EP0052030B1 - Vorrichtung zum Sammeln einer freifallenden Flüssigkeit und ihre Anwendung in einer Flüssigkeit-Gas-Gegenstromkontaktiereinrichtung - Google Patents

Vorrichtung zum Sammeln einer freifallenden Flüssigkeit und ihre Anwendung in einer Flüssigkeit-Gas-Gegenstromkontaktiereinrichtung Download PDFInfo

- Publication number

- EP0052030B1 EP0052030B1 EP81401609A EP81401609A EP0052030B1 EP 0052030 B1 EP0052030 B1 EP 0052030B1 EP 81401609 A EP81401609 A EP 81401609A EP 81401609 A EP81401609 A EP 81401609A EP 0052030 B1 EP0052030 B1 EP 0052030B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- liquid

- main trough

- trough

- flow

- wall

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

- 239000007788 liquid Substances 0.000 title claims abstract description 80

- 238000009434 installation Methods 0.000 title claims abstract description 7

- 230000000694 effects Effects 0.000 description 2

- 239000002184 metal Substances 0.000 description 2

- 238000010276 construction Methods 0.000 description 1

- 238000001816 cooling Methods 0.000 description 1

- 230000007423 decrease Effects 0.000 description 1

- 239000012530 fluid Substances 0.000 description 1

- 210000002445 nipple Anatomy 0.000 description 1

- 238000005086 pumping Methods 0.000 description 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F28—HEAT EXCHANGE IN GENERAL

- F28F—DETAILS OF HEAT-EXCHANGE AND HEAT-TRANSFER APPARATUS, OF GENERAL APPLICATION

- F28F25/00—Component parts of trickle coolers

- F28F25/02—Component parts of trickle coolers for distributing, circulating, and accumulating liquid

- F28F25/04—Distributing or accumulator troughs

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10S—TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10S261/00—Gas and liquid contact apparatus

- Y10S261/11—Cooling towers

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10S—TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10S261/00—Gas and liquid contact apparatus

- Y10S261/85—Droplet catchers

Definitions

- the present invention relates to installations for contacting a liquid against a current with a gas, in particular those used for cooling a liquid such as water with atmospheric air, and more particularly relates to a device for collecting a liquid falling freely in the form of rain or the like in such installations.

- Installations for contacting a liquid with a gas against the current generally comprise a chamber provided at its lower part with at least one gas inlet opening and at its upper part with at least one outlet opening gas and, inside said chamber, a liquid distribution network, a body for bringing the liquid into direct contact with the gas disposed under the distribution network, and means for collecting the liquid which flows in free fall in the form of rain or the like of the contacting body.

- These means can be constituted by a basin provided at the base of the chamber and into which the liquid falls directly.

- a basin has the disadvantage of being of a relatively expensive construction, of generating a significant noise due to the impact of the liquid falling over a significant height of the contacting body on the liquid present in the basin.

- the aim of the present invention is to improve the flow of liquid in the chutes and is based on the observation that this poor flow is due to the significant disturbances which are created by the fall of the liquid coming from the inclined walls and entering the flow of liquid flowing in the chutes.

- the subject of the present invention is a device for collecting a liquid falling freely in the form of rain or the like, of the type comprising a wall inclined to the vertical and a chute, hereinafter called main chute, extending along from the lower edge of the wall, characterized in that it comprises, on the path of the liquid collected by the inclined wall, and before it enters the main chute, means for significantly reducing or canceling the vertical speed component of the liquid to its entry into the chute.

- the means for appreciably reducing or canceling the vertical speed component of the liquid comprise deflecting surfaces which give the liquid as it enters the main chute a component of notable speed in the direction of flow of the liquid in the main chute.

- deflecting surfaces can be, for example, constituted by small inclined troughs or intermediate buckets disposed at the inlet of the main trough, which give the liquid a direction close to that of the flow of the liquid in the main trough.

- deflecting surfaces can also be constituted by ribs arranged on the inclined wall, along the line of greatest slope, and the lower part of which is curved in the direction of the flow of the liquid in the main chute or even by ribs arranged on the inclined wall and themselves inclined in the direction of the flow of the liquid in the main chute.

- Such deflecting surfaces subject the liquid to a change of direction in the direction of flow in the main chute and give it a speed which may be greater than that of the liquid in the main chute. This decreases the disturbances in the flow, but also accelerates the flow of the liquid in the main chute.

- the means for reducing or canceling the vertical speed component comprise one or more obstacles tending to cancel the speed of the liquid as it enters the main chute.

- Obstacles can for example consist of pins arranged on the inclined wall, a rib parallel to the chute main and arranged at the entrance to the latter, or better by a fine mesh grid covering the main chute.

- the invention also relates to an installation for contacting a liquid with a gas against the current, comprising a chamber provided at its lower part with at least one gas inlet opening and at its upper part with at least one gas outlet opening and, inside said chamber, a liquid distribution network, a body for bringing the liquid into direct contact with the gas placed under the distribution network, and liquid receiving devices as defined above arranged under said body to collect the liquid which flows therefrom.

- the devices for collecting a freely falling liquid in the form of rain represented in FIGS. 1 to 9 comprise, in known manner, a wall 1 inclined to the vertical and a chute 2 called main chute extending along the lower edge of the inclined wall 1.

- the inclined wall 1 which is planar is connected to the chute 2 by a rounded part 3 which extends downwards, towards the chute, by a short vertical part 4.

- the chute 2 has a rounded bottom 5 and two vertical edges 6 and 7 on either side, the one, the edge 6, is in the extension of the vertical part 4.

- the device shown in FIG. 1 comprises a horizontal succession of small inclined troughs 8 placed end to end on the vertical part 4.

- Each small inclined trough 8 comprises a flat bottom 9 fixed on the vertical part 4 and strongly inclined relative to the vertical and a vertical edge 10 which is extended by a horizontal strip 11 inclined towards the outside of the small inclined chute 8.

- the upper edge portions 10, as well as the bands 11 of the successive small inclined chutes are fixed between them.

- each small inclined chute 8 parallel to this bottom. It leaves each small inclined chute 8 having a significantly reduced vertical speed component and enters the main chute 2 in the direction of the flow of the liquid in this chute.

- each small inclined chute 12 consists of a half truncated cone whose small base 13 is closed and the large base is open.

- Each small inclined chute is fixed to the part 4 by one of its upper edges 14 arranged horizontally.

- the liquid is deflected by the bottom of each small inclined trough 12, parallel to this bottom and leaves each small inclined trough by the large base of the truncated cone, having a significantly reduced vertical speed component.

- the device shown in FIG. 3 comprises a horizontal succession of cups 15 arranged on the vertical part 4 and which each consist of a quarter of a sphere.

- Each bucket 15 deflects the liquid which flows on the wall 1 and sends it into the chute 2 with a component of vertical speed practically canceled.

- the device shown in FIG. 4 comprises a succession of ribs 16 arranged on the inclined wall 1 along the line of greatest slope.

- the lower part 17 of each of these ribs at the level of the rounded part 3 is curved in the direction of the flow of the liquid in the chute 2 and deflects the liquid flowing over the wall 1 in the direction of the flow of the liquid in this chute 2.

- the device shown in FIG. 5 comprises a succession of ribs 18 arranged on the wall 1 up to the inlet of the chute 2 and inclined in the direction of the flow of the liquid in the chute 2. Thanks to these ribs, the liquid flowing on the wall 1 receives a speed component in the direction of flow of the fluid in the chute 2.

- the device shown in FIG. 6 comprises a rib 19 parallel to the main chute 2 and disposed at the entrance of the latter on the vertical edge 6. This rib has the effect of "breaking" the flow of the liquid flowing on the inclined wall 1 when it arrives in the chute 2.

- the device shown in FIG. 7 comprises, on the one hand, nipples 20 projecting from the inclined wall intended to slow down the liquid flowing on this wall and, on the other hand, a grid 21 with fine meshes constituted by a lattice of metal wires and covering the chute 2.

- This grid 21 has, like the rib 19, the effect of "breaking" the flow of the liquid so as to practically cancel the speed of the liquid when it arrives in the chute 2.

- the device shown in FIG. 8 is a variant of FIG. 7 and comprises, in place of the grid with metallic wires, a grid 22 constituted by a plate provided with vertical channels.

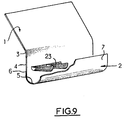

- the device shown in FIG. 9 is a combination of the devices shown in FIGS. 2 and 7 and includes a succession of small inclined troughs 23 in the form of half truncated cones constituted by a lattice of metal wires which, at the same time, practically cancel the speed of the liquid passing through them and divert the excess of the liquid in the direction of the flow of the liquid in the chute 2.

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Vaporization, Distillation, Condensation, Sublimation, And Cold Traps (AREA)

- Chutes (AREA)

- Physical Or Chemical Processes And Apparatus (AREA)

- Electrical Discharge Machining, Electrochemical Machining, And Combined Machining (AREA)

Claims (11)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT81401609T ATE3084T1 (de) | 1980-11-12 | 1981-10-15 | Vorrichtung zum sammeln einer freifallenden fluessigkeit und ihre anwendung in einer fluessigkeit-gas-gegenstromkontaktiereinrichtung |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR8024018 | 1980-11-12 | ||

| FR8024018A FR2493718A1 (fr) | 1980-11-12 | 1980-11-12 | Dispositif pour recueillir un liquide tombant librement et son application a une installation de mise en contact a contre-courant d'un liquide avec un gaz |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0052030A1 EP0052030A1 (de) | 1982-05-19 |

| EP0052030B1 true EP0052030B1 (de) | 1983-04-13 |

Family

ID=9247880

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP81401609A Expired EP0052030B1 (de) | 1980-11-12 | 1981-10-15 | Vorrichtung zum Sammeln einer freifallenden Flüssigkeit und ihre Anwendung in einer Flüssigkeit-Gas-Gegenstromkontaktiereinrichtung |

Country Status (5)

| Country | Link |

|---|---|

| US (2) | US4385010A (de) |

| EP (1) | EP0052030B1 (de) |

| AT (1) | ATE3084T1 (de) |

| DE (1) | DE3160185D1 (de) |

| FR (1) | FR2493718A1 (de) |

Families Citing this family (39)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FI65468C (fi) * | 1981-06-02 | 1984-05-10 | Kontekla Oy | Takbrunn eller liknande foer en byggnad |

| CH664591A5 (de) * | 1982-03-09 | 1988-03-15 | Kontekla Oy | Apparat fuer das abfuehren von wasser vom dach. |

| FR2529655B1 (fr) * | 1982-07-01 | 1986-05-16 | Hamon | Refrigerant atmospherique a ruissellement comportant des goulottes |

| DE3465775D1 (en) * | 1984-05-29 | 1987-10-08 | Gea Luftkuehler Happel Gmbh | Wet or combined wet-dry cooling tower |

| US5170597A (en) * | 1992-04-27 | 1992-12-15 | Stearns Carl D | Roof flashing with improved drip guard |

| US5487849A (en) * | 1993-12-03 | 1996-01-30 | Tower Tech, Inc. | Pultruded cooling tower construction |

| DE69427994T2 (de) * | 1993-12-03 | 2002-04-11 | Tower Tech, Inc. | Zweistufiges flüssigkeitssammelsystem |

| US5545356A (en) * | 1994-11-30 | 1996-08-13 | Tower Tech, Inc. | Industrial cooling tower |

| US5529365A (en) * | 1995-02-24 | 1996-06-25 | Saunders; Charles A. | Trim edging for motorcycle fairing |

| US5653068A (en) * | 1996-04-29 | 1997-08-05 | Moody; Ben A. | Water diverting strip |

| US5953861A (en) * | 1997-04-21 | 1999-09-21 | Podgwaite; Frank C. | Roof freeze protection apparatus and method |

| US5958306A (en) * | 1997-10-16 | 1999-09-28 | Curtis; Harold D. | Pre-collectors for cooling towers |

| US6151836A (en) * | 1997-10-30 | 2000-11-28 | Mcglothlin; W. Neal | Gutter system |

| US6527258B2 (en) * | 1999-03-19 | 2003-03-04 | Sulzer Chemtech Ag | Apparatus for the collection and distribution of liquid in a column |

| US6089188A (en) * | 1999-04-26 | 2000-07-18 | Corley; Mary Elizabeth | Animal spraying and scratching property protector |

| US6758463B2 (en) * | 2001-11-21 | 2004-07-06 | Air Products And Chemicals, Inc. | Liquid distributor internal baffling |

| US7100331B2 (en) * | 2002-06-03 | 2006-09-05 | Walter Wayne Nehring | Directional flow flashing |

| JP4554372B2 (ja) * | 2002-11-22 | 2010-09-29 | フルー・コーポレイシヨン | リブ付きダウンカマー壁の構成および方法 |

| WO2004091748A1 (en) * | 2003-04-07 | 2004-10-28 | Koch-Glitsch, Lp | Combined liquid collector and mixer for mass tranfer column |

| US7125004B2 (en) * | 2003-12-15 | 2006-10-24 | Koch-Glitsch, Lp | Liquid distributor for use in mass transfer column |

| US9463397B2 (en) * | 2008-04-04 | 2016-10-11 | Gtc Technology Us Llc | System and method for liquid distribution |

| MX2011009109A (es) * | 2009-03-03 | 2011-10-19 | Harol Dean Curtis | Enfriador/torre de enfriamiento de fluido de tiro forzado directo y colector de liquido para el mismo. |

| US20150330710A1 (en) * | 2009-03-03 | 2015-11-19 | Harold D. Curtis Revocable Trust | Direct Forced Draft Fluid Cooling Tower |

| US9273915B2 (en) * | 2009-07-17 | 2016-03-01 | Amistco Seperation Products, Inc. | Enhanced capacity, reduced turbulence, trough-type liquid collector trays |

| CA2689266A1 (en) * | 2009-12-23 | 2011-06-23 | Aker Solutions Canada Inc. | Improved distributor |

| FR2983079B1 (fr) * | 2011-11-30 | 2017-04-28 | Ge Energy Products France Snc | Module pour dispositif de generation d'au moins un rideau d'eau, et dispositif correspondant |

| EP2676738A1 (de) * | 2012-06-19 | 2013-12-25 | General Electric Company | Modul für eine Vorrichtung zur Erzeugung von mindestens einem Wasservorhang und entsprechende Vorrichtung |

| CN103234380B (zh) * | 2013-04-19 | 2016-03-09 | 国核电力规划设计研究院 | 一种冷却塔的集水装置和方法 |

| WO2015071822A1 (en) * | 2013-11-12 | 2015-05-21 | Stellenbosch University | Water collection trough assembly |

| US10107001B2 (en) | 2014-03-28 | 2018-10-23 | Syntech Towers, L.L.C. | CMU cooling tower and method of construction |

| US9612034B1 (en) * | 2015-11-04 | 2017-04-04 | Zdislav David Lasevski | Air conditioner water drop noise blocker |

| CN106931610B (zh) * | 2015-12-28 | 2020-09-08 | 夏普株式会社 | 给水装置以及包括给水装置的加湿器和净化器 |

| CN106091795B (zh) * | 2016-06-21 | 2019-05-07 | 四川中乙制冷设备有限公司 | 免风机节能冷却塔高效收水器 |

| US10844604B2 (en) | 2017-06-06 | 2020-11-24 | Roofers Advantage Products, LLC | Field shingle layout marks on roof drip edge |

| US10852079B2 (en) | 2017-07-24 | 2020-12-01 | Harold D. Curtis | Apparatus for cooling liquid and collection assembly therefor |

| CN109186314A (zh) * | 2018-10-29 | 2019-01-11 | 赵金海 | 一种冷却塔用底部鼓风装置 |

| KR102077521B1 (ko) * | 2019-02-18 | 2020-02-19 | 주식회사 오티티 | 충전재가 다단으로 형성되며 충전재 사이에 냉각수 혼합부가 설치된 냉각탑 |

| US11609051B2 (en) | 2020-04-13 | 2023-03-21 | Harold D. Revocable Trust | Apparatus for cooling liquid and collection assembly therefor |

| CN111750724B (zh) * | 2020-06-18 | 2021-04-20 | 上海交通大学 | 一种用于水流冷却降温的非能动脉冲式水流调节装置 |

Family Cites Families (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB1047454A (de) * | 1900-01-01 | |||

| US883632A (en) * | 1907-06-13 | 1908-03-31 | William Feyler | Eaves-trough and fastening therefor. |

| US1647281A (en) * | 1926-04-01 | 1927-11-01 | Frank M Doyle | Cooling tower |

| US2209741A (en) * | 1939-02-17 | 1940-07-30 | Leo E Sullivan | Roofing gutter and guard therefor |

| US2288121A (en) * | 1940-08-04 | 1942-06-30 | American Steel & Wire Co | Protector for eave troughs |

| US2626129A (en) * | 1950-02-24 | 1953-01-20 | Ind Manufacturers Ltd | Liquid distributor for cooling apparatus |

| GB734185A (en) * | 1951-03-27 | 1955-07-27 | Samuel Couzin | Improvements in installations for contacting liquids and gases particularly applicable to water cooling towers |

| US2669950A (en) * | 1952-10-08 | 1954-02-23 | George A Bartholomew | Nonclogging eaves structure |

| US3081987A (en) * | 1959-07-13 | 1963-03-19 | George W Meek | Cooling towers |

| FR1351499A (fr) * | 1962-12-20 | 1964-02-07 | Perfectionnements aux appareils refroidisseurs de liquide | |

| DE1484382B1 (de) * | 1964-02-18 | 1969-11-20 | Uhl & Moos Betonwaren Und Baus | Bauteilsatz aus Beton zur Herstellung von Schussgerinnen |

| DE1950241U (de) * | 1966-09-07 | 1966-11-24 | Maschb A G Balcke | Vorrichtung zur verminderung des wasserrauschens bei kuehltuermen. |

| US3611731A (en) * | 1968-12-27 | 1971-10-12 | Plastiers Ltd | Gutters and gutter fittings |

| DE2250776A1 (de) * | 1972-10-17 | 1974-04-18 | Schoell Guenter | Verfahren nebst vorrichtungen zur verminderung der pumpenarbeit fuer den kuehlwasserkreislauf in nasskuehltuermen |

| FR2407449A1 (fr) * | 1977-10-26 | 1979-05-25 | Hamon | Dispositif pour recueillir un liquide tombant librement et son application a une installation de mise en contact d'un liquide avec un gaz |

-

1980

- 1980-11-12 FR FR8024018A patent/FR2493718A1/fr active Granted

-

1981

- 1981-10-15 EP EP81401609A patent/EP0052030B1/de not_active Expired

- 1981-10-15 AT AT81401609T patent/ATE3084T1/de not_active IP Right Cessation

- 1981-10-15 DE DE8181401609T patent/DE3160185D1/de not_active Expired

- 1981-11-09 US US06/319,372 patent/US4385010A/en not_active Expired - Fee Related

-

1983

- 1983-01-03 US US06/455,253 patent/US4416835A/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| FR2493718A1 (fr) | 1982-05-14 |

| US4385010A (en) | 1983-05-24 |

| ATE3084T1 (de) | 1983-04-15 |

| US4416835A (en) | 1983-11-22 |

| EP0052030A1 (de) | 1982-05-19 |

| FR2493718B1 (de) | 1982-12-10 |

| DE3160185D1 (en) | 1983-05-19 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0052030B1 (de) | Vorrichtung zum Sammeln einer freifallenden Flüssigkeit und ihre Anwendung in einer Flüssigkeit-Gas-Gegenstromkontaktiereinrichtung | |

| FR2558247A1 (fr) | Ensemble collecteur d'egouttage et plateau collecteur de liquide pour tour de refroidissement | |

| EP0017517A2 (de) | Leitvorrichtung zur Mischung trockener und nasser paralleler Kühlluftströme | |

| CA2496512A1 (fr) | Simulateur de vol en chute libre | |

| FR2669000A1 (fr) | Dispositif pour collecter et detourner l'eau de pluie projetee vers le haut par une roue de vehicule. | |

| EP1034337B1 (de) | Wasserabführungseinrichtung | |

| EP0891461A1 (de) | Vorrichtung zum abführen des regenwassers von dächern | |

| FR2465166A1 (fr) | Dispositif de repartition d'air, en particulier pour air sursature | |

| FR2670718A1 (fr) | Canal d'aspiration d'air frais pour un vehicule automobile. | |

| FR3017634A1 (fr) | Descente d'eau pluviale en sortie d'une gouttiere de toit d'une construction | |

| FR2484072A1 (fr) | Dispositif destine a l'arrosage de plaques de ruissellement avec de l'eau de refroidissement a refroidir | |

| FR2702235A1 (fr) | Récepteur de réseaux d'assainissement en élévation avec déversoir d'orage, ouverture de surcharge et clapet de décharge. | |

| EP1496165B1 (de) | Öffentliche Sanitärvorrichtung mit einem Bodenreinigungsgerät | |

| CA1269961A (fr) | Dispositif de distribution d'un produit sur une surface | |

| CH615264A5 (en) | Ventilation device for buildings | |

| FR2675171A1 (fr) | Dispositif pour la recuperation de l'eau pluviale. | |

| EP0098770B1 (de) | Rieselkühlturm mit Rinnen | |

| FR3140497A1 (fr) | Système comprenant un panneau photovoltaïque et un répartiteur d’eau de pluie | |

| FR2713323A1 (fr) | Aéro-réfrigérants atmosphériques à ruissellement. | |

| FR2467375A1 (fr) | Installation pour la mise en contact d'un courant gazeux et d'un liquide | |

| FR2593483A1 (fr) | Dispositif pour le transport pneumatique ou hydraulique de matieres en vrac | |

| EP0626485A1 (de) | Regenwasserablaufvorrichtung | |

| EP1213235B1 (de) | Austragsvorrichtung für Silos | |

| EP0373089A1 (de) | Vorrichtung zum Waschen eines verunreinigten Gases | |

| EP2806081B1 (de) | Wasserkasten |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH DE FR GB IT LU NL SE |

|

| 17P | Request for examination filed |

Effective date: 19820413 |

|

| ITF | It: translation for a ep patent filed | ||

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH DE FR GB IT LI LU NL SE |

|

| REF | Corresponds to: |

Ref document number: 3084 Country of ref document: AT Date of ref document: 19830415 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 3160185 Country of ref document: DE Date of ref document: 19830519 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: LU Payment date: 19831019 Year of fee payment: 3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19831031 |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| 26 | Opposition filed |

Opponent name: GEA KUEHLTURMBAU UND LUFTKONDENSATION GMBH Effective date: 19831121 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19840925 Year of fee payment: 4 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 19840930 Year of fee payment: 4 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 19841004 Year of fee payment: 4 |

|

| PLBN | Opposition rejected |

Free format text: ORIGINAL CODE: 0009273 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: OPPOSITION REJECTED |

|

| 27O | Opposition rejected |

Effective date: 19850301 |

|

| NLR2 | Nl: decision of opposition | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 19860922 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19871031 Year of fee payment: 7 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Effective date: 19881015 Ref country code: GB Effective date: 19881015 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19881016 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Effective date: 19881031 Ref country code: LI Effective date: 19881031 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19890501 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee | ||

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19890701 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee | ||

| ITTA | It: last paid annual fee | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 19911113 Year of fee payment: 11 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Effective date: 19921031 |

|

| BERE | Be: lapsed |

Owner name: HAMON-SOBELCO S.A. Effective date: 19921031 |

|

| EUG | Se: european patent has lapsed |

Ref document number: 81401609.3 Effective date: 19890509 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19980928 Year of fee payment: 18 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000630 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |