CN219069393U - Pretreatment desilt cleaning equipment for potato processing - Google Patents

Pretreatment desilt cleaning equipment for potato processing Download PDFInfo

- Publication number

- CN219069393U CN219069393U CN202320085194.4U CN202320085194U CN219069393U CN 219069393 U CN219069393 U CN 219069393U CN 202320085194 U CN202320085194 U CN 202320085194U CN 219069393 U CN219069393 U CN 219069393U

- Authority

- CN

- China

- Prior art keywords

- conveyor belt

- circulating conveyor

- pretreatment

- cleaning

- brush

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02A—TECHNOLOGIES FOR ADAPTATION TO CLIMATE CHANGE

- Y02A40/00—Adaptation technologies in agriculture, forestry, livestock or agroalimentary production

- Y02A40/90—Adaptation technologies in agriculture, forestry, livestock or agroalimentary production in food processing or handling, e.g. food conservation

Landscapes

- Apparatuses For Bulk Treatment Of Fruits And Vegetables And Apparatuses For Preparing Feeds (AREA)

Abstract

The utility model belongs to the technical field of vegetable washer production, and particularly relates to pretreatment desilt washing equipment for potato processing, which comprises a rack and a first circulating conveyor belt, wherein the first circulating conveyor belt penetrates through a brushing section and a washing section; a second circulating conveyor belt is arranged in the brushing section and is positioned above the first circulating conveyor belt; the surfaces of the second circulating conveyor belt and the first circulating conveyor belt are provided with hairbrush layers; compared with the prior art, the potato pretreatment desilting and cleaning method has the advantages that (1) the potatoes with soil on the surfaces smoothly enter between the second circulating conveyor belt and the first circulating conveyor belt, and the potatoes with soil on the surfaces continuously roll between the two belts due to the speed difference between the two belts, so that the brush layers on the surfaces of the first circulating conveyor belt and the second circulating conveyor belt can brush the soil on the surfaces of the potatoes comprehensively; (2) The wetting spray head cleans the brush layer of the second circulating conveyor belt, and the cleaning spray head cleans the brush layer of the first circulating conveyor belt.

Description

Technical Field

The utility model belongs to the technical field of vegetable washer production, and particularly relates to pretreatment desilting and cleaning equipment for potato processing.

Background

After the potatoes are dug out of the soil, a series of impurity removal steps such as cleaning are needed, and impurities such as soil in the potatoes can be put into the subsequent processing steps after the impurities such as the soil in the potatoes are cleaned; but at present, when potatoes are cleaned through cleaning equipment, the potatoes are all piled up and then are cleaned through clear water in a static state, so that impurities such as soil on the potatoes are not thoroughly cleaned, and meanwhile, the potatoes cannot be timely air-dried after being cleaned, so that the conditions of rotting or bacteria breeding of the potatoes are easily caused, and the quality of subsequent potato processing is seriously affected.

Disclosure of Invention

The utility model provides pretreatment desilt cleaning equipment for potato processing aiming at the problems in the potato cleaning process.

In order to achieve the above purpose, the utility model adopts the following technical scheme: the pretreatment desilt cleaning equipment for potato processing comprises a rack and a first circulating conveyor belt, wherein the rack comprises a brushing section and a cleaning section which are arranged from front to back, and the circulating conveyor belt penetrates through the brushing section and the cleaning section; a second circulating conveyor belt is arranged in the brushing section and is positioned above the first circulating conveyor belt; the surfaces of the second circulating conveyor belt and the first circulating conveyor belt are provided with hairbrush layers; when potatoes are placed on the conveying surface of the first circulating conveyor belt, the brush layer on the second surface of the circulating conveyor belt can be in contact with the surfaces of the potatoes; the inlet of the brushing section is provided with a wetting spray head.

Preferably, the second endless conveyor belt and the first endless conveyor belt are both mesh belt type endless conveyor belts.

Preferably, the brush layer includes a plurality of brush units, each of the brush units including a brush substrate and having a length direction perpendicular to a conveying direction of the endless conveyor belt two and the endless conveyor belt one.

Preferably, the second circulating conveyor belt is driven by a first servo motor; the first circulating conveyor belt is driven by a second servo motor.

Preferably, the cleaning section is provided with a plurality of cleaning spray heads; the cleaning spray head and the wetting spray head are respectively connected with an external water supply device through pipelines.

Preferably, a waste water collecting tank is arranged below the frame, a filtering device is arranged at the outlet of the waste water collecting tank, and one side, far away from the waste water collecting tank, of the filtering device is communicated with an external water supply device.

Preferably, the wetting spray head is obliquely arranged, and the water outlet faces the end part of the second circulating conveyor belt, which is close to the inlet of the brushing section.

Preferably, the frame is provided with baffles at both sides of the endless conveyor belt perpendicular to the conveying direction.

Preferably, the first endless conveyor is a low-speed clockwise endless conveyor, and the second endless conveyor is a high-speed counterclockwise endless conveyor.

Compared with the prior art, the utility model has the advantages and positive effects that:

compared with the prior art, the pretreatment desilt washing method for potato processing comprises the steps of (1) using the first circulating conveyor belt as a low-speed clockwise circulating conveyor belt and using the second circulating conveyor belt as a high-speed anticlockwise circulating conveyor belt, so that potatoes with soil on the surfaces smoothly enter between the second circulating conveyor belt and the first circulating conveyor belt, and the potatoes with soil on the surfaces continuously roll between the two belts due to the speed difference between the two belts (the potatoes roll between an upper brush layer and a lower brush layer, and the brush layers cannot scratch the surfaces of the potatoes), so that the brush layers on the surfaces of the first circulating conveyor belt and the second circulating conveyor belt can brush the soil on the surfaces of the potatoes comprehensively;

(2) The brush layers on the first and second surfaces of the circulating conveyor belts are utilized to clean the potato mud, and the wetting spray head is used to clean the brush layer of the second circulating conveyor belt, so that the pretreatment mud-removing cleaning equipment for potato processing can effectively operate for a long time;

(3) A waste water collecting tank is arranged below the frame, a filtering device is arranged at the outlet of the waste water collecting tank, and one side, far away from the waste water collecting tank, of the filtering device is communicated with an external water supply device to recycle the water for cleaning;

(4) The second circulating conveyor belt and the first circulating conveyor belt are both mesh belt type circulating conveyor belts, so that water on the second circulating conveyor belt and the first circulating conveyor belt can fall into a wastewater collecting tank below.

Drawings

In order to more clearly illustrate the technical solution of the embodiments of the present utility model, the following description of the embodiments will briefly describe the drawings that are required to be used in the description:

FIG. 1 is a schematic view of a pretreatment desilting and cleaning apparatus for potato processing in accordance with the utility model;

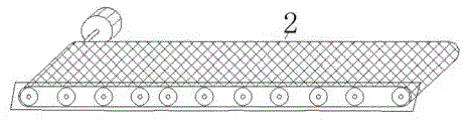

FIG. 2 is a schematic diagram of a circulating conveyor belt in a pretreatment de-mud cleaning apparatus for potato processing;

FIG. 3 is a schematic view of a brush unit in a pretreatment de-mud cleaning apparatus for potato processing;

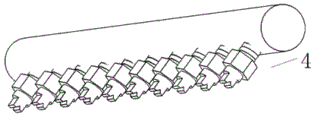

fig. 4 is a schematic view of a wetting spray head in a pretreatment desilting and cleaning apparatus for potato processing.

Reference numerals illustrate:

1-brushing section, 2-circulation conveyor belt II, 3-circulation conveyor belt I, 4-wetting spray nozzle, 5-cleaning section, 6-cleaning spray nozzle and 7-frame;

8-brush layer, 81-brush unit.

Detailed Description

In order that the above objects, features and advantages of the utility model will be more clearly understood, a further description of the utility model will be rendered by reference to the appended drawings and examples.

In the following description, numerous specific details are set forth in order to provide a thorough understanding of the present utility model, however, the present utility model may be practiced otherwise than as described herein, and therefore the present utility model is not limited to the specific embodiments of the disclosure that follow.

Example 1

The utility model will be further described with reference to fig. 1-4, wherein the pretreatment desliming and cleaning device for potato processing as shown in fig. 1 comprises a frame 7 and a circulating conveyor belt 3, wherein the frame 7 comprises a brushing section 1 and a cleaning section 5 which are arranged from front to back, and the circulating conveyor belt 3 penetrates through the brushing section 1 and the cleaning section 5.

As shown in fig. 1, a second circulating conveyor belt 2 is arranged in the brushing section 1, and the second circulating conveyor belt 2 is positioned above the first circulating conveyor belt 3; the surfaces of the circulating conveyor belt II 2 and the circulating conveyor belt I3 are provided with hairbrush layers 8; when potatoes are placed on the conveying surface of the first circulating conveyor belt 3, the brush layer 8 on the surface of the second circulating conveyor belt 2 can be contacted with the surfaces of the potatoes; the inlet of the brushing section 1 is provided with a wetting spray head 4 (as shown in fig. 4).

As shown in fig. 1, the endless conveyor 3 is a low-speed clockwise endless conveyor, and the endless conveyor 2 is a high-speed counterclockwise endless conveyor.

As shown in fig. 2, the circulating conveyor belt two 2 and the circulating conveyor belt one 3 are both mesh belt type circulating conveyor belts, so that water on the circulating conveyor belt two 2 and the circulating conveyor belt one 3 conveniently falls into a wastewater collecting tank below.

As shown in fig. 1 and 3, the brush layer 8 includes a plurality of brush units 81, and the length direction of each brush unit 81 is perpendicular to the conveying direction of the endless conveyor belt 2 and the endless conveyor belt 3. The brush unit 81 is mounted to the surfaces of the endless conveyor belt 2 and the endless conveyor belt 3 by means of tying or bolting. When the bolts are used for connection, the brush substrate of the brush unit 81, which is close to one side of the mesh belt type circulating conveyor belt, is provided with an internal threaded hole, the opposite side of the brush unit 81 is provided with a base plate, the base plate is provided with a through hole, and the bolts pass through the through hole of the base plate and the mesh belt type circulating conveyor belt and are in threaded connection with the internal threaded hole on the brush substrate.

As shown in fig. 2, the circulating conveyor belt two 2 is driven by a servo motor one; the first circulating conveyor belt 3 is driven by a second servo motor.

As shown in fig. 1, the cleaning section 5 is provided with a plurality of cleaning nozzles 6; the cleaning spray head 6 and the wetting spray head 4 are respectively connected with an external water supply device through pipelines.

A waste water collecting tank is arranged below the frame 7, a filtering device is arranged at the outlet of the waste water collecting tank, and one side, far away from the waste water collecting tank, of the filtering device is communicated with an external water supply device.

As shown in fig. 1, the wetting spray head 4 is obliquely arranged, and the water outlet faces the end part of the second circulating conveyor belt 2 close to the inlet of the brushing section 1, so that not only the potato with soil at the inlet of the first circulating conveyor belt 3 can be surface-wetted, but also the brush layer 8 of the second circulating conveyor belt 2 can be cleaned. The cleaning of the brush layer 8 on the surface of the endless conveyor belt 3 is completed by the cleaning nozzle 6 of the cleaning section 5.

The frame 7 is provided with baffles at both sides of the endless conveyor belt 3 perpendicular to the conveying direction.

The working principle of the pretreatment desliming cleaning equipment for potato processing is as follows:

starting pretreatment desliming cleaning equipment for potato processing, and placing potatoes excavated from soil to a feeding end 3 of a circulating conveyor belt by an operator; the potato with soil on the surface enters the brushing section 1 and is firstly wetted by a wetting nozzle 4 at the inlet of the brushing section 1; because the first circulating conveyor belt 3 is a low-speed clockwise circulating conveyor belt, the second circulating conveyor belt 2 is a high-speed anticlockwise circulating conveyor belt, potatoes with soil on the surfaces smoothly enter between the first circulating conveyor belt 2 and the second circulating conveyor belt 3, and the brush layers 8 of the first circulating conveyor belt 2 continuously push the potatoes below due to the speed difference between the first circulating conveyor belt 2 and the second circulating conveyor belt, so the potatoes with soil on the surfaces continuously roll between the first circulating conveyor belt and the second circulating conveyor belt (the potatoes roll between the upper brush layer 8 and the lower brush layer 8, and the brush layers 8 cannot scratch the surfaces of the potatoes), so that the brush layers on the surfaces of the first circulating conveyor belt 3 and the second circulating conveyor belt 2 can comprehensively brush the soil on the surfaces of the potatoes.

After the brushing section 1 is used for brushing, although the surface of the potato is provided with mud, the mud only floats on the surface of the potato and is not adhered to the surface of the potato any more, and after the surface is flushed by water sprayed by the cleaning nozzle 6 of the cleaning section 5, the mud on the surface of the potato is cleaned, so that the pretreatment mud removal cleaning of the potato processing is completed.

The present utility model is not limited to the above-mentioned embodiments, and any equivalent embodiments which can be changed or modified by the technical content disclosed above can be applied to other fields, but any simple modification and equivalent changes to the above-mentioned embodiments according to the technical substance of the present utility model are still within the protection scope of the technical solution of the present utility model.

Claims (9)

1. The pretreatment desilt cleaning equipment for potato processing is characterized by comprising a rack (7) and a first circulating conveyor belt (3), wherein the rack (7) comprises a brushing section (1) and a cleaning section (5) which are arranged from front to back, and the first circulating conveyor belt (3) penetrates through the brushing section (1) and the cleaning section (5);

a second circulating conveyor belt (2) is arranged in the brushing section (1), and the second circulating conveyor belt (2) is arranged above the first circulating conveyor belt (3); the surfaces of the second circulating conveyor belt (2) and the first circulating conveyor belt (3) are provided with hairbrush layers (8); when potatoes are placed on the conveying surface of the first circulating conveyor belt (3), the hairbrush layer (8) on the surface of the second circulating conveyor belt (2) can be contacted with the surfaces of the potatoes; the inlet of the brushing section (1) is provided with a wetting spray head (4).

2. Pretreatment desilt washing device for potato processing according to claim 1, characterized in that the endless conveyor two (2) and the endless conveyor one (3) are both mesh endless conveyors.

3. A potato processing pretreatment desilt washing apparatus according to claim 2, wherein the brush layer (8) comprises a plurality of brush units (81), each brush unit (81) comprising a brush base plate and having a length direction perpendicular to the conveying direction of the endless conveyor belt two (2) and the endless conveyor belt one (3).

4. A potato processing pretreatment desilting and cleaning apparatus according to any one of claims 1-3, wherein said endless conveyor belt two (2) is driven by a servo motor one; the first circulating conveyor belt (3) is driven by a second servo motor.

5. The pretreatment desilting washing apparatus of potato processing of claim 4, wherein the washing section (5) is equipped with a plurality of washing jets (6); the cleaning spray head (6) and the wetting spray head (4) are respectively connected with an external water supply device through pipelines.

6. The pretreatment desilt cleaning device for potato processing according to claim 5, wherein a waste water collecting tank is arranged below the frame (7), a filtering device is arranged at the outlet of the waste water collecting tank, and one side, far away from the waste water collecting tank, of the filtering device is communicated with an external water supply device.

7. Pretreatment desilt washing device for potato treatment according to claim 5, characterized in that the moistening nozzle (4) is arranged inclined and the water outlet is directed towards the end of the endless conveyor belt two (2) close to the inlet of the brush section (1).

8. A potato-processing pretreatment desilting washing apparatus according to claim 1, characterized in that the frame (7) is provided with baffles at both sides of the endless conveyor belt (3) perpendicular to the conveying direction.

9. Pretreatment desilting and cleaning device for potato processing according to claim 1, characterized in that the first endless conveyor belt (3) is a low-speed clockwise endless conveyor belt and the second endless conveyor belt (2) is a high-speed anticlockwise endless conveyor belt.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202320085194.4U CN219069393U (en) | 2023-01-30 | 2023-01-30 | Pretreatment desilt cleaning equipment for potato processing |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202320085194.4U CN219069393U (en) | 2023-01-30 | 2023-01-30 | Pretreatment desilt cleaning equipment for potato processing |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN219069393U true CN219069393U (en) | 2023-05-26 |

Family

ID=86401221

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202320085194.4U Active CN219069393U (en) | 2023-01-30 | 2023-01-30 | Pretreatment desilt cleaning equipment for potato processing |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN219069393U (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN117958456A (en) * | 2024-03-29 | 2024-05-03 | 山东鑫正达机械制造有限公司 | Potato pretreatment cleaning machine for food processing |

-

2023

- 2023-01-30 CN CN202320085194.4U patent/CN219069393U/en active Active

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN117958456A (en) * | 2024-03-29 | 2024-05-03 | 山东鑫正达机械制造有限公司 | Potato pretreatment cleaning machine for food processing |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN205512227U (en) | Cleaning equipment for fruit and vegetable processing | |

| CN219069393U (en) | Pretreatment desilt cleaning equipment for potato processing | |

| CN206380636U (en) | A kind of potato washing collection device | |

| CN103689755B (en) | A kind of automation red date purging system | |

| CN221209121U (en) | Raw material cleaning device for metallurgy | |

| CN212856862U (en) | Multi-functional food raw materials belt cleaning device | |

| CN107364429B (en) | Automatic cleaning system for large-scale cabinet body of rail transit vehicle | |

| CN201674981U (en) | Automatic disinfectant spaying machine for honey pomelos | |

| CN210450052U (en) | Float glass cleaning machine platform | |

| CN210726636U (en) | Lotus root belt cleaning device | |

| CN209174509U (en) | A kind of ultrasonic wave bubbling cleaning device | |

| CN204657030U (en) | PCB Water-cutting type washes panel assembly | |

| DE102006003990A1 (en) | Method and device for processing or processing silicon material | |

| CN217616196U (en) | 3D apron brush and spray belt cleaning device that block through brattice | |

| CN213922899U (en) | Curtain frame transmission device of laver processing machine | |

| CN2189498Y (en) | Showering type cleaning machine | |

| CN214207019U (en) | Shellfish sorting and cleaning device | |

| CN211211374U (en) | Automatic vegetable washing machine | |

| CN112657911A (en) | Equipment belt cleaning device for machining | |

| CN219253494U (en) | Continuous belt cleaning device of battery case | |

| CN2208455Y (en) | Foods cleaning machine | |

| CN217550528U (en) | Spraying type cleaning device with good cleaning effect | |

| CN218474017U (en) | Dry fresh fruit belt cleaning device of matrimony vine | |

| CN217411674U (en) | Atomizing oscillation dripping and sprinkling double-cleaning mechanism and cleaning production line | |

| CN219357135U (en) | Glass cleaning machine |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GR01 | Patent grant | ||

| GR01 | Patent grant |