CN210891663U - Domestic waste is processing system in coordination based on cement kiln - Google Patents

Domestic waste is processing system in coordination based on cement kiln Download PDFInfo

- Publication number

- CN210891663U CN210891663U CN201921779398.8U CN201921779398U CN210891663U CN 210891663 U CN210891663 U CN 210891663U CN 201921779398 U CN201921779398 U CN 201921779398U CN 210891663 U CN210891663 U CN 210891663U

- Authority

- CN

- China

- Prior art keywords

- fixedly connected

- bolt

- cement kiln

- motor

- wall

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000004568 cement Substances 0.000 title claims abstract description 28

- 239000010791 domestic waste Substances 0.000 title claims abstract description 18

- 238000012545 processing Methods 0.000 title claims abstract description 9

- 239000010813 municipal solid waste Substances 0.000 claims abstract description 47

- 238000002485 combustion reaction Methods 0.000 claims description 29

- 244000309464 bull Species 0.000 claims description 8

- 238000003466 welding Methods 0.000 claims description 8

- 238000012856 packing Methods 0.000 claims 1

- 238000000034 method Methods 0.000 abstract description 9

- 238000004519 manufacturing process Methods 0.000 abstract description 6

- 238000003860 storage Methods 0.000 abstract description 6

- 238000002309 gasification Methods 0.000 abstract description 3

- 239000002893 slag Substances 0.000 description 6

- 239000007789 gas Substances 0.000 description 4

- 239000002994 raw material Substances 0.000 description 3

- 230000007547 defect Effects 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 239000002910 solid waste Substances 0.000 description 2

- 239000000126 substance Substances 0.000 description 2

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 1

- 238000004891 communication Methods 0.000 description 1

- 238000013461 design Methods 0.000 description 1

- 238000001125 extrusion Methods 0.000 description 1

- 238000010304 firing Methods 0.000 description 1

- 238000000227 grinding Methods 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 239000001301 oxygen Substances 0.000 description 1

- 229910052760 oxygen Inorganic materials 0.000 description 1

- 239000013049 sediment Substances 0.000 description 1

Images

Abstract

The utility model discloses a domestic waste deals with system in coordination based on cement kiln, concretely relates to domestic waste technical field, the on-line screen storage device comprises a base, there is the hopper inside top of base through bolt fixedly connected with, there is the burning furnace through bolt fixedly connected with in the top of hopper, one side position department that the top of base is close to burning furnace smashes the case through bolt fixedly connected with, the top of smashing the case is through the hopper under bolt fixedly connected with, the top of hopper is through bolt fixedly connected with rubbish feed bin down. The utility model discloses in through having set up burning furnace, crushing case and garbage bin, carry out the pool storage with domestic waste through garbage bin to smash through smashing the case in follow-up processing, burn domestic waste through burning furnace at last, the gasification gas and the rubbish lime-ash that burn the in-process can all drop into the cement production line, all obtain resource utilization and innocent treatment.

Description

Technical Field

The utility model relates to a domestic waste technical field, more specifically say, the utility model relates to a domestic waste deals with system in coordination based on cement kiln.

Background

The domestic waste refers to solid waste generated in daily life or activities for providing services to daily life, and solid waste regarded as domestic waste by laws and administrative laws.

Through the retrieval, the chinese utility model patent discloses a refuse treatment system (the grant publication number is CN 201795495U), including rubbish storage silo, rubbish breaker, rubbish feeder, decomposing furnace and cement kiln. The utility model provides a refuse handling system carries out stable burning to rubbish, and the rubbish gas that the simultaneous combustion produced gets into the dore furnace and further burns, handles to make cement getting into the cement kiln.

However, when the incinerator is actually used, the defects still exist, the states of the garbage are different, so that the garbage is difficult to stably convey and block in the feeding process, the incombustible slag generated in the incineration process of the incinerator is difficult to separate from the comburent, and the incombustible slag is inconvenient to stably discharge.

SUMMERY OF THE UTILITY MODEL

In order to overcome prior art's above-mentioned defect, the embodiment of the utility model provides a domestic waste is processing system in coordination based on cement kiln through having set up burning furnace, crushing case and rubbish feed bin, carries out the pool storage with domestic waste through the rubbish feed bin to smash through crushing case in follow-up processing, burn domestic waste through burning furnace at last, burn gasification gas and the garbage ash sediment of in-process and can all drop into cement manufacture line, all obtain resource utilization and innocent treatment.

In order to achieve the above object, the utility model provides a following technical scheme: the household garbage co-processing system based on the cement kiln comprises a base, wherein a discharge hopper is fixedly connected to the top of the inside of the base through a bolt, a combustion furnace is fixedly connected to the top of the discharge hopper through a bolt, a crushing box is fixedly connected to one side, close to the combustion furnace, of the top of the base through a bolt, the top of the crushing box is fixedly connected with a discharge hopper through a bolt, and the top of the discharge hopper is fixedly connected with a garbage bin through a bolt.

In a preferred embodiment, the inside bottom of base is through bolt fixedly connected with bracing piece, the welding of the top of bracing piece has the auger conveyer pipe, pass through the first motor of bolt fixedly connected with on one side outer wall of auger conveyer pipe.

In a preferred embodiment, there is the second motor in top central point department of rubbish feed bin through bolt fixedly connected with, the one end of second motor is connected with the bull stick through the pivot rotation, the bottom welding of bull stick has the auger, the top of rubbish feed bin is close to one side position department of second motor and is connected with the case lid through the hinge rotation.

In a preferred embodiment, a third motor is fixedly connected to an outer wall of one side of the crushing box through a bolt, one end of the third motor is rotatably connected to the third motor through a rotating shaft, one end of the third motor is rotatably connected to the crushing roller through a rotating shaft, and a gear is welded to the outer wall of one side of the crushing roller.

In a preferred embodiment, an air cylinder is fixedly connected to the outer wall of the crushing box adjacent to one side of the third motor through a bolt, and one end of the air cylinder is connected with a push plate through an expansion link.

In a preferred embodiment, an inclined plate is welded on one side inner wall of the crushing box at a position close to the lower part of the push plate, and a baffle is rotatably connected on one side inner wall of the combustion furnace.

In a preferred embodiment, a burner nozzle is fixedly connected to one side of the outer wall of the combustion furnace through a bolt, a fan box is fixedly connected to one side of the outer wall of the combustion furnace through a bolt, a fan is fixedly connected to the inside of the fan box through a bolt, and an air pipe is arranged between the fan box and the combustion furnace.

In a preferred embodiment, a first grating and a second grating are welded at the bottom of the interior of the combustion furnace, and the first grating and the second grating are vertically crossed.

The utility model discloses a technological effect and advantage:

1. the utility model discloses in through having set up burning furnace, crushing case and garbage bin, carry out the pool storage with domestic waste through garbage bin to smash through smashing the case in follow-up processing, burn domestic waste through burning furnace at last, the gasification gas and the rubbish lime-ash that burn the in-process can all drop into the cement production line, all obtain resource utilization and innocent treatment.

2. The utility model discloses in through having set up the auger conveyer pipe, can carry out the incombustibles that produces after burning out and fire burning furnace, guarantee the space in the burning furnace to timely carry out the grinding with the incombustibles and handle the utilization, the slag fungible part cement raw materials reduces the input cost of cement production, and the utilization degree is high.

Drawings

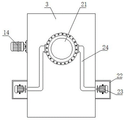

Fig. 1 is an overall structure front view of the present invention.

Fig. 2 is a side view of the combustion furnace of the present invention.

Fig. 3 is a top view of the interior of the combustion furnace of the present invention.

The reference signs are: 1-base, 2-discharge hopper, 3-combustion furnace, 4-crushing box, 5-discharge hopper, 6-garbage bin, 7-support rod, 8-auger delivery pipe, 9-first motor, 10-second motor, 11-rotating rod, 12-auger, 13-box cover, 14-third motor, 15-crushing roller, 16-gear, 17-air cylinder, 18-push plate, 19-inclined plate, 20-baffle plate, 21-flame nozzle, 22-fan box, 23-fan, 24-air pipe, 25-first grid and 26-second grid.

Detailed Description

The technical solutions in the embodiments of the present invention will be described clearly and completely with reference to the accompanying drawings in the embodiments of the present invention, and it is obvious that the described embodiments are only some embodiments of the present invention, not all embodiments. Based on the embodiments in the present invention, all other embodiments obtained by a person skilled in the art without creative work belong to the protection scope of the present invention.

The cement kiln-based household garbage co-processing system as shown in the attached drawings 1 and 3 comprises a base 1, wherein a discharge hopper 2 is fixedly connected to the top of the inside of the base 1 through a bolt, a combustion furnace 3 is fixedly connected to the top of the discharge hopper 2 through a bolt, a crushing box 4 is fixedly connected to one side of the top of the base 1 close to the combustion furnace 3 through a bolt, a discharge hopper 5 is fixedly connected to the top of the crushing box 4 through a bolt, and a garbage bin 6 is fixedly connected to the top of the discharge hopper 5 through a bolt.

The inside bottom of base 1 is through bolt fixedly connected with bracing piece 7, the welding of the top of bracing piece 7 has auger conveyer pipe 8, through the first motor 9 of bolt fixedly connected with on one side outer wall of auger conveyer pipe 8.

The top central point department of rubbish feed bin 6 is through bolt fixedly connected with second motor 10, the one end of second motor 10 is rotated through the pivot and is connected with bull stick 11, the bottom welding of bull stick 11 has auger 12, one side position department that the top of rubbish feed bin 6 is close to second motor 10 is connected with case lid 13 through the hinge rotation.

Smash and to have third motor 14 through bolt fixedly connected with on the one side outer wall of case 4, the one end of third motor 14 is rotated through the pivot and is connected with third motor 14, the one end of third motor 14 is rotated through the pivot and is connected with crushing roller 15, the welding has gear 16 on one side outer wall of crushing roller 15.

The crushing box 4 is adjacent to the outer wall of one side of the third motor 14 and is fixedly connected with an air cylinder 17 through a bolt, and one end of the air cylinder 17 is connected with a push plate 18 through an expansion rod.

An inclined plate 19 is welded on the inner wall of one side of the crushing box 4 at a position close to the lower part of the push plate 18, and a baffle plate 20 is rotatably connected on the inner wall of one side of the combustion furnace 3.

The implementation mode is specifically as follows: in implementing the utility model discloses in the time, open case lid 13, pour domestic waste into rubbish feed bin 6, second motor 10 drives bull stick 11 through the pivot and rotates, bull stick 11 drives auger 12 and rotates, even stable transport to smashing the case 4 of rubbish in the rubbish feed bin 6 through auger 12's rotation, third motor 14 drives crushing roller 15 through the pivot and rotates, it smashes rubbish extrusion to make two crushing rollers 15 rotate in opposite directions through meshing between the gear 16, cylinder 17 drives push pedal 18 through the telescopic link and removes, push pedal 18 pushes the rubbish after smashing on the swash plate 19 and fires in burning furnace 3, burn combustible substance through firing burning furnace 3 at last, incombustible substance is filtered out, realize domestic waste's storage, smash and burn.

Fig. 1 and 3 show a cement kiln-based household garbage co-disposal system, wherein a burner 21 is fixedly connected to an outer wall of one side of a combustion furnace 3 through a bolt, a fan box 22 is fixedly connected to an outer wall of one side of the combustion furnace 3 through a bolt, a fan 23 is fixedly connected to the inside of the fan box 22 through a bolt, and an air duct 24 is arranged between the fan box 22 and the combustion furnace 3.

The inner bottom of the combustion furnace 3 is welded with a first grating 25 and a second grating 26, and the first grating 25 and the second grating 26 are vertically crossed.

The implementation mode is specifically as follows: in implementing the utility model discloses in the time, fan 23 blows in the burning furnace 3 with outside air through tuber pipe 24 in, for the msw incineration who fires in the burning furnace 3 provides oxygen, burns the in-process incombustible thing and falls on first grid 25 and second grid 26, makes tiny slag fall through the hole between first grid 25 and the second grid 26, directly sends into cement raw materials pulverizer direct utilization behind the incombustible thing becomes the slag.

The utility model discloses the theory of operation:

referring to the attached drawings 1 and 3 of the specification, by arranging a combustion furnace 3, a crushing box 4 and a garbage bin 6, the household garbage is stored in a comprehensive mode through the garbage bin 6, and is crushed through the crushing box 4 in the subsequent treatment process, and finally is burnt through the combustion furnace 3, and gasified gas and garbage ash in the burning process can be all put into a cement production line and are subjected to resource utilization and harmless treatment;

referring to the attached drawings 1 and 3 of the specification, the screw conveyer pipe 8 is arranged, so that the incombustibles generated after burning can be conveyed out of the combustion furnace 3, the space in the combustion furnace 3 is ensured, the incombustibles can be ground and utilized in time, the slag can replace part of cement raw materials, the investment cost of cement production is reduced, and the resource utilization degree is high.

The points to be finally explained are: first, in the description of the present application, it should be noted that, unless otherwise specified and limited, the terms "mounted," "connected," and "connected" should be understood broadly, and may be a mechanical connection or an electrical connection, or a communication between two elements, and may be a direct connection, and "upper," "lower," "left," and "right" are only used to indicate a relative positional relationship, and when the absolute position of the object to be described is changed, the relative positional relationship may be changed;

secondly, the method comprises the following steps: in the drawings of the disclosed embodiments of the present invention, only the structures related to the disclosed embodiments are referred to, and other structures can refer to the common design, and under the condition of no conflict, the same embodiment and different embodiments of the present invention can be combined with each other;

and finally: the above description is only for the preferred embodiment of the present invention and should not be taken as limiting the invention, and any modifications, equivalent replacements, improvements, etc. made within the spirit and principle of the present invention should be included in the protection scope of the present invention.

Claims (8)

1. The utility model provides a domestic waste is processing system in coordination based on cement kiln, includes base (1), its characterized in that: the garbage bin is characterized in that a discharge hopper (2) is fixedly connected to the top inside the base (1) through bolts, a combustion furnace (3) is fixedly connected to the top of the discharge hopper (2) through bolts, a crushing box (4) is fixedly connected to one side, close to the combustion furnace (3), of the top of the base (1), a discharge hopper (5) is fixedly connected to the top of the crushing box (4) through bolts, and a garbage bin (6) is fixedly connected to the top of the discharge hopper (5) through bolts.

2. The cement kiln based household garbage co-disposal system according to claim 1, wherein: the utility model discloses a packing machine, including base (1), the inside bottom of base (1) is through bolt fixedly connected with bracing piece (7), the top welding of bracing piece (7) has auger conveyer pipe (8), through the first motor of bolt fixedly connected with (9) on one side outer wall of auger conveyer pipe (8).

3. The cement kiln based household garbage co-disposal system according to claim 1, wherein: the top central point department of rubbish feed bin (6) is through bolt fixedly connected with second motor (10), the one end of second motor (10) is rotated through the pivot and is connected with bull stick (11), the bottom welding of bull stick (11) has auger (12), the top of rubbish feed bin (6) is close to one side position department of second motor (10) and is connected with case lid (13) through the hinge rotation.

4. The cement kiln based household garbage co-disposal system according to claim 1, wherein: smash on one side outer wall of case (4) through bolt fixedly connected with third motor (14), the one end of third motor (14) is rotated through the pivot and is connected with crushing roller (15), the welding has gear (16) on one side outer wall of crushing roller (15).

5. The cement kiln based household garbage co-disposal system according to claim 1, wherein: smash case (4) and be adjacent to on one side outer wall of third motor (14) through bolt fixedly connected with cylinder (17), the one end of cylinder (17) is connected with push pedal (18) through the telescopic link.

6. The cement kiln based household garbage co-disposal system according to claim 1, wherein: an inclined plate (19) is welded on the inner wall of one side of the crushing box (4) and is close to the lower position of the push plate (18), and a baffle plate (20) is rotatably connected on the inner wall of one side of the combustion furnace (3).

7. The cement kiln based household garbage co-disposal system according to claim 1, wherein: the burner is characterized in that a flame nozzle (21) is fixedly connected to the outer wall of one side of the combustion furnace (3) through a bolt, a fan box (22) is fixedly connected to the outer wall of one side of the combustion furnace (3) through a bolt, a fan (23) is fixedly connected to the inside of the fan box (22) through a bolt, and an air pipe (24) is arranged between the fan box (22) and the combustion furnace (3).

8. The cement kiln based household garbage co-disposal system according to claim 1, wherein: the bottom of the interior of the combustion furnace (3) is welded with a first grating (25) and a second grating (26), and the first grating (25) and the second grating (26) are vertically crossed.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201921779398.8U CN210891663U (en) | 2019-10-22 | 2019-10-22 | Domestic waste is processing system in coordination based on cement kiln |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201921779398.8U CN210891663U (en) | 2019-10-22 | 2019-10-22 | Domestic waste is processing system in coordination based on cement kiln |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN210891663U true CN210891663U (en) | 2020-06-30 |

Family

ID=71340333

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201921779398.8U Active CN210891663U (en) | 2019-10-22 | 2019-10-22 | Domestic waste is processing system in coordination based on cement kiln |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN210891663U (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112628744A (en) * | 2020-12-18 | 2021-04-09 | 玉禾田环境发展集团股份有限公司 | Process method and equipment for pyrolysis treatment of household garbage |

-

2019

- 2019-10-22 CN CN201921779398.8U patent/CN210891663U/en active Active

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112628744A (en) * | 2020-12-18 | 2021-04-09 | 玉禾田环境发展集团股份有限公司 | Process method and equipment for pyrolysis treatment of household garbage |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN205299540U (en) | Waste incinerator for refuse treatment | |

| CN109681882B (en) | Garbage incineration device for garbage disposal | |

| CN112648620B (en) | Garbage crushing device | |

| CN109654510B (en) | Environment-friendly waste incineration device | |

| CN103486593B (en) | A kind of waste incineration boiler and its application method | |

| CN105889936A (en) | Incinerator for domestic garbage | |

| CN107388258A (en) | A kind of environment-protecting garbage incinerating stove | |

| CN208846430U (en) | Solid waste treatment device is used in a kind of production of triazine | |

| CN210891663U (en) | Domestic waste is processing system in coordination based on cement kiln | |

| CN206709080U (en) | A kind of automatic lime-ash fire grate device of pyrolytic gasification | |

| CN204345644U (en) | Refuse incinerator | |

| CN2252939Y (en) | Living garbage incinerator | |

| CN201506594U (en) | Structure of rubbish hopper | |

| CN223294827U (en) | A garbage crushing device for garbage power generation project | |

| CN209165416U (en) | A kind of continuous pyrolysis type waste incinerator | |

| CN208090679U (en) | A kind of solid waste multi-cycle coupling collaboration processing unit | |

| US5297494A (en) | Incinerator for burning waste | |

| CN108954331B (en) | Building waste processing is with melting down processing unit (plant) | |

| CN215507678U (en) | Waste incinerator lime-ash sieving mechanism | |

| CN214619552U (en) | A scraper continuous waste incinerator | |

| CN214501241U (en) | Refuse incinerator | |

| CN207622026U (en) | A kind of refuse incinerator | |

| CN220852152U (en) | Solid industrial refuse incineration treatment device | |

| CN212157175U (en) | Burning device for waste garbage in coal mine | |

| CN1133041C (en) | Garbage pretreating process and pretreater for garbage incinerating fluidized bed boiler |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GR01 | Patent grant | ||

| GR01 | Patent grant |