EP0061980B1 - Easily openable can with pull tab and score line - Google Patents

Easily openable can with pull tab and score line Download PDFInfo

- Publication number

- EP0061980B1 EP0061980B1 EP82420036A EP82420036A EP0061980B1 EP 0061980 B1 EP0061980 B1 EP 0061980B1 EP 82420036 A EP82420036 A EP 82420036A EP 82420036 A EP82420036 A EP 82420036A EP 0061980 B1 EP0061980 B1 EP 0061980B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- panel

- rib

- axis

- discontinuities

- tab

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D17/00—Rigid or semi-rigid containers specially constructed to be opened by cutting or piercing, or by tearing of frangible members or portions

- B65D17/28—Rigid or semi-rigid containers specially constructed to be opened by cutting or piercing, or by tearing of frangible members or portions at lines or points of weakness

- B65D17/401—Rigid or semi-rigid containers specially constructed to be opened by cutting or piercing, or by tearing of frangible members or portions at lines or points of weakness characterised by having the line of weakness provided in an end wall

- B65D17/4011—Rigid or semi-rigid containers specially constructed to be opened by cutting or piercing, or by tearing of frangible members or portions at lines or points of weakness characterised by having the line of weakness provided in an end wall for opening completely by means of a tearing tab

Definitions

- the front part of the panel the part which is located near the tongue and, by the rear part, the one which is the farthest from it and which detaches last. of the cover when opening.

- the axis of the panel will be designated its greatest axis of symmetry. It will also be considered that the line of incision and the peripheral rib consist of two branches originating on either side of the tongue and joining at the rear end of the panel.

- the nose of the tongue penetrates slightly inside the container.

- the wall folds under said tongue towards the inside of the box along a line perpendicular to the axis of the tongue and very close to the means of fixing the tongue to the wall.

- This first fold line is thus adjacent and substantially parallel to the line of incision at the level of the perforation.

- the consumer continuing his action generally pulls the tongue outwards obliquely towards the rear of the opening panel.

- the tearing continues on both sides along two branches substantially parallel to the axis of the panel.

- the tear must be gradual. Indeed, the block opening of the panel would require excessive effort on the part of the consumer, and also no less excessive tear resistance of the means for fixing the tongue to the panel. A carefully studied rigidification of the panel is required.

- the covers are often in the form of trays arranged in concentric stairs. They are often still stiffened by ribs or grooves.

- the panel which has bent regularly towards the rear tends to turn over at the rear of the box. It has become very flexible, like a spring.

- the consumer has difficulty exerting a backward force in a direction substantially tangential to the cover.

- the panel can deploy suddenly and, by spring effect, may come to close abruptly splashing the consumer. To avoid these inconveniences, it is advantageous to stiffen the rear of the panel.

- the consumer At the end of opening, the consumer must also be able to exert shearing by a back-and-forth movement, without producing a spring effect when the panel is completely detached from the box.

- the lids with easy opening must satisfy contradictory requirements: good resistance before opening and, however, a puncture then an easy tear according to a well defined course during opening.

- the opening panel for long-shaped covers must be able to be torn off completely without difficulty, even for covers of large dimensions, that is to say with a length of the order of 120 mm or more, greater length. hand-width.

- the cover object of the invention, has a shape reminiscent of that of the cover according to patent FR-A No 407604. It however responds in a particularly happy manner to the various and even contradictory constraints imposed on easy-opening covers.

- This cover preferably of long shape, with easy opening, with tearing tab and incision line defining an opening panel which has a stiffening rib (or groove) which borders the incision line at the inside the panel, this cover has the particularity that each of the branches of its rib has at least one slight very localized discontinuity of the shape of its cross section, this discontinuity consisting of a partial and local flattening, or rather a primer of transverse fold on its ridge line.

- the discontinuities of one and the other branch are asymmetrical with respect to the major axis of the panel. If the tab is not in the axis of the cover, the discontinuities will be arranged asymmetrically both with respect to the axis of the panel and with respect to the axis of the tab.

- the tearing of the wall then continues alternately along one branch of the incision line and then the other. This splits the effort required from the consumer, who is concentrated successively on one and then on the other branch.

- the rib folds successively according to the discontinuities located on one then on the other branch.

- the panel itself folds in a succession of zigzag lines which join the discontinuities arranged on both branches of the rib. It is gradually divided into planar elements of small area which gradually rise from the cover and somehow form leverage for the consumer.

- the panel is stiffened during opening by the zigzag folds and cannot be closed suddenly in the manner of a spring if, by mistake, the consumer releases the tab before tearing off said panel completely.

- the maximum distance between two discontinuities on the same rib will preferably be of the order of 40 mm.

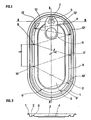

- Fig. 1 shows, seen in plan, from above, a cover according to the invention.

- Fig. 2 shows a cross section of the same cover.

- Fig. 3 shows, in plan view, a second variant of the cover according to the invention.

- Fig. 4 shows a cross section of the cover according to FIG. 3.

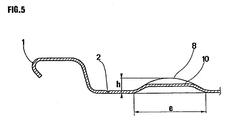

- Fig. 5 shows, in section, on a large scale, the discontinuities of the reinforcing rib.

- FIG. 1 In fig. 1, 2, 3 and 4 are shown two types of cover with easy opening, according to the invention. These covers are both bordered by a rim 1 intended to be folded and crimped on the edge of a box not shown here. Along this rim has been engraved an incision line 2 defining an opening panel 3. A tongue 4 is fixed to the panel by an integrated rivet (5); this tongue 4 comprises a gripping ring 6 at the rear and a perforation spout 7 the front end of which is disposed substantially in line with the incision line 2.

- the two covers shown have a rib 8 of relief reinforcement disposed at the edge of the panel 3 along the line of incision 2.

- this rib 8 is not continuous like that the FR-A patent? 407604, but has slight discontinuities 9, 10, 11, 12, 9 ', 10', 11 ', 12' distributed along the rib 8 on either side of the large axis of symmetry (XX ') of the cover .

- These discontinuities are, preferably, simple transverse gradations 9, 10, 11, 12, 9 ', 10', 11 ', 12' interrupting the crest line of the rib 8, as shown in fig. 1, 3 and 5.

- the cover of Figs. 1 and 2 is substantially symmetrical with a tongue 4 arranged in the longitudinal axis of the cover (XX ').

- the cover of fig. 3 and 4 is clearly asymmetrical with its tongue 4 oriented along the axis (ZZ ') oblique to the axis (XX') of the cover.

- the rear discontinuities 9, 9 ' are arranged symmetrically with respect to the axis (XX') of the cover. But, more generally, their location is determined experimentally according to the type of cover so that the continuous portion of rib 8 which connects them stiffens the panel transversely and longitudinally in this area. Thus, at the end of the opening, the user can easily complete the tearing off of the panel 3 by back and forth movement.

- the other discontinuities, at least partial, 10,10 ', 11,11', 12,12 'must be asymmetrical with respect to the axis (XX'), as shown here.

- the lines joining two homologous discontinuities 9-10 ', 10'-10, 10-11', 11'-11, 11-12 ', 12'-12 form with this axis an angle (a) between 60 and 80 ° .

- the rib 8 is interrupted under the tongue 4 fixed directly on the plane of the periphery of the panel 3.

- the opening of the boxes according to fig. 1 or 3 is carried out very easily: as in the prior art, after the initial perforation by the rigid nose 7, the tearing of the wall continues following the line of incision 2 according to two symmetrical branches on both sides other of the tongue 4.

- the panel 3 is stiffened transversely by its initial fold according to (AB), which contributes to preventing the bulging of the panel according to a longitudinal fold very harmful for the rest of the opening.

- the transverse rigidity of the panel at the start of opening is reinforced by the two branches of the rib 8 which extend substantially in line with the straight line (AB).

- the two branches of the rib 8 also help guide the initial tearing of the wall along the two branches of the incision line 2, on either side of the tongue 4.

- the asymmetry of the discontinuities 12 and 12 ′ with respect to the axis (XX ′) of the cover results in an asymmetry of the rigidity of the two branches of the rib 8 and, consequently, of the panel 3 itself, by report to said axis (XX ').

- the pulling force transmitted by the tongue 4 is concentrated on one then the other side of the cover until the discontinuities 12 and 12 '.

- the wall gives way on one side then on the other.

- the force transmitted by the rivet 5 then concentrates on the nearest non-torn part 11, 12 which in turn tears by creating a new transverse fold 11, 12 '.

- the tear continues alternately along one branch and then the other of the incision line 2, without the consumer having to exert significant effort.

- the tear line is well guided by both the incision line 2 and the rib 8 which borders it.

- the panel 3 is stiffened by the folds joining in a zigzag the discontinuities located alternately on the two branches of the rib 8 as well as by the rear transverse part of the rib 8 which extends without interruption between the discontinuities 9 , 9 '.

- the zigzag folds are shown in dotted lines in fig. 1.

- the maximum distance (L) between two successive discontinuities such as 10, 11 is of the order of 40 mm.

- L The maximum distance between two successive discontinuities such as 10, 11 is of the order of 40 mm.

- discontinuities shown in fig. 1,3 and 5 are simple, partial and localized flattenings of the rib 8, leaving it with a residual height of the order of ta% to% of its height (h). They are more simple transverse weakenings than real discontinuities. They are sufficient to locally reduce the moment of inertia of the rib and, consequently, that of the panel in a vertical plane.

- the width (e) and height (h) of the ribs 8, the size and spacing (L) of the discontinuities obviously vary with the dimensions of the covers, the thickness of the wall and the characteristics of the metal used. Tests are necessary to determine the best solution in each particular case according to the thickness and dimensions of the cover, as well as the quality of the material.

- the two lids shown here are lids for elongated boxes

- the rib stiffening device with ribs with discontinuities can also be successfully used on lids for large circular boxes.

- the axis of symmetry of the cover is then that passing through the center of the panel and the axis of the tongue fixing rivet.

- the surface of the panel When opened, the surface of the panel is divided into asymmetrical curvilinear asymmetrical triangles or quadrilaterals by the folds joining the discontinuities of the rib, on either side of the axis.

- a peripheral rib 8 comprising discontinuities can just as easily be used on panels 3 whose incision 2 is not completely closed but is interrupted over a certain length, for example at the rear of the panel. This provision encourages the consumer not to tear the cover panel completely and to leave it attached to the box by the connecting tab which remains at the site of the interruption of the incision.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Containers Opened By Tearing Frangible Portions (AREA)

- Food-Manufacturing Devices (AREA)

- Table Equipment (AREA)

- Cartons (AREA)

- Packages (AREA)

- Devices For Use In Laboratory Experiments (AREA)

- Closures For Containers (AREA)

Abstract

Description

Depuis longtemps, les fabricants de boîtes de conserve s'efforcent de réaliser des boîtes métalliques qui soient assez solides pour résister sans défaillance à la pression lors des opérations de stérilisation, aux chocs lors des manutentions et à l'écrasement lors du stockage, et qui soient, cependant, faciles à ouvrir par le consommateur.For a long time, manufacturers of cans have endeavored to produce metal cans which are strong enough to withstand pressure without failure during sterilization operations, impacts during handling and crushing during storage, and which are, however, easy for the consumer to open.

Comme le montrent, par exemple, les brevets FR-A Nos 407604, 2000528 et le brevet US-A No 2085200, il y a longtemps que l'on a eu l'idée, d'une part, de graver sur la paroi une ligne d'incision qui facilite, le moment venu, la déchirure de la paroi autour d'un panneau d'ouverture, d'autre part, de fixer à la paroi une languette d'arrachage et de préhension qui facilite d'abord la perforation initiale de la paroi, puis l'arrachage du panneau. Comme on le voit sur le brevet FR-A No 407604, il est connu de raidir la surface du panneau par une nervure en relief, ou une nervure en creux, qui borde le panneau le long de la ligne d'incision afin de procurer au panneau une bonne résistance mécanique dans toutes les phases de sa vie: production, sertissage, stérilisation, manutentions diverses avant l'utilisation finale. La nervure (ou rainure) est largement interrompue à l'emplacement de la languette.As shown, for example, in patents FR-A Nos 407604, 2000528 and in patent US-A No 2085200, it has been a long time since we had the idea, on the one hand, of engraving on the wall a incision line which facilitates, when the time comes, the tearing of the wall around an opening panel, on the other hand, to fix to the wall a tear-off and gripping tab which first facilitates the perforation initial of the wall, then the tearing of the panel. As can be seen in patent FR-A No 407604, it is known to stiffen the surface of the panel by a raised rib, or a hollow rib, which borders the panel along the line of incision in order to provide the panel good mechanical resistance in all phases of its life: production, crimping, sterilization, various handling before final use. The rib (or groove) is largely interrupted at the location of the tongue.

Pour la clarté de l'exposé, on désignera, ci-après, par partie avant du panneau, la partie qui se trouve à proximité de la languette et, par partie arrière, celle qui en est la plus éloignée et qui se détache en dernier du couvercle lors de l'ouverture. On désignera par axe du panneau son plus grand axe de symétrie. On considérera également que la ligne d'incision ainsi que la nervure périphérique sont constituées de deux branches prenant naissance de part et d'autre de la languette et se rejoignant à l'extrémité arrière du panneau.For the sake of clarity, we will denote, below, by the front part of the panel, the part which is located near the tongue and, by the rear part, the one which is the farthest from it and which detaches last. of the cover when opening. The axis of the panel will be designated its greatest axis of symmetry. It will also be considered that the line of incision and the peripheral rib consist of two branches originating on either side of the tongue and joining at the rear end of the panel.

Cependant, on sait que l'ouverture d'une boîte de conserve à l'aide d'une languette telle que celles représentées dans les brevets FR-A Nos 200528 ou FR-A 2074598 est une opération qui se fait en plusieurs étapes:

- 1. Le consommateur passe le doigt entre l'arrière de la languette et la paroi. La languette, fixée à la paroi par un moyen de fixation tel qu'un rivet, situé en son milieu, bascule vers l'avant. Elle appuie fortement par son nez avant rigide sur la paroi au niveau de la ligne d'incision. Le moyen de fixation doit résister et le nez rigide de la languette perforer la paroi à l'aplomb de l'incision.

- 1. The consumer passes his finger between the back of the tab and the wall. The tongue, fixed to the wall by a fixing means such as a rivet, located in the middle, swings forward. She presses strongly with her rigid front nose on the wall at the level of the incision line. The fixing means must resist and the rigid nose of the tongue perforate the wall directly above the incision.

Le nez de la languette pénètre légèrement à l'intérieur du récipient.The nose of the tongue penetrates slightly inside the container.

Sous la pression de la partie avant de la languette, la paroi se plie sous ladite languette vers l'intérieur de la boîte selon une ligne perpendiculaire à l'axe de la languette et très voisine du moyen de fixation de la languette à la paroi. Cette première ligne de pliure est ainsi voisine et sensiblement parallèle à la ligne d'incision au niveau de la perforation.Under the pressure of the front part of the tongue, the wall folds under said tongue towards the inside of the box along a line perpendicular to the axis of the tongue and very close to the means of fixing the tongue to the wall. This first fold line is thus adjacent and substantially parallel to the line of incision at the level of the perforation.

2. Le consommateur tire alors fortement sur la languette dans une direction perpendiculaire à la paroi. La perforation de la paroi doit se poursuivre en une déchirure qui s'écarte de part et d'autre en suivant la ligne d'incision dans des directions opposées sensiblement perpendiculaires à l'axe de la languette.2. The consumer then pulls strongly on the tab in a direction perpendicular to the wall. The perforation of the wall must continue in a tear which deviates on either side by following the line of incision in opposite directions substantially perpendicular to the axis of the tongue.

3. Le consommateur poursuivant son action tire en général la languette vers l'extérieur obliquement en direction de l'arrière du panneau d'ouverture. La déchirure se poursuit de part et d'autre selon deux branches sensiblement parallèles à l'axe du panneau.3. The consumer continuing his action generally pulls the tongue outwards obliquely towards the rear of the opening panel. The tearing continues on both sides along two branches substantially parallel to the axis of the panel.

La déchirure doit être progressive. En effet, l'ouverture en bloc du panneau exigerait un effort excessif du consommateur, et aussi une résistance à l'arrachement non moins excessive du moyen de fixation de la languette sur le panneau. Il faut une rigidification du panneau soigneusement étudiée. Les couvercles ont souvent la forme de plateaux disposés en escaliers concentriques. Ils sont souvent encore rigidifiés par des nervures ou rainures.The tear must be gradual. Indeed, the block opening of the panel would require excessive effort on the part of the consumer, and also no less excessive tear resistance of the means for fixing the tongue to the panel. A carefully studied rigidification of the panel is required. The covers are often in the form of trays arranged in concentric stairs. They are often still stiffened by ribs or grooves.

4. Enfin, le consommateur souhaite souvent arracher complètement le panneau d'ouverture. La déchirure se poursuit alors bien loin de la languette, en particulier pour les couvercles à ouverture totale deforme longue, c'est-à-dire ceux dont le rapport longueur sur largeur est de l'ordre de 2 ou supérieur.4. Finally, the consumer often wants to completely tear off the opening panel. The tearing then continues well away from the tongue, in particular for covers with total opening of long shape, that is to say those whose length to width ratio is of the order of 2 or greater.

Pour les couvercles longs à ouverture totale, le panneau qui s'est cintré de façon régulière vers l'arrière tend à se retourner à l'arrière de la boîte. Il est devenu très souple, tel un ressort. Le consommateur a des difficultés à exercer un effort vers l'arrière dans une direction sensiblement tangentielle au couvercle. De plus, si le consommateur lâche par maladresse la languette, le panneau peut se déployer brusquement et, par effet de ressort, risque de venir se refermer brutalement en éclaboussant le consommateur. Pour éviter ces désagréments, on a intérêt à raidir l'arrière du panneau.For long covers with full opening, the panel which has bent regularly towards the rear tends to turn over at the rear of the box. It has become very flexible, like a spring. The consumer has difficulty exerting a backward force in a direction substantially tangential to the cover. In addition, if the consumer awkwardly releases the tab, the panel can deploy suddenly and, by spring effect, may come to close abruptly splashing the consumer. To avoid these inconveniences, it is advantageous to stiffen the rear of the panel.

En fin d'ouverture, le consommateur doit pouvoir également exercer un cisaillement par un mouvement de va-et-vient, sans qu'il y ait production d'un effet de ressort au moment où le panneau se détache totalement de la boîte.At the end of opening, the consumer must also be able to exert shearing by a back-and-forth movement, without producing a spring effect when the panel is completely detached from the box.

Ainsi, les couvercles à ouverture facile doivent satisfaire à des impératifs contradictoires: une bonne résistance avant ouverture et, cependant, une perforation puis une déchirure facile selon un tracé bien défini lors de l'ouverture. En particulier le panneau d'ouverture des couvercles de forme longue doit pouvoir être arraché complètement sans difficulté, cela même pour les couvercles de dimensions importantes, c'est-à-dire de longueur de l'ordre de 120 mm ou davantage, longueur supérieure à la largeur de la main.Thus, the lids with easy opening must satisfy contradictory requirements: good resistance before opening and, however, a puncture then an easy tear according to a well defined course during opening. In particular, the opening panel for long-shaped covers must be able to be torn off completely without difficulty, even for covers of large dimensions, that is to say with a length of the order of 120 mm or more, greater length. hand-width.

Il s'avère que les couvercles à nervure de raidissement périphérique continue selon le brevet FR-A No 407604 n'ont guère eu de succès. En effet, cette nervure s'étendant autour du panneau d'ouverture contribue à guider efficacement la déchirure de la paroi le long de la tige d'incision qui se trouve enserrée entre la nervure et le bord du couvercle. Cette nervure donne une bonne rigidité d'ensemble au panneau, principalement dans le sens axial, mais, de ce fait, l'effort du consommateur sur la languette se transmet, en quelque sorte, à l'ensemble du panneau. L'effort demandé au consommateur est très important, souvent prohibitif. Trop souvent, cet effort fait céder le moyen de fixation de la languette à la paroi avant l'ouverture complète.It turns out that the covers with a continuous peripheral stiffening rib according to patent FR-A No. 407604 have had little success. In fact, this rib extending around the opening panel contributes to effectively guiding the tearing of the wall along the incision rod which is clamped between the rib and the edge of the cover. This rib gives a good overall rigidity to the panel, mainly in the axial direction, but, as a result, the consumer's effort on the tongue is transmitted, in a way, to the entire panel. The effort required of the consumer is very important, often prohibitive. Too often, this effort causes the fastening means of the tongue to yield to the wall before complete opening.

Comme on peut. le voir par les brevets US-A No 3698590 et FR-A No 2158505, on a pensé à utiliser ce type de couvercle raidi par une nervure périphérique mais en fractionnant par des interruptions cette nervure. En quelque sorte, le panneau est divisé en éléments successifs raidis individuellement par des éléments de nervure symétriques par rapport à l'axe du panneau. Ainsi, dans le brevet US-A No 3698590, le couvercle à ouverture facile est muni de nervures de dimensions limitées raidissant de façon intermittente le panneau d'ouverture et définisssant entre elles, grâce à leurs discontinuités symétriques, des lignes de pliage de ce panneau lors de son ouverture. Ces pliages se font dans des zones souples du panneau et, bien que les éclaboussements par effet de ressort du couvercle soient évités, le mode de déchirement et de pliage reste pratiquement inchangé, ce qui peut expliquer que les couvercles de ce type n'aient eu jusqu'ici guère plus de succès que le couvercle selon le brevet FR-A No 407604.As we can. to see it by the patents US-A No 3698590 and FR-A No 2158505, we thought of using this type of cover stiffened by a peripheral rib but by dividing by interruptions this rib. In a way, the panel is divided into successive elements individually stiffened by rib elements symmetrical with respect to the axis of the panel. Thus, in patent US-A No. 3698590, the easy-opening cover is provided with ribs of limited dimensions intermittently stiffening the opening panel and defining between them, thanks to their symmetrical discontinuities, fold lines of this panel when opened. These folds are made in flexible areas of the panel and, although splashing by the spring effect of the cover is avoided, the mode of tearing and folding remains practically unchanged, which may explain that the covers of this type have not until no more successful than the lid according to patent FR-A No. 407604.

Malgré les échecs ou les insuffisances des tentatives faites jusqu'ici pour éviter à la fois les difficultés d'ouverture et les incidents dus à l'effet de ressort du panneau en cours d'arrachage, la demanderesse a constaté que, moyennant des modifications relativement simples, on pouvait réaliser des couvercles à panneau d'ouverture raidi par une nervure périphérique qui donnent des résultats remarquables: très bonne résistance avant utilisation, ouverture facile, coût de réalisation faible, cela grâce à la simplicité du dessin.Despite the failures or inadequacies of the attempts made so far to avoid both the opening difficulties and the incidents due to the spring effect of the panel being torn off, the applicant has found that, with relatively modifications simple, we could make covers with opening panel stiffened by a peripheral rib which give remarkable results: very good resistance before use, easy opening, low cost of realization, this thanks to the simplicity of the drawing.

Le couvercle, objet de l'invention, a une forme qui rappelle celle du couvercle selon le brevet FR-A No 407604. Il répond cependant de façon particulièrement heureuse aux sujétions diverses et même contradictoires imposées aux couvercles à ouverture facile.The cover, object of the invention, has a shape reminiscent of that of the cover according to patent FR-A No 407604. It however responds in a particularly happy manner to the various and even contradictory constraints imposed on easy-opening covers.

Ce couvercle, de préférence de forme longue, à ouverture facile, à languette d'arrachage et ligne d'incision définissant un panneau d'ouverture qui comporte une nervure (ou une rainure) de raidissement qui borde la ligne d'incision à l'intérieur du panneau, ce couvercle a pour particularité que chacune des branches de sa nervure comporte au moins une légère discontinuité très localisée de la forme de sa section droite, cette discontinuité consistant en un aplatissement partiel et local, ou plutôt une amorce de pliure transversale sur sa ligne de crête. De plus, les discontinuités de l'une et l'autre branche sont dissymétriques par rapport au grand axe du panneau. Si la languette ne se trouve pas dans l'axe du couvercle, les discontinuités seront disposées de façon dissymétrique aussi bien par rapport à l'axe du panneau que par rapport à l'axe de la languette.This cover, preferably of long shape, with easy opening, with tearing tab and incision line defining an opening panel which has a stiffening rib (or groove) which borders the incision line at the inside the panel, this cover has the particularity that each of the branches of its rib has at least one slight very localized discontinuity of the shape of its cross section, this discontinuity consisting of a partial and local flattening, or rather a primer of transverse fold on its ridge line. In addition, the discontinuities of one and the other branch are asymmetrical with respect to the major axis of the panel. If the tab is not in the axis of the cover, the discontinuities will be arranged asymmetrically both with respect to the axis of the panel and with respect to the axis of the tab.

Ces discontinuités, même partielles et localisées, créent sur la nervure des points de faiblesse. Elles facilitent des pliures transversales de la nervure, et par suite du panneau. Leur dissymétrie fait que la nervure, et par suite le panneau, se plie selon les discontinuités se trouvant alternativement sur l'une puis sur l'autre branche. L'effort du consommateur se trouve concentré alternativement sur l'une puis l'autre branche de la ligne d'incision bordant la nervure. Inversement, cela réduit l'effort minimal exercé sur le moyen de fixation de la languette. Au début de l'ouverture, cette concentration de l'effort sur l'une des branches est encore accentuée lorsque la languette est disposée dans un angle du couvercle.These discontinuities, even partial and localized, create points of weakness on the rib. They facilitate transverse folds of the rib, and consequently of the panel. Their asymmetry means that the rib, and consequently the panel, bends according to the discontinuities found alternately on one then on the other branch. The consumer's effort is concentrated alternately on one and then the other branch of the incision line bordering the rib. Conversely, this reduces the minimum force exerted on the tongue fixing means. At the start of the opening, this concentration of the force on one of the branches is further accentuated when the tongue is arranged in a corner of the cover.

A l'exception des couvercles en aluminium de faibles dimensions, il est utile de réaliser plusieurs discontinuités sur chacune des branches de la nervure. Ainsi, dans les panneaux où l'une des branches est plus longue que l'autre, tels que les panneaux à languette désaxée, il faut au moins deux discontinuités sur la branche la plus longue.With the exception of small aluminum covers, it is useful to make several discontinuities on each of the branches of the rib. Thus, in panels where one of the branches is longer than the other, such as panels with an offset tongue, at least two discontinuities are required on the longest branch.

Avec des couvercles selon l'invention, l'ouverture s'effectue de la façon suivante:

- Après la perforation initiale par le nez de la languette et la première pliure de la paroi vers l'intérieur de la boîte, sous la languette, le consommateur peut, sans effort exagéré, déchirer le couvercle le long de la ligne d'incision jusqu'aux extrémités avant des deux branches de la nervure, cela comme avec les couvercles de l'art antérieur.

- After the initial perforation by the nose of the tongue and the first folding of the wall towards the inside of the box, under the tongue, the consumer can, without exaggerated effort, tear the lid along the line of incision until at the front ends of the two branches of the rib, as with the covers of the prior art.

La déchirure de la paroi se poursuit alors alternativement selon une branche de la ligne d'incision puis l'autre. Cela fractionne l'effort demandé au consommateur, qui se trouve concentré successivement sur l'une puis sur l'autre branche.The tearing of the wall then continues alternately along one branch of the incision line and then the other. This splits the effort required from the consumer, who is concentrated successively on one and then on the other branch.

La nervure se plie successivement selon les discontinuités se trouvant sur l'une puis sur l'autre branche. Le panneau lui-même se plie selon une succession de lignes en zigzag qui joignent les discontinuités disposées sur l'une et l'autre branche de nervure. Il se trouve progressivement fractionné en éléments plans de faible surface qui se soulèvent progressivement du couvercle et forment en quelque sorte des bras de levier pour le consommateur. Le panneau se trouve rigidifié en cours d'ouverture par les plis en zigzag et ne peut se refermer brutalement à la façon d'un ressort si, par maladresse, le consommateur lâche la languette avant arrachage complet dudit panneau.The rib folds successively according to the discontinuities located on one then on the other branch. The panel itself folds in a succession of zigzag lines which join the discontinuities arranged on both branches of the rib. It is gradually divided into planar elements of small area which gradually rise from the cover and somehow form leverage for the consumer. The panel is stiffened during opening by the zigzag folds and cannot be closed suddenly in the manner of a spring if, by mistake, the consumer releases the tab before tearing off said panel completely.

Le phénomène d'arrachage du panneau est ainsi bien fractionné et contrôlé, à la fois par la nervure et ses discontinuités.The phenomenon of tearing off the panel is thus well divided and controlled, both by the rib and its discontinuities.

Pour une ouverture facile, la distance maximale entre deux discontinuités sur une même nervure sera, de préférence, de l'ordre de 40 mm.For easy opening, the maximum distance between two discontinuities on the same rib will preferably be of the order of 40 mm.

On a ainsi:

- a) grâce à la nervure périphérique de forte épaisseur, une bonne résistance du couvercle lors des diverses phases d'utilisation avant ouverture: fabrication, sertissage, stérilisation du contenu de la boîte;

- b) une ouverture facile grâce aux discontinuités dissymétriques, qui permettent un arrachage progressif du panneau et, de ce fait, limitent l'effort demandé à l'utilisateur, effort que doit supporter la languette et surtout son moyen de fixation au panneau;

- c) un bon guidage de la ligne de déchirure le long de la ligne d'incision par une nervure de forte épaisseur. Le phénomène de déchirure de la paroi et d'arrachage du panneau est bien contrôlé à la fois par la nervure et ses discontinuités transversales;

- d) une rigidification progressive du panneau en cours d'ouverture par des plis obliques qui interdisent sa fermeture brutale par effet ressort si le consommateur lâche prématurément la languette d'arrachage.

- a) thanks to the very thick peripheral rib, good resistance of the cover during the various phases of use before opening: manufacture, crimping, sterilization of the contents of the box;

- b) easy opening thanks to asymmetrical discontinuities, which allow tearing progressive of the panel and, therefore, limit the effort required of the user, effort that must support the tongue and especially its means of attachment to the panel;

- c) good guidance of the tear line along the incision line by a very thick rib. The phenomenon of tearing of the wall and tearing of the panel is well controlled both by the rib and its transverse discontinuities;

- d) progressive stiffening of the panel during opening by oblique folds which prohibit its abrupt closure by spring effect if the consumer prematurely releases the tear-off tab.

L'invention sera mieux comprise par la description ci-après de deux exemples particuliers de couvercles correspondant aux figures jointes.The invention will be better understood from the following description of two particular examples of covers corresponding to the attached figures.

La fig. 1 représente, vu en plan, par-dessus, un couvercle selon l'invention.Fig. 1 shows, seen in plan, from above, a cover according to the invention.

La fig. 2 représente une coupe transversale du même couvercle.Fig. 2 shows a cross section of the same cover.

La fig. 3 représente, vue en plan, une deuxième variante de couvercle selon l'invention.Fig. 3 shows, in plan view, a second variant of the cover according to the invention.

La fig. 4 représente une coupe transversale du couvercle selon fig. 3.Fig. 4 shows a cross section of the cover according to FIG. 3.

La fig. 5 représente, en coupe, à grande échelle, les discontinuités de la nervure de renforcement.Fig. 5 shows, in section, on a large scale, the discontinuities of the reinforcing rib.

Dans ces dessins, les éléments semblables portent les mêmes repères.In these drawings, similar elements have the same references.

Sur les fig. 1, 2, 3 et 4 sont représentés deux types de couvercle à ouverture facile, selon l'invention. Ces couvercles sont tous deux bordés d'un rebord 1 destiné à être replié et serti sur le bord d'une boîte non représentée ici. Le long de ce rebord a été gravée une ligne d'incision 2 définissant un panneau d'ouverture 3. Une languette 4 est fixée sur le panneau par un rivet intégré (5); cette languette 4 comporte un anneau de préhension 6 à l'arrière et un bec de perforation 7 dont l'extrémité avant est disposée sensiblement à l'aplomb de la ligne d'incision 2.In fig. 1, 2, 3 and 4 are shown two types of cover with easy opening, according to the invention. These covers are both bordered by a

Les deux couvercles représentés comportent une nervure 8 de renforcement en relief disposée au bord du panneau 3 le long de la ligne d'incision 2. Cependant, dans l'un et l'autre cas, cette nervure 8 n'est pas continue comme celle du brevet FR-A ? 407604, mais présente de légères discontinuités 9, 10, 11, 12, 9', 10', 11', 12' réparties le long de la nervure 8 de part et d'autre du grand axe de symétrie (XX') du couvercle. Ces discontinuités sont, de préférence, de simples dénivellations transversales 9, 10, 11, 12, 9', 10', 11', 12' interrompant la ligne de crête de la nervure 8, comme représenté en fig. 1, 3 et 5.The two covers shown have a

On remarque que le couvercle des fig. 1 et 2 est sensiblement symétrique avec une languette 4 disposée dans l'axe longitudinal du couvercle (XX'). Le couvercle des fig. 3 et 4 est nettement dissymétrique avec sa languette 4 orientée selon l'axe (ZZ') oblique par rapport à l'axe (XX') du couvercle.Note that the cover of Figs. 1 and 2 is substantially symmetrical with a

Dans les deux cas représentés, les discontinuités arrière 9, 9' sont disposées symétriquement par rapport à l'axe (XX') du couvercle. Mais, de façon plus générale, leur emplacement est déterminé expérimentalement selon le type de couvercle pour que la portion continue de nervure 8 qui les relie rigidifie transversalement et longitudinalement le panneau dans cette zone. Ainsi, à la fin de l'ouverture, l'utilisateur pourra facilement terminer l'arrachage du panneau 3 par mouvement de va-et-vient.In the two cases shown, the

Les autres discontinuités, au moins partielles, 10,10',11,11',12,12' doivent être dissymétriques par rapport à l'axe (XX'), comme représenté ici. Les lignes joignant deux discontinuités homologues 9-10', 10'-10, 10-11', 11'-11, 11-12', 12'-12 forment avec cet axe un angle (a) compris entre 60 et 80°. On peut remarquer que la nervure 8 est interrompue sous la languette 4 fixée directement sur le plan du pourtour du panneau 3.The other discontinuities, at least partial, 10,10 ', 11,11', 12,12 'must be asymmetrical with respect to the axis (XX'), as shown here. The lines joining two homologous discontinuities 9-10 ', 10'-10, 10-11', 11'-11, 11-12 ', 12'-12 form with this axis an angle (a) between 60 and 80 ° . We can notice that the

Avec ce type de languette 4 utilisée dans les deux exemples de couvercles représentés, aussitôt après la perforation initiale par le nez 7, l'extrémité avant du panneau 3 se plie de façon connue vers l'intérieur de la boîte. La pliure initiale du panneau s'effectue selon une droite (AB) perpendiculaire à l'axe (ZZ') de la languette et sensiblement tangente au rivet 5 à l'arrière de ce rivet. Pour d'autres types de languettes reliées au rivet 5 par une patte souple, la ligne de pliure (AB) est tangente au rivet 5 à l'avant de ce rivet. La nervure 8 est interrompue sous la languette 4, les extrémités avant 13, 13' de chacune des branches de la nervure 8 sont disposées, par rapport au nez 7 de la languette, légèrement en arrière de la droite (AB) de pliure.With this type of

L'ouverture des boîtes selon fig. 1 ou 3 s'effectue très facilement: comme dans l'art antérieur, après la perforation initiale par le nez rigide 7, la déchirure de la paroi se poursuit en suivant la ligne d'incision 2 selon deux branches symétriques de part et d'autre de la languette 4. Comme dans l'art antérieur, le panneau 3 se trouve rigidifié transversalement par sa pliure initiale selon (AB), ce qui contribue à empêcher le bombement du panneau selon un pli longitudinal très nuisible pour la suite de l'ouverture.The opening of the boxes according to fig. 1 or 3 is carried out very easily: as in the prior art, after the initial perforation by the rigid nose 7, the tearing of the wall continues following the line of

Dans le cas des deux couvercles représentés, la rigidité transversale du panneau en début d'ouverture est renforcée par les deux branches de la nervue 8 qui s'étendent sensiblement dans le prolongement de la droite (AB). Les deux branches de la nervure 8 contribuent également à guider la déchirure initiale de la paroi selon les deux branches de la ligne d'incision 2, de part et d'autre de la languette 4.In the case of the two covers shown, the transverse rigidity of the panel at the start of opening is reinforced by the two branches of the

En ce qui concerne le couvercle globalement symétrique des fig. 1 et 2, la dissymétrie des discontinuités 12 et 12' par rapport à l'axe (XX') du couvercle entraîne une dissymétrie de la rigidité des deux branches de la nervure 8 et, par suite, du panneau 3 lui-même, par rapport audit axe (XX').As regards the generally symmetrical cover of FIGS. 1 and 2, the asymmetry of the

Après la perforation initiale, l'effort d'arrachage transmis par la languette 4 se concentre sur l'un puis l'autre côté du couvercle jusqu'aux discontinuités 12 et 12'. La paroi cède d'un côté puis de l'autre. Le panneau 3, déchiré selon une portion de la ligne d'incision 2 limitée par une corde correspondant sensiblement aux discontinuités avant 12,12', se plie le long de cette ligne 12, 12'. L'efforttransmis par le rivet 5 se concentre alors sur la partie non déchirée la plus voisine 11, 12 qui se déchire à son tour en créant un nouveau pli transversal 11, 12'. La déchirure se poursuit alternativement le long d'une branche puis l'autre de la ligne d'incision 2, sans que le consommateur ait à exercer d'effort important. La ligne de déchirure est bien guidée à la fois par la ligne d'incision 2 et la nervure 8 qui la borde. En fin d'ouverture, le panneau 3 est rigidifié par les plis joignant en zigzag les discontinuités situées alternativement sur les deux branches de la nervure 8 ainsi que par la partie arrière transversale de la nervure 8 qui s'étend sans interruption entre les discontinuités 9, 9'. Les plis en zigzag sont représentés en pointillé sur la fig. 1.After the initial perforation, the pulling force transmitted by the

Pour le couvercle dissymétrique des fig. 3 et 4, l'excentration de la languette 4 par rapport à l'axe (XX') suffirait à elle seule à initier une déchirure dissymétrique. Cette déchirure dissymétrique se poursuit grâce à la position dissymétrique des discontinuités. Après la pliure initiale du panneau 3 vers l'intérieur de la boîte 12 selon la ligne (AB), le consommateur tire le panneau vers l'extérieur de la boîte dans un plan vertical passant sensiblement par (XX'). La partie antérieure de la ligne d'incision 2 la plus sollicitée cède en premier jusqu'au niveau de la discontinuité 12. La déchirure du couvercle se poursuit alors de l'autre côté vers la discontinuité 12' et, ainsi, alternativement vers les discontinuités arrière 9,9'. Cette déchirure alternative de l'un puis de l'autre côté du couvercle n'exige qu'un effort réduit du consommateur et, par voie de conséquence, une résistance relativement faible du rivet 5. Comme dans l'exemple des fig. 1 et 2, l'angle (a) entre l'axe (XX') et les lignes figurées ici en pointillé, qui relient deux discontinuités homologues (10'-10, 10-11', 11'-11, 11-12',12'-12,12-13, est le plus souvent compris entre 60 et 80°. Il n'est d'ailleurs pas indispensable d'avoir un nombre pair de discontinuités sur la nervure. La forme de couvercle selon fig. 3 et 4, avec une languette 4 dans un angle du couvercle, est particulièrement recommandée.For the asymmetrical cover of fig. 3 and 4, the eccentricity of the

La distance maximale (L) entre deux discontinuités successives telles que 10, 11 est de l'ordre de 40 mm. Pour un couvercle en feuille d'aluminium d'épaisseur 0,25 mm, de largeur 55 mm et de longueur 150 mm selon (XX'), de bons résultats ont été obtenus avec une nervure de largeur e = 7 mm et hauteur h = 0,7 mm.The maximum distance (L) between two successive discontinuities such as 10, 11 is of the order of 40 mm. For an aluminum foil cover 0.25 mm thick, 55 mm wide and 150 mm long along (XX '), good results have been obtained with a rib of width e = 7 mm and height h = 0.7 mm.

Les discontinuités représentées sur tes fig. 1,3 et 5 sont de simples aplatissements, partiels et localisés, de la nervure 8, lui laissant une hauteur résiduelle de l'ordre de ta % à % de sa hauteur (h). Ce sont plus de simples affaiblissements transversaux que de réelles discontinuités. Elles suffisent à réduire localement le moment d'inertie de la nervure et, par suite, celui du panneau dans un plan vertical.The discontinuities shown in fig. 1,3 and 5 are simple, partial and localized flattenings of the

La largeur (e) et la hauteur (h) des nervures 8, l'importance et l'espacement (L) des discontinuités varient évidemment avec les dimensions des couvercles, l'épaisseur de la paroi et les caractéristiques du métal employé. Des essais sont nécessaires pour déterminer la solution la meilleure dans chaque cas particulier en fonction de l'épaisseur et des dimensions du couvercle, ainsi que de la qualité du matériau.The width (e) and height (h) of the

Bien que les deux couvercles représentés ici soient des couvercles pour boîtes allongées, le dispositif de raidissement ménagé du couvercle par nervure avec discontinuités peut également être utilisé avec succès sur des couvercles pour boîtes circulaires de grandes dimensions. L'axe de symétrie du couvercle est alors celui passant par le centre du panneau et l'axe du rivet de fixation de la languette.Although the two lids shown here are lids for elongated boxes, the rib stiffening device with ribs with discontinuities can also be successfully used on lids for large circular boxes. The axis of symmetry of the cover is then that passing through the center of the panel and the axis of the tongue fixing rivet.

Lors de l'ouverture, la surface du panneau se trouve fractionnée en triangles ou quadrilatères asymétriques curvilignes irréguliers par les plis joignant les discontinuités de la nervure, de part et d'autre de l'axe.When opened, the surface of the panel is divided into asymmetrical curvilinear asymmetrical triangles or quadrilaterals by the folds joining the discontinuities of the rib, on either side of the axis.

Une nervure périphérique 8 comportant des discontinuités peut tout aussi bien être utilisée sur des panneaux 3 dont l'incision 2 n'est pas complètement fermée mais est interrompue sur une certaine longueur, par exemple à l'arrière du panneau. Cette disposition incite le consommateur à ne pas déchirer complètement le panneau du couvercle et à le laisser attaché à la boîte par la patte de liaison qui subsiste à l'emplacement de l'interruption de l'incision.A

Claims (7)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT82420036T ATE9306T1 (en) | 1981-03-20 | 1982-03-18 | EASY OPEN CONTAINER WITH TEAR TAPE AND TEAR LINE. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR8106035A FR2502122B1 (en) | 1981-03-20 | 1981-03-20 | EASY OPENING COVER WITH PULL-OUT TONG AND INCISION LINE |

| FR8106035 | 1981-03-20 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0061980A1 EP0061980A1 (en) | 1982-10-06 |

| EP0061980B1 true EP0061980B1 (en) | 1984-09-12 |

Family

ID=9256651

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP82420036A Expired EP0061980B1 (en) | 1981-03-20 | 1982-03-18 | Easily openable can with pull tab and score line |

Country Status (5)

| Country | Link |

|---|---|

| EP (1) | EP0061980B1 (en) |

| AT (1) | ATE9306T1 (en) |

| DE (1) | DE3260691D1 (en) |

| ES (1) | ES277879Y (en) |

| FR (1) | FR2502122B1 (en) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2602485B1 (en) * | 1986-08-06 | 1988-11-25 | Franpac | METALLIC COVER WITH PRE-INCISED OPENING PANELS |

| FR2954290B1 (en) * | 2009-12-17 | 2012-03-23 | Impress Group Bv | MONOBLOC METAL COVER WITH PARALLELOGRAM FORMED RUPTURE PRIMER LINE |

| GB2580900B (en) * | 2019-01-23 | 2021-05-19 | Crown Packaging Technology Inc | Can end with ribs to increase panel stiffness |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3478918A (en) * | 1968-08-14 | 1969-11-18 | American Can Co | Full open end closure |

Family Cites Families (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR407604A (en) * | 1909-10-05 | 1910-03-07 | Leon Delpeut | Opening device for metal boxes |

| US2085200A (en) * | 1933-03-08 | 1937-06-29 | Transitoria Ab | Closed container such as preserving cans |

| FR950090A (en) * | 1946-12-02 | 1949-09-16 | Lofts Canning Patents Ltd | Ribbed lid closure for cans, kegs, metal boxes or similar containers |

| FR1215451A (en) * | 1958-07-12 | 1960-04-19 | Inst Portugues De Conservas De | Lid stamp for cans |

| US3490643A (en) * | 1968-01-22 | 1970-01-20 | Dorn Co V | Full opening container end |

| US3698590A (en) * | 1968-02-16 | 1972-10-17 | Cookson Sheet Metal Dev Ltd | Frangible elements in sheet material |

| FR2074598A1 (en) * | 1970-01-08 | 1971-10-08 | Cebal Gp | |

| BE790950A (en) * | 1971-11-03 | 1973-03-01 | Nat Can Corp | FULLY OPENING CONTAINER BOTTOM CLOSURE |

-

1981

- 1981-03-20 FR FR8106035A patent/FR2502122B1/en not_active Expired

-

1982

- 1982-03-18 DE DE8282420036T patent/DE3260691D1/en not_active Expired

- 1982-03-18 EP EP82420036A patent/EP0061980B1/en not_active Expired

- 1982-03-18 AT AT82420036T patent/ATE9306T1/en not_active IP Right Cessation

- 1982-03-18 ES ES1982277879U patent/ES277879Y/en not_active Expired

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3478918A (en) * | 1968-08-14 | 1969-11-18 | American Can Co | Full open end closure |

Also Published As

| Publication number | Publication date |

|---|---|

| ES277879Y (en) | 1985-06-16 |

| ES277879U (en) | 1984-12-16 |

| FR2502122A1 (en) | 1982-09-24 |

| FR2502122B1 (en) | 1985-07-05 |

| DE3260691D1 (en) | 1984-10-18 |

| ATE9306T1 (en) | 1984-09-15 |

| EP0061980A1 (en) | 1982-10-06 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CH429480A (en) | Metal closure element for a tubular container | |

| CH376424A (en) | Plastic bag and method of making this bag | |

| FR2550767A1 (en) | IMPROVED DRAWER FOR EASY OPENING CAN LID AND MANUFACTURING METHOD THEREOF | |

| FR2482074A1 (en) | TONG FOR CLOSING END OF A CAN | |

| FR2459181A1 (en) | CONTAINER COVER, EASILY OPENED, WITH NON-DETACHABLE OPENING LEG AND RESISTANT TO RUPTURE AND ARRACHEMENT | |

| WO1996039334A1 (en) | Raised pouring spout, recessed in an inverted position in a can lid | |

| EP0794070A1 (en) | Document holder and its method of fabrication | |

| FR2711357A1 (en) | Box of rigid sheet material with handle, blank and method for manufacturing such a box. | |

| EP0061980B1 (en) | Easily openable can with pull tab and score line | |

| CH425505A (en) | Quick-open container | |

| EP0057644B1 (en) | Easily openable package e.g. for foodstuff in paste form | |

| EP0043786B1 (en) | Pull-tap for easily openable cans and method of manufacturing the same | |

| CH429481A (en) | Easy-open box and manufacturing process | |

| EP0997380A1 (en) | Easy-open collapsible cardboard box | |

| EP1103487B1 (en) | Packaging bag with reclosable opening | |

| EP0425401A1 (en) | Easy-open metal cover for a container | |

| FR2597436A1 (en) | Packing package with integral opening, particularly for pasty food products | |

| EP0222705B1 (en) | Wrapper for packaging products, and process for producing the same | |

| EP0256920B1 (en) | Metal closure with a preincised opening panel | |

| EP0618149B1 (en) | Sealed closing device for a container as well as a container with the same | |

| EP2512940B1 (en) | Integral metal lid having parallelogram-shaped predetermined break-off line | |

| FR2803579A1 (en) | CASE FOR PACKAGING WIPES | |

| WO2020109284A1 (en) | Cover for a container body, in particular for a container of the preserving can type | |

| EP3887273A1 (en) | Lid for a container body, in particular for a container such as a can | |

| FR2632934A1 (en) | Dispensing package for rolls of paper for household and/or professional uses |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH DE FR GB IT LU NL SE |

|

| 17P | Request for examination filed |

Effective date: 19821015 |

|

| ITF | It: translation for a ep patent filed |

Owner name: ING. A. GIAMBROCONO & C. S.R.L. |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH DE FR GB IT LI LU NL SE |

|

| REF | Corresponds to: |

Ref document number: 9306 Country of ref document: AT Date of ref document: 19840915 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 3260691 Country of ref document: DE Date of ref document: 19841018 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19850331 |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| 26 | Opposition filed |

Opponent name: SCHMALBACH - LUBECA AG Effective date: 19850604 |

|

| NLR1 | Nl: opposition has been filed with the epo |

Opponent name: SCHMALBACH - LUBECA AG |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: LU Payment date: 19860404 Year of fee payment: 5 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 19870210 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19870331 Year of fee payment: 6 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19890318 Ref country code: AT Effective date: 19890318 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19890319 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19890331 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19890331 Ref country code: BE Effective date: 19890331 |

|

| BERE | Be: lapsed |

Owner name: CEBAL Effective date: 19890331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19891001 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee | ||

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19891130 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19891201 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| RDAG | Patent revoked |

Free format text: ORIGINAL CODE: 0009271 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: PATENT REVOKED |

|

| 27W | Patent revoked |

Effective date: 19910711 |

|

| EUG | Se: european patent has lapsed |

Ref document number: 82420036.4 Effective date: 19900125 |

|

| APAC | Appeal dossier modified |

Free format text: ORIGINAL CODE: EPIDOS NOAPO |

|

| APAC | Appeal dossier modified |

Free format text: ORIGINAL CODE: EPIDOS NOAPO |

|

| APAH | Appeal reference modified |

Free format text: ORIGINAL CODE: EPIDOSCREFNO |