EP0148334A2 - Device for the attachment of accessories on the wall of a lighting fixture - Google Patents

Device for the attachment of accessories on the wall of a lighting fixture Download PDFInfo

- Publication number

- EP0148334A2 EP0148334A2 EP84112316A EP84112316A EP0148334A2 EP 0148334 A2 EP0148334 A2 EP 0148334A2 EP 84112316 A EP84112316 A EP 84112316A EP 84112316 A EP84112316 A EP 84112316A EP 0148334 A2 EP0148334 A2 EP 0148334A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- wall

- edge

- accessory holder

- foot

- leg

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 210000000078 claw Anatomy 0.000 claims description 16

- 229910000639 Spring steel Inorganic materials 0.000 claims description 6

- 230000001154 acute effect Effects 0.000 claims description 2

- 230000000903 blocking effect Effects 0.000 abstract 1

- 238000006073 displacement reaction Methods 0.000 abstract 1

- 239000004020 conductor Substances 0.000 description 3

- 239000002184 metal Substances 0.000 description 3

- 241000158147 Sator Species 0.000 description 1

- 239000011324 bead Substances 0.000 description 1

- 239000003990 capacitor Substances 0.000 description 1

- 239000004922 lacquer Substances 0.000 description 1

- 230000001681 protective effect Effects 0.000 description 1

- 239000007858 starting material Substances 0.000 description 1

- 230000007704 transition Effects 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F21—LIGHTING

- F21V—FUNCTIONAL FEATURES OR DETAILS OF LIGHTING DEVICES OR SYSTEMS THEREOF; STRUCTURAL COMBINATIONS OF LIGHTING DEVICES WITH OTHER ARTICLES, NOT OTHERWISE PROVIDED FOR

- F21V17/00—Fastening of component parts of lighting devices, e.g. shades, globes, refractors, reflectors, filters, screens, grids or protective cages

- F21V17/10—Fastening of component parts of lighting devices, e.g. shades, globes, refractors, reflectors, filters, screens, grids or protective cages characterised by specific fastening means or way of fastening

- F21V17/16—Fastening of component parts of lighting devices, e.g. shades, globes, refractors, reflectors, filters, screens, grids or protective cages characterised by specific fastening means or way of fastening by deformation of parts; Snap action mounting

- F21V17/164—Fastening of component parts of lighting devices, e.g. shades, globes, refractors, reflectors, filters, screens, grids or protective cages characterised by specific fastening means or way of fastening by deformation of parts; Snap action mounting the parts being subjected to bending, e.g. snap joints

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F21—LIGHTING

- F21V—FUNCTIONAL FEATURES OR DETAILS OF LIGHTING DEVICES OR SYSTEMS THEREOF; STRUCTURAL COMBINATIONS OF LIGHTING DEVICES WITH OTHER ARTICLES, NOT OTHERWISE PROVIDED FOR

- F21V17/00—Fastening of component parts of lighting devices, e.g. shades, globes, refractors, reflectors, filters, screens, grids or protective cages

- F21V17/10—Fastening of component parts of lighting devices, e.g. shades, globes, refractors, reflectors, filters, screens, grids or protective cages characterised by specific fastening means or way of fastening

- F21V17/107—Fastening of component parts of lighting devices, e.g. shades, globes, refractors, reflectors, filters, screens, grids or protective cages characterised by specific fastening means or way of fastening using hinge joints

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F21—LIGHTING

- F21V—FUNCTIONAL FEATURES OR DETAILS OF LIGHTING DEVICES OR SYSTEMS THEREOF; STRUCTURAL COMBINATIONS OF LIGHTING DEVICES WITH OTHER ARTICLES, NOT OTHERWISE PROVIDED FOR

- F21V23/00—Arrangement of electric circuit elements in or on lighting devices

- F21V23/02—Arrangement of electric circuit elements in or on lighting devices the elements being transformers, impedances or power supply units, e.g. a transformer with a rectifier

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F21—LIGHTING

- F21V—FUNCTIONAL FEATURES OR DETAILS OF LIGHTING DEVICES OR SYSTEMS THEREOF; STRUCTURAL COMBINATIONS OF LIGHTING DEVICES WITH OTHER ARTICLES, NOT OTHERWISE PROVIDED FOR

- F21V23/00—Arrangement of electric circuit elements in or on lighting devices

Definitions

- the invention relates to an arrangement for holding accessories on a lamp wall according to the preamble of claim 1 or 6.

- the main part of such a luminaire wall which for example can form a rectangular luminaire frame, delimits an assembly space on three sides in which accessories, for example ballasts, compensation capacitors, starters etc. can be accommodated.

- accessories for example ballasts, compensation capacitors, starters etc.

- a reliable ground connection and a possibility of connecting an earth conductor must also be provided.

- the wiring of the luminaire itself and, if necessary, through-wiring that is continuous from luminaire to luminaire must be accommodated and fastened.

- the wiring is therefore also counted as an accessory.

- the invention has for its object to provide an accessory holder that can be easily and reliably installed at any point on a lamp wall according to the preamble of claim 1.

- the end opposite the foot of the accessory holder itself is designed as a spring, which hooks in its desired position with a click seat on the edge of the lamp wall.

- the accessory holder is clamped in the lamp wall with the aid of a spring arm, which is only tensioned by means of a screw connection.

- Both embodiments therefore have in common that the accessory holder can be resiliently clamped at any point on the luminaire wall, that is to say no screws for fastening the accessory holder to the luminaire wall and therefore no holes in the latter are required.

- the accessory holder is to be used to fix heavy accessories, it is advisable to use spring steel. It is also possible to arrange claws on the accessory holder, which provide an electrical connection between the accessory and the accessory holder and, if applicable, between the accessory holder and the luminaire wall.

- the accessory holder can thus also be used to establish a connection between an earth conductor and the lamp wall.

- a sheet metal strip in the form of a flat plug can be bent out of a central part of the accessory holder, onto which a suitable cable lug of an earth conductor can be plugged.

- the accessory holder is only intended to fix the wiring, it is preferably made of plastic.

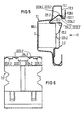

- FIG. 1 shows in cross section a luminaire wall 1 with a main part 10, which is delimited by a main wall 101 and two transverse walls 102 running approximately perpendicular to it.

- This main part 10 is adjoined at the top and bottom by two identical edge parts 11, each of which is formed by a mounting leg 112, a base 113 and an edge wall 114, which surround a channel 110.

- Each edge part 11 is connected via its edge wall 114 to the transverse wall 102 of the main part 10 such that the openings of the grooves 110 of the two edge parts 11 are directed towards one another.

- a luminaire wall with such a profile has high rigidity and encloses a relatively large mounting space 100 between the main wall 101 and the plane delimited by the mounting leg 112; a ballast, a compensation condenser, for example sator or other accessories.

- a ballast for example sator or other accessories.

- these are lines or cables, they are preferably guided within the channels 110 of the edge parts 11 and secured therein by the accessory holder 2.1 shown in FIG. 1.

- Such an accessory holder 2.1 specializing in this function is a plastic molded part of approximately 1 cm in width (in the direction perpendicular to the plane of the drawing) and has a central part 20.1 which extends approximately in the extension of the mounting leg 112, that is to say leaves the mounting space 100 free.

- a C-shaped foot 21.1 with a semicircular end piece 211.1 and a connecting piece 212.1 is formed on one end of the middle part 20.1.

- a V-shaped spring 22.1 is formed with a spring leg 221.1 and a connecting leg 222.1; at the end of the spring leg 221.1 there is a detent seat 223.1 with a locking stop 2231.1 and a travel stop 2232.1 running at right angles thereto, which limits the travel of the spring 22.1.

- the accessory holder 2.1 is supported on the inside with the locking stop 2231.1 and resiliently on the edge 1120 of the mounting leg 112 with the travel stop 2232.1.

- the spring leg 221.1 also bears against the transition between the walls I02 and 114, as a result of which the position shown in FIG. 1 is additionally secured.

- the accessory holder 2.1 is thus resiliently clamped between the bottom 113 of the lower edge part 11 of the lamp wall 1 and the edge 1120 of the upper edge part 11.

- the distance between the end piece 211.1 of the foot of the accessory holder and the detent seat 223.1 is therefore greater in the relaxed state - shown in broken lines in FIG. 1 - than the distance between the bottom 113 of the one edge part 11 and the edge 1120 of the other edge part 11 of the lamp wall 1.

- the opening 210.1 of the C-shaped foot 21.1 projects beyond the height of the mounting leg 112 at least to such an extent that the accessory holder can be used in the oblique position shown in dashed lines in FIG.

- the outer diameter of the end piece 211.1 of the foot 21.1 is only slightly larger than the inside width of the groove 110 of the edge 11 of the lamp wall 1, so that a practically play-free storage of the accessory holder and at the same time a rotation in the lamp wall is possible.

- the accessory holder 2.1 closes the groove 110 of the upper edge part 11 of the lamp wall 1 with its spring leg 221.1 and secures the lines accommodated therein against falling out. By pressing down the spring leg 221.1, individual lines can be easily inserted or removed.

- Cables in particular for through-wiring, can also be accommodated in the C-shaped foot 21.1. They are secured against falling out by a resilient locking leg 202.1, which is directed from the middle part 20.1 against the end piece 211.1 and which blocks the part of the opening 210.1 lying above the mounting leg 112.

- FIGS. 2 to 4 relate to an accessory holder 2 made of spring steel, which is suitable for holding heavier accessories and at the same time for earthing them, and which accordingly has a greater extent in the direction perpendicular to the plane of the drawing (FIG. 3).

- the detent seats 223 are designed in particular: for this purpose, the spring leg 221 has at its end two end pieces 224, which are angled against the foot 21 of the accessory holder 2, approximately vertically stand on the spring leg 221 and serve as a locking stop 2231. Each of these end pieces 224 has an edge tab 225 at both ends, which in turn is perpendicular to the end piece 224 (FIG.

- edge tabs 225 point away from the central part 20.

- Each of these edge tabs 225 now has a cutting edge 2251 which is at an angle to the plane of the end piece 224 and serves as a travel stop 2232 (FIG. 2).

- the accessory holder 2 is inserted into the lamp wall 1 in the same way as that according to FIG. 1: the spring leg 221 is pressed down again by the edge 1120 of the mounting leg 112 until the edge 1120 snaps into the detent seat 223 of the accessory holder 2.

- the accessory holder 2 is supported with the locking stop 2231 against the inside of the mounting leg 112;

- the sharp cutting edges 2251 of the four edge tabs 225 (FIG. 3) notch into the bare edge 1120 and thus ensure a reliable electrical connection and a limitation of the spring travel.

- the end piece 224.2 is angled downwards relative to the spring leg 221.2 and additionally has a handle 2234.2.

- At the end of the spring leg there are two locking stops 2231.2 and two on each side of the end piece Claws 2233.2 are provided for each stop.

- the claws 2233.2 penetrate any protective lacquer that may be present and impress themselves in the bare metal of the luminaire wall 1.1. Since the tips of the claws can be deformed somewhat, these claws are preferably slightly longer than the locking stops 2231.2 which transmit the pressure forces, so that perfect electrical contact is ensured under all conditions.

- the accessories can be attached directly to the middle part 20.2 of the accessory holder 2.2, e.g. attached to a bent rag by screws.

- the accessories for example a ballast 3

- claws 201.2 in the middle part 20.2 can ensure a reliable electrical connection between the accessories and the accessory holder.

- the middle part 20.2 can have a curvature directed against the lamp wall 1.1 or can be provided with stiffening beads.

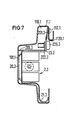

- the accessory holder 2.3 is resiliently clamped on the lamp wall in such a way that the middle part 20.3 and claws 201.3 rest on the inside of the main wall 101.1 of the lamp wall 1.1.

- a foot 21.3 with the features already described is arranged at one end of the middle part 20.3.

- the accessory holder 2.3 has a connecting leg 222.3 which is directed upwards against the channel 110.1 and in which two screw connections 226.3 are arranged one behind the other at a distance.

- a clamping plate 23.3 is fastened to the connecting leg 222.3 and engages with a spring arm 231.3 in the channel 110.1.

- This spring arm - the relaxed position of which is shown in dashed lines in FIG. 7 - presses the middle part 20.3 against the main wall 101.1 when the screw connection is tightened - shown in the figure.

- the free end of the spring arm has additional claws.

- the clamping plate 23.3 has a slot 226.3 each screw, which extends transversely to the longitudinal axis of the lamp wall as far into the spring arm 231.3 that the clamping plate can be pulled down so far after loosening the screw connection 226.3 that the accessory holder 2.3 around its foot 21.3 under the opposite edge 1120.1 is pivotable outwards.

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Power Engineering (AREA)

- Fastening Of Light Sources Or Lamp Holders (AREA)

- Non-Portable Lighting Devices Or Systems Thereof (AREA)

- Golf Clubs (AREA)

- Lighters Containing Fuel (AREA)

- Lighting Device Outwards From Vehicle And Optical Signal (AREA)

- Arrangement Of Elements, Cooling, Sealing, Or The Like Of Lighting Devices (AREA)

- Sheet Holders (AREA)

- Vessels And Coating Films For Discharge Lamps (AREA)

Abstract

Description

Die Erfindung betrifft eine Anordnung zur Halterung von Zubehör an einer Leuchtenwand gemäß Oberbegriff von Anspruch 1 oder 6.The invention relates to an arrangement for holding accessories on a lamp wall according to the preamble of claim 1 or 6.

Der Hauptteil einer solchen Leuchtenwand, die beispielsweise einen rechteckigen Leuchtenrahmen bilden kann, begrenzt an drei Seiten einen Montageraum, in dem Zubehör, beispielsweise Vorschaltgeräte, Kompensationskondensatoren, Starter etc. untergebracht werden können. Hierbei ist in der Regel auch für eine zuverlässige Masseverbindung sowie für eine Möglichkeit zum Anschluß eines Erdleiters zu sorgen.The main part of such a luminaire wall, which for example can form a rectangular luminaire frame, delimits an assembly space on three sides in which accessories, for example ballasts, compensation capacitors, starters etc. can be accommodated. As a rule, a reliable ground connection and a possibility of connecting an earth conductor must also be provided.

Im Bereich der Leuchtenwand ist ferner die Verdrahtung der Leuchte selbst und ggf. eine von Leuchte zu Leuchte durchgezogene Durchgangsverdrahtung unterzubringen und zu befestigen. Die Verdrahtung wird daher im Sinne der vorliegenden Erfindung ebenfalls zum Zubehör gerechnet.In the area of the luminaire wall, the wiring of the luminaire itself and, if necessary, through-wiring that is continuous from luminaire to luminaire must be accommodated and fastened. For the purposes of the present invention, the wiring is therefore also counted as an accessory.

Der Erfindung liegt die Aufgabe zugrunde, einen Zubehörhalter anzugeben, der an beliebiger Stelle einer Leuchtenwand gemäß Oberbegriff von Anspruch 1 einfach und zuverlässig montierbar ist.The invention has for its object to provide an accessory holder that can be easily and reliably installed at any point on a lamp wall according to the preamble of claim 1.

Bei einer ersten, in Anspruch 1 gekennzeichneten Lösung dieser Aufgabe ist das dem Fuß des Zubehörhalters gegenüberliegende Ende selbst als Feder ausgebildet, die sich in ihrer Sollposition mit einem Rastsitz am Rand der Leuchtenwand verhakt.In a first solution to this task, which is characterized in claim 1, the end opposite the foot of the accessory holder itself is designed as a spring, which hooks in its desired position with a click seat on the edge of the lamp wall.

_ Bei einer zweiten, in Anspruch 6 gekennzeichneten Lösung der Aufgabe wird der Zubehörhalter mit Hilfe eines Federarmes in der Leuchtenwand eingeklemmt, der erst mittels einer Verschraubung gespannt wird.In a second solution to the task, characterized in claim 6, the accessory holder is clamped in the lamp wall with the aid of a spring arm, which is only tensioned by means of a screw connection.

Beiden Ausführungsformen ist somit gemeinsam, daß der Zubehörhalter an beliebiger Stelle der Leuchtenwand federnd einspannbar ist, also keine Schrauben zur Befestigung des Zubehörhalters an der Leuchtenwand und damit auch keine Bohrungen in dieser erforderlich sind.Both embodiments therefore have in common that the accessory holder can be resiliently clamped at any point on the luminaire wall, that is to say no screws for fastening the accessory holder to the luminaire wall and therefore no holes in the latter are required.

Sofern der Zubehörhalter zur Fixierung von schwerem Zubehör verwendet werden soll, besteht er zweckmäßig aus Federstahl. Hierbei besteht auch die Möglichkeit, an dem Zubehörhalter Krallen anzuordnen, die für eine elektrische Verbindung zwischen Zubehör und Zubehörhalter und gegebenenfalls zwischen Zubehörhalter und Leuchtenwand sorgen.If the accessory holder is to be used to fix heavy accessories, it is advisable to use spring steel. It is also possible to arrange claws on the accessory holder, which provide an electrical connection between the accessory and the accessory holder and, if applicable, between the accessory holder and the luminaire wall.

Der Zubehörhalter kann somit auch zur Herstellung einer Verbindung zwischen einem Erdleiter und der Leuchtenwand dienen. Hierzu kann zusätzlich aus einem Mittelteil des Zubehörhalters ein Blechstreifen in Form eines Flachsteckers herausgebogen sein, auf den ein dazu passender Kabelschuh eines Erdleiters aufsteckbar ist.The accessory holder can thus also be used to establish a connection between an earth conductor and the lamp wall. For this purpose, a sheet metal strip in the form of a flat plug can be bent out of a central part of the accessory holder, onto which a suitable cable lug of an earth conductor can be plugged.

Sofern der Zubehörhalter lediglich zur Fixierung der Verdrahtung dienen soll, besteht er vorzugsweise aus Kunststoff.If the accessory holder is only intended to fix the wiring, it is preferably made of plastic.

Weitere vorteilhafte Ausgestaltungen der Erfindung sind in den Unteransprüchen gekennzeichnet.Further advantageous embodiments of the invention are characterized in the subclaims.

Die Erfindung wird anhand der in den Figuren dargestellten Ausführungsbeispiele näher erläutert; es zeigen

- FIG 1 einen Querschnitt durch eine Leuchtenwand mit einem eingesetzten Zubehörhalter für die Sicherung von Leitungen und Kabeln,

- FIG 2 eine Seitenansicht eines aus Federstahl bestehenden Zubehörhalters in einer ersten Ausführungsform,

- FIG 3 eine Ansicht des Federschenkels in Richtung des Pfeiles III in FIG 2,

- FIG 4 eine Teilansicht des Federschenkels in Richtung des Pfeiles IV in FIG 2,

- FIG 5 einen Querschnitt durch eine Leuchtenwand mit einem eingesetzten Zubehörhalter aus Federstahl in einer zweiten Ausführungsform,

- FIG 6 eine Draufsicht auf den Zubehörhalter nach FIG 5 in Richtung des Pfeiles VI ohne Leuchtenwand, und

- FIG 7 einen Querschnitt durch eine Leuchtenwand mit einem eingesetzten Zubehörhalter aus Blech in einer dritten Ausführungsform.

- 1 shows a cross section through a luminaire wall with an inserted accessory holder for securing lines and cables,

- 2 shows a side view of an accessory holder made of spring steel in a first embodiment,

- 3 shows a view of the spring leg in the direction of arrow III in FIG. 2,

- 4 shows a partial view of the spring leg in the direction of arrow IV in FIG. 2,

- 5 shows a cross section through a luminaire wall with an inserted accessory holder made of spring steel in a second embodiment,

- 6 shows a plan view of the accessory holder according to FIG 5 in the direction of arrow VI without lamp wall, and

- 7 shows a cross section through a lamp wall with an inserted sheet metal accessory holder in a third embodiment.

In FIG 1 ist im Querschnitt eine Leuchtenwand 1 mit einem Hauptteil 10 dargestellt, der von einer Hauptwandung 101 und zwei etwa senkrecht zu ihr verlaufende Querwandungen 102 begrenzt ist. An diesen Hauptteil 10 schließen oben und unten zwei gleichartig ausgebildete Randteile 11 an, die jeweils von einem Montageschenkel 112, einem Boden 113 und einer Randwandung 114 gebildet sind, die eine Rinne 110 umschließen. Jeder Randteil 11 ist über seine Randwandung 114 mit der Querwandung 102 des Hauptteiles 10 so verbunden, daß die Öffnungen der Rinnen 110 der beiden Randteile 11 gegeneinander gerichtet sind. Eine Leuchtenwand mit einem solchen Profil hat eine hohe Steifigkeit und umschließt einen verhältnismäßig großen Montageraum 100 zwischen der Hauptwandung 101 und der durch die Montageschenkel 112 begrenzten Ebene; darin kann beispielsweise ein Vorschaltgerät, ein Kompensationskondensator oder anderes Zubehör untergebracht sein. Soweit es sich dabei um Leitungen oder Kabel handelt, werden diese vorzugsweise innerhalb der Rinnen 110 der Randteile 11 geführt und darin durch den in FIG 1 gezeigten Zubehörhalter 2.1 gesichert.1 shows in cross section a luminaire wall 1 with a main part 10, which is delimited by a

Ein solcher, auf diese Funktion spezialisierter Zubehörhalter 2.1 ist ein Kunststoff-Formteil von etwa 1 cm Breite (in Richtung senkrecht zur Zeichenebene) und hat einen Mittelteil 20.1, der etwa in der Verlängerung der Montageschenkel 112 verläuft, also den Montageraum 100 frei läßt. An einem Ende des Mittelteiles 20.1 ist ein C-förmiger Fuß 21.1 mit einem halbkreisförmigen Endstück 211.1 und einem Verbindungsstück 212.1 angeformt.Such an accessory holder 2.1 specializing in this function is a plastic molded part of approximately 1 cm in width (in the direction perpendicular to the plane of the drawing) and has a central part 20.1 which extends approximately in the extension of the

Am anderen Ende des Mittelteiles 20.1 ist eine V-förmige Feder 22.1 mit einem Federschenkel 221.1 und einem Verbindungsschenkel 222.1 angeformt; am Ende des Federschenkels 221.1 befindet sich ein Rastsitz 223.1 mit einem Sperranschlag 2231.1 und einem dazu rechtwinklig verlaufenden Weganschlag 2232.1, der den Weg der Feder 22.1 begrenzt. Mit dem Sperranschlag 2231.1 stützt sich der Zubehörhalter 2.1 an der Innenseite und mit dem Weganschlag 2232.1 federnd an dem Rand 1120 des Montageschenkels 112 ab. Dabei liegt der Federschenkel 221.1 auch an dem Übergang zwischen den Wandungen I02 und 114 an, wodurch die in FIG 1 gezeichnete Position noch zusätzlich gesichert ist. Der Zubehörhalter 2.1 ist somit zwischen dem Boden 113 des unteren Randteiles 11 der Leuchtenwand 1 und dem Rand 1120 des oberen Randteiles 11 federnd eingespannt. Der Abstand zwischen dem Endstück 211.1 des Fußes des Zubehörhalters und dem Rastsitz 223.1 ist daher im entspannten Zustand - in FIG 1 gestrichelt dargestellt - größer als der Abstand zwischen dem Boden 113 des einen Randteiles 11 und dem Rand 1120 des anderen Randteiles 11 der Leuchtenwand 1.At the other end of the middle part 20.1, a V-shaped spring 22.1 is formed with a spring leg 221.1 and a connecting leg 222.1; at the end of the spring leg 221.1 there is a detent seat 223.1 with a locking stop 2231.1 and a travel stop 2232.1 running at right angles thereto, which limits the travel of the spring 22.1. The accessory holder 2.1 is supported on the inside with the locking stop 2231.1 and resiliently on the

Die Öffnung 210.1 des C-förmigen Fußes 21.1 überragt die Höhe des Montageschenkels 112 mindestens so weit, daß der Zubehörhalter in der in FIG 1 gestrichelt gezeichneten schrägen Position einsetzbar ist.The opening 210.1 of the C-shaped foot 21.1 projects beyond the height of the

Der Außendurchmesser des Endstückes 211.1 des Fußes 21.1 ist nur geringfügig größer als die lichte Weite der Rinne 110 des Randes 11 der Leuchtenwand 1, so daß eine praktisch spielfreie Lagerung des Zubehörhalters und zugleich eine Drehung in der Leuchtenwand möglich ist.The outer diameter of the end piece 211.1 of the foot 21.1 is only slightly larger than the inside width of the

Der Zubehörhalter 2.1 schließt mit seinem Federschenkel 221.1 die Rinne 110 des oberen Randteiles 11 der Leuchtenwand 1 ab und sichert darin untergebrachte Leitungen gegen Herausfallen. Durch Niederdrücken des Federschenkels 221.1 können einzelne Leitungen leicht eingelegt oder herausgenommen werden.The accessory holder 2.1 closes the

Auch in dem C-förmigen Fuß 21.1 können Leitungen, insbesondere für die Durchgangsverdrahtung, untergebracht werden. Sie werden darin gegen Herausfallen durch einen federnden Sperrschenkel 202.1 gesichert, der vom Mittelteil 20.1 gegen das Endstück 211.1 gerichtet ist und der den über dem Montageschenkel 112 liegenden Teil der Öffnung 210.1 sperrt.Cables, in particular for through-wiring, can also be accommodated in the C-shaped foot 21.1. They are secured against falling out by a resilient locking leg 202.1, which is directed from the middle part 20.1 against the end piece 211.1 and which blocks the part of the opening 210.1 lying above the

Die FIG 2 bis 4 beziehen sich auf einen Zubehörhalter 2 aus Federstahl, der zur Halterung von schwererem Zubehör und zugleich zu dessen Erdung geeignet ist und der dementsprechend in Richtung senkrecht zur Zeichenebene eine größere Ausdehnung hat (FIG 3). Abweichend von der in FIG 1 dargestellten Ausführungsform sind vor allem die Rastsitze 223 ausgebildet: Hierzu hat der Federschenkel 221 an seinem Ende zwei Endstücke 224, die gegen den Fuß 21 des Zubehörhalters 2 abgewinkelt sind, etwa senkrecht auf dem Federschenkel 221 stehen und als Sperranschlag 2231 dienen. Jedes dieser Endstücke 224 hat an den beiden Enden einen Randlappen 225, der wiederum senkrecht auf dem Endstück 224 steht (FIG 4), und zwar so, daß die Randlappen 225 von dem Mittelteil 20 wegweisen. Jeder dieser Randlappen 225 hat nun eine Schnittkante 2251, die schräg zu der Ebene des Endstückes 224 steht und als Weganschlag 2232 dient (FIG 2).FIGS. 2 to 4 relate to an accessory holder 2 made of spring steel, which is suitable for holding heavier accessories and at the same time for earthing them, and which accordingly has a greater extent in the direction perpendicular to the plane of the drawing (FIG. 3). In a departure from the embodiment shown in FIG. 1, the

Der Zubehörhalter 2 wird ebenso wie der nach FIG 1 in die Leuchtenwand 1 eingesetzt: Dabei wird der Federschenkel 221 von dem Rand 1120 des Montageschenkels 112 wieder nach unten gedrückt, bis der Rand 1120 in den Rastsitz 223 des Zubehörhalters 2 einschnappt. Hierbei stützt sich der Zubehörhalter 2 mit dem Sperranschlag 2231 gegen die Innenseite des Montageschenkels 112 ab; ferner kerben sich die scharfen Schnittkanten 2251 der vier Randlappen 225 (FIG 3) in den blanken Rand 1120 ein und sorgen so für eine zuverlässige elektrische Verbindung und für eine Begrenzung des Federweges.The accessory holder 2 is inserted into the lamp wall 1 in the same way as that according to FIG. 1: the

Die Ausführungsform des Zubehörhalters 2.2 nach den FIG 5 und 6 unterscheidet sich von dem Zubehörhalter 2 nach den FIG 2 bis 4 lediglich durch die Art des Rastsitzes :

- Der Weganschlag 2232.2 wird hier von einem abgewinkelten Endstück 224.2 des Federschenkels 221.2 gebildet, so daß diese Ausführungsform auch dann brauchbar ist, wenn der Rand 1120.1 am unteren Ende des Montageschenkels 112.1 der ebene Boden eines U-förmigen Tragrandes 1121.1 ist.

- The travel stop 2232.2 is formed here by an angled end piece 224.2 of the spring leg 221.2, so that this embodiment can also be used if the edge 1120.1 at the lower end of the mounting leg 112.1 is the flat bottom of a U-shaped supporting edge 1121.1.

Das Endstück 224.2 ist gegenüber dem Federschenkel 221.2 nach unten abgewinkelt und hat zusätzlich eine Handhabe 2234.2. Am Ende des Federschenkels sind zu beiden Seiten des Endstückes zwei Sperranschläge 2231.2 sowie je zwei Krallen 2233.2 je Sperranschlag vorgesehen. Die Ebenen, in denen der Weganschlag einerseits und die Sperranschläge und Krallen andererseits liegen, bilden einen kleinen spitzen Winkel, wobei die Formen und Abmessungen gemäß FIG 5 so gewählt sind, daß der Zubehörhalter den Montageschenkel 112.1 beim Einsetzen zuerst mit den Krallen 2233.2 und Sperranschlägen 2231.2 und danach mit dem Weganschlag 2234.2 berührt. Dabei durchdringen die Krallen 2233.2 eine eventuell vorhandene Schutzlackierung und prägen sich in das blanke Metall der Leuchtenwand 1.1 ein. Da hierbei die Spitzen der Krallen etwas verformt werden können, sind diese Krallen vorzugsweise geringfügig länger als die die Andruckkräfte übertragenden Sperranschläge 2231.2, so daß unter allen Bedingungen ein einwandfreier elektrischer Kontakt gewährleistet ist.The end piece 224.2 is angled downwards relative to the spring leg 221.2 and additionally has a handle 2234.2. At the end of the spring leg there are two locking stops 2231.2 and two on each side of the end piece Claws 2233.2 are provided for each stop. The planes, in which the travel stop on the one hand and the locking stops and claws on the other, form a small acute angle, the shapes and dimensions according to FIG. 5 being selected such that the accessory holder first fits the mounting leg 112.1 with the claws 2233.2 and locking stops 2231.2 and then touched with the way stop 2234.2. The claws 2233.2 penetrate any protective lacquer that may be present and impress themselves in the bare metal of the luminaire wall 1.1. Since the tips of the claws can be deformed somewhat, these claws are preferably slightly longer than the locking stops 2231.2 which transmit the pressure forces, so that perfect electrical contact is ensured under all conditions.

An dem Mittelteil 20.2 des Zubehörhalters 2.2 kann das Zubehör direkt, z.B. durch Schrauben an einem herausgebogenen Lappen, befestigt sein. Bei entsprechenden Abmessungen kann das Zubehör, beispielsweise ein Vorschaltgerät 3, auch direkt zwischen der Hauptwandung 101.1 der Leuchtenwand 1.1 und dem Mittelteil 20.2 des Zubehörhalters 2.2 eingespannt sein. Hierbei können Krallen 201.2 im Mittelteil 20.2 für eine zuverlässige elektrische Verbindung zwischen dem Zubehör und dem Zubehörhalter sorgen. Zur Erhöhung der Andruckkraft kann dabei das Mittelteil 20.2 eine gegen die Leuchtenwand 1.1 gerichtete Wölbung haben oder mit Versteifungssicken versehen sein.The accessories can be attached directly to the middle part 20.2 of the accessory holder 2.2, e.g. attached to a bent rag by screws. With appropriate dimensions, the accessories, for example a

Bei der Ausführungsform nach FIG 7 ist der Zubehörhalter 2.3 an der Leuchtenwand derart federnd eingespannt, daß das Mittelteil 20.3 und Krallen 201.3 an der Innenseite der Hauptwandung 101.1 der Leuchtenwand 1.1 anliegen. An dem einen Ende des Mittelteiles 20.3 ist ein Fuß 21.3 mit den bereits beschriebenen Merkmalen angeordnet. Diesem gegenüber weist der Zubehörhalter 2.3 einen Verbindungsschenkel 222.3 auf, der nach oben gegen die Rinne 110.1 gerichtet ist und in dem im Abstand hintereinander zwei Verschraubungen 226.3 angeordnet sind. Durch diese Verschraubungen ist an dem Verbindungsschenkel 222.3 eine Klemmplatte 23.3 befestigt, die mit einem Federarm 231.3 in die Rinne 110.1 eingreift. Dieser Federarm - dessen entspannte Position in FIG 7 gestrichelt dargestellt ist - drückt das Mittelteil 20.3 bei angezogener Verschraubung - in der Figur dargestellt - gegen die Hauptwandung 101.1. Das freie Ende des Federarmes weist zusätzliche Krallen auf.In the embodiment according to FIG. 7, the accessory holder 2.3 is resiliently clamped on the lamp wall in such a way that the middle part 20.3 and claws 201.3 rest on the inside of the main wall 101.1 of the lamp wall 1.1. A foot 21.3 with the features already described is arranged at one end of the middle part 20.3. This opposite, the accessory holder 2.3 has a connecting leg 222.3 which is directed upwards against the channel 110.1 and in which two screw connections 226.3 are arranged one behind the other at a distance. By means of these screw connections, a clamping plate 23.3 is fastened to the connecting leg 222.3 and engages with a spring arm 231.3 in the channel 110.1. This spring arm - the relaxed position of which is shown in dashed lines in FIG. 7 - presses the middle part 20.3 against the main wall 101.1 when the screw connection is tightened - shown in the figure. The free end of the spring arm has additional claws.

Die Klemmplatte 23.3 hat je Verschraubung 226.3 ein Langloch, das sich quer zur Längsachse der Leuchtenwand soweit in den Federarm 231.3 hinein erstreckt, daß sich die Klemmplatte nach Lösen der Verschraubung 226.3 soweit nach unten ziehen läßt, daß der Zubehörhalter 2.3 um seinen Fuß 21.3 unter dem gegenüberliegenden Rand 1120.1 nach außen schwenkbar ist.The clamping plate 23.3 has a slot 226.3 each screw, which extends transversely to the longitudinal axis of the lamp wall as far into the spring arm 231.3 that the clamping plate can be pulled down so far after loosening the screw connection 226.3 that the accessory holder 2.3 around its foot 21.3 under the opposite edge 1120.1 is pivotable outwards.

- 1; 1.1 Leuchtenwand1; 1.1 Luminaire wall

- 10 Hauptteil10 main part

- 100 Montageraum100 assembly room

- 101; 101.1 Hauptwandung101; 101.1 main wall

- 102 Querwandung102 transverse wall

- 11; 11.1 Randteil11; 11.1 edge part

- 110; 110.1 Rinne110; 110.1 gutter

- 112; 112.1 Montageschenkel112; 112.1 Assembly leg

- 1120; 1120.1 Rand1120; 1120.1 margin

- 1121.1 Tragrand1121.1 carrying rim

- 113 Boden113 floor

- 114 Randwandung114 edge wall

- 2; 2.1; 2.2; 2.3 Zubehörhalter2; 2.1; 2.2; 2.3 Accessory holder

- 20; 20.1; 20.2; 20.3 Mittelteil20; 20.1; 20.2; 20.3 middle section

- 201; 201.3 Krallen201; 201.3 claws

- 202.1 Sperrschenkel202.1 locking leg

- 21; 21.1; 21.2; 21.3 Fuß21; 21.1; 21.2; 21.3 feet

- 210; 210.1 Öffnung210; 210.1 opening

- 211; 211.1 Endstück211; 211.1 end piece

- 212; 212.1 Verbindungsstück212; 212.1 connector

- 22; 22.1; 22.2 Feder22; 22.1; 22.2 spring

- 221; 221.1; 221.2 Federschenkel221; 221.1; 221.2 spring legs

- 222; 222.1; 222.3 Verbindungsschenkel222; 222.1; 222.3 connecting leg

- 2221.3 Langloch2221.3 slot

- 223; 223.1; 223.2 Rastsitz223; 223.1; 223.2 Rest seat

- 2231; 2231.1; 2231.2 Sperranschlag2231; 2231.1; 2231.2 Stopper

- 2232; 2232.1; 2232.2 Weganschlag2232; 2232.1; 2232.2 Limit stop

- 2233.2 Krallen2233.2 claws

- 2234.2 Handhabe2234.2 handle

- 224; 224.2 Endstück224; 224.2 end piece

- 225 Randlappen225 marginal lobes

- 2251 Schnittkante2251 cut edge

- 226.3 Verschraubung226.3 Screw connection

- 23.3 Klemmplatte23.3 Clamping plate

- 231.3 Federarm231.3 spring arm

- 3 Vorschaltgerät3 ballast

Claims (11)

mit einem im Querschnitt U-förmigen Hauptteil (10) mit Haupt- und Querwandungen (101; 101.1; 102),

mit zwei Randteilen (11; 11.1), von denen jeder mit einem Montageschenkel (112; 112.1), einem Boden (113) und einer Randwandung (114) eine Rinne (110; 110.1) umschließt,

derart, daß die Öffnungen der Rinnen (110; 110.1) der beiden Randteile gegeneinander gerichtet sind und die Randwandung (114) jedes Randteiles (11; 11.1) mit der angrenzenden Querwandung (102) des Hauptteiles (10) verbunden ist,

mit einem Zubehörhalter (2; 2.1; 2.2), der mit einem Fuß (21; 21.1; 21.2) in der Rinne (110; 110.1) des einen Randteiles (11: 11.1) der Leuchtenwand (1) steckt und an dem gegenüberliegenden Randteil lösbar befestigt ist,

dadurch gekennzeichnet , daß der Zubehörhalter (2; 2.1; 2.2) an dem seinem Fuß (21; 21.1; 21.2) gegenüberliegenden Ende eine V-förmige Feder (22; 22.1; 22.2) mit einem freien Federschenkel (221; 221.1; 221.2) und einem Rastsitz (223; 223.1; 223.2) aufweist,

daß jeder Rastsitz einen Sperranschlag (2231; 2231.1; 2231.2) und einen Weganschlag (2232; 2232.1; 2232.2) hat,

und daß der Zubehörhalter (2; 2.1; 2.2) zwischen den Rinnen (110; 110.1) der Leuchtenwand (1) federnd eingespannt ist, indem sich der Sperranschlag (2231; 2231.1; 2231.2) des Rastsitzes gegen die Innenseite und sein Weganschlag (2232; 232;1, 232.2) gegen den Rand (1120; 1120.1) des Montageschenkels (112; 112.1) der Leuchtenwand (1; 1.1) abstützt.1. arrangement for holding accessories on a lamp wall (l; 1.1),

with a main part (10) with a U-shaped cross section with main and transverse walls (101; 101.1; 102),

with two edge parts (11; 11.1), each of which surrounds a channel (110; 110.1) with a mounting leg (112; 112.1), a bottom (113) and an edge wall (114),

such that the openings of the grooves (110; 110.1) of the two edge parts are directed towards one another and the edge wall (114) of each edge part (11; 11.1) is connected to the adjacent transverse wall (102) of the main part (10),

with an accessory holder (2; 2.1; 2.2) which is inserted with a foot (21; 21.1; 21.2) in the groove (110; 110.1) of one edge part (11: 11.1) of the lamp wall (1) and detachable on the opposite edge part is attached

characterized in that the accessory holder (2; 2.1; 2.2) at the end opposite its base (21; 21.1; 21.2) has a V-shaped spring (22; 22.1; 22.2) with a free spring leg (221; 221.1; 221.2) and has a rest seat (223; 223.1; 223.2),

that each rest seat has a locking stop (2231; 2231.1; 2231.2) and a travel stop (2232; 2232.1; 2232.2),

and that the accessory holder (2; 2.1; 2.2) is resiliently clamped between the channels (110; 110.1) of the lamp wall (1) by the locking stop (2231; 2231.1; 2231.2) of the rest seat against the inside and its stop (2232; 232; 1, 232.2) against the edge (1120; 1120.1) of the mounting leg (112; 112.1) of the lamp wall (1; 1.1).

der Zubehörhalter (2.2) aus Federstahl besteht,

daß der Weganschlag (2232.2) ein Endstück (224.2) des freien Federschenkels (221.2) ist, das diesem gegenüber abgewinkelt ist,

daß der Federschenkel (221.2) an seinem Ende mindestens einen Sperranschlag (2231.2) und diesem benachbart mindestens eine Kralle (2233.2) hat,

und daß die Ebenen, in denen Weganschlag einerseits und Sperranschlag und Kralle andererseits liegen, einen spitzen Winkel zwischen sich einschließen (FIG 5, 6).3. Arrangement according to claim 1, characterized in that

the accessory holder (2.2) is made of spring steel,

that the travel stop (2232.2) is an end piece (224.2) of the free spring leg (221.2), which is angled relative to it,

that the spring leg (221.2) has at least one locking stop (2231.2) at its end and at least one claw (2233.2) adjacent to it,

and that the planes, in which the path stop on the one hand and the locking stop and claw on the other hand, enclose an acute angle between them (FIGS. 5, 6).

mit einem im Querschnitt U-förmigen Hauptteil (10) mit Haupt- und Querwandungen (101; 101.1; 102),

mit zwei Randteilen (11; 11.1), von denen jeder mit einem Montageschenkel (112; 112.1), einem Boden (113) und einer Randwandung (114) eine Rinne (110; 110.1) umschließt,

derart, daß die Öffnungen der Rinnen (110) der beiden Randteile (11) gegeneinander gerichtet sind und die Randwandung (114) jedes Randteiles (11) mit der angrenzenden Querwandung (102) des Hauptteiles (10) verbunden ist,

mit einem Zubehörhalter (2; 2.1, 2.2), der mit einem Fuß (21; 21.1, 21.2) in der einen Rinne (110) der Leuchtenwand (1) steckt und an dem gegenüberliegenden Randteil (11; 11.1) lösbar befestigt ist,

dadurch gekennzeichnet , daß der Zubehörhalter (2.3) einen innen an der Hauptwandung (101.1) der Leuchtenwand (1.1) anliegenden Mittelteil (20.3) und auf der seinem Fuß (21.3) gegenüberliegenden Seite einen Verbindungsschenkel (222.3) hat, daß mit dem Verbindungsschenkel (222.3) durch mindestens eine Verschraubung (226.3) eine Klemmplatte (23.3) verbunden ist, die mit einem freien Federarm (231.3) in die dem Fuß (21.3) gegenüberliegende Rinne (110.1) der Leuchtenwand (1.1) ragt,

und daß der Zubehörhalter (2.3) und die Klemmplatte (23.3) so geformt und auf die Abmessungen des Profils der Leuchtenwand (1.1) abgestimmt sind, daß der Zubehörhalter bei festgezogener Verschraubung (226.3) zwischen der Hauptwandung (101.1) und dem Montageschenkel (112.1) der Leuchtenwand (1.1) eingespannt ist.6. arrangement for holding accessories on a lamp wall (1; 1.1),

with a main part (10) with a U-shaped cross section with main and transverse walls (101; 101.1; 102),

with two edge parts (11; 11.1), each of which surrounds a channel (110; 110.1) with a mounting leg (112; 112.1), a base (113) and an edge wall (114),

such that the openings of the grooves (110) of the two edge parts (11) are directed towards one another and the edge wall (114) of each edge part (11) is connected to the adjacent transverse wall (102) of the main part (10),

with an accessory holder (2; 2.1, 2.2), which is inserted with a foot (21; 21.1, 21.2) in one channel (110) of the lamp wall (1) and is releasably attached to the opposite edge part (11; 11.1),

characterized in that the accessory holder (2.3) has a central part (20.3) lying against the inside of the main wall (101.1) of the lamp wall (1.1) and a connecting leg (222.3) on the side opposite its base (21.3), that a clamping plate (23.3) is connected to the connecting leg (222.3) by at least one screw connection (226.3), which projects with a free spring arm (231.3) into the channel (110.1) of the lamp wall (1.1) opposite the foot (21.3),

and that the accessory holder (2.3) and the clamping plate (23.3) are shaped and matched to the dimensions of the profile of the lamp wall (1.1) such that the accessory holder, when the screw connection (226.3) is tightened, between the main wall (101.1) and the mounting leg (112.1) the lamp wall (1.1) is clamped.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT84112316T ATE49286T1 (en) | 1983-12-23 | 1984-10-12 | ARRANGEMENT FOR MOUNTING ACCESSORIES ON A LUMINAIRE WALL. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19833346826 DE3346826A1 (en) | 1983-12-23 | 1983-12-23 | ACCESSORIES FOR A LUMINAIRE WALL |

| DE3346826 | 1983-12-23 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0148334A2 true EP0148334A2 (en) | 1985-07-17 |

| EP0148334A3 EP0148334A3 (en) | 1987-07-22 |

| EP0148334B1 EP0148334B1 (en) | 1990-01-03 |

Family

ID=6217960

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP84112316A Expired - Lifetime EP0148334B1 (en) | 1983-12-23 | 1984-10-12 | Device for the attachment of accessories on the wall of a lighting fixture |

Country Status (6)

| Country | Link |

|---|---|

| EP (1) | EP0148334B1 (en) |

| AT (1) | ATE49286T1 (en) |

| DE (2) | DE3346826A1 (en) |

| GR (1) | GR82581B (en) |

| NO (1) | NO162168C (en) |

| ZA (1) | ZA848223B (en) |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0377109A1 (en) * | 1988-12-03 | 1990-07-11 | Licentia Patent-Verwaltungs-GmbH | Housing for a street-lamp |

| GB2300471A (en) * | 1995-04-03 | 1996-11-06 | Louvre Company Limited The | A reflector unit |

| EP1052452A1 (en) * | 1999-05-11 | 2000-11-15 | Koninklijke Philips Electronics N.V. | Luminaire having an elongate shape |

| AT13774U1 (en) * | 2013-04-30 | 2014-08-15 | Zumtobel Lighting Gmbh | lamp |

| EP2876366A1 (en) * | 2013-11-25 | 2015-05-27 | Bega Gantenbrink-Leuchten KG | Lamp with clamping element |

| EP3301346A1 (en) * | 2016-09-30 | 2018-04-04 | GE Lighting Solutions, LLC | Clamping system for luminaire electronic drivers |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4947301A (en) * | 1989-05-04 | 1990-08-07 | Charles Steele | Neon tube electrode housing |

| CN112032621B (en) * | 2020-08-04 | 2022-01-14 | 厦门普为光电科技有限公司 | Track lamp |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| BE506075A (en) * | ||||

| DE1751296U (en) * | 1957-02-18 | 1957-08-29 | Licentia Gmbh | TOUCH PROTECTION FOR CONTROL GEAR AND CONNECTING PARTS IN LUMINAIRES WITH TUBE-SHAPED LAMPS. |

| US3101922A (en) * | 1962-03-07 | 1963-08-27 | Gen Motors Corp | Snap fastener |

| DE1489520A1 (en) * | 1965-07-10 | 1969-04-03 | Siemens Ag | Light for fluorescent lamps with a clamped choke coil |

| DE8220827U1 (en) * | 1982-07-21 | 1982-11-25 | Siemens AG, 1000 Berlin und 8000 München | MOUNTING AN ACCESSORY BRACKET ON A LIGHT BRACKET |

| EP0076096A1 (en) * | 1981-09-24 | 1983-04-06 | Henry Lindsay Limited | Fixing device for mounting a plate on the flange of a beam |

-

1983

- 1983-12-23 DE DE19833346826 patent/DE3346826A1/en not_active Withdrawn

-

1984

- 1984-10-12 AT AT84112316T patent/ATE49286T1/en active

- 1984-10-12 DE DE8484112316T patent/DE3480946D1/en not_active Expired - Lifetime

- 1984-10-12 EP EP84112316A patent/EP0148334B1/en not_active Expired - Lifetime

- 1984-10-19 NO NO844186A patent/NO162168C/en unknown

- 1984-10-22 ZA ZA848223A patent/ZA848223B/en unknown

- 1984-12-21 GR GR82581A patent/GR82581B/en unknown

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| BE506075A (en) * | ||||

| DE1751296U (en) * | 1957-02-18 | 1957-08-29 | Licentia Gmbh | TOUCH PROTECTION FOR CONTROL GEAR AND CONNECTING PARTS IN LUMINAIRES WITH TUBE-SHAPED LAMPS. |

| US3101922A (en) * | 1962-03-07 | 1963-08-27 | Gen Motors Corp | Snap fastener |

| DE1489520A1 (en) * | 1965-07-10 | 1969-04-03 | Siemens Ag | Light for fluorescent lamps with a clamped choke coil |

| EP0076096A1 (en) * | 1981-09-24 | 1983-04-06 | Henry Lindsay Limited | Fixing device for mounting a plate on the flange of a beam |

| DE8220827U1 (en) * | 1982-07-21 | 1982-11-25 | Siemens AG, 1000 Berlin und 8000 München | MOUNTING AN ACCESSORY BRACKET ON A LIGHT BRACKET |

Cited By (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0377109A1 (en) * | 1988-12-03 | 1990-07-11 | Licentia Patent-Verwaltungs-GmbH | Housing for a street-lamp |

| GB2300471A (en) * | 1995-04-03 | 1996-11-06 | Louvre Company Limited The | A reflector unit |

| EP1052452A1 (en) * | 1999-05-11 | 2000-11-15 | Koninklijke Philips Electronics N.V. | Luminaire having an elongate shape |

| AT13774U1 (en) * | 2013-04-30 | 2014-08-15 | Zumtobel Lighting Gmbh | lamp |

| EP2876366A1 (en) * | 2013-11-25 | 2015-05-27 | Bega Gantenbrink-Leuchten KG | Lamp with clamping element |

| US9739456B2 (en) | 2013-11-25 | 2017-08-22 | Bega Gantenbrink-Leuchten Kg | Luminaire having a clamping member |

| EP3301346A1 (en) * | 2016-09-30 | 2018-04-04 | GE Lighting Solutions, LLC | Clamping system for luminaire electronic drivers |

Also Published As

| Publication number | Publication date |

|---|---|

| ATE49286T1 (en) | 1990-01-15 |

| DE3480946D1 (en) | 1990-02-08 |

| EP0148334B1 (en) | 1990-01-03 |

| ZA848223B (en) | 1985-07-31 |

| NO162168B (en) | 1989-08-07 |

| GR82581B (en) | 1985-04-23 |

| NO844186L (en) | 1985-06-24 |

| EP0148334A3 (en) | 1987-07-22 |

| NO162168C (en) | 1989-11-15 |

| DE3346826A1 (en) | 1985-07-11 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE2544893C2 (en) | Electrical connecting element for a clamp connection and an electrical connection | |

| DE69007819T2 (en) | Mounting system for car phones. | |

| DD274317A5 (en) | DEVICE FOR MOUNTING CONNECTING BARS OF REMOTE DETECTION TECHNOLOGY | |

| DE3882421T2 (en) | Electrical device base for installation in a cable duct. | |

| EP3477792A1 (en) | Pickup connector and grounding contact for same | |

| EP0010251A1 (en) | Device for the internal mounting of installation equipment | |

| EP0926791B1 (en) | Adapter having a base housing for a busbar system with a number of busbars | |

| EP0939980B1 (en) | Rack with a lower frame and an upper frame made of a continuous section | |

| EP0148334A2 (en) | Device for the attachment of accessories on the wall of a lighting fixture | |

| EP0140058B1 (en) | Support for a recessed light fitting | |

| DE19524381C2 (en) | Installation duct with a metallic duct profile open to one side | |

| DE3342382C2 (en) | ||

| DE2852829A1 (en) | QUICK-MOUNTED PLASTIC BASE | |

| DE102018119525A1 (en) | Tap connector and protective ground contact thereto | |

| DE3201169C2 (en) | Device for clamping electrical conductors, in particular wires | |

| DE19949508A1 (en) | Fixing device for attaching electric power cable shield terminal e.g. to bus-bar base, has one-piece sheet-metal carrier with opening for receiving terminal | |

| DE69600846T2 (en) | Device carrier for a housing partially submerged in a line, and method for carrying it out | |

| DE8500148U1 (en) | Device for equipotential bonding for earth conductors in electrical installations | |

| DE2320982C3 (en) | Multi-conductor busbar | |

| EP3419128A1 (en) | Power strip for a distribution box | |

| DE29502779U1 (en) | Potential distribution device for electrical systems | |

| EP0675583B1 (en) | Arrangement for wall mounting of an electrical device such as switch, outlet or similar | |

| DE3220456A1 (en) | Lamp carrier | |

| DE69504403T2 (en) | Terminal strip holder in control cabinet or the like | |

| DE9416757U1 (en) | Table leg |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): AT CH DE IT LI SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT CH DE IT LI SE |

|

| 17P | Request for examination filed |

Effective date: 19871218 |

|

| 17Q | First examination report despatched |

Effective date: 19881122 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT CH DE IT LI SE |

|

| REF | Corresponds to: |

Ref document number: 49286 Country of ref document: AT Date of ref document: 19900115 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 3480946 Country of ref document: DE Date of ref document: 19900208 |

|

| ITF | It: translation for a ep patent filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| ITTA | It: last paid annual fee | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 19950118 Year of fee payment: 11 |

|

| EAL | Se: european patent in force in sweden |

Ref document number: 84112316.9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 19951019 Year of fee payment: 12 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Effective date: 19951031 Ref country code: CH Effective date: 19951031 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19961013 |

|

| EUG | Se: european patent has lapsed |

Ref document number: 84112316.9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 19970926 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19971218 Year of fee payment: 14 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19981012 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19990803 |