EP1045975B1 - Control unit for controlling the build-up of pressure in a pump unit - Google Patents

Control unit for controlling the build-up of pressure in a pump unit Download PDFInfo

- Publication number

- EP1045975B1 EP1045975B1 EP99952396A EP99952396A EP1045975B1 EP 1045975 B1 EP1045975 B1 EP 1045975B1 EP 99952396 A EP99952396 A EP 99952396A EP 99952396 A EP99952396 A EP 99952396A EP 1045975 B1 EP1045975 B1 EP 1045975B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- valve

- control valve

- valve body

- control

- small

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M59/00—Pumps specially adapted for fuel-injection and not provided for in groups F02M39/00 -F02M57/00, e.g. rotary cylinder-block type of pumps

- F02M59/44—Details, components parts, or accessories not provided for in, or of interest apart from, the apparatus of groups F02M59/02 - F02M59/42; Pumps having transducers, e.g. to measure displacement of pump rack or piston

- F02M59/46—Valves

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04B—POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS

- F04B53/00—Component parts, details or accessories not provided for in, or of interest apart from, groups F04B1/00 - F04B23/00 or F04B39/00 - F04B47/00

- F04B53/10—Valves; Arrangement of valves

- F04B53/102—Disc valves

- F04B53/1022—Disc valves having means for guiding the closure member axially

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M45/00—Fuel-injection apparatus characterised by having a cyclic delivery of specific time/pressure or time/quantity relationship

- F02M45/02—Fuel-injection apparatus characterised by having a cyclic delivery of specific time/pressure or time/quantity relationship with each cyclic delivery being separated into two or more parts

- F02M45/04—Fuel-injection apparatus characterised by having a cyclic delivery of specific time/pressure or time/quantity relationship with each cyclic delivery being separated into two or more parts with a small initial part, e.g. initial part for partial load and initial and main part for full load

- F02M45/06—Pumps peculiar thereto

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M59/00—Pumps specially adapted for fuel-injection and not provided for in groups F02M39/00 -F02M57/00, e.g. rotary cylinder-block type of pumps

- F02M59/20—Varying fuel delivery in quantity or timing

- F02M59/36—Varying fuel delivery in quantity or timing by variably-timed valves controlling fuel passages to pumping elements or overflow passages

- F02M59/366—Valves being actuated electrically

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04B—POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS

- F04B49/00—Control, e.g. of pump delivery, or pump pressure of, or safety measures for, machines, pumps, or pumping installations, not otherwise provided for, or of interest apart from, groups F04B1/00 - F04B47/00

- F04B49/22—Control, e.g. of pump delivery, or pump pressure of, or safety measures for, machines, pumps, or pumping installations, not otherwise provided for, or of interest apart from, groups F04B1/00 - F04B47/00 by means of valves

- F04B49/225—Control, e.g. of pump delivery, or pump pressure of, or safety measures for, machines, pumps, or pumping installations, not otherwise provided for, or of interest apart from, groups F04B1/00 - F04B47/00 by means of valves with throttling valves or valves varying the pump inlet opening or the outlet opening

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04B—POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS

- F04B2205/00—Fluid parameters

- F04B2205/17—Opening width of a throttling device

- F04B2205/172—Opening width of a throttling device after the pump outlet

Definitions

- the present invention relates to a control unit for Control of pressure build-up by a pump unit in a system, the control unit being a control valve and a valve actuation unit connected to it has and the control valve as a in the flow direction inward-opening I-valve is formed, the one in a housing of the control unit axially displaceable has mounted valve body, which when closed Control valve from the inside on a valve seat of the Control valve sits.

- the control unit has one Throttle arrangement through which the flow through the Control valve when opened by a small stroke Control valve is throttled.

- the present invention also relates to a Injection system for supplying fuel to one Combustion chamber of direct injection Internal combustion engines with a pump unit for Build up an injection pressure and then to inject the Fuel through an injector in the Combustion chamber.

- the present invention also relates to a Method for controlling the pressure build-up by means of a Control unit with a control valve and one with this connected valve actuation unit, the Control valve as an inward flow direction opening I-valve is formed, the one in one Housing of the control unit mounted axially displaceable Has valve body, when the control valve is closed from the inside sits on a valve seat of the control valve.

- Control units are known from the prior art. She are used, for example, to control the fuel supply in a combustion chamber of direct injection Internal combustion engines used.

- the Internal combustion engines have a pump unit Build up an injection pressure and then to inject the Fuel through an injection nozzle into the combustion chamber on.

- the injection system of the internal combustion engine can For example, as a pump-nozzle unit (PDE) or as a pump-line nozzle (PLD) system.

- Solenoid valves These known control units are usually called Solenoid valves designed.

- Valve actuation unit designed as an electromagnet, which actuates the control valve.

- the solenoid valve is in the open state. This is a free one Flow from the pump unit to the low pressure area given the injection system and thus filling the Pump room with fuel during the suction stroke of the Pump piston and a backflow of fuel during of the delivery stroke possible.

- a control of the solenoid valve during the delivery stroke of the pump piston closes it Bypass. This leads to a pressure build-up in the High pressure area of the system.

- Control unit of the pressure build-up in the pump unit to be controlled.

- the control valve is downstream as one in the flow direction internally opening I-valve.

- I valves have small strokes are usually very steep Flow curve. The course is in a flow curve the flow through a valve depending on the Stroke of the valve applied. Because of the steep course the flow curve of I-valves with small valve strokes already lead to slight fluctuations in the valve lift relatively large fluctuations in the flow rate. Basically, a fluctuation in the flow rate would have small strokes hardly affect the total amount of funded medium.

- the flow rate through the valve at small Valve strokes should be as independent of the valve stroke as possible should and where it should be as flat as possible the flow curve arrives at small strokes.

- Such an application is, for example, the control of the Direct injection fuel supply Internal combustion engines.

- Pre-injection performed, d. H. before the actual Main injection a small amount of fuel into the Injection chamber injected.

- the Amount of pre-injected fuel needs to be accurately determined can be the behavior of the To be able to control the internal combustion engine in a targeted manner.

- the Pre-injection takes place with small strokes of the control valve instead of. Already have slight fluctuations in the valve lift large in the prior art control unit Effects on the amount of pre-injected Fuel. To the pre-injection quantity as accurately as possible To be able to determine, it would therefore be advantageous if the Flow curve with small strokes a flat course having.

- a control unit is known from US 4,470,548 of the type mentioned, in which the Flow rate through a mechanical throttle arrangement is throttled.

- the flow rate is there through the control unit through a cross section of a Expiration of a housing of the control unit throttled.

- the invention is based on from a control unit of the type mentioned Control unit in front by a throttle arrangement is characterized by the flow through the Control valve when opened by a small stroke Control valve is throttled.

- control valve open by a large stroke control unit is a free flow from the pump unit via the valve seat of the control valve to a low pressure area of a system in which the Pressure build-up to be controlled is given. So is a Filling the pump room with the pumped medium during the suction stroke of the pump piston and a backflow of the medium possible during the delivery stroke. In the system so no pressure is built up.

- valve actuation unit moves the valve piston in the direction of the closed position of the Control valve. This allows the control valve to turn around a small stroke open valve position.

- the control valve is opened by a small stroke, after as before a flow, but only one throttled flow, from the pump unit through the Valve seat of the control valve and via the throttle arrangement given to the low pressure area of the system. So is conditional filling of the pump room with the pumped Medium during the suction stroke of the pump piston and a Backflow of the medium possible during the delivery stroke. In the high pressure area of the system becomes a low pressure built up.

- valve actuation unit Another actuation of the valve actuation unit during of the delivery stroke of the pump piston closes the control valve completely, causing the bypass from the pump unit to the low pressure area of the system is interrupted. This leads to the build-up of high pressure in the high pressure area of the system.

- the flow rate of the flow through the control valve Medium does not fall off steeply during the closing process a maximum value when the control valve is fully open to zero when fully closed Control valve. Rather, when one reaches small hubs so long an almost constant small amount of the pumped medium through the control valve until the Control valve is completely closed.

- the course of the Flow curve of the control valve for small strokes is in advantageously very flat. This ensures that Fluctuations in valve lift hardly fluctuations in Cause flow rate.

- the flow rate is at small strokes almost independent of the valve stroke.

- the throttle arrangement is integrated in the valve body. This has the advantage that it is not controlled separately must, but together with the valve body an inactive position when fully open Control valve in an active position at around a small Stroke open control valve can be brought.

- the small strokes of the Control valve is in a closed position and the has at least one throttle bore, which when open Control valve with an inlet and an outlet of the Control valve is connected.

- the further valve body is preferably in the Valve body is axially displaceable.

- the other The valve body sits with the control valve closed and at a small stroke of the control valve in the direction of flow from the inside on another valve seat of the control valve.

- the conveyed medium can through the valve seat and additional valve seat free from the pump unit to the Low pressure area of the system flow.

- valve body of the control valve still from that Lifted valve seat, the further valve body of the Throttle arrangement, however, sits on the other Valve seat.

- the pumped medium can only be throttled through the valve seat and the throttle bore further Valve body flow. Doing so will result in the system low pressure built up.

- Control valve sits on the valve body of the control valve the valve seat and the pumped medium is on the Valve seat retained. Now one in the system higher pressure built up.

- the further valve body is advantageously replaced by a between the valve body and the further valve body acting spring element with closed control valve or with a small stroke of the control valve on the other Valve seat pressed.

- the further valve body preferably has a stop on the with a large stroke of the control valve on the Valve body rests. With the control valve closed corresponds to the distance between the stop and the Valve body the size of the small valve lift during which the throttle arrangement is active.

- the invention proposes that the further Valve body in the flow direction on the outside of the valve body is formed and that the further valve body at closed control valve and with a small stroke of the Control valve sealed in a mounting hole is included from which the drain from the control valve out leads.

- the further valve body and the Location bore form the further valve seat, which during the small strokes of the control valve are closed.

- at fully open control valve d. H. with a big one Stroke, is the valve body of the control valve from which Lifted valve seat and the further valve body of the Throttle assembly is outside of the Bore.

- the funded medium can through the Valve seat and the other valve seat free from the Pump unit to the low pressure area of the system flow.

- valve body of the control valve still lifted from the valve seat, the other Valve body of the throttle arrangement is, however, of the Location bore sealed sealed.

- the funded Medium can only be throttled through the valve seat and the throttle bore of the further valve body flow. This creates a low pressure in the system.

- the Valve body of the control valve on the valve seat and that conveyed medium is retained on the valve seat. In a higher pressure is now built up in the system.

- the present invention also relates to a Injection system for supplying fuel to one Combustion chamber of direct injection Internal combustion engines with a pump unit for Build up an injection pressure and then to inject the Fuel through an injector in the Combustion chamber, the injection system means has to before the actual main injection small amount of fuel in the combustion chamber voreinzuspritzen.

- the present invention also relates to a Method for controlling the pressure build-up by a Pump unit in a system by means of a control unit, which is a control valve and one connected to it Has valve actuation unit, wherein the control valve as an I-valve opening inwards in the direction of flow is formed, the one in a housing Control unit axially displaceably mounted valve body has from the inside when the control valve is closed a valve seat of the control valve sits, and wherein to Building up a pressure in the system of the valve body Control valve from an open by a large stroke Position over a position opened by a small stroke is brought into a closed position.

- the invention proposes that the flow through the Control valve from the time the valve body is open to a small stroke, up to the point of time which the valve body is closed by a in the Valve body integrated throttle assembly is throttled.

- the method for controlling the Fuel supply into a combustion chamber direct-injection internal combustion engine with a Pump unit for building up an injection pressure and after for injecting fuel through an injector used the combustion chamber.

- Advantages of the invention to bear. So it is with that inventive method possible Fuel quantity of a pre-injection is particularly accurate and to control reliably because the flow rate through the Control valve due to the flat course of the Flow curve is almost independent of the valve lift of the Control valve. With fluctuating small strokes it is Flow rate therefore only a small fluctuation subjected.

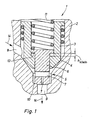

- FIG. 1 is a control valve 1 of an inventive Control unit according to a first embodiment shown.

- the control unit is used to control the Pressure build-up by a pump unit in any System. It has the control valve 1 and one with it connected valve actuation unit (not shown) on.

- the control valve 1 is in the direction of flow 14 inward opening I-valve. It has one axially displaceable in a housing 2 of the control unit mounted valve body 3, the closed Control valve 1 from the inside on a valve seat 4 of the Control valve 1 sits.

- the control valve 1 has one Throttle arrangement 5 through which the flow through the Control valve 1 when opened by a small stroke Control valve 1 is throttled.

- the throttle arrangement 5 is in the valve body 3 Integrated further valve body 6 formed.

- the further valve body 6 is in the direction of flow arranged on the outside of the valve body 3.

- the other Valve body 6 is at a small stroke of the control valve 1 in a closed position and has two throttle bores 7 which, when the control valve 1 is open, has an inlet 8 and an outlet 9 of the control valve 1 in connection stand.

- the further valve body 6 is in the valve body 3 axially slidably mounted. The further valve body 6 sits with control valve 1 closed and one small stroke of the control valve 1 from the inside on one further valve seat 10 of the control valve 1.

- valve seat 4 With control valve 1 open by a large stroke both the valve seat 4 and the further valve seat 10 open. There is free flow from the pump unit given to a low pressure area of the system, and thus is filling the pump room with the pumped medium during the suction stroke of the pump piston and a backflow of the medium possible during the delivery stroke. In the system no pressure is built up.

- the further valve body 10 is by a between the Valve body 3 and the further valve body 6 acting Spring element 11 with closed control valve 1 or at a small stroke of the control valve 1 on the other Valve seat 10 pressed.

- the further valve body 6 has a stop 12 on the at a large stroke of Control valve 1 rests on the valve body 3.

- the further valve seat 10 is particularly flat, so with large strokes of the control valve 1 after opening of the further valve seat 10 as quickly as possible Flow value Q (see. Fig. 3) is reached.

- FIG 2 is a control valve 1 of the invention Control unit according to a second embodiment shown.

- the other one Valve body 6 in the flow direction on the outside Valve body 3 formed.

- the further valve body 6 is with control valve 1 closed and with a small stroke of the control valve 1 sealed in a receiving bore 13 added.

- the drain 9 leads out of the receiving bore 13 out of the control valve 1.

- the further valve body 6 forms together with the edge of the receiving bore 13 another valve seat 10.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Fuel-Injection Apparatus (AREA)

- Details Of Reciprocating Pumps (AREA)

Description

Die vorliegende Erfindung betrifft eine Steuereinheit zur Steuerung des Druckaufbaus durch eine Pumpeneinheit in einem System, wobei die Steuereinheit ein Steuerventil und eine mit diesem verbundene Ventilbetätigungseinheit aufweist und das Steuerventil als ein in Strömungsrichtung nach innen öffnendes I-Ventil ausgebildet ist, das einen in einem Gehäuse der Steuereinheit axial verschiebbar gelagerten Ventilkörper aufweist, der bei geschlossenem Steuerventil von innen auf einem Ventilsitz des Steuerventils sitzt. Die Steuereinheit weist eine Drosselanordnung auf, durch die der Durchfluss durch das Steuerventil bei um einen kleinen Hub geöffnetem Steuerventil gedrosselt wird.The present invention relates to a control unit for Control of pressure build-up by a pump unit in a system, the control unit being a control valve and a valve actuation unit connected to it has and the control valve as a in the flow direction inward-opening I-valve is formed, the one in a housing of the control unit axially displaceable has mounted valve body, which when closed Control valve from the inside on a valve seat of the Control valve sits. The control unit has one Throttle arrangement through which the flow through the Control valve when opened by a small stroke Control valve is throttled.

Die vorliegende Erfindung betrifft außerdem ein Einspritzsystem zur Kraftstoffzufuhr in einen Verbrennungsraum von direkteinspritzenden Verbrennungskraftmaschinen mit einer Pumpeneinheit zum Aufbau eines Einspritzdrucks und dann zum Einspritzen des Kraftstoffs über eine Einspritzdüse in den Verbrennungsraum.The present invention also relates to a Injection system for supplying fuel to one Combustion chamber of direct injection Internal combustion engines with a pump unit for Build up an injection pressure and then to inject the Fuel through an injector in the Combustion chamber.

Schließlich betrifft die vorliegende Erfindung auch ein Verfahren zur Steuerung des Druckaufbaus mittels einer Steuereinheit mit einem Steuerventil und einer mit diesem verbundenen Ventilbetätigungseinheit, wobei das Steuerventil als ein in Strömungsrichtung nach innen öffnendes I-Ventil ausgebildet ist, das einen in einem Gehäuse der Steuereinheit axial verschiebbar gelagerten Ventilkörper aufweist, der bei geschlossenem Steuerventil von innen auf einem Ventilsitz des Steuerventils sitzt.Finally, the present invention also relates to a Method for controlling the pressure build-up by means of a Control unit with a control valve and one with this connected valve actuation unit, the Control valve as an inward flow direction opening I-valve is formed, the one in one Housing of the control unit mounted axially displaceable Has valve body, when the control valve is closed from the inside sits on a valve seat of the control valve.

Zur Steuerung des Druckaufbaus beliebiger Pumpeneinheiten sind aus dem Stand der Technik Steuereinheiten bekannt. Sie werden beispielsweise zur Steuerung der Kraftstoffzufuhr in einen Verbrennungsraum von direkteinspritzenden Verbrennungskraftmaschinen eingesetzt. Die Verbrennungskraftmaschinen weisen eine Pumpeneinheit zum Aufbau eines Einspritzdrucks und dann zum Einspritzen des Kraftstoffs über eine Einspritzdüse in den Verbrennungsraum auf. Das Einspritzsystem der Verbrennungskraftmaschine kann bspw. als eine Pumpe-Düse-Einheit (PDE) oder als ein Pumpe-Leitung-Düse (PLD)-System ausgebildet sein.To control the pressure build-up of any pump units Control units are known from the prior art. she are used, for example, to control the fuel supply in a combustion chamber of direct injection Internal combustion engines used. The Internal combustion engines have a pump unit Build up an injection pressure and then to inject the Fuel through an injection nozzle into the combustion chamber on. The injection system of the internal combustion engine can For example, as a pump-nozzle unit (PDE) or as a pump-line nozzle (PLD) system.

Diese bekannten Steuereinheiten sind üblicherweise als Magnetventile ausgebildet. Dabei ist die Ventilbetätigungseinheit als ein Elektromagnet ausgebildet, der das Steuerventil betätigt. Das Magnetventil ist im nicht erregten Zustand geöffnet. Dadurch ist ein freier Durchfluss von der Pumpeneinheit zu dem Niederdruckbereich des Einspritzsystems gegeben und somit ein Befüllen des Pumpenraumes mit Kraftstoff während des Saughubs des Pumpenkolbens und ein Rückströmen des Kraftstoffs während des Förderhubes möglich. Ein Ansteuern des Magnetventils während des Förderhubes des Pumpenkolbens schließt diesen Bypass. Dies führt zu einem Druckaufbau in dem Hochdruckbereich des Systems. Somit kann mittels der Steuereinheit der Druckaufbau in der Pumpeneinheit gesteuert werden.These known control units are usually called Solenoid valves designed. Here is the Valve actuation unit designed as an electromagnet, which actuates the control valve. The solenoid valve is in the open state. This is a free one Flow from the pump unit to the low pressure area given the injection system and thus filling the Pump room with fuel during the suction stroke of the Pump piston and a backflow of fuel during of the delivery stroke possible. A control of the solenoid valve during the delivery stroke of the pump piston closes it Bypass. This leads to a pressure build-up in the High pressure area of the system. Thus, by means of Control unit of the pressure build-up in the pump unit to be controlled.

Das Steuerventil ist als ein in Strömungsrichtung nach innen öffnendes I-Ventil ausgebildet. I-Ventile haben bei kleinen Hüben üblicherweise eine sehr steile Durchflusskurve. In einer Durchflusskurve wird der Verlauf des Durchflusses durch ein Ventil in Abhängigkeit von dem Hub des Ventils aufgetragen. Aufgrund des steilen Verlaufs der Durchflusskurve von I-Ventilen bei kleinen Ventilhüben führen bereits geringe Schwankungen des Ventilhubs zu relativ großen Schwankungen der Durchflussmenge. Grundsätzlich hätte eine Schwankung der Durchflussmenge bei kleinen Hüben kaum Auswirkungen auf die Gesamtmenge des geförderten Mediums. Es gibt jedoch Anwendungen, bei denen die Durchflussmenge durch das Ventil bei kleinen Ventilhüben möglichst unabhängig von dem Ventilhub sein sollte und bei denen es auf einen möglichst flachen Verlauf der Durchflusskurve bei kleinen Hüben ankommt.The control valve is downstream as one in the flow direction internally opening I-valve. I valves have small strokes are usually very steep Flow curve. The course is in a flow curve the flow through a valve depending on the Stroke of the valve applied. Because of the steep course the flow curve of I-valves with small valve strokes already lead to slight fluctuations in the valve lift relatively large fluctuations in the flow rate. Basically, a fluctuation in the flow rate would have small strokes hardly affect the total amount of funded medium. However, there are applications where the flow rate through the valve at small Valve strokes should be as independent of the valve stroke as possible should and where it should be as flat as possible the flow curve arrives at small strokes.

Eine derartige Anwendung ist bspw. die Steuerung der Kraftstoffzufuhr bei direkteinspritzenden Verbrennungskraftmaschinen. Dort wird häufig eine sog. Voreinspritzung durchgeführt, d. h. vor der eigentlichen Haupteinspritzung eine geringe Menge Kraftstoff in den Verbrennungsraum gespritzt. Mit Hilfe der voreinspritzung kann das Geräusch- und Abgasverhalten der Verbrennungskraftmaschine positiv beeinflusst werden. Die Menge des voreingespritzten Kraftstoffs muss genau bestimmt werden können, um das Verhalten der Verbrennungskraftmaschine gezielt steuern zu können. Die Voreinspritzung findet bei kleinen Hüben des Steuerventils statt. Bereits geringe Schwankungen des Ventilhubs haben bei der Steuereinheit nach dem Stand der Technik große Auswirkungen auf die Menge des voreingespritzten Kraftstoffs. Um die Voreinspritzmenge möglichst genau bestimmen zu können, wäre es deshalb vorteilhaft, wenn die Durchflusskurve bei kleinen Hüben einen flachen Verlauf aufweist.Such an application is, for example, the control of the Direct injection fuel supply Internal combustion engines. There is often a so-called Pre-injection performed, d. H. before the actual Main injection a small amount of fuel into the Injection chamber injected. With the help of the pre-injection can the noise and exhaust behavior of the Internal combustion engine can be influenced positively. The Amount of pre-injected fuel needs to be accurately determined can be the behavior of the To be able to control the internal combustion engine in a targeted manner. The Pre-injection takes place with small strokes of the control valve instead of. Already have slight fluctuations in the valve lift large in the prior art control unit Effects on the amount of pre-injected Fuel. To the pre-injection quantity as accurately as possible To be able to determine, it would therefore be advantageous if the Flow curve with small strokes a flat course having.

Um den Verlauf der Durchflusskurve bei kleinen Hüben möglichst flach auszubilden, ist es aus dem Stand der Technik bekannt, die Durchflussmenge elektronisch zu steuern. Eine elektronische Steuerung ist jedoch aufwendig und teuer.The course of the flow curve for small strokes Training as flat as possible, it is from the state of the art Technology known to electronically increase the flow rate Taxes. However, electronic control is complex and expensive.

Darüber hinaus ist aus der US 4,470,548 eine Steuereinheit der eingangs genannten Art bekannt, bei der die Durchflussmenge durch eine mechanische Drosselanordnung gedrosselt wird. Allerdings wird dort die Durchflussmenge durch die Steuereinheit durch einen Querschnitt eines Ablaufs eines Gehäuses der Steuereinheit gedrosselt.In addition, a control unit is known from US 4,470,548 of the type mentioned, in which the Flow rate through a mechanical throttle arrangement is throttled. However, the flow rate is there through the control unit through a cross section of a Expiration of a housing of the control unit throttled.

Aus den vorgenannten Nachteilen des Standes der Technik ergibt sich die Aufgabe der vorliegenden Erfindung, eine Steuereinheit der eingangs genannten Art dahingehend weiterzubilden, dass die Durchflusskurve bei kleinen Hüben des Steuerventils einen möglichst flachen Verlauf aufweist.From the aforementioned disadvantages of the prior art there is the object of the present invention, a Control unit of the type mentioned in this regard to further develop the flow curve for small strokes of the control valve is as flat as possible.

Zur Lösung dieser Aufgabe schlägt die Erfindung ausgehend von einer Steuereinheit der eingangs genannten Art eine Steuereinheit vor, die durch eine Drosselanordnung gekennzeichnet ist, durch die der Durchfluss durch das Steuerventil bei um einen kleinen Hub geöffnetem Steuerventil gedrosselt wird.To achieve this object, the invention is based on from a control unit of the type mentioned Control unit in front by a throttle arrangement is characterized by the flow through the Control valve when opened by a small stroke Control valve is throttled.

Bei um einen großen Hub geöffnetem Steuerventil der erfindungsgemäßen Steuereinheit ist ein freier Durchfluss von der Pumpeneinheit über den Ventilsitz des Steuerventils zu einem Niederdruckbereich eines Systems, in dem der Druckaufbau gesteuert werden soll, gegeben. Somit ist ein Befüllen des Pumpenraumes mit dem geförderten Medium während des Saughubs des Pumpenkolbens und ein Rückströmen des Mediums während des Förderhubes möglich. In dem System wird also kein Druck aufgebaut.With the control valve open by a large stroke control unit according to the invention is a free flow from the pump unit via the valve seat of the control valve to a low pressure area of a system in which the Pressure build-up to be controlled is given. So is a Filling the pump room with the pumped medium during the suction stroke of the pump piston and a backflow of the medium possible during the delivery stroke. In the system so no pressure is built up.

Durch Ansteuern der Ventilbetätigungseinheit bewegt sich der Ventilkolben in Richtung der Schließstellung des Steuerventils. Dadurch kann das Steuerventil in eine um einen kleinen Hub geöffnete Ventilstellung gebracht werden. Bei um einen kleinen Hub geöffnetem Steuerventil ist nach wie vor ein Durchfluss, allerdings lediglich ein gedrosselter Durchfluss, von der Pumpeneinheit über den Ventilsitz des Steuerventils und über die Drosselanordnung zu dem Niederdruckbereich des Systems gegeben. Somit ist ein bedingtes Befüllen des Pumpenraumes mit dem geförderten Medium während des Saughubs des Pumpenkolbens und ein Rückströmen des Mediums während des Förderhubes möglich. In dem Hochdruckbereich des Systems wird ein geringer Druck aufgebaut.Activating the valve actuation unit moves the valve piston in the direction of the closed position of the Control valve. This allows the control valve to turn around a small stroke open valve position. When the control valve is opened by a small stroke, after as before a flow, but only one throttled flow, from the pump unit through the Valve seat of the control valve and via the throttle arrangement given to the low pressure area of the system. So is conditional filling of the pump room with the pumped Medium during the suction stroke of the pump piston and a Backflow of the medium possible during the delivery stroke. In the high pressure area of the system becomes a low pressure built up.

Ein weiteres Ansteuern der Ventilbetätigungseinheit während des Förderhubes des Pumpenkolbens schließt das Steuerventil vollständig, wodurch der Bypass von der Pumpeneinheit zu dem Niederdruckbereich des Systems unterbrochen wird. Dies führt zum Aufbau eines hohen Drucks in dem Hochdruckbereich des Systems.Another actuation of the valve actuation unit during of the delivery stroke of the pump piston closes the control valve completely, causing the bypass from the pump unit to the low pressure area of the system is interrupted. This leads to the build-up of high pressure in the high pressure area of the system.

Die Durchflussmenge des durch das Steuerventil fließenden Mediums fällt während des Schließvorgangs nicht steil von einem Maximalwert bei vollständig geöffnetem Steuerventil auf den Wert Null bei vollständig geschlossenem Steuerventil ab. Vielmehr fließt bei Erreichen eines kleinen Hubs so lange eine nahezu konstante geringe Menge des.geförderten Mediums durch das Steuerventil, bis das Steuerventil vollständig geschlossen ist. Der Verlauf der Durchflusskurve des Steuerventils bei kleinen Hüben ist in vorteilhafter Weise sehr flach. Dadurch wird erreicht, dass Schwankungen des Ventilhubs kaum Schwankungen der Durchflussmenge hervorrufen. Die Durchflussmenge ist bei kleinen Hüben nahezu unabhängig von dem Ventilhub.The flow rate of the flow through the control valve Medium does not fall off steeply during the closing process a maximum value when the control valve is fully open to zero when fully closed Control valve. Rather, when one reaches small hubs so long an almost constant small amount of the pumped medium through the control valve until the Control valve is completely closed. The course of the Flow curve of the control valve for small strokes is in advantageously very flat. This ensures that Fluctuations in valve lift hardly fluctuations in Cause flow rate. The flow rate is at small strokes almost independent of the valve stroke.

Die Drosselanordnung ist in den Ventilkörper integriert. Das hat den Vorteil, dass sie nicht gesondert angesteuert werden muss, sondern zusammen mit dem Ventilkörper aus einer inaktiven Stellung bei vollständig geöffnetem Steuerventil in eine aktive Stellung bei um einen kleinen Hub geöffnetem Steuerventil gebracht werden kann. The throttle arrangement is integrated in the valve body. This has the advantage that it is not controlled separately must, but together with the valve body an inactive position when fully open Control valve in an active position at around a small Stroke open control valve can be brought.

Gemäß einer vorteilhaften Weiterbildung der Erfindung ist an dem Ventilkörper in Strömungsrichtung außenliegend ein weiterer Ventilkörper angeordnet, der bei kleinen Hüben des Steuerventils in einer Schließstellung ist und der mindestens eine Drosselbohrung aufweist, die bei geöffnetem Steuerventil mit einem Zulauf und einem Ablauf des Steuerventils in Verbindung steht.According to an advantageous development of the invention on the valve body in the flow direction on the outside further valve body arranged, the small strokes of the Control valve is in a closed position and the has at least one throttle bore, which when open Control valve with an inlet and an outlet of the Control valve is connected.

Vorzugsweise ist der weitere Ventilkörper in dem Ventilkörper axial verschiebbar gelagert. Der weitere Ventilkörper sitzt bei geschlossenem Steuerventil und bei einem kleinen Hub des Steuerventils in Strömungsrichtung von innen auf einem weiteren Ventilsitz des Steuerventils. Bei vollständig geöffnetem Steuerventil, d. h. bei einem großen Hub, ist der Ventilkörper des Steuerventils von dem Ventilsitz und der weitere Ventilkörper der Drosselanordnung von dem weiteren Ventilsitz abgehoben. Das geförderte Medium kann durch den Ventilsitz und den weiteren Ventilsitz frei von der Pumpeneinheit zu dem Niederdruckbereich des Systems fließen. Bei teilweise geöffnetem Steuerventil, d. h. bei einem kleinen Hub, ist der Ventilkörper des Steuerventils nach wie vor von dem Ventilsitz abgehoben, der weitere Ventilkörper der Drosselanordnung sitzt allerdings auf dem weiteren Ventilsitz. Das geförderte Medium kann nur noch gedrosselt durch den Ventilsitz und die Drosselbohrung des weiteren Ventilkörpers fließen. Dabei wird in dem System ein geringer Druck aufgebaut. Bei vollständig geschlossenem Steuerventil sitzt der Ventilkörper des Steuerventils auf dem Ventilsitz und das geförderte Medium wird an dem Ventilsitz zurückgehalten. Nun wird in dem System ein höherer Druck aufgebaut.The further valve body is preferably in the Valve body is axially displaceable. The other The valve body sits with the control valve closed and at a small stroke of the control valve in the direction of flow from the inside on another valve seat of the control valve. With the control valve fully open, i. H. at a large stroke, is the valve body of the control valve from which Valve seat and the further valve body of the Throttle assembly lifted from the further valve seat. The conveyed medium can through the valve seat and additional valve seat free from the pump unit to the Low pressure area of the system flow. With partial open control valve, d. H. with a small stroke, is the valve body of the control valve still from that Lifted valve seat, the further valve body of the Throttle arrangement, however, sits on the other Valve seat. The pumped medium can only be throttled through the valve seat and the throttle bore further Valve body flow. Doing so will result in the system low pressure built up. When completely closed Control valve sits on the valve body of the control valve the valve seat and the pumped medium is on the Valve seat retained. Now one in the system higher pressure built up.

Vorteilhafterweise wird der weitere Ventilkörper durch ein zwischen dem Ventilkörper und dem weiteren Ventilkörper wirkendes Federelement bei geschlossenem Steuerventil oder bei einem kleinen Hub des Steuerventils auf den weiteren Ventilsitz gedrückt.The further valve body is advantageously replaced by a between the valve body and the further valve body acting spring element with closed control valve or with a small stroke of the control valve on the other Valve seat pressed.

Vorzugsweise weist der weitere Ventilkörper einen Anschlag auf, der bei einem großen Hub des Steuerventils auf dem Ventilkörper aufliegt. Bei geschlossenem Steuerventil entspricht der Abstand zwischen dem Anschlag und dem Ventilkörper der Größe des kleinen Ventilhubs, während dem die Drosselanordnung aktiv ist.The further valve body preferably has a stop on the with a large stroke of the control valve on the Valve body rests. With the control valve closed corresponds to the distance between the stop and the Valve body the size of the small valve lift during which the throttle arrangement is active.

Alternativ schlägt die Erfindung vor, daß der weitere Ventilkörper in Strömungsrichtung außen an dem Ventilkörper ausgebildet ist und daß der weitere Ventilkörper bei geschlossenem Steuerventil und bei einem kleinen Hub des Steuerventils in einer Aufnahmebohrung abgedichtet aufgenommen ist, aus der der Ablauf aus dem Steuerventil herausführt. Der weitere Ventilkörper und die Aufnahmebohrung bilden den weiteren Ventilsitz, der während der kleinen Hübe des Steuerventils geschlossen ist. Bei vollständig geöffnetem Steuerventil, d. h. bei einem großen Hub, ist der Ventilkörper des Steuerventils von dem Ventilsitz abgehoben und der weitere Ventilkörper der Drosselanordnung befindet sich außerhalb der Aufnahmebohrung. Das geförderte Medium kann durch den Ventilsitz und den weiteren Ventilsitz frei von der Pumpeneinheit zu dem Niederdruckbereich des Systems fließen. Bei teilweise geöffnetem Steuerventil, d. h. bei einem kleinen Hub, ist der Ventilkörper des Steuerventils nach wie vor von dem Ventilsitz abgehoben, der weitere Ventilkörper der Drosselanordnung ist allerdings von der Aufnahmebohrung abgedichtet aufgenommen. Das geförderte Medium kann nur noch gedrosselt durch den Ventilsitz und die Drosselbohrung des weiteren Ventilkörpers fließen. Dadurch wird in dem System ein geringer Druck aufgebaut. Bei vollständig geschlossenem Steuerventil sitzt der Ventilkörper des Steuerventils auf dem Ventilsitz und das geförderte Medium wird an dem Ventilsitz zurückgehalten. In dem System wird nun ein höherer Druck aufgebaut.Alternatively, the invention proposes that the further Valve body in the flow direction on the outside of the valve body is formed and that the further valve body at closed control valve and with a small stroke of the Control valve sealed in a mounting hole is included from which the drain from the control valve out leads. The further valve body and the Location bore form the further valve seat, which during the small strokes of the control valve are closed. at fully open control valve, d. H. with a big one Stroke, is the valve body of the control valve from which Lifted valve seat and the further valve body of the Throttle assembly is outside of the Bore. The funded medium can through the Valve seat and the other valve seat free from the Pump unit to the low pressure area of the system flow. With the control valve partially open, i.e. H. at a small stroke, is the valve body of the control valve still lifted from the valve seat, the other Valve body of the throttle arrangement is, however, of the Location bore sealed sealed. The funded Medium can only be throttled through the valve seat and the throttle bore of the further valve body flow. This creates a low pressure in the system. When the control valve is completely closed, the Valve body of the control valve on the valve seat and that conveyed medium is retained on the valve seat. In a higher pressure is now built up in the system.

Die vorliegende Erfindung betrifft außerdem ein Einspritzsystem zur Kraftstoffzufuhr in einen Verbrennungsraum von direkteinspritzenden Verbrennungskraftmaschinen mit einer Pumpeneinheit zum Aufbau eines Einspritzdrucks und dann zum Einspritzen des Kraftstoffs über eine Einspritzdüse in den Verbrennungsraum, wobei das Einspritzsystem Mittel aufweist, um vor der eigentlichen Haupteinspritzung eine geringe Menge Kraftstoff in den Verbrennungsraum voreinzuspritzen.The present invention also relates to a Injection system for supplying fuel to one Combustion chamber of direct injection Internal combustion engines with a pump unit for Build up an injection pressure and then to inject the Fuel through an injector in the Combustion chamber, the injection system means has to before the actual main injection small amount of fuel in the combustion chamber voreinzuspritzen.

Um ein solches Einspritzsystem dahingehend weiterzubilden, daß die Kraftstoffmenge der Voreinspritzung besonders genau und zuverlässig gesteuert werden kann, schlägt die Erfindung vor, daß das Einspritzsystem eine Steuereinheit der oben genannten Art aufweist.In order to further develop such an injection system, that the fuel quantity of the pre-injection is particularly accurate and can be controlled reliably, suggests Invention before that the injection system is a control unit of the type mentioned above.

Schließlich betrifft die vorliegende Erfindung auch ein Verfahren zur Steuerung des Druckaufbaus durch eine Pumpeneinheit in einem System mittels einer Steuereinheit, die ein Steuerventil und eine mit diesem verbundene Ventilbetätigungseinheit aufweist, wobei das Steuerventil als ein in Strömungsrichtung nach innen öffnendes I-Ventil ausgebildet ist, das einen in einem Gehäuse der Steuereinheit axial verschiebbar gelagerten Ventilkörper aufweist, der bei geschlossenem Steuerventil von innen auf einem Ventilsitz des Steuerventils sitzt, und wobei zum Aufbau eines Drucks in dem System der Ventilkörper des Steuerventils aus einer um einen großen Hub geöffneten Stellung über eine um einen kleinen Hub geöffnete Stellung in eine geschlossene Stellung gebracht wird.Finally, the present invention also relates to a Method for controlling the pressure build-up by a Pump unit in a system by means of a control unit, which is a control valve and one connected to it Has valve actuation unit, wherein the control valve as an I-valve opening inwards in the direction of flow is formed, the one in a housing Control unit axially displaceably mounted valve body has from the inside when the control valve is closed a valve seat of the control valve sits, and wherein to Building up a pressure in the system of the valve body Control valve from an open by a large stroke Position over a position opened by a small stroke is brought into a closed position.

Damit die Durchflußkurve bei kleinen Hüben des Steuerventils einen möglichst flachen Verlauf aufweist, schlägt die Erfindung vor, dass der Durchfluss durch das Steuerventil von dem Zeitpunkt an, zu dem der Ventilkörper um einen kleinen Hub geöffnet ist, bis zu dem Zeitpunkt, zu dem der Ventilkörper geschlossen ist, durch eine in den Ventilkörper integrierte Drosselanordnung gedrosselt wird.So that the flow curve for small strokes of the Control valve is as flat as possible, the invention proposes that the flow through the Control valve from the time the valve body is open to a small stroke, up to the point of time which the valve body is closed by a in the Valve body integrated throttle assembly is throttled.

Vorteilhafterweise wird das Verfahren zur Steuerung der Kraftstoffzufuhr in einen Verbrennungsraum einer direkteinspritzenden Verbrennungskraftmaschine mit einer Pumpeneinheit zum Aufbau eines Einspritzdrucks und danach zum Einspritzen des Kraftstoffs über eine Einspritzdüse in den Verbrennungsraum eingesetzt. Insbesondere bei einem solchen Einsatz des erfindungsgemäßen Verfahrens kommen die Vorteile der Erfindung zum Tragen. So ist es mit dem erfindungsgemäßen Verfahren bspw. möglich, die Kraftstoffmenge einer Voreinspritzung besonders genau und zuverlässig zu steuern, da die Durchflussmenge durch das Steuerventil aufgrund des flachen Verlaufs der Durchflusskurve nahezu unabhängig ist von dem Ventilhub des Steuerventils. Bei schwankenden kleinen Hüben ist die Durchflussmenge somit nur einer geringen Schwankung unterworfen.The method for controlling the Fuel supply into a combustion chamber direct-injection internal combustion engine with a Pump unit for building up an injection pressure and after for injecting fuel through an injector used the combustion chamber. Especially with one such use of the method according to the invention Advantages of the invention to bear. So it is with that inventive method possible Fuel quantity of a pre-injection is particularly accurate and to control reliably because the flow rate through the Control valve due to the flat course of the Flow curve is almost independent of the valve lift of the Control valve. With fluctuating small strokes it is Flow rate therefore only a small fluctuation subjected.

Zwei bevorzugte Ausführungsbeispiele der Erfindung werden im Folgenden anhand der Zeichnungen näher erläutert. Es zeigen:

- Fig. 1

- ein Steuerventil einer erfindungsgemäßen Steuereinheit einer ersten Ausführungsform im Schnitt;

- Fig. 2

- ein Steuerventil einer erfindungsgemäßen Steuereinheit gemäß einer zweiten Ausführungsform und

- Fig. 3

- den Verlauf der Durchflusskurve durch ein Steuerventil einer erfindungsgemäßen Steuereinheit.

- Fig. 1

- a control valve of a control unit according to the invention of a first embodiment in section;

- Fig. 2

- a control valve of a control unit according to the invention according to a second embodiment and

- Fig. 3

- the course of the flow curve through a control valve of a control unit according to the invention.

In Figur 1 ist ein Steuerventil 1 einer erfindungsgemäßen

Steuereinheit gemäß einer ersten Ausführungsform

dargestellt. Die Steuereinheit dient zur Steuerung des

Druckaufbaus durch eine Pumpeneinheit in einem beliebigen

System. Sie weist das Steuerventil 1 und eine mit diesem

verbundene Ventilbetätigungseinheit (nicht dargestellt)

auf. Das Steuerventil 1 ist als ein in Strömungsrichtung 14

nach innen öffnendes I-Ventil ausgebildet. Es weist einen

in einem Gehäuse 2 der Steuereinheit axial verschiebbar

gelagerten Ventilkörper 3 auf, der bei geschlossenem

Steuerventil 1 von innen auf einem Ventilsitz 4 des

Steuerventils 1 sitzt. Das Steuerventil 1 weist eine

Drosselanordnung 5 auf, durch die der Durchfluß durch das

Steuerventil 1 bei um einen kleinen Hub geöffnetem

Steuerventil 1 gedrosselt wird.In Figure 1 is a control valve 1 of an inventive

Control unit according to a first embodiment

shown. The control unit is used to control the

Pressure build-up by a pump unit in any

System. It has the control valve 1 and one with it

connected valve actuation unit (not shown)

on. The control valve 1 is in the direction of

Dis Drosselanordnung 5 ist als ein in den Ventilkörper 3

integrierten weiterer Ventilkörper 6 ausgebildet. Der

weitere Ventilkörper 6 ist in Strömungsrichtung

außenliegend an dem Ventilkörper 3 angeordnet. Der weitere

Ventilkörper 6 ist bei einem kleinen Hub des Steuerventils

1 in einer Schließstellung und weist zwei Drosselbohrungen

7 auf, die bei geöffnetem Steuerventil 1 mit einem Zulauf 8

und einem Ablauf 9 des Steuerventils 1 in Verbindung

stehen. Der weitere Ventilkörper 6 ist in dem Ventilkörper

3 axial verschiebbar gelagert. Der weitere Ventilkörper 6

sitzt bei geschlossenem Steuerventil 1 und bei einem

kleinen Hub des Steuerventils 1 von innen auf einem

weiteren Ventilsitz 10 des Steuerventils 1.The

Bei um einen großen Hub geöffnetem Steuerventil 1 ist

sowohl der Ventilsitz 4 als auch der weitere Ventilsitz 10

geöffnet. Es ist ein freier Durchfluß von der Pumpeneinheit

zu einem Niederdruckbereich des Systems gegeben, und somit

ist ein Befüllen des Pumpenraums mit dem geförderten Medium

während des Saughubs des Pumpenkolbens und ein Rückströmen

des Mediums während des Förderhubs möglich. In dem System

wird kein Druck aufgebaut.With control valve 1 open by a large stroke

both the valve seat 4 and the

Bei um einen kleinen Hub geöffnetem Steuerventil 1 ist der

Ventilsitz 4 zwar nach wie vor geöffnet, der weitere

Ventilsitz 10 ist jedoch geschlossen, so dass das

geförderte Medium über die Drosselbohrungen 7 durch das

Steuerventil 1 fließen muß. Aufgrund dieses gedrosselten

Durchflusses durch das Steuerventil 1 wird in dem

Hochdruckbereich des Systems ein niedriger Druck aufgebaut.When the control valve 1 is open by a small stroke, the

Valve seat 4 is still open, the other one

Bei vollständig geschlossenem Steuerventil 1 ist sowohl der

Ventilsitz 4 als auch der weitere Ventilsitz 10

geschlossen, wodurch der Bypass unterbrochen wird. Dies

führt zum Aufbau eines hohen Drucks von der Pumpeneinheit

zu dem Niederdruckbereich des Systems in dem

Hochdruckbereich des Systems.When the control valve 1 is completely closed, both the

Valve seat 4 as well as the

Der weitere Ventilkörper 10 wird durch ein zwischen dem

Ventilkörper 3 und dem weiteren Ventilkörper 6 wirkendes

Federelement 11 bei geschlossenem Steuerventil 1 oder bei

einem kleinen Hub des Steuerventils 1 auf den weiteren

Ventilsitz 10 gedrückt. Der weitere Ventilkörper 6 weist

einen Anschlag 12 auf, der bei einem großen Hub des

Steuerventils 1 auf dem Ventilkörper 3 aufliegt. Der

weitere Ventilsitz 10 ist besonders flach ausgebildet,

damit bei großen Hüben des Steuerventils 1 nach dem Öffnen

des weiteren Ventilsitzes 10 möglichst rasch der hohe

Durchflußwert Q (vgl. Fig. 3) erreicht wird.The

In Figur 2 ist ein Steuerventil 1 einer erfindungsgemäßen

Steuereinheit gemäß einer zweiten Ausführungsform

dargestellt. Bei dieser Ausführungsform ist der weitere

Ventilkörper 6 in Strömungsrichtung außen an dem

Ventilkörper 3 ausgebildet. Der weitere Ventilkörper 6 wird

bei geschlossenem Steuerventil 1 und bei einem kleinen Hub

des Steuerventils 1 in einer Aufnahmebohrung 13 abgedichtet

aufgenommen. Aus der Aufnahmebohrung 13 führt der Ablauf 9

aus dem Steuerventil 1 heraus. Der weitere Ventilkörper 6

bildet zusammen mit dem Rand der Aufnahmebohrung 13 den

weiteren Ventilsitz 10.In Figure 2 is a control valve 1 of the invention

Control unit according to a second embodiment

shown. In this embodiment, the other one

In den Figuren 1 und 2 sind die kleinen Hübe mit hklein bezeichnet. In Figur 3 ist der Verlauf der Durchflußkurve Q=f(h) in Abhängigkeit von dem Hub h des Steuerventils 1 aufgetragen. Die Durchflußkurve des Steuerventils 1 der erfindungsgemäßen Steuereinheit ist durchgezogen dargestellt, wohingegen der Verlauf der Durchflußkurve Q durch das Steuerventil einer Steuereinheit nach dem Stand der Technik gestrichelt dargestellt ist. In Figur 3 ist deutlich zu erkennen, dass die Durchflußmenge Q durch das Steuerventil 1 bei der erfindungsgemäßen Steuereinheit bei kleinen Hüben hklein einen sehr flachen, nahezu konstanten Verlauf hat. Das hat den Vorteil, dass bei der erfindungsgemäßen Steuereinheit die Durchflußmenge Q durch das Steuerventil 1 bei kleinen Hüben hklein nicht in dem Maße von dem Hub h des Steuerventils 1 abhängt, wie das bei der Steuereinheit aus dem Stand der Technik der Fall ist. Bei größeren Hüben zwischen hklein und hmax steigt die Durchlußmenge rasch auf einen Wert an, der auch von den aus dem Stand der Technik bekannten Steuereinheiten erreicht wird. Der sehr steile Anstieg zwischen hklein und hmax ergibt sich aufgrund des flachen Verlaufs des weiteren Ventilsitzes 10 (vgl. Fig. 1).In Figures 1 and 2, the small strokes are denoted by h small . 3 shows the course of the flow curve Q = f (h) as a function of the stroke h of the control valve 1. The flow curve of the control valve 1 of the control unit according to the invention is shown as a solid line, whereas the flow curve Q through the control valve of a control unit according to the prior art is shown in broken lines. It can be clearly seen in FIG. 3 that the flow rate Q through the control valve 1 in the control unit according to the invention has a very flat, almost constant course for small strokes h small . This has the advantage that in the control unit according to the invention the flow rate Q through the control valve 1 with small strokes h small does not depend to the extent of the stroke h of the control valve 1 as is the case with the control unit from the prior art. With larger strokes between h small and h max , the flow rate increases rapidly to a value which is also achieved by the control units known from the prior art. The very steep increase between h small and h max results from the flat course of the further valve seat 10 (cf. FIG. 1).

Claims (9)

- Control unit for controlling the build-up of pressure by a pump unit in a system, the control unit having a control valve (1) and a valve actuation unit which is connected thereto, and the control valve (1) being embodied as an I valve which opens inwards in the direction of flow and which has a valve body (3) which is mounted in an axially displaceable fashion in a housing (2) of the control unit and which, when the control valve (1) is closed, is seated from the inside on a valve seat (4) of the control valve (1), and the control unit having a throttle arrangement (7) by means of which the flow through the control valve (1) is throttled when the control valve (1) is opened by the amount equal to a small stroke (hsmall), characterized in that the throttle arrangement (5) is integrated into the valve body (3).

- Control unit according to Claim 1, characterized in that a further valve body (6) which is in a closed position when there is a small stroke (hsmall) of the control valve (1) and which has at least one throttle hole (7) which is connected, when the control valve (1) is opened, to an inflow (8) and to an outflow (9) of the control valve (1) is arranged on the outside of the valve body (3) in the direction of flow.

- Control unit according to Claim 2, characterized in that the further valve body (6) is mounted in an axially displaceable fashion in the valve body (3), and in that the further valve body (6) is seated, when the control valve (1) is closed and when there is a small stroke (hsmall) of the control valve (1), from the inside on a further valve seat (10) of the control valve (1) in the direction of flow.

- Control unit according to Claim 3, characterized in that the further valve body (6) is pressed onto the further valve seat (10) by a spring body (11) which acts between the valve body (3) and the further valve body (6), when the control valve (1) is closed or when there is a small stroke (hsmall) of the control valve (1).

- Control unit according to Claim 4, characterized in that the further valve body (6) has a stop (12) which rests on the valve body (3) when there is a large stroke (h > hsmall) of the control valve (1).

- Control unit according to Claim 2, characterized in that the further valve body (6) is formed on the outside of the valve body (3) in the direction of flow, and in that, when the control valve (1) is closed and when there is a small stroke (hsmall) of the control valve (1) the further valve body (6) is held in a sealed fashion in a receptacle hole (13) from which the outflow (9) leads out of the control valve (1).

- Injection system for feeding fuel into a combustion chamber of direct-injection internal combustion engines with a pump unit for building up an injection pressure and then for injecting the fuel into the combustion chamber via an injection nozzle, the injection system having means for pre-injecting a small quantity of fuel into the combustion chamber before the actual main injection, characterized in that the injection system has a control unit according to one of Claims 1 to 6.

- Method for controlling the build-of pressure by a pump unit in a system by means of a control unit which has a control valve (1) and a valve actuation unit which is connected thereto, the control valve (1) being embodied as an I valve which opens inwards in the direction of flow and which has a valve body (3) which is mounted in an axially displaceable fashion in a housing (2) of the control unit and which, when the control valve (1) is closed, is seated from the inside on a valve seat (4) of the control valve (1), and the valve body (3) of the control valve (1) being moved, for the purpose of building up pressure, from a position which is opened by an amount equal to a large stroke, through a position in which it is opened by an amount equal to a small stroke, into a closed position, characterized in that the flow through the control valve (1) is throttled, by a throttle arrangement (7) integrated into the valve body (3), from the time at which the valve body (3) is opened by an amount equal to a small stroke (hsmall), to the time at which the valve body (3) is closed.

- Method according to Claim 8, characterized in that the method for controlling the supply of fuel is used in a combustion chamber of direct-injection internal combustion engines with a pump unit for building up an injection pressure and then injecting the fuel into the combustion chamber via an injection nozzle.

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19837332A DE19837332A1 (en) | 1998-08-18 | 1998-08-18 | Control unit for controlling the build up of pressure in a pump unit such as an internal combustion engine fuel pump |

| DE19837332 | 1998-08-18 | ||

| PCT/DE1999/002544 WO2000011339A1 (en) | 1998-08-18 | 1999-08-17 | Control unit for controlling the build-up of pressure in a pump unit |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1045975A1 EP1045975A1 (en) | 2000-10-25 |

| EP1045975B1 true EP1045975B1 (en) | 2004-05-19 |

Family

ID=7877840

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP99952396A Expired - Lifetime EP1045975B1 (en) | 1998-08-18 | 1999-08-17 | Control unit for controlling the build-up of pressure in a pump unit |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US6425539B1 (en) |

| EP (1) | EP1045975B1 (en) |

| JP (1) | JP2002523670A (en) |

| KR (1) | KR20010031172A (en) |

| DE (2) | DE19837332A1 (en) |

| WO (1) | WO2000011339A1 (en) |

Families Citing this family (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE19963370C2 (en) * | 1999-12-28 | 2002-12-19 | Bosch Gmbh Robert | Pump injector unit with pre-injection |

| DE10023960A1 (en) * | 2000-05-16 | 2001-11-22 | Bosch Gmbh Robert | Fuel injection device for internal combustion engine has choke gap formed between choke section upstream of valve seat in bore and casing surface |

| ES2280318T3 (en) * | 2000-07-18 | 2007-09-16 | Delphi Technologies, Inc. | FUEL INJECTOR. |

| JP2002098021A (en) * | 2000-09-25 | 2002-04-05 | Toyota Motor Corp | Compound solenoid valve, high-pressure pump, and high- pressure pump controller |

| DE10059399B4 (en) * | 2000-11-30 | 2005-05-12 | Robert Bosch Gmbh | Device for improving the injection sequence in fuel injection systems |

| US6390069B1 (en) * | 2001-01-26 | 2002-05-21 | Detroit Diesel Corporation | Fuel injector assembly and internal combustion engine including same |

| EP1236885B1 (en) * | 2001-02-28 | 2005-03-30 | Robert Bosch Gmbh | Fuel injection device for an internal combustion engine |

| US7210640B2 (en) * | 2001-11-30 | 2007-05-01 | Caterpillar Inc | Fuel injector spray alteration through a moveable tip sleeve |

| DE10209527A1 (en) | 2002-03-04 | 2003-09-25 | Bosch Gmbh Robert | Device for pressure-modulated shaping of the injection process |

| DE10210282A1 (en) | 2002-03-08 | 2003-09-25 | Bosch Gmbh Robert | Device for injecting fuel into stationary internal combustion engines |

| DE102004022268A1 (en) * | 2004-05-06 | 2005-12-01 | Robert Bosch Gmbh | A driving method for influencing the opening speed of a control valve on a fuel injector |

Family Cites Families (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1663472A (en) * | 1924-01-22 | 1928-03-20 | Busch Sulzer Bros Diesel Engine Co | Fuel-injection device for internal-combustion engines |

| DE2749378A1 (en) * | 1977-11-04 | 1979-05-10 | Bosch Gmbh Robert | FUEL INJECTOR |

| JPS5882068A (en) * | 1981-11-09 | 1983-05-17 | Nissan Motor Co Ltd | Fuel injection nozzle |

| JP2615174B2 (en) * | 1988-12-28 | 1997-05-28 | 株式会社ゼクセル | Booster type fuel injection device |

| FR2672366B1 (en) * | 1991-01-31 | 1993-08-27 | Bendix Europ Services Tech | BLEEDING SCREW FOR HYDRAULIC CIRCUIT. |

| DE4142940C2 (en) * | 1991-12-24 | 1994-01-27 | Bosch Gmbh Robert | Electrically controlled pump nozzle |

| DE4238727C2 (en) * | 1992-11-17 | 2001-09-20 | Bosch Gmbh Robert | magnetic valve |

| US5301714A (en) * | 1993-03-01 | 1994-04-12 | Johnson Keith E | Multi-position valve apparatus having a return port |

| SE507374C3 (en) * | 1996-09-10 | 1998-06-29 | Volvo Lastvagnar Ab | Seat and device for controlling the injection pressure of liquid fuel |

-

1998

- 1998-08-18 DE DE19837332A patent/DE19837332A1/en not_active Ceased

-

1999

- 1999-08-17 JP JP2000566566A patent/JP2002523670A/en active Pending

- 1999-08-17 KR KR1020007004094A patent/KR20010031172A/en not_active Application Discontinuation

- 1999-08-17 EP EP99952396A patent/EP1045975B1/en not_active Expired - Lifetime

- 1999-08-17 WO PCT/DE1999/002544 patent/WO2000011339A1/en not_active Application Discontinuation

- 1999-08-17 DE DE59909524T patent/DE59909524D1/en not_active Expired - Fee Related

- 1999-08-17 US US09/529,656 patent/US6425539B1/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| JP2002523670A (en) | 2002-07-30 |

| EP1045975A1 (en) | 2000-10-25 |

| DE19837332A1 (en) | 2000-02-24 |

| WO2000011339A1 (en) | 2000-03-02 |

| KR20010031172A (en) | 2001-04-16 |

| DE59909524D1 (en) | 2004-06-24 |

| US6425539B1 (en) | 2002-07-30 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0657642B1 (en) | Fuel injection device for internal combustion engines | |

| DE19822503C1 (en) | Control valve for fuel injector | |

| DE4440182C2 (en) | Fuel injection valve for internal combustion engines | |

| DE4341545A1 (en) | Fuel injection device for internal combustion engines | |

| EP1045975B1 (en) | Control unit for controlling the build-up of pressure in a pump unit | |

| EP1252437A2 (en) | Injection device and method for injecting a fluid | |

| DE19910589A1 (en) | Injection valve for internal combustion engine | |

| EP0064146B1 (en) | Injection system for injecting two fuels through one injection nozzle | |

| WO2000019089A1 (en) | Fuel injection valve for internal combustion engines | |

| DE60128504T2 (en) | Fuel injection valve with a control rod, controlled by the fuel pressure in a control room | |

| DE102009000181A1 (en) | Fuel injector | |

| DE69824860T2 (en) | HYDRAULICALLY ACTUATED ELECTRONIC INJECTION SYSTEM | |

| DE69625992T2 (en) | Injector | |

| CH686845A5 (en) | Control arrangement for an injection valve for internal combustion engines. | |

| EP1144842B1 (en) | Injector for a fuel injection system for internal combustion engines comprising an injector needle that projects into the valve control space | |

| DE4106813A1 (en) | FUEL INJECTION PUMP FOR INTERNAL COMBUSTION ENGINES | |

| WO2001088367A1 (en) | Fuel injection system for an internal combustion engine | |

| EP1483499A1 (en) | Installation for the pressure-modulated formation of the injection behavior | |

| DE10155850A1 (en) | Dual flow rate fuel injector and motor using it | |

| DE19963370C2 (en) | Pump injector unit with pre-injection | |

| EP1377745B1 (en) | Method for operating a pump-nozzle unit and a corresponding pump-nozzle unit | |

| DE10160490B4 (en) | Fuel injection device, fuel system and internal combustion engine | |

| EP3775527B1 (en) | Injector for injecting fuel | |

| EP1176306A2 (en) | Fuel injection system for internal combustion engine | |

| WO2017050463A1 (en) | Electromagnetically actuable inlet valve and high-pressure pump having an inlet valve |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| 17P | Request for examination filed |

Effective date: 20000904 |

|

| 17Q | First examination report despatched |

Effective date: 20030530 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE FR GB IT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20040519 Ref country code: GB Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040519 Ref country code: FR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040519 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: GERMAN |

|

| REF | Corresponds to: |

Ref document number: 59909524 Country of ref document: DE Date of ref document: 20040624 Kind code of ref document: P |

|

| GBV | Gb: ep patent (uk) treated as always having been void in accordance with gb section 77(7)/1977 [no translation filed] |

Effective date: 20040519 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050301 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20050222 |

|

| EN | Fr: translation not filed |