EP0042806A1 - Dispositif à récurer - Google Patents

Dispositif à récurer Download PDFInfo

- Publication number

- EP0042806A1 EP0042806A1 EP19810401015 EP81401015A EP0042806A1 EP 0042806 A1 EP0042806 A1 EP 0042806A1 EP 19810401015 EP19810401015 EP 19810401015 EP 81401015 A EP81401015 A EP 81401015A EP 0042806 A1 EP0042806 A1 EP 0042806A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- pad

- foam

- pores

- paste

- abrasive

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

- 238000009991 scouring Methods 0.000 title claims abstract description 7

- 239000011148 porous material Substances 0.000 claims abstract description 16

- 239000006260 foam Substances 0.000 claims abstract description 15

- 238000004140 cleaning Methods 0.000 claims abstract description 13

- 239000002245 particle Substances 0.000 claims abstract description 8

- 239000003082 abrasive agent Substances 0.000 claims abstract description 4

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 claims description 10

- VTYYLEPIZMXCLO-UHFFFAOYSA-L Calcium carbonate Chemical compound [Ca+2].[O-]C([O-])=O VTYYLEPIZMXCLO-UHFFFAOYSA-L 0.000 claims description 8

- 239000011230 binding agent Substances 0.000 claims description 7

- 229920005830 Polyurethane Foam Polymers 0.000 claims description 6

- 239000011496 polyurethane foam Substances 0.000 claims description 6

- 239000003795 chemical substances by application Substances 0.000 claims description 5

- 239000000391 magnesium silicate Substances 0.000 claims description 5

- 229910052919 magnesium silicate Inorganic materials 0.000 claims description 5

- 235000019792 magnesium silicate Nutrition 0.000 claims description 5

- 239000000463 material Substances 0.000 claims description 5

- 238000005498 polishing Methods 0.000 claims description 5

- 239000000377 silicon dioxide Substances 0.000 claims description 5

- 229910000019 calcium carbonate Inorganic materials 0.000 claims description 4

- HCWCAKKEBCNQJP-UHFFFAOYSA-N magnesium orthosilicate Chemical compound [Mg+2].[Mg+2].[O-][Si]([O-])([O-])[O-] HCWCAKKEBCNQJP-UHFFFAOYSA-N 0.000 claims 1

- 229920001296 polysiloxane Polymers 0.000 claims 1

- 239000000203 mixture Substances 0.000 description 7

- ZADYMNAVLSWLEQ-UHFFFAOYSA-N magnesium;oxygen(2-);silicon(4+) Chemical compound [O-2].[O-2].[O-2].[Mg+2].[Si+4] ZADYMNAVLSWLEQ-UHFFFAOYSA-N 0.000 description 5

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 5

- 239000000843 powder Substances 0.000 description 4

- VBICKXHEKHSIBG-UHFFFAOYSA-N 1-monostearoylglycerol Chemical compound CCCCCCCCCCCCCCCCCC(=O)OCC(O)CO VBICKXHEKHSIBG-UHFFFAOYSA-N 0.000 description 3

- 229920002134 Carboxymethyl cellulose Polymers 0.000 description 3

- -1 brighteners Substances 0.000 description 3

- 239000001768 carboxy methyl cellulose Substances 0.000 description 3

- 235000010948 carboxy methyl cellulose Nutrition 0.000 description 3

- 239000008112 carboxymethyl-cellulose Substances 0.000 description 3

- 239000007787 solid Substances 0.000 description 3

- YKTSYUJCYHOUJP-UHFFFAOYSA-N [O--].[Al+3].[Al+3].[O-][Si]([O-])([O-])[O-] Chemical compound [O--].[Al+3].[Al+3].[O-][Si]([O-])([O-])[O-] YKTSYUJCYHOUJP-UHFFFAOYSA-N 0.000 description 2

- 239000001913 cellulose Substances 0.000 description 2

- 229920002678 cellulose Polymers 0.000 description 2

- 239000003599 detergent Substances 0.000 description 2

- 239000006185 dispersion Substances 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 229920003023 plastic Polymers 0.000 description 2

- 239000004033 plastic Substances 0.000 description 2

- 229920000728 polyester Polymers 0.000 description 2

- 229920002545 silicone oil Polymers 0.000 description 2

- 235000001674 Agaricus brunnescens Nutrition 0.000 description 1

- 235000013162 Cocos nucifera Nutrition 0.000 description 1

- 244000060011 Cocos nucifera Species 0.000 description 1

- DCXXMTOCNZCJGO-UHFFFAOYSA-N Glycerol trioctadecanoate Natural products CCCCCCCCCCCCCCCCCC(=O)OCC(OC(=O)CCCCCCCCCCCCCCCCC)COC(=O)CCCCCCCCCCCCCCCCC DCXXMTOCNZCJGO-UHFFFAOYSA-N 0.000 description 1

- 239000004743 Polypropylene Substances 0.000 description 1

- 238000005299 abrasion Methods 0.000 description 1

- 239000000654 additive Substances 0.000 description 1

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 1

- 229910052782 aluminium Inorganic materials 0.000 description 1

- 238000005282 brightening Methods 0.000 description 1

- 230000009172 bursting Effects 0.000 description 1

- 150000001875 compounds Chemical class 0.000 description 1

- 230000006835 compression Effects 0.000 description 1

- 238000007906 compression Methods 0.000 description 1

- 235000014113 dietary fatty acids Nutrition 0.000 description 1

- ZBCBWPMODOFKDW-UHFFFAOYSA-N diethanolamine Chemical compound OCCNCCO ZBCBWPMODOFKDW-UHFFFAOYSA-N 0.000 description 1

- 230000003670 easy-to-clean Effects 0.000 description 1

- 239000003995 emulsifying agent Substances 0.000 description 1

- 230000001804 emulsifying effect Effects 0.000 description 1

- 239000000194 fatty acid Substances 0.000 description 1

- 229930195729 fatty acid Natural products 0.000 description 1

- 150000004665 fatty acids Chemical class 0.000 description 1

- 239000010419 fine particle Substances 0.000 description 1

- 229920002457 flexible plastic Polymers 0.000 description 1

- 230000005484 gravity Effects 0.000 description 1

- 229910052500 inorganic mineral Inorganic materials 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 239000011707 mineral Substances 0.000 description 1

- 230000002093 peripheral effect Effects 0.000 description 1

- 229920001155 polypropylene Polymers 0.000 description 1

- 229920002635 polyurethane Polymers 0.000 description 1

- 239000004814 polyurethane Substances 0.000 description 1

- 238000007127 saponification reaction Methods 0.000 description 1

- 238000007790 scraping Methods 0.000 description 1

- 239000003381 stabilizer Substances 0.000 description 1

- 239000000080 wetting agent Substances 0.000 description 1

Images

Classifications

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L17/00—Apparatus or implements used in manual washing or cleaning of crockery, table-ware, cooking-ware or the like

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L13/00—Implements for cleaning floors, carpets, furniture, walls, or wall coverings

- A47L13/10—Scrubbing; Scouring; Cleaning; Polishing

- A47L13/16—Cloths; Pads; Sponges

- A47L13/17—Cloths; Pads; Sponges containing cleaning agents

Definitions

- the present invention relates to devices that can be used to clean household items, and more particularly to scour kitchen utensils.

- these projects could not be followed by satisfactory achievements.

- One of the reasons for this is that the abrasive material is consumed far too quickly compared to the life expectancy that one is entitled to expect from the sponge.

- the present invention makes it possible to avoid these drawbacks by virtue of the fact that most of the abrasive action is reserved for a synthetic foam pad to which a reservoir of cleaning paste is added, allowing each sample to be taken a little of paste to impregnate the tampon.

- the subject of the invention is a scouring device which comprises a pad of abrasive synthetic foam, with open pores, supported on a perforated wall of a tank of cleaning paste, containing an abrasive material with a particle size significantly smaller than the dimensions of buffer foam pores.

- the pad of the device according to the invention advantageously consists of a polyurethane foam with exploded pores.

- foams are known in themselves.

- the pore bursting technique as described for example in US Patent No. 3,175,025, results in a product in which at least 90%, and of preferably at least 95% of the pores are open and in which the walls of these open cells are relatively rigid, much more than in a flexible foam.

- the tampon may consist of a rigid type of foam, preferably based on polyurethane and with exploded pores, of thickness between 5 mm and 20 mm, of density on the order of 30 to 50 kg per m 3 and in which the cells or pores are of average dimensions, expressed for example by a number of 5 to 15 pores per linear centimeter.

- the rigidity of the foam, useful for the scraping action ensured by means of the pad, can result, for example, in a compressive strength of the order of 30 to 40 kpascal to 40%.

- the paste used in connection with such a pad, in a device according to the invention contains an abrasive powder, or possibly several abrasive powders of different natures, of relatively fine particle size, for example less than 500 microns. This allows the abrasive paste to play a polishing and polishing role, preventing scratches. From this point of view, it is possible in particular to use calcium carbonate and / or silica, with a particle size between 20 and 400 microns. An average particle size of the order of 30 to 100 microns is particularly advantageous.

- the abrasive powder is formed in the form of a paste with a viscosity advantageously of the order of 2000 to 6000 and preferably 3000 to 4500 centistock at 20 ° C., in a binder which may in particular be a mineral binder such as magnesium silicate and / or an organic binder such as cellulose binders, and more particularly carboxymethylcellulose.

- a binder which may in particular be a mineral binder such as magnesium silicate and / or an organic binder such as cellulose binders, and more particularly carboxymethylcellulose.

- the dough also contains other additives which are in themselves conventional, in particular agents wetting agents, emulsifiers, brighteners, and water to adjust viscosity.

- the proportion of abrasive powder which acts as a polishing agent is advantageously of the order of 40 to 80% by weight in the paste. If magnesium silicate (talc) or aluminum silicate is used as a binder, this has the advantage of simultaneously constituting a polishing agent.

- a preferred paste contains for example from 40 to 70% and preferably 35 to 50% of calcium carbonate and / or silica, from 5 to 15% by weight of aluminum or magnesium silicate and from 15 to 25% by weight.

- weight of emulsifying detergent the whole being in dispersion in water optionally added with approximately 0.5 to 5% by weight of cellulose binder.

- a brightening agent such as glycerol stearate, in proportion of the order of 1 to 5% by weight

- a dispersion stabilizer such as coconut diethanolamine

- silica has a particle size of 20 to 80 microns and aluminum silicate having a particle size of less than 60 microns is used instead of magnesium silicate.

- the compound known under the trade name SIPON is replaced by carboxymethylcellulose.

- the calcium carbonate can be removed and replaced with silica and the magnesium silicate can be replaced more or less completely with carboxymethylcellulose.

- the paste according to the preceding detailed composition has a kinematic viscosity of the order of 1200 cSk at 20 ° C. (test ASTM D445).

- this paste is contained in the reservoir so that it can be consumed through the pad of synthetic foam, impregnating it at each use, but also so that this pad is easy to clean after use, without any disassembly.

- the quantity of dough in the tank is advantageously of the order of 50 to 200 g initially.

- the reservoir can have various shapes, while still retaining the advantage of being able to be easily held in the hand and of allowing the user to easily maneuver the tampon without getting his hands dirty or even getting them wet.

- the reservoir containing the cleaning paste is closed by a perforated cover separate from the perforated wall which supports the tampon and distant from it so as to form an airlock through which it passes. the dough before impregnating the tampon.

- the mounting of the buffer on the device can also be carried out advantageously by means of the perforated wall, snapped onto the reservoir, above the cover.

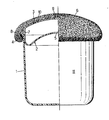

- the device according to the invention is shown partially in vertical section, partially in external view.

- the reservoir is formed by a container 1 of rigid or semi-rigid plastic material, here made of injected polypropylene, of cylindrical shape with a tight bottom. It may for example have a diameter of 55 mm and a height of 45 mm.

- a cover 2 forcibly engaged.

- this cover has a curved shape towards the outside, upwards in the figure, with however a periphery which rises along the side wall of the container 1 and which ends above this wall by a flange 4. It also comprises an orifice 5, in the axis of the device, which may for example have a diameter of the order of 5-8 mm.

- the device Over the cover 2, the device comprises a perforated wall 3 which supports the pad 6.

- the wall 3 is also curved outwards. It has an annular rim 7 which snaps into the rim 4 of the cover.

- a crown 8 engaged on the wall 3, extends beyond, over its entire periphery.

- the wall 3 has perforations, in particular in the case described, an orifice 9 in the axis, from 3 to 6 mm in diameter and four orifices 10 distributed around it, from 1 to 1.2 mm of diameter.

- the buffer 6 is mounted on the reservoir via the crown 8 and the wall 3. On its periphery, it is turned around the crown 8 to be wedged between it and the periphery of the reservoir.

- the wall 3 and the cover 2 can be made in one piece.

- the pad 6 has a mushroom cap shape on the container 1, with a peripheral overflow which allows the pad to access all the parts of the scouring utensil.

- the periphery of the crown can be made relatively flexible to increase this effect.

- the space between the cover 2 and the upper wall 3 constitutes an airlock in which the cleaning paste penetrates by gravity through the orifice 5.

- this paste dilutes and impregnates the tampon through the openings 9 and 10 and over its entire surface.

- a suction effect of the diluted paste is created which can be further promoted if the support wall 3 is made of relatively flexible plastic.

- the pad is produced by an 11 mm thick layer of polyurethane foam of the type sold under the name V10 by the company Reisgies, having a density of 35 kg / m 3 and a resistance to compression of 35 kpascal to 40% and comprising approximately 10 pores per linear centimeter. It is a foam formed in the presence of silicone oil from a polyester prepolymer. It has self-cleaning qualities which mean that after each use the tampon is easily rid of the excess cleaning paste by passage under water and that it remains clean after each use. But it enters the tank enough moisture to keep the dough always at the right screw cosity.

- the pad is impregnated with an abrasive paste having essentially the same composition as that of the paste contained in the reservoir, but which is in the form of a mass to both solid and flexible which softens easily as soon as it comes into contact with water.

- the paste of the specific composition indicated above can be made solid by a saponification reaction when a proportion of 10 to 30% of fatty acid such as stearin is added, the proportion being in relation to the solid components of the dough.

- the invention is not limited to the particular nature of the polyurethane foam used, or to the particular composition of the cleaning paste, no more than to the form of reservoir described by way of example.

- a cap of any desired material to constitute the surface of the tampon; for example, a metallic net easily clings to the surface of the tampon, to which it gives its own appearance and properties.

Landscapes

- Cleaning Implements For Floors, Carpets, Furniture, Walls, And The Like (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR8014073A FR2485362A1 (fr) | 1980-06-25 | 1980-06-25 | Dispositif a recurer |

| FR8014073 | 1980-06-25 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| EP0042806A1 true EP0042806A1 (fr) | 1981-12-30 |

Family

ID=9243486

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP19810401015 Ceased EP0042806A1 (fr) | 1980-06-25 | 1981-06-24 | Dispositif à récurer |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP0042806A1 (OSRAM) |

| FR (1) | FR2485362A1 (OSRAM) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0103818A1 (en) * | 1982-09-21 | 1984-03-28 | Miles Laboratories, Inc. | Device for cleaning soil from soiled surfaces |

| WO1996033650A1 (en) * | 1995-04-24 | 1996-10-31 | S.C. Johnson & Son, Inc. | Cleaning system |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CH280116A (fr) * | 1949-10-26 | 1952-01-15 | Mestral Gerard De | Installation pour laver la vaisselle et les ustensiles de cuisine. |

| FR1243684A (fr) * | 1959-12-24 | 1960-10-14 | Dispositif pour le nettoyage d'articles ménagers | |

| US3581447A (en) * | 1969-04-21 | 1971-06-01 | Colgate Palmolive Co | Reversible scouring pad |

| FR2066293A5 (OSRAM) * | 1969-10-23 | 1971-08-06 | Roth Gmbh Chemische | |

| GB1325295A (en) * | 1971-05-07 | 1973-08-01 | Ross J C | Applicator for liquids |

| DE2504177A1 (de) * | 1974-04-01 | 1975-10-09 | Kores Holding Zug Ag | Reinigungsgeraet |

-

1980

- 1980-06-25 FR FR8014073A patent/FR2485362A1/fr active Granted

-

1981

- 1981-06-24 EP EP19810401015 patent/EP0042806A1/fr not_active Ceased

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CH280116A (fr) * | 1949-10-26 | 1952-01-15 | Mestral Gerard De | Installation pour laver la vaisselle et les ustensiles de cuisine. |

| FR1243684A (fr) * | 1959-12-24 | 1960-10-14 | Dispositif pour le nettoyage d'articles ménagers | |

| US3581447A (en) * | 1969-04-21 | 1971-06-01 | Colgate Palmolive Co | Reversible scouring pad |

| FR2066293A5 (OSRAM) * | 1969-10-23 | 1971-08-06 | Roth Gmbh Chemische | |

| GB1325295A (en) * | 1971-05-07 | 1973-08-01 | Ross J C | Applicator for liquids |

| DE2504177A1 (de) * | 1974-04-01 | 1975-10-09 | Kores Holding Zug Ag | Reinigungsgeraet |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0103818A1 (en) * | 1982-09-21 | 1984-03-28 | Miles Laboratories, Inc. | Device for cleaning soil from soiled surfaces |

| US4475835A (en) * | 1982-09-21 | 1984-10-09 | Miles Laboratories, Inc. | Device for cleaning soil from oven surfaces |

| WO1996033650A1 (en) * | 1995-04-24 | 1996-10-31 | S.C. Johnson & Son, Inc. | Cleaning system |

Also Published As

| Publication number | Publication date |

|---|---|

| FR2485362A1 (fr) | 1981-12-31 |

| FR2485362B1 (OSRAM) | 1984-02-24 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2849625B1 (fr) | Éponge à cavité débouchante | |

| FR2759873A1 (fr) | Dispositif d'application d'un produit de maquillage de fibres keratiniques, notamment des cils, et ensemble de conditionnement et d'application utilisant un tel dispositif | |

| FR2472046A1 (fr) | Distributeur d'agent de conditionnement, notamment pour le blanchissage du linge et ensemble le comportant | |

| EP0042806A1 (fr) | Dispositif à récurer | |

| TR202013110A2 (tr) | Temi̇zli̇k kovasinda yeni̇li̇k | |

| FR2462153A1 (fr) | Article absorbant notamment serviette hygienique | |

| CN103458933B (zh) | 用于清洁用具的抗菌支持器 | |

| EP0564362B1 (fr) | Dispositif pour imprégner de peinture un outil d'application | |

| FR2531853A1 (fr) | Tampon pour le traitement, le nettoyage et le polissage a longue conservation, en particulier des verres de lunettes | |

| FR3104009A1 (fr) | Procédé de remplissage d’un dispositif de conditionnement et de distribution d’une composition cosmétique | |

| CN202477621U (zh) | 内置喷头的洗涤刷 | |

| FR2653059A1 (fr) | Article pour traitement de surface contenant un materiau de traitement loge in situ et liberable au moment de l'utilisation. | |

| FR2538303A1 (fr) | Procede pour la realisation d'un produit composite pourvu d'une couche de surface en resine polyester et produit ainsi obtenu | |

| EP3871581B1 (fr) | Eponge grattante non rayante | |

| JP3190819U (ja) | 食器洗い泡立てスポンジ | |

| EP0987097B1 (fr) | Têtes de balai à franges lavantes et asséchantes | |

| US6596676B1 (en) | Protective composition and method for ovens | |

| US20070205200A1 (en) | Soap bar holder and method of supporting a soap bar | |

| FR2804313A1 (fr) | Applicateur pour produit visqueux | |

| JP3074300U (ja) | 竹炭クリーナー | |

| JP2004174293A (ja) | 部分洗浄補助具 | |

| BE509602A (OSRAM) | ||

| US20150196184A1 (en) | Multi-purpose cleaning device | |

| WO2004011277A2 (fr) | Bac de mouillage pour pinceau et boite de peinture equipee dudit bac | |

| FR2997005A1 (fr) | Dispositif pour l'impregnation et l'essorage d'un ustensile de traitement de surface relie a un manche |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): BE DE FR GB IT SE |

|

| 17P | Request for examination filed |

Effective date: 19820521 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION HAS BEEN REFUSED |

|

| 18R | Application refused |

Effective date: 19840603 |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: AMANN, ANDRE |