CN1088237C - 光盘金属模和记录光盘 - Google Patents

光盘金属模和记录光盘 Download PDFInfo

- Publication number

- CN1088237C CN1088237C CN96117981A CN96117981A CN1088237C CN 1088237 C CN1088237 C CN 1088237C CN 96117981 A CN96117981 A CN 96117981A CN 96117981 A CN96117981 A CN 96117981A CN 1088237 C CN1088237 C CN 1088237C

- Authority

- CN

- China

- Prior art keywords

- information signal

- compact disc

- signal surface

- die

- concordant

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000002184 metal Substances 0.000 title claims abstract description 65

- 239000000758 substrate Substances 0.000 claims abstract description 57

- 239000011347 resin Substances 0.000 claims abstract description 12

- 229920005989 resin Polymers 0.000 claims abstract description 12

- 230000001681 protective effect Effects 0.000 claims description 19

- 238000005266 casting Methods 0.000 claims description 9

- 230000015572 biosynthetic process Effects 0.000 claims description 5

- LENZDBCJOHFCAS-UHFFFAOYSA-N tris Chemical compound OCC(N)(CO)CO LENZDBCJOHFCAS-UHFFFAOYSA-N 0.000 claims description 2

- 230000014509 gene expression Effects 0.000 description 9

- 238000000034 method Methods 0.000 description 6

- 238000004519 manufacturing process Methods 0.000 description 5

- 239000000463 material Substances 0.000 description 5

- 238000003825 pressing Methods 0.000 description 5

- 230000003287 optical effect Effects 0.000 description 4

- 230000003321 amplification Effects 0.000 description 2

- 238000003199 nucleic acid amplification method Methods 0.000 description 2

- 238000005498 polishing Methods 0.000 description 2

- 238000007634 remodeling Methods 0.000 description 2

- 238000005987 sulfurization reaction Methods 0.000 description 2

- 239000003814 drug Substances 0.000 description 1

- 230000005489 elastic deformation Effects 0.000 description 1

- 238000009434 installation Methods 0.000 description 1

- 238000012423 maintenance Methods 0.000 description 1

- 229920000515 polycarbonate Polymers 0.000 description 1

- 239000004417 polycarbonate Substances 0.000 description 1

- 230000011514 reflex Effects 0.000 description 1

- 238000010008 shearing Methods 0.000 description 1

Images

Classifications

-

- G—PHYSICS

- G11—INFORMATION STORAGE

- G11B—INFORMATION STORAGE BASED ON RELATIVE MOVEMENT BETWEEN RECORD CARRIER AND TRANSDUCER

- G11B7/00—Recording or reproducing by optical means, e.g. recording using a thermal beam of optical radiation by modifying optical properties or the physical structure, reproducing using an optical beam at lower power by sensing optical properties; Record carriers therefor

- G11B7/24—Record carriers characterised by shape, structure or physical properties, or by the selection of the material

- G11B7/26—Apparatus or processes specially adapted for the manufacture of record carriers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C45/00—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor

- B29C45/17—Component parts, details or accessories; Auxiliary operations

- B29C45/26—Moulds

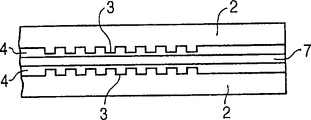

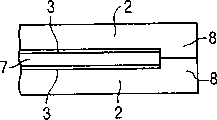

- B29C45/263—Moulds with mould wall parts provided with fine grooves or impressions, e.g. for record discs

- B29C45/2632—Stampers; Mountings thereof

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C45/00—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor

- B29C45/17—Component parts, details or accessories; Auxiliary operations

- B29C45/26—Moulds

- B29C45/263—Moulds with mould wall parts provided with fine grooves or impressions, e.g. for record discs

- B29C45/2632—Stampers; Mountings thereof

- B29C2045/264—Holders retaining the inner periphery of the stamper

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10S—TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10S428/00—Stock material or miscellaneous articles

- Y10S428/913—Material designed to be responsive to temperature, light, moisture

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10S—TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10S430/00—Radiation imagery chemistry: process, composition, or product thereof

- Y10S430/146—Laser beam

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/21—Circular sheet or circular blank

Landscapes

- Engineering & Computer Science (AREA)

- Manufacturing & Machinery (AREA)

- Mechanical Engineering (AREA)

- Manufacturing Optical Record Carriers (AREA)

- Moulds For Moulding Plastics Or The Like (AREA)

- Optical Record Carriers And Manufacture Thereof (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP351356/95 | 1995-12-26 | ||

| JP35135695A JP3264419B2 (ja) | 1995-12-26 | 1995-12-26 | 記録ディスク及び成形用金型装置 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN1161540A CN1161540A (zh) | 1997-10-08 |

| CN1088237C true CN1088237C (zh) | 2002-07-24 |

Family

ID=18416751

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN96117981A Expired - Lifetime CN1088237C (zh) | 1995-12-26 | 1996-12-24 | 光盘金属模和记录光盘 |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US5851620A (enExample) |

| JP (1) | JP3264419B2 (enExample) |

| KR (1) | KR100228845B1 (enExample) |

| CN (1) | CN1088237C (enExample) |

| TW (1) | TW322576B (enExample) |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE29619143U1 (de) * | 1996-11-05 | 1997-01-02 | Claußnitzer, Werner, 42329 Wuppertal | Etikettenbogen |

| US6020042A (en) * | 1998-10-14 | 2000-02-01 | First Light Technology, Inc. | Substrate design for bonded storage disks and method of making same |

| JP4248197B2 (ja) * | 2002-07-04 | 2009-04-02 | Tdk株式会社 | 光記録媒体、光記録媒体の製造方法及び製造装置 |

| TWI241948B (en) * | 2002-11-18 | 2005-10-21 | Sumitomo Heavy Industries | Molding die, molding method, disk substrate, and molding machine |

| JP4064871B2 (ja) * | 2003-06-05 | 2008-03-19 | 株式会社東芝 | 光ディスク及び光ディスク製造方法 |

| US20080291815A1 (en) * | 2007-05-23 | 2008-11-27 | Imation Corp. | Topographical surface label formed in an optical disk substrate |

| US8741394B2 (en) | 2010-03-25 | 2014-06-03 | Novellus Systems, Inc. | In-situ deposition of film stacks |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4795127A (en) * | 1986-09-27 | 1989-01-03 | Kabushikik Kaisha Meiki Seisakusho | Mold assembly of injection-molding machine |

| JP2642158B2 (ja) * | 1988-08-16 | 1997-08-20 | 住友重機械工業株式会社 | 光ディスク基板成形用金型 |

| US5059462A (en) * | 1988-11-24 | 1991-10-22 | Mitsui Petrochemical Industries, Ltd. | Information recording medium |

| JPH05205320A (ja) * | 1992-01-28 | 1993-08-13 | Victor Co Of Japan Ltd | ディスク製造方法及びディスク |

| JP3099168B2 (ja) * | 1994-05-25 | 2000-10-16 | 株式会社名機製作所 | ディスク基板成形用金型 |

-

1995

- 1995-12-26 JP JP35135695A patent/JP3264419B2/ja not_active Expired - Lifetime

-

1996

- 1996-12-11 TW TW085115307A patent/TW322576B/zh not_active IP Right Cessation

- 1996-12-18 US US08/769,592 patent/US5851620A/en not_active Expired - Lifetime

- 1996-12-24 CN CN96117981A patent/CN1088237C/zh not_active Expired - Lifetime

- 1996-12-26 KR KR1019960082413A patent/KR100228845B1/ko not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| KR100228845B1 (ko) | 1999-11-01 |

| KR970050426A (ko) | 1997-07-29 |

| JPH09174618A (ja) | 1997-07-08 |

| JP3264419B2 (ja) | 2002-03-11 |

| CN1161540A (zh) | 1997-10-08 |

| US5851620A (en) | 1998-12-22 |

| TW322576B (enExample) | 1997-12-11 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN1175408C (zh) | 光学信息记录介质及其生产方法 | |

| CN1088237C (zh) | 光盘金属模和记录光盘 | |

| KR20010079941A (ko) | 이중층 디브이디 디스크와 그 제조 방법 및 제조장치 | |

| US5345436A (en) | Recording medium of flat surface with resin filled ring grove | |

| CN1573996A (zh) | 两面光盘及其制造方法 | |

| CN1127727C (zh) | 光盘模制装置和光盘模制方法 | |

| CN1062966C (zh) | 用于制作供压制特定光盘用的模具的主盘及其制作方法 | |

| US6758664B1 (en) | Self-leveling stamper module | |

| US6815029B2 (en) | Stamper, mold system, recording medium substrate, recording medium, optical disc substrate, optical disc, and method for producing stamper | |

| US20090010147A1 (en) | Optical disk and molding die apparatus | |

| KR100207908B1 (ko) | 접착형 디스크와 그의 제조방법 및 디스크 성형장치 | |

| JPH0444818B2 (enExample) | ||

| EP1429322A1 (en) | Optical recording medium | |

| US6692246B1 (en) | Apparatus for uninterrupted multi-layer disc manufacturing | |

| KR100364667B1 (ko) | 광기록매체 및 그 제조방법과 광기록매체 성형용 금형장치 | |

| EP2216786A1 (en) | Dual layer optical disc and manufacturing method therefor | |

| CN2445404Y (zh) | 带图案的光盘 | |

| JPH03295041A (ja) | 射出成形用スタンパー | |

| KR100219690B1 (ko) | 광기록매체용 스탬퍼 | |

| CN1277263C (zh) | 混合型光盘记录媒体 | |

| JP2006297639A (ja) | 光ディスク基板成形用スタンパ | |

| Morita et al. | High quality optical disc stampers with round edge grooves | |

| JPS6242345A (ja) | 光デイスク用基板の製造方法 | |

| JPH0763991B2 (ja) | フォーマット入り光ディスク基板成形用金型 | |

| JPH10128807A (ja) | 型押えと型とこれを用いた成形装置とこれにより成形された成型品 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| ASS | Succession or assignment of patent right |

Owner name: JVC KENWOOD CORPORATION Free format text: FORMER OWNER: VICTORY CO. LTD. Effective date: 20140306 |

|

| TR01 | Transfer of patent right | ||

| TR01 | Transfer of patent right |

Effective date of registration: 20140306 Address after: Kanagawa Patentee after: JVC Kenwood Corp. Address before: Kanagawa Patentee before: Victory Co., Ltd. |

|

| CX01 | Expiry of patent term |

Granted publication date: 20020724 |

|

| EXPY | Termination of patent right or utility model |