WO2020116118A1 - Fan - Google Patents

Fan Download PDFInfo

- Publication number

- WO2020116118A1 WO2020116118A1 PCT/JP2019/044714 JP2019044714W WO2020116118A1 WO 2020116118 A1 WO2020116118 A1 WO 2020116118A1 JP 2019044714 W JP2019044714 W JP 2019044714W WO 2020116118 A1 WO2020116118 A1 WO 2020116118A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- fluid

- passage

- centrifugal fan

- air

- suction passage

- Prior art date

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60H—ARRANGEMENTS OF HEATING, COOLING, VENTILATING OR OTHER AIR-TREATING DEVICES SPECIALLY ADAPTED FOR PASSENGER OR GOODS SPACES OF VEHICLES

- B60H1/00—Heating, cooling or ventilating [HVAC] devices

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60H—ARRANGEMENTS OF HEATING, COOLING, VENTILATING OR OTHER AIR-TREATING DEVICES SPECIALLY ADAPTED FOR PASSENGER OR GOODS SPACES OF VEHICLES

- B60H1/00—Heating, cooling or ventilating [HVAC] devices

- B60H1/32—Cooling devices

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04D—NON-POSITIVE-DISPLACEMENT PUMPS

- F04D29/00—Details, component parts, or accessories

- F04D29/26—Rotors specially for elastic fluids

- F04D29/28—Rotors specially for elastic fluids for centrifugal or helico-centrifugal pumps for radial-flow or helico-centrifugal pumps

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04D—NON-POSITIVE-DISPLACEMENT PUMPS

- F04D29/00—Details, component parts, or accessories

- F04D29/40—Casings; Connections of working fluid

- F04D29/42—Casings; Connections of working fluid for radial or helico-centrifugal pumps

- F04D29/44—Fluid-guiding means, e.g. diffusers

Definitions

- the present disclosure relates to a blower that sucks in and blows out a first fluid and a second fluid.

- the centrifugal fan since the centrifugal fan has a pressure difference between the suction side and the blowing side of the air, a part of the air blown out from the centrifugal fan passes through the gap between the centrifugal fan and the casing housing the centrifugal fan so that a part of the centrifugal fan is discharged. May flow back to the suction side.

- the gap between the centrifugal fan and the casing containing the centrifugal fan constitutes a backflow passage through which air flows from the blow side to the suction side of the centrifugal fan.

- the air blown out from the centrifugal fan has a rotation component in the rotation direction of the centrifugal fan, and when the air flowing into the backflow passage from the blowout side of the centrifugal fan flows in the backflow passage, it advances in the rotation direction of the centrifugal fan. ..

- the first fluid blown out from the centrifugal fan passes through the backflow passage and becomes the second fluid in the centrifugal fan. It may flow into the suction side. Further, the second fluid blown out from the centrifugal fan may flow into the suction side of the first fluid in the centrifugal fan via the backflow passage.

- the present disclosure aims to improve the separability of the first fluid and the second fluid in a blower that sucks in and blows out the first fluid and the second fluid.

- the blower that sucks in and blows out the first fluid and the second fluid is A centrifugal fan that rotates around the fan axis to blow out the first fluid and the second fluid sucked from one side in the axial direction of the fan axis in a direction away from the fan axis.

- a casing in which the centrifugal fan is housed forms a fluid suction passage on one side in the axial direction with respect to the centrifugal fan, and forms a fluid discharge passage on the outer side in the radial direction of the centrifugal fan;

- An inlet-side partition that partitions the fluid suction passage into a first suction passage through which the first fluid flows and a second suction passage through which the second fluid flows;

- the centrifugal fan has a plurality of blades arranged around the fan axis, a ring-shaped shroud that connects the portions of the plurality of blades located on one side in the axial direction,

- the casing has a shroud facing portion that faces the shroud with a predetermined gap and forms a backflow passage

- the backflow passage is a suction passage in which one of the first fluid flowing through the first blow passage and the second fluid flowing through the second blow passage receives the other fluid of the first suction passage and the second suction passage. It has a structure that prevents the flow.

- the first fluid and the second fluid Mixing of the first fluid and the second fluid due to backflow is suppressed. That is, in a blower that sucks in and blows out the first fluid and the second fluid, it is possible to improve the separability of the first fluid and the second fluid.

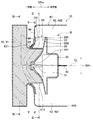

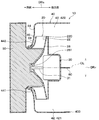

- FIG. 2 is a sectional view taken along line II-II in FIG. 1.

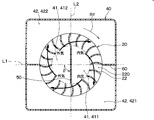

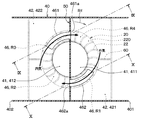

- FIG. 3 is a sectional view taken along line III-III in FIG. 2.

- FIG. 4 is an enlarged view of a portion IV in FIG. 2.

- FIG. 5 is a sectional view taken along line VV of FIG. 2.

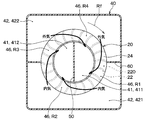

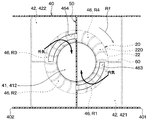

- FIG. 6 is a VI-VI sectional view of FIG. 2.

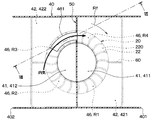

- FIG. 7 is a sectional view taken along line VII-VII in FIG. 6. It is sectional drawing corresponding to FIG. 6 in the air blower of 2nd Embodiment.

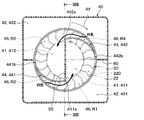

- FIG. 9 is a sectional view taken along line IX-IX in FIG. 8.

- FIG. 9 is a sectional view taken along line XX of FIG.

- FIG. 12 is a sectional view taken along line XII-XII of FIG. 11. It is sectional drawing corresponding to FIG. 6 in the air blower of 4th Embodiment. It is sectional drawing corresponding to FIG. 5 in the air blower of 5th Embodiment.

- FIG. 15 is a sectional view taken along line XV-XV in FIG. 14. It is sectional drawing corresponding to FIG. 5 in the air blower of 6th Embodiment.

- FIG. 17 is a sectional view taken along line XVII-XVII of FIG. 16.

- the vehicle air conditioner is arranged inside a frontmost instrument panel in the vehicle compartment.

- the vehicle air conditioner is configured as an inside/outside air two-layer air conditioner capable of distinguishing the air sucked in from the outside of the vehicle compartment and the air sucked in from the vehicle compartment.

- the vehicle air conditioner circulates the inside air in the vehicle interior while blowing the outside air toward the inside of the window glass of the vehicle by using the inside air that is the air inside the vehicle as the first fluid and the outside air that is the air outside the vehicle as the second fluid.

- the inside/outside air two-layer mode can be implemented.

- the vehicle air conditioner includes an inside/outside air switching box and a temperature adjustment unit, which are not shown, in addition to the blower 10 of the present disclosure.

- the inside/outside air switching box takes in outside air and inside air.

- the inside/outside air switching box of the present embodiment is connected to the air flow upstream side of the blower 10.

- the inside/outside air switching box is formed with an outside air inlet for introducing outside air and an inside air inlet for introducing inside air.By adjusting the opening area of each inlet with the inside/outside air door, The amount introduced with and can be adjusted.

- the inside/outside air switching box multiple air passages are set so that the outside air and the inside air can be introduced separately.

- the plurality of air passages are partitioned by a partition plate so that air having different properties such as temperature or humidity can flow without being mixed.

- the temperature adjustment unit adjusts the temperature of the air blown into the passenger compartment.

- the temperature adjustment unit of the present embodiment is connected to the blower 10 on the downstream side of the air flow.

- the temperature adjustment unit is configured to include a cooling heat exchanger that cools air and a heating heat exchanger that heats air.

- a cooling heat exchanger for example, a vapor compression refrigeration cycle evaporator is adopted.

- the heating heat exchanger for example, a heater core that radiates engine cooling water is adopted.

- the temperature control unit includes a defroster outlet that blows air toward the inside of the window glass of the vehicle, a face outlet that blows air toward the upper body side of the passenger in the passenger compartment, and a lower body side of the passenger in the passenger compartment.

- a foot outlet or the like that blows air toward the air outlet is provided.

- the blower 10 is arranged between the inside/outside air switching box and the temperature adjustment unit.

- the blower 10 is configured such that the inside air is the first fluid and the outside air is the second fluid, and the inside air and the outside air can be distinguished and blown.

- the blower 10 includes a centrifugal fan 20, an electric motor 30 that drives the centrifugal fan 20, and a casing 40 that houses the centrifugal fan 20.

- the centrifugal fan 20 is a fan that rotates around the fan axis CL to blow out air sucked from one side of the fan axis CL in the axial direction DRa in a direction away from the fan axis CL.

- the centrifugal fan 20 is composed of a turbo fan having a characteristic that the static pressure is high among the centrifugal fans 20.

- the centrifugal fan 20 is not limited to the turbo fan, but may be a radial fan or a sirocco fan.

- the axial direction DRa is a direction extending along the fan axis CL.

- the radial direction DRr of the centrifugal fan 20 is a direction that is orthogonal to the fan axis CL and that extends radially around the fan axis CL.

- the centrifugal fan 20 has a plurality of blades 22, a shroud 24, and a fan boss 26.

- each blade 22, the shroud 24, and the fan boss 26 are configured as an integrally molded product made of resin.

- the centrifugal fan 20 is not limited to resin, and at least a part thereof may be made of a material other than resin (for example, a metal material).

- the plurality of blades 22 are arranged at regular intervals in the circumferential direction around a cylindrical space centered on the fan axis CL. In the centrifugal fan 20, each blade 22 rotates around the fan axis CL, so that air is sucked from one side of the fan axis CL.

- Each of the plurality of blades 22 has a one-side blade tip 221 which is an end on one side of the axial direction DRa and another blade tip 222 which is an end portion on the other side of the axial direction DRa.

- An inter-blade passage 220 through which air flows is formed between the plurality of blades 22.

- the shroud 24 is a member that connects parts of the blades 22 located on one side in the axial direction DRa.

- the shroud 24 is formed in a ring shape and is connected to one side of each blade 22 in the axial direction DRa. Specifically, the shroud 24 is connected to the one-side wing tip 221 of each blade 22.

- the shroud 24 has a shape having a spread in the radial direction DRr so as to cover one side of the blade 22 in the axial direction DRa.

- the fan boss 26 is a member that connects the parts of the blades 22 located on the other side in the axial direction DRa and is connected to the output shaft 31 of the electric motor 30.

- the fan boss 26 is formed in a disc shape.

- the fan boss 26 is connected to the other blade tip 222 of each blade 22.

- the inner part of the fan boss 26 in the fan radial direction DR projects to one side of the fan axial center CL as compared with the outer part in the fan radial direction DR.

- the fan boss 26 has an axisymmetric shape with the fan axis CL as the axis of symmetry.

- a boss portion 261 that connects the centrifugal fan 20 to the output shaft 31 of the electric motor 30 is provided at a substantially central portion of the fan boss 26.

- the electric motor 30 is an electric motor that drives the centrifugal fan 20 to rotate.

- the electric motor 30 is housed inside the casing 40.

- the output shaft 31 of the electric motor 30 is connected to the centrifugal fan 20.

- the rotational driving force of the electric motor 30 is transmitted to the centrifugal fan 20 via the output shaft 31, so that the centrifugal fan 20 rotates around the fan axis CL.

- the casing 40 is a member that forms the outer shell of the blower 10, and an air passage through which air flows is formed inside thereof.

- the casing 40 houses the centrifugal fan 20 and the electric motor 30 inside thereof.

- the casing 40 has a first suction port 401 and a second suction port 402 for sucking air introduced from the inside/outside air switching box, and blows the air blown from the centrifugal fan 20 to the temperature adjustment unit.

- An outlet 403 is formed.

- the first suction port 401 is a suction port that sucks the inside air that is the first fluid through the inside/outside air switching box in the inside/outside air two-layer mode.

- the second suction port 402 is a suction port that sucks the outside air, which is the second fluid, through the inside/outside air switching box in the inside/outside air two-layer mode.

- the first suction port 401 and the second suction port 402 are formed in a portion of the casing 40 located on one side of the centrifugal fan 20 in the axial direction DRa. Specifically, the first suction port 401 and the second suction port 402 are opened in a portion of the casing 40 that extends along the axial direction DRa. The first suction port 401 and the second suction port 402 are formed in portions of the casing 40 that face each other with the fan axis CL interposed therebetween.

- the outlet 403 is formed in a portion of the casing 40 located on the other side of the centrifugal fan 20 in the axial direction DRa. Specifically, the air outlet 403 is formed of a portion of the casing 40 that opens toward the other side in the axial direction DRa.

- a fluid suction passage 41 is formed on one side of the centrifugal fan 20 in the axial direction DRa, and a fluid outlet passage 42 is formed outside the centrifugal fan 20 in the radial direction DRr.

- the fluid suction passage 41 is an air passage for guiding the air sucked from the first suction opening 401 and the second suction opening 402 to the centrifugal fan 20.

- the fluid suction passage 41 is formed by a space located on one side of the centrifugal fan 20 in the axial direction DRa inside the casing 40.

- the inlet-side partition section 50 includes a first suction passage 411 through which air (that is, a first fluid) sucked through the fluid suction passage 41 from the first suction port 401 flows, and air sucked through the second suction port 402 (that is, the first suction passage 411). It is a partition wall for partitioning into the second suction passage 412 through which the (two fluids) flow.

- the entrance-side partition section 50 is arranged at a distance from the centrifugal fan 20.

- the entrance-side partition section 50 is fixed to the inner wall surface of the casing 40 with an adhesive or the like so as not to rotate.

- the inlet-side partition portion 50 includes a base portion 51 that includes the fan axis CL and has a plate surface that extends along the axial direction DRa.

- the base portion 51 has one side portion in the axial direction DRa connected to the casing 40, and the other side portion in the axial direction DRa extends to the front of the substantially central portion of the fan boss 26 of the centrifugal fan 20.

- An enlarged portion 52 is connected to the base portion 51 at the other end in the axial direction DRa.

- the enlarged portion 52 is a disk-shaped member and is arranged at a predetermined distance from the fan boss 26 so as not to interfere with the fan boss 26.

- the entrance-side partition section 50 of this embodiment includes not only the base section 51 but also an expansion section 52. Therefore, it is possible to prevent the air flowing through the first suction passage 411 and the air flowing through the second suction passage 412 from being mixed with each other through the gap formed between the fan boss 26 and the fan boss 26.

- the fluid outlet passage 42 is an air passage for guiding the air blown out from the centrifugal fan 20 to the outlet 403.

- the fluid outlet passage 42 is formed inside the casing 40 by a space located outside of the centrifugal fan 20 in the radial direction DRr and a space located on the other side of the centrifugal fan 20 in the axial direction DRa. ..

- An outlet side partition portion 60 is arranged in the fluid outlet passage 42.

- the outlet side partition part 60 partitions the fluid outlet passage 42 into a first outlet passage 421 through which the first fluid blown out from the centrifugal fan 20 flows and a second outlet passage 422 through which the second fluid blown out from the centrifugal fan 20 flows. It is a partition for.

- the first outlet passage 421 is an air passage through which the first fluid sucked from the first suction passage 411 and passing through the blade passage 220 of the centrifugal fan 20 is blown out.

- the second outlet passage 422 is an air passage through which the second fluid sucked from the second inlet passage 412 and passing through the inter-blade passage 220 of the centrifugal fan 20 is blown out.

- the air flowing into the inter-blade passage 220 of the centrifugal fan 20 flows from the inlet of the inter-blade passage 220 toward the outlet thereof, while the centrifugal fan 20 rotates. Therefore, for example, as shown in FIG. 3, the inflow position of air into the inter-blade passage 220 and the outflow position of air from the inter-blade passage 220 are displaced in the rotational direction Rf of the centrifugal fan 20.

- the outflow position of the air from the inter-blade passage 220 is a position advanced in the rotation direction Rf of the centrifugal fan 20 with respect to the inflow position of the air into the inter-blade passage 220.

- the angle between the imaginary line connecting the outflow position of the air from the inter-blade passage 220 and the fan axis CL and the imaginary line connecting the inflow position of the air from the inter-blade passage 220 and the fan axis CL is blown out. Call it an angle.

- the blowout deviation angle can be specified by simulation, experiment, or the like.

- the centrifugal fan 20 of the present embodiment is designed so that the blowout deviation angle is about 90° when operated at the rotation speed assumed during normal operation.

- the outside air and the inside air that have flowed into the inter-blade passage 220 flow out from a position advanced by about 90° in the rotation direction Rf of the centrifugal fan 20.

- the outlet side partitioning portion 60 is controlled so as to suppress the inflow of the inside air into the second outlet passage 422 and the outside air into the first outlet passage 421 in the two-layer mode of the inside and outside air.

- the outlet-side partition portion 60 is arranged such that the angle ⁇ formed by the outlet-side partition portion 60 and the inlet-side partition portion 50 is the same as the blowout deviation angle.

- the virtual line L1 connecting the plate surface of the outlet-side partition 60 and the fan axis CL is the plate surface of the base 51 of the inlet-side partition 50 and the fan axis CL. It is arranged so as to form an angle equivalent to the blowout deviation angle with respect to the imaginary line L2 connecting with.

- the casing 40 has a shroud facing portion 44 that faces the shroud 24 of the centrifugal fan 20 with a predetermined gap.

- the shroud facing portion 44 is configured by a portion of the casing 40 that is located between the portion forming the fluid suction passage 41 and the shroud 24.

- the shroud facing portion 44 overlaps the portion of the casing 40 that forms the fluid suction passage 41 and the shroud 24 in the axial direction DRa.

- a predetermined gap is set between the shroud facing portion 44 and the shroud 24 so that the shroud 24 does not contact the shroud facing portion 44 when the centrifugal fan 20 rotates.

- the centrifugal fan 20 has a pressure difference between the air intake side and the air outlet side. That is, in the centrifugal fan 20, the pressure on the air intake side is lower than that on the air outlet side. As a result, as shown by the dotted arrow in FIG. 4, a part of the air blown from the centrifugal fan 20 can flow back to the suction side of the centrifugal fan 20 through the gap between the shroud 24 and the shroud facing portion 44. is there.

- the gap formed between the shroud 24 and the shroud facing portion 44 constitutes a backflow passage 46 that allows air to flow from the outlet side to the inlet side of the centrifugal fan 20.

- the air flowing through the backflow passage 46 is the air blown from the centrifugal fan 20 and has a rotation component in the rotation direction Rf of the centrifugal fan 20. Therefore, the air that has flowed into the reverse flow passage 46 from the outlet side of the centrifugal fan 20 advances in the rotation direction Rf of the centrifugal fan 20 when flowing through the reverse flow passage 46.

- the outflow position of air from the backflow passage 46 is a position advanced in the rotation direction Rf of the centrifugal fan 20 with respect to the inflow position of air into the backflow passage 46.

- the outflow position of the air from the backflow passage 46 is the same as the blowout deviation angle in the rotational direction Rf of the centrifugal fan 20 with respect to the inflow position of the air into the backflow passage 46. It tends to be in an advanced position.

- the inside air blown out from the centrifugal fan 20 may flow into the outside air suction side of the centrifugal fan 20 through the backflow passage 46.

- the window becomes liable to fog. If the window becomes fogged, the operation of the vehicle by the user will be hindered, so it must be avoided.

- one of the air flowing through the first blowout passage 421 and the air flowing through the second blowout passage 422 and the other air of the first suction passage 411 and the second suction passage 412 are provided.

- the structure is such that flow into the suction passage that is sucked is suppressed.

- a first fluid for guiding at least a part of the first fluid flowing through the reverse flow passage 46 to the first suction passage 411.

- a fluid bypass passage 461 is provided.

- the backflow passage 46 is formed in the first region R1 and the second region 421 based on the positional relationship between the first suction passage 411 and the second suction passage 412 and the first outlet passage 421 and the second outlet passage 422. It is divided into four regions, a region R2, a third region R3, and a fourth region R4.

- the region where the first outlet passage 421 is located outside the first suction passage 411 in the radial direction DRr is defined as the first region R1, and the first outlet passage 421 is disposed outside the second suction passage 412 in the radial direction DRr.

- the region where is located is referred to as a second region R2.

- a region where the second outlet passage 422 is located outside the second suction passage 412 in the radial direction DRr is defined as a third region R3, and the second outlet is provided outside the first suction passage 411 in the radial direction DRr.

- a region where the passage 422 is located is referred to as a fourth region R4.

- the blower 10 has a structure in which the reverse flow passage 46 overlaps the fluid suction passage 41 and the fluid discharge passage 42 in the axial direction DRa.

- the first region R1 overlaps with the first suction passage 411 and the first blowout passage 421 in the axial direction DRa

- the third region R3 has the second suction passage 412 and the second blowout passage in the axial direction DRa.

- the structure is such that it overlaps with the passage 422.

- the second region R2 overlaps with the second suction passage 412 and the first outlet passage 421 in the axial direction DRa

- the fourth region R4 overlaps with the first suction passage 411 and the second outlet passage 422 in the axial direction DRa. It has a structure that overlaps.

- the third region R3 of the backflow passage 46 is a region that advances in the rotation direction Rf of the centrifugal fan 20 with respect to the first outlet passage 421, and the first fluid flowing through the first outlet passage 421 may flow in.

- the third region R3 of the backflow passage 46 is continuous with the second suction passage 412, and the first fluid tends to flow into the second suction passage 412 via the backflow passage 46.

- the first fluid bypass passage 461 is provided in the shroud facing portion 44 at a portion forming the third region R3 of the backflow passage 46.

- the first fluid bypass passage 461 of the present embodiment is configured to guide the fluid flowing in the third region R3 of the reverse flow passage 46 to the first suction passage 411.

- the first fluid bypass passage 461 is configured by an arcuate passage extending along the rotation direction Rf of the centrifugal fan 20.

- the first fluid bypass passage 461 is located in a portion of the shroud facing portion 44 forming the third region R3 from a position where the base portion 51 of the inlet-side partition portion 50 is set, and from the base portion 51 to the rotation direction of the centrifugal fan 20. It is provided in a range up to a position delayed by about 60° from Rf. That is, the first fluid bypass passage 461 extends from the vicinity of the base portion 51 of the inlet-side partitioning portion 50 to the rotation direction Rf of the centrifugal fan 20 in the portion forming the third region R3 of the shroud facing portion 44. Is provided in a range up to a position advanced by about 60° in the opposite direction.

- the first fluid bypass passage 461 is configured by a portion of a portion of the shroud facing portion 44 that forms the third region R3 bulged to one side in the axial direction DRa. ..

- an outlet hole 461a serving as a passage outlet is formed in the base portion 51 of the inlet-side partition portion 50. Since the passage height in the axial direction DRa of the first fluid bypass passage 461 is sufficiently larger than the passage height of the backflow passage 46, the fluid flowing through the third region R3 of the backflow passage 46 easily flows. Is becoming

- the centrifugal fan 20 when the centrifugal fan 20 is driven by the electric motor 30 in the inside/outside air two-layer mode, as shown in FIG. 1, the inside air is sucked from the first suction port 401 and the outside air is discharged. It is sucked in through the second suction port 402.

- the inside air sucked from the first suction port 401 flows into the inter-blade passage 220 of the centrifugal fan 20 via the first suction passage 411.

- the outside air sucked from the second suction port 402 flows into the centrifugal fan 20 via the second suction passage 412. Since the first suction passage 411 and the second suction passage 412 are partitioned by the inlet-side partitioning portion 50, the outside air and the inside air hardly mix in the fluid suction passage 41 and flow into the inter-blade passage 220.

- the outside air and the inside air that have flowed into the centrifugal fan 20 flow from the inlet to the outlet of the inter-blade passage 220, the inside air is blown out to the first outlet passage 421, and the outside air is discharged to the second outlet passage. It is blown out to 422.

- the inside air blown into the first blow passage 421 is adjusted to a desired temperature inside the temperature adjustment unit, and then blown toward the occupants in the passenger compartment.

- the outside air blown into the second blowing passage 422 is adjusted to a desired temperature inside the temperature adjusting unit and then blown toward the inside of the window glass of the vehicle. This makes it possible to prevent window fogging and reduce the air conditioning load.

- a part of the inside air blown into the first blowing passage 421 flows into the backflow passage 46.

- the inflow of the inside air into the backflow passage 46 may be a factor that causes the inside air and the outside air to be mixed on the suction side of the centrifugal fan 20.

- the first fluid bypass passage 461 is provided in the shroud facing portion 44 forming the backflow passage 46. Therefore, as shown in FIG. 6 and FIG. 7, even if a part of the inside air blown out from the first outlet passage 421 flows into the backflow passage 46, the inside air passes through the first fluid bypass passage 461. 1 Suction passage 411 flows. That is, it is possible to prevent a part of the inside air blown from the first blow passage 421 from flowing into the second suction passage 412 via the backflow passage 46.

- the inside air blown out from the first outlet passage 421 may flow to the second suction passage 412 into which the outside air is sucked. Suppressed. As a result, the mixing of the inside air and the outside air due to the backflow of the inside air is suppressed, so that the separability of the inside air and the outside air in the blower 10 can be improved.

- the inside air is suppressed from flowing into the second suction passage 412 into which the outside air is sucked, so that the centrifugal fan 20 is supplied with the outside air having low humidity.

- low-humidity air that is, outside air

- the inside/outside air two-layer mode low-humidity air (that is, outside air) is blown toward the inside of the window glass of the vehicle, so that sufficient antifogging performance can be exhibited.

- the first fluid bypass passage 461 is provided in the portion of the shroud facing portion 44 that forms the third region R3 of the backflow passage 46, but is not limited thereto. Not done. In the backflow passage 46, the first fluid flowing through the first outlet passage 421 may flow into not only the third region R3 but also the second region R2 that is continuous with the second suction passage 412. Therefore, the first fluid bypass passage 461 is provided so as to straddle not only the portion forming the third region R3 of the backflow passage 46 but also the portion forming the second region R2 in the shroud facing portion 44. May be.

- a second fluid for guiding at least a part of the second fluid flowing through the backflow passage 46 to the second suction passage 412.

- a bypass passage 462 is provided in the shroud facing portion 44.

- the first fluid bypass passage 461 has the same configuration as that described in the first embodiment, as shown in FIG. 9.

- the first region R1 of the backflow passage 46 is a region that advances in the rotation direction Rf of the centrifugal fan 20 with respect to the second outlet passage 422, and the second fluid flowing through the second outlet passage 422 may flow in.

- the first region R1 of the backflow passage 46 is continuous with the first suction passage 411, and the second fluid tends to flow into the first suction passage 411 through the backflow passage 46.

- the second fluid bypass passage 462 is provided in the portion of the shroud facing portion 44 that forms the first region R1 of the backflow passage 46.

- the second fluid bypass passage 462 of the present embodiment is configured to guide the fluid flowing in the first region R1 of the reverse flow passage 46 to the second suction passage 412.

- the second fluid bypass passage 462 is configured by an arcuate passage extending along the rotation direction Rf of the centrifugal fan 20.

- the second fluid bypass passage 462 extends from the position where the base portion 51 of the inlet-side partition portion 50 is set in the portion forming the first region R1 of the shroud facing portion 44 to the rotation direction of the centrifugal fan 20 from the base portion 51. It is provided in a range up to a position delayed by about 60° from Rf. That is, the second fluid bypass passage 462 extends from the vicinity of the base portion 51 of the inlet side partition portion 50 to the rotation direction Rf of the centrifugal fan 20 in the portion forming the first region R1 of the shroud facing portion 44. Is provided in a range up to a position advanced by about 60° in the opposite direction.

- the second fluid bypass passage 462 is configured by a part of the shroud facing portion 44 that forms the first region R ⁇ b>1 and that bulges to one side in the axial direction DRa. ..

- an outlet hole 462a serving as a passage outlet is formed in the base portion 51 of the inlet-side partition portion 50. Since the passage height in the axial direction DRa of the second fluid bypass passage 462 is sufficiently larger than the passage height of the backflow passage 46, the second fluid bypass passage 462 has a structure in which the fluid flowing through the first region R1 of the backflow passage 46 easily flows. Is becoming

- blower 10 of the present embodiment has the same configuration as the blower 10 described in the first embodiment, it is possible to obtain the same effect as that of the first embodiment.

- the blower 10 of the present embodiment not only the first fluid bypass passage 461 but also the second fluid bypass passage 462 is provided for the shroud facing portion 44. According to this, the outside air blown out from the second outlet passage 422 is suppressed from flowing into the first intake passage 411 into which the inside air is sucked. As a result, the mixing of the inside air and the outside air due to the backflow of the outside air is suppressed, so that the separability of the inside air and the outside air in the blower 10 can be improved.

- the blower 10 of the present embodiment suppresses the outside air from flowing into the first suction passage 411 into which the inside air is sucked, it is possible to realize efficient air conditioning with reduced ventilation loss. That is, the blower 10 of the present embodiment can achieve both the securing of anti-fogging performance and the efficient air conditioning with suppressed ventilation loss.

- the second fluid bypass passage 462 is illustrated as being provided in the portion of the shroud facing portion 44 that forms the first region R1 of the backflow passage 46, but is not limited thereto. Not done. In the backflow passage 46, the second fluid flowing in the second outlet passage 422 may flow not only into the first region R1 but also into the fourth region R4 continuous with the first suction passage 411. Therefore, the second fluid bypass passage 462 is provided so as to straddle not only the portion of the backflow passage 46 that forms the first region R1 but also the portion that forms the fourth region R4 of the shroud facing portion 44. May be.

- the first fluid bypass passage 461 and the second fluid bypass passage 462 are formed for the shroud facing portion 44, but the invention is not limited to this.

- the blower 10 may have a structure in which only one of the first fluid bypass passage 461 and the second fluid bypass passage 462 is provided for the shroud facing portion 44, for example.

- the present embodiment is different from the first embodiment in that a first fluid communication hole 463 that communicates the first suction passage 411 and the first outlet passage 421 with the shroud facing portion 44 is formed. ..

- parts different from the first embodiment will be mainly described, and description of the same parts as the first embodiment may be omitted.

- the shroud facing portion 44 is provided with a first fluid communication hole 463 instead of the first fluid bypass passage 461.

- the first fluid communication hole 463 is a through hole that penetrates in the axial direction DRa.

- the first region R1 of the reverse flow passage 46 is a region where the first blowout passage 421 is located outside the radial direction DRr of the first suction passage 411, and the first fluid flowing through the first blowout passage 421 flows in. Since the first fluid that has flowed into the first region R1 has a rotational component in the rotational direction Rf of the centrifugal fan 20, it advances in the rotational direction Rf of the centrifugal fan 20 due to this rotational component and flows into the second suction passage 412. try to.

- the first region R1 is a region that overlaps the first suction passage 411 and the first outlet passage 421 in the axial direction DRa. Therefore, the first fluid communication hole 463 is provided in a portion of the shroud facing portion 44 that forms the first region R1 of the backflow passage 46.

- the first fluid communication hole 463 has a hole shape that extends in an arc shape along the rotation direction Rf of the centrifugal fan 20.

- the communication hole 463 for the first fluid is located in the portion forming the first region R1 of the shroud facing portion 44, from the position where the base portion 51 of the inlet side partition portion 50 is set to the rotation direction of the centrifugal fan 20 from the base portion 51. It is provided in a range up to a position delayed by about 90° from Rf. That is, the first fluid communication hole 463 is formed in the portion forming the first region R1 of the shroud facing portion 44 from the vicinity of the base portion 51 of the inlet side partition portion 50 to the rotation direction Rf of the centrifugal fan 20 from the base portion 51. Are provided in a range up to a position advanced by about 90° in the opposite direction.

- the blower 10 of the present embodiment is provided with a first fluid communication hole 463 for communicating the first suction passage 411 and the first blowout passage 421 with the shroud facing portion 44.

- the inside air is first sucked through the first fluid communication hole 463. It flows into the passage 411. That is, it is possible to prevent a part of the inside air blown from the first blow passage 421 from flowing into the second suction passage 412 via the backflow passage 46. As a result, the mixing of the inside air and the outside air due to the backflow of the inside air is suppressed, so that the separability of the inside air and the outside air in the blower 10 can be improved.

- the first fluid communication hole 463 is in the range from the position where the base portion 51 of the inlet-side partition portion 50 is set to the position which is delayed by about 90° in the rotational direction Rf of the centrifugal fan 20.

- the provided ones are illustrated, but the present invention is not limited to this.

- the first fluid communication hole 463 may have a shape and range other than those exemplified in the third embodiment as long as it is provided in the first region R1 of the shroud facing portion 44.

- the first fluid communication hole 463 is formed in the shroud facing portion 44 instead of the first fluid bypass passage 461, but the invention is not limited thereto. ..

- the blower 10 may have a structure in which the first fluid bypass passage 461 and the first fluid communication hole 463 are provided in the shroud facing portion 44, for example.

- a fourth embodiment will be described with reference to FIG.

- the present embodiment is different from the third embodiment in that a second fluid communication hole 464 that connects the second suction passage 412 and the second outlet passage 422 to the shroud facing portion 44 is formed. ..

- the shroud facing portion 44 is provided with a second fluid communication hole 464 in addition to the first fluid communication hole 463.

- the second fluid communication hole 464 is a through hole that penetrates in the axial direction DRa.

- the third region R3 of the backflow passage 46 is a region in which the second outlet passage 422 is located outside the second suction passage 412 in the radial direction DRr, and the second fluid flowing through the second outlet passage 422 flows in. Since the second fluid that has flowed into the second region R2 has a rotational component in the rotational direction Rf of the centrifugal fan 20, it advances in the rotational direction Rf of the centrifugal fan 20 due to this rotational component and flows into the first suction passage 411. try to.

- the second region R2 is a region that overlaps the second suction passage 412 and the second outlet passage 422 in the axial direction DRa. Therefore, the second fluid communication hole 464 is provided in a portion of the shroud facing portion 44 that forms the third region R3 of the backflow passage 46.

- the second fluid communication hole 464 has a hole shape that extends in an arc shape along the rotation direction Rf of the centrifugal fan 20.

- the second fluid communication hole 464 is formed in the rotation direction of the centrifugal fan 20 from the position where the base portion 51 of the inlet-side partition portion 50 is set in the portion forming the third region R3 of the shroud facing portion 44. It is provided in a range up to a position delayed by about 90° from Rf. That is, the second fluid communication hole 464 is located in the portion forming the third region R3 of the shroud facing portion 44, from the vicinity of the base portion 51 of the inlet side partition portion 50 to the rotation direction Rf of the centrifugal fan 20 from the base portion 51. Are provided in a range up to a position advanced by about 90° in the opposite direction.

- blower 10 of the present embodiment is provided with a second fluid communication hole 464 that communicates the second suction passage 412 and the second outlet passage 422 with the shroud facing portion 44.

- the outside air flows into the second suction passage 412 via the second fluid communication hole 464. That is, it is possible to prevent a part of the outside air blown from the second blow passage 422 from flowing into the first suction passage 411 via the backflow passage 46. As a result, the mixing of the inside air and the outside air due to the backflow of the outside air is suppressed, so that the separability of the inside air and the outside air in the blower 10 can be improved.

- the second fluid communication hole 464 is in the range from the position where the base portion 51 of the inlet-side partition portion 50 is set to the position which is delayed by about 90° in the rotational direction Rf of the centrifugal fan 20.

- the provided ones are illustrated, but the present invention is not limited to this.

- the second fluid communication hole 464 may have a shape and range other than those exemplified in the fourth embodiment as long as it is provided in the third region R3 of the shroud facing portion 44.

- the first fluid communication hole 463 and the second fluid communication hole 464 are formed in the shroud facing portion 44, but the invention is not limited thereto.

- the blower 10 may have a structure in which only one of the first fluid communication hole 463 and the second fluid communication hole 464 is formed in the shroud facing portion 44, for example.

- FIGS. 14 and 15 a fifth embodiment will be described with reference to FIGS. 14 and 15.

- This embodiment differs from the first embodiment in that a fluid guide 241 is formed for the shroud 24.

- parts different from the first embodiment will be mainly described, and description of the same parts as the first embodiment may be omitted.

- the shroud 24 has a plurality of fluid guides 241 formed therein.

- the first fluid bypass passage 461 described in the first embodiment is not formed for the shroud facing portion 44.

- the fluid guide 241 guides the first fluid flowing from the first outlet passage 421 to the backflow passage 46 to the first suction passage 411, and guides the second fluid flowing from the second outlet passage 422 into the second suction passage 421. 412.

- the fluid guide 241 projects toward the shroud facing portion 44.

- the fluid guide 241 is located at a position where the inner end 242 located on the fluid suction passage 41 side advances in the direction opposite to the rotational direction Rf of the centrifugal fan 20 with respect to the outer end 243 located on the fluid outlet passage 42 side. It has a shape. That is, the fluid guide 241 has a shape such that the inner end 242 located on the fluid suction passage 41 side is behind the outer end 243 located on the fluid outlet passage 42 side in the rotational direction Rf of the centrifugal fan 20. Is becoming

- the inner end portion 242 located on the air outlet side of the backflow passage 46 has a rotation direction Rf of the centrifugal fan 20 with respect to the outer end portion 243 located on the air inlet side of the backflow passage 46. It has been set to a position behind.

- an angle ⁇ formed by an imaginary line L3 connecting the inner end 242 and the fan axis CL and an imaginary line L4 connecting the outer end 243 and the fan axis CL becomes a backflow deviation angle.

- the positions of the inner end portion 242 and the outer end portion 243 are set.

- the fluid guide 241 is set so that the direction extending from the outer end 243 toward the inner end 242 is opposite to the rotation direction Rf of the centrifugal fan 20. That is, the fluid guide 241 has a curved shape so that the inflow position of the air into the reverse flow passage 46 is behind the outflow position of the air in the rotation direction Rf of the centrifugal fan 20.

- the blower 10 guides the first fluid, which has flowed into the backflow passage 46 from the first outlet passage 421, to the first suction passage 411 with respect to the shroud 24, and the second fluid which has flowed into the backflow passage 46 from the second outlet passage 422.

- a fluid guide 241 for guiding the fluid to the second suction passage 412 is provided.

- the inside air is guided to the first suction passage 411 by the fluid guide 241. That is, it is possible to prevent a part of the inside air blown from the first blow passage 421 from flowing into the second suction passage 412 via the backflow passage 46.

- the outside air is guided to the second suction passage 412 by the fluid guide 241. That is, it is possible to prevent a part of the outside air blown from the second blow passage 422 from flowing into the first suction passage 411 via the backflow passage 46.

- the mixing of the inside air and the outside air due to the backflow of the inside air and the outside air is suppressed, so that the separability of the inside air and the outside air in the blower 10 can be improved.

- the fifth embodiment described above exemplifies the one in which the plurality of fluid guides 241 are formed on the shroud facing portion 44, but the present invention is not limited to this.

- the blower 10 may have at least one fluid guide 241 formed on the shroud facing portion 44.

- the fluid guide 241 is curved so that the inflow position of the air into the reverse flow passage 46 is behind the outflow position of the air in the rotational direction Rf of the centrifugal fan 20.

- the shape is not limited to this. If the fluid guide 241 can suppress the mixture of the inside air and the outside air due to the backflow of the inside air and the outside air, for example, the inflow position of the air into the backflow passage 46 is the rotational direction Rf of the centrifugal fan 20 with respect to the outflow position of the air.

- the shape may be such that the position is advanced to.

- FIGS. 10-12 a sixth embodiment will be described with reference to FIGS.

- the present embodiment is different from the first embodiment in that a first fluid guide 441 and a second fluid guide 442 are provided for the shroud facing portion 44.

- parts different from the first embodiment will be mainly described, and description of the same parts as the first embodiment may be omitted.

- the shroud facing portion 44 is provided with a first fluid guide 441 and a second fluid guide 442.

- the first fluid bypass passage 461 described in the first embodiment is not formed for the shroud facing portion 44.

- the first fluid guide 441 guides the first fluid flowing from the first outlet passage 421 to the backflow passage 46 to the first suction passage 411.

- the first fluid guide 441 projects toward the shroud 24.

- the first fluid guide 441 is provided at a portion of the backflow passage 46 that forms the second region R2.

- the rotation direction Rf of the centrifugal fan 20 with respect to the first fluid outer end 441b located on the fluid blow-out passage 42 side is defined by the first fluid inner end 441a located on the fluid suction passage 41 side.

- the shape is such that it moves in the opposite direction to. That is, the first fluid guide 441 rotates the centrifugal fan 20 with respect to the first fluid outer end 441b located on the fluid outlet passage 42 side of the first fluid inner end 441a located on the fluid suction passage 41 side.

- the shape is such that the position is delayed in the direction Rf.

- the inner end portion 441a for the first fluid is set at a position close to the base portion 51 of the inlet-side partition portion 50 among the portions forming the second region R2 of the shroud facing portion 44.

- the first fluid outer end portion 441b is set at a position close to the outlet side partition portion 60 in a portion forming the second region R2 of the shroud facing portion 44. That is, the inner end portion 441a for the first fluid is set at a position behind the outer end portion 441b for the first fluid by about 90° in the rotation direction Rf of the centrifugal fan 20.

- the first fluid guide 441 is set so that the direction extending from the first fluid outer end 441b toward the first fluid inner end 441a is opposite to the rotation direction Rf of the centrifugal fan 20. That is, the first fluid guide 441 has a curved shape so that the inflow position of the air into the reverse flow passage 46 is behind the outflow position of the air in the rotation direction Rf of the centrifugal fan 20.

- the second fluid guide 442 guides the second fluid flowing from the second outlet passage 422 into the reverse flow passage 46 to the second suction passage 412.

- the second fluid guide 442 projects toward the shroud 24.

- the second fluid guide 442 is provided in a portion of the backflow passage 46 that forms the fourth region R4.

- the second fluid guide 442 has a second fluid inner end 442a located on the fluid suction passage 41 side with respect to a second fluid outer end 442b located on the fluid outlet passage 42 side.

- the shape is such that it moves in the opposite direction to. That is, the second fluid guide 442 rotates the centrifugal fan 20 with respect to the second fluid outer end 442b located on the fluid outlet passage 42 side, while the second fluid inner end 442a located on the fluid suction passage 41 side rotates.

- the shape is such that the position is delayed in the direction Rf.

- the inner end portion 442a for the second fluid is set at a position of the portion forming the fourth region R4 of the shroud facing portion 44, which is close to the base portion 51 of the inlet side partition portion 50.

- the second fluid outer end portion 442b is set at a position close to the outlet side partition portion 60 in the portion forming the fourth region R4 of the shroud facing portion 44. That is, the inner end portion 442a for the second fluid is set at a position delayed by about 90° in the rotation direction Rf of the centrifugal fan 20 with respect to the outer end portion 442b for the second fluid.

- the second fluid guide 442 is set such that the direction extending from the second fluid outer end 442b toward the second fluid inner end 442a is opposite to the rotation direction Rf of the centrifugal fan 20. That is, the second fluid guide 442 has a curved shape so that the inflow position of the air into the reverse flow passage 46 is behind the outflow position of the air in the rotation direction Rf of the centrifugal fan 20.

- the blower 10 is provided with a first fluid guide 441 for the shroud facing portion 44, which guides the first fluid flowing from the first outlet passage 421 into the backflow passage 46 to the first suction passage 411. Further, the blower 10 is provided with a second fluid guide 442 for the shroud facing portion 44, which guides the second fluid flowing from the second outlet passage 422 into the backflow passage 46 to the second suction passage 412.

- the inside air is guided to the first suction passage 411 by the first fluid guide 441. That is, it is possible to prevent a part of the inside air blown from the first blow passage 421 from flowing into the second suction passage 412 via the backflow passage 46.

- the outside air is guided to the second suction passage 412 by the second fluid guide 442. That is, it is possible to prevent a part of the outside air blown from the second blow passage 422 from flowing into the first suction passage 411 via the backflow passage 46.

- the mixing of the inside air and the outside air due to the backflow of the inside air and the outside air is suppressed, so that the separability of the inside air and the outside air in the blower 10 can be improved.

- the shroud facing portion 44 is provided with the first fluid guide 441 and the second fluid guide 442, but the shroud facing portion 44 is not limited to this.

- the blower 10 may have a structure in which only one of the first fluid guide 441 and the second fluid guide 442 is provided for the shroud facing portion 44, for example.

- the first fluid is the inside air and the second fluid is the outside air

- the first fluid and the second fluid are not limited to this.

- the first fluid may be outside air and the second fluid may be inside air.

- the outside air flows through the first suction passage 411 and the first outlet passage 421, and the inside air flows through the second suction passage 412 and the second outlet passage 422.

- the vehicle air conditioner may have, for example, a configuration in which a temperature adjusting unit is arranged on the upstream side of the air flow of the blower 10. Further, the vehicle air conditioner may be configured such that the cooling heat exchanger is arranged upstream of the air flow of the blower 10 and the heating heat exchanger is arranged downstream of the air flow of the blower 10. Good.

- blower 10 of the present disclosure is applied to a vehicle air conditioner

- the application target of the blower 10 is not limited to this.

- the blower 10 of the present disclosure can be widely applied to a device (for example, a humidifier) that needs to avoid mixing fluids having different temperatures and humidity.

- the blower is configured so that the fluid flows from the fluid outlet passage toward the fluid inlet passage between the shroud of the centrifugal fan and the shroud facing portion of the casing.

- a backflow passage is formed.

- the backflow passage is a suction passage in which one of the first fluid flowing through the first blow passage and the second fluid flowing through the second blow passage receives the other fluid of the first suction passage and the second suction passage. It is structured so that it can be prevented from flowing into.

- the shroud facing portion is provided with the first fluid bypass passage for guiding at least a part of the first fluid flowing through the backflow passage to the first suction passage.

- at least a part of the first fluid flowing in the backflow passage flows into the first suction passage from the backflow passage, so that the first fluid is suppressed from flowing into the second suction passage.

- the mixing of the first fluid and the second fluid in the second suction passage is suppressed, so that the separability of the first fluid and the second fluid in the blower can be improved.

- the shroud facing portion is provided with a second fluid bypass passage for guiding at least a part of the second fluid flowing through the backflow passage to the second suction passage.

- at least a part of the second fluid flowing through the backflow passage flows into the second suction passage from the backflow passage, so that the second fluid is suppressed from flowing into the first suction passage.

- the mixing of the first fluid and the second fluid in the first suction passage is suppressed, so that the separability of the first fluid and the second fluid in the blower can be improved.

- the shroud facing portion is formed with a first fluid communication hole that communicates at least a part of a region in which the first fluid flows in the backflow passage with the first suction passage. ..

- the first fluid flowing through the backflow passage flows into the first suction passage through the first fluid communication hole, so that the first fluid is suppressed from flowing into the second suction passage.

- the mixing of the first fluid and the second fluid in the second suction passage is suppressed, so that the separability of the first fluid and the second fluid in the blower can be improved.

- the shroud facing portion has a first fluid communication hole that communicates a region in which the first fluid flows in the backflow passage and the first suction passage, and a second fluid in the backflow passage.

- a communication hole for the second fluid is formed that connects the region in which is flowing and the second suction passage.

- At least a part of the first fluid flowing through the backflow passage flows into the first suction passage through the first fluid communication hole, so that the first fluid is suppressed from flowing into the second suction passage.

- at least a part of the second fluid flowing through the backflow passage flows into the second suction passage via the communication hole for the second fluid, so that the first fluid is suppressed from flowing into the second suction passage.

- the blower guides the first fluid, which has flowed into the backflow passage from the first outlet passage, into the shroud, while introducing the second fluid, which has flowed into the backflow passage from the second outlet passage, into the first suction passage.

- At least one fluid guide that leads to the second suction passage is formed.

- the fluid guide projects toward the shroud facing portion, and the inner end located on the fluid suction passage side advances in the direction opposite to the rotation direction of the centrifugal fan with respect to the outer end located on the fluid discharge passage side.

- the first fluid flowing into the backflow passage is guided to the first suction passage by the first fluid guide formed in the shroud, so that the first fluid is suppressed from flowing into the second suction passage.

- the second fluid flowing into the backflow passage is guided to the second suction passage by the second fluid guide formed in the shroud, so that the second fluid is suppressed from flowing into the first suction passage.

- the shroud facing portion is provided with a first fluid guide that guides the first fluid that has flowed into the reverse flow passage from the first blow passage to the first suction passage.

- the first fluid guide projects toward the shroud facing portion, and an inner end portion of the first fluid located on the fluid suction passage side of the first fluid guide of the centrifugal fan with respect to an outer end portion of the first fluid located on the fluid outlet passage side.

- the shape is such that the position advances in the direction opposite to the rotation direction.

- the first fluid that has flowed into the backflow passage is guided to the first suction passage by the first fluid guide formed in the shroud facing portion, so that the first fluid is suppressed from flowing into the second suction passage. ..

- the mixing of the first fluid and the second fluid in the second suction passage is suppressed, so that the separability of the first fluid and the second fluid in the blower can be improved.

- the shroud facing portion is formed with a second fluid guide that guides the second fluid that has flowed into the backflow passage from the second outlet passage to the second suction passage.

- the second fluid guide projects toward the shroud facing portion, and the inner end of the second fluid located on the fluid suction passage side of the second fluid guide of the centrifugal fan with respect to the outer end of the second fluid located on the fluid discharge passage side.

- the shape is such that the position advances in the direction opposite to the rotation direction.

- the second fluid flowing into the backflow passage is guided to the second suction passage by the second fluid guide formed in the shroud facing portion, so that the second fluid is suppressed from flowing into the first suction passage. ..

- the mixing of the first fluid and the second fluid in the first suction passage is suppressed, so that the separability of the first fluid and the second fluid in the blower can be improved.

- a blower is applied to a vehicle air conditioner capable of performing an inside/outside air two-layer mode in which outside air is introduced from the outside of the vehicle compartment while the inside air introduced from the inside of the vehicle compartment is circulated in the vehicle interior.

- the first fluid is one of outside air and inside air.

- the second fluid is the other of the outside air and the inside air.

- the blower it is possible to suppress the mixture of the inside air and the outside air in the blower.

- the inflow of the inside air into the suction passage that sucks the outside air it is possible to supply low-humidity air (that is, outside air) toward the inside of the window glass for the vehicle.

- the ventilation loss is reduced and the air conditioning efficiency by the inside air circulation is improved, so that the efficient air conditioning can be realized.

Abstract

This fan (10) comprises: a centrifugal fan (20); and a casing (40) having the centrifugal fan housed therein. The fan (10) comprises: an intake-side partition (50) which partitions a fluid suction passage (41) into a first suction passage (411) and a second suction passage (412); and an outlet-side partition (60) which partitions a fluid blowing passage (42) into a first blowing passage (421) and a second blowing passage (422). The casing includes a shroud-facing portion (44) which faces a shroud (24) of the centrifugal fan with a predetermined interval therebetween, and which forms a reverse flow passage (46) through which a first fluid and a second fluid flow from the fluid blowing passage between the shroud, towards the fluid suction passage. The reverse flow passage has a structure which curbs one of either the first fluid which flows through the first blowing passage or the second fluid which flows through the second blowing passage from flowing into the suction passage into which the other fluid is sucked, that being the other of the first suction passage and the second suction passage.

Description

本出願は、2018年12月5日に出願された日本特許出願番号2018-228405号に基づくもので、ここにその記載内容が参照により組み入れられる。

This application is based on Japanese Patent Application No. 2018-228405 filed on December 5, 2018, the description of which is incorporated herein by reference.

本開示は、第1流体と第2流体を吸い込んで吹き出す送風機に関する。

The present disclosure relates to a blower that sucks in and blows out a first fluid and a second fluid.

従来、異なる温度の空気を区別して送風するために、遠心ファンの吸込側および吹出側それぞれに仕切部材が設けられた送風機が知られている(例えば、特許文献1参照)。この特許文献1には、空気を吸い込んでから吹き出すまでの遠心ファンの回転角度を考慮して、遠心ファンの吸込側の仕切部材および吹出側の仕切部材の相対位置を遠心ファンの回転方向にずらした送風機が開示されている。

Conventionally, there has been known a blower in which partition members are provided on the suction side and the blowing side of a centrifugal fan in order to separately blow air of different temperatures (for example, see Patent Document 1). In this patent document 1, the relative position of the partition member on the suction side and the partition member on the outlet side of the centrifugal fan is shifted in the rotational direction of the centrifugal fan in consideration of the rotation angle of the centrifugal fan from the time of sucking air to the time of blowing air. A blower is disclosed.

ところで、遠心ファンは、空気の吸込側と吹出側に圧力差が生ずるため、遠心ファンから吹き出された空気の一部が、遠心ファンと遠心ファンを収容するケーシングとの隙間を介して遠心ファンの吸込側に逆流することがある。この場合、遠心ファンと遠心ファンを収容するケーシングとの隙間が、遠心ファンの吹出側から吸込側に空気が流れる逆流通路を構成する。

By the way, since the centrifugal fan has a pressure difference between the suction side and the blowing side of the air, a part of the air blown out from the centrifugal fan passes through the gap between the centrifugal fan and the casing housing the centrifugal fan so that a part of the centrifugal fan is discharged. May flow back to the suction side. In this case, the gap between the centrifugal fan and the casing containing the centrifugal fan constitutes a backflow passage through which air flows from the blow side to the suction side of the centrifugal fan.

また、遠心ファンから吹き出された空気は遠心ファンの回転方向の回転成分を有しており、遠心ファンの吹出側から逆流通路に流入した空気が逆流通路を流れる際に遠心ファンの回転方向に進む。

Further, the air blown out from the centrifugal fan has a rotation component in the rotation direction of the centrifugal fan, and when the air flowing into the backflow passage from the blowout side of the centrifugal fan flows in the backflow passage, it advances in the rotation direction of the centrifugal fan. ..

このため、例えば、遠心ファンによって温度が異なる第1流体と第2流体とを区別して送風しようとしても、遠心ファンから吹き出された第1流体が、逆流通路を介して遠心ファンにおける第2流体の吸込側に流れ込んでしまう可能性がある。また、遠心ファンから吹き出された第2流体が、逆流通路を介して遠心ファンにおける第1流体の吸込側に流れ込んでしまう可能性もある。

Therefore, for example, even if an attempt is made to separate the first fluid and the second fluid having different temperatures by the centrifugal fan to blow the air, the first fluid blown out from the centrifugal fan passes through the backflow passage and becomes the second fluid in the centrifugal fan. It may flow into the suction side. Further, the second fluid blown out from the centrifugal fan may flow into the suction side of the first fluid in the centrifugal fan via the backflow passage.

つまり、従来技術では、遠心ファンの吹出側から吸込側への流体の逆流による第1流体と第2流体との混合を抑えることができず、送風機における第1流体と第2流体との分離性が低い。これらは、本発明者らの鋭意検討の末に見出された知見である。

本開示は、第1流体と第2流体を吸い込んで吹き出す送風機において、第1流体と第2流体との分離性の向上を図ることを目的とする。 That is, in the prior art, it is not possible to suppress the mixing of the first fluid and the second fluid due to the reverse flow of the fluid from the outlet side to the inlet side of the centrifugal fan, and the separability of the first fluid and the second fluid in the blower is suppressed. Is low. These are the findings that have been found after intensive studies by the present inventors.

The present disclosure aims to improve the separability of the first fluid and the second fluid in a blower that sucks in and blows out the first fluid and the second fluid.

本開示は、第1流体と第2流体を吸い込んで吹き出す送風機において、第1流体と第2流体との分離性の向上を図ることを目的とする。 That is, in the prior art, it is not possible to suppress the mixing of the first fluid and the second fluid due to the reverse flow of the fluid from the outlet side to the inlet side of the centrifugal fan, and the separability of the first fluid and the second fluid in the blower is suppressed. Is low. These are the findings that have been found after intensive studies by the present inventors.

The present disclosure aims to improve the separability of the first fluid and the second fluid in a blower that sucks in and blows out the first fluid and the second fluid.

本開示の1つの観点によれば、

第1流体と第2流体を吸い込んで吹き出す送風機は、

ファン軸心を中心に回転することで、ファン軸心の軸方向の一方側から吸い込んだ第1流体および第2流体をファン軸心から遠ざかる方向に吹き出す遠心ファンと、

遠心ファンが内部に収容されて、遠心ファンに対して軸方向の一方側に流体吸込通路を形成するとともに、遠心ファンの径方向の外側に流体吹出通路を形成するケーシングと、

流体吸込通路を第1流体が流れる第1吸込通路と第2流体が流れる第2吸込通路とに仕切る入口側仕切部と、

流体吹出通路を遠心ファンから吹き出された第1流体が流れる第1吹出通路と遠心ファンから吹き出された第2流体が流れる第2吹出通路とに仕切る出口側仕切部と、を備え、

遠心ファンは、ファン軸心の周りに配置された複数のブレード、複数のブレードにおける軸方向の一方側に位置する部位同士を連結するリング状のシュラウドと、を有しており、

ケーシングは、シュラウドに対して所定の隙間をあけて対向するとともに、シュラウドとの間に流体吹出通路から流体吸込通路に向けて第1流体および第2流体が流れる逆流通路を形成するシュラウド対向部を含んでおり、

逆流通路は、第1吹出通路を流れる第1流体および第2吹出通路を流れる第2流体のうち一方の流体が、第1吸込通路および第2吸込通路のうち他方の流体が吸い込まれる吸込通路に流れることが抑制される構造になっている。 According to one aspect of the disclosure,

The blower that sucks in and blows out the first fluid and the second fluid is

A centrifugal fan that rotates around the fan axis to blow out the first fluid and the second fluid sucked from one side in the axial direction of the fan axis in a direction away from the fan axis.

A casing in which the centrifugal fan is housed, forms a fluid suction passage on one side in the axial direction with respect to the centrifugal fan, and forms a fluid discharge passage on the outer side in the radial direction of the centrifugal fan;

An inlet-side partition that partitions the fluid suction passage into a first suction passage through which the first fluid flows and a second suction passage through which the second fluid flows;

An outlet-side partition part for partitioning the fluid outlet passage into a first outlet passage through which the first fluid blown out from the centrifugal fan flows and a second outlet passage through which the second fluid blown out from the centrifugal fan flows,

The centrifugal fan has a plurality of blades arranged around the fan axis, a ring-shaped shroud that connects the portions of the plurality of blades located on one side in the axial direction,

The casing has a shroud facing portion that faces the shroud with a predetermined gap and forms a backflow passage between the shroud and the first fluid and the second fluid from the fluid discharge passage toward the fluid suction passage. Including,

The backflow passage is a suction passage in which one of the first fluid flowing through the first blow passage and the second fluid flowing through the second blow passage receives the other fluid of the first suction passage and the second suction passage. It has a structure that prevents the flow.

第1流体と第2流体を吸い込んで吹き出す送風機は、

ファン軸心を中心に回転することで、ファン軸心の軸方向の一方側から吸い込んだ第1流体および第2流体をファン軸心から遠ざかる方向に吹き出す遠心ファンと、

遠心ファンが内部に収容されて、遠心ファンに対して軸方向の一方側に流体吸込通路を形成するとともに、遠心ファンの径方向の外側に流体吹出通路を形成するケーシングと、

流体吸込通路を第1流体が流れる第1吸込通路と第2流体が流れる第2吸込通路とに仕切る入口側仕切部と、

流体吹出通路を遠心ファンから吹き出された第1流体が流れる第1吹出通路と遠心ファンから吹き出された第2流体が流れる第2吹出通路とに仕切る出口側仕切部と、を備え、

遠心ファンは、ファン軸心の周りに配置された複数のブレード、複数のブレードにおける軸方向の一方側に位置する部位同士を連結するリング状のシュラウドと、を有しており、

ケーシングは、シュラウドに対して所定の隙間をあけて対向するとともに、シュラウドとの間に流体吹出通路から流体吸込通路に向けて第1流体および第2流体が流れる逆流通路を形成するシュラウド対向部を含んでおり、

逆流通路は、第1吹出通路を流れる第1流体および第2吹出通路を流れる第2流体のうち一方の流体が、第1吸込通路および第2吸込通路のうち他方の流体が吸い込まれる吸込通路に流れることが抑制される構造になっている。 According to one aspect of the disclosure,

The blower that sucks in and blows out the first fluid and the second fluid is

A centrifugal fan that rotates around the fan axis to blow out the first fluid and the second fluid sucked from one side in the axial direction of the fan axis in a direction away from the fan axis.

A casing in which the centrifugal fan is housed, forms a fluid suction passage on one side in the axial direction with respect to the centrifugal fan, and forms a fluid discharge passage on the outer side in the radial direction of the centrifugal fan;

An inlet-side partition that partitions the fluid suction passage into a first suction passage through which the first fluid flows and a second suction passage through which the second fluid flows;

An outlet-side partition part for partitioning the fluid outlet passage into a first outlet passage through which the first fluid blown out from the centrifugal fan flows and a second outlet passage through which the second fluid blown out from the centrifugal fan flows,

The centrifugal fan has a plurality of blades arranged around the fan axis, a ring-shaped shroud that connects the portions of the plurality of blades located on one side in the axial direction,

The casing has a shroud facing portion that faces the shroud with a predetermined gap and forms a backflow passage between the shroud and the first fluid and the second fluid from the fluid discharge passage toward the fluid suction passage. Including,

The backflow passage is a suction passage in which one of the first fluid flowing through the first blow passage and the second fluid flowing through the second blow passage receives the other fluid of the first suction passage and the second suction passage. It has a structure that prevents the flow.

このように、第1吹出通路および第2吹出通路に吹き出された一方の流体が、他方の流体が吸い込まれる吸込通路に流れることが抑制される構造であれば、第1流体および第2流体の逆流による第1流体と第2流体との混合が抑制される。すなわち、第1流体と第2流体を吸い込んで吹き出す送風機において、第1流体と第2流体との分離性の向上を図ることができる。

As described above, as long as the structure in which one of the fluids blown into the first outlet passage and the second outlet passage is suppressed from flowing into the suction passage into which the other fluid is sucked, the first fluid and the second fluid Mixing of the first fluid and the second fluid due to backflow is suppressed. That is, in a blower that sucks in and blows out the first fluid and the second fluid, it is possible to improve the separability of the first fluid and the second fluid.

なお、各構成要素等に付された括弧付きの参照符号は、その構成要素等と後述する実施形態に記載の具体的な構成要素等との対応関係の一例を示すものである。

Note that the reference numerals in parentheses attached to the respective constituent elements and the like indicate an example of a correspondence relationship between the constituent elements and the like and specific constituent elements and the like described in the embodiments described later.

以下、本開示の実施形態について図面を参照して説明する。なお、以下の実施形態において、先行する実施形態で説明した事項と同一もしくは均等である部分には、同一の参照符号を付し、その説明を省略する場合がある。また、実施形態において、構成要素の一部だけを説明している場合、構成要素の他の部分に関しては、先行する実施形態において説明した構成要素を適用することができる。以下の実施形態は、特に組み合わせに支障が生じない範囲であれば、特に明示していない場合であっても、各実施形態同士を部分的に組み合わせることができる。

Hereinafter, embodiments of the present disclosure will be described with reference to the drawings. In the following embodiments, parts that are the same as or equivalent to those described in the preceding embodiments may be assigned the same reference numerals and the description thereof may be omitted. Further, in the embodiment, when only a part of the constituent elements is described, the constituent elements described in the preceding embodiments can be applied to the other parts of the constituent elements. In the following embodiments, the embodiments can be partially combined with each other as long as the combination is not hindered, unless otherwise specified.

(第1実施形態)

本実施形態について、図1~図7を参照して説明する。本実施形態では、本開示の送風機10を車両に搭載される車両用空調装置に適用した例について説明する。車両用空調装置は、車室内の最前部のインストルメントパネルの内側に配置されている。車両用空調装置は、車室外と車室内から吸い込んだ空気を区別して車室内に吹き出すことが可能な内外気二層式の空調装置として構成されている。車両用空調装置は、車室内空気である内気を第1流体とし車室外空気である外気を第2流体として、外気を車両の窓ガラスの内側に向けて吹き出しつつ、内気を車室内で循環させる内外気二層モードを実施可能となっている。車両用空調装置は、本開示の送風機10に加えて、図示しない内外気切替箱および温度調整ユニットを備えている。 (First embodiment)

This embodiment will be described with reference to FIGS. 1 to 7. In the present embodiment, an example in which theblower 10 of the present disclosure is applied to a vehicle air conditioner mounted on a vehicle will be described. The vehicle air conditioner is arranged inside a frontmost instrument panel in the vehicle compartment. The vehicle air conditioner is configured as an inside/outside air two-layer air conditioner capable of distinguishing the air sucked in from the outside of the vehicle compartment and the air sucked in from the vehicle compartment. The vehicle air conditioner circulates the inside air in the vehicle interior while blowing the outside air toward the inside of the window glass of the vehicle by using the inside air that is the air inside the vehicle as the first fluid and the outside air that is the air outside the vehicle as the second fluid. The inside/outside air two-layer mode can be implemented. The vehicle air conditioner includes an inside/outside air switching box and a temperature adjustment unit, which are not shown, in addition to the blower 10 of the present disclosure.

本実施形態について、図1~図7を参照して説明する。本実施形態では、本開示の送風機10を車両に搭載される車両用空調装置に適用した例について説明する。車両用空調装置は、車室内の最前部のインストルメントパネルの内側に配置されている。車両用空調装置は、車室外と車室内から吸い込んだ空気を区別して車室内に吹き出すことが可能な内外気二層式の空調装置として構成されている。車両用空調装置は、車室内空気である内気を第1流体とし車室外空気である外気を第2流体として、外気を車両の窓ガラスの内側に向けて吹き出しつつ、内気を車室内で循環させる内外気二層モードを実施可能となっている。車両用空調装置は、本開示の送風機10に加えて、図示しない内外気切替箱および温度調整ユニットを備えている。 (First embodiment)

This embodiment will be described with reference to FIGS. 1 to 7. In the present embodiment, an example in which the

内外気切替箱は、外気および内気を取り入れるものである。本実施形態の内外気切替箱は、送風機10の空気流れ上流側に接続されている。内外気切替箱は、外気を導入するための外気導入口、内気を導入するための内気導入口が形成されており、各導入口の開口面積を内外気ドアによって調整することで、内気と外気との導入量を調整可能になっている。

The inside/outside air switching box takes in outside air and inside air. The inside/outside air switching box of the present embodiment is connected to the air flow upstream side of the blower 10. The inside/outside air switching box is formed with an outside air inlet for introducing outside air and an inside air inlet for introducing inside air.By adjusting the opening area of each inlet with the inside/outside air door, The amount introduced with and can be adjusted.

内外気切替箱には、外気および内気を区別して導入可能なように、複数の空気通路が設定されている。この複数の空気通路は、温度または湿度等の性質の異なる空気が混ざり合うことなく流れるように仕切板によって仕切られている。

In the inside/outside air switching box, multiple air passages are set so that the outside air and the inside air can be introduced separately. The plurality of air passages are partitioned by a partition plate so that air having different properties such as temperature or humidity can flow without being mixed.