CN1214180C - Variable compression pistol assembly - Google Patents

Variable compression pistol assembly Download PDFInfo

- Publication number

- CN1214180C CN1214180C CNB988090643A CN98809064A CN1214180C CN 1214180 C CN1214180 C CN 1214180C CN B988090643 A CNB988090643 A CN B988090643A CN 98809064 A CN98809064 A CN 98809064A CN 1214180 C CN1214180 C CN 1214180C

- Authority

- CN

- China

- Prior art keywords

- piston

- axis

- arm

- assembly

- transition arm

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02B—INTERNAL-COMBUSTION PISTON ENGINES; COMBUSTION ENGINES IN GENERAL

- F02B75/00—Other engines

- F02B75/04—Engines with variable distances between pistons at top dead-centre positions and cylinder heads

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02B—INTERNAL-COMBUSTION PISTON ENGINES; COMBUSTION ENGINES IN GENERAL

- F02B75/00—Other engines

- F02B75/26—Engines with cylinder axes coaxial with, or parallel or inclined to, main-shaft axis; Engines with cylinder axes arranged substantially tangentially to a circle centred on main-shaft axis

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02B—INTERNAL-COMBUSTION PISTON ENGINES; COMBUSTION ENGINES IN GENERAL

- F02B75/00—Other engines

- F02B75/02—Engines characterised by their cycles, e.g. six-stroke

- F02B2075/022—Engines characterised by their cycles, e.g. six-stroke having less than six strokes per cycle

- F02B2075/025—Engines characterised by their cycles, e.g. six-stroke having less than six strokes per cycle two

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Output Control And Ontrol Of Special Type Engine (AREA)

- Transmission Devices (AREA)

- Compressors, Vaccum Pumps And Other Relevant Systems (AREA)

- Pistons, Piston Rings, And Cylinders (AREA)

- Valve Device For Special Equipments (AREA)

Abstract

A variable compression piston assembly (300) includes a plurality of pistons, e.g., double ended pistons (330, 332), a rotating member, e.g., a flywheel (322) or a zero-stroke pivot member, coupled to the transition arm (310) and configured for movement relative to the transition arm (310) along the axis of rotation of the rotating member (322). The movement of the rotating member (322) relative to the transition arm (310) changes the compression ratio of the piston assembly (330, 332). The transition arm (310) is coupled to each of the double ended pistons (330, 332) at approximately a center of each piston (330, 332). The movement of the rotating member (322) relative to the transition arm (310) changes the compression ratio and displacement of each double ended piston (330, 332).

Description

Technical field

The present invention relates to the piston assembly and a motor of a variable compression, this motor has the double ended piston that is connected on the universal joint, is converted to rotational motion with the straight line motion with this piston.

Background technique

Most piston-driven engines has the piston on the biasing part that is connected a bent axle, therefore when piston when vertically the reciprocating direction of the axis of this bent axle moves, this bent axle will rotate.

U. S. Patent 5,535,709 have disclosed a kind of motor that has double ended piston, and this double ended piston is connected on the bent axle that has a biasing part.A bar that is connected between piston and the bent axle is limited in the fulcrum accent splicer, rotational motion is offered this bent axle.

U. S. Patent 4,011,842 have disclosed the piston engine of one or four cylinders, and this motor has utilized two double ended pistons that are connected on the T-connecting piece, and this motor can cause bent axle to rotate.T-connecting piece is connected to a both-end piston at each T shape transposition arm place.A point that is positioned at the center is rotatably connected on the immovable point on the T shape transposition arm, and the bottom of T shape is rotatably connected on the crank pin, and this crank pin is connected on this bent axle by a crank radius, and this bent axle has an equilibrium block.

In above each example, used double ended piston to drive a bent axle, this bent axle has an axis of vertical piston axis.

Summary of the invention

According to one aspect of the present invention, a kind of piston assembly of variable compression is provided, it comprises: a plurality of pistons, a transition arm that is connected with each piston, this transition arm comprises the actuator with an axis, and a rotating component that is connected slidably along the axis of actuator and actuator, this rotating component with respect to the determining positions of actuator the compression ratio of piston assembly.

The embodiment of this aspect of the present invention can have one or more following features.

This piston is a double ended piston.This transition arm is connected about center of each double ended piston.The motion of relative this transition arm of this rotating component has changed the compression ratio and the displacement of each double ended piston.

This assembly has two pistons, and the axis place of the rotation axis of rotating component and two-piston at grade.This rotating component is a flywheel.One controlling rod is operably connected on the described flywheel, so the transmission of controlling rod provides this flywheel straight line motion of this transition arm relatively.

In some illustrated embodiment, this rotating component is configured to the position that can be positioned at one zero strokes, wherein need not the corresponding piston motion, and the rotation of this rotating component just can take place.This rotating component comprises a pivot member that is pivotally connected on the control piece, and the transmission of this control piece has caused the motion of this pivot member, to change compression ratio.

Each piston is set, makes its parallel axes or not parallel.

Driving pin is connected transition arm on the piston.This actuator extends in the opening of this rotating component and the periphery of contiguous this rotating component.This driving arm extends into a pivot pin that is arranged in this rotating component.One main driving axle is connected on this rotating component.The parallel axes of this live axle is in the axis of each piston.One universal joint is connected to this transition arm on one supporting member.

Have at least one to have a rear pump piston in a plurality of pistons, to drive a pump.

According to another aspect of the present invention, a kind of method that is used to change the piston assembly compression ratio is provided, it comprises: provide: a plurality of pistons; A transition arm that is connected with each piston, this transition arm comprises the actuator with an axis; And a rotating component that is connected slidably along the axis of actuator and actuator, and this rotating component with respect to the actuator motion to change the compression ratio of piston assembly.

According to another aspect of the present invention, a kind of method that is used to improve piston assembly efficient is provided, it comprises: provide: a plurality of double ended pistons; With the transition arm that about center of each double ended piston is connected, this transition arm comprises the actuator with an axis; And a rotating component that is connected slidably along the axis of actuator and actuator, and rotating component with respect to the actuator motion to change the compression ratio and the displacement of double ended piston assembly.

Description of drawings

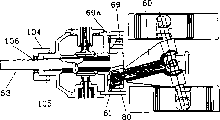

Fig. 1 and Fig. 2 are the side views of a four-banger reduced graph of the present invention;

Fig. 3,4,5 and 6 is plan views of the motor of Fig. 1, shows the piston and the flywheel that are in four diverse locations;

Fig. 7 is the plan view of the broken section of an eight cylinder engine of the present invention;

Fig. 8 is the side view of analysing and observe of the motor of Fig. 7;

Fig. 9 is the right side view of Fig. 7;

Figure 10 is the side view of Fig. 7;

Figure 11 is the left side view of Fig. 7;

Figure 12 is the partial top view of the motor of Fig. 7; Show each piston, actuator and the flywheel that are in the high compression position.

Figure 13 is the partial top view of motor among Fig. 7, shows to be in each piston, actuator and the flywheel that low compressed-bit is put.

Figure 14 is the plan view of a piston;

Figure 15 is the side view of a piston, shows the actuator two positions;

Figure 16 shows the supporting surface of actuator and piston;

Figure 17 is an air driven motor embodiment;

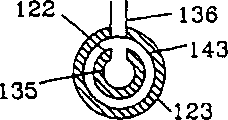

Figure 18 illustrates the air valve that is in the first position;

Figure 18 a, 18b and 18c are the sectional views of three cross sections of air valve shown in Figure 180;

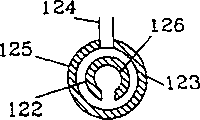

Figure 19 illustrates the air valve that is in the second place;

Figure 19 a, 19b and 19c are the sectional views of three cross sections of air valve shown in Figure 19;

Figure 20 shows the embodiment who has the inclination cylinder;

Figure 21 shows the embodiment who has single-ended piston;

Figure 22 is the plan view of one or two cylinder, double ended piston assembly;

Figure 23 is one of them double ended piston plan view of the assembly of Figure 22;

Figure 23 a is the side view of the double ended piston of Figure 23 23A along the line, 23A;

Figure 24 is the transition arm of piston assembly of Figure 22 and the plan view of universal joint;

Figure 24 a is the transition arm of Figure 24 and the side view of universal joint 24a along the line, 24a;

Figure 25 is the stereogram that is connected to the driving arm on the transition arm of piston assembly of Figure 22;

Figure 25 a be the rotating component of piston assembly of Figure 22 along the line 25a of Figure 22, the side view of 25a, show the connection between driving arm and the rotating component;

Figure 25 b is that this rotating component is along the line 25b of Figure 25 a, the side view of 25b;

Figure 26 is the plan view that the piston assembly of Figure 22 is analysed and observe;

Figure 27 is the end elevation of this transition arm along the line 27,27 of Figure 24;

Figure 27 a is a sectional view that drives pin of the piston assembly of Figure 22;

Figure 28-28b is respectively the overlooking of piston assembly, backsight and the side view of Figure 22;

Figure 28 c is the plan view of an auxiliary axis of the piston assembly of Figure 22;

Figure 29 is the side view of analysing and observe that zero stroke engages;

Figure 29 a is the exploded view that the zero stroke of Figure 29 engages;

Figure 30 shows the plotted curve of the 8 fonts motion of a non-horizontal piston assembly;

Figure 31 shows a driving pin of strengthening;

Figure 32 is the plan view that is used for directly firing pressure being applied to the four-banger on the pump piston, and

Figure 32 a is that this four-banger is along the line 32a of Figure 32, the side view of 32a.

Embodiment

Fig. 1 is the schematic representation according to four piston engines 10 of the present invention.Motor 10 has two cylinders 11 (Fig. 3) and 12. Cylinder 11 and 12 all accommodates a double ended piston.Each double ended piston is connected on the transition arm 13, and transition arm 13 is connected on the flywheel 15 by axle 14.Transition arm 13 is connected on the supporting member 19 by a universal joint mechanism, and this universal joint mechanism comprises can make transition arm 13 axle 18 that moves up and down and the axle 17 that can make transition arm 13 sides to lateral movement.Fig. 1 shows flywheel 15 and is in the position that axle 14 is positioned at the top of wheel 15.

In motor shown in Figure 2 10, flywheel 15 rotates, and therefore axle 14 is in the bottom of flywheel 15.Transition arm 13 axle 18 relatively rotates.

Shown in Fig. 3-6 is the plan view of schematic representation, and wherein transition arm 13 is in four positions, and the flywheel 15 of motion all has 90 ° increment than a position on it.Fig. 3 shows flywheel 15, and axle 14 is in the position shown in Fig. 3 a at this moment.During when piston 1 burning and towards the middle part motion of cylinder 11, transition arm 13 is rotated on universal joint 16, makes flywheel 15 turn to position shown in Figure 2.Axle 14 will be in the position shown in Fig. 4 a.When piston 4 is lighted, transition arm 13 will move to position shown in Figure 5.Flywheel 15 and axle 14 will be in the position shown in Fig. 5 a.Next piston 2 will burn, and transition arm 13 will move to position shown in Figure 6.Flywheel 15 and axle 14 will be in the position shown in Fig. 6 a.When piston 3 is lighted, transition arm 13 and flywheel 15 will turn back to the initial position shown in Fig. 3 and the 3a.

When each piston combustion, transition arm will be moved to and fro along with the motion of piston.Because transition arm 13 is connected on the universal joint 16, and be connected on the flywheel 15 by axle 14 again, the rotation of flywheel 15 makes the straight line motion of piston be converted to rotational motion.

Shown in Fig. 7 (with broken section) is plan view according to an embodiment of a kind of motor 30 that includes four double-pistons, eight cylinders of the present invention.In fact have only four cylinders, but have a double-piston in each cylinder.This motor is equivalent to an eight cylinder engine.Show two cylinders 31 and 46.Cylinder 31 has the double ended piston 32,33 that has piston ring 32a and 33a respectively.Piston 32,33 is connected on the transition arm 60 (Fig. 8) by piston arm 54a, and piston arm 54a extends into the opening 55a that is arranged in piston 32,33 and sleeve bearing 55.Similarly, the piston in the cylinder 46 47,49 is connected on the transition arm 60 by piston arm 54b.

Every end of cylinder 31 all has the entrance and exit valve by a rocking arm and spark plug control.Piston end 32 has rocking arm 35a, 35b and spark plug 44, and piston end 33 has rocking arm 34a, 34b and spark plug 41.Each piston all has relative cover valve, rocking arm and a spark plug.The synchronous belt 51 that the time of light up plug and unlatching and closed inlet and escape cock is connected on the belt pulley 50a is controlled.Belt pulley 50a is connected on the gear 64 by axle 63 (Fig. 8), and axle 63 is provided the output shaft 53 of power to drive by flywheel 69.Belt pulley 50a has also driven belt pulley 50b and the gear 39 that is connected on the distributor 38.Gear 39 has also driven gear 40.Gear 39 and 40 is connected on the camshaft 75 (Fig. 8), and camshaft 75 has driven the push rod that is connected on rocking arm 34,35 and other the not shown rocking arms.

Shown gas exhaust manifold 48 and 56 is connected on cylinder 46 and 31.Each gas exhaust manifold has connected four relief openings.

Fig. 8 is a side view of removing a rear flank motor 30 along Fig. 7 middle section 8-8.Transition arm 60 is installed on the supporting member 70 by pin 72 and pin 71, and pin 72 makes transition arm can move up and down (as shown in Figure 8), and pin 71 makes transition arm 60 to move on side to side ground.Because transition arm 60 can move up and down in lateral movement in side, so axle 61 can drive flywheel 69 with circular path.The piston arm of four connections ( piston arm 54b and 54d are illustrated among Fig. 8) is centered on pin 71 and makes four double ended pistons of oscillating movement and drive.When link arm moved back and forth, the end of the axle 61 in the flywheel 69 caused transition arm to move up and down.Flywheel 69 has the wheel tooth 69a around a side, available it drive flywheel, make itself and actuating motor 100 (Figure 11) ato unit of coming together.

The rotation of flywheel 69 and connected live axle 68 has driven gear 65, and gear 65 has driven gear 64 and 66 again.Gear 64 is connected on the axle 63 that has driven belt pulley 50a.Belt pulley 50a connects belt 51.Belt 51 has driven belt pulley 50b and gear 39,40 (Fig. 7).Camshaft 75 has cam 88-91 that is positioned on the end and the cam 84-87 that is positioned on the other end.Cam 88 and 90 has driven push rod 76 and 77 respectively.Cam 89 and 91 has driven push rod 93 and 94 respectively.Cam 84 and 86 has driven push rod 95 and 96 respectively.And cam 85 and 87 has driven push rod 78 and 79 respectively.Push rod 77,76,93,94,95,96 and 78,79 entering and escape cock in order to the cylinder on unlatching and the closed piston.The left side of this motor that is cutd open accommodate identical, but relative valve driving mechanism.

The gear 66 that gear 65 on the driven shaft 68 rotates has rotated pump 67, and pump 67 can be to use the water pump in engine-cooling system (figure does not show), perhaps an oil pump.

Fig. 9 shows the rear view of motor 30 of the relative position of cylinder and double ended piston.Piston 32,33 is shown in broken lines, and valve 35c and 35d lay respectively under lift arm 35a and the 35b.Shown belt 51 and belt pulley 50b are positioned under the distributor 38.Among piston 32-33,32a-33a, 47-49 and 47a-49a.Show two 54c and 54d among transition arm 60 and four piston arm 54a, 54b, 54c and the 54d.

Figure 10 shows a side view of the motor 30 of gas exhaust manifold 56, intake manifold 56a and vaporizer 56e.The belt pulley 50a and the 50b that have synchronous belt also illustrate in the drawings.

Figure 11 shows the front view of the motor 30 of cylinder and double ended piston 32-33,32a-33a, 47-49 and 47a-49a relative position, and four piston arm 54a, 54b, 54c and 54d are arranged in each piston.Shown pump 67 is positioned under the axle 53, and shown belt pulley 50a and synchronous belt 51 are positioned at the top of motor 30.Shown starter 100 has the gear 101 of the wheel tooth 69a on the engagement flywheel 69.

A feature of the present invention is exactly the compression ratio that can change motor in the motor operation.The end that is installed in the arm 61 on the flywheel 69 enters into flywheel 69 on one point to move in the circular path at this arm 61.Referring to Figure 13, the end of arm 61 is in the sleeve bearing ball bushing assembly (sleevebearing ball bushing assembly) 80.The stroke of piston is by arm 61 controls.Arm 61 has formed an angle, for example about 15 ° with axle 53., as shown in figure 13, can change the angle of arm 61 to the right by the flywheel on the axle 53 69 or motion left, change the stroke of piston, change compression ratio thus.By rotating the nut 104 on the screw thread 105, can change the position of flywheel 69.Nut 104 is solid on axle 53 by thrust-bearing 106a key, and thrust-bearing 106a is fixed on its position by ring 106b.In position shown in Figure 12, flywheel 69 has moved to right-hand, has extended the stroke of piston.

In Figure 12, flywheel moves to increases the right-hand of stroke of piston, and this provides higher compression ratio.Nut 105 has been threaded to right-hand, makes axle 53 and flywheel 69 move to right-hand.Arm 61 extends much further in the bush assembly 80 and the rear portion of stretching out flywheel 69.

In Figure 13, flywheel moves to the left that reduces stroke of piston, and this provides lower compression ratio.Nut 105 has been threaded to left, makes axle 53 and flywheel 69 move to left.Arm 61 less stretches and enters into bush assembly 80.

Each piston arm on the transition arm is inserted in the sleeve bearing in the lining in the piston.Figure 14 shows a double-piston 110, and this double-piston has piston ring 111 that is positioned on the one end and the piston ring 112 that is positioned on its other end.Groove 113 is positioned at the avris of this piston.The position of sleeve bearing is with shown in 114.

Figure 15 shows a piston arm 116, and piston arm 116 extends in the piston 110, has passed through groove 113 and has entered into the sleeve bearing 117 of lining 115.Piston arm 116 is illustrated in a second place with 116a.Two- piston arm 116 and 116a show the limit movement scope of piston arm 116 in the engine operation process.

As shown in figure 16, piston arm 116 is in the sleeve bearing 117.Sleeve bearing 117 is in the trunnion 115.Piston arm 116 can freely rotate in the assembly of sleeve bearing 117 and piston arm 116, sleeve bearing 117 and trunnion 115 and sleeve bearing 118a, 118b rotate in piston 110, piston arm 116 can move axially along the axis of sleeve bearing 117, with straight line motion that allows double ended piston 110 and the motion that has connected the transition arm of piston arm 116.

It is how to be configured to use the four-way rotating valve 123 that is positioned on the output shaft 122 as an air engine that Figure 17 shows four cylinder engines 10 among Fig. 1.Each cylinder 1,2,3 and 4 is connected on the rotating valve 123 by flexible pipe 131,132,133 and 144 respectively.Suction port 124 is used to provide air, with operation motor 120.Continuously air is offered each piston 1a, 2a, 3a and 4a, with mobile piston to and fro in cylinder.By relief opening 136 exhausting air from cylinder.Be connected transition arm 126 on each piston as to the description of Fig. 1-6, moving, with rotary flywheel 129 and output shaft 22 by connecting pin 127 and 128.

Figure 18 is the sectional view of rotating valve 123, and at this moment, the air of supercharging or gas just enter into cylinder 1 by suction port 124, annular pass 125, passage 126, passage 130 and air hose 131.Rotating valve 123 is made up of a plurality of passages in the housing 123 and output shaft 122.The air of supercharging enters cylinder 1 makes piston 1a, 3a move to right-hand (as shown in figure 18).Discharge gas and enter into cavity 134, then from outlet pipe 136, discharge by passage 135 by pipeline 133 discharge cylinders 3.

Figure 18 a, 18b and 18c are the sectional views of valve 23, and they show when locating as shown in figure 18, and the air passageways of valve is along valve 23 residing three positions.

Shown in Figure 19 is has rotated 180 ° rotating valve 123 when the air of supercharging has been changed the direction of piston 1a, 3a and entered into cylinder 3.The air of supercharging enters into suction port 124, enters into cylinder 3 by annular chamber 125, passage 126, cavity 134 and air conduit 133.This makes the air in the cylinder 1 be discharged from by pipeline 131, cavity 130, pipeline 135, annular chamber 137 and relief opening 136 again.When piston 1a, 3a finished it to the stroke of left, axle 122 will rotate and rotate counterclockwise 360 °.

Only show the running that piston 1a, 3a illustrate air engine and valve 123 relative piston motions.The running of piston 2a, 4a is identical on function, and 360 ° the cycle that is this piston 2a, 4a is when axle turns over 90 °, and is reverse when axle turns over 270 °, gets back to 90 ° and finishes its cycle.Power stroke occurs in each 90 ° of rotation.

Figure 19 a, 19b and 19c are the sectional views of valve 123, and they show when locating as shown in figure 19, and the air passageways of valve is along valve 123 residing three positions.

The operating principle of the air engine of operation Figure 17 can be put upside down, and the motor 120 of Figure 17 is to be used as air or gas compressor or pump.Clockwise rotate motor 10 by applying rotational power for axle 122, relief opening 136 can be incorporated into gas in the cylinder, and mouthfuls 124 will air supply, and this air for example is used for driving pneumatic tool or is stored in the air tank.

In the above-described embodiment, shown cylinder is parallel to each other.But cylinder does not need parallel.Figure 20 shows and the similar embodiment of Fig. 1-6, and cylinder 150 and 151 is also not parallel each other.Relative transmission arm 154 formation with 153 of universal joint 160 permission piston arms 152 are not angles of 90 °.Even each cylinder is not parallel to each other mutually, motor is the same on function.

Also can carry out another remodeling to the motor 10 of Fig. 1-6.As shown in figure 21, this embodiment has single-ended piston.Piston 1a and 2a are connected on the universal joint 170 by transmission arm 171 and 172, are connected on the flywheel 173 by transmission arm 174.Basic difference is to make flywheel 173 rotate 360 ° piston 1a and the number of strokes of 2a.

Referring to Figure 22, one or two steam-cylinder piston assembly 300 has the cylinder 302,304 that has held a stroke changeable, double ended piston 306,308 respectively.Piston assembly 300 provides and the identical power stroke of traditional four-banger revolution.Each double ended piston 306,308 is connected on the transition arm 310 by a driving pin 312,314 respectively.Transition arm 310 is installed on the supporting member 316 by for example a universal joint 318 (U-joint), constant velocity joint or spherical bearing.A transmission arm 320 that extends from transition arm 310 is connected a rotating member for example on the flywheel 322.

Referring to Figure 22 and 23, cylinder 302,304 respectively has left and right sides cylinder halfbody 301a, the 301b that is installed on the package shell structure 303.Double ended piston 306,308 respectively has two-piston 330 and 332,330a and the 332a that connects by a center sub 334,334a respectively.Shown piston has equal lengths, although also can consider other length.For example, joint 334 is off center, so piston 330 is longer than piston 332.When piston is lighted successively with 330a, 332,330,332a, from position shown in Figure 22, flywheel is observed from the direction of arrow 333 to rotate counterclockwise, piston assembly 300 is motors of a four stroke cycle, and promptly each piston is lighted once in two of flywheel 322 changes.

When piston moves back and forth, driving pin 312,314 must be free to rotate around their common axis line E (arrow 305), can slide along axis E (arrow 307), can change along with the waving angle [alpha] (approximately ± 15 ° wave) of transition arm 310 simultaneously, and can center on center F (arrow 309) rotation with respect to the radial distance of the center line B of piston.Joint 334 is configured to the degrees of freedom that this motion can be provided.

If being configured to, two cylinders of piston assembly not 180 ° interval, perhaps used cylinder more than two, the cylinder 341 that is arranged in sleeve bearing 338 provides the extra freedom of movement that prevents that when each piston carries out moving of 8 fonts their interlocks (binding) are required along moving of arrow 350 directions, below will discuss.The size of groove 340 also must can provide enough clearances, to allow the 8 fonts motion of pin.

Referring to Figure 24 and 24a, U-joint 318 has defined a centrally-pivoted axle 352 (driving pin axis E has passed centrally-pivoted axle 352), and has a setting pin 354 and one horizontal pin 356.Transition arm 310 can 356 rotations along arrow 358 around pin 354, along arrow 360 around pin.

Referring to Figure 25,25a and 25b, as the replacement scheme that transition arm 310 is connected the spherical bearing on the flywheel 322, transmission arm 320 is received within the columniform pivot pin 370 that is installed on the flywheel, and center 372 certain distances that radially depart from flywheel, for example 2.125 inches, need this side-play amount to produce the required angle [alpha] (Figure 22) of waving in the transition arm.

Referring to Figure 26,, change by rotatingshaft 400 along the axial position of the flywheel 322 of axis A for compression and the displacement that changes piston assembly 300.Sprocket wheel 410 is installed on the axle 400, to rotate with axle 400.One second sprocket wheel 412 is connected on the sprocket wheel 410 by roller chain 413.Sprocket wheel 412 is installed on the threaded rotating cylinder 414.The screw thread 418 of the screw thread 416 contacts one static outer cylinder 420 of cylinder 414.Axle 400 rotates along arrow 401, so sprocket wheel 410 and 412 has driven the rotation of cylinder 414.Because outer cylinder 420 is fixed, the rotation of cylinder 414 makes it along axis A, arrow 403 straight line motions.Cylinder 414 is between the axle collar 422 and gear 424, and back both is fixed on the main driving axle 408.Live axle 408 itself is fixed on again on the flywheel 322.Therefore, cylinder 414 is converted into the straight line motion of flywheel 322 along axis A along moving of axis A.This causes flywheel 322 to slide along the axis H of the driving arm 320 of transition arm 310, has changed angle beta, has therefore changed the stroke of piston.Thrust-bearing 430 is positioned at the two ends of cylinder 414, and a sleeve bearing 432 is between cylinder 414 and axle 408.

In order to keep sprocket wheel 410 and 412 alignment, axle 400 has screw thread at regional 402 places, and is received in the tapped hole 404 of cross bar 406 of package shell structure 303.The number of teeth ratio of the relative sprocket wheel 410 of the number of teeth of sprocket wheel 412 for example is 4: 1.Therefore, rotate a week, around axle 400 essential the rotations for making cylinder 414.In order to keep alignment, the number of threads of threaded portion 402 per inch is four times of cylinder screw thread 416, and for example, threaded portion 402 per inch have 32 screw threads, and then cylinder screw thread 416 per inch have eight screw threads.

When flywheel motion is extremely right-hand, as shown in figure 26, just increased the stroke and the compression ratio of piston.Flywheel is moved to left then reduced stroke and compression ratio.The further advantage that changes stroke is the change of each piston displacement, is the variation of motor displacement therefore.The horsepower of internal-combustion engine is closely related with the displacement of motor.For example, in two cylinder horizontal engines, when compression ratio when increase to 12: 1 at 6: 1, displacement has increased about 20%.Only increase displacement and just increased by about 20% horsepower.The increase of compression ratio also makes horsepower increase or increase about 25% horsepower with about every 5% speed.If horsepower keeps constant, and compression ratio increased to 12: 1 from 6: 1, and the consumption of oil will reduce 25%.

When assembly 300 operated as a motor, flywheel had enough intensity and bears bigger centrifugal force.When piston assembly moves, can change the position of flywheel and the compression ratio of piston assembly.

Piston assembly 300 has a force-feed lubrication system.Provide pressure by an engine-driven displacement pump (figure does not show) with pressure relief valve (excessive) to prevent pressure.Lubricate the bearing 430 and 432 and the surface of contact of driving arm 320 and flywheel 322 of live axle 408 by means of aperture 433 (Figure 26).

Referring to Figure 27, for lubricated U-joint 318, wrist pin joint 306,308 and cylinder wall, the oil under the pressure effect is sent to the top and the bottom of the trunnion 354 of setting from oil pump by fixing U-joint carriage.Hydraulic fluid port 450,452 is sold the opening 454,456 that guides to the transition arm from erectting respectively.Shown in Figure 27 A, pin 312,314 has respectively defined a through hole 458.Corresponding fluid in each through hole 458 and the opening 454,456 is logical.As shown in figure 23, the hole in each pin 460,462 is connected on the chamber 465 in each piston by groove 461 and the aperture 463 by sleeve bearing 338.Several oil pipes 464 stretch out from these chambers, and are connected on the piston skirt 466 of each piston, provide lubricated to give cylinder wall and piston ring 467.Also draw from chamber 465 in a hole, oil is injected directly on the inboard of each piston head, in order to cooling.

Referring to Figure 28-28c, the assembly 300 shown in it is configured to as airplane engine 300a and uses, and engine ignitor comprises two magnetogenerators 600, with light up plug (figure does not show).The driving gear 604 and 606 (Figure 28 c) that a magnetogenerator 600 and a starter 602 are positioned at respectively on the low axle 608 drives, and axle 608 is parallel to main driving axle 408 installations and is positioned under it.The whole length that axle 608 extends to motor, and the gear 424 (Figure 26) of driven shaft 408 drives, and to live axle 408 with one to one speed ratio engagement driving.The transmission device that is used for magnetogenerator is reduced to their speed half of axle 608 speed.Engagement driving starter 602 is so that enough torques to be provided, with ato unit.

Referring to Figure 29 and 29a, shown in it is compressor or the pump with variable compression of zero stroke performance.At this, flywheel 322 is replaced by a Runner assembly 500.Assembly 500 has a hollow shaft 502 and a pivot arm 504, and pivot arm 504 is rotatably connected on the propeller boss 508 of axle 502 by a pin 506.Propeller boss 508 has defined a hole 510, and pivot arm 504 has defined a hole 512, to admit pin 506.One controlling rod 514 is arranged in axle 502.Controlling rod 514 comprises a connecting rod 516, and connecting rod 516 is rotatably connected on the remainder of bar 514 by a pin 518.Bar 514 has defined a hole 511, has defined a hole 513 and connect part 516, to admit pin 518.Controlling rod 514 is supported by two sleeve bearings, to move along its axis M.Connecting rod 516 and pivot arm 504 link together by a pin 522.Connecting rod 516 has defined a hole 523, and pivot arm 504 has defined a hole 524, to admit pin 522.

Admitted the cylindrical pivot pin 370 of Figure 25 of driving arm 320 to be positioned in the pivot arm 504.Pivot arm 504 has defined hole 526, to admit cylindrical extended portion 378,380.Axle 502 is supported so that rotate by bearing 530, and bearing 530 can be for example ball, sleeve or roller bearing.Be installed in the driver on the axle 502, for example belt pulley 532 or gear, Driven Compressor or pump.

In operation, in order to set required stroke of piston, controlling rod 514 moves along its axis M with the direction of arrow 515, cause pivot arm 504 506 rotations along arrow 517 around pin, therefore when pivot arm 504 during along axis H (Figure 26) slip of transition arm driving arm 320, trunnion 370 axis N no longer align (shown in dotted line) with axis M.When needing the zero stroke of piston, axis M and N align, and therefore the rotation of axle 514 can not cause the motion of piston.This structure is applicable to double ended piston and one-sided piston.

The ability that can change stroke of piston allows axle 514 to turn round with single speed by drive unit 532, and the output of pump or compressor simultaneously can change according to need continuously.When not needing to export, around driving arm 320 rotations of transition arm 310, simultaneously do not swing simply by driving arm for pivot arm 504.When needs were exported, axle 514 full-speed operations were so when pivot arm 504 controlled bars 514 are pulled to off-axis, will produce an instant impact, and reach goal pace after can not letting out.Because therefore the action that is not activated/stops to exist less mechanical load on drive system.Fast stroke is reduced to zero ability protection is provided, particularly when downstream block takes place, prevent the infringement in liquid pump.

If not spaced apart 180 ° of two cylinders (observing from the end) have perhaps been used two with casing top half in piston assembly 300, the motion of 8 fonts will be carried out in the end that is connected the pin 312,314 of joint 306,308, as shown in figure 30.Figure 30 shows the 8 fonts motion of the piston assembly with four double ended pistons.In the piston two are configured to horizontal (not carrying out the motion of 8 fonts) shown in Figure 22, and that other two pistons are provided in is spaced between two horizontal pistons (8 fonts that therefore are oriented to carry out maximum possible depart from).Be connected the degree that second group of pin on the piston depart from a straight line (the Y-axis line of Figure 30) and depend on the pendulum angle (pillar angle (mast angle)) of driving arm and the distance of this pin decentre pivoting point 352 (the X-axis line of Figure 30).

In the form of four cylinders, the axis by the relative centrally-pivoted axle of pin of the piston pintle assembly of each in four double ended pistons is provided with at 45, and splay motion equates at each piston pin place.Provide the motion in the piston pivot bushings in the place that the splayed shape motion takes place, to prevent interlock.

When piston assembly 300 is configured to when for example using as diesel engine, powerful supporting is provided at the joint of pin 312,314 and transition arm 310, compares with spark ignition engine, to produce the higher compression of diesel engine.Referring to Figure 31, supporting member 550 is connected on the transition arm 310 by bolt 551, and comprises an opening 552, to admit the end 554 of pin.

Can be used to directly firing pressure is applied in the pump piston according to motor of the present invention.Referring to Figure 32 and 32a, one or four cylinders, two-stroke cycle motor 600 (each in four pistons 602 is burnt once in a revolution) firing pressure is applied on each in four pump pistons 604.Each pump piston 604 is connected on the outlet side 606 of a respective pistons cylinder 608.Pump piston extends in the pump head 610.

As mentioned above, a transition arm 620 is connected on each cylinder 608 and the flywheel 622.Also as mentioned above, an auxiliary output shaft 624 is connected on the flywheel 622, to rotate with flywheel.

This motor is the motor of a two-stroke cycle because the impact each time of piston 602 (shown in figure 32, piston 602 moves to right-hand.) must be power stroke.The quantity of engine cylinder is selected according to the needs of pump.This pump can be liquid pump or air pump.When using as a multistage compressor, each pump piston 606 can have different diameters.Pumping function does not produce bearing load, therefore, except the friction that pump piston itself is produced, does not cause friction.

Other embodiments are within the scope of following claims.

Claims (30)

1. the piston assembly of a variable compression, it comprises:

A plurality of pistons,

A transition arm that is connected with each piston, described transition arm comprises the actuator with an axis, and

Along the rotating component that the axis of described actuator and described actuator are connected slidably, described rotating component with respect to the determining positions of described actuator the compression ratio of described piston assembly.

2. assembly as claimed in claim 1 is characterized in that, each piston comprises a both-end piston.

3. assembly as claimed in claim 2 is characterized in that, this transition arm is connected about center of each double ended piston.

4. assembly as claimed in claim 2 is characterized in that this transition arm is connected on each piston, makes the straight line motion of relative this transition arm of this rotating component change the compression ratio and the displacement of each double ended piston.

5. assembly as claimed in claim 1 is characterized in that, these a plurality of pistons comprise two pistons, and the axis place of the rotation axis of rotating component and two-piston at grade.

6. assembly as claimed in claim 5 is characterized in that, each piston comprises a both-end piston.

7. assembly as claimed in claim 1 is characterized in that this rotating component comprises a flywheel.

8. assembly as claimed in claim 7 is characterized in that, also comprises a controlling rod that is operatively coupled to described flywheel, and the transmission of controlling rod provides this flywheel straight line motion of this transition arm relatively.

9. assembly as claimed in claim 1 is characterized in that this rotating component is configured to the position that can be positioned at one zero strokes, in this position, need not the corresponding piston motion, and the rotation of this rotating component just can take place.

10. assembly as claimed in claim 9 is characterized in that, this rotating component comprises a pivot member that is pivotally connected on the control piece, and the transmission of this control piece has caused the motion of this pivot member, to change compression ratio.

11. assembly as claimed in claim 1 is characterized in that, each piston has an axis, make they parallel axes each piston is set.

12. assembly as claimed in claim 1 is characterized in that, also comprises a plurality of driving pins, each drives pin this transition arm is connected to a corresponding piston.

13. assembly as claimed in claim 1 is characterized in that, this actuator extends in the opening of this rotating component and the periphery of contiguous this rotating component.

14. assembly as claimed in claim 13 is characterized in that, this driving arm extends into a pivot pin that is arranged in this rotating component.

15. assembly as claimed in claim 1 is characterized in that, also comprises a main driving axle that is connected on this rotating component, a parallel axes of this live axle is in the axis of each piston.

16. assembly as claimed in claim 1 is characterized in that, also comprises this transition arm is connected to a universal joint on the supporting member.

17. assembly as claimed in claim 1 is characterized in that, each piston is not parallel each other.

18. assembly as claimed in claim 1 is characterized in that, has at least one also to comprise a rear pump piston in a plurality of pistons, to drive a pump.

19. a method that is used to change the piston assembly compression ratio, it comprises:

Provide: a plurality of pistons; A transition arm that is connected with each piston, described transition arm comprises the actuator with an axis; And a rotating component that is connected slidably along the axis of described actuator and described actuator, and

Described rotating component moves to change the compression ratio of described piston assembly with respect to described actuator.

20. a method that is used to improve piston assembly efficient, it comprises:

Provide: a plurality of double ended pistons; With the transition arm that about center of each double ended piston is connected, described transition arm comprises the actuator with an axis; And a rotating component that is connected slidably along the axis of described actuator and described actuator, and

Described rotating component is with respect to compression ratio and the displacement of described actuator motion to change described double ended piston assembly.

21. a piston assembly, it comprises:

A plurality of double ended pistons,

Be connected the transition arm on each double ended piston, this transition arm comprises a plurality of driving arms, and each driving arm has defined a drive arm axis,

A plurality of joints, each joint is connected this transition arm on the relevant double ended piston, each joint provides the degrees of freedom of the four direction between this transition arm and the relevant double ended piston, four degrees of freedom be around drive arm axis rotation, along the slip of drive arm axis, around perpendicular to the rotation of an axis of drive arm axis with along the slip of this vertical axis direction, and

This transition arm is connected a universal joint on the supporting member.

22. piston assembly as claimed in claim 21 is characterized in that, these a plurality of pistons comprise two double ended pistons, and the axis place that is connected the rotation axis of the rotating component on this transition arm and two double ended pistons at grade.

23. piston assembly as claimed in claim 21 is characterized in that, these a plurality of pistons comprise two double ended pistons, and the axis of this double ended piston not with the rotation axis place that is connected the rotating component on this transition arm at grade.

24. piston assembly as claimed in claim 23 is characterized in that, the axis of this two double ended piston becomes about 90 degree each other.

25. a piston assembly, it comprises:

At least two double ended pistons, the axis of this double ended piston not with the rotation axis place that is connected the rotating component on this transition arm at grade,

Be connected the transition arm on each double ended piston, and

This transition arm is connected a universal joint on the supporting member.

26. piston assembly as claimed in claim 25, it is characterized in that, this transition arm comprises a plurality of driving arms, each driving arm has defined a drive arm axis, this piston assembly also comprises at least two joints, each joint is connected this transition arm on the relevant double ended piston, each joint provides four degrees of freedom between this transition arm and the relevant double ended piston, four degrees of freedom be around drive arm axis rotation, along the slip of drive arm axis, around perpendicular to the rotation of an axis of drive arm axis with along the slip of this vertical axis direction.

27. a piston assembly, it comprises:

At least two pistons, the axis place of these two pistons at grade, the piston rod of each piston is constituted as and is used for straight line motion,

Be connected the transition arm on each piston, and

Described transition arm is connected a universal joint on the supporting member, and wherein, the center of described universal joint is not on the described same plane.

28. a piston assembly, it comprises:

A plurality of pistons, the piston rod of each piston are constituted as and are used for straight line motion,

One transition arm,

A plurality of actuators, each actuator is connected described transition arm on the wherein corresponding piston, and

Described transition arm is connected a universal joint on the supporting member, and wherein each actuator can move with respect to described universal joint.

29. a piston assembly, it comprises:

A plurality of double end parts, each double end parts have and are constituted as first and second parts that are used for along same axis moving linearly, described first and second parts one of them is a piston at least,

Be connected the transition arm on the fixed support, described transition arm includes a plurality of driving arms, and each driving arm limits a drive arm axis, and

A plurality of joints, each joint is used for described a plurality of driving arms one of them is connected wherein corresponding double end parts, each joint provides the rotation around described drive arm axis, and slides on one of them the direction at least perpendicular to first and second quadrature-axis of described same axis.

30. a piston assembly, it comprises:

A plurality of double end parts, each double end parts have and are constituted as first and second parts that are used for along same axis moving linearly, described first and second parts one of them is a piston at least,

Be connected the transition arm on the fixed support, described transition arm includes a plurality of driving arms, and each driving arm limits a drive arm axis, and

A plurality of joints, each joint is used for described transition arm is connected wherein corresponding double end parts, each joint is provided at the degrees of freedom on the four direction between transition arm and the corresponding double end parts, four degrees of freedom be around drive arm axis rotation, along the slip of drive arm axis, around perpendicular to the rotation of an axis of drive arm axis with along the slip of this vertical axis direction.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US92904297A | 1997-09-15 | 1997-09-15 | |

| US08/929,042 | 1997-09-15 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN1336982A CN1336982A (en) | 2002-02-20 |

| CN1214180C true CN1214180C (en) | 2005-08-10 |

Family

ID=25457228

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CNB988090643A Expired - Fee Related CN1214180C (en) | 1997-09-15 | 1998-09-15 | Variable compression pistol assembly |

Country Status (9)

| Country | Link |

|---|---|

| EP (1) | EP1015744B1 (en) |

| JP (1) | JP4260363B2 (en) |

| KR (1) | KR100599138B1 (en) |

| CN (1) | CN1214180C (en) |

| AT (1) | ATE397149T1 (en) |

| CA (1) | CA2300111C (en) |

| DE (1) | DE69839565D1 (en) |

| RU (1) | RU2219358C2 (en) |

| WO (1) | WO1999014471A1 (en) |

Families Citing this family (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6460450B1 (en) * | 1999-08-05 | 2002-10-08 | R. Sanderson Management, Inc. | Piston engine balancing |

| AU6399100A (en) * | 1999-08-05 | 2001-03-05 | R. Sanderson Management, Inc. | Piston assembly |

| JP2003506618A (en) * | 1999-08-05 | 2003-02-18 | アール サンダーソン マネージメント インコーポレイテッド | Piston / engine balancing |

| WO2002063139A1 (en) * | 2001-02-08 | 2002-08-15 | R. Sanderson Management, Inc. | Variable stroke/clearance mechanism |

| US6854377B2 (en) * | 2001-11-02 | 2005-02-15 | R. Sanderson Management, Inc. | Variable stroke balancing |

| US7438029B2 (en) | 2004-03-18 | 2008-10-21 | R. Sanderson Management, Inc. | Piston waveform shaping |

| EP1766187A1 (en) * | 2004-05-26 | 2007-03-28 | R. Sanderson Management, Inc. | Variable stroke and clearance mechanism |

| AU2013202222B2 (en) * | 2008-03-14 | 2015-07-09 | Torkildsen, Odd Bernhard MR | Combustion engine having mutually connected pistons |

| US8511265B2 (en) * | 2009-06-01 | 2013-08-20 | Steven Don Arnold | Variable stroke and compression ratio engine |

Family Cites Families (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1772977A (en) * | 1929-02-25 | 1930-08-12 | Italien American Motors Inc | Internal-combustion engine |

| US2940325A (en) * | 1957-02-15 | 1960-06-14 | Nakesch Michael | Internal combustion engine with swash plate drive |

| FR1416219A (en) * | 1964-11-27 | 1965-10-29 | System for transforming linear movement into circular, for heat engines and compressors | |

| DE1451926A1 (en) * | 1965-05-07 | 1970-03-05 | Pattas Dr Ing Konstantin | Internal combustion piston engine with automatic adjustment of the piston stroke adapted to the respective requirements of the operation with simultaneous adjustment of the compression ratio |

| US4011842A (en) | 1975-09-08 | 1977-03-15 | Francis William Davies | Piston machine |

| US4174684A (en) * | 1977-05-23 | 1979-11-20 | Hallmann Eckhard P | Variable stroke internal combustion engine |

| US5007385A (en) * | 1989-07-15 | 1991-04-16 | Hiromasa Kitaguchi | Crankless engine |

| CN1042974C (en) * | 1993-05-07 | 1999-04-14 | 威斯坡尔技术有限公司 | Wobble yoke assembly |

| GB2287766B (en) | 1994-03-18 | 1998-01-28 | Yoshiki Kogyo Kk | Apparatus for mutual conversion between circular motion and reciprocal motion |

| US5553582A (en) * | 1995-01-04 | 1996-09-10 | Speas; Danny E. | Nutating disc engine |

-

1998

- 1998-09-15 CN CNB988090643A patent/CN1214180C/en not_active Expired - Fee Related

- 1998-09-15 RU RU2000109597/06A patent/RU2219358C2/en not_active IP Right Cessation

- 1998-09-15 AT AT98948218T patent/ATE397149T1/en not_active IP Right Cessation

- 1998-09-15 CA CA002300111A patent/CA2300111C/en not_active Expired - Fee Related

- 1998-09-15 JP JP2000511989A patent/JP4260363B2/en not_active Expired - Lifetime

- 1998-09-15 WO PCT/US1998/019164 patent/WO1999014471A1/en active IP Right Grant

- 1998-09-15 DE DE69839565T patent/DE69839565D1/de not_active Expired - Lifetime

- 1998-09-15 KR KR1020007002573A patent/KR100599138B1/en not_active IP Right Cessation

- 1998-09-15 EP EP98948218A patent/EP1015744B1/en not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| EP1015744A1 (en) | 2000-07-05 |

| JP4260363B2 (en) | 2009-04-30 |

| KR20010023889A (en) | 2001-03-26 |

| KR100599138B1 (en) | 2006-07-12 |

| EP1015744B1 (en) | 2008-05-28 |

| CA2300111C (en) | 2009-05-26 |

| ATE397149T1 (en) | 2008-06-15 |

| JP2001516837A (en) | 2001-10-02 |

| EP1015744A4 (en) | 2004-03-03 |

| CA2300111A1 (en) | 1999-03-25 |

| CN1336982A (en) | 2002-02-20 |

| RU2219358C2 (en) | 2003-12-20 |

| DE69839565D1 (en) | 2008-07-10 |

| WO1999014471A1 (en) | 1999-03-25 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN1217087C (en) | Rotary engine | |

| CN1175172C (en) | Charged two or four stroke internal-combustion engine | |

| US6446587B1 (en) | Piston engine assembly | |

| US8316817B2 (en) | Rotary piston engine | |

| CN1676905A (en) | Power plant including an internal combustion engine with a variable compression ratio system | |

| CN2700581Y (en) | Engine | |

| CN1112641A (en) | Apparatus for mutual conversion between circular motion and reciprocal motion | |

| CN1957166A (en) | Double action piston assembly | |

| CN1173215A (en) | Axial piston rotary engine | |

| CN1093590C (en) | Axial piston machines | |

| CN1214180C (en) | Variable compression pistol assembly | |

| CN1171144A (en) | Reciprocating machine | |

| CN100335775C (en) | Air and fuel jet engine | |

| CN101205812A (en) | Four-piston cylinder engine | |

| CN1902388A (en) | Reciprocating engine | |

| CN100338336C (en) | Ball shape rotary engine | |

| US4612882A (en) | Rotating cylinder internal combustion engine | |

| WO2021102303A1 (en) | Internal combustion engine with rotating pistons and cylinders and related devices and methods of using the same | |

| JP2006516695A (en) | Improved engine | |

| JP4404488B2 (en) | Piston engine balancing | |

| CN1580494A (en) | Reciprocating-rotating power converting mechanism without crank, and its engine and compressor | |

| CN1272592A (en) | Rotating linkage mechanism | |

| CN2833136Y (en) | Spherical rotary engine | |

| CN2315299Y (en) | Main machine for drawing type engine | |

| JP2003510495A (en) | Piston assembly |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| C10 | Entry into substantive examination | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| C19 | Lapse of patent right due to non-payment of the annual fee | ||

| CF01 | Termination of patent right due to non-payment of annual fee |