EP0058078A2 - Spender für Papierrollen - Google Patents

Spender für Papierrollen Download PDFInfo

- Publication number

- EP0058078A2 EP0058078A2 EP82300617A EP82300617A EP0058078A2 EP 0058078 A2 EP0058078 A2 EP 0058078A2 EP 82300617 A EP82300617 A EP 82300617A EP 82300617 A EP82300617 A EP 82300617A EP 0058078 A2 EP0058078 A2 EP 0058078A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- housing

- loading means

- aperture

- roll

- dispenser

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47K—SANITARY EQUIPMENT NOT OTHERWISE PROVIDED FOR; TOILET ACCESSORIES

- A47K10/00—Body-drying implements; Toilet paper; Holders therefor

- A47K10/24—Towel dispensers, e.g. for piled-up or folded textile towels; Toilet paper dispensers; Dispensers for piled-up or folded textile towels provided or not with devices for taking-up soiled towels as far as not mechanically driven

- A47K10/32—Dispensers for paper towels or toilet paper

- A47K10/34—Dispensers for paper towels or toilet paper dispensing from a web, e.g. with mechanical dispensing means

- A47K10/38—Dispensers for paper towels or toilet paper dispensing from a web, e.g. with mechanical dispensing means the web being rolled up with or without tearing edge

- A47K10/3809—Dispensers for paper towels or toilet paper dispensing from a web, e.g. with mechanical dispensing means the web being rolled up with or without tearing edge with roll spindles which are not directly supported

- A47K10/3827—Dispensers for paper towels or toilet paper dispensing from a web, e.g. with mechanical dispensing means the web being rolled up with or without tearing edge with roll spindles which are not directly supported with a distribution opening which is parallel to the rotation axis

Definitions

- the invention relates to a dispenser for paper in roll form, such as rolled toilet tissue or paper towel.

- Such dispensers may include a lockable housing or spindle for a single roll.

- the measures do not overcome the problem of providing spare rolls which will not be stolen and, in fact, suffer a further disadvantage of the janitor requiring specialised equipment, such as a key for releasing the housing or spindle. Furthermore the key or the spindle may become lost.

- the present invention aims to minimise or overcome the above difficulties and disadvantages.

- a dispenser for paper in roll form comprising a housing for holding one or more rolls of paper, the housing having an aperture through which the rolls can be loaded, and a paper dispensing slot, and movable loading means adapted for admitting a paper roll to the housing through the aperture, said movable loading means being movable between an open position, in which it can receive a roll, and a closed position, said movable loading means being so shaped and so disposed, relative to said aperture that, for all possible positions of the loading means, removal of a roll from the housing through the aperture is prevented.

- the loading means are so shaped and so disposed relative to the dispenser's loading aperture that, for all possible positions of the loading means, access of a hand to the interior of the housing is not even possible.

- the loading means comprises a first element which effectively closes the aperture when the loading means is in its closed position, and a second element which effectively closes the aperture when the loading means is in its open position.

- the second element may act as a support for a roll during loading of that roll into the housing.

- the first and second elements of the loading means may be integral.

- the loading means comprises a first- plate and a second plate mutually angled and rigidly interconnected along a respective one of their edges, the plates being hinged on the housing for limited pivotal movement relative thereto, about an axis parallel to their interconnected edges, between an open and a closed position, said first plate acting as a lid for the housing closing the aperture when the loading means is in its closed position, said second plate being pivotable within the housing and being angled with respect to the first plate by an angle great enough to receive a paper roll between said plates yet not so great as to allow removal of a roll past that edge of the second plate remote from its edge connected to the first plate for all possible pivotal positions of the loading means, the second plate being dimensioned so as to obstruct said aperture in the housing when the loading means is in its open position, whereby, after pivoting the loading means into its open position, a paper roll may be inserted between the two plates and, on pivoting the loading means into its closed position, the roll is released from between the plates and admitted to the interior of the housing.

- Such a loading means preferably further comprises a pair of spaced walls extending between respective edges of the plates, those edges being adjacent the interconnected edges of the plates.

- the pivotal movement of the plates is preferably limited by stop means to define the open position of the loading means.

- the stop means preferably comprise a flange projecting from the housing into the aperture and adapted to abut that edge of the second plate remote from its edge connected to the first plate when the loading means in in its open position.

- the stop means may instead comprise at least one projection disposed on the walls of the loading means and adapted to abut the housing when the loading means is in its open position.

- the loading means comprise a pair of spaced walls extending between respective edges of the plates, those edges being adjacent the interconnected edges of the plates.

- the loading means comprises an inverted drawer having first and second mutually opposite walls and being slidable through the aperture in the housing between a closed position, in which said first wall obstructs said aperture, and an open position in which said second wall obstructs said aperture, whereby, when the drawer is in the open position, a paper roll may be inserted into the drawer, and, on closing the drawer, the paper roll is released from the drawer and admitted to the interior of the housing.

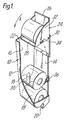

- a dispenser comprising a housing 10 having a front wall 12, a rear wall 14, -and two opposite side walls 16.

- the housing is of a size suitable to take one or more paper rolls, such as toilet tissue or paper towel.

- the housing is of suitable capacity to hold a plurality of cylindrical rolls 18 one above the other.

- a paper dispensing slot 20 through which paper from that roll 18' adjacent the slot 20 may be withdrawn from the roll.

- an aperture 22 which, in this case, is disposed at that end of the housing remote from the dispensing slot 20. It is through this aperture 22 that paper rolls 18 are loaded into the housing 10.

- Loading means 24 are arranged to load a roll 18, one at a time, through the aperture 22, into the interior of the housing 10.

- the loading means 24 comprise a first plate 26 disposed substantially at right angles to a second plate 28, the plates being joined along one of their edges.

- the plates are hinged to the rear wall 14 of the housing 10 so as to pivot about an axis 30 coincident with their joined edges.

- the loading means in this embodiment, further comprises two side walls 32 of a generally quadrant configuration and each extending between respective edges of the plates 26, 28.

- the loading means 24 is adapted to pivot between an open position ( Figure 1) in which a roll 18 may be received therein for loading into the housing 10, and a closed position ( Figure 2) in which the roll 18 is released for admission to the interior of the housing 10.

- the first plate 26 acts as a lid for the housing 10, closing off its aperture 22, and in the open position, the second plate 28 closes the aperture.

- the pivotal movement is limited, the closed position being defined when the first plate 26 engages one or more of the walls 12, 14, 16 of the housing 10 and the open position of the loading means 24 being defined by a projection 34 engaging stop means (not shown in Figures 1 and 2) on the side wall or walls 16 of the housing 10.

- the loading means 24 are so constructed and so arranged in relation to the aperture 22,that in the open and the closed positions, as well as positions therebetween, removal of a roll 18, 18' from the housing through the aperture 22 is prevented.

- the loading means 24 are pivoted into the open position ( Figure 1) by lifting the first plate 26 and a roll 18 placed on the second plate 28.

- the loading means 24 are then pivoted in the direction of arrow A, either by pushing downwardly or because of the weight of the roll 18, into the closed position ( Figure 2), the roll 18 dropping into the housing.

- roll position limiting means 36 Disposed within the housing, in this case attached to the rear wall 14, are roll position limiting means 36.

- the limiting means hold rolls 18 clear of roll 18', nearest the dispensing slot 20 so that paper may be unrolled freely from the roll in use 18', without rotation of roll 18' being impeded by frictional engagement of rolls 18 resting on it. Once the paper has been exhausted from roll 18', the roll core of roll 18' may be removed through the slot 20. The next roll 18 may then be brought into a position for use by manipulating the roll 18 which is resting on the limiting means 36 past the limiting means to a position resting adjacent the slot 20. Manipulation of the roll may be carried out through one or more openings 38 provided in one or more walls, in the illustrated case in the side walls 16, of the housing 10.

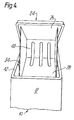

- FIG. 3 and 4 of the drawings there is shown a second embodiment of a dispenser according to the invention.

- This dispenser is similar in many respects to that of the first embodiment, having loading means 24 hinged for pivotal movement relative to the housing 10.

- the first plate 26 is not directly connected to the second plate but is connected to it via a rear plate 40.

- the projection 34 engages stop means on the housing which comprise an inwardly projecting rim 42 of the side walls 16.

- the roll position limiting means 36 are in the form of two curved resilient flanges 44, 46 secured respectively to the front wall 12 and rear wall 14 of the housing 10.

- the projections 34 may be omitted, 'the pivotal movement of the loading means being instead limited by abutment of the free edge of the second plate 28 against the inwardly extending rim 42 or ( Figure 5) against an inwardly projecting ledge 43.

- the ledge has the added advantage of making the passage for a hand into the dispenser through the aperture 22 more tortuous.

- Figure 5 illustrates further desirable features of the dispenser which may be incorporated into any of the other embodiments described herein.

- the lower region 12' of the front wall 12 may be made of a transparent material, so that a user can assess how much paper is left on the roll in use.

- an opening 39 through which it is possible to manipulate the roll which is in use and resting on the bottom wall. For instance, it would be possible to rotate a new roll until the free end of the paper is adjacent the slot 20.

- the free end of the roll is often glued to the rest of the roll to prevent premature unravelling. So as to make it easier for a user to start a new roll, there may be provided a cut-away portion 21 in the lower region 12' of the dispenser front wall which opens into the slot 20 to facilitate release of the glued end of the roll.

- the loading means 24 in this embodiment is again movable with respect to the housing 10 but is not hinged thereto. Instead, the loading means- 24 comprises an inverted drawer 48 slidably mounted on the side walls 16 of the housing 10.

- the drawer comprises a front wall 50, a rear wall 52 and side walls 54.

- the front wall 50 of the drawer 54 substantially fills and therefore closes the aperture 22 in the housing 10.

- thesperture 22 comprises a rectangular opening in the front wall 12 of the housing 10 of a size just big enough to receive a roll 18 therethrough.

- the upper region of the housing 10 is dome shaped and has the aperture 22 disposed therein.

- a hollow cylindrical drum 60 Rotatably mounted within the domed portion of the housing 10 is a hollow cylindrical drum 60, which is rotatably mounted on the side walls 16 of the housing 10.

- the drum 60 has a slot 62 in its wall 64 extending along substantially its full length, the slot 62 being at least equal to the diameter of a roll 18 which is to be loaded into the dispenser.

- the drum 60 is rotated until its slot 62 is coincident with the aperture 22. In this position, the entire wall 64 of the drum 60 effectively closes the aperture 22.

- a roll 18 is then inserted through the aperture.22 and through slot 62 into the drum 60, and the wall 64 of the drum supports the roll 18.

- the.roll 18 On rotation of the drum 60 into the position shown in Figure 7, the.roll 18 will fall through the slot 62 into the interior of the housing 10. In this position of the drum 60, it is a portion 64' of its wall 64 which closes the aperture 22.

- drum 60 could equally well be arranged to be rotatable about an axis perpendicular thereto, i.e. parallel to the side walls 16 of the housing 10, the aperture 22 being arranged in one of the side walls 16.

- the dispenser may be made of any suitable material such as enamel-coated mild steel, or a tough plastics material.

Landscapes

- Health & Medical Sciences (AREA)

- Public Health (AREA)

- Unwinding Webs (AREA)

- Storage Of Web-Like Or Filamentary Materials (AREA)

- Replacement Of Web Rolls (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| GB8103893 | 1981-02-09 | ||

| GB8103893 | 1981-02-09 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0058078A2 true EP0058078A2 (de) | 1982-08-18 |

| EP0058078A3 EP0058078A3 (de) | 1982-09-08 |

Family

ID=10519549

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP82300617A Withdrawn EP0058078A3 (de) | 1981-02-09 | 1982-02-08 | Spender für Papierrollen |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP0058078A3 (de) |

| NO (1) | NO820360L (de) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO1995008940A1 (en) * | 1993-09-29 | 1995-04-06 | Mccraw Ian R | Improvements in or relating to a dispenser |

| CN102811654A (zh) * | 2009-12-18 | 2012-12-05 | Sca卫生用品公司 | 用于从中心供给薄纸卷分配纸的分配器 |

| US8573398B2 (en) | 2002-05-28 | 2013-11-05 | Georgia-Pacific Consumer Products Lp | Refillable flexible sheet dispenser |

Family Cites Families (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB888012A (en) * | 1957-07-24 | 1962-01-24 | Ernest Penney | A new or improved holder for toilet paper |

| US2943777A (en) * | 1959-02-20 | 1960-07-05 | Burroughs Mfg Corp | Combination towel and wrap dispenser |

-

1982

- 1982-02-08 NO NO820360A patent/NO820360L/no unknown

- 1982-02-08 EP EP82300617A patent/EP0058078A3/de not_active Withdrawn

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO1995008940A1 (en) * | 1993-09-29 | 1995-04-06 | Mccraw Ian R | Improvements in or relating to a dispenser |

| GB2298410A (en) * | 1993-09-29 | 1996-09-04 | Ian R Mccraw | Improvements in or relating to a dispenser |

| GB2298410B (en) * | 1993-09-29 | 1998-01-07 | Ian Richard Mccraw | Improvements in or relating to a dispenser |

| AU688385B2 (en) * | 1993-09-29 | 1998-03-12 | Ian Richard Mccraw | Improvements in or relating to a dispenser |

| US8573398B2 (en) | 2002-05-28 | 2013-11-05 | Georgia-Pacific Consumer Products Lp | Refillable flexible sheet dispenser |

| CN102811654A (zh) * | 2009-12-18 | 2012-12-05 | Sca卫生用品公司 | 用于从中心供给薄纸卷分配纸的分配器 |

Also Published As

| Publication number | Publication date |

|---|---|

| EP0058078A3 (de) | 1982-09-08 |

| NO820360L (no) | 1982-08-10 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US4389026A (en) | Dispensing container for rolled products | |

| US4807823A (en) | Bathroom tissue dispenser | |

| US3580651A (en) | Toilet tissue holding and dispensing apparatus | |

| US3211504A (en) | Dispenser for rolls of paper | |

| US5271574A (en) | Dispenser for flexible sheet material | |

| EP0419063B1 (de) | Blattspender | |

| US4684075A (en) | Toilet paper dispenser | |

| US4872601A (en) | Two large roll toilet tissue dispenser | |

| US5765717A (en) | Wet hygienic towel dispenser | |

| US4765475A (en) | Holder and dispenser for multiple rolls of tissue | |

| US4796832A (en) | Dispenser for jumbo roll of toilet tissue | |

| US3084006A (en) | Two-roll paper dispenser | |

| ITMI960859A1 (it) | Contenitore-erogatore di carta a strappo manuale con rotolo di riserva | |

| US2307994A (en) | Roll paper dispenser | |

| US20080283546A1 (en) | Paper Dispenser | |

| US4058354A (en) | Storage container for rolls of toilet tissues | |

| AU760517B2 (en) | Dispenser for rolls of web-shaped material | |

| EP0058078A2 (de) | Spender für Papierrollen | |

| US20070023563A1 (en) | Multiple toilet paper holder and dispenser | |

| US3418029A (en) | Cabinet for dispensing paper toweling in roll form | |

| US4879150A (en) | Jumbo roll of toilet tissue | |

| EP0026241B1 (de) | Halter und Ausgeber für aufgestapelte Rollen | |

| US4896826A (en) | Tamper-deterrent fee collecting box for buses | |

| KR20230007380A (ko) | 기계적 전달 및 방법을 갖는 분배기 | |

| AU688385B2 (en) | Improvements in or relating to a dispenser |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH DE FR GB IT LU NL SE |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH DE FR GB IT LU NL SE |

|

| 17P | Request for examination filed |

Effective date: 19821016 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 19860127 |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: BRAID, WILLIAM Inventor name: ARDUINI, GIANNI Inventor name: SALVEMINI, FRANCO Inventor name: DEL CORNO, MARCO |