EP0072739A1 - Verfahren zum Herstellen von Platten mit flachgedrückten Wellen - Google Patents

Verfahren zum Herstellen von Platten mit flachgedrückten Wellen Download PDFInfo

- Publication number

- EP0072739A1 EP0072739A1 EP82401489A EP82401489A EP0072739A1 EP 0072739 A1 EP0072739 A1 EP 0072739A1 EP 82401489 A EP82401489 A EP 82401489A EP 82401489 A EP82401489 A EP 82401489A EP 0072739 A1 EP0072739 A1 EP 0072739A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- panel

- edges

- rib

- pressing

- folds

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D—WORKING OR PROCESSING OF SHEET METAL OR METAL TUBES, RODS OR PROFILES WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D22/00—Shaping without cutting, by stamping, spinning, or deep-drawing

- B21D22/02—Stamping using rigid devices or tools

- B21D22/027—Stamping using rigid devices or tools for flattening the ends of corrugated sheets

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D—WORKING OR PROCESSING OF SHEET METAL OR METAL TUBES, RODS OR PROFILES WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D13/00—Corrugating sheet metal, rods or profiles; Bending sheet metal, rods or profiles into wave form

- B21D13/02—Corrugating sheet metal, rods or profiles; Bending sheet metal, rods or profiles into wave form by pressing

Definitions

- the present invention relates to a method of manufacturing ribbed panels, intended to obtain at the end of the ribs a practically straight edge of the panel, allowing the sealed assembly by welding of the panel with a support frame.

- Such a panel can be produced in different ways, the most common of which are folding and stamping.

- Bending consists of making open ribs at their two ends by pressing a flat metal profile between a punch and a die carried by a press brake so as not to stretch the metal, which has the enormous advantage of requiring a extremely low press brake power.

- Stamping consists in pressing the profile between a punch and a die carried by a stamping press so as to produce the closed ribs by a single digging operation with stretching of the metal.

- This process has the advantage of making it possible to produce a perfectly sealed assembly by a quick operation; on the other hand, the power to be used is considerable compared to that required for folding, so this method requires high power manufacturing means, not only very expensive but also more difficult to obtain on the market.

- a panel with open ribs in the shape of a straight U is firstly folded, and, with special tools, the ends are crushed or folded so as to flatten the edges of the panel.

- Another known method consists in pressing the panel between a punch and a die whose complementary profiles ensure the formation of a stamped rib by creep of the metal and connecting to the general surface of the profile, on the edges thereof, by slopes comprising several plies absorbing the excess of stamped material, and therefore forming necking ribs.

- This method has the disadvantage of still making use of the actual stamping for the formation of the necking ribs, and therefore of requiring a press power substantially greater than that required for a simple folding.

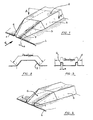

- the method of manufacturing panels with closed ribs according to the invention does not have the drawbacks of all the methods known hitherto. It is characterized in that it consists in pressing the sheet to be profiled between a punch and a die whose complementary profiles ensure for each rib a constant development as well as of the ends of each rib with quasi-rectilinear edges by absorption of the difference between said developed and its projection on the horizontal plane by one or more folds whose folds are almost contiguous on the edges of the panel, and perpendicular to the plane of said panel.

- the constant press can over the entire length of each rib, apart from its two ends, be in different known geometric forms (trapezoid, rectangle, half-circumference, etc.).

- each rib 2 of the panel 1 has a central portion 3 of regular section and which is connected at each end with the straight edge 4 of the panel by means of a connection profile 5 forming a slope and furnished with two corrugations (6,7) so that the rib opens in a quasi-rectilinear manner, with the clearances of the corrugations 6 and 7 near, on the edge 4 of the panel.

- the developed of the two profiles 2 and 5 are always equal along these, so that the panel of the invention is produced by simple folding and therefore at using very low press brake power.

- the variant of the method of the invention resulting in the form of rib shown in FIG. 4 consists, after obtaining, using the above defined method, ribs as shown diagrammatically in FIG. 1, to carry out an additional operation consisting of, for example using a special tool fitted with one or more pliers, to join the ends of the corrugations 6 and 7 by pressing them at their ends so as to remove the play e.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Bending Of Plates, Rods, And Pipes (AREA)

- Body Structure For Vehicles (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR8115421 | 1981-08-07 | ||

| FR8115421A FR2510915A1 (fr) | 1981-08-07 | 1981-08-07 | Procede de fabrication de panneaux a nervures fermees |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| EP0072739A1 true EP0072739A1 (de) | 1983-02-23 |

Family

ID=9261311

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP82401489A Ceased EP0072739A1 (de) | 1981-08-07 | 1982-08-06 | Verfahren zum Herstellen von Platten mit flachgedrückten Wellen |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP0072739A1 (de) |

| FR (1) | FR2510915A1 (de) |

| PT (1) | PT75216B (de) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0654312A1 (de) * | 1993-11-24 | 1995-05-24 | UMFORMTECHNIK STADE GmbH | Vorrichtung und Verfahren zur Herstellung von Sickenblechen mit planparallelen Aussenkantenflächen |

| EP1276589A1 (de) * | 2000-03-07 | 2003-01-22 | Pullman Industries, Inc. | Fahrzeugplattformkanten und herstellungsverfahren |

| WO2006105590A1 (en) * | 2005-04-04 | 2006-10-12 | Fielders Australia Pty Ltd | Trapezoidal steel decking with press-folded ends |

| WO2008079182A1 (en) * | 2006-12-22 | 2008-07-03 | Noble Advanced Technologies, Inc. | Vehicle bed edge construction and manufacturing process therefor |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE459074C (de) * | 1924-08-10 | 1928-04-26 | E H Hugo Junkers Dr Ing | Verfahren zum Flachdruecken von Wellblechwellen |

| GB965759A (en) * | 1960-08-08 | 1964-08-06 | Cookson Sheet Metal Dev Ltd | Improvements in or relating to machines for working sheet metal |

| GB966747A (en) * | 1960-05-19 | 1964-08-12 | Cookson Sheet Metal Dev Ltd | Improvements in or relating to machines for working sheet metal |

| FR2051730A1 (fr) * | 1969-07-14 | 1971-04-09 | Svenska Flaektfabriken Ab | Procede et dispositif de raidissage de surfaces de toles planes |

| FR2339449A1 (fr) * | 1976-02-02 | 1977-08-26 | Francon Jean | Procede et moyens de fabrication de profiles metalliques nervures, et les profiles obtenus par le procede |

| FR2354831A2 (fr) * | 1976-06-15 | 1978-01-13 | Francon Jean | Procede et moyens de fabrication de profiles metalliques nervures et les profiles obtenus par le procede |

-

1981

- 1981-08-07 FR FR8115421A patent/FR2510915A1/fr active Granted

-

1982

- 1982-07-08 PT PT7521682A patent/PT75216B/pt unknown

- 1982-08-06 EP EP82401489A patent/EP0072739A1/de not_active Ceased

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE459074C (de) * | 1924-08-10 | 1928-04-26 | E H Hugo Junkers Dr Ing | Verfahren zum Flachdruecken von Wellblechwellen |

| GB966747A (en) * | 1960-05-19 | 1964-08-12 | Cookson Sheet Metal Dev Ltd | Improvements in or relating to machines for working sheet metal |

| GB965759A (en) * | 1960-08-08 | 1964-08-06 | Cookson Sheet Metal Dev Ltd | Improvements in or relating to machines for working sheet metal |

| FR2051730A1 (fr) * | 1969-07-14 | 1971-04-09 | Svenska Flaektfabriken Ab | Procede et dispositif de raidissage de surfaces de toles planes |

| FR2339449A1 (fr) * | 1976-02-02 | 1977-08-26 | Francon Jean | Procede et moyens de fabrication de profiles metalliques nervures, et les profiles obtenus par le procede |

| FR2354831A2 (fr) * | 1976-06-15 | 1978-01-13 | Francon Jean | Procede et moyens de fabrication de profiles metalliques nervures et les profiles obtenus par le procede |

Cited By (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0654312A1 (de) * | 1993-11-24 | 1995-05-24 | UMFORMTECHNIK STADE GmbH | Vorrichtung und Verfahren zur Herstellung von Sickenblechen mit planparallelen Aussenkantenflächen |

| EP1276589A1 (de) * | 2000-03-07 | 2003-01-22 | Pullman Industries, Inc. | Fahrzeugplattformkanten und herstellungsverfahren |

| JP2003525802A (ja) * | 2000-03-07 | 2003-09-02 | プルマン インダストリーズ, インク. | 車両荷台の端部およびその製造方法 |

| EP1276589A4 (de) * | 2000-03-07 | 2004-12-29 | Pullman Ind Inc | Fahrzeugplattformkanten und herstellungsverfahren |

| WO2006105590A1 (en) * | 2005-04-04 | 2006-10-12 | Fielders Australia Pty Ltd | Trapezoidal steel decking with press-folded ends |

| GB2439899A (en) * | 2005-04-04 | 2008-01-09 | Fielders Australia Pty Ltd | Trapezoidal steel decking with press-folded ends |

| AU2010100581B4 (en) * | 2005-04-04 | 2010-09-23 | Fielders Australia Pty Ltd | Trapezoidal steel decking with press-folded ends |

| WO2008079182A1 (en) * | 2006-12-22 | 2008-07-03 | Noble Advanced Technologies, Inc. | Vehicle bed edge construction and manufacturing process therefor |

| US7731271B2 (en) | 2006-12-22 | 2010-06-08 | Noble Advanced Technologies, Inc. | Vehicle bed edge construction and manufacturing process therefor |

Also Published As

| Publication number | Publication date |

|---|---|

| PT75216B (fr) | 1984-11-19 |

| FR2510915B1 (de) | 1984-07-06 |

| FR2510915A1 (fr) | 1983-02-11 |

| PT75216A (fr) | 1982-08-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| FR2556461A1 (fr) | Procede pour le sertissage d'une plaque collectrice d'un echangeur de chaleur sur une boite a eau et echangeur obtenu par ce procede | |

| EP0826943B1 (de) | Anordnung für einen Wärmetauscher bestehend aus einem Verteiler auf Aluminiumbasis und Rohren und Verfahren zur Herstellung einer solchen Anordnung | |

| FR2523483A1 (fr) | Outil de pliage a plat | |

| EP1523387A1 (de) | Metallplatte, dessen herstellungs- und biegeverfahren | |

| FR2461782A1 (fr) | Element d'etancheite | |

| FR2574704A1 (fr) | Machine de fabrication de carton ondule simple face | |

| EP0072739A1 (de) | Verfahren zum Herstellen von Platten mit flachgedrückten Wellen | |

| EP1190786B1 (de) | Verfahren zum Hochdruckumformen von Blechen und Vorrichtung zur Durchführung des Verfahrens | |

| EP0133401A1 (de) | Verbindungsvorrichtung zwischen einer Rohrplatte und einem Vorratsbehälter eines Wärmetauschers und Verfahren zu deren Ausführung | |

| FR2690870A1 (fr) | Procédé de fabrication de profilés en un matériau composite. | |

| EP0239490B1 (de) | Spiralwärmetauscher und Verfahren zu seiner Herstellung | |

| FR2572362A1 (fr) | Recipient et procede pour sertir ses extremites | |

| EP0038237B1 (de) | Einseitige Wellpappenmaschine | |

| FR2789758A1 (fr) | Procede d'assemblage d'un echangeur de chaleur, en particulier de vehicule automobile, et echangeur ainsi obtenu | |

| EP2145755B1 (de) | Verfahren zur Formung von Winkelprofilen und Vorrichtung zur Umsetzung dieses Verfahrens | |

| FR2487702A1 (fr) | Nouveau procede d'obtention de profils creux de formes variees a partir de profiles standard | |

| FR2656829A1 (fr) | Systeme de fendage notamment pour plaque de carton ondule. | |

| FR2523742A1 (fr) | Pedale pour vehicule automobile et notamment pedale de frein ou de debrayage, et son procede de fabrication | |

| FR2517572A1 (fr) | Procede pour l'assemblage d'un tube avec une paroi a trou et dispositif pour la mise en oeuvre de ce procede | |

| EP0102978B1 (de) | Herstellungsverfahren für verankerungskörper zur verankerung im boden insbesondere von pfählen oder pflöcken, und verankerungskörper erhalten mittels des genannten verfahrens | |

| FR2570679A1 (fr) | Element de boite a ouverture par arrachement, ainsi que procede et installation pour sa fabrication | |

| FR2645796A1 (fr) | Organe conformateur pour la realisation d'une chemise de classement a volets articules avec au moins un rabat | |

| FR2693942A1 (fr) | Plaque alvéolaire pliable en matière plastique, procédé de fabrication de cette plaque et dispositif pour la mise en Óoeuvre du procédé. | |

| FR2553495A1 (fr) | Dispositif mecanique permettant d'assembler et de renforcer des profiles, et procede d'assemblage de profiles | |

| EP0209450B1 (de) | Vorrichtung zum Formen von parallelen Wellen in einer Platte und zum Verschweissen jeder dieser Wellen an ihren Längsenden |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): BE DE FR GB IT NL SE |

|

| 17P | Request for examination filed |

Effective date: 19830317 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION HAS BEEN REFUSED |

|

| 18R | Application refused |

Effective date: 19851104 |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: RENARD, MICHEL |