EP0115975B1 - Filtre électromagnétique permettant une évacuation en continu des produits de filtration et procédé de filtrage utilisant un tel filtre - Google Patents

Filtre électromagnétique permettant une évacuation en continu des produits de filtration et procédé de filtrage utilisant un tel filtre Download PDFInfo

- Publication number

- EP0115975B1 EP0115975B1 EP84400026A EP84400026A EP0115975B1 EP 0115975 B1 EP0115975 B1 EP 0115975B1 EP 84400026 A EP84400026 A EP 84400026A EP 84400026 A EP84400026 A EP 84400026A EP 0115975 B1 EP0115975 B1 EP 0115975B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- section

- filtration

- solution

- phase

- filter

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

- 238000001914 filtration Methods 0.000 title claims description 60

- 230000005291 magnetic effect Effects 0.000 claims description 37

- 238000005406 washing Methods 0.000 claims description 36

- 230000010349 pulsation Effects 0.000 claims description 29

- 238000012856 packing Methods 0.000 claims description 14

- 238000000034 method Methods 0.000 claims description 12

- 238000007599 discharging Methods 0.000 claims description 7

- 238000000605 extraction Methods 0.000 claims description 3

- 230000001174 ascending effect Effects 0.000 claims 4

- 230000007423 decrease Effects 0.000 claims 1

- 239000000047 product Substances 0.000 description 19

- 239000007787 solid Substances 0.000 description 11

- 238000005352 clarification Methods 0.000 description 6

- 239000000725 suspension Substances 0.000 description 5

- 230000005484 gravity Effects 0.000 description 4

- 239000007788 liquid Substances 0.000 description 4

- 238000011001 backwashing Methods 0.000 description 3

- 239000012535 impurity Substances 0.000 description 3

- 238000012958 reprocessing Methods 0.000 description 3

- 229910000831 Steel Inorganic materials 0.000 description 2

- 238000004090 dissolution Methods 0.000 description 2

- 230000000717 retained effect Effects 0.000 description 2

- 239000010959 steel Substances 0.000 description 2

- 238000004804 winding Methods 0.000 description 2

- 241001080024 Telles Species 0.000 description 1

- 239000002253 acid Substances 0.000 description 1

- 239000007900 aqueous suspension Substances 0.000 description 1

- 239000011324 bead Substances 0.000 description 1

- 238000000254 composite pulse decoupling sequence Methods 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 239000004744 fabric Substances 0.000 description 1

- 230000005294 ferromagnetic effect Effects 0.000 description 1

- 244000144992 flock Species 0.000 description 1

- 239000012530 fluid Substances 0.000 description 1

- 239000000446 fuel Substances 0.000 description 1

- 238000009434 installation Methods 0.000 description 1

- 239000000696 magnetic material Substances 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 229910052751 metal Inorganic materials 0.000 description 1

- 230000005298 paramagnetic effect Effects 0.000 description 1

- 230000002035 prolonged effect Effects 0.000 description 1

- 230000001869 rapid Effects 0.000 description 1

- 239000012265 solid product Substances 0.000 description 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 1

Images

Classifications

-

- G—PHYSICS

- G21—NUCLEAR PHYSICS; NUCLEAR ENGINEERING

- G21C—NUCLEAR REACTORS

- G21C19/00—Arrangements for treating, for handling, or for facilitating the handling of, fuel or other materials which are used within the reactor, e.g. within its pressure vessel

- G21C19/42—Reprocessing of irradiated fuel

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B03—SEPARATION OF SOLID MATERIALS USING LIQUIDS OR USING PNEUMATIC TABLES OR JIGS; MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03C—MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03C1/00—Magnetic separation

- B03C1/02—Magnetic separation acting directly on the substance being separated

- B03C1/025—High gradient magnetic separators

- B03C1/031—Component parts; Auxiliary operations

- B03C1/032—Matrix cleaning systems

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E30/00—Energy generation of nuclear origin

- Y02E30/30—Nuclear fission reactors

Definitions

- the present invention relates to an electromagnetic filter allowing continuous evacuation of filtration products and a filtering process using such a filter. It finds an application in particular in the reprocessing of irradiated fuels.

- Pulsed filters consist of a sintered metal cartridge through which filters the solution to be clarified; the principle of filtration is clearly different from that of the present invention.

- the present invention relates to a filter specially adapted for this application insofar as it allows the evacuation of the filtration products continuously (that is to say in complete stopping of the filter or at least without prolonged stopping, a disturbance of short term being inevitable) with a simple installation, without moving parts and perfectly accommodating the presence of exothermic products in the solution.

- the filter of the invention is of the electromagnetic type.

- a filter is essentially constituted by an envelope of non-magnetic material filled with a magnetizable lining and placed inside a winding.

- the passage of an electric current in the winding causes the appearance of a magnetic field having the effect of magnetizing the lining.

- the lining can be fixed, in the form of flock, steel wire cloth or stack of grids. But it is most often achieved by a bed of steel balls.

- the filter of the invention is of this type and, as such, it comprises a filtration section consisting of a magnetizable lining associated with a means for applying a magnetic field, a conduit for introducing a solution loaded with products to be filtered opening at the top of this section and a clarified solution extraction duct opening at the bottom of the section, see US-A-4 244 822.

- this filter is characterized in that it further comprises, disposed above the filtration section, a section for removing the filtration products, this section consisting of a magnetizable lining associated with a means for applying a adjustable magnetic field, this discharge section having a discharge duct opening at its upper part; the filter further comprises a pulsation leg opening at the lower part of the filtration section and capable of producing at least one pulsation comprising a first phase in which the column of solution present in the filter is subjected to an upward movement and a second phase in which this column is subjected to a downward movement.

- the means for applying the magnetic fields to the linings of the filtration and discharge sections are adjustable in synchronism with the pulsation, so that these fields are capable of causing, in the linings of the two sections, the filtration of the solution which passes through them during the second phase of the pulsation and that these fields are reduced to a value which allows their training during the first phase.

- the filter of the invention further comprises at least one section for backwashing the discharged products, this section being disposed between the filtration section and the discharge section and constituted by a magnetizable lining associated with a means of applying an adjustable magnetic field in synchronism with the fields applied to the linings of the filtration and evacuation section, this washing section having a conduit for introducing a washing solution opening at the top of said section.

- the pulsation is asymmetrical and comprises a first phase in which the column of solution present in the filter is subjected a rapid upward movement and a second phase in which this column is subjected to a slow downward movement.

- the present invention also relates to a method of filtering a solution loaded with products to be filtered.

- the process is of the kind in which this solution is introduced at the top of a filtration section consisting of a magnetizable lining to which a magnetic field is applied and a clarified solution is extracted at the base of this section.

- This process is characterized in that an operation for removing the filtration products is carried out, which consists in applying a pulsation at the base of the filtration section comprising a first phase in which the solution contained in the filter is subjected to an upward movement which causes at least a portion of the solution to pass through an evacuation section disposed above the filtration section and composed of a magnetizable lining to which an adjustable magnetic field is applied, and a second phase in which the solution is subjected to a downward movement which causes the said lining to pass back through the discharge section, the evacuation of the filtration products being effected by the upper part of the discharge section.

- a magnetic field is applied to the linings capable of causing them to filter during the second phase of the pulsation and a reduced magnetic field capable of reducing this filtration during the first phase of the pulsation.

- a zero magnetic field is applied to the linings during the first phase of the pulsation.

- the pulsation is asymmetrical and includes a rapid upward movement and a slow downward movement.

- a washing operation is carried out against the current of the evacuated filtration products, which consists in causing the solution to pass through, during the first phase of the pulsation, at least one washing section disposed between the section. filtration and discharge section, this washing section being composed of a magnetizable lining to which an adjustable magnetic field is applied, and a washing solution is introduced to the upper part of this washing section.

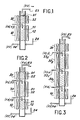

- the electromagnetic filter shown in FIG. 1 comprises, in a conventional manner, a filtration section 10 consisting of a magnetizable lining 11 associated with a means for applying a magnetic field 12.

- This section is connected to an introduction conduit of a solution loaded with products to be filtered 13 opening out at the upper part and an extraction duct for the clarified solution 14 opening out at the lower part of the section.

- the flows of these two solutions are denoted FA and FF respectively.

- the filter shown is characterized by the fact that it further comprises, disposed above the filtration section 10, a section for discharging the filtration products 20, the latter consisting of a magnetizable lining 21 associated with a means for applying an adjustable magnetic field 22.

- This discharge section has a discharge conduit 23 opening at its upper part.

- the filter comprises a pulsation leg 24 opening at the lower part of the filtration section 10.

- This leg is capable of producing at least one asymmetrical pulsation comprising a first phase in which the column of solution present in the filter is subjected a rapid upward movement and a second phase in which this column is subjected to a slow downward movement.

- the filter further comprises a section 30 for backwashing the discharged products, this section being disposed between the filtration section 10 and the discharge section 20. It consists of a magnetizable lining 31 associated with means for applying an adjustable magnetic field 32 controlled in synchronism with the fields applied to the linings 11 and 21 of the filtration and evacuation sections; this washing section 30 has a conduit 33 for introducing a washing solution opening into the upper part of said section, the flow of the washing solution being denoted FL.

- FIG 3 a filter according to the invention which is characterized in that it comprises several superimposed washing sections 30 1 , 30 2 , each supplied with washing solution by a particular conduit 33 1 , 33 2 (for example acid solution and water).

- a particular conduit 33 1 , 33 2 for example acid solution and water.

- the filter shown in FIG. 4 comprises a first filter without a washing section (filtration section 10 1 and discharge 20 1 ) and a second filter with a washing section 30 2 , the discharge duct 23 1 of the first filter being connected to the conduit for introducing the solution loaded with the second 13 2 .

- This arrangement makes it possible to adapt the dimensions of the filters to their function and in particular to give the washing section 30 2 a smaller section than that of the filtration section 10 1 .

- the means 26 1 , 26 2 disposed at the top of the filters are agitating means tion of the solution intended to keep the solid products in suspension.

- FIG. 5 represents the different operating phases of the filter of the invention, in the case where the washing section is present.

- the operation comprises six phases represented by diagrams a to f

- phase a

- phase b

- the first phase of the asymmetric pulsation is applied; it abruptly moves the column of liquid up; volumes V 1 and V 2 are found in V ' 1 and V' 2 ; the centers of gravity GS 'and GS' 2 of the products in suspension may be slightly lower than the geometric centers due to the greater difficulty that these products encounter when crossing the linings or a delay in their initial stalling from the filling; it will be observed that this first phase of the asymmetrical pulsation makes it possible to tear off the filtration products which clog the lining of the filtration section, to reassemble these products in the washing section and to pass the products located at the top of this washing section (due to previous pulsations), in the evacuation section;

- the magnetic field is restored in the linings; the filtering properties of these packings are restored, which makes it possible to fix the suspended solids;

- the second asymmetric pulse phase is applied; it causes the liquid column to descend slowly, the suspended solids being retained in the linings; the centers of gravity GS " i and GS" 2 of these solids are now located above the volumes of liquid returned to positions V "i, V" 2 ; overall, the solids were therefore moved to the top of the filter.

- the magnetic field is zero during the first phase of the pulsation, to allow the slides to go up through the linings.

- this extreme situation is not compulsory: it is possible to reduce only the field, without canceling it. In certain cases, it is even possible to maintain it at its nominal value, if the asymmetry between the upward movement and the downward movement of the column is sufficiently marked and allows the entrainment of the solids trapped in the packing during the rise of the liquid.

Landscapes

- Physics & Mathematics (AREA)

- Engineering & Computer Science (AREA)

- Plasma & Fusion (AREA)

- General Engineering & Computer Science (AREA)

- High Energy & Nuclear Physics (AREA)

- Filtration Of Liquid (AREA)

- Water Treatment By Electricity Or Magnetism (AREA)

- Surgical Instruments (AREA)

- Reciprocating, Oscillating Or Vibrating Motors (AREA)

- Dry Shavers And Clippers (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR8300330A FR2539050A1 (fr) | 1983-01-11 | 1983-01-11 | Filtre electromagnetique permettant une evacuation en continu des produits de filtration et procede de filtrage utilisant un tel filtre |

| FR8300330 | 1983-01-11 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0115975A1 EP0115975A1 (fr) | 1984-08-15 |

| EP0115975B1 true EP0115975B1 (fr) | 1986-08-27 |

Family

ID=9284837

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP84400026A Expired EP0115975B1 (fr) | 1983-01-11 | 1984-01-06 | Filtre électromagnétique permettant une évacuation en continu des produits de filtration et procédé de filtrage utilisant un tel filtre |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US4588507A (fi) |

| EP (1) | EP0115975B1 (fi) |

| JP (1) | JPS59162497A (fi) |

| DE (1) | DE3460512D1 (fi) |

| FR (1) | FR2539050A1 (fi) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CA1268426A (en) * | 1985-05-08 | 1990-05-01 | Yasuyuki Oishi | Method for removing iron content in petroleum series mineral oil therefrom |

| MX2014009596A (es) | 2012-02-10 | 2015-11-18 | Luvata Espoo Oy | Una artesa pivotante y un metodo para colar continuamente una aleacion de metal, uso de una artesa pivotante y una barra colada alargada de una aleacion de metal. |

| CN102861666B (zh) * | 2012-09-27 | 2015-01-21 | 沈阳隆基电磁科技股份有限公司 | 一种双摇杆式脉动箱 |

Family Cites Families (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2711248A (en) * | 1951-06-01 | 1955-06-21 | Jones & Laughlin Steel Corp | Concentration of iron ores |

| GB1204324A (en) * | 1966-11-30 | 1970-09-03 | Ronald John Stevens | Improvements in and relating to filters for liquid and gaseous fluids |

| DE1277488B (de) * | 1967-06-08 | 1968-09-12 | Siemens Ag | Einrichtung zur elektromagnetischen Entfernung von Eisenoxyden aus Fluessigkeit |

| US3838773A (en) * | 1973-03-16 | 1974-10-01 | Massachusetts Inst Technology | Vibrating-matrix magnetic separators |

| US4054513A (en) * | 1973-07-10 | 1977-10-18 | English Clays Lovering Pochin & Company Limited | Magnetic separation, method and apparatus |

| FR2341347A1 (fr) * | 1976-02-19 | 1977-09-16 | Commissariat Energie Atomique | Procede de decolmatage d'un filtre electromagnetique |

| DE2806340A1 (de) * | 1978-02-15 | 1979-08-30 | Kloeckner Humboldt Deutz Ag | Verfahren und vorrichtung zur abreinigung der matrix eines magnetscheiders, insbesondere eines nass-magnetscheiders |

| JPS55104617A (en) * | 1979-02-02 | 1980-08-11 | British Nuclear Fuels Ltd | Method and device for separating particle from liquid |

| US4244822A (en) * | 1979-08-09 | 1981-01-13 | The Babcock & Wilcox Company | Industrial technique magnetic apparatus |

| US4282105A (en) * | 1980-01-28 | 1981-08-04 | J. R. Schneider Co., Inc. | Filter |

-

1983

- 1983-01-11 FR FR8300330A patent/FR2539050A1/fr active Granted

-

1984

- 1984-01-06 DE DE8484400026T patent/DE3460512D1/de not_active Expired

- 1984-01-06 US US06/568,741 patent/US4588507A/en not_active Expired - Fee Related

- 1984-01-06 EP EP84400026A patent/EP0115975B1/fr not_active Expired

- 1984-01-09 JP JP59001806A patent/JPS59162497A/ja active Granted

Also Published As

| Publication number | Publication date |

|---|---|

| FR2539050B1 (fi) | 1985-03-08 |

| US4588507A (en) | 1986-05-13 |

| FR2539050A1 (fr) | 1984-07-13 |

| EP0115975A1 (fr) | 1984-08-15 |

| DE3460512D1 (en) | 1986-10-02 |

| JPS59162497A (ja) | 1984-09-13 |

| JPH0523806B2 (fi) | 1993-04-05 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| Hesslein et al. | Fates of metal radiotracers added to a whole lake: sediment–water interactions | |

| EP0115975B1 (fr) | Filtre électromagnétique permettant une évacuation en continu des produits de filtration et procédé de filtrage utilisant un tel filtre | |

| US2452220A (en) | Magnetic separator | |

| WO1993001877A1 (en) | Separator | |

| WO2006072729A1 (fr) | Perfectionnement du procede purex et ses utilisations | |

| JP5704618B2 (ja) | 混合物の分離方法及び分離装置 | |

| FR2479059A1 (fr) | Dispositif pour attenuer les eclaboussures et purifier un liquide d'usinage | |

| US4366065A (en) | Separating particles from a liquid | |

| RU2070097C1 (ru) | Способ разделения относительно магнитных минеральных частиц | |

| JP2014071025A (ja) | 固液分離方法および固液分離装置 | |

| FR2466282A1 (fr) | Procede d'elimination des elements metalliques lourds en suspension dans un liquide a l'aide d'un adjuvant ferromagnetique finement divise | |

| EP0038767A2 (fr) | Procédé et dispositif pour séparer par induction des particules de matériaux | |

| FR2641983A1 (fr) | Filtre electromagnetique a fort gradient de champ pour l'extraction de particules en suspension dans un fluide | |

| JP2001104822A (ja) | 磁性体粉除去装置 | |

| EP0169774B1 (fr) | Filtre électromagnétique à fonctionnement continu | |

| GB1511488A (en) | Magnetic separation | |

| Bielek et al. | Taylor vortices in short fluid columns with large radius ratio | |

| JPS61153117A (ja) | 磁気フイルタ | |

| GB1107954A (en) | Polonium recovery | |

| JPS6048213B2 (ja) | 電磁フイルタ−の再生方法 | |

| Leslie et al. | Separating particles from a liquid | |

| BE544561A (fr) | Filtre magnetique | |

| GB1572722A (en) | Magnetic separator | |

| FR2488149A1 (fr) | Procede et appareil de separation de poussieres | |

| GB2041789A (en) | Separating particles from a liquid |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): BE DE GB IT |

|

| 17P | Request for examination filed |

Effective date: 19850118 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): BE DE GB IT |

|

| REF | Corresponds to: |

Ref document number: 3460512 Country of ref document: DE Date of ref document: 19861002 |

|

| ITF | It: translation for a ep patent filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 19890104 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19890110 Year of fee payment: 6 |

|

| ITTA | It: last paid annual fee | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Effective date: 19900131 |

|

| BERE | Be: lapsed |

Owner name: COMMISSARIAT A L'ENERGIE ATOMIQUE ETABLISSEMENT D Effective date: 19900131 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19901002 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19921230 Year of fee payment: 10 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19940106 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19940106 |