EP0064146B1 - Injection system for injecting two fuels through one injection nozzle - Google Patents

Injection system for injecting two fuels through one injection nozzle Download PDFInfo

- Publication number

- EP0064146B1 EP0064146B1 EP82102059A EP82102059A EP0064146B1 EP 0064146 B1 EP0064146 B1 EP 0064146B1 EP 82102059 A EP82102059 A EP 82102059A EP 82102059 A EP82102059 A EP 82102059A EP 0064146 B1 EP0064146 B1 EP 0064146B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- fuel

- injection

- nozzle needle

- pressure

- main

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

- 239000000446 fuel Substances 0.000 title claims abstract description 145

- 238000002347 injection Methods 0.000 title claims abstract description 64

- 239000007924 injection Substances 0.000 title claims abstract description 64

- 238000002485 combustion reaction Methods 0.000 abstract description 9

- 238000011144 upstream manufacturing Methods 0.000 description 8

- 238000000034 method Methods 0.000 description 6

- 230000006835 compression Effects 0.000 description 4

- 238000007906 compression Methods 0.000 description 4

- 238000006073 displacement reaction Methods 0.000 description 3

- 239000007921 spray Substances 0.000 description 2

- 238000010276 construction Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 230000000149 penetrating effect Effects 0.000 description 1

- 108090000623 proteins and genes Proteins 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M43/00—Fuel-injection apparatus operating simultaneously on two or more fuels, or on a liquid fuel and another liquid, e.g. the other liquid being an anti-knock additive

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M43/00—Fuel-injection apparatus operating simultaneously on two or more fuels, or on a liquid fuel and another liquid, e.g. the other liquid being an anti-knock additive

- F02M43/04—Injectors peculiar thereto

Definitions

- the invention relates to an injection system for injecting two fuels through a single injection valve, in which the two fuels are fed separately from separate injection pumps and only meet in the area of the tip of a nozzle needle of the injection valve, a main fuel line through a pressure relief valve, in particular on the injection pump can be relieved of pressure for the main fuel, a non-return valve being assigned to a pilot fuel line in the immediate vicinity of the outlet opening of the pilot fuel line and a spring-loaded piston being provided within the injection valve, which piston is in operative connection with the main fuel line.

- an injection valve for injecting ignition fuel on the one hand and ignition-resistant main fuel on the other hand for diesel engines is known.

- This injection valve has a separate feed for the main fuel and the pilot fuel to the nozzle needle seat.

- the pilot fuel and the main fuel are delivered by two separate pumps, with the main fuel pump being a high-pressure injection pump and the pilot fuel pump being a commercially available delivery pump which operates at a delivery pressure of 20-50 bar.

- the pilot fuel is deposited on one side and the main fuel on the other side of the nozzle needle above the seat thereof.

- a spring-loaded pre-injection piston with differential pistons is provided in the pilot fuel channel, which is connected on its spring-loaded side to the main fuel channel via a branch channel.

- the pilot fuel is supplied on the side opposite the spring-loaded piston side, so that the piston must be displaced by the pilot fuel against the pressure of the spring so that the necessary quantity of pilot fuel can be supplied.

- the main fuel If the main fuel is then only slightly pressurized, it can act via the branch channel on the spring-loaded side of the pre-injection piston and, due to the differential piston, increases the pressure in such a way that the nozzle needle is raised so that the pilot fuel is injected into the combustion chamber. Then the pressure of the pilot fuel collapses, the nozzle needle closes again and only after a sufficient pressure has built up in the main fuel does it open again and allow the main fuel to enter the combustion chamber.

- pilot fuel pre-charges to the main fuel without the need for a differential piston.

- the main fuel line is relieved of pressure on the injection pump by a pressure relief valve.

- the pilot fuel compresses the pressure-relieved main fuel inside the nozzle and in the main fuel line and thereby displaces the main fuel at the nozzle needle tip.

- the pilot fuel upstream of the nozzle needle tip is injected first in time.

- a check valve arranged in the vicinity of the outlet opening of the pilot fuel line prevents the pilot fuel from flowing back. If the amount of pilot fuel is to be metered exactly, further separate devices, such as solenoid valves and metering pistons, are provided.

- pilot fuel injection pump must provide the relatively high pressure of 20-50 bar. Injection pumps of this type require a relatively large amount of construction work and are therefore expensive in comparison with simple feed pumps. In a disadvantageous manner, additional devices, such as solenoid valves, are still required for the exact metering of the pilot fuel.

- an injection valve for injecting ignition and main fuel is also known.

- both fuel lines are equipped with check valves.

- a spring-loaded displacement piston is arranged in a branch line of the main fuel line and, depending on its position, provides relief space for the main fuel.

- Both fuel lines open near the nozzle needle tip. If pilot fuel is to be upstream of the main fuel, the check valve of the main fuel line is closed and the main fuel is pressed into the piston chamber of the displacer piston by the pressure of the pilot fuel against the spring force of the displacer.

- the pilot fuel thus creates space in that it presses the main fuel against the spring force virtually in front of it into the relief space created by the displacement piston.

- DE-A-2 908 375 proposes an injection valve for injecting two fuels gene, in which two high-pressure injection pumps deliver the two fuels, i.e. both the main fuel and the pilot fuel, separately. Only in the vicinity of the nozzle needle tip do the two fuel channels meet, separated by a check valve each located there. Both injection pumps work at very high pressure, ie around 250 bar. Thus, here too, the pilot fuel injection pump is disadvantageously designed as an expensive high-pressure injection pump.

- an injection pump which provides the high pressure necessary for injection for a fuel.

- a pressure relief valve is provided on the outlet line of the injection pump in this injection pump.

- a defined relief volume is made available by the stroke of a piston. This relief volume allows the fuel line to be relieved of pressure after the delivery stroke has been completed.

- the object of the present invention is therefore to propose an injection system of the type mentioned at the outset, with which a sufficient quantity of pilot fuel is surely injected into the combustion chamber ahead of the main fuel.

- the pilot fuel is to be upstream of the main fuel at the tip of the nozzle needle using a low-pressure low-pressure feed pump.

- the main fuel acts directly on the pilot fuel.

- the pressure of the main fuel raises the nozzle needle and first injects the pilot fuel.

- Any differential pistons can advantageously be omitted entirely.

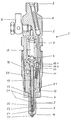

- the single figure shows a cross section through an injection nozzle according to the invention.

- the injection nozzle 1 consists, in a manner known per se, of the nozzle body 2, in which the nozzle needle 3 is arranged centrally and is held in the closed position by the force of the compression spring 6.

- the nozzle body 2 is fastened to the nozzle holder 5 by a union nut 4.

- the main fuel is fed into the nozzle holder 5 at 7. It passes through a rod filter 8 into an inlet bore 9, which can be closed by a piston 10, which is loaded by a spring 11.

- the piston 10 and the spring 11 form a relief valve.

- the piston 10 has a blind bore 10.1 which is equipped with drain openings 10.2 which are closed in the position shown.

- the distance of the drain openings 10.2 from the seat of the piston 10 is a measure of the size of the relief volume. The greater this distance, the greater the relief volume.

- the main fuel After passing through the piston 10, the main fuel reaches the pressure chamber 12, which is arranged concentrically around the nozzle needle 3.

- the nozzle needle 3 has a pressure shoulder 3.1 within the pressure chamber, so that it can be raised against the force of the compression spring at a corresponding pressure of the main fuel.

- An annular channel 13 runs from the pressure chamber 12 to the nozzle needle seat surface. This Ring channel is closed by the nozzle needle in the closed state. In the open state of the nozzle needle, the annular channel 13 ′ merges into an intermediate bore 14, from which one or more spray holes 15 branch off.

- the pilot fuel is preferably supplied according to the invention through the leakage system provided in conventional injectors.

- the pilot fuel passes through its connecting line 16 and bores in the nozzle holder to the compression spring chamber 17 and from there to the nozzle needle.

- the nozzle needle has a blind hole 18 in which a cylindrical insert 19 with a flattened side wall is inserted. As a result, a gap 20 is formed between the flattened side wall and the nozzle needle inner wall.

- the device according to the invention works as follows.

- the injection valve 1 is in the position shown, i. H. the nozzle needle 3 is closed and the piston 10 is in its position shown. He can take this because a pressure relief valve is provided in the main fuel system, so that the pressure in the inlet bore 9 drops after the end of the injection process, so that the spring 11 can move the piston 10 into the position shown.

- the pilot fuel Since the pilot fuel is to be injected first with every injection process, it must also be supplied first. For this purpose, it is supplied by a constant delivery pump with a pressure of 3 to 4 bar via the connecting line 16, the pressure spring chamber 17 into the gap 20 and from there via the central bore 21 to the check valve.

- the spring 23 of the check valve is set such that the check valve opens at a pressure of 2 bar. As a result, the ignition fuel flows into the annular channel 13 via the outlet openings 24.

- the main fuel remaining in the annular channel 13 from the last injection process is also depressurized, since the closing movement of the piston 10 and the nozzle needle seat results in the volume existing between the piston 10 and the nozzle needle seat due to the closing movement of the piston 10, e.g. B. was increased by 10 or 15 mm 3 . As a result, the pilot fuel easily gets into the ring channel and can accumulate around the nozzle needle tip.

- the main fuel is then supplied under pressure.

- the force of the spring 11 of the relief valve is dimensioned such that the main fuel can move the piston 10 so that the main fuel can flow via the discharge openings 10.2 to the pressure chamber 12 and from there into the annular channel 13.

- Due to the pressure of the main fuel the nozzle needle is raised over the pressure shoulder 3.1.

- the pilot fuel upstream of the nozzle needle seat can enter the combustion chamber via the intermediate bore 14 and the spray holes 15, followed by the main fuel.

- both the nozzle needle 3 and the piston 10 close again.

- the relief volume is thus again formed in the main fuel channel between the piston 10 and the nozzle needle seat surface, so that the pilot fuel can be supplied.

- the check valve in the pilot fuel line Due to the check valve in the pilot fuel line, the main fuel is prevented from penetrating into the pilot fuel line during the injection process, so that the main fuel only has to be pushed out again when pilot fuel is supplied. Since this would then fill the relief volume created in the ring channel 13, too little pilot fuel could be stored upstream. For this reason, the check valve is also arranged as close as possible to the outlet openings 24 and has such a low mass that it can react without delay.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Fuel-Injection Apparatus (AREA)

- Feeding, Discharge, Calcimining, Fusing, And Gas-Generation Devices (AREA)

Abstract

Description

Die Erfindung bezieht sich auf ein Einspritzsystem zum Einspritzen zweier Brennstoffe durch ein einziges Einspritzventil, bei dem die beiden Brennstoffe von separaten Einspritzpumpen getrennt zugeführt werden und erst im Bereich der Spitze einer Düsennadel des Einspritzventils aufeinandertreffen, wobei eine Hauptbrennstoffleitung durch ein Druckentlastungsventil, insbesondere an der Einspritzpumpe, für den Hauptbrennstoff druckentlastbar ist, wobei einer Zündbrennstoffleitung ein Rückschlagventil in unmittelbarer Nähe der Austrittsöffnung der Zündbrennstoffleitung zugeordnet ist und wobei innerhalb des Einspritzventils ein federbelasteter Kolben vorgesehen ist, der mit der Hauptbrennstoffleitung in Wirkverbindung steht.The invention relates to an injection system for injecting two fuels through a single injection valve, in which the two fuels are fed separately from separate injection pumps and only meet in the area of the tip of a nozzle needle of the injection valve, a main fuel line through a pressure relief valve, in particular on the injection pump can be relieved of pressure for the main fuel, a non-return valve being assigned to a pilot fuel line in the immediate vicinity of the outlet opening of the pilot fuel line and a spring-loaded piston being provided within the injection valve, which piston is in operative connection with the main fuel line.

Aus der DE-A-2 924 128 ist ein Einspritzventil zum Einspritzen von Zündkraftstoff einerseits und zündunwilligem Hauptkraftstoff andererseits für Dieselmotoren bekannt. Dieses Einspritzventil weist eine getrennte Zuführung für den Hauptbrennstoff und den Zündbrennstoff zum Düsennadelsitz auf. Der Zündbrennstoff und der Hauptbrennstoff werden durch zwei getrennte Pumpen gefördert, wobei die Hauptbrennstoffpumpe als Hochdruckeinspritzpumpe und die Zündbrennstoffpumpe als handelsübliche Förderpumpe ausgebildet ist, die mit einem Förderdruck von 20-50 bar arbeitet.From DE-A-2 924 128 an injection valve for injecting ignition fuel on the one hand and ignition-resistant main fuel on the other hand for diesel engines is known. This injection valve has a separate feed for the main fuel and the pilot fuel to the nozzle needle seat. The pilot fuel and the main fuel are delivered by two separate pumps, with the main fuel pump being a high-pressure injection pump and the pilot fuel pump being a commercially available delivery pump which operates at a delivery pressure of 20-50 bar.

In einer bevorzugten Ausführung der DE-A wird der Zündbrennstoff auf der einen und der Hauptbrennstoff auf der anderen Seite der Düsennadel oberhalb des Sitzes derselben angelagert. Um dafür Sorge zu tragen, daß der Zündbrennstoff vor dem Hauptbrennstoff in den Brennraum gelangt, ist in dem Zündbrennstoffkanal ein federbelasteter Voreinspritzkolben mit Differentialkolben vorgesehen, der auf seiner federbelasteten Seite über einen Stichkanal mit dem Hauptbrennstoffkanal verbunden ist. Der Zündbrennstoff wird auf der der federbelasteten Kolbenseite gegenüberliegenden Seite zugeführt, so daß vom Zündbrennstoff der Kolben gegen den Druck der Feder verschoben werden muß, damit die notwendige Zündbrennstoffmenge zugeführt werden kann. Wird dann der Hauptbrennstoff nur wenig druckbeaufschlagt, so kann er über den Stichkanal auf die federbelastete Seite des Voreinspritzkolbens wirken und erhöht aufgrund des Differentialkolbens den Druck derart, daß die Düsennadel angehoben wird, so daß der Zündbrennstoff in den Brennraum eingespritzt wird. Sodann bricht der Druck des Zündbrennstoffs zusammen, die Düsennadel schließt wieder und erst nach Aufbau eines ausreichenden Druckes im Hauptbrennstoff öffnet sie wieder und läßt den Hauptbrennstoff in den Brennraum eintreten.In a preferred embodiment of DE-A, the pilot fuel is deposited on one side and the main fuel on the other side of the nozzle needle above the seat thereof. In order to ensure that the pilot fuel reaches the combustion chamber before the main fuel, a spring-loaded pre-injection piston with differential pistons is provided in the pilot fuel channel, which is connected on its spring-loaded side to the main fuel channel via a branch channel. The pilot fuel is supplied on the side opposite the spring-loaded piston side, so that the piston must be displaced by the pilot fuel against the pressure of the spring so that the necessary quantity of pilot fuel can be supplied. If the main fuel is then only slightly pressurized, it can act via the branch channel on the spring-loaded side of the pre-injection piston and, due to the differential piston, increases the pressure in such a way that the nozzle needle is raised so that the pilot fuel is injected into the combustion chamber. Then the pressure of the pilot fuel collapses, the nozzle needle closes again and only after a sufficient pressure has built up in the main fuel does it open again and allow the main fuel to enter the combustion chamber.

Weiterhin ist ebenfalls in dieser DE-A-2924128 vorgesehen, den Zündbrennstoff dem Hauptbrennstoff ohne das Erfordernis eines Differentialkolbens vorzulagern. Die Hauptbrennstoffleitung wird dabei an der Einspritzpumpe durch ein Druckentlastungsventil druckentlastet. In diesem Fall komprimiert der Zündbrennstoff den druckentlasteten Hauptbrennstoff innerhalb der Düse sowie in der Hauptbrennstoffleitung und verdrängt dadurch den Hauptbrennstoff an der Düsennadelspitze. Beim nachfolgenden Einspritzhub der Einspritzpumpe für den Hauptbrennstoff wird der an der Düsennadelspitze vorgelagerte Zündbrennstoff zeitlich zuerst eingespritzt. Ein in der Nähe der Austrittsöffnung der Zündbrennstoffleitung angeordnetes Rückschlagventil verhindert das Zurückfließen des Zündbrennstoffes. Soll die Menge des Zündbrennstoffes exakt dosiert werden, so sind weitere separate Einrichtungen, wie beispielsweise Magnetventile und Zumeßkolben, vorgesehen.Furthermore, it is also provided in this DE-A-2924128 to pre-charge the pilot fuel to the main fuel without the need for a differential piston. The main fuel line is relieved of pressure on the injection pump by a pressure relief valve. In this case, the pilot fuel compresses the pressure-relieved main fuel inside the nozzle and in the main fuel line and thereby displaces the main fuel at the nozzle needle tip. During the subsequent injection stroke of the injection pump for the main fuel, the pilot fuel upstream of the nozzle needle tip is injected first in time. A check valve arranged in the vicinity of the outlet opening of the pilot fuel line prevents the pilot fuel from flowing back. If the amount of pilot fuel is to be metered exactly, further separate devices, such as solenoid valves and metering pistons, are provided.

Insgesamt ist bei den vorbeschriebenen Vorrichtungen nach der DE-A-2 924128 als nachteilig anzusehen, daß der Zündbrennstoff entweder entgegen einer Federkraft eines Voreinspritzkolbens wirken muß oder den Hauptbrennstoff zu komprimieren hat. Daraus ergibt sich aber zwingend, daß die Zündbrennstoffeinspritzpumpe den relativ hohen Druck von 20-50 bar bereitstellen muß. Derartige Einspritzpumpen erfordern einen relativ hohen Bauaufwand und sind deshalb im Vergleich zu einfachen Förderpumpen teuer. In nachteiliger Weise werden weiterhin zur exakten Zumessung des Zündbrennstoffes noch zusätzliche Einrichtungen, wie beispielsweise Magnetventile, benötigt.Overall, in the above-described devices according to DE-A-2 924128 it is to be regarded as disadvantageous that the pilot fuel either has to act against the spring force of a pre-injection piston or has to compress the main fuel. However, this means that the pilot fuel injection pump must provide the relatively high pressure of 20-50 bar. Injection pumps of this type require a relatively large amount of construction work and are therefore expensive in comparison with simple feed pumps. In a disadvantageous manner, additional devices, such as solenoid valves, are still required for the exact metering of the pilot fuel.

Aus der DE-C-568 366 ist ebenfalls ein Einspritzventil zum Einspritzen von Zünd- und Hauptbrennstoff bekannt. Hier sind beide Brennstoffleitungen mit Rückschlagventilen versehen. In einer Abzweigleitung der Hauptbrennstoffleitung ist ein federbelasteter Verdrängerkolben angeordnet, der je nach seiner Stellung Entlastungsraum für den Hauptbrennstoff zur Verfügung stellt. Beide Brennstoffleitungen münden in der Nähe der Düsennadelspitze. Wenn Zündbrennstoff dem Hauptbrennstoff vorgelagert werden soll, ist das Rückschlagventil der Hauptbrennstoffleitung geschlossen, und der Hauptbrennstoff wird durch den Druck des Zündbrennstoffes entgegen der Federkraft des Verdrängerkolbens in den Kolbenraum des Verdrängerkolbens gedrückt. Der Zündbrennstoff schafft sich somit dadurch Raum, daß er den Hauptbrennstoff entgegen der Federkraft quasi vor sich her in den vom Verdrängerkolben geschaffenen Entlastungsraum preßt. Im darauffolgenden Förderhub der Einspritzpumpe für den Hauptbrennstoff gelangt der jetzt vorgelagerte Zündbrennstoff infolge des starken Druckanstieges im Hauptbrennstoff zeitlich vor diesem zur Einspritzung in den Brennraum. Auch bei einer derartigen Vorrichtung ist es nachteilig, daß der zum Eindrükken der Feder des Verdrängerkolbens nötige Druck des Zündbrennstoffes relativ hoch sein muß.From DE-C-568 366 an injection valve for injecting ignition and main fuel is also known. Here both fuel lines are equipped with check valves. A spring-loaded displacement piston is arranged in a branch line of the main fuel line and, depending on its position, provides relief space for the main fuel. Both fuel lines open near the nozzle needle tip. If pilot fuel is to be upstream of the main fuel, the check valve of the main fuel line is closed and the main fuel is pressed into the piston chamber of the displacer piston by the pressure of the pilot fuel against the spring force of the displacer. The pilot fuel thus creates space in that it presses the main fuel against the spring force virtually in front of it into the relief space created by the displacement piston. In the subsequent delivery stroke of the injection pump for the main fuel, the pilot fuel now upstream arrives for injection into the combustion chamber ahead of the main fuel due to the sharp rise in pressure. Even with such a device, it is disadvantageous that the pressure of the pilot fuel required to press in the spring of the displacement piston must be relatively high.

In der DE-A-2 908 375 wird ein Einspritzventil zum Einspritzen zweier Brennstoffe vorgeschlagen, bei dem zwei Hochdruckeinspritzpumpen die beiden Brennstoffe, also sowohl den Hauptbrennstoff als auch den Zündbrennstoff, getrennt fördern. Erst in der Nähe der Düsennadelspitze treffen die beiden Brennstoffkanäle, getrennt durch je ein dort angeordnetes Rückschlagventil, aufeinander. Beide Einspritzpumpen arbeiten mit sehr hohem Druck, d. h. etwa 250 bar. Somit ist auch hier die Zündbrennstoffeinspritzpumpe in nachteiliger Weise als teure Hochdruckeinspritzpumpe ausgebildet.DE-A-2 908 375 proposes an injection valve for injecting two fuels gene, in which two high-pressure injection pumps deliver the two fuels, i.e. both the main fuel and the pilot fuel, separately. Only in the vicinity of the nozzle needle tip do the two fuel channels meet, separated by a check valve each located there. Both injection pumps work at very high pressure, ie around 250 bar. Thus, here too, the pilot fuel injection pump is disadvantageously designed as an expensive high-pressure injection pump.

Aus der DE-A-2 547 783 ist eine Einspritzpumpe bekannt, die für einen Brennstoff den zur Einspritzung nötigen Hochdruck bereitstellt. Zur Verhinderung des sogenannten Nachspritzens ist bei dieser Einspritzpumpe ein Druckentlastungsventil an der Auslaßleitung der Einspritzpumpe vorgesehen. Dabei wird durch den Hub eines Kolbens ein definiertes Entlastungsvolumen zur Verfügung gestellt. Durch dieses Entlastungsvolumen kann die Brennstoffleitung nach dem Abschluß des Förderhubes druckentlastet werden.From DE-A-2 547 783 an injection pump is known which provides the high pressure necessary for injection for a fuel. To prevent the so-called post-injection, a pressure relief valve is provided on the outlet line of the injection pump in this injection pump. A defined relief volume is made available by the stroke of a piston. This relief volume allows the fuel line to be relieved of pressure after the delivery stroke has been completed.

Aufgabe der vorliegenden Erfindung ist es daher, ein Einspritzsystem der eingangs genannten Art vorzuschlagen, mit dem sicher eine ausreichende Zündbrennstoffmenge zeitlich vor dem Hauptbrennstoff in den Brennraum eingespritzt wird. Dabei soll der Zündbrennstoff mit einem geringen Druck und unter Verwendung einer preiswerten Niederdruckförderpumpe dem Hauptbrennstoff an der Spitze der Düsennadel vorgelagert werden.The object of the present invention is therefore to propose an injection system of the type mentioned at the outset, with which a sufficient quantity of pilot fuel is surely injected into the combustion chamber ahead of the main fuel. The pilot fuel is to be upstream of the main fuel at the tip of the nozzle needle using a low-pressure low-pressure feed pump.

Diese Aufgabe wird erfindungsgemäß durch die kennzeichnenden Merkmale des Anspruchs 1 gelöst.This object is achieved by the characterizing features of

Der Vorteil dieser Anordnung ist darin zu sehen, daß in dem Moment, wenn der Druck in der Hauptbrennstoffleitung zusammenbricht, ein Druckentlastungsvolumen in dem Einspritzventil geschaffen wird, das den Druck entlastet und durch die Größe des Entlastungsvolumens bzw. des freigegebenen Zylinderraumes die zuzuführende Zündbrennstoffmenge exakt vorbestimmt. Der Zündbrennstoff ist so in der Lage, mit einem geringen Druck von etwa 2-4 bar nachzufließen und sich an der Düsennadelspitze vorzulagern. Die für den Zündbrennstoff benötigte Förderpumpe kann daher besonders preiswert ausgebildet sein.The advantage of this arrangement can be seen in the fact that, when the pressure in the main fuel line collapses, a pressure relief volume is created in the injection valve, which relieves the pressure and precisely predetermines the quantity of pilot fuel to be supplied by the size of the relief volume or the released cylinder space . The pilot fuel is then able to flow in at a low pressure of about 2-4 bar and pre-accumulate at the tip of the nozzle needle. The feed pump required for the pilot fuel can therefore be designed to be particularly inexpensive.

Im nachfolgenden Einspritzhub der Einspritzpumpe wirkt der Hauptbrennstoff direkt auf den Zündbrennstoff. Der Druck des Hauptbrennstoffes hebt die Düsennadel an und spritzt zeitlich zuerst den Zündbrennstoff ein. Etwaige Differenzkolben können in vorteilhafter Weise ganz entfallen.In the subsequent injection stroke of the injection pump, the main fuel acts directly on the pilot fuel. The pressure of the main fuel raises the nozzle needle and first injects the pilot fuel. Any differential pistons can advantageously be omitted entirely.

Die räumliche Anordnung des Rückschlagventils in der Zündbrennstoffleitung nahe dem Sitz der Düsennadel führt zu einem äußerst geringen Totvolumen des Zündbrennstoffes. Es wird daher fast die gesamte vorgelagerte Zündbrennstoffmenge eingespritzt. Nur ein sehr kleiner Rest dieses Zündbrennstoffes verbleibt während der Einspritzperiode zwischen dem Düsennadelsitz und dem Rückschlagventil. Dies ist hier von besonderer Bedeutung, da der Hauptbrennstoff beim Einspritzen in den Brennraum einen Druck von etwa 250 bar erreicht und den Zündbrennstoff daher bei Beginn der Einspritzphase zunächst stark komprimiert. Je größer dann das Totvolumen des Zündbrennstoffes zwischen Rückschlagventil und Düsennadelsitz ist, desto mehr Zündbrennstoff wird wieder aus dem Vorlagerungsraum infolge der Kompression des Zündbrennstoffes in den vom Totvolumen eingenommenen Raum zurückgedrückt. Wegen des sehr geringen Totvolumens ist hier erfindungsgemäß dieser Effekt vernachlässigbar klein, so daß sich die Menge des vorgelagerten Zündbrennstoffes in besonders vorteilhafter Weise stets exakt vorherbestimmen läßt. Außerdem wird während der Einspritzphase eine geringe Vermischung der beiden Brennstoffe erzielt.The spatial arrangement of the check valve in the pilot fuel line near the seat of the nozzle needle leads to an extremely low dead volume of the pilot fuel. Almost the entire amount of pilot fuel upstream is therefore injected. Only a very small remnant of this pilot fuel remains between the nozzle needle seat and the check valve during the injection period. This is of particular importance here since the main fuel reaches a pressure of about 250 bar when it is injected into the combustion chamber and therefore initially strongly compresses the pilot fuel at the beginning of the injection phase. The larger the dead volume of the pilot fuel between the check valve and the nozzle needle seat, the more pilot fuel is pushed back out of the storage space due to the compression of the pilot fuel into the space occupied by the dead volume. Because of the very small dead volume, this effect is negligibly small here according to the invention, so that the amount of pilot fuel upstream can always be precisely predetermined in a particularly advantageous manner. In addition, little mixing of the two fuels is achieved during the injection phase.

Die Weiterbildung nach Anspruch 2 beschreibt eine besonders bevorzugte Ausführungsform des Rückschlagventils, das gemäß Anspruch 3 dimensioniert werden kann. Dadurch erzielt man kleinstmögliche Abmessungen, was den Vorteil hat, daß beim Einsetzen des Einspritzvorganges ein rasches Schließen und eine geringe Undichtigkeit erzielt wird.The development according to

Aufgrund der Ausbildung gemäß Anspruch 4 sind in der Düsennadel nur geringe Mengen Zündbrennstoff enthalten, die die Bewegung der Düsennadel in keiner Weise beeinflussen.Due to the design according to

Im folgenden wird die Erfindung anhand eines bevorzugten Ausführungsbeispiels näher erläutert.The invention is explained in more detail below on the basis of a preferred exemplary embodiment.

In der einzigen Abbildung ist ein Querschnitt durch eine Einspritzdüse gemäß der Erfindung dargestellt. Die Einspritzdüse 1 besteht in an sich bekannter Weise aus dem Düsenkörper 2, in dem zentrisch die Düsennadel 3 angeordnet ist, die durch die Kraft der Druckfeder 6 in Schließstellung gehalten wird. Der Düsenkörper 2 wird von einer Überwurfmutter 4 an dem Düsenhalter 5 befestigt.The single figure shows a cross section through an injection nozzle according to the invention. The

Der Hauptbrennstoff wird in den Düsenhalter 5 bei 7 zugeführt. Er gelangt durch ein Stabfilter 8 in eine Zulaufbohrung 9, die durch einen Kolben 10, welcher von einer Feder 11 belastet wird, verschließbar ist. Der Kolben 10 und die Feder 11 bilden ein Entlastungsventil. Der Kolben 10 weist hierzu eine Sacklochbohrung 10.1 auf, die mit Abflußöffnungen 10.2 ausgerüstet ist, die in der dargestellten Position verschlossen sind. Der Abstand der Abflußöffnungen 10.2 vom Sitz des Kolbens 10 ist ein Maß für die Größe des Entlastungsvolumens. Je größer dieser Abstand ist, desto größer ist das Entlastungsvolumen. Nach Passieren des Kolbens 10 gelangt der Hauptbrennstoff in die Druckkammer 12, die konzentrisch um die Düsennadel 3 angeordnet ist. Die Düsennadel 3 weist innerhalb der Druckkammer eine Druckschulter 3.1 auf, so daß sie bei einem entsprechenden Druck des Hauptbrennstoffes gegen die Kraft der Druckfeder angehoben werden kann. Von der Druckkammer 12 verläuft ein Ringkanal 13 zur Düsennadelsitzfläche. Dieser Ringkanal wird von der Düsennadel im geschlossenen Zustand verschlossen. In geöffnetem Zustand der Düsennadel geht der Ringkanal 13'in eine Zwischenbohrung 14 über, von der aus ein oder mehrere Spritzlöcher 15 abzweigen.The main fuel is fed into the

Der Zündbrennstoff wird bevorzugt gemäß der Erfindung durch das bei üblichen Einspritzdüsen vorgesehene Leckagesystem zugeführt. Hierzu gelangt der Zündbrennstoff über seine Anschlußleitung 16 und Bohrungen in den Düsenhalter zum Druckfederraum 17 und von dort zur Düsennadel. Um ihn im Inneren der Düsennadel bis kurz oberhalb der Nadelsitzfläche zu führen, weist die Düsennadel eine Sacklochbohrung 18 auf, in der ein zylindrischer Einsatz 19 mit einer abgeflachten Seitenwand eingesetzt ist. Dadurch wird zwischen der abgeflachten Seitenwand und der Düsennadelinnenwand ein Spalt 20 gebildet. Dieser ist im unteren Bereich der Düsennadel mit einer zentralen Bohrung 21 im Einsatz 19 und der Düsennadel 3 verbunden, von deren Ende kurz oberhalb der Düsennadelsitzfläche mehrere Austrittsöffnungen 24 zu dem Ringkanal 13 vorgesehen sind. In der Bohrung 21 ist eine Kugel 22 und eine Feder 23, die zusammen ein Rückschlagventil bilden und sie verschließen, angeordnet.The pilot fuel is preferably supplied according to the invention through the leakage system provided in conventional injectors. For this purpose, the pilot fuel passes through its connecting

Die erfindungsgemäße Vorrichtung arbeitet folgendermaßen.The device according to the invention works as follows.

Zwischen zwei Einspritzvorgängen befindet sich das Einspritzventil 1 in der dargestellten Position, d. h. die Düsennadel 3 ist geschlossen und der Kolben 10 befindet sich in seiner dargestellten Stellung. Diese kann er deshalb einnehmen, weil im Hauptbrennstoffsystem ein Druckentlastungsventil vorgesehen ist, so daß der Druck in der Zulaufbohrung 9 nach Beendigung des Einspritzvorganges absinkt, so daß die Feder 11 den Kolben 10 in die dargestellte Stellung verschieben kann.Between two injection processes, the

Da der Zündbrennstoff bei jedem Einspritzvorgang zuerst eingespritzt werden soll, muß er auch zuerst zugeführt werden. Hierzu wird er von einer Konstantförderpumpe mit einem Druck von 3 bis 4 bar über die Anschlußleitung 16, dem Druckfederraum 17 in den Spalt 20 und von dort über die zentrale Bohrung 21 bis zu dem Rückschlagventil geliefert. Die Feder 23 des Rückschlagventils ist derart eingestellt, daß das Rückschlagventil bei einem Druck von 2 bar öffnet. Dadurch fließt der Zündkraftstoff über die Austrittsöffnungen 24 in den Ringkanal 13.Since the pilot fuel is to be injected first with every injection process, it must also be supplied first. For this purpose, it is supplied by a constant delivery pump with a pressure of 3 to 4 bar via the connecting

Der in dem Ringkanal 13 vom letzten Einspritzvorgang übriggebliebene Hauptbrennstoff liegt ebenfalls drucklos vor, da durch die Verschließbewegung des als Entlastungsventil ausgebildeten Kolbens 10 das zwischen dem Kolben 10 und dem Düsennadelsitz vorhandene Volumen durch die Schließbewegung des Kolbens 10, z. B. um 10 oder 15 mm3 vergrößert wurde. Dadurch gelangt der Zündbrennstoff leicht in den Ringkanal und kann sich um die Düsennadelspitze ansammeln.The main fuel remaining in the

Anschließend wird der Hauptbrennstoff unter Druck zugeführt. Die Kraft der Feder 11 des Entlastungsventils ist derart bemessen, daß der Hauptbrennstoff den Kolben 10 verschieben kann, so daß der Hauptbrennstoff über die Abflußöffnungen 10.2 zur Druckkammer 12 und von dort in den Ringkanal 13 fließen kann. Aufgrund des Druckes des Hauptbrennstoffes wird die Düsennadel über die Druckschulter 3.1 angehoben. Dadurch kann der an dem Düsennadelsitz vorgelagerte Zündbrennstoff über die Zwischenbohrung 14 und die Spritzlöcher 15 in den Brennraum eintreten, gefolgt von dem Hauptbrennstoff.The main fuel is then supplied under pressure. The force of the

Ist die Förderung des Hauptbrennstoffes beendet und bricht der Druck in der Hauptbrennstoffleitung zusammen, so schließt sowohl die Düsennadel 3 als auch der Kolben 10 wieder. Damit wird in dem Hauptbrennstoffkanal zwischen dem Kolben 10 und der Düsennadelsitzfläche wieder das Entlastungsvolumen gebildet, so daß der Zündbrennstoff zugeführt werden kann.When the delivery of the main fuel has ended and the pressure in the main fuel line breaks down, both the

Aufgrund des Rückschlagventils in der Zündbrennstoffleitung wird während des Einspritzvorgangs verhindert, daß Hauptbrennstoff in die Zündbrennstoffleitung eindringt, so daß beim Zuführen von Zündbrennstoff der Hauptbrennstoff erst wieder herausgedrückt werden muß. Da dieser dann das geschaffene Entlastungsvolumen im Ringkanal 13 ausfüllen würde, könnte zuwenig Zündbrennstoff vorgelagert werden. Aus diesem Grunde ist das Rückschlagventil auch so nahe wie möglich an den Austrittsöffnungen 24 angeordnet und weist eine derart geringe Masse auf, daß es verzögerungsfrei reagieren kann.Due to the check valve in the pilot fuel line, the main fuel is prevented from penetrating into the pilot fuel line during the injection process, so that the main fuel only has to be pushed out again when pilot fuel is supplied. Since this would then fill the relief volume created in the

Claims (4)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT82102059T ATE13931T1 (en) | 1981-05-06 | 1982-03-13 | INJECTION SYSTEM FOR INJECTING TWO FUELS THROUGH ONE INJECTOR. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19813117796 DE3117796A1 (en) | 1981-05-06 | 1981-05-06 | INJECTION SYSTEM FOR INJECTING TWO FUELS THROUGH ONE INJECTION NOZZLE |

| DE3117796 | 1981-05-06 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0064146A1 EP0064146A1 (en) | 1982-11-10 |

| EP0064146B1 true EP0064146B1 (en) | 1985-06-19 |

Family

ID=6131527

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP82102059A Expired EP0064146B1 (en) | 1981-05-06 | 1982-03-13 | Injection system for injecting two fuels through one injection nozzle |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US4465237A (en) |

| EP (1) | EP0064146B1 (en) |

| AT (1) | ATE13931T1 (en) |

| DE (2) | DE3117796A1 (en) |

Families Citing this family (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB2126650B (en) * | 1982-08-31 | 1988-02-10 | George Stan Baranescu | I c engine injection system providing a stratified charge of two fuels |

| DE3237932A1 (en) * | 1982-10-13 | 1984-04-19 | Robert Bosch Gmbh, 7000 Stuttgart | FUEL INJECTION NOZZLE FOR INTERNAL COMBUSTION ENGINES |

| JP2526856B2 (en) * | 1984-12-19 | 1996-08-21 | トヨタ自動車株式会社 | Fuel injection device capable of injecting two kinds of fuel sequentially |

| DE3770275D1 (en) * | 1986-07-30 | 1991-06-27 | Elsbett L | INJECTION DEVICE FOR INPUTING FUELS INTO THE COMBUSTION ROOM OF AN INTERNAL COMBUSTION ENGINE. |

| JP2538908B2 (en) * | 1987-03-15 | 1996-10-02 | 三菱重工業株式会社 | Two-fuel engine injection system |

| US5311902A (en) * | 1991-07-02 | 1994-05-17 | Overfield Norbert W | Reciprocating compressor valve |

| EP0694123A1 (en) * | 1994-02-11 | 1996-01-31 | Mtu Motoren- Und Turbinen-Union Friedrichshafen Gmbh | Injection system |

| US5899385A (en) * | 1995-07-21 | 1999-05-04 | Robert Bosch Gmbh | Fuel injection valve for internal combustion engines |

| DE602006008377D1 (en) * | 2005-04-28 | 2009-09-24 | Delphi Tech Inc | injection |

| DE602007011961D1 (en) | 2006-10-13 | 2011-02-24 | Parker Hannifin Corp | Three-PLATE VALVE |

| US9068539B2 (en) | 2012-08-03 | 2015-06-30 | Caterpillar Inc. | Dual check fuel injector and fuel system using same |

| GB201309122D0 (en) | 2013-05-21 | 2013-07-03 | Delphi Tech Holding Sarl | Fuel Injector |

| GB2543826B (en) * | 2015-10-30 | 2019-07-24 | Caterpillar Inc | A fuel injector, a fuel injector assembly and an associated method |

| DE102015015518B4 (en) | 2015-11-26 | 2023-04-27 | Hermann GOLLE | Fuel/air injection system for internal combustion engines |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CH305822A (en) * | 1950-11-17 | 1955-03-15 | Nat Res Dev | Fuel injection device with an injection nozzle and a piston pump. |

| DE2547783A1 (en) * | 1974-12-19 | 1976-06-24 | Friedmann & Maier Ag | FUEL INJECTION PUMP |

Family Cites Families (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR484774A (en) * | 1916-03-14 | 1917-11-06 | Edward Gardner | Improvements to fuel injectors for internal combustion engines |

| GB120609A (en) * | 1917-11-10 | 1918-11-11 | Kenneth Irwin Crossley | Improvements in Oil Fuel Injection Devices for Internal Combustion Engines. |

| DE479273C (en) * | 1925-11-03 | 1929-07-13 | Motorenfabrik Deutz Akt Ges | Injection device for diesel engines with Zuendoelvorlagerung |

| DE568366C (en) * | 1931-12-09 | 1933-01-18 | Fried Krupp Germaniawerft Akt | Fuel needle valve for fuel injection engines |

| DE577810C (en) * | 1932-02-13 | 1933-06-06 | Motorenfabrik Herford Ges M B | Injector for two different fuels |

| CH172170A (en) * | 1933-12-22 | 1934-09-30 | Sulzer Ag | Fuel pump for internal combustion engines working with ignition and propellant fuel. |

| DE849325C (en) * | 1940-09-19 | 1952-09-15 | Bosch Gmbh Robert | Injection valve for internal combustion engines |

| CH234210A (en) * | 1943-05-29 | 1944-09-15 | Sulzer Ag | Method and device for injecting inert fuel under pressure. |

| US2602703A (en) * | 1947-09-22 | 1952-07-08 | Atlas Diesel Ab | Fuel injection valve |

| DE969853C (en) * | 1952-12-25 | 1958-07-24 | Maschf Augsburg Nuernberg Ag | Device for using different types and amounts of fuel in injection nozzles of internal combustion engines |

| GB1357887A (en) * | 1970-11-05 | 1974-06-26 | Cav Ltd | Fuel injection system for an internal combustion engine |

| DE2908375A1 (en) * | 1979-03-03 | 1980-09-11 | Klaus Dipl Ing Starke | Diesel engine operating system - has igniting and main fuels injected in succession through common nozzle hole |

| DE2924128A1 (en) * | 1979-06-15 | 1980-12-18 | Motoren Werke Mannheim Ag | Diesel engine using different fuel for starting and running - has single injector delivering starting and running fuel in sequence |

-

1981

- 1981-05-06 DE DE19813117796 patent/DE3117796A1/en not_active Withdrawn

-

1982

- 1982-03-13 DE DE8282102059T patent/DE3264208D1/en not_active Expired

- 1982-03-13 AT AT82102059T patent/ATE13931T1/en not_active IP Right Cessation

- 1982-03-13 EP EP82102059A patent/EP0064146B1/en not_active Expired

- 1982-05-04 US US06/374,911 patent/US4465237A/en not_active Expired - Fee Related

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CH305822A (en) * | 1950-11-17 | 1955-03-15 | Nat Res Dev | Fuel injection device with an injection nozzle and a piston pump. |

| DE2547783A1 (en) * | 1974-12-19 | 1976-06-24 | Friedmann & Maier Ag | FUEL INJECTION PUMP |

Also Published As

| Publication number | Publication date |

|---|---|

| US4465237A (en) | 1984-08-14 |

| DE3117796A1 (en) | 1982-11-25 |

| ATE13931T1 (en) | 1985-07-15 |

| EP0064146A1 (en) | 1982-11-10 |

| DE3264208D1 (en) | 1985-07-25 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE2954686C2 (en) | ||

| EP0064146B1 (en) | Injection system for injecting two fuels through one injection nozzle | |

| DE60125098T2 (en) | Fuel injection valve | |

| EP0694123A1 (en) | Injection system | |

| DE3629751C2 (en) | Pre-injection device for internal combustion engines | |

| WO2004003376A1 (en) | Boosted fuel injector with rapid pressure reduction at end of injection | |

| DE4421714A1 (en) | Fuel injection system | |

| DE10229415A1 (en) | Device for damping the needle stroke on pressure-controlled fuel injectors | |

| EP0432402B1 (en) | Injection device for self-ignition internal combustion engines | |

| EP2410168A1 (en) | Fluid dispenser and method for providing an operating fluid using a fluid dispenser | |

| EP1045975B1 (en) | Control unit for controlling the build-up of pressure in a pump unit | |

| DE3401658C2 (en) | ||

| DE19802828A1 (en) | Hydraulically operated injector with needle valve operated overflow passage | |

| CH671809A5 (en) | ||

| EP0610585B1 (en) | Fuel injection device with pilot- and main-injection | |

| DE1751080B1 (en) | Fuel injection nozzle for diesel engines | |

| DE10023960A1 (en) | Fuel injection device for internal combustion engine has choke gap formed between choke section upstream of valve seat in bore and casing surface | |

| DE3009750C2 (en) | Fuel injection device for internal combustion engines | |

| EP0610584B1 (en) | Fuel injection de vice with pilot- and main-injection of different fuels through a one-needle injection valve | |

| DE4425339C2 (en) | Injection system | |

| DE102008000082B4 (en) | Injector | |

| EP1483499A1 (en) | Installation for the pressure-modulated formation of the injection behavior | |

| DE19746490A1 (en) | Dual fluid injection system for IC engine | |

| AT512439A1 (en) | DEVICE FOR INJECTING FUEL IN THE COMBUSTION ENGINE OF AN INTERNAL COMBUSTION ENGINE | |

| DE3700359C2 (en) | Fuel injection device for internal combustion engines, in particular pump nozzle |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): AT CH DE FR GB IT NL SE |

|

| 17P | Request for examination filed |

Effective date: 19821216 |

|

| ITF | It: translation for a ep patent filed | ||

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Designated state(s): AT CH DE FR GB IT LI NL SE |

|

| REF | Corresponds to: |

Ref document number: 13931 Country of ref document: AT Date of ref document: 19850715 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 3264208 Country of ref document: DE Date of ref document: 19850725 |

|

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 19870209 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19870331 Year of fee payment: 6 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19890313 Ref country code: AT Effective date: 19890313 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19890314 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Effective date: 19890331 Ref country code: CH Effective date: 19890331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19891001 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee | ||

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19891130 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19891201 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| EUG | Se: european patent has lapsed |

Ref document number: 82102059.1 Effective date: 19900124 |