profile preferably via a sealing strip inserted in a receiving groove formed on the lower end of the clamping piece.

- a roof edge covering of this type is known from DE-A 1 32 38 879.

- the cladding profile is provided in the upper region with a receiving pocket which is formed on a horizontal leg and runs at an angle to the cladding profile, which is U-shaped and has internal teeth.

- the upper bent end of the clamping piece, which can be inserted into the receiving pocket, is provided with a corresponding counter-toothing, so that the clamping piece can be locked with the cladding profile by the interlocking teeth and thus the roof skin can be tensioned.

- the roof cladding can be reliably fixed to the cladding profile, but a relatively great force is required to press the clamping piece into the receiving pocket, since the contact pressure, by means of which the clamping piece is supposed to act on the roof cladding, must be applied by hand at almost full height. Handling at a construction site is therefore often difficult. Furthermore, the arrangement of the U-shaped receiving pocket on the cladding profile raises pressing problems which can only be solved by additional measures, but which make the production of the cladding profile very expensive.

- a comparable roof edge cladding is known, in which a horizontally projecting web that can be locked with the clamping piece is formed on the cladding profile.

- the tensioning force acting on the roof skin which is to be pressed onto the back of the cladding profile, is also to be applied in this embodiment when the clamping piece is snapped on, and considerable resistances have to be overcome.

- a locking toothing provided on the underside of the projecting web extends over its entire length and a receiving pocket provided on the clamping piece is adapted to the thickness of the web, so that a nose which engages in its toothing and is usually formed over a large part on the lower leg of the receiving pocket the teeth must be pushed away.

- the legs of the receiving pockets are more or less to bend, and a dismantling of the clamping piece without causing damage is usually not possible.

- the object of the innovation is therefore to improve the roof edge cladding of the type mentioned in such a way that the clamping piece can be snapped onto the cladding profile with little effort, but that nevertheless always provides reliable and secure tensioning of the roof cladding and, if appropriate, non-destructive dismantling of the clamping piece are guaranteed.

- the cladding profile and the clamping piece should be able to be pressed without difficulty, so that the individual parts of the roof edge cladding are also economical to manufacture.

- the cladding profile in the upper area has an inwardly projecting, approximately horizontally extending and provided with a downward locking projection retaining web that at the upper end of the clamping piece or a clamping profile or a clamping strip one by two approximately parallel leg formed receiving pocket is attached, and that in the lower leg delimiting the receiving pocket, a toothing is incorporated into which the locking projection provided on the projecting retaining web of the cladding profile engages.

- the receiving pocket of the clamping piece in height greater than the strength of the retaining web engaging in it with ratchet jump, so that an easy introduction is given and the bracing can be accomplished by tilting.

- the upper leg delimiting the receiving pocket of the clamping piece at its free end internally facing bevelled edge, a landing stage or the like it is furthermore expedient to move the upper leg delimiting the receiving pocket of the clamping piece at its free end internally facing bevelled edge, a landing stage or the like.

- the length of the lower leg of the receiving pocket should be shorter than its upper leg and the projected opening width between the bend of the upper leg and the lower leg should correspond in height to approximately the thickness of the retaining web formed on the cladding profile with a locking projection. In this way, an alignment of the individual components aligned with one another is ensured in spite of the fact that the receiving chambers have to be dimensioned large in terms of press technology.

- the cladding profile should be provided by means of an integrally formed connecting web which is inclined in a partial area to the roof surface, and the receiving groove, which is attached to the lower end of the clamping profile and carries the sealing strip, should have an inclination corresponding to the inclined part of the connecting web. so that the roof skin can be clamped on this part by means of the clamping piece.

- the roof edge cladding designed according to the innovation is not only economically producible, since the cladding profile and the clamping piece can be pressed without difficulty, but the proposed design allows, above all, always secure tensioning of the roof skin without a great effort being required to snap the clamping piece on .

- the clamping piece is only more or less to be pushed onto the retaining web of the cladding profile in order to allow a satisfactory pressing of the roof skin.

- the clamping piece can also be easily and without being damaged, for example, when the roof skin is renewed. It is therefore always easy to use.

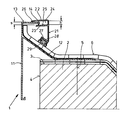

- the roof edge cladding designated 1 serves to cover the upper roof edge 4 of a building 2 and to brace a roof skin 6 laid on its roof surface 3 and consists of a cladding profile 11 and a clamping piece 21 which can be locked with the cladding profile 11.

- a connecting web 12 is formed on it, which extends in a partial area inclined to the roof surface 3 and is fastened to the building 2 by means of screws 5.

- the clamping piece 21 is of an angular design and is provided at its upper end with a receiving pocket 24 formed by two legs 22 and 23 running parallel to one another and at its lower end with a receiving groove 28 for a sealing strip 29 created by a projecting web 27. Furthermore, the lower leg 23 of the receiving pocket 24, which is shorter than its upper leg 22, has an internal toothing 25, the upper leg 22, on the other hand, is equipped at its end with an inwardly bent edge 26.

- a horizontally protruding retaining web 13 is integrally formed thereon, at the end of which a downwardly directed latching projection 14, which cooperates with the toothing 25 of the leg 23, is formed.

- the clear height h of the receiving pocket 24 is dimensioned larger than the thickness S of the retaining web 13 with the locking projection 14, on the other hand corresponds to projected opening width between the fold 26 of the upper leg 22 and the lower leg 23 of the thickness S of the retaining web 13 with locking projection 14.

- the clamping piece 21 is easy to manufacture by pressing, since the distance between the two legs 22 and 23 is kept large can be, but this can also be pushed onto the retaining web 13 of the cladding profile 11 without difficulty and with little effort and still securely locked with it, the clamping piece 21 being arranged in alignment with the cladding profile 11 in the installed position. And since the receiving groove 28 runs parallel to the inclined part of the connecting web 12, the roof skin 6 is always securely braced with the cladding profile 11.

Landscapes

- Engineering & Computer Science (AREA)

- Architecture (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Fittings On The Vehicle Exterior For Carrying Loads, And Devices For Holding Or Mounting Articles (AREA)

- Roof Covering Using Slabs Or Stiff Sheets (AREA)

- Seal Device For Vehicle (AREA)

- Vehicle Interior And Exterior Ornaments, Soundproofing, And Insulation (AREA)

- Sealing Battery Cases Or Jackets (AREA)

Abstract

Description

Die Neuerung bezieht sich auf eine Dachrandverkleidung, die aus einem Verkleidungsprofil und einem mit diesem verrastbaren winkelförmig ausgebildeten Klemmstück besteht, mittels dem die Dachhaut mit dem Verkleidungsprofil vorzugsweise über einen in einer an dem unteren Ende des Klemmstückes angeformten Aufnahmenuteingesetzten Dichtstreifen verspannbar ist.The innovation relates to a roof edge cladding which consists of a cladding profile and an angularly designed clamping piece which can be locked therewith, by means of which the roof skin can be clamped to the cladding profile preferably via a sealing strip inserted in a receiving groove formed on the lower end of the clamping piece.

Eine Dachrandverkleidung dieser Art ist durch die DE-A 1 32 38 879 bekannt. Das Verkleidungsprofil ist bei dieser Ausgestaltung im oberen Bereich mit einer an einem waagrechten Schenkel angeformten und zu dem Verkleidungsprofil hin geneigt verlaufenden Aufnahmetasche versehen, die U-förmig ausgebildet ist und eine Innenverzahnung aufweist. Und das obere abgebogene Ende des Klemmstückes, das in die Aufnahmetasche einführbar ist, ist mit einer entsprechenden Gegenverzahnung versehen,so daß durch die ineinandergreifenden Verzahnungen das Klemmstück mit dem Verkleidungsprofil verrastbar und somit die Dachhaut verspannbar ist.A roof edge covering of this type is known from DE-A 1 32 38 879. In this embodiment, the cladding profile is provided in the upper region with a receiving pocket which is formed on a horizontal leg and runs at an angle to the cladding profile, which is U-shaped and has internal teeth. And the upper bent end of the clamping piece, which can be inserted into the receiving pocket, is provided with a corresponding counter-toothing, so that the clamping piece can be locked with the cladding profile by the interlocking teeth and thus the roof skin can be tensioned.

Bei dieser Dachrandverkleidung ist die Dachhaut zwar zuverlässig am Verkleidungsprofil festzulegen, zum Eindrücken des Klemmstückes in die Aufnahmetasche ist aber eine verhältnismäßig große Kraft erforderlich, da die Anpreßkraft, mittels der das Klemmstück auf die Dachhaut einwirken soll, in nahezu voller Höhe von Hand aufzubringen ist. Die Handhabung an einer Baustelle ist daher oftmals mit Schwierigkeiten verbunden. Des weiteren wirft die Anordnung der U-förmig gestalteten Aufnahmetasche an dem Verkleidungsprofil preßtechnische Probleme auf, die nur durch zusätzliche Maßnahmen zu lösen sind, durch die aber die Herstellung des Verkleidungsprofils in einem erheblichen Maße verteuert wird.With this roof edge cladding, the roof cladding can be reliably fixed to the cladding profile, but a relatively great force is required to press the clamping piece into the receiving pocket, since the contact pressure, by means of which the clamping piece is supposed to act on the roof cladding, must be applied by hand at almost full height. Handling at a construction site is therefore often difficult. Furthermore, the arrangement of the U-shaped receiving pocket on the cladding profile raises pressing problems which can only be solved by additional measures, but which make the production of the cladding profile very expensive.

Durch das DE-U-72 41 842 ist zwar eine vergleichbare Dachrandverkleidung bekannt, bei der an dem Verkleidungsprofil ein waagrecht abstehender mit dem Klemmstück verrastbarer Steg angeformt ist. Die auf die Dachhaut, die an der Rückseite des Verkleidungsprofils anzupressen ist, einwirkende Spannkraft ist bei dieser Ausgestaltung aber ebenfalls beim Aufrasten des Klemmstückes aufzubringen und es sind dabei erhebliche Widerstände zu überwinden. Eine an der Unterseite des abstehenden Steges vorgesehene Rastverzahnung erstreckt sich nämlich über dessen gesamte Länge und eine an dem Klemmstück vorgesehene Aufnahmetasche ist der Stärke des Steges angepaßt, so daß eine in dessen Verzahnung eingreifende an dem unteren Schenkel der Aufnahmetasche angeformte Nase meist über einen großen Teil der Verzahnung hinweggeschoben werden muß. Die Schenkel der Aufnahmetaschen sind dabei mehr oder weniger aufzubiegen, auch ist eine Demontage des Klemmstückes,ohne daß Beschädigungen auftreten, meist nicht möglich.From DE-U-72 41 842 a comparable roof edge cladding is known, in which a horizontally projecting web that can be locked with the clamping piece is formed on the cladding profile. The tensioning force acting on the roof skin, which is to be pressed onto the back of the cladding profile, is also to be applied in this embodiment when the clamping piece is snapped on, and considerable resistances have to be overcome. A locking toothing provided on the underside of the projecting web extends over its entire length and a receiving pocket provided on the clamping piece is adapted to the thickness of the web, so that a nose which engages in its toothing and is usually formed over a large part on the lower leg of the receiving pocket the teeth must be pushed away. The legs of the receiving pockets are more or less to bend, and a dismantling of the clamping piece without causing damage is usually not possible.

Aufgabe der Neuerung ist es daher, die Dachrandverkleidung der eingangs genannten Gattung in der Weise zu verbessern, daß das Klemmstück mit geringem Kraftaufwand auf dem Verkleidungsprofil aufrastbar ist, daß aber dennoch stets eine zuverlässige und auch unter Beanspruchung sichere Verspannung der Dachhaut sowie gegebenenfalls eine zerstörungsfreie Demontage des Klemmstückes gewährleistet sind. Außerdem sollen das Verkleidungsprofil und auch das Klemmstück ohne Schwierigkeiten zu pressen sein, so daß auch eine wirtschaftliche Fertigung der einzelnen Teile der Dachrandverkleidung gegeben ist.The object of the innovation is therefore to improve the roof edge cladding of the type mentioned in such a way that the clamping piece can be snapped onto the cladding profile with little effort, but that nevertheless always provides reliable and secure tensioning of the roof cladding and, if appropriate, non-destructive dismantling of the clamping piece are guaranteed. In addition, the cladding profile and the clamping piece should be able to be pressed without difficulty, so that the individual parts of the roof edge cladding are also economical to manufacture.

Gemäß der Neuerung wird dies dadurch erreicht, daß das Verkleidungsprofil im oberen Bereich einen nach innen abstehenden, etwa waagrecht verlaufenden und mit einem nach unten gerichteten Rastvorsprung versehenen Haltesteg aufweist, daß an dem oberen Ende des Klemmstückes oder eines Klemmprofils oder einer Klemmleiste eine durch zwei etwa parallel zueinander verlaufende Schenkel gebildete Aufnahmetasche angebracht ist, und daß in den unteren die Aufnahmetasche begrenzenden Schenkel eine Verzahnung eingearbeitet ist, in die der an dem abstehenden Haltesteg des Verkleidungsprofils vorgesehene Rastvorsprung eingreift.According to the innovation, this is achieved in that the cladding profile in the upper area has an inwardly projecting, approximately horizontally extending and provided with a downward locking projection retaining web that at the upper end of the clamping piece or a clamping profile or a clamping strip one by two approximately parallel leg formed receiving pocket is attached, and that in the lower leg delimiting the receiving pocket, a toothing is incorporated into which the locking projection provided on the projecting retaining web of the cladding profile engages.

Zweckmäßig ist es hierbei, den Rastvorsprung an dem freien Ende des Haltesteges anzuformen.It is expedient here to form the locking projection on the free end of the holding web.

Außerdem ist es angebracht, die Aufnahmetasche des Klemmstückes in der Höhe größer zu bemessen als die Stärke des in diese eingreifenden Haltesteges mit Rastsorsprung, so daß eine leichte Einführung gegeben und die Verspannung durch Verkanten zu bewerkstelligen ist.In addition, it is appropriate to dimension the receiving pocket of the clamping piece in height greater than the strength of the retaining web engaging in it with ratchet jump, so that an easy introduction is given and the bracing can be accomplished by tilting.

Bei dieser Ausgestaltung ist es jedoch des weiteren zweckmäßig, den oberen die Aufnahmetasche des Klemmstückes begrenzenden Schenkel an seinem freien Ende mit einer nach innen gerichteten Abkantung, einem Anlagesteg oder dgl. zur Abstützung auf dem Haltesteg des Verkleidungsprofils zu versehen, wobei, um das Aufrasten des Klemmstückes zu erleichtern, der untere Schenkel der Aufnahmetasche in seiner Länge kürzer bemessen sein sollte als deren oberer Schenkel und die projizierte öffnungsweite zwischen der Abkantung des oberen Schenkels und dem unteren Schenkel in der Höhe etwa der Stärke des an dem Verkleidungsprofil angeformten Haltesteges mit Rastvorsprung entsprechen sollte. Auf diese Weise ist, trotz aus preßtechnischen Gründen groß zu bemessender Aufnahmekammern eine zueinander fluchtende Anordnung der einzelnen Bauteile gewährleistet.In this embodiment, however, it is furthermore expedient to move the upper leg delimiting the receiving pocket of the clamping piece at its free end internally facing bevelled edge, a landing stage or the like. To be supported on the retaining web of the cladding profile, in order to make it easier to snap on the clamping piece, the length of the lower leg of the receiving pocket should be shorter than its upper leg and the projected opening width between the bend of the upper leg and the lower leg should correspond in height to approximately the thickness of the retaining web formed on the cladding profile with a locking projection. In this way, an alignment of the individual components aligned with one another is ensured in spite of the fact that the receiving chambers have to be dimensioned large in terms of press technology.

Eine besonders leichte Verrastung des Klemmstückes auf dem Verkleidungsprofil ist gegeben, wenn die Dachhaut auf einer geneigt verlaufenden Fläche festklemmbar ist. Um dies auf einfache Weise zu ermöglichen, sollte das Verkleidungsprofil mittels einem in einem Teilbereich geneigt zur Dachfläche gerichteten angeformten Anschlußsteg versehen sein und die an dem unteren Ende des Klemmprofils angebrachten, den Dichtstreifen tragende Aufnahmenut sollte eine dem schräg verlaufenden Teil des Anschlußsteges entsprechende Neigung aufweisen, so daß die Dachhaut mittels des Klemmstückes auf diesem Teil verspannbar ist.A particularly easy latching of the clamping piece on the cladding profile is given when the roof skin can be clamped on an inclined surface. In order to make this possible in a simple manner, the cladding profile should be provided by means of an integrally formed connecting web which is inclined in a partial area to the roof surface, and the receiving groove, which is attached to the lower end of the clamping profile and carries the sealing strip, should have an inclination corresponding to the inclined part of the connecting web. so that the roof skin can be clamped on this part by means of the clamping piece.

Die gemäß der Neuerung ausgebildete Dachrandverkleidung ist nicht nur wirtschaftlich herstellbar, da das Verkleidungsprofil und auch das Klemmstück ohne Schwierigkeiten zu pressen sind, sondern die vorschlagsgemäße Ausgestaltung ermöglicht vor allem eine stets sichere Verspannung der Dachhaut, ohne daß zum Aufrasten des Klemmstückes ein großer Kraftaufwand erforderlich ist. Das Klemmstück ist dabei lediglich mehr oder weniger auf den Haltesteg des Verkleidungsprofils aufzuschieben, um eine zufriedenstellende Anpressung der Dachhaut zu ermöglichen. Auch kann das Klemmstück ohne weiteres und ohne daß dieses dabei beschädigt wird, beispielsweise bei Erneuerung der Dachhaut demontiert werden. Eine einfache Handhabung ist somit stets gegeben.The roof edge cladding designed according to the innovation is not only economically producible, since the cladding profile and the clamping piece can be pressed without difficulty, but the proposed design allows, above all, always secure tensioning of the roof skin without a great effort being required to snap the clamping piece on . The clamping piece is only more or less to be pushed onto the retaining web of the cladding profile in order to allow a satisfactory pressing of the roof skin. The clamping piece can also be easily and without being damaged, for example, when the roof skin is renewed. It is therefore always easy to use.

In der Zeichnung ist ein Ausführungsbeispiel der gemäß der Neuerung ausgebildeten Dachrandverkleidung, das nachfolgend im einzelnen erläutert ist, dargestellt.In the drawing, an embodiment of the roof edge cladding designed according to the innovation, which is explained in detail below, is shown.

Die mit 1 bezeichnete Dachrandverkleidung dient zur Abdeckung des oberen Dachrandes 4 eines Gebäudes 2 sowie zur Verspannung einer auf dessen Dachfläche 3 verlegten Dachhaut 6 und besteht aus einem Verkleidungsprofil 11 und einem Klemmstück 21, das mit dem Verkleidungsprofil 11 verrastbar ist. Zur Befestigung des Verkleidungsprofils 11 ist an diesem ein Anschlußsteg 12 angeformt, der in einem Teilbereich geneigt zur Dachfläche 3 verläuft und mittels Schrauben 5 an dem Gebäude 2 befestigt ist.The roof edge cladding designated 1 serves to cover the upper roof edge 4 of a

Das Klemmstück 21 ist winkelig gestaltet und an seinem oberen Ende mit einer durch zwei parallel zueinander verlaufende Schenkel 22 und 23 gebildeten Aufnahmetasche 24 und an seinem unteren Ende mit einer durch einen abstehenden Steg 27 geschaffenen Aufnahmenut 28 für einen Dichtstreifen 29 versehen. Des weiteren weist der untere Schenkel 23 der Aufnahmetasche 24, der kürzer bemessen ist als deren oberer Schenkel 22, eine Innenverzahnung 25 auf, der obere Schenkel 22 ist dagegen an seinem Ende mit einer nach innen gerichteten Abkantung 26 ausgestattet.The

Um das Klemmstück 21 auf dem Verkleidungsprofil 11 aufrasten zu können, ist an diesem ein waagrecht abstehender Haltesteg 13 angeformt, an dessen Ende ein nach unten gerichteter mit der Verzahnung 25 des Schenkels 23 zusammenwirkender Rastvorsprung 14 angeformt ist. Die lichte Höhe h der Aufnahmetasche 24 ist hierbei größer bemessen als die Stärke S des Haltesteges 13 mit Rastvorsprung 14, dagegen entspricht die projizierte Öffnungsweite zwischen der Abkantung 26 des oberen Schenkels 22 und dem unteren Schenkel 23 der Stärke S des Haltesteges 13 mit Rastvorsprung 14. Auf diese Weise ist nicht nur das Klemmstück 21 preßtechnisch leicht herstellbar, da der Abstand zwischen den beiden Schenkeln 22 und 23 groß gehalten werden kann, sondern dieses kann auch ohne Schwierigkeiten und mit geringem Kraftaufwand auf den Haltesteg 13 des Verkleidungsprofils 11 aufgeschoben und mit diesem dennoch sicher verrastet werden, wobei in Einbaulage das Klemmstück 21 mit dem Verkleidungsprofil 11 fluchtend angeordnet ist. Und da die Aufnahmenut 28 parallel zu dem geneigten Teil des Anschlußsteges 12 verläuft, ist eine stets sichere Verspannung der Dachhaut 6 mit dem Verkleidungsprofil 11 gegeben.In order to be able to snap the

Claims (7)

dadurch gekennzeichnet ,

characterized ,

dadurch gekennzeichnet,

daß der Rastvorsprung (14) an dem freien Ende des Haltesteges (13) angeformt ist.2. roof edge cladding according to claim 1,

characterized,

that the locking projection (14) is integrally formed on the free end of the retaining web (13).

dadurch gekennzeichnet,

daß die Aufnahmetasche (24) des Klemmstückes (21) in ihrer Höhe (h) größer bemessen ist als die Stärke (s) des in diese eingreifenden Haltesteges (13) mit Rastvorsprung (14).3. roof edge cladding according to claim 1 or 2, '

characterized,

that the receiving pocket (24) of the clamping piece (21) is dimensioned higher in height (h) than the thickness (s) of the retaining web (13) engaging in it with the locking projection (14).

dadurch gekennzeichnet,

daß der obere die Aufnahmetasche (24) des Klemmstückes (21) begrenzende Schenkel (22) an seinem freien Ende mit einer nach innen gerichteten Abkantung (26), einem Anlagesteg oder dgl. zur Abstützung auf dem Haltesteg (13) des Verkleidungsprofils (11) versehen ist.4. Roof edge cladding according to one or more of claims 1 to 3,

characterized,

that the upper leg (22) delimiting the receiving pocket (24) of the clamping piece (21) at its free end with an inward bend (26), an abutment web or the like for support on the retaining web (13) of the cladding profile (11) is provided.

dadurch gekennzeichnet,

daß der untere die Aufnahmetasche (24) des Klemmstückes (21) begrenzende Schenkel (23) in seiner Länge kürzer bemessen ist als der obere Schenkel (22).5. roof edge cladding according to one or more of claims 1 to 4,

characterized,

that the lower leg (23) delimiting the receiving pocket (24) of the clamping piece (21) has a shorter length than the upper leg (22).

dadurch gekennzeichnet,

daß die projizierte öffnungsweite zwischen der Abkantung (26) des oberen Schenkels (22) und dem unteren Schenkel (23) der Aufnahmetasche (24) in der Höhe etwa der Stärke (S) des an dem Verkleidungsprofil (5) angeformten Haltesteges (13) mit Rastvorsprüngen (14) entspricht.6. roof edge cladding according to claim 4 or 5,

characterized,

that the projected opening width between the fold (26) of the upper leg (22) and the lower leg (23) of the receiving pocket (24) in the amount of approximately the thickness (S) of the retaining web (13) formed on the lining profile (5) Corresponding locking projections (14).

mit einem in einem Teilbereich geneigt zur Dachfläche verlaufenden an dem Verkleidungsprofil angeformten Anschlußsteg,

dadurch gekennzeichnet,

daß die an dem unteren Ende des Klemmstückes (21) angeformte, den Dichtstreifen (29) haltende Aufnahmenut (28) eine dem schräg verlaufenden Teil des Anschlußsteges (12) entsprechende Neigung aufweist.7. roof edge cladding according to one or more of claims 1 to 6,

with a connecting web which is inclined to the roof surface in a partial area and is integrally formed on the cladding profile,

characterized,

that the formed on the lower end of the clamping piece (21), the sealing strip (29) holding the receiving groove (28) has an inclination corresponding to the inclined part of the connecting web (12).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT85113057T ATE42787T1 (en) | 1984-11-13 | 1985-10-15 | ROOF EDGE PANELING. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19848433179U DE8433179U1 (en) | 1984-11-13 | 1984-11-13 | ROOF EDGE |

| DE8433179U | 1984-11-13 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0184635A1 true EP0184635A1 (en) | 1986-06-18 |

| EP0184635B1 EP0184635B1 (en) | 1989-05-03 |

Family

ID=6772644

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP85113057A Expired EP0184635B1 (en) | 1984-11-13 | 1985-10-15 | Roof edge cover |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP0184635B1 (en) |

| AT (1) | ATE42787T1 (en) |

| DE (2) | DE8433179U1 (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102018009461A1 (en) | 2018-12-05 | 2020-06-10 | Klaus Peter Abel | Edge sealing device for flexible barrier layers |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102024101991A1 (en) * | 2024-01-24 | 2025-07-24 | Emdatec Gmbh | Roof edge finishing profile for attaching a roof waterproofing on a flat roof |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2260438A (en) * | 1938-12-21 | 1941-10-28 | Cheney Allan | Waterproofed building construction |

| FR1551549A (en) * | 1967-07-18 | 1968-12-27 | ||

| DE2333959A1 (en) * | 1973-07-04 | 1975-01-16 | Halfeneisen Gmbh & Co Kg | Edging-section for flat roof - includes rail, cover-piece, wedge shaped heat insulation section and retainer arms for roof sheet |

-

1984

- 1984-11-13 DE DE19848433179U patent/DE8433179U1/en not_active Expired

-

1985

- 1985-10-15 DE DE8585113057T patent/DE3569950D1/en not_active Expired

- 1985-10-15 EP EP85113057A patent/EP0184635B1/en not_active Expired

- 1985-10-15 AT AT85113057T patent/ATE42787T1/en active

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2260438A (en) * | 1938-12-21 | 1941-10-28 | Cheney Allan | Waterproofed building construction |

| FR1551549A (en) * | 1967-07-18 | 1968-12-27 | ||

| DE2333959A1 (en) * | 1973-07-04 | 1975-01-16 | Halfeneisen Gmbh & Co Kg | Edging-section for flat roof - includes rail, cover-piece, wedge shaped heat insulation section and retainer arms for roof sheet |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102018009461A1 (en) | 2018-12-05 | 2020-06-10 | Klaus Peter Abel | Edge sealing device for flexible barrier layers |

Also Published As

| Publication number | Publication date |

|---|---|

| ATE42787T1 (en) | 1989-05-15 |

| DE8433179U1 (en) | 1985-02-28 |

| DE3569950D1 (en) | 1989-06-08 |

| EP0184635B1 (en) | 1989-05-03 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE8102895U1 (en) | PROFILE FOR AN EXTERNAL STRIP FROM A BLIND CEILING OR FRONT WALL | |

| DE3400110C2 (en) | ||

| DE29808197U1 (en) | Drainage channel | |

| DE29600057U1 (en) | Joint profile for floor coverings | |

| DE2910325A1 (en) | Reusable building site guard-rail holder - has clamp with mutually movable jaws at base of support bar | |

| EP0184635B1 (en) | Roof edge cover | |

| DE3223049C2 (en) | Carpet fitting | |

| DE4239051C2 (en) | Building wall cladding | |

| DE29916138U1 (en) | Strip arrangement for covering or bridging joints, especially for floors | |

| EP3658721B1 (en) | Cover device for floor coverings | |

| DE3910647C2 (en) | Kit | |

| DE1659340B2 (en) | LOCAL CORNER CLADDING FOR FLAT ROOFS OR DGL | |

| DE8915947U1 (en) | Fastening device for facade panels, especially facade bricks | |

| DE8524910U1 (en) | Bracket for height-adjustable support of facing masonry | |

| DE2727289A1 (en) | BUILDING CLADDING | |

| DE3517303A1 (en) | Hollow profile for the frame of a shuttering panel | |

| DE29501224U1 (en) | Substructure for pitched roofs covered with roof tiles | |

| DE8633382U1 (en) | Lockable roof rack | |

| DE1659329C3 (en) | Cover for walls or the like | |

| DE8705794U1 (en) | Plastic roof covering | |

| DE2624120C3 (en) | Device for jointly fastening an eaves cover and a gutter on a pitched roof | |

| DE2255950A1 (en) | ONE-PIECE ROOF CLADDING | |

| DE2150398C3 (en) | Height-adjustable bracket for the cladding profile of a verge cladding | |

| DE2924805A1 (en) | CLEANING PROFILE BAR | |

| DE20103079U1 (en) | Insulation for a building wall |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE DE FR NL |

|

| 17P | Request for examination filed |

Effective date: 19861114 |

|

| 17Q | First examination report despatched |

Effective date: 19880212 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE DE FR NL |

|

| REF | Corresponds to: |

Ref document number: 42787 Country of ref document: AT Date of ref document: 19890515 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 3569950 Country of ref document: DE Date of ref document: 19890608 |

|

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| NLT1 | Nl: modifications of names registered in virtue of documents presented to the patent office pursuant to art. 16 a, paragraph 1 |

Owner name: HOOGOVENS ALUMINIUM PROFILTECHNIK GMBH TE VOGT, BO |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: CD |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19950918 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 19951110 Year of fee payment: 11 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Effective date: 19961031 |

|

| BERE | Be: lapsed |

Owner name: HOOGOVENS ALUMINIUM PROFILTECHNIK G.M.B.H. Effective date: 19961031 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19970630 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 19971021 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19971029 Year of fee payment: 13 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19981015 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19981223 Year of fee payment: 14 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19990501 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 19990501 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000801 |