CN1016071B - 固体燃料气化反应器用的渣滓排除装置 - Google Patents

固体燃料气化反应器用的渣滓排除装置Info

- Publication number

- CN1016071B CN1016071B CN86105182A CN86105182A CN1016071B CN 1016071 B CN1016071 B CN 1016071B CN 86105182 A CN86105182 A CN 86105182A CN 86105182 A CN86105182 A CN 86105182A CN 1016071 B CN1016071 B CN 1016071B

- Authority

- CN

- China

- Prior art keywords

- mud

- conduit

- reactor

- pressure

- reliever

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

- 238000002309 gasification Methods 0.000 title claims abstract description 11

- 239000004449 solid propellant Substances 0.000 title claims abstract description 11

- 239000002893 slag Substances 0.000 title description 5

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims abstract description 21

- 238000000034 method Methods 0.000 claims abstract description 15

- 238000001816 cooling Methods 0.000 claims abstract description 4

- 239000011440 grout Substances 0.000 claims description 17

- 239000007787 solid Substances 0.000 claims description 12

- 239000002245 particle Substances 0.000 claims description 10

- 239000012530 fluid Substances 0.000 claims description 4

- 238000013467 fragmentation Methods 0.000 claims description 4

- 238000006062 fragmentation reaction Methods 0.000 claims description 4

- 238000007599 discharging Methods 0.000 claims description 3

- 230000000712 assembly Effects 0.000 claims 1

- 238000000429 assembly Methods 0.000 claims 1

- 238000002347 injection Methods 0.000 claims 1

- 239000007924 injection Substances 0.000 claims 1

- 239000000203 mixture Substances 0.000 claims 1

- 239000002002 slurry Substances 0.000 abstract description 5

- 239000004568 cement Substances 0.000 abstract 1

- 239000000463 material Substances 0.000 description 5

- 239000003245 coal Substances 0.000 description 3

- 239000000571 coke Substances 0.000 description 3

- 239000003077 lignite Substances 0.000 description 3

- 239000003034 coal gas Substances 0.000 description 2

- TWNQGVIAIRXVLR-UHFFFAOYSA-N oxo(oxoalumanyloxy)alumane Chemical compound O=[Al]O[Al]=O TWNQGVIAIRXVLR-UHFFFAOYSA-N 0.000 description 2

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 1

- 229910000975 Carbon steel Inorganic materials 0.000 description 1

- 238000005299 abrasion Methods 0.000 description 1

- 239000003082 abrasive agent Substances 0.000 description 1

- 230000009286 beneficial effect Effects 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 229910052799 carbon Inorganic materials 0.000 description 1

- 239000010962 carbon steel Substances 0.000 description 1

- 239000003575 carbonaceous material Substances 0.000 description 1

- 238000002485 combustion reaction Methods 0.000 description 1

- 230000001276 controlling effect Effects 0.000 description 1

- 230000007423 decrease Effects 0.000 description 1

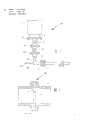

- 238000010586 diagram Methods 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 239000010419 fine particle Substances 0.000 description 1

- 239000000446 fuel Substances 0.000 description 1

- 229910052751 metal Inorganic materials 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 239000003921 oil Substances 0.000 description 1

- 230000001105 regulatory effect Effects 0.000 description 1

- 230000000452 restraining effect Effects 0.000 description 1

- HBMJWWWQQXIZIP-UHFFFAOYSA-N silicon carbide Chemical compound [Si+]#[C-] HBMJWWWQQXIZIP-UHFFFAOYSA-N 0.000 description 1

- 229910010271 silicon carbide Inorganic materials 0.000 description 1

- 239000000126 substance Substances 0.000 description 1

- 238000003786 synthesis reaction Methods 0.000 description 1

- WFKWXMTUELFFGS-UHFFFAOYSA-N tungsten Chemical compound [W] WFKWXMTUELFFGS-UHFFFAOYSA-N 0.000 description 1

- 238000011144 upstream manufacturing Methods 0.000 description 1

- 239000002699 waste material Substances 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10J—PRODUCTION OF PRODUCER GAS, WATER-GAS, SYNTHESIS GAS FROM SOLID CARBONACEOUS MATERIAL, OR MIXTURES CONTAINING THESE GASES; CARBURETTING AIR OR OTHER GASES

- C10J3/00—Production of combustible gases containing carbon monoxide from solid carbonaceous fuels

- C10J3/46—Gasification of granular or pulverulent flues in suspension

- C10J3/48—Apparatus; Plants

- C10J3/52—Ash-removing devices

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10J—PRODUCTION OF PRODUCER GAS, WATER-GAS, SYNTHESIS GAS FROM SOLID CARBONACEOUS MATERIAL, OR MIXTURES CONTAINING THESE GASES; CARBURETTING AIR OR OTHER GASES

- C10J3/00—Production of combustible gases containing carbon monoxide from solid carbonaceous fuels

- C10J3/46—Gasification of granular or pulverulent flues in suspension

- C10J3/48—Apparatus; Plants

- C10J3/52—Ash-removing devices

- C10J3/526—Ash-removing devices for entrained flow gasifiers

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10J—PRODUCTION OF PRODUCER GAS, WATER-GAS, SYNTHESIS GAS FROM SOLID CARBONACEOUS MATERIAL, OR MIXTURES CONTAINING THESE GASES; CARBURETTING AIR OR OTHER GASES

- C10J2300/00—Details of gasification processes

- C10J2300/09—Details of the feed, e.g. feeding of spent catalyst, inert gas or halogens

- C10J2300/0913—Carbonaceous raw material

- C10J2300/093—Coal

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10J—PRODUCTION OF PRODUCER GAS, WATER-GAS, SYNTHESIS GAS FROM SOLID CARBONACEOUS MATERIAL, OR MIXTURES CONTAINING THESE GASES; CARBURETTING AIR OR OTHER GASES

- C10J2300/00—Details of gasification processes

- C10J2300/09—Details of the feed, e.g. feeding of spent catalyst, inert gas or halogens

- C10J2300/0913—Carbonaceous raw material

- C10J2300/0943—Coke

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10J—PRODUCTION OF PRODUCER GAS, WATER-GAS, SYNTHESIS GAS FROM SOLID CARBONACEOUS MATERIAL, OR MIXTURES CONTAINING THESE GASES; CARBURETTING AIR OR OTHER GASES

- C10J2300/00—Details of gasification processes

- C10J2300/09—Details of the feed, e.g. feeding of spent catalyst, inert gas or halogens

- C10J2300/0913—Carbonaceous raw material

- C10J2300/0946—Waste, e.g. MSW, tires, glass, tar sand, peat, paper, lignite, oil shale

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10J—PRODUCTION OF PRODUCER GAS, WATER-GAS, SYNTHESIS GAS FROM SOLID CARBONACEOUS MATERIAL, OR MIXTURES CONTAINING THESE GASES; CARBURETTING AIR OR OTHER GASES

- C10J2300/00—Details of gasification processes

- C10J2300/16—Integration of gasification processes with another plant or parts within the plant

- C10J2300/1625—Integration of gasification processes with another plant or parts within the plant with solids treatment

- C10J2300/1628—Ash post-treatment

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Combustion & Propulsion (AREA)

- Oil, Petroleum & Natural Gas (AREA)

- Organic Chemistry (AREA)

- Processing Of Solid Wastes (AREA)

- Disintegrating Or Milling (AREA)

- Devices And Processes Conducted In The Presence Of Fluids And Solid Particles (AREA)

- Crushing And Grinding (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN86105182A CN1016071B (zh) | 1986-08-06 | 1986-08-22 | 固体燃料气化反应器用的渣滓排除装置 |

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CA000515369A CA1320642C (en) | 1986-08-06 | 1986-08-06 | Slag removal system for a solid fuels gasification reactor |

| EP86306344A EP0256186B1 (en) | 1986-08-06 | 1986-08-15 | Slag removal system for a solid fuels gasification reactor |

| CN86105182A CN1016071B (zh) | 1986-08-06 | 1986-08-22 | 固体燃料气化反应器用的渣滓排除装置 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN86105182A CN86105182A (zh) | 1988-03-02 |

| CN1016071B true CN1016071B (zh) | 1992-04-01 |

Family

ID=42651236

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN86105182A Expired CN1016071B (zh) | 1986-08-06 | 1986-08-22 | 固体燃料气化反应器用的渣滓排除装置 |

Country Status (7)

| Country | Link |

|---|---|

| EP (1) | EP0256186B1 (enExample) |

| CN (1) | CN1016071B (enExample) |

| AU (1) | AU582267B2 (enExample) |

| CA (1) | CA1320642C (enExample) |

| DE (1) | DE3686720T2 (enExample) |

| IN (1) | IN167905B (enExample) |

| ZA (1) | ZA866011B (enExample) |

Families Citing this family (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3714915A1 (de) * | 1987-05-05 | 1988-11-24 | Shell Int Research | Verfahren und vorrichtung fuer die herstellung von synthesegas |

| JP5682623B2 (ja) | 2010-03-31 | 2015-03-11 | 日立金属株式会社 | スラリーの再生方法、希土類系焼結磁石の製造方法およびスラリーの再生装置 |

| JP5743093B2 (ja) * | 2011-09-07 | 2015-07-01 | 三菱日立パワーシステムズ株式会社 | スラグ排出システム、ガス化装置、およびガス化発電装置 |

| US9222040B2 (en) | 2012-06-07 | 2015-12-29 | General Electric Company | System and method for slurry handling |

| CN102732325A (zh) * | 2012-07-06 | 2012-10-17 | 东南大学 | 一种高压高温炉渣风水共冷排渣装置 |

| US10018416B2 (en) | 2012-12-04 | 2018-07-10 | General Electric Company | System and method for removal of liquid from a solids flow |

| US9156631B2 (en) | 2012-12-04 | 2015-10-13 | General Electric Company | Multi-stage solids feeder system and method |

| US9181046B2 (en) | 2012-12-04 | 2015-11-10 | General Electric Company | System and method to supply a solid feedstock to a solids feeder |

| US9592963B2 (en) | 2013-03-15 | 2017-03-14 | Mark E. Koenig | Outlet tube for a material transfer system |

| GB2511890B8 (en) * | 2013-03-15 | 2018-09-05 | Koenig Mark | Outlet tube for a material transfer system |

| US10190065B2 (en) | 2013-03-15 | 2019-01-29 | Mark E. Koenig | Feed delivery system and method for gasifier |

| US9784121B2 (en) | 2013-12-11 | 2017-10-10 | General Electric Company | System and method for continuous solids slurry depressurization |

| US9702372B2 (en) | 2013-12-11 | 2017-07-11 | General Electric Company | System and method for continuous solids slurry depressurization |

| CN111978993B (zh) * | 2020-07-17 | 2022-01-07 | 新奥科技发展有限公司 | 一种减压装置及排焦系统 |

| CN115028344B (zh) * | 2022-07-14 | 2024-10-29 | 咸宁南玻光电玻璃有限公司 | 耳池放料回收装置及其应用 |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB801803A (en) * | 1954-06-05 | 1958-09-24 | Svein Berger Evensen | An automatic closing device for doors |

| GB801103A (en) * | 1955-12-03 | 1958-09-10 | Kohlenscheidungs Gmbh | Gas producer or furnace with continuous discharge of molten residue |

| ZA751337B (en) * | 1974-03-18 | 1976-02-25 | Lummus Co | Ash removal system in coal or coke gasification |

| US4472171A (en) * | 1983-05-31 | 1984-09-18 | Texaco Development Corporation | Method and system for removing slag |

-

1986

- 1986-08-06 CA CA000515369A patent/CA1320642C/en not_active Expired - Lifetime

- 1986-08-11 IN IN642/MAS/86A patent/IN167905B/en unknown

- 1986-08-15 ZA ZA866011A patent/ZA866011B/xx unknown

- 1986-08-15 DE DE8686306344T patent/DE3686720T2/de not_active Expired - Lifetime

- 1986-08-15 EP EP86306344A patent/EP0256186B1/en not_active Expired - Lifetime

- 1986-08-21 AU AU61707/86A patent/AU582267B2/en not_active Expired

- 1986-08-22 CN CN86105182A patent/CN1016071B/zh not_active Expired

Also Published As

| Publication number | Publication date |

|---|---|

| DE3686720D1 (de) | 1992-10-15 |

| ZA866011B (enExample) | 1988-02-11 |

| EP0256186B1 (en) | 1992-09-09 |

| CN86105182A (zh) | 1988-03-02 |

| EP0256186A1 (en) | 1988-02-24 |

| CA1320642C (en) | 1993-07-27 |

| DE3686720T2 (de) | 1993-01-28 |

| AU6170786A (en) | 1988-02-25 |

| AU582267B2 (en) | 1989-03-16 |

| IN167905B (enExample) | 1991-01-05 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN1016071B (zh) | 固体燃料气化反应器用的渣滓排除装置 | |

| EP1027407B1 (de) | Verfahren und vorrichtung zur erzeugung von brenn-, synthese- und reduktionsgas aus festen brennstoffen | |

| US7048782B1 (en) | Apparatus and process for power recovery | |

| DE3019937C2 (enExample) | ||

| EP2377911B1 (de) | Verfahren und Vorrichtung zur Erzeugung von Brenngas aus einem festen Brennstoff | |

| DE2321423A1 (de) | Wirbelbettsystem fuer festen abfall | |

| WO2013087521A9 (de) | Verfahren und vorrichtung zur flugstromvergasung fester brennstoffe unter druck | |

| EP2122252A2 (de) | Verfahren und anlage zur nutzenergieerzeugung durch müllvergasung | |

| DE102006040077B4 (de) | Verfahren und Vorrichtung zum Austrag von Schlacke aus Vergasungsreaktoren | |

| DE69806960T2 (de) | Düse mit hals und konus und gasverteiler für schlammreaktoren | |

| EP0241866B1 (en) | Gasification process for coal gasification furnace and apparatus therefor | |

| DE4226015C9 (de) | Verfahren zur Entsorgung von festen und flüssigen Abfallstoffen im Vergasungsprozeß bei der Festbettdruckvergasung | |

| EP4263888A1 (de) | Vorrichtung zum aufarbeiten von chemisch belasteten feststoffpartikeln | |

| EP0632122B1 (de) | Verfahren und Vorrichtung zum Abscheiden von Schlacketröpfchen aus einem heissen Rohgas aus der Verbrennung oder Vergasung fester oder flüssiger Brennstoffe | |

| CN107955647A (zh) | 一种气液混相料上流式加氢反应器的收集液分流方法 | |

| DE102004001708B4 (de) | Verfahren und Vorrichtung zur kontinuierlichen Beschickung von Festbett-Druckvergasungsreaktoren | |

| EP0071320A2 (en) | Apparatus and method for let down of a high pressure abrasive slurry | |

| US4705432A (en) | Apparatus for preparing sulfur particles having uniform size distribution | |

| EP1325950B1 (de) | Gleichstrom-Schacht-Reaktor | |

| DE68905681T2 (de) | Methode zur umaenderung der schmutzstoffe in einem rohen hochtemperatur-hochdruck-synthesegasstrom. | |

| KR930011926B1 (ko) | 고체연료 가스화 장치의 슬래그 제거 시스템 | |

| US4461673A (en) | Process for cooling, depressurizing, and moisturizing retorted oil shale | |

| JPH08209155A (ja) | 乾式フィード方式と湿式フィード方式の同時ガス化による難スラリー化固体炭素質原料のガス化処理法 | |

| US4556458A (en) | Apparatus for cooling, depressurizing, and moisturizing retorted oil shale | |

| DE10119149C1 (de) | Drehrost für Abfallvergaser |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C13 | Decision | ||

| GR02 | Examined patent application | ||

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| C53 | Correction of patent of invention or patent application | ||

| COR | Change of bibliographic data |

Free format text: CORRECT: PATENTEE; FROM: THE DOW CHEMICAL CO. TO: DESTEC ENERGY CO.,LTD. |

|

| CP03 | Change of name, title or address |

Address after: Dallas USA Patentee after: Destec Energy, Inc. Address before: Michigan Patentee before: The Dow Chemical Co. |

|

| C17 | Cessation of patent right | ||

| CX01 | Expiry of patent term |