CN1614858A - 自动平衡装置及其制造方法 - Google Patents

自动平衡装置及其制造方法 Download PDFInfo

- Publication number

- CN1614858A CN1614858A CN200410085888.XA CN200410085888A CN1614858A CN 1614858 A CN1614858 A CN 1614858A CN 200410085888 A CN200410085888 A CN 200410085888A CN 1614858 A CN1614858 A CN 1614858A

- Authority

- CN

- China

- Prior art keywords

- lubricant

- outer circumferential

- rotary body

- circumferential side

- automatic balancing

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 238000004519 manufacturing process Methods 0.000 title claims description 8

- 239000000314 lubricant Substances 0.000 claims abstract description 101

- 239000007788 liquid Substances 0.000 claims description 39

- 239000000463 material Substances 0.000 claims description 17

- 239000007787 solid Substances 0.000 claims description 14

- 239000011347 resin Substances 0.000 claims description 9

- 229920005989 resin Polymers 0.000 claims description 9

- 239000011248 coating agent Substances 0.000 claims description 8

- 238000000576 coating method Methods 0.000 claims description 8

- YCKRFDGAMUMZLT-UHFFFAOYSA-N Fluorine atom Chemical compound [F] YCKRFDGAMUMZLT-UHFFFAOYSA-N 0.000 claims description 7

- 150000001336 alkenes Chemical class 0.000 claims description 7

- 239000011737 fluorine Substances 0.000 claims description 7

- 229910052731 fluorine Inorganic materials 0.000 claims description 7

- 238000000034 method Methods 0.000 claims description 7

- JRZJOMJEPLMPRA-UHFFFAOYSA-N olefin Natural products CCCCCCCC=C JRZJOMJEPLMPRA-UHFFFAOYSA-N 0.000 claims description 7

- 230000005484 gravity Effects 0.000 claims description 4

- 230000002093 peripheral effect Effects 0.000 abstract description 4

- 239000010687 lubricating oil Substances 0.000 abstract 2

- 238000010586 diagram Methods 0.000 description 7

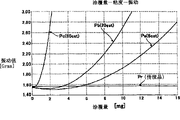

- 238000012360 testing method Methods 0.000 description 7

- 230000000694 effects Effects 0.000 description 6

- 238000005259 measurement Methods 0.000 description 6

- NJPPVKZQTLUDBO-UHFFFAOYSA-N novaluron Chemical compound C1=C(Cl)C(OC(F)(F)C(OC(F)(F)F)F)=CC=C1NC(=O)NC(=O)C1=C(F)C=CC=C1F NJPPVKZQTLUDBO-UHFFFAOYSA-N 0.000 description 6

- 230000008020 evaporation Effects 0.000 description 4

- 238000001704 evaporation Methods 0.000 description 4

- 239000003921 oil Substances 0.000 description 3

- VGGSQFUCUMXWEO-UHFFFAOYSA-N Ethene Chemical compound C=C VGGSQFUCUMXWEO-UHFFFAOYSA-N 0.000 description 2

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 description 2

- 230000004888 barrier function Effects 0.000 description 2

- 230000033228 biological regulation Effects 0.000 description 2

- 230000007797 corrosion Effects 0.000 description 2

- 238000005260 corrosion Methods 0.000 description 2

- 230000006866 deterioration Effects 0.000 description 2

- 230000001050 lubricating effect Effects 0.000 description 2

- 238000005461 lubrication Methods 0.000 description 2

- 239000000203 mixture Substances 0.000 description 2

- -1 on sliding surface Substances 0.000 description 2

- 230000000452 restraining effect Effects 0.000 description 2

- 238000004904 shortening Methods 0.000 description 2

- 230000006641 stabilisation Effects 0.000 description 2

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 1

- 229910000976 Electrical steel Inorganic materials 0.000 description 1

- 238000010521 absorption reaction Methods 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 238000009792 diffusion process Methods 0.000 description 1

- 230000008030 elimination Effects 0.000 description 1

- 238000003379 elimination reaction Methods 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- ZZUFCTLCJUWOSV-UHFFFAOYSA-N furosemide Chemical compound C1=C(Cl)C(S(=O)(=O)N)=CC(C(O)=O)=C1NCC1=CC=CO1 ZZUFCTLCJUWOSV-UHFFFAOYSA-N 0.000 description 1

- 229910002804 graphite Inorganic materials 0.000 description 1

- 239000010439 graphite Substances 0.000 description 1

- 229910052742 iron Inorganic materials 0.000 description 1

- 230000001678 irradiating effect Effects 0.000 description 1

- 239000000696 magnetic material Substances 0.000 description 1

- 238000012423 maintenance Methods 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 229910052751 metal Inorganic materials 0.000 description 1

- 230000000116 mitigating effect Effects 0.000 description 1

- 238000012856 packing Methods 0.000 description 1

- 229920000515 polycarbonate Polymers 0.000 description 1

- 239000004417 polycarbonate Substances 0.000 description 1

- 239000004810 polytetrafluoroethylene Substances 0.000 description 1

- 229920001343 polytetrafluoroethylene Polymers 0.000 description 1

- 238000004080 punching Methods 0.000 description 1

- 238000005096 rolling process Methods 0.000 description 1

- 239000000126 substance Substances 0.000 description 1

- 238000004804 winding Methods 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16F—SPRINGS; SHOCK-ABSORBERS; MEANS FOR DAMPING VIBRATION

- F16F15/00—Suppression of vibrations in systems; Means or arrangements for avoiding or reducing out-of-balance forces, e.g. due to motion

- F16F15/32—Correcting- or balancing-weights or equivalent means for balancing rotating bodies, e.g. vehicle wheels

- F16F15/36—Correcting- or balancing-weights or equivalent means for balancing rotating bodies, e.g. vehicle wheels operating automatically, i.e. where, for a given amount of imbalance, there is movement of masses until balance is achieved

- F16F15/363—Correcting- or balancing-weights or equivalent means for balancing rotating bodies, e.g. vehicle wheels operating automatically, i.e. where, for a given amount of imbalance, there is movement of masses until balance is achieved using rolling bodies, e.g. balls free to move in a circumferential direction

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T74/00—Machine element or mechanism

- Y10T74/21—Elements

- Y10T74/2109—Balancing for drum, e.g., washing machine or arm-type structure, etc., centrifuge, etc.

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Acoustics & Sound (AREA)

- Aviation & Aerospace Engineering (AREA)

- Mechanical Engineering (AREA)

- Connection Of Motors, Electrical Generators, Mechanical Devices, And The Like (AREA)

- Lubricants (AREA)

- Sliding-Contact Bearings (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2003379117 | 2003-11-07 | ||

| JP2003379117A JP2005140288A (ja) | 2003-11-07 | 2003-11-07 | 自動平衡装置およびその製造方法 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN1614858A true CN1614858A (zh) | 2005-05-11 |

Family

ID=34674796

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN200410085888.XA Pending CN1614858A (zh) | 2003-11-07 | 2004-11-05 | 自动平衡装置及其制造方法 |

Country Status (3)

| Country | Link |

|---|---|

| US (1) | US20050132840A1 (enExample) |

| JP (1) | JP2005140288A (enExample) |

| CN (1) | CN1614858A (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN104781580A (zh) * | 2012-11-01 | 2015-07-15 | 丰田自动车株式会社 | 扭转振动衰减装置 |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN106168526B (zh) * | 2016-08-15 | 2019-03-22 | 上海交通大学 | 一种转子系统在线动平衡系统及方法 |

-

2003

- 2003-11-07 JP JP2003379117A patent/JP2005140288A/ja not_active Withdrawn

-

2004

- 2004-11-03 US US10/980,913 patent/US20050132840A1/en not_active Abandoned

- 2004-11-05 CN CN200410085888.XA patent/CN1614858A/zh active Pending

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN104781580A (zh) * | 2012-11-01 | 2015-07-15 | 丰田自动车株式会社 | 扭转振动衰减装置 |

Also Published As

| Publication number | Publication date |

|---|---|

| US20050132840A1 (en) | 2005-06-23 |

| JP2005140288A (ja) | 2005-06-02 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN1086857C (zh) | 磁盘转动机构 | |

| CN1614859A (zh) | 主轴马达和包括该主轴马达的记录磁盘驱动装置 | |

| HK1039408A1 (zh) | 自動平衡裝置 | |

| CN1177813A (zh) | 光盘装置 | |

| US6851859B2 (en) | Bearing unit, production method therefor and spindle motor | |

| US6412984B2 (en) | Dynamic pressure bearing apparatus | |

| US20020018603A1 (en) | Hydrodynamic bearing device | |

| US6731588B2 (en) | Disk player, and self-compensating-dynamic-balancer (SCDB) integrated turntable, SCDB integrated clamper and SCDB integrated spindle motor employed in the same | |

| CN1521416A (zh) | 动压轴承装置 | |

| CN1614858A (zh) | 自动平衡装置及其制造方法 | |

| CN1201465C (zh) | 流体动压轴承电动机 | |

| CN1237726A (zh) | 带有改进的自动平衡装置的盘驱动装置 | |

| KR101097498B1 (ko) | 스핀들 모터 | |

| JPH11182533A (ja) | 動圧型多孔質含油軸受ユニット | |

| US20090106782A1 (en) | Auto balancing device and disc chucking device and disc driving device having the same | |

| CN1350129A (zh) | 空气动压轴承及其光偏转器 | |

| CN1658480A (zh) | 无刷电机 | |

| CN1638239A (zh) | 主轴电动机和具有该主轴电动机的盘装置 | |

| KR100352484B1 (ko) | 스핀들 모터 | |

| CN1249557A (zh) | 旋转驱动机构 | |

| US8294312B2 (en) | Bearing and spindle motor | |

| KR20090040978A (ko) | 오토 밸런싱 장치 및 이를 구비한 턴테이블 장치 | |

| JPH1182479A (ja) | 情報機器のスピンドル用モータの支持装置 | |

| CN1099106A (zh) | 轴承装置 | |

| KR100904920B1 (ko) | 디스크 구동 장치 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| AD01 | Patent right deemed abandoned | ||

| C20 | Patent right or utility model deemed to be abandoned or is abandoned |