EP0033320B1 - Transfer apparatus and printing machine for sheets - Google Patents

Transfer apparatus and printing machine for sheets Download PDFInfo

- Publication number

- EP0033320B1 EP0033320B1 EP19800901275 EP80901275A EP0033320B1 EP 0033320 B1 EP0033320 B1 EP 0033320B1 EP 19800901275 EP19800901275 EP 19800901275 EP 80901275 A EP80901275 A EP 80901275A EP 0033320 B1 EP0033320 B1 EP 0033320B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- sheets

- sheet

- conveyor

- path

- edge

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41F—PRINTING MACHINES OR PRESSES

- B41F23/00—Devices for treating the surfaces of sheets, webs, or other articles in connection with printing

- B41F23/04—Devices for treating the surfaces of sheets, webs, or other articles in connection with printing by heat drying, by cooling, by applying powders

- B41F23/044—Drying sheets, e.g. between two printing stations

- B41F23/0443—Drying sheets, e.g. between two printing stations after printing

Definitions

- This invention relates to transfer apparatus for sheets, particularly but not exclusively in connection with printing machines for printing sheets of metal or other non-limp material. It is also concerned with such printing machines per se.

- first horizontal conveyor feeds each sheet between a respective pair of wickets or oven trays secured to and upstanding from a second horizontal conveyor, and each sheet is then continuously advanced by the wickets, first through a heating station in the form of an oven for curing the ink, and then a cooling station where the sheet is cooled before being discharged from the wickets at a downstream end of the second conveyor on to a stack of printed sheets.

- the printing ink application station, the oven and the cooling station are arranged in line with each other, with the result that they occupy extensive floor space.

- the wickets comprise metal lattices which provide support for the sheets whilst allowing air to circulate freely around the sheets in the oven and the cooling station.

- heating of the sheets in the curing oven to the correct temperature for curing the ink is delayed until the wickets themselves reach this temperature.

- the second conveyor may have to have as many as 4,000 wickets.

- steel can ends are conveyed flat along a first conveyor to a magnetic roll which rotates the ends through approximately 90°.

- a stationary chute extending from an upper region of the roll receives the ends and allows them to accumulate on the chute in nesting relationship with each other.

- One object of the present invention is to provide sheet transfer apparatus, having means providing a magnetic field to cause sheets of magnetisable material to follow a conveyor path, conveyor means arranged downstream of the path for advancing the sheets on edge and in face-to-face spaced relation, for example through a cooling station of a printing machine according to the invention.

- a further object of the invention is to provide a printing system occupying less floor space than the system just described. Another object is to provide a compact transfer arrangement for use in such a system, for transferring sheets from the curing oven to the cooling station.

- Another object is to provide sheet transfer apparatus which is suitable for use in a printing system in place of the abovementioned wicket- carrying further conveyor and which eliminates or reduces at least some of the disadvantages mentioned above.

- a further object of the invention is to provide sheet transfer apparatus wherein magnetic fields or equivalent means are provided to support the sheets during a portion of their travel so that the number of moving parts in the apparatus may be reduced by comparison with the earlier apparatus (including the wicket- carrying type of conveyor).

- Yet another object is to reduce the size and complexity of curing ovens by eliminating the use of wickets.

- the invention provides transfer apparatus for sheets, said apparatus comprising sheet-advancing means arranged continuously to advance the sheets in succession in edge-to-edge relationship along a predetermined path; conveyor means which are so spaced from an upwardly-inclined downstream end portion of the sheet-advancing means at the downstream end of said path that sheets arriving at said end of the path are carried therefrom by their own momentum towards the conveyor means, the conveyor means having means for locating the leading edges of the sheets thereon and support means for receiving the trailing edges of the sheets falling thereon, the conveyor means being arranged to advance the sheets on edge, away from said end portion in spaced, face-to-face relationship.

- the invention provides a printing machine for sheets, comprising a printer; horizontally-extending ink-curing means for curing ink on the sheets by application of heat; cooling means below the ink-curing means; and transfer apparatus for transferring a succession of the printed sheets from the curing means to the cooling means, the curing means being arranged to operate with the sheets moving therethrough in a first direction in edge-to-edge relationship in substantially the same plane, and the transfer apparatus being adapted to turn the direction of motion of said sheets through an angle such that, upon transfer to the cooling means, one face of each sheet is facing in a second direction substantially opposite to said first direction, the cooling means having conveyor means for advancing the sheets in said second direction on edge, in spaced, face-to-face relationship.

- the curing oven can have a conveyor for carrying sheets through the oven substantially flat thereon, thus permitting direct flame curing, the sheets then being transferred to the cooling station by the transfer apparatus which preferably has magnetic means for holding the sheets as they are advanced to the cooling station.

- the conveyor of the cooling station may conveniently have magnetic means for locating the edges of sheets thereon.

- Such apparatus has the advantage when used in a printing machine that less space and energy may be used for heating the sheets for curing the printing ink in the absence of wickets. Additionally, it is expected that elimination of the wickets will reduce both the initial and maintenance costs of the machine, the latter because the reduction in moving parts tends to cut down wear.

- a further advantage is that relative timing of the conveyors is less critical than when a feed conveyor has to feed the sheets between the closely spaced wickets of the oven conveyor.

- the machine includes a destacker 10 having a frame 12 which supports a vertically-movable table 14.

- the table 14 carries a pallet 16 bearing a stack of metallic sheets 18.

- a pair of discharge rollers 20 are arranged for supplying the uppermost sheet 18 to a printer 22.

- the printer 22 has an inlet conveyor arranged to receive each sheet 18 from the rollers 20, and a rotary printing drum 26 mounted in a frame 28 to accept sheets from the inlet conveyor.

- the drum 26 is arranged to carry the sheets past ink applicators 30 and discharge them on to a feed conveyor 32 which extends between the printer 22 and a long, horizontally-extending curing oven 34.

- a horizontal oven conveyor 36 has an upper stringer 38 passing through the oven 34 on a support plate 40.

- This conveyor comprises a pair of endless steel belts extending around an idle pulley 42 and a driven pulley 44.

- heat from a flame burner unit indicated diagrammatically at 35 is directed straight on to sheets 18 carried on the upper stringer 38 of the conveyor 36, whilst downstream of the burner unit, there is provided a heated air zone for blowing away solvent evaporated from the hot sheets by directing heated air at the sheets under pressure.

- the downstream end 46 of the oven conveyor 36 is arranged to discharge the sheets on to a transfer conveyor 48 of the transfer apparatus 47, by way of an intermediate conveyor 50 comprising steel belts 51 mounted on rotatable idle pulleys 52 and further pulleys 54 carried by a driven shaft 55.

- the transfer conveyor 48 follows a path 56 which is partly curved and partly straight in a vertical plane, and which turns through approximately 260°.

- the conveyor path 56 is at least partially defined by an elongate steel plate 58. Endless conveyor belts 60 are moved along the plate 58 by further pulleys 54 carried by the driven shaft 55, and extend around idle pulleys 62 and adjustable tensioning pulley 64.

- the belts 60 are driven by the pulleys on shaft 55 along the outside of the plate 58. Behind the plate 58, in relation to the belts 60, there is fixed a series of permanent magnets 66. These are mounted between a pair of fixed side supports 68 which also carry the plate 58 and which in turn are carried by a fixed frame 70 of the transfer apparatus. A magnetic field is thus created along the conveyor path 56 to hold the sheets 18 against the belts 60, thus causing the sheets to be carried around the path 56 by the latter.

- the magnets 66 are arranged along substantially the whole of the path 56. However, those in the upwardly-inclined final part 72 of the curved path 56, i.e.

- the upwardly-inclined final part of the conveyor path 56 is directed towards the lower stringer of a horizontal cooling station conveyor or cooler conveyor 74 which is arranged below the oven conveyor 36.

- the cooler conveyor 74 comprises a pair of endless steel belts 76 extending around driven pulleys 78, a pair of freely rotatable idle pulleys 80, 82 and adjustable tensioning pulleys 84 ( Figure 4).

- the pulleys 78, 80 are adjustable in a vertical direction (by means not shown), to alter the height of the lower stringer 75 as desired.

- a horizontal magnetic rail 85 typically comprising a flat steel plate 86 above which a series of permanent magnets 88 are fixed between a pair of fixed side supports 90 carrying the plate 86.

- the magnets 88 provide a magnetic field for holding the upper edges 19 of the sheets 18 leaving the transfer conveyor 48 against the lower stringer of conveyor 74, so that the sheets are thereafter suspended from the cooler conveyor 74.

- a horizontal drag rail 92 spaced below the magnetic rail 85 serves to hold the sheets in compression, in slightly bowed form as seen in Figures 3 and 4, against the rail 85 so that they cannot swing into and scratch or scuff one another and to preserve a gap 91 (typically of 2.5 cm) between each sheet and the next.

- the cooler conveyor 74 passes through a cooling station 93.

- a blower (diagrammatically indicated at 94) or other suitable means for directing cooling air at the sheets 18 as they travel along the cooler conveyor 74.

- the air-directing means 94 are not, however, an essential part of the printing system since the sheets may sometimes be cooled in the station 93 merely by contact with the atmosphere during their advance by the conveyor 74.

- a stacking device 96 ( Figures 1 and 4) is arranged to receive the sheets 18.

- This device 96 comprises a table 98 mounted on a stand 100 and forwardly inclined to the horizontal, so that the rear, higher edge of the table is located adjacent to a downstream end of the rail 92. The latter terminates in advance of the magnetic rail 85 as seen in Figure 4. The downstream end of the rail 85 thus lies above the table 98.

- Upwardly-extending fingers 102 at a lower edge and sides of the table 98 serve to position the sheets on the table in a stack.

- the sheet 18 is conveyed by the belts 60, with its unprinted face against the plate 58, along the path 56 and assumes a tangential relationship with the path where the latter is curved.

- the magnetic field provided by the magnets 66 holds the sheet 18 against the belts 60 as the sheet is carried thereby from the horizontal intermediate conveyor 50, around the path 56, until the sheet is upwardly inclined at the downstream end 72 of the path 56 with its upper edge 19 facing toward the cooler conveyor 74.

- the sheet 18 continues to advance towards the conveyor 74 under its own momentum, the diminishing local magnetic field of the transfer conveyor 48, due to the weak magnets 66A, no longer determining the direction of motion of the sheet 18, which instead comes under the influence of the magnets 88.

- the sheet 18 is flung from the transfer conveyor 48 in the direction of the cooler conveyor 74.

- the relative positioning of the conveyors 48, 74, and the speed of the belts 60 is selected to be such that the kinetic energy of the sheet leaving the transfer conveyor is mostly, but not quite entirely, converted into potential energy.

- the leading edge 19 of the sheet just reaches the underside of the cooler conveyor 74 and is held against the belts 76 of the latter by the magnets 88.

- the reduced magnetic field provided by the magnets 66A and the downstream end of the path 56 allows the trailing edge of the sheet 18 to leave the path 56; and as the belts 76 of the cooler conveyor 74 advance the uppermost edge 19 of the sheet, its lowermost edge slides along the drag rail 92. The sheet is thus prevented from swinging into the sheet in front, the gap 91 being in this way maintained.

- the sheet 18 is advanced by the belts 76 relatively slowly by comparison with the speed of the sheet on the oven and transfer conveyors 36, 48, this being possible since the distance between one sheet and the next can be very much smaller when they are suspended face to face, as in the conveyor 74, than when they lie flat in edge-to-edge relationship as on the transfer conveyor 48.

- the conveyor 74 can achieve a similar throughput to the conveyor 36 with a much slower rate of advance.

- the sheet 18, whilst being advanced by the cooler conveyor 74, is cooled down as already mentioned, and is finally stacked on the preceding sheets by delivery on to the device 96.

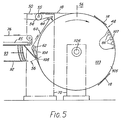

- Figure 5 shows a large diameter wheel 103, in the form of a pair of identical discs 105 mounted on a rotatable shaft 106, which may be driven through suitable gearing by the main driver motor (not shown) of the machine.

- the belts 60 extend around the wheel 103, the wheel may freely rotate with the belts 60, the latter being driven as before by the pulleys 54 on the shaft 55.

- the wheel 103 takes the place of the fixed plate 58 and its associated parts 68 shown in Figure 3.

- the magnets 66 are located in the periphery of the wheel and all are of the same field strength.

- a cylindrical plate 107 may be provided about the rim of the wheel 103, the belts 60 bearing on the plate 107.

- the conveyor path 56 extends between the two arrows 56 in Figure 5, and at the downstream end 108 of the path, the belts 60 are diverted by the pulley 62 away from the wheel 103, thus weakening the magnetic field due to magnets 66 exerted on the sheets 18 and enabling the latter to be flung as already described into engagement with the cooler conveyor 74.

- the pulley 62 may be omitted, the belts 60 then following the rim of the wheel 103 well beyond the point 108 (as indicated by a phantom line in Figure 5).

- a fixed plough 104 may then be provided to divert each sheet 18 from contact with the wheel-type transfer conveyor 48 and towards the cooler conveyor 74.

- the belt 60 may be omitted, the intermediate conveyor being extended so as to transfer the sheets direct on to the rim of the wheel 103, over a deadplate if necessary. The sheets will then be carried round in direct contact with the rim of the wheel until diverted therefrom by the plough 104 and flung by their own momentum towards the cooler conveyor 74.

- the transfer conveyor 48 in either of the embodiments described, may employ air suction in known manner.

- the magnets 88 of the cooler conveyor may be absent, the lower stringer of the belts 76 being provided with for example dogs against which the sheet edges 19 impinge as they are flung from the transfer conveyor. The lower edges of the sheets will then fall on to the rail 92-as before.

- the sheets need not be of magnetisable material but may be of any non-limp material capable of being handled by the apparatus, for example relatively thick cardboard, non-magnetic metals, or certain plastics.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Discharge By Other Means (AREA)

- Supply, Installation And Extraction Of Printed Sheets Or Plates (AREA)

- Belt Conveyors (AREA)

- Delivering By Means Of Belts And Rollers (AREA)

- Specific Conveyance Elements (AREA)

- Ink Jet (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| GB7926889 | 1979-08-02 | ||

| GB7926889 | 1979-08-02 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0033320A1 EP0033320A1 (en) | 1981-08-12 |

| EP0033320B1 true EP0033320B1 (en) | 1983-05-25 |

Family

ID=10506938

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP19800901275 Expired EP0033320B1 (en) | 1979-08-02 | 1981-02-24 | Transfer apparatus and printing machine for sheets |

Country Status (7)

| Country | Link |

|---|---|

| EP (1) | EP0033320B1 (enExample) |

| JP (1) | JPH0151425B2 (enExample) |

| BE (1) | BE884615A (enExample) |

| DE (1) | DE3063478D1 (enExample) |

| DK (1) | DK198181A (enExample) |

| ES (1) | ES493907A0 (enExample) |

| WO (1) | WO1981000377A1 (enExample) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102018205157A1 (de) * | 2018-04-05 | 2019-10-10 | Ekra Automatisierungssysteme Gmbh | Druckvorrichtung |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3216127A (en) * | 1962-02-09 | 1965-11-09 | Universal Oil Prod Co | Coating oven with catalytic incineration of volatiles |

| US3109532A (en) * | 1962-07-02 | 1963-11-05 | Magnatron Corp | Magnetic conveyor |

| DE2104440C3 (de) * | 1971-01-30 | 1974-07-11 | Windmoeller & Hoelscher, 4540 Lengerich | Vorrichtung zum Ablegen von ohne Überlappung hintereinander voranbewegten, flachen, schmiegsamen Werkstücken, z.B. Schlauchstücken |

| JPS5012826A (enExample) * | 1973-06-05 | 1975-02-10 | ||

| US4085673A (en) * | 1974-08-12 | 1978-04-25 | Xerox Corporation | Sheet feeding apparatus |

-

1980

- 1980-07-25 JP JP55501523A patent/JPH0151425B2/ja not_active Expired

- 1980-07-25 WO PCT/GB1980/000122 patent/WO1981000377A1/en not_active Ceased

- 1980-07-25 DE DE8080901275T patent/DE3063478D1/de not_active Expired

- 1980-07-31 ES ES493907A patent/ES493907A0/es active Granted

- 1980-08-01 BE BE0/201638A patent/BE884615A/fr unknown

-

1981

- 1981-02-24 EP EP19800901275 patent/EP0033320B1/en not_active Expired

- 1981-05-04 DK DK198181A patent/DK198181A/da unknown

Also Published As

| Publication number | Publication date |

|---|---|

| BE884615A (fr) | 1980-12-01 |

| JPS56500962A (enExample) | 1981-07-16 |

| ES8105634A1 (es) | 1981-06-16 |

| DK198181A (da) | 1981-05-19 |

| DE3063478D1 (en) | 1983-07-07 |

| WO1981000377A1 (en) | 1981-02-19 |

| ES493907A0 (es) | 1981-06-16 |

| JPH0151425B2 (enExample) | 1989-11-02 |

| EP0033320A1 (en) | 1981-08-12 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US8047535B2 (en) | Apparatus and method for conveying a sheet | |

| US5052667A (en) | Device for the collection of folded printed sheets | |

| US4817934A (en) | Dual tote sorter and stacker | |

| EP1803668B1 (en) | Feeder with adjustable time cycle and method | |

| US3968960A (en) | Sheet inverting and stacking apparatus | |

| US4579330A (en) | Pneumatic sheet feeder | |

| US4058908A (en) | Apparatus for drying flat printed material | |

| JP2005015229A (ja) | 搬出装置 | |

| CA1221712A (en) | Tail stopping and knockdown device | |

| JPH0578000A (ja) | 鱗状に重り合つた一連の物品の形成装置 | |

| US2474997A (en) | Sheet delivery controlling method and means therefor | |

| US20070040316A1 (en) | Device for inserting sheets into an envelope | |

| GB1118471A (en) | Method and apparatus for attaching cans to carriers | |

| EP0033320B1 (en) | Transfer apparatus and printing machine for sheets | |

| US3120384A (en) | Pneumatic sheet stacking mechanism | |

| JPH10273219A (ja) | 扁平箱状物品の切出しコンベヤ装置 | |

| US4087087A (en) | Sheet stacking apparatus for sorter | |

| GB2055696A (en) | Sheet printing machine | |

| US3101942A (en) | Pressure vacuum stacker | |

| US3032340A (en) | Sheet handling apparatus | |

| EP0768260B1 (en) | Paper handling apparatus | |

| CN211619511U (zh) | 喷码点数收料机 | |

| JPH08301513A (ja) | シートソーティング装置 | |

| JP2009221019A (ja) | 印刷製品を引継および引渡しするための搬送装置 | |

| EP2206669B1 (en) | Method for conveying a series of veneer sheets and the use of an apparatus for succesively conveying a series of veneer sheets |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19810521 |

|

| AK | Designated contracting states |

Designated state(s): DE FR GB NL SE |

|

| DET | De: translation of patent claims | ||

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: METAL BOX P.L.C. |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Designated state(s): DE FR GB NL SE |

|

| REF | Corresponds to: |

Ref document number: 3063478 Country of ref document: DE Date of ref document: 19830707 |

|

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19900611 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19900614 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 19900615 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19900629 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19900731 Year of fee payment: 11 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19910725 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19910726 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19920201 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee | ||

| GBPC | Gb: european patent ceased through non-payment of renewal fee | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19920331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19920401 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| EUG | Se: european patent has lapsed |

Ref document number: 80901275.0 Effective date: 19920210 |