CN210395119U - Face novel bridge beam supports frame that combines forever - Google Patents

Face novel bridge beam supports frame that combines forever Download PDFInfo

- Publication number

- CN210395119U CN210395119U CN201921130133.5U CN201921130133U CN210395119U CN 210395119 U CN210395119 U CN 210395119U CN 201921130133 U CN201921130133 U CN 201921130133U CN 210395119 U CN210395119 U CN 210395119U

- Authority

- CN

- China

- Prior art keywords

- bridge

- support

- bailey

- pier stud

- pile foundation

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Landscapes

- Bridges Or Land Bridges (AREA)

Abstract

The utility model discloses a face and combine novel bridge beam supports frame forever, the bridge includes the bridge pile foundation and supports in bridge pile foundation top bridge pier stud, bridge pile foundation and bridge pier stud junction are pile extension post step, bridge pier stud top is equipped with the bridge girder body, face to combine novel bridge beam supports frame forever and include the bracket that connects gradually from bottom to top along bridge pier stud direction, combination beam and support template system, the bracket includes steel staple bolt and concrete support, the setting of bridge pile foundation and bridge pier stud periphery wall and being close to pile extension post step is located to steel staple bolt cover, concrete support pours between the periphery wall and the steel staple bolt of bridge pile foundation and bridge pier stud, the combination beam supports on concrete support, the bridge girder body supports on support template system. The utility model has the advantages of simple structure, convenient and quick assembly and disassembly and low cost.

Description

Technical Field

The utility model relates to a stride across soft base cast-in-place beam bridge construction field especially relates to a face and combine novel bridge beam supports forever.

Background

China has wide range of members and complex and various geographic environments, and particularly, bridges need to be built at soft foundations such as ponds, beaches, wetlands and the like. At present, the construction of cast-in-place beam bridges mainly comprises a full framing method and a combined framing method, and supports spanning soft foundations are generally driven into piles to form combined supports. The construction of the driven pile needs to use hoisting machinery, a matched clamp holder, a vibration hammer and the like, more large-scale equipment is needed, the driven pile in soft foundation geology has longer depth as a drawing, the one-time input material quantity is large, the driven pile is difficult to pull out during dismantling, the driven pile with limited clearance cannot be pulled out, and the material loss is serious. Therefore, the driven pile reduces the cost of soft foundation treatment compared with a full support, but still needs to invest large-scale equipment and materials, and has low economic benefit.

SUMMERY OF THE UTILITY MODEL

The to-be-solved technical problem of the utility model is to overcome the not enough of prior art, provide a simple structure, install and remove convenient quick, but with low costs repeatedly usable faces forever and combines novel bridge support frame.

In order to solve the technical problem, the utility model discloses a following technical scheme:

the utility model provides a face to combine novel bridge support frame forever, the bridge includes the bridge pile foundation and supports in bridge pile foundation top bridge pier stud, bridge pile foundation and bridge pier stud junction are pile extension post step, and bridge pier stud top is equipped with the bridge girder body, face to combine novel bridge support frame forever and include bracket, composite beam and the support template system that connects gradually from bottom to top along bridge pier stud direction, the bracket includes steel staple bolt and concrete support, the steel staple bolt cover is located bridge pile foundation and bridge pier stud periphery wall and is close to the setting of pile extension post step, concrete support pour in between the periphery wall and the steel staple bolt of bridge pile foundation and bridge pier stud, the composite beam supports on concrete support, and the bridge girder body supports on the support template system.

As a further improvement to the above technical solution:

the combined beam comprises a Bailey beam, a Bailey longitudinal beam, a column steel pipe, a riding bolt and a section steel small beam, wherein the Bailey beam and the bridge pier column are arranged in parallel and are fixedly connected with the bridge pier column through the column steel pipe, the bottom of the Bailey beam is supported on a concrete support, the Bailey longitudinal beam is horizontally arranged at the top of the Bailey beam and is fixedly connected with the Bailey beam through the riding bolt, and the section steel small beam is positioned between the Bailey longitudinal beam and a support template system and is connected with the Bailey longitudinal beam and the support template system into a whole through the riding bolt.

The bracket formwork system comprises a bowl buckle bracket, a square wood main rib, a square wood secondary rib and a bamboo plywood which are sequentially connected from bottom to top, wherein the bowl buckle bracket is connected with the composite beam, and the bamboo plywood is positioned below the bridge beam body and plays a supporting role on the bridge beam body.

The bowl buckle support is connected with the small section steel cross beam and the Bailey longitudinal beam into a whole through a riding bolt.

Compared with the prior art, the utility model has the advantages of:

the novel bridge support frame combined with the permanent temporary structure is improved according to the common combined support, the load is transmitted from top to bottom, the structural stress is clear, the concrete support does not settle, and the settlement deformation crack caused by the secondary pouring of the bridge body can be avoided; during installation, large-scale equipment such as a pile hammer, a clamp holder and the like is not needed, and compared with pile pulling, the dismounting construction is simple and the mounting and dismounting construction is rapid; the basis materials are few, only need steel staple bolt and pour a small amount of little expansive concrete as concrete support, and the steel staple bolt can make the concrete support of bracket be in multidirectional pressurized, improves concrete support bearing capacity, and equal used repeatedly of staple bolt, composite beam and support template system just, the utility model discloses possess safe and reliable, construction is convenient, economy, characteristics such as with low costs.

Drawings

Fig. 1 is a schematic structural diagram of the present invention.

Fig. 2 is a schematic sectional view of the present invention.

Fig. 3 is a partially enlarged view of a portion a in fig. 2.

Fig. 4 is a partially enlarged view at B in fig. 1.

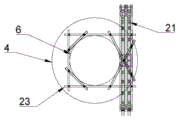

Fig. 5 is a top view of fig. 4.

The reference numerals in the figures denote:

1. a bracket; 11. steel anchor ear; 12. a concrete support; 2. a composite beam; 21. a bailey beam; 22. a beret stringer; 23. a pole embracing steel pipe; 24. a riding bolt; 25. a section steel small cross beam; 3. a scaffold template system; 31. a bowl buckle bracket; 32. main edges of the square wood are processed; 33. secondary corrugation of square wood; 34. bamboo plywood; 4. a bridge pile foundation; 5. pile extension step; 6. bridge pier stud; 7. bridge beam body.

Detailed Description

The invention will be described in further detail with reference to the drawings and specific examples.

As shown in fig. 1 to 5, the utility model discloses a face to combine novel bridge beam supports frame forever, the bridge includes bridge pile foundation 4 and supports in bridge pile foundation 4 top bridge pier stud 6, bridge pile foundation 4 and bridge pier stud 6 junction are pile extension post step 5, bridge pier stud 6 top is equipped with bridge girder 7, face to combine novel bridge beam supports frame forever and include bracket 1 that connects gradually from bottom to top along bridge pier stud 6 direction, combination beam 2 and support template system 3, bracket 1 includes steel staple bolt 11 and concrete support 12, 11 covers of steel staple bolt are located bridge pile foundation 4 and 6 periphery walls of bridge pier stud and are close to pile extension post step 5 and set up, concrete support 12 is pour between the periphery wall and the steel staple bolt 11 of bridge pile foundation 4 and bridge pier stud 6, combination beam 2 supports on concrete support 12, bridge girder 7 supports on support template system 3. The novel bridge support frame combined with the permanent temporary structure is improved according to the common combined support, the load is transmitted from top to bottom, the structural stress is clear, the concrete support 12 is not settled, and the settlement deformation crack caused by the secondary pouring of the bridge body 7 is avoided; during installation, large-scale equipment such as a pile hammer, a clamp holder and the like is not needed, and compared with pile pulling, the dismounting construction is simple and the mounting and dismounting construction is rapid; the basis materials are few, only need steel staple bolt 11 and pour a small amount of little expansive concrete as concrete support 12, and steel staple bolt 11 can make concrete support 12 of bracket 1 be in multidirectional pressurized, improves concrete support 12 bearing capacity, the utility model discloses possess characteristics such as safe and reliable, construction are convenient, economy.

The combination beam 2 comprises a Bailey beam 21, a Bailey longitudinal beam 22, a column-embracing steel pipe 23, a riding bolt 24 and a section steel small cross beam 25, the Bailey beam 21 and the bridge pier stud 6 are arranged in parallel and are connected with the bridge pier stud 6 through the column-embracing steel pipe 23, the bottom of the Bailey beam 21 is supported on a concrete support 12, the Bailey longitudinal beam 22 is horizontally arranged at the top of the Bailey beam 21 and is fixedly connected with the Bailey beam 21 through the riding bolt 24, and the section steel small cross beam 25 is positioned between the Bailey longitudinal beam 22 and a support template system 3 and is connected with the Bailey longitudinal beam 22 and the support template system 3 into a whole through the riding bolt 24. The steel embracing columns 23 and the riding bolts 24 play a role in fixing the composite beam 2, and ensure that the composite beam 2 stably bears and stably transmits upper load.

In this embodiment, the support template system 3 is disposed on the small section steel beam 25, and the support template system 3 is set up according to a common bowl buckle type full-space support frame.

The support template system 3 comprises a bowl buckle support 31, a square wood main rib 32, a square wood secondary rib 33 and a bamboo plywood 34 which are sequentially connected from bottom to top, the bowl buckle support 31 is connected with the composite beam 2, and the bamboo plywood 34 is positioned below the bridge beam body 7 and plays a role in supporting the bridge beam body 7.

The bowl buckle bracket 31 is connected with the small section steel cross beam 25 and the Bailey longitudinal beam 22 into a whole through the riding bolt 24.

The utility model discloses a face to combine novel bridge support frame forever, when concrete construction, according to construction position bridge parameter, can satisfy single bridge or stride bridge construction more, sheathe in 5 pile extension post steps of each bridge pier stud 6 and 4 junctions of bridge pile foundation steel staple bolt 11, with 11 welded fastening of steel staple bolt as the template, pour the concrete support 12 of bracket 1, control each concrete support 12 top surface elevation and level.

In this embodiment, when each corbel 1 has equal strength, the bailey cross beam 21 and the bailey longitudinal beam 22 of the composite beam 2 are assembled, so that time can be saved. The bailey cross beams 21 are hung and installed, so that the contact surfaces of the bailey cross beams 21 and the brackets 1 are horizontally attached, the bailey cross beams 21 are locked on the bridge pier studs 6 through the embracing column steel pipes 23, and the top surfaces of the bailey cross beams 21 in all groups are guaranteed to be the same in height. And (3) hoisting and installing the Bailey longitudinal beam 22, adjusting the position of the Bailey longitudinal beam 22 according to a design drawing, and locking the lower chord of the Bailey longitudinal beam 22 and the upper chord of the Bailey cross beam 21 by using a riding bolt 24. And mounting a small section steel cross beam 25, and fixing the small section steel cross beam and the upper chord of the Bailey longitudinal beam 22 by using a riding bolt 24. The support template system 3 comprises a bowl buckle support 31, square wood main ridges 32, square wood secondary ridges 33 and bamboo plywood 34, wherein the bowl buckle support 31 is erected according to the specification, and the square wood main ridges 32 and the square wood secondary ridges 33 are arranged according to the actual design.

Although the present invention has been described with reference to the preferred embodiments, it is not intended to limit the present invention. The technical solution of the present invention can be used by anyone skilled in the art to make many possible variations and modifications, or to modify equivalent embodiments, without departing from the scope of the technical solution of the present invention, using the technical content disclosed above. Therefore, any simple modification, equivalent change and modification made to the above embodiments by the technical entity of the present invention should fall within the protection scope of the technical solution of the present invention.

Claims (4)

1. The utility model provides a face to combine novel bridge bracing frame forever, the bridge includes bridge pile foundation (4) and supports in bridge pile foundation (4) top bridge pier stud (6), bridge pile foundation (4) and bridge pier stud (6) junction are pile extension post step (5), and bridge pier stud (6) top is equipped with bridge girder body (7), its characterized in that: face combination novel bridge support frame forever and include bracket (1), composite beam (2) and support template system (3) that connect gradually from bottom to top along bridge pier stud (6) direction, bracket (1) includes steel staple bolt (11) and concrete support (12), bridge pile foundation (4) and bridge pier stud (6) periphery wall and be close to pile butt column step (5) setting are located to steel staple bolt (11) cover, concrete support (12) pour in between the periphery wall and steel staple bolt (11) of bridge pile foundation (4) and bridge pier stud (6), composite beam (2) support on concrete support (12), and bridge girder body (7) support is on support template system (3).

2. The temporary combined novel bridge support frame according to claim 1, which is characterized in that: the combined beam (2) comprises a Bailey beam (21), a Bailey longitudinal beam (22), a column-embracing steel pipe (23), a horse-riding bolt (24) and a section steel small beam (25), the Bailey beam (21) and a bridge pier column (6) are arranged in parallel and are fixedly connected with the bridge pier column (6) through the column-embracing steel pipe (23), the bottom of the Bailey beam (21) is supported on a concrete support (12), the Bailey longitudinal beam (22) is horizontally arranged at the top of the Bailey beam (21) and is fixedly connected with the Bailey beam (21) through the horse-riding bolt (24), and the section steel small beam (25) is positioned between the Bailey longitudinal beam (22) and a support template system (3) and is connected with the Bailey longitudinal beam (22) and the support template system (3) into a whole through the horse-riding bolt (24).

3. The temporary combined novel bridge support frame according to claim 2, which is characterized in that: support template system (3) are detained support (31), square timber owner stupefied (32), square timber inferior stupefied (33) and bamboo offset plate (34) including the bowl that connects gradually from bottom to top, bowl is detained support (31) and is connected with composite beam (2), bamboo offset plate (34) are located bridge girder body (7) below and play the supporting role to bridge girder body (7).

4. The temporary combined novel bridge support frame according to claim 3, wherein: the bowl buckle support (31) is connected with the section steel small cross beam (25) and the Bailey longitudinal beam (22) into a whole through a riding bolt (24).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201921130133.5U CN210395119U (en) | 2019-07-18 | 2019-07-18 | Face novel bridge beam supports frame that combines forever |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201921130133.5U CN210395119U (en) | 2019-07-18 | 2019-07-18 | Face novel bridge beam supports frame that combines forever |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN210395119U true CN210395119U (en) | 2020-04-24 |

Family

ID=70355080

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201921130133.5U Active CN210395119U (en) | 2019-07-18 | 2019-07-18 | Face novel bridge beam supports frame that combines forever |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN210395119U (en) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN111663449A (en) * | 2020-05-23 | 2020-09-15 | 中交路桥建设有限公司 | Combined cast-in-place box girder support system and construction method |

| CN111827119A (en) * | 2020-07-15 | 2020-10-27 | 中国建筑土木建设有限公司 | Connecting structure of cast-in-situ variable cross-section beam body formwork and construction method thereof |

| CN115125855A (en) * | 2022-07-04 | 2022-09-30 | 广州大学 | Anti-seismic auxiliary structure for continuous beam and construction method thereof |

-

2019

- 2019-07-18 CN CN201921130133.5U patent/CN210395119U/en active Active

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN111663449A (en) * | 2020-05-23 | 2020-09-15 | 中交路桥建设有限公司 | Combined cast-in-place box girder support system and construction method |

| CN111827119A (en) * | 2020-07-15 | 2020-10-27 | 中国建筑土木建设有限公司 | Connecting structure of cast-in-situ variable cross-section beam body formwork and construction method thereof |

| CN115125855A (en) * | 2022-07-04 | 2022-09-30 | 广州大学 | Anti-seismic auxiliary structure for continuous beam and construction method thereof |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN210395119U (en) | Face novel bridge beam supports frame that combines forever | |

| WO2022142999A1 (en) | Hoisting device for bridge water surface pile tie beam and construction method therefor | |

| CN102021889A (en) | Bridge erection method | |

| CN212200750U (en) | Assembled building frame structure combination braced system | |

| CN103410102A (en) | H-shaped double column pier wide-bridge-surface cantilever temporary consolidation structure and construction method thereof | |

| CN112095495A (en) | Bridge underpinning support structure and construction method | |

| CN113846746A (en) | Basement structure beneficial to efficient construction and construction method | |

| CN107100322B (en) | Post stretching vertical prestressing cast-in-place concrete rod structure and construction method | |

| CN209194354U (en) | High-altitude long-span binder base-supporting shellfish thunder support construction | |

| CN217870026U (en) | Bridge side span construction structure | |

| CN216475804U (en) | Steel bar truss floor support plate | |

| CN215977664U (en) | Basement structure beneficial to efficient construction | |

| CN216109354U (en) | Conversion layer steel column mounting structure | |

| CN213571600U (en) | Bridge underpins bearing structure | |

| KR101050291B1 (en) | Head reinforce structure of a steel pipe pile for construction | |

| CN212612004U (en) | Modular cast-in-place box girder braced system | |

| CN211395312U (en) | Upper structure for wide box girder and short tower cable-stayed bridge | |

| CN210216491U (en) | Easily build formula tower crane foundation structure | |

| CN209585427U (en) | A kind of assembled steel tube bank prestressed concrete combination beam | |

| CN208717939U (en) | A kind of efficiently molding building hoist foundation structure | |

| CN202850486U (en) | Aluminum-wood combined beam stressed template system | |

| CN102418417A (en) | Long-slab-span cast-in-situ beam ribbed floor early-dismantling template formwork system | |

| CN201095721Y (en) | Soft soil foundation porous double suspension arms arched bridge structure | |

| CN213143380U (en) | Wet-type longitudinal column reinforcing bar beam column high strength concrete connection structure | |

| CN216586210U (en) | Side-hanging type full-suspension cover beam combined support platform |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GR01 | Patent grant | ||

| GR01 | Patent grant |