CN102725120A - 预测和优化螺杆挤压机和/或挤压方法的基于数据的模型 - Google Patents

预测和优化螺杆挤压机和/或挤压方法的基于数据的模型 Download PDFInfo

- Publication number

- CN102725120A CN102725120A CN2010800577856A CN201080057785A CN102725120A CN 102725120 A CN102725120 A CN 102725120A CN 2010800577856 A CN2010800577856 A CN 2010800577856A CN 201080057785 A CN201080057785 A CN 201080057785A CN 102725120 A CN102725120 A CN 102725120A

- Authority

- CN

- China

- Prior art keywords

- screw

- profile

- data

- screw extruder

- elements

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/25—Component parts, details or accessories; Auxiliary operations

- B29C48/251—Design of extruder parts, e.g. by modelling based on mathematical theories or experiments

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29B—PREPARATION OR PRETREATMENT OF THE MATERIAL TO BE SHAPED; MAKING GRANULES OR PREFORMS; RECOVERY OF PLASTICS OR OTHER CONSTITUENTS OF WASTE MATERIAL CONTAINING PLASTICS

- B29B7/00—Mixing; Kneading

- B29B7/30—Mixing; Kneading continuous, with mechanical mixing or kneading devices

- B29B7/34—Mixing; Kneading continuous, with mechanical mixing or kneading devices with movable mixing or kneading devices

- B29B7/38—Mixing; Kneading continuous, with mechanical mixing or kneading devices with movable mixing or kneading devices rotary

- B29B7/46—Mixing; Kneading continuous, with mechanical mixing or kneading devices with movable mixing or kneading devices rotary with more than one shaft

- B29B7/48—Mixing; Kneading continuous, with mechanical mixing or kneading devices with movable mixing or kneading devices rotary with more than one shaft with intermeshing devices, e.g. screws

- B29B7/488—Parts, e.g. casings, sealings; Accessories, e.g. flow controlling or throttling devices

- B29B7/489—Screws

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/03—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor characterised by the shape of the extruded material at extrusion

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/25—Component parts, details or accessories; Auxiliary operations

- B29C48/251—Design of extruder parts, e.g. by modelling based on mathematical theories or experiments

- B29C48/2517—Design of extruder parts, e.g. by modelling based on mathematical theories or experiments of intermeshing screws

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/25—Component parts, details or accessories; Auxiliary operations

- B29C48/36—Means for plasticising or homogenising the moulding material or forcing it through the nozzle or die

- B29C48/395—Means for plasticising or homogenising the moulding material or forcing it through the nozzle or die using screws surrounded by a cooperating barrel, e.g. single screw extruders

- B29C48/40—Means for plasticising or homogenising the moulding material or forcing it through the nozzle or die using screws surrounded by a cooperating barrel, e.g. single screw extruders using two or more parallel screws or at least two parallel non-intermeshing screws, e.g. twin screw extruders

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/25—Component parts, details or accessories; Auxiliary operations

- B29C48/36—Means for plasticising or homogenising the moulding material or forcing it through the nozzle or die

- B29C48/395—Means for plasticising or homogenising the moulding material or forcing it through the nozzle or die using screws surrounded by a cooperating barrel, e.g. single screw extruders

- B29C48/40—Means for plasticising or homogenising the moulding material or forcing it through the nozzle or die using screws surrounded by a cooperating barrel, e.g. single screw extruders using two or more parallel screws or at least two parallel non-intermeshing screws, e.g. twin screw extruders

- B29C48/402—Means for plasticising or homogenising the moulding material or forcing it through the nozzle or die using screws surrounded by a cooperating barrel, e.g. single screw extruders using two or more parallel screws or at least two parallel non-intermeshing screws, e.g. twin screw extruders the screws having intermeshing parts

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/25—Component parts, details or accessories; Auxiliary operations

- B29C48/36—Means for plasticising or homogenising the moulding material or forcing it through the nozzle or die

- B29C48/50—Details of extruders

- B29C48/505—Screws

- B29C48/59—Screws characterised by details of the thread, i.e. the shape of a single thread of the material-feeding screw

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/25—Component parts, details or accessories; Auxiliary operations

- B29C48/36—Means for plasticising or homogenising the moulding material or forcing it through the nozzle or die

- B29C48/50—Details of extruders

- B29C48/505—Screws

- B29C48/64—Screws with two or more threads

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/25—Component parts, details or accessories; Auxiliary operations

- B29C48/92—Measuring, controlling or regulating

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2948/00—Indexing scheme relating to extrusion moulding

- B29C2948/92—Measuring, controlling or regulating

- B29C2948/92009—Measured parameter

- B29C2948/92019—Pressure

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2948/00—Indexing scheme relating to extrusion moulding

- B29C2948/92—Measuring, controlling or regulating

- B29C2948/92009—Measured parameter

- B29C2948/92038—Torque

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2948/00—Indexing scheme relating to extrusion moulding

- B29C2948/92—Measuring, controlling or regulating

- B29C2948/92009—Measured parameter

- B29C2948/92085—Velocity

- B29C2948/92095—Angular velocity

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2948/00—Indexing scheme relating to extrusion moulding

- B29C2948/92—Measuring, controlling or regulating

- B29C2948/92009—Measured parameter

- B29C2948/92209—Temperature

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2948/00—Indexing scheme relating to extrusion moulding

- B29C2948/92—Measuring, controlling or regulating

- B29C2948/92323—Location or phase of measurement

- B29C2948/92361—Extrusion unit

- B29C2948/9238—Feeding, melting, plasticising or pumping zones, e.g. the melt itself

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2948/00—Indexing scheme relating to extrusion moulding

- B29C2948/92—Measuring, controlling or regulating

- B29C2948/92323—Location or phase of measurement

- B29C2948/92361—Extrusion unit

- B29C2948/9238—Feeding, melting, plasticising or pumping zones, e.g. the melt itself

- B29C2948/9239—Screw or gear

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2948/00—Indexing scheme relating to extrusion moulding

- B29C2948/92—Measuring, controlling or regulating

- B29C2948/92323—Location or phase of measurement

- B29C2948/92485—Start-up, shut-down or parameter setting phase; Emergency shut-down; Material change; Test or laboratory equipment or studies

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/25—Component parts, details or accessories; Auxiliary operations

- B29C48/36—Means for plasticising or homogenising the moulding material or forcing it through the nozzle or die

- B29C48/395—Means for plasticising or homogenising the moulding material or forcing it through the nozzle or die using screws surrounded by a cooperating barrel, e.g. single screw extruders

- B29C48/40—Means for plasticising or homogenising the moulding material or forcing it through the nozzle or die using screws surrounded by a cooperating barrel, e.g. single screw extruders using two or more parallel screws or at least two parallel non-intermeshing screws, e.g. twin screw extruders

- B29C48/405—Intermeshing co-rotating screws

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Physics & Mathematics (AREA)

- Algebra (AREA)

- General Physics & Mathematics (AREA)

- Mathematical Analysis (AREA)

- Mathematical Optimization (AREA)

- Mathematical Physics (AREA)

- Pure & Applied Mathematics (AREA)

- Extrusion Moulding Of Plastics Or The Like (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102009059073.0 | 2009-12-18 | ||

| DE102009059073A DE102009059073A1 (de) | 2009-12-18 | 2009-12-18 | Datenbasierte Modelle zur Prognose und Optimierung von Schneckenextrudern und/oder Extrusionsverfahren |

| PCT/EP2010/069608 WO2011073181A1 (de) | 2009-12-18 | 2010-12-14 | Datenbasierte modelle zur prognose und optimierung von schneckenextrudern und/oder extrusionsverfahren |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN102725120A true CN102725120A (zh) | 2012-10-10 |

Family

ID=43498743

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN2010800577856A Pending CN102725120A (zh) | 2009-12-18 | 2010-12-14 | 预测和优化螺杆挤压机和/或挤压方法的基于数据的模型 |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US20120245909A1 (enExample) |

| EP (1) | EP2512776B1 (enExample) |

| JP (1) | JP2013514205A (enExample) |

| KR (1) | KR20120115270A (enExample) |

| CN (1) | CN102725120A (enExample) |

| DE (1) | DE102009059073A1 (enExample) |

| WO (1) | WO2011073181A1 (enExample) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN105612041A (zh) * | 2013-06-24 | 2016-05-25 | 科思创德国股份有限公司 | 用于多轴螺杆式机器的螺杆元件 |

| CN109472103A (zh) * | 2018-11-20 | 2019-03-15 | 蓬莱中柏京鲁船业有限公司 | 一种型材套料管理方法、装置、计算机设备及可存储介质 |

| CN111805958A (zh) * | 2020-07-13 | 2020-10-23 | 武汉轻工大学 | 螺旋榨油机的参数优化方法及系统 |

| CN119148656A (zh) * | 2024-11-04 | 2024-12-17 | 广东广铝铝型材有限公司 | 一种高效能耗挤压速度调节系统及方法 |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP3276511A1 (de) | 2016-07-27 | 2018-01-31 | Covestro Deutschland AG | Herstellung von extrudern umfassend deren automatisierte auslegung |

| US11534951B2 (en) * | 2017-06-13 | 2022-12-27 | The Japan Steel Works, Ltd. | Apparatus, method and computer program product for screw configuration inference |

| DE102019215876A1 (de) | 2019-10-15 | 2021-04-15 | Greiner Extrusion Group Gmbh | Extrusionsvorrichtung und Extrusionsverfahren |

| KR102376703B1 (ko) * | 2020-04-22 | 2022-03-23 | 한국생산기술연구원 | 회전자가 트위스트 된 용적식 수차의 설계방법 |

| CN115512784A (zh) * | 2022-08-24 | 2022-12-23 | 中国环境科学研究院 | 一种根据水质指标确定催化剂制备的工艺指标的方法 |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1093905A2 (de) * | 1999-10-21 | 2001-04-25 | Degussa-Hüls Aktiengesellschaft | Doppelschneckenextruder mit neuen Schneckenelementen |

| CN1595404A (zh) * | 2004-06-24 | 2005-03-16 | 上海交通大学 | 橡胶制品挤出口模的数字化设计方法 |

Family Cites Families (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH03288620A (ja) * | 1990-04-05 | 1991-12-18 | Sekisui Chem Co Ltd | 2軸押出機内樹脂流路の熱流動解析方法 |

| JPH06335953A (ja) * | 1993-05-31 | 1994-12-06 | Sekisui Chem Co Ltd | 2軸押出機におけるスクリュー設計方法 |

| CA2414707C (en) * | 2000-06-29 | 2011-08-16 | Aspen Technology, Inc. | Computer method and apparatus for constraining a non-linear approximator of an empirical process |

| DE10119853A1 (de) * | 2001-04-24 | 2003-01-09 | Bayer Ag | Hybridmodell und Verfahren zur Bestimmung von mechanischen Eigenschaften und von Verarbeitungseigenschaften eines Spritzgiessformteils |

| DE10209146A1 (de) * | 2002-03-01 | 2003-09-18 | Bayer Ag | Verfahren und System zur automatischen Planung von Experimenten |

| US7158847B2 (en) * | 2004-03-09 | 2007-01-02 | Advanced Blending Technologies, Llc | System and method for determining components of a blended plastic material |

| JP4643373B2 (ja) * | 2005-06-29 | 2011-03-02 | 東芝機械株式会社 | 押出スクリュの均一溶融シミュレーション方法およびその方法を実行するコンピュータプログラムおよび押出スクリュの均一溶融シミュレーション装置 |

| US7788070B2 (en) * | 2007-07-30 | 2010-08-31 | Caterpillar Inc. | Product design optimization method and system |

| DE102008029304A1 (de) | 2008-06-20 | 2009-12-24 | Bayer Technology Services Gmbh | Verfahren zur Erzeugung von Schneckenelementen |

-

2009

- 2009-12-18 DE DE102009059073A patent/DE102009059073A1/de not_active Withdrawn

-

2010

- 2010-12-14 US US13/515,486 patent/US20120245909A1/en not_active Abandoned

- 2010-12-14 CN CN2010800577856A patent/CN102725120A/zh active Pending

- 2010-12-14 JP JP2012543680A patent/JP2013514205A/ja active Pending

- 2010-12-14 WO PCT/EP2010/069608 patent/WO2011073181A1/de not_active Ceased

- 2010-12-14 KR KR1020127015511A patent/KR20120115270A/ko not_active Ceased

- 2010-12-14 EP EP10798752.1A patent/EP2512776B1/de not_active Not-in-force

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1093905A2 (de) * | 1999-10-21 | 2001-04-25 | Degussa-Hüls Aktiengesellschaft | Doppelschneckenextruder mit neuen Schneckenelementen |

| CN1595404A (zh) * | 2004-06-24 | 2005-03-16 | 上海交通大学 | 橡胶制品挤出口模的数字化设计方法 |

Non-Patent Citations (2)

| Title |

|---|

| SIMPSON T W,ET AL: "Metamodels for computer-based engineering design survey and recommendations", 《ENGINEERING WITH COMPUTER》, vol. 17, no. 2, 1 January 2001 (2001-01-01), XP002402392 * |

| 林武等: "挤出机计量段螺杆的优化设计", 《橡塑技术与装备》, vol. 34, no. 05, 15 May 2008 (2008-05-15) * |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN105612041A (zh) * | 2013-06-24 | 2016-05-25 | 科思创德国股份有限公司 | 用于多轴螺杆式机器的螺杆元件 |

| CN105612041B (zh) * | 2013-06-24 | 2018-12-18 | 科思创德国股份有限公司 | 用于多轴螺杆式机器的螺杆元件 |

| CN109472103A (zh) * | 2018-11-20 | 2019-03-15 | 蓬莱中柏京鲁船业有限公司 | 一种型材套料管理方法、装置、计算机设备及可存储介质 |

| CN111805958A (zh) * | 2020-07-13 | 2020-10-23 | 武汉轻工大学 | 螺旋榨油机的参数优化方法及系统 |

| CN111805958B (zh) * | 2020-07-13 | 2022-06-14 | 武汉轻工大学 | 螺旋榨油机的参数优化方法及系统 |

| CN119148656A (zh) * | 2024-11-04 | 2024-12-17 | 广东广铝铝型材有限公司 | 一种高效能耗挤压速度调节系统及方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| KR20120115270A (ko) | 2012-10-17 |

| JP2013514205A (ja) | 2013-04-25 |

| EP2512776B1 (de) | 2018-02-21 |

| US20120245909A1 (en) | 2012-09-27 |

| WO2011073181A1 (de) | 2011-06-23 |

| DE102009059073A1 (de) | 2011-06-22 |

| EP2512776A1 (de) | 2012-10-24 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN102725120A (zh) | 预测和优化螺杆挤压机和/或挤压方法的基于数据的模型 | |

| Lewandowski et al. | Modeling of twin screw extrusion of polymeric materials | |

| Fernandes et al. | Modeling and Optimization of the Injection‐Molding Process: A Review | |

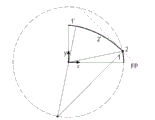

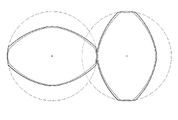

| US8876360B2 (en) | Method for constructing co-rotating, contiguous bodies and computer program product for carrying out said method | |

| Fard et al. | Simulation of distributive mixing inside mixing elements of co-rotating twin-screw extruders | |

| Sarhangi Fard et al. | Tools to simulate distributive mixing in twin‐screw extruders | |

| RU2516172C2 (ru) | Шнековые элементы с улучшенной эффективностью диспергирования и уменьшенным поступлением энергии | |

| Wilczynski et al. | A composite model for melting, pressure and fill factor profiles in a metered fed closely intermeshing counter-rotating twin screw extruder | |

| Nastaj et al. | Optimization and scale-up for polymer extrusion | |

| Malik et al. | 3d finite element simulation of processing of generalized newtonian fluids in counter-rotating and tangential tse and die combination | |

| Teixeira et al. | Flow and heat transfer along the length of a co-rotating twin screw extruder | |

| Nakayama et al. | Strain mode of general flow: Characterization and implications for flow pattern structures | |

| Gaspar‐Cunha et al. | Defining the configuration of co‐rotating twin‐screw extruders with multiobjective evolutionary algorithms | |

| Roland et al. | Heuristic analysis of viscous dissipation in single‐screw extrusion | |

| Gaspar-Cunha et al. | The design of extrusion screws: An optimization approach | |

| Potente et al. | Design and processing optimization of extruder screws | |

| RU2673517C2 (ru) | Шнековые элементы для многовальных шнековых машин | |

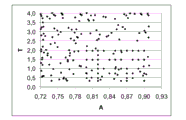

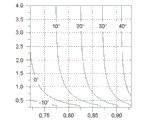

| Stritzinger et al. | Modeling melt conveying and power consumption of co‐rotating twin‐screw extruder kneading blocks: Part A. Data generation | |

| Zhang et al. | Modeling of residual stress profile in finish hard turning | |

| Gaspar-Cunha et al. | An engineering scale-up approach using multi-objective optimization | |

| Wei et al. | Evaluation of the mixing performance for one novel twin screw kneader with particle tracking | |

| Winck et al. | Numerical simulation of fluid flow and mixing dynamics inside planetary roller extruders | |

| Cegla et al. | Optimal design and operation of reactive extrusion processes: Modeling, model validation, and optimization algorithm | |

| Xin et al. | Hydrodynamics and mixing performance in a continuous miniature conical counter-rotating twin-screw extruder | |

| Raj et al. | Analyzing pellet agglomeration in underwater polymer extrusion pelletizers: a numerical simulation study |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C02 | Deemed withdrawal of patent application after publication (patent law 2001) | ||

| WD01 | Invention patent application deemed withdrawn after publication |

Application publication date: 20121010 |