EP0096635A2 - Verfahren und Vorrichtung zum Regeln der Vorausdehnung einer Plastikfolie, insbesondere bei dem Verpacken einer Ladung - Google Patents

Verfahren und Vorrichtung zum Regeln der Vorausdehnung einer Plastikfolie, insbesondere bei dem Verpacken einer Ladung Download PDFInfo

- Publication number

- EP0096635A2 EP0096635A2 EP83401119A EP83401119A EP0096635A2 EP 0096635 A2 EP0096635 A2 EP 0096635A2 EP 83401119 A EP83401119 A EP 83401119A EP 83401119 A EP83401119 A EP 83401119A EP 0096635 A2 EP0096635 A2 EP 0096635A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- film

- stretching

- tension

- load

- cylinder

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B11/00—Wrapping, e.g. partially or wholly enclosing, articles or quantities of material, in strips, sheets or blanks, of flexible material

- B65B11/04—Wrapping, e.g. partially or wholly enclosing, articles or quantities of material, in strips, sheets or blanks, of flexible material the articles being rotated

- B65B11/045—Wrapping, e.g. partially or wholly enclosing, articles or quantities of material, in strips, sheets or blanks, of flexible material the articles being rotated by rotating platforms supporting the articles

Definitions

- the invention relates to a method and a device for regulating the pre-stretching of a film of stretchable plastic, in particular for the packaging of a load.

- a device for packaging loads is described by means of a film of stretchable plastic material, which comprises first and second successive pairs of stretching cylinders between which the film passes, the downstream cylinders of the second pair rotating at a peripheral speed higher than that of the upstream cylinders of the first pair, the free end of the stretched film being driven by suitable means, placed downstream of the second pair of cylinders, at a lower speed or equal to the peripheral speed of the cylinders of this second pair.

- the object of the invention is to remedy this operating deficiency in the above-mentioned elongation range by continuously adapting the degree of pre-stretching of the plastic film to the tension generated in this film by the wrapping of the load. to be packaged, so that the sum of the elongation produced by the pre-stretching and the additional elongation produced by the tension created in the film before its arrival on the load to be packaged does not exceed the elongation at break.

- a method of regulating the degree of pre-stretching of a film of stretchable plastic material which passes over one or more pre-stretching means before reaching a station. of film use, this process consisting in continuously sensing the tension in the part of film included, considering the direction of movement of the film, between the last pre-stretching means and the station of use, and in making vary, in correspondence with the sensed tension, the speed of at least one of said pre-stretching and / or film use means, so that the sum of the elongation produced by the pre-stretching and the elongation additional produced by the tension created in the film before its arrival at the station of use does not exceed the elongation a break.

- the method in the case where the pre-stretching means consist of several pre-stretching cylinders, the last of which is driven by an independent motor, the method consists in continuously capturing the tension in the film in the area between the last pre-stretching cylinder and the use station and reacting on the speed of this last pre-stretching cylinder in correspondence with the sensed tension.

- the method is implemented for packaging a load.

- the method and the device according to the invention are applicable in particular to the packaging of loads, in particular palletized loads consisting of a certain number of elementary packages. It should also be noted that the invention is applicable both when the packaging is carried out by progressive winding of the film around the load and in the case where it is operated by the so-called "curtain” method. ie where the charge is pushed against the plastic film so as to be wrapped as a whole.

- fig. 2 represents a machine operating by progressive wrapping of a load P which is placed on a rotary table T.

- This load can be formed of several unitary packages which are held in place on a pallet in the form of an assembly which must be wrapped a plastic film.

- This film designated by FP in fig.

- pre-stretching means such as CI and C Z , which are constituted in the example represented by cylinders coated with 'a substance, rubberized or otherwise, exerting a great friction force on the plastic film.

- the film thus undergoes a first pre-stretching on the cylinder CI and a second pre-stretching on the cylinder C 2 which rotates at a speed greater than C 1 .

- the film then reaches the load P directly to ensure its envelopment.

- Such a structure corresponds to what is called a progressive wrapping machine, which gradually wraps the film FP around the load P, the rotary table being able to execute a movement of vertical translation.

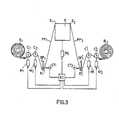

- FIG. 3 There is also another structure of a packaging machine, to which the invention can be applied and which is shown in FIG. 3.

- a wrapping machine of the curtain wrapping type according to which the load P is wrapped by being pushed in the direction F against the film FP1, FP2 unwound simultaneously from two reels B1, B2.

- the two parts of film unwound from the reels Bl, B2 are welded before the start of the load transfer movement in the direction F so as to form in front of this load what is called a "curtain".

- the two film strands FP1, FP2 are brought together using a device, not shown, so as to completely envelop the load and the two strands FP1, FP2 are welded together behind the load to complete its packaging.

- a machine of this type also provides a prestretching of the two strands FP1, FP2 of the plastic film using d'- suitable stretching means known, which have been evidenced to f ig. 3 by the two pairs of cylinders C 1 , C 2 and C ' 1 , C' 2 ' In the known machine, the film strands FP1 and FP2 then arrive directly on the load to be packaged.

- the plastics used to form a packaging film can undergo a stretching of 400% until breaking while having, after exceeding the limit elastic which roughly corresponds to an elongation of 40 to 50%, a significant improvement in their properties, in particular the tensile strength.

- the pre-stretching of a plastic film before it arrives at the load to be packaged is therefore extremely advantageous since not only does it improve the properties of the film but also makes significant savings in material since It is possible, by lengthening it considerably within the range indicated above, to pack many more products with the same initial length of film. However, if the pre-stretch is pushed too far, approaching the 400% limit excessively, there is a risk of a film rupture.

- the loads to be packaged often consist of sets of unitary packages of parallelepipedic or cubic shape and there occurs, during the rotation or translation movement of the load to be packaged, a variation in the tension generated in the film of material plastic.

- fig. l is a graphic representation giving the tension in the plastic film as a function of the angle ⁇ of rotation of the load.

- the method and the device in accordance with the invention aim to remedy the shortcomings of known embodiments by simultaneously taking into account the degree of pre-stretching of the plastic film and the tension generated in it when it arrives on the load. to pack.

- the method according to the invention for regulating the degree of pre-stretching of a film of stretchable plastic material which passes, during the packaging of a load, on one or more means pre-stretching before reaching the load said method consisting in continuously sensing the tension in the part of the film included, considering the direction of movement of the film, between the last pre-stretching means and the load to be packaged , and to vary, in correspondence to the sensed tension, the speed of at least one of said pre-stretching means and / or of the load, so that the sum of the elongation produced by the pre-stretching and of the The additional elongation produced by the tension created in the film before it reaches the load to be packaged does not exceed the elongation at break.

- the method consists in continuously sensing the tension in the film in the area between the last pre-stretching cylinder. -drawing and the load to react on the speed of this last pre-stretching cylinder in correspondence with the sensed tension.

- the method according to the invention makes it possible to continuously adapt the operating conditions of the machine to the parameters governing the packaging of a determined load, in particular the shape of this load, its fragility in the corners, its speed of entrainment, nature and strength of the plastic film, etc.

- the method according to the invention is absolutely not limited to the field of packaging and that it is possible to envisage its application in all cases where it is advantageous, for reasons of improvement of the film's resistance and profitability properties, of ensuring its pre-stretching before its implementation.

- FIGS 2 and 3 highlight the implementation of the method according to the invention in the two types of packaging machines which have been defined above.

- FIG. 2 corresponds to the progressive wrapping packaging machine. After the pre-stretching of the film by the cylinders C1, C2, it is necessary to measure the tension of this film in the strand between the point S and the point of tangency to the cylinder C2 so as to be able to react on the conditions of pre stretching the film to prevent it from breaking while making the most of the stretching range available.

- the regulating device further comprises a servo control SC which is connected to the tension sensor so as to permanently receive signals representing the film tension; furthermore the servo-control SC is connected by conductors L1, L2. L3 respectively to the motor Ml for actuating the stretching cylinder Cl, to the motor M2 for actuating the stretching cylinder C2 and to the motor M3 for driving the rotary table T on which the load P is placed.

- It also includes means for analyzing instantly the actual tension and pre-stretching conditions of the film to modify in correspondence, as indicated by the links L1, L2, L3, the speed of one or more of the motors Ml, M2, M3 so that the sum of the elongation caused by pre-stretching and elongation caused by tension in the final film strand remains below the allowable limit.

- the LC servo-control reacts, as a function of the signal supplied by the film tension sensor, on the last pre-stretching cylinder C2 before the load in order to thus modify the degree film pre-stretch.

- the corresponding roller R3, R'3 is mounted on a support SP1, SP'l which can execute a rectilinear or circular movement; it is provided opposite the corresponding return roller R3, R'3 a sensor CT 1 , CT 2 ' which has the function of measuring the tension in the associated film strand FP1, FP2 by analysis of the rectilinear or circular displacement of the corresponding roller R3, R '3.

- the signals from the two sensors CT 1 , CT 2 are applied to a servo-control SC which analyzes them and which reacts accordingly on one or more of the motors Ml, M2, M'l, M'2 for driving the pre cylinders. -drawing Cl, C2, C'l, C'2 and / or on the motor M3 ensuring the translation of the load P.

- the deflection roller R 2 placed immediately before the load P is intended to modify the angle of arrival of the film strand FP on the load in order to adapt this angle to the packaging conditions of the charge; in fact, when the load is fragile, for example when it is formed from thin cardboard packages whose corners can collapse, it is recommended to reduce this angle to the minimum while in other applications such a parameter may have less important.

- the method and the device according to the invention are applicable to the particular field of packaging, in particular of charges formed of unitary packages and placed on pallets, but also more generally in all cases. where it is necessary to control the degree of pre-stretching of a plastic film in order to make the most of these strength properties and also to obtain maximum production profitability.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Basic Packing Technique (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR8209878A FR2528020A1 (fr) | 1982-06-07 | 1982-06-07 | Procede et dispositif de regulation du pre-etirage d'un film de matiere plastique, en particulier en vue de l'emballage d'une charge |

| FR8209878 | 1982-06-07 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0096635A2 true EP0096635A2 (de) | 1983-12-21 |

| EP0096635A3 EP0096635A3 (en) | 1984-10-03 |

| EP0096635B1 EP0096635B1 (de) | 1986-12-03 |

Family

ID=9274705

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP19830401119 Expired EP0096635B1 (de) | 1982-06-07 | 1983-06-02 | Verfahren und Vorrichtung zum Regeln der Vorausdehnung einer Plastikfolie, insbesondere bei dem Verpacken einer Ladung |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP0096635B1 (de) |

| DE (1) | DE3368034D1 (de) |

| ES (1) | ES523016A0 (de) |

| FR (1) | FR2528020A1 (de) |

Cited By (31)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2555961A1 (fr) * | 1983-12-01 | 1985-06-07 | Emco International | Procede et dispositif permettant d'envelopper une charge avec un film de matiere plastique etirable |

| GB2154536A (en) * | 1984-02-23 | 1985-09-11 | Lancaster Patrick R | Improved supply control rotating stretch wrapping apparatus and process |

| EP0224766A1 (de) * | 1985-12-04 | 1987-06-10 | Lantech, Inc. | Verfahren und Vorrichtung zum Einwickeln unter hoher Dehnung |

| EP0237649A1 (de) * | 1986-03-15 | 1987-09-23 | Hans Hugo Büttner | Stretchfolien-Wickelmaschine |

| EP0246659A1 (de) * | 1986-05-23 | 1987-11-25 | Mima Incorporated | Umwickelvorrichtung und -verfahren mit Vorstreckung der Folie in verschiedenen Schritten |

| EP0312868A3 (de) * | 1987-10-13 | 1989-08-30 | SANPACK-GESELLSCHAFT LOHSS & CO. (GMBH & CO.) | Verfahren und Vorrichtung zum Umwickeln einer Ware mit Folie |

| US4866909A (en) * | 1985-12-04 | 1989-09-19 | Lantech, Inc. | High tensile wrapping process |

| FR2639023A1 (fr) * | 1988-11-16 | 1990-05-18 | Pack Junior | Dispositif d'emballage d'une charge a l'aide d'un film en matiere plastique etirable |

| CH683578A5 (fr) * | 1990-03-08 | 1994-03-31 | Suisse Electronique Microtech | Résonateur piézoélectrique. |

| WO1994020367A1 (en) * | 1993-03-12 | 1994-09-15 | Kenneth Stephen Eddin Orpen | Hydraulic bale wrapper |

| US5797240A (en) * | 1992-08-25 | 1998-08-25 | Newtec International | Method of wrapping loads by means of a stretchable film, a machine and a film for implementing the method |

| EP1083126A1 (de) * | 1999-08-10 | 2001-03-14 | Sekisui Jushi Kabushiki Kaisha | Stretchfolien-Wickelvorrichtung |

| US8079201B2 (en) * | 2006-07-07 | 2011-12-20 | Aetna Group S.P.A. | Wrapping machine and wrapping methods |

| US8276346B2 (en) | 2006-02-23 | 2012-10-02 | Lantech.Com, Llc | Wrapping apparatus and method including metered pre-stretch film delivery assembly |

| US9187193B2 (en) | 2005-04-08 | 2015-11-17 | Lantech.Com, Llc | Method and apparatus for dispensing an amount of film relative to girth |

| US9290282B2 (en) | 2003-01-31 | 2016-03-22 | Lantech.Com, Llc | Apparatus for securing a load to a pallet with a roped film web |

| US20170101205A1 (en) * | 2014-06-19 | 2017-04-13 | Crawford Packaging Inc. | Pallet Wrap Machine Monitor |

| US9776748B2 (en) | 2013-02-13 | 2017-10-03 | Lantech.Com, Llc | Containment force-based wrapping |

| US9908648B2 (en) | 2008-01-07 | 2018-03-06 | Lantech.Com, Llc | Demand based wrapping |

| US9932137B2 (en) | 2012-10-25 | 2018-04-03 | Lantech.Com, Llc | Corner geometry-based wrapping |

| US10005580B2 (en) | 2012-10-25 | 2018-06-26 | Lantech.Com, Llc | Rotation angle-based wrapping |

| US10005581B2 (en) | 2012-10-25 | 2018-06-26 | Lantech.Com, Llc | Effective circumference-based wrapping |

| EP3137402B1 (de) * | 2014-05-02 | 2018-07-11 | Aetna Group S.P.A. | Messvorrichtung, -system und -verfahren zur messung einer wicklungskraft |

| US10053253B2 (en) | 2014-10-07 | 2018-08-21 | Lantech.Com, Llc | Graphical depiction of wrap profile for load wrapping apparatus |

| US10227152B2 (en) | 2014-01-14 | 2019-03-12 | Lantech.Com, Llc | Dynamic adjustment of wrap force parameter responsive to monitored wrap force and/or for film break reduction |

| US10934034B2 (en) | 2015-09-25 | 2021-03-02 | Lantech.Com, Llc | Stretch wrapping machine with automated determination of load stability by subjecting a load to a disturbance |

| US11208225B2 (en) | 2018-08-06 | 2021-12-28 | Lantech.Com, Llc | Stretch wrapping machine with curve fit control of dispense rate |

| US11479378B2 (en) | 2019-09-09 | 2022-10-25 | Lantech.Com, Llc | Stretch wrapping machine with dispense rate control based on sensed rate of dispensed packaging material and predicted load geometry |

| US11518557B2 (en) | 2019-09-19 | 2022-12-06 | Lantech.Com, Llc | Packaging material grading and/or factory profiles |

| US11667416B2 (en) | 2017-09-22 | 2023-06-06 | Lantech.Com, Llc | Load wrapping apparatus wrap profiles with controlled wrap cycle interruptions |

| US12221242B2 (en) | 2008-01-07 | 2025-02-11 | Lantech.Com, Llc | Electronic control of metered film dispensing in a wrapping apparatus |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP2865600B1 (de) | 2010-10-29 | 2016-07-13 | Lantech.Com LLC | Verfahren zur Erzeugung von Daten während der Verpackung einer Last sowie Verpackungsmaschine |

Family Cites Families (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3784123A (en) * | 1971-04-05 | 1974-01-08 | Whiteley Ind Inc | Tension control system |

| US3724733A (en) * | 1972-02-03 | 1973-04-03 | Harris Intertype Corp | Web infeed mechanism |

| FR2202509A5 (de) * | 1972-10-05 | 1974-05-03 | Piazzon Maurice | |

| DE2750780A1 (de) * | 1977-11-14 | 1979-05-17 | Franpack Gmbh Verpackungsmasch | Streckfolieneinschlagmaschine mit kompensiervorrichtung |

| US4199118A (en) * | 1979-01-10 | 1980-04-22 | The Black Clawson Company | Method and apparatus for controlling the braking system for an unwinder |

| CA1169349A (en) * | 1979-09-12 | 1984-06-19 | Lantech Inc. | Stretch wrapping apparatus and process |

| US4413463A (en) * | 1980-10-23 | 1983-11-08 | Lantech, Inc. | Roller stretch pass through stretching apparatus and process |

| US4458467A (en) * | 1981-03-31 | 1984-07-10 | Infra Pak (Dallas), Inc. | Pretensioner for stretchable film web with dancer roller compensation |

-

1982

- 1982-06-07 FR FR8209878A patent/FR2528020A1/fr not_active Withdrawn

-

1983

- 1983-06-02 EP EP19830401119 patent/EP0096635B1/de not_active Expired

- 1983-06-02 DE DE8383401119T patent/DE3368034D1/de not_active Expired

- 1983-06-06 ES ES523016A patent/ES523016A0/es active Granted

Cited By (55)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2555961A1 (fr) * | 1983-12-01 | 1985-06-07 | Emco International | Procede et dispositif permettant d'envelopper une charge avec un film de matiere plastique etirable |

| EP0144266A3 (en) * | 1983-12-01 | 1985-07-10 | Emco International Societe Dite: | Process and device for wrapping a load with a stretchable plastic film |

| GB2154536A (en) * | 1984-02-23 | 1985-09-11 | Lancaster Patrick R | Improved supply control rotating stretch wrapping apparatus and process |

| EP0224766A1 (de) * | 1985-12-04 | 1987-06-10 | Lantech, Inc. | Verfahren und Vorrichtung zum Einwickeln unter hoher Dehnung |

| US4866909A (en) * | 1985-12-04 | 1989-09-19 | Lantech, Inc. | High tensile wrapping process |

| EP0237649A1 (de) * | 1986-03-15 | 1987-09-23 | Hans Hugo Büttner | Stretchfolien-Wickelmaschine |

| EP0246659A1 (de) * | 1986-05-23 | 1987-11-25 | Mima Incorporated | Umwickelvorrichtung und -verfahren mit Vorstreckung der Folie in verschiedenen Schritten |

| EP0312868A3 (de) * | 1987-10-13 | 1989-08-30 | SANPACK-GESELLSCHAFT LOHSS & CO. (GMBH & CO.) | Verfahren und Vorrichtung zum Umwickeln einer Ware mit Folie |

| FR2639023A1 (fr) * | 1988-11-16 | 1990-05-18 | Pack Junior | Dispositif d'emballage d'une charge a l'aide d'un film en matiere plastique etirable |

| CH683578A5 (fr) * | 1990-03-08 | 1994-03-31 | Suisse Electronique Microtech | Résonateur piézoélectrique. |

| US5797240A (en) * | 1992-08-25 | 1998-08-25 | Newtec International | Method of wrapping loads by means of a stretchable film, a machine and a film for implementing the method |

| US5816026A (en) * | 1993-03-12 | 1998-10-06 | Orpen; Kenneth Stephen Eddin | Hydraulic bale wrapper |

| WO1994020367A1 (en) * | 1993-03-12 | 1994-09-15 | Kenneth Stephen Eddin Orpen | Hydraulic bale wrapper |

| EP1083126A1 (de) * | 1999-08-10 | 2001-03-14 | Sekisui Jushi Kabushiki Kaisha | Stretchfolien-Wickelvorrichtung |

| US6370839B1 (en) | 1999-08-10 | 2002-04-16 | Sekisui Jushi Kabushiki Kaisha | Stretch wrapping machine |

| US9290282B2 (en) | 2003-01-31 | 2016-03-22 | Lantech.Com, Llc | Apparatus for securing a load to a pallet with a roped film web |

| US9187193B2 (en) | 2005-04-08 | 2015-11-17 | Lantech.Com, Llc | Method and apparatus for dispensing an amount of film relative to girth |

| US8276346B2 (en) | 2006-02-23 | 2012-10-02 | Lantech.Com, Llc | Wrapping apparatus and method including metered pre-stretch film delivery assembly |

| US8276354B2 (en) | 2006-02-23 | 2012-10-02 | Lantech.Com, Llc | Apparatus for securing a load to a pallet with a roped film web |

| US8079201B2 (en) * | 2006-07-07 | 2011-12-20 | Aetna Group S.P.A. | Wrapping machine and wrapping methods |

| US8250838B2 (en) | 2006-07-07 | 2012-08-28 | Aetna Group Spa | Wrapping machine |

| US8448412B2 (en) | 2006-07-07 | 2013-05-28 | Aetna Group S.P.A | Wrapping method |

| US9908648B2 (en) | 2008-01-07 | 2018-03-06 | Lantech.Com, Llc | Demand based wrapping |

| US12221242B2 (en) | 2008-01-07 | 2025-02-11 | Lantech.Com, Llc | Electronic control of metered film dispensing in a wrapping apparatus |

| US10005580B2 (en) | 2012-10-25 | 2018-06-26 | Lantech.Com, Llc | Rotation angle-based wrapping |

| US9932137B2 (en) | 2012-10-25 | 2018-04-03 | Lantech.Com, Llc | Corner geometry-based wrapping |

| US11111045B2 (en) | 2012-10-25 | 2021-09-07 | Lantech.Com, Llc | Dynamic rotation angle-based wrapping |

| US10005581B2 (en) | 2012-10-25 | 2018-06-26 | Lantech.Com, Llc | Effective circumference-based wrapping |

| US11104464B2 (en) | 2012-10-25 | 2021-08-31 | Lantech.Com, Llc | Rotation angle-based wrapping of loads with varying dimensions |

| US11174056B2 (en) | 2012-10-25 | 2021-11-16 | Lantech.Com, Llc | Load wrapping apparatus with controlled interventions |

| US11111046B2 (en) | 2012-10-25 | 2021-09-07 | Lantech.Com, Llc | Load wrapping apparatus with rotational data shift |

| US10717554B2 (en) | 2013-02-13 | 2020-07-21 | Lantech.Com, Llc | Containment force-based wrapping |

| US10239645B2 (en) | 2013-02-13 | 2019-03-26 | Lantech.Com, Llc | Packaging material profiling for containment force-based wrapping |

| US11912445B2 (en) | 2013-02-13 | 2024-02-27 | Lantech.Com, Llc | Containment force-based wrapping |

| US11518558B2 (en) | 2013-02-13 | 2022-12-06 | Lantech.Com, Llc | Containment force-based wrapping |

| US9776748B2 (en) | 2013-02-13 | 2017-10-03 | Lantech.Com, Llc | Containment force-based wrapping |

| US10227152B2 (en) | 2014-01-14 | 2019-03-12 | Lantech.Com, Llc | Dynamic adjustment of wrap force parameter responsive to monitored wrap force and/or for film break reduction |

| US11597554B2 (en) | 2014-01-14 | 2023-03-07 | Lantech.Com, Llc | Dynamic adjustment of wrap force parameter responsive to monitored wrap force and/or for film break reduction |

| US12378029B2 (en) | 2014-01-14 | 2025-08-05 | Lantech.Com, Llc | Dynamic adjustment of wrap force parameter responsive to monitored wrap force and/or for film break reduction |

| EP3137402B1 (de) * | 2014-05-02 | 2018-07-11 | Aetna Group S.P.A. | Messvorrichtung, -system und -verfahren zur messung einer wicklungskraft |

| US10384822B2 (en) * | 2014-06-19 | 2019-08-20 | Crawford Packaging Inc. | Pallet wrap machine monitor |

| US20170101205A1 (en) * | 2014-06-19 | 2017-04-13 | Crawford Packaging Inc. | Pallet Wrap Machine Monitor |

| US10435191B2 (en) | 2014-10-07 | 2019-10-08 | Lantech.Com, Llc | Projecting containment force for load wrapping apparatus |

| US10926906B2 (en) | 2014-10-07 | 2021-02-23 | Lantech.Com, Llc | Load stability-based wrapping |

| US10053253B2 (en) | 2014-10-07 | 2018-08-21 | Lantech.Com, Llc | Graphical depiction of wrap profile for load wrapping apparatus |

| US11505343B2 (en) | 2015-09-25 | 2022-11-22 | Lantech.Com, Llc | Stretch wrapping machine with automated determination of load stability by subjecting a load to a disturbance |

| US10934034B2 (en) | 2015-09-25 | 2021-03-02 | Lantech.Com, Llc | Stretch wrapping machine with automated determination of load stability by subjecting a load to a disturbance |

| US11731793B2 (en) | 2015-09-25 | 2023-08-22 | Lantech.Com, Llc | Stretch wrapping machine with automatic load profiling |

| US11034470B2 (en) | 2015-09-25 | 2021-06-15 | Lantech.Com, Llc | Stretch wrapping machine with automatic load profiling |

| US12172779B2 (en) | 2015-09-25 | 2024-12-24 | Lantech.Com, Llc | Stretch wrapping machine with automatic load profiling |

| US11667416B2 (en) | 2017-09-22 | 2023-06-06 | Lantech.Com, Llc | Load wrapping apparatus wrap profiles with controlled wrap cycle interruptions |

| US11208225B2 (en) | 2018-08-06 | 2021-12-28 | Lantech.Com, Llc | Stretch wrapping machine with curve fit control of dispense rate |

| US11479378B2 (en) | 2019-09-09 | 2022-10-25 | Lantech.Com, Llc | Stretch wrapping machine with dispense rate control based on sensed rate of dispensed packaging material and predicted load geometry |

| US11518557B2 (en) | 2019-09-19 | 2022-12-06 | Lantech.Com, Llc | Packaging material grading and/or factory profiles |

| US12103719B2 (en) | 2019-09-19 | 2024-10-01 | Lantech.Com, Llc | Packaging material grading and/or factory profiles |

Also Published As

| Publication number | Publication date |

|---|---|

| DE3368034D1 (en) | 1987-01-15 |

| ES8403415A1 (es) | 1984-03-16 |

| EP0096635B1 (de) | 1986-12-03 |

| ES523016A0 (es) | 1984-03-16 |

| EP0096635A3 (en) | 1984-10-03 |

| FR2528020A1 (fr) | 1983-12-09 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0096635B1 (de) | Verfahren und Vorrichtung zum Regeln der Vorausdehnung einer Plastikfolie, insbesondere bei dem Verpacken einer Ladung | |

| FR2470056A1 (fr) | Procedes et appareils pour realiser un emballage unitaire avec un materiau plastique etire | |

| EP0419299B1 (de) | Wagen zum Abwickeln von einem Film zu einer Verpackungsmaschine | |

| EP0656853B1 (de) | Verfahren zum verpacken von ladungen mittels einer streckfolie, maschine und folie zur ausübung des verfahrens | |

| EP0213969B1 (de) | Verfahren und Vorrichtung zum biaxialen Strecken von Kunststoffmaterialien und so hergestellte Produkte | |

| EP0144266B1 (de) | Vorrichtung zum Umhüllen einer Last mit einer dehnbaren Kunststoffolie | |

| FR2562867A1 (fr) | Procede pour maintenir la tension d'une feuille de materiau d'emballage dans une emballeuse | |

| FR2489780A1 (fr) | Procede et dispositif pour confectionner une unite d'emballage maintenant plusieurs elements | |

| FR2468506A1 (fr) | Procede et appareil d'emballage de plusieurs charges elementaires dans un paquet unique | |

| FR2617123A1 (fr) | Bande avec renfort longitudinal, procede d'emballage et emballage comportant une telle bande, installation et machine pour la mise en oeuvre du procede d'emballage, et dispositif pour la realisation d'une telle bande | |

| EP0270426A1 (de) | Durchlauf-Verpackungsverfahren und -maschine | |

| EP0676332A1 (de) | Optimiertes Verfahren für Überverpackung und Transport einer überverpackten, palettisierten Ladung | |

| CH671633A5 (de) | ||

| EP0806284B1 (de) | Umverpackungsfilm, Vorrichtung zum Filmvorstrecken und Umverpackungsverfahren | |

| FR2535298A1 (fr) | Dispositif pour raccorder l'une a l'autre deux bobines de matiere en bande | |

| FR2595674A1 (fr) | Machine pour la realisation de bottes de fils sans torsion | |

| FR2568219A1 (fr) | Procede et machine d'emballage du type permettant de placer un film autour d'un ensemble d'articles | |

| FR2595675A1 (fr) | Procede et appareil pour distribuer et enrouler du papier d'empaquetage | |

| US20020174628A1 (en) | Method and apparatus for wrapping a load using variable roller stretch | |

| FR2534112A1 (fr) | Machine destinee a recolter du materiau fibreux au niveau du champ et a le mettre en ballots de forme cylindrique | |

| EP0332510B1 (de) | Vorrichtung zum Strecken einer Kunststoff-Folie | |

| FR2650555A1 (fr) | Procede et machine pour deposer une bande de film de facon helicoidale sur les faces verticales d'une charge palettisee | |

| FR2707081A1 (fr) | Procédé pour commander le fonctionnement d'une unité de fermeture à mâchoires rotatives pour machine d'emballage. | |

| EP0041006A2 (de) | Bindekopf von Faden auf Verpackungen und Maschine mit einem solchen Bindekopf | |

| EP1188671A1 (de) | Verfahren und Vorrichtung zum Vorstrecken einer Dehnfolie |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): BE DE FR GB IT NL |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Designated state(s): BE DE FR GB IT NL |

|

| 17P | Request for examination filed |

Effective date: 19841022 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): BE DE FR GB IT NL |

|

| REF | Corresponds to: |

Ref document number: 3368034 Country of ref document: DE Date of ref document: 19870115 |

|

| ITF | It: translation for a ep patent filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| ITTA | It: last paid annual fee | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19960524 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19960611 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19960612 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19960626 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 19960731 Year of fee payment: 14 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19970602 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Effective date: 19970630 |

|

| BERE | Be: lapsed |

Owner name: PROCTER & GAMBLE EUROPEAN TECHNICAL CENTER Effective date: 19970630 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19980101 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19970602 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19980227 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 19980101 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19980303 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |