EP0062418A2 - Schutzsystem für eine an einem Boot befestigbare Antriebseinheit - Google Patents

Schutzsystem für eine an einem Boot befestigbare Antriebseinheit Download PDFInfo

- Publication number

- EP0062418A2 EP0062418A2 EP82301268A EP82301268A EP0062418A2 EP 0062418 A2 EP0062418 A2 EP 0062418A2 EP 82301268 A EP82301268 A EP 82301268A EP 82301268 A EP82301268 A EP 82301268A EP 0062418 A2 EP0062418 A2 EP 0062418A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- propulsion unit

- release

- detent means

- cage

- detent

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B63—SHIPS OR OTHER WATERBORNE VESSELS; RELATED EQUIPMENT

- B63H—MARINE PROPULSION OR STEERING

- B63H20/00—Outboard propulsion units, e.g. outboard motors or Z-drives; Arrangements thereof on vessels

- B63H20/08—Means enabling movement of the position of the propulsion element, e.g. for trim, tilt or steering; Control of trim or tilt

- B63H20/10—Means enabling trim or tilt, or lifting of the propulsion element when an obstruction is hit; Control of trim or tilt

- B63H20/106—Means enabling lifting of the propulsion element in a substantially vertical, linearly sliding movement

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B63—SHIPS OR OTHER WATERBORNE VESSELS; RELATED EQUIPMENT

- B63H—MARINE PROPULSION OR STEERING

- B63H20/00—Outboard propulsion units, e.g. outboard motors or Z-drives; Arrangements thereof on vessels

- B63H20/36—Transporting or testing stands ; Use of outboard propulsion units as pumps; Protection of power legs, e.g. when not in use

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B63—SHIPS OR OTHER WATERBORNE VESSELS; RELATED EQUIPMENT

- B63H—MARINE PROPULSION OR STEERING

- B63H5/00—Arrangements on vessels of propulsion elements directly acting on water

- B63H5/07—Arrangements on vessels of propulsion elements directly acting on water of propellers

- B63H5/125—Arrangements on vessels of propulsion elements directly acting on water of propellers movably mounted with respect to hull, e.g. adjustable in direction, e.g. podded azimuthing thrusters

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B63—SHIPS OR OTHER WATERBORNE VESSELS; RELATED EQUIPMENT

- B63H—MARINE PROPULSION OR STEERING

- B63H5/00—Arrangements on vessels of propulsion elements directly acting on water

- B63H5/07—Arrangements on vessels of propulsion elements directly acting on water of propellers

- B63H5/16—Arrangements on vessels of propulsion elements directly acting on water of propellers characterised by being mounted in recesses; with stationary water-guiding elements; Means to prevent fouling of the propeller, e.g. guards, cages or screens

- B63H5/165—Propeller guards, line cutters or other means for protecting propellers or rudders

Definitions

- This invention relates to a protection system for a propulsion unit which is pendently attachable to a boat or a pontoon, an outboard motor for example.

- Protection systems which rely upon mounting the propulsion unit on a horizontal pivot and providing a shear pin to hold the unit in a vertical position. If the unit is struck from the front by an underwater obstruction the pin shears and the unit pivots upwards to clear the obstruction. This system suffers from the disadvantage that the shear pin has to be replaced before the unit can be deployed. Furthermore the system only protects against blows from the front, no protection being provided against blows in an upwards or sideways direction, such as may occur when a pontoon, for example, is swept sideways by a current or is loaded rapidly in shallow water and its draught changes in a few seconds crushing the propulsion unit against the bottom.

- the present invention seeks to provide a readily re-deployable system which will protect against blows received in forward, reverse, sideways and upwards directions.

- a propulsion unit protection system includes: a support frame from which a propulsion unit is slideably protrusible by an externally applied force; retraction means energisable by protrusion of the propulsion unit; detent means for maintaining the propulsion unit in a protruded state against the pressure exerted by the energised retraction means; a sensing cage disposed about the propulsion unit and resiliently attached thereto; and a release means coupled between the sensing cage and the detent means so as to release the detent means when the disposition of the sensing cage relative to the propulsion unit is disturbed.

- the release means may be mechanical, hydraulic or pneumatic.

- One convenient mechanical arrangement comprises a contractible release arm which may consist of two articulated rigid members or alternatively a single flexible member,coupled at one end to the sensing cage via a ball joint and at the other to the detent means via a deflection amplifying lever.

- An impact against the cage in any direction other than outwardly from the support frame will cause increased cranking or bending of the release arm and hence contraction of the overall length of the arm so as to deflect the amplifying lever thereby to release the detent means.

- An alternative pneumatic arrangement may comprise one or more pneumatic chambers compressible between the sensing cage and the propulsion unit, which chambers are pneumatically coupled with a cylinder and piston arrangement operative upon the detent means so as to release the detent means when any one of the chambers is compressed.

- the pneumatic chambers may be replaced by piston and cylinder assemblies hydraulically coupled with the release means.

- the retraction means may conveniently comprise one or more helical compression springs axially disposed in the direction of sliding and compressible between the propulsion unit and the support frame when the propulsion unit is protruded.

- pneumatic or hydraulic compression springs may be similarly employed or tension springs may be attached between the unit and the frame so as to be extended When the unit is protruded.

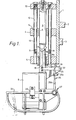

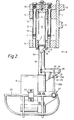

- Figures 1 and 2 are part-sectioned side elevations of a propulsion unit protection system having a mechanical detent release means, and drawn respectively with the propulsion unit retracted and protruded

- Figure 3 is an end elevation of the same system viewed in the direction A of Figure 2

- Figures 4. and 5 are part views of alternative pneumatic and hydraulic detent release means respectively.

- the system illustrated in Figs. 1 and 2 comprises a support frame 1 which is attachable to a vessel to be propelled via members 2 and 3 having any convenient attachment means (not shown).

- the frame has an upper platform 4 and a lower platform 5 respectively having coaxial bores 6 and 7 within which a cylindrical post 8 is slideable.

- the post 8 supports at its lower end a propulsion unit 9 and is suspended from a bearer plate 10, within which bearer plate it is captively rotatable about its own axis.

- the propulsion unit 9 can be manually protruded in a downwards direction from the frame 1 by pressing the bearer plate 10 towards the upper platform 4.

- a detent means is provided for holding the propulsion unit in the protruded position which comprises a spring biassed catch 1,5 rotatably attached to the post 8, within a bifurcated portion 8a thereof, at a transverse pivot 16. The catch deflects upwardly to pass through the bore 7 when the post 8 is depressed, thereafter to snap into engagement with a lock ring 17 mounted at the lower end of the bore 7.

- a pull rod 18 rotatably attached to the catch 15 is articulated to a deflection amplifying lever 19 which is rotatable about a pivot 20 laterally disposed between a pair of cheek plates 21 attached to the post 8.

- a jointed detent release arm 25 consisting of two pivotally interconnected members 25 a and 25 b, member 25 a being attached to the lever 19 at a pivot 26 and member 25 b being connected to the cage 22 via a ball joint 27 ( Figure 3). Any upwardly or laterally acting blow upon the cage will cause the jointed arm 25 to momentarily flex thus shortening its overall length and so rotating the lever 19 anti-clockwise (as drawn). This in turn pulls the pull rod 18 downwards to release the catch 15 from the lock ring 17 thereby releasing the energy stored in the springs 11 to rapidly raise the propulsion unit.

- the length and weight of the springs are selected to raise the propulsion unit in approximately 0.1 seconds, the estimated time for preventing damage to the unit when travelling at speeds of up to 7 knots.

- FIG. 4 An alternative pneumatic detent release means is illustrated in Figure 4 which comprises a plurality of compressible chambers 29 evenly disposed interjacent the propulsion unit 9 and a sensing oage 30 so as to be compressed between them when the cage is struck, at least one being compressed whatever the direction of the blow.

- the chambers are pneumatically coupled in series connection via a tube 31 to an inlet port 32 of a cylinder block 33 attached to the lower platform 5.

- the cylinder block 33 contains a piston 34 bearing a detent stub 35 which engages with a recess 36 in the post 8, the stub being biassed into engagement with the recess by a spring 37.

- any impact to the cage 30 causes at least one of the chambers 29 to be compressed, thus transmitting a pressure pulse via the tube 31 which overrides the pressure of the spring 37 to disengage the detent stub 35 from the recess 36.

- FIG. 5 An alternative, hydraulically operated detent release means is illustrated in Figure 5 in which the compressible chambers 29 of Figure 4 are replaced by piston and cylinder assemblies 40 hydraulically coupled via the tube 31 to the detent release means.

- a particular advantage of the invention is that the propulsion unit can be speedily reset to the protruded position once an obstruction has been cleared, by simple manual pressure upon the bearer plate, no replacement of components being necessary.

- the specific propulsion unit illustrated has a hydraulic drive (not shown) but the invention is of course equally applicable to conventional propulsion units having mechanical drive.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- Ocean & Marine Engineering (AREA)

- Transportation (AREA)

- Earth Drilling (AREA)

- Current-Collector Devices For Electrically Propelled Vehicles (AREA)

- Investigating Or Analyzing Materials By The Use Of Magnetic Means (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| GB8110674 | 1981-04-06 | ||

| GB8110674 | 1981-04-06 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0062418A2 true EP0062418A2 (de) | 1982-10-13 |

| EP0062418A3 EP0062418A3 (de) | 1983-04-06 |

Family

ID=10520952

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP82301268A Withdrawn EP0062418A3 (de) | 1981-04-06 | 1982-03-12 | Schutzsystem für eine an einem Boot befestigbare Antriebseinheit |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP0062418A3 (de) |

| GB (1) | GB2096082B (de) |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR16519E (fr) * | 1911-12-12 | 1913-02-21 | Jean De Bosredon | Canot automobile à très faible tirant d'eau et son dispositif d'armement pour la chasse |

| US2479119A (en) * | 1943-07-30 | 1949-08-16 | Harold I Johnson | Propeller drive unit with automatic depth regulation |

| US2706959A (en) * | 1953-10-20 | 1955-04-26 | Alva D Downs | Safety mount for an outboard motor |

| GB934877A (en) * | 1960-09-20 | 1963-08-21 | Instr Res Lab Ltd | Marine propulsion unit attachable to boats |

| GB1040621A (en) * | 1962-03-23 | 1966-09-01 | Reiners Walter | A marine outboard drive |

-

1982

- 1982-03-12 EP EP82301268A patent/EP0062418A3/de not_active Withdrawn

- 1982-04-02 GB GB8209868A patent/GB2096082B/en not_active Expired

Also Published As

| Publication number | Publication date |

|---|---|

| GB2096082B (en) | 1984-06-27 |

| GB2096082A (en) | 1982-10-13 |

| EP0062418A3 (de) | 1983-04-06 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US4895479A (en) | Lift for watercraft | |

| US3839986A (en) | Power trimming and tilting system | |

| US4119225A (en) | Mounting means for attaching an implement to a vehicle | |

| US4320589A (en) | Snowplow apparatus | |

| US4843744A (en) | Snowplow | |

| US4331431A (en) | Transom saver | |

| US4501561A (en) | Brace device for motor boat drive unit | |

| SE458534B (sv) | Anordning vid en snabbkoppling foer loesbar sammankoppling av ett arbetsredskap och en graevmaskins manoeverarm | |

| US4561505A (en) | Hinge mechanism for folding tool bar assembly including hook engageable over pivotal connection | |

| US4053174A (en) | Load transferring trailer hitch device | |

| US5720122A (en) | Plow blade with adjustable scraping bar | |

| US5111945A (en) | Boom extension alignment device | |

| US5855245A (en) | Disk opener carrier hitch | |

| US7066102B1 (en) | Moorage for affixing to a floating dock and allowing a user to single handedly soft land, dock and moor a boat thereto | |

| GB2040260A (en) | Boom apparatus | |

| EP0062418A2 (de) | Schutzsystem für eine an einem Boot befestigbare Antriebseinheit | |

| US5927226A (en) | Combined towing and docking hitch for watercraft | |

| US12459613B2 (en) | Retractable hull mounting data collecting system | |

| US4222442A (en) | Method and apparatus for power mounting an implement on a tractor | |

| JP2923174B2 (ja) | 船舶係留・離接岸支援装置。 | |

| GB1587979A (en) | Device for keeping constant the tensile stress in a cable | |

| US3145003A (en) | Outboard motor mounting | |

| US3977699A (en) | Shock-absorbing push-pull coupling for tandem scrapers | |

| US5353263A (en) | Soft sonar suspension system | |

| US4792006A (en) | Drive shaft coupling |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): BE CH DE FR IT NL SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Designated state(s): BE CH DE FR IT LI NL SE |

|

| 17P | Request for examination filed |

Effective date: 19830329 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION HAS BEEN WITHDRAWN |

|

| 18W | Application withdrawn |

Withdrawal date: 19850208 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: LU Payment date: 19890405 Year of fee payment: 8 |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: HANCE, JOHN EDWARD Inventor name: FITZGERALD-SMITH, JAMES PATRICK |