WO2019167385A1 - Liquid discharge head and liquid discharge device - Google Patents

Liquid discharge head and liquid discharge device Download PDFInfo

- Publication number

- WO2019167385A1 WO2019167385A1 PCT/JP2018/046316 JP2018046316W WO2019167385A1 WO 2019167385 A1 WO2019167385 A1 WO 2019167385A1 JP 2018046316 W JP2018046316 W JP 2018046316W WO 2019167385 A1 WO2019167385 A1 WO 2019167385A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- circulation

- path

- circulation path

- liquid

- pressure chamber

- Prior art date

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41J—TYPEWRITERS; SELECTIVE PRINTING MECHANISMS, i.e. MECHANISMS PRINTING OTHERWISE THAN FROM A FORME; CORRECTION OF TYPOGRAPHICAL ERRORS

- B41J2/00—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed

- B41J2/005—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed characterised by bringing liquid or particles selectively into contact with a printing material

- B41J2/01—Ink jet

- B41J2/17—Ink jet characterised by ink handling

- B41J2/18—Ink recirculation systems

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41J—TYPEWRITERS; SELECTIVE PRINTING MECHANISMS, i.e. MECHANISMS PRINTING OTHERWISE THAN FROM A FORME; CORRECTION OF TYPOGRAPHICAL ERRORS

- B41J2/00—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed

- B41J2/005—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed characterised by bringing liquid or particles selectively into contact with a printing material

- B41J2/01—Ink jet

- B41J2/135—Nozzles

- B41J2/14—Structure thereof only for on-demand ink jet heads

- B41J2/14201—Structure of print heads with piezoelectric elements

- B41J2/14233—Structure of print heads with piezoelectric elements of film type, deformed by bending and disposed on a diaphragm

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41J—TYPEWRITERS; SELECTIVE PRINTING MECHANISMS, i.e. MECHANISMS PRINTING OTHERWISE THAN FROM A FORME; CORRECTION OF TYPOGRAPHICAL ERRORS

- B41J2/00—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed

- B41J2/005—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed characterised by bringing liquid or particles selectively into contact with a printing material

- B41J2/01—Ink jet

- B41J2/135—Nozzles

- B41J2/14—Structure thereof only for on-demand ink jet heads

- B41J2/14201—Structure of print heads with piezoelectric elements

- B41J2/14233—Structure of print heads with piezoelectric elements of film type, deformed by bending and disposed on a diaphragm

- B41J2002/14241—Structure of print heads with piezoelectric elements of film type, deformed by bending and disposed on a diaphragm having a cover around the piezoelectric thin film element

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41J—TYPEWRITERS; SELECTIVE PRINTING MECHANISMS, i.e. MECHANISMS PRINTING OTHERWISE THAN FROM A FORME; CORRECTION OF TYPOGRAPHICAL ERRORS

- B41J2/00—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed

- B41J2/005—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed characterised by bringing liquid or particles selectively into contact with a printing material

- B41J2/01—Ink jet

- B41J2/135—Nozzles

- B41J2/14—Structure thereof only for on-demand ink jet heads

- B41J2002/14411—Groove in the nozzle plate

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41J—TYPEWRITERS; SELECTIVE PRINTING MECHANISMS, i.e. MECHANISMS PRINTING OTHERWISE THAN FROM A FORME; CORRECTION OF TYPOGRAPHICAL ERRORS

- B41J2/00—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed

- B41J2/005—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed characterised by bringing liquid or particles selectively into contact with a printing material

- B41J2/01—Ink jet

- B41J2/135—Nozzles

- B41J2/14—Structure thereof only for on-demand ink jet heads

- B41J2002/14419—Manifold

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41J—TYPEWRITERS; SELECTIVE PRINTING MECHANISMS, i.e. MECHANISMS PRINTING OTHERWISE THAN FROM A FORME; CORRECTION OF TYPOGRAPHICAL ERRORS

- B41J2/00—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed

- B41J2/005—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed characterised by bringing liquid or particles selectively into contact with a printing material

- B41J2/01—Ink jet

- B41J2/135—Nozzles

- B41J2/14—Structure thereof only for on-demand ink jet heads

- B41J2002/14467—Multiple feed channels per ink chamber

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41J—TYPEWRITERS; SELECTIVE PRINTING MECHANISMS, i.e. MECHANISMS PRINTING OTHERWISE THAN FROM A FORME; CORRECTION OF TYPOGRAPHICAL ERRORS

- B41J2/00—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed

- B41J2/005—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed characterised by bringing liquid or particles selectively into contact with a printing material

- B41J2/01—Ink jet

- B41J2/135—Nozzles

- B41J2/14—Structure thereof only for on-demand ink jet heads

- B41J2002/14491—Electrical connection

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41J—TYPEWRITERS; SELECTIVE PRINTING MECHANISMS, i.e. MECHANISMS PRINTING OTHERWISE THAN FROM A FORME; CORRECTION OF TYPOGRAPHICAL ERRORS

- B41J2202/00—Embodiments of or processes related to ink-jet or thermal heads

- B41J2202/01—Embodiments of or processes related to ink-jet heads

- B41J2202/12—Embodiments of or processes related to ink-jet heads with ink circulating through the whole print head

Definitions

- the present invention relates to a technique for discharging a liquid such as ink.

- a liquid discharge head that discharges a liquid such as ink in a pressure chamber from a nozzle by causing a pressure change in the pressure chamber by a driving element such as a piezoelectric element is known.

- a liquid discharge head there is a possibility that nozzle discharge defects may occur due to bubbles mixed in the liquid or the viscosity of the liquid increasing.

- a circulation flow path (a supply branch flow path and a recovery branch flow path) is disposed below the pressure chamber, and the pressure chamber and the nozzle are separated from each other (a first recovery throttle flow path, a second recovery flow path).

- the recovery throttle channel communicates with the circulation channel.

- a liquid discharge head includes a nozzle plate provided with a nozzle, a pressure chamber to which a liquid is supplied, and a communication path that communicates the pressure chamber with the nozzle.

- a flow path forming portion provided with a circulating fluid chamber, a pressure generating portion that generates a pressure change in the pressure chamber, a first circulation path that connects the pressure chamber to the circulating fluid chamber, and a communicating passage as the circulating fluid chamber.

- a second circulation path that communicates, and the flow path resistance of the second circulation path is smaller than the flow path resistance of the first circulation path.

- FIG. 6 is an explanatory diagram of ink circulation in the liquid discharge head.

- FIG. 6 is a plan view and a cross-sectional view of the vicinity of a circulating fluid chamber in the liquid discharge head. It is sectional drawing of the vicinity of the circulating fluid chamber in the liquid discharge head of a 1st modification. It is sectional drawing of the vicinity of the circulating fluid chamber in the liquid discharge head of a 2nd modification. It is sectional drawing of the liquid discharge head of 2nd Embodiment. It is sectional drawing of the liquid discharge head of 3rd Embodiment. It is sectional drawing of the liquid discharge head of 4th Embodiment. It is sectional drawing of the liquid discharge head of a 3rd modification.

- FIG. 1 is a configuration diagram illustrating a liquid ejection apparatus 100 according to the first embodiment of the invention.

- the liquid ejection apparatus 100 according to the first embodiment is an ink jet printing apparatus that ejects ink, which is an example of a liquid, onto the medium 12.

- the medium 12 is typically a printing paper, but the medium 12 can be a printing target of an arbitrary material such as a resin film or a fabric.

- the liquid ejection apparatus 100 is provided with a liquid container 14 that stores ink.

- a cartridge that can be attached to and detached from the liquid ejection device 100, a bag-like ink pack formed of a flexible film, or an ink tank that can be refilled with ink is used as the liquid container 14.

- a plurality of types of inks having different colors are stored in the liquid container 14.

- the ink may be a dye ink containing a dye as a color material or a pigment ink containing a pigment as a color material.

- the liquid ejection device 100 includes a control unit 20, a transport mechanism 22, a movement mechanism 24, and a liquid ejection head 26.

- the control unit 20 includes, for example, a processing circuit such as a CPU (Central Processing Unit) or FPGA (Field Programmable Gate Array) and a storage circuit such as a semiconductor memory, and comprehensively controls each element of the liquid ejection apparatus 100.

- the transport mechanism 22 transports the medium 12 in the Y direction under the control of the control unit 20.

- the moving mechanism 24 reciprocates the liquid ejection head 26 in the X direction under the control of the control unit 20.

- the X direction is a direction that intersects (typically orthogonal) the Y direction in which the medium 12 is conveyed.

- the moving mechanism 24 of the first embodiment includes a substantially box-shaped carriage 242 (conveyance body) that accommodates the liquid ejection head 26 and a conveyance belt 244 to which the carriage 242 is fixed.

- a configuration in which a plurality of liquid ejection heads 26 are mounted on the carriage 242 or a configuration in which the liquid container 14 is mounted on the carriage 242 together with the liquid ejection heads 26 may be employed.

- the liquid discharge head 26 discharges ink supplied from the liquid container 14 to the medium 12 from a plurality of nozzles N (discharge holes) under the control of the control unit 20.

- Each liquid ejection head 26 ejects ink onto the medium 12 in parallel with the transport of the medium 12 by the transport mechanism 22 and the reciprocating reciprocation of the carriage 242, thereby forming a desired image on the surface of the medium 12.

- a direction perpendicular to the XY plane (for example, a plane parallel to the surface of the medium 12) is hereinafter referred to as a Z direction.

- the ink ejection direction (typically the vertical direction) by each liquid ejection head 26 corresponds to the Z direction.

- the plurality of nozzles N of the liquid discharge head 26 are arranged in the Y direction.

- the plurality of nozzles N of the first embodiment are divided into a first nozzle row L1 and a second nozzle row L2 that are arranged in parallel in the X direction with a space therebetween.

- Each of the first nozzle row L1 and the second nozzle row L2 is a set of a plurality of nozzles N arranged linearly in the Y direction.

- a configuration in which the positions of the nozzles N in the Y direction are matched with each other in the two-nozzle row L2 will be exemplified below for convenience.

- a plane parallel to the YZ plane in the liquid discharge head 26 is referred to as a virtual plane O.

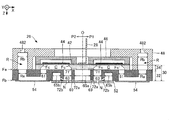

- FIG. 2 is a cross-sectional view of the liquid discharge head 26 taken along a cross section perpendicular to the Y direction

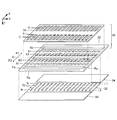

- FIG. 3 is a partial exploded perspective view of the liquid discharge head 26.

- the liquid ejection head 26 according to the first embodiment includes elements related to the nozzles N (illustrative examples of the first nozzles) of the first nozzle row L1 and the nozzles of the second nozzle row L2. This is a structure in which elements related to N (example of the second nozzle) are arranged symmetrically with respect to the virtual plane O.

- first portion a positive portion

- second portion a negative portion

- the structure is substantially common.

- the plurality of nozzles N of the first nozzle row L1 are formed in the first portion P1

- the plurality of nozzles N of the second nozzle row L2 are formed in the second portion P2.

- the virtual plane O corresponds to a boundary surface between the first portion P1 and the second portion P2.

- the liquid discharge head 26 includes a flow path forming unit 30.

- the flow path forming unit 30 is a structure that forms a flow path for supplying ink to the plurality of nozzles N.

- the flow path forming unit 30 of the first embodiment is configured by stacking a communication plate 32 and a pressure chamber forming plate 34 (pressure chamber forming plate).

- Each of the communication plate 32 and the pressure chamber forming plate 34 is a plate-like member that is long in the Y direction.

- a pressure chamber forming plate 34 is installed on the negative surface Fa in the Z direction of the communication plate 32 using, for example, an adhesive.

- a vibrating portion 42 As shown in FIG. 2, on the surface Fa of the communication plate 32, in addition to the pressure chamber forming plate 34, a vibrating portion 42, a plurality of piezoelectric elements 44, a protective member 46, and a housing portion 48 are installed. (Not shown in FIG. 3).

- a nozzle plate 52 and a vibration absorber 54 are installed on the front surface Fb of the communication plate 32 on the positive side in the Z direction (that is, the side opposite to the surface Fa).

- Each element of the liquid discharge head 26 is a plate-like member that is long in the Y direction as in the case of the communication plate 32 and the pressure chamber forming plate 34, and is joined to each other by using, for example, an adhesive.

- the direction in which the communication plate 32 and the pressure chamber forming plate 34 are laminated and the direction in which the communication plate 32 and the nozzle plate 52 are laminated are grasped as the Z direction. It is also possible.

- the nozzle plate 52 is a plate-like member on which a plurality of nozzles N are formed, and is installed on the surface Fb of the communication plate 32 using, for example, an adhesive.

- Each of the plurality of nozzles N is a cylindrical through hole that allows ink to pass therethrough.

- a plurality of nozzles N constituting the first nozzle row L1 and a plurality of nozzles N constituting the second nozzle row L2 are formed.

- a plurality of nozzles N of the first nozzle row L1 are formed along the Y direction in the positive side region in the X direction when viewed from the virtual plane O of the nozzle plate 52, and the negative side region in the X direction.

- the nozzle plate 52 of the first embodiment is a single plate-like member that is continuous over a portion where the plurality of nozzles N of the first nozzle row L1 are formed and a portion where the plurality of nozzles N of the second nozzle row L2 are formed. It is.

- the nozzle plate 52 of the first embodiment is manufactured by processing a silicon (Si) single crystal substrate using a semiconductor manufacturing technique such as dry etching or wet etching. However, known materials and manufacturing methods can be arbitrarily employed for manufacturing the nozzle plate 52.

- the communication plate 32 is formed with a space Ra, a plurality of supply paths 61, and a plurality of communication paths 63 for each of the first portion P1 and the second portion P2.

- the space Ra is an opening formed in an elongated shape along the Y direction in plan view (as viewed from the Z direction), and the supply path 61 and the communication path 63 are through holes formed for each nozzle N.

- the plurality of communication paths 63 are arranged in the Y direction in plan view, and the plurality of supply paths 61 are arranged in the Y direction between the arrangement of the plurality of communication paths 63 and the space Ra.

- the plurality of supply paths 61 communicate with the space Ra in common.

- any one communication path 63 overlaps the nozzle N corresponding to the communication path 63 in plan view. Specifically, any one communication path 63 of the first portion P1 communicates with one nozzle N corresponding to the communication path 63 in the first nozzle row L1. Similarly, any one communication path 63 of the second portion P2 communicates with one nozzle N corresponding to the communication path 63 in the second nozzle row L2.

- the pressure chamber forming plate 34 is a plate-like member in which a plurality of pressure chambers C (cavities) are formed for each of the first portion P1 and the second portion P2.

- the plurality of pressure chambers C are arranged in the Y direction.

- Each pressure chamber C is a rectangular space that is formed for each nozzle N and is long in the X direction in plan view.

- each pressure chamber C is defined by two side surfaces parallel to the YZ plane and an upper surface (ceiling surface) parallel to the XY plane.

- the communication plate 32 and the pressure chamber forming plate 34 are manufactured by processing a single crystal substrate of silicon using, for example, a semiconductor manufacturing technique, similarly to the nozzle plate 52 described above.

- a semiconductor manufacturing technique similarly to the nozzle plate 52 described above.

- known materials and manufacturing methods can be arbitrarily employed for manufacturing the communication plate 32 and the pressure chamber forming plate 34.

- the flow path forming unit 30 (the communication plate 32 and the pressure chamber forming plate 34) and the nozzle plate 52 in the first embodiment include a substrate formed of silicon. Therefore, for example, there is an advantage that a fine flow path can be formed in the flow path forming unit 30 and the nozzle plate 52 with high accuracy by using the semiconductor manufacturing technology as illustrated above.

- a vibrating part 42 is installed on the surface of the pressure chamber forming plate 34 opposite to the communication plate 32.

- the vibration part 42 of the first embodiment is a plate-like member (diaphragm) that can elastically vibrate.

- the pressure chamber forming plate 34 and the vibration part 42 are integrally formed by selectively removing a part in the plate thickness direction in the region corresponding to the pressure chamber C of the plate-like member having a predetermined plate thickness. It is also possible.

- the surface Fa of the communication plate 32 and the vibrating portion 42 are opposed to each other with an interval inside each pressure chamber C.

- the pressure chamber C is a space located between the surface Fa of the communication plate 32 and the vibration part 42, and generates a pressure change in the ink filled in the space.

- Each pressure chamber C is a space whose longitudinal direction is, for example, the X direction, and is formed individually for each nozzle N.

- a plurality of pressure chambers C are arranged in the Y direction for each of the first nozzle row L1 and the second nozzle row L2. As shown in FIG. 2 and FIG. 3, an end portion closer to the imaginary plane O of any one pressure chamber C overlaps the communication path 63 in plan view, and an end portion far from the imaginary plane O is a plane.

- the pressure chamber C communicates with the nozzle N via the communication path 63 and also communicates with the space Ra via the supply path 61. It is also possible to add a predetermined channel resistance by forming a throttle channel having a narrow channel cross-sectional area in the pressure chamber C.

- a plurality of piezoelectric elements 44 corresponding to different nozzles N for each of the first portion P1 and the second portion P2 on the surface of the vibrating portion 42 opposite to the pressure chamber C.

- the piezoelectric element 44 is a passive element that is deformed by supplying a drive signal.

- the plurality of piezoelectric elements 44 are arranged in the Y direction so as to correspond to each pressure chamber C.

- one arbitrary piezoelectric element 44 is a drive element in which a piezoelectric layer 443 is interposed between a first electrode 441 and a second electrode 442 facing each other.

- one of the first electrode 441 and the second electrode 442 can be an electrode that is continuous across the plurality of piezoelectric elements 44 (that is, a common electrode).

- a portion where the first electrode 441, the second electrode 442, and the piezoelectric layer 443 overlap in plan view functions as the piezoelectric element 44.

- a portion that is deformed by a drive signal supplied from the wiring board 28 that is, an active portion that vibrates the vibration portion 42

- the piezoelectric element 44 of the present embodiment functions as a pressure generating unit that generates a pressure change in the pressure chamber C.

- the plurality of piezoelectric elements 44 are divided into a first piezoelectric element and a second piezoelectric element.

- the first piezoelectric elements are a plurality of piezoelectric elements 44 arranged on one side in the X direction (for example, the right side in FIG. 2) when viewed from the virtual plane O.

- the second piezoelectric elements are a plurality of piezoelectric elements 44 arranged on the other side in the X direction (for example, the left side in FIG. 2) when viewed from the virtual plane O.

- the protective member 46 is a plate-like member for protecting the plurality of piezoelectric elements 44, and is installed on the surface of the vibration part 42 (or the surface of the pressure chamber forming plate 34).

- the material and manufacturing method of the protective member 46 are arbitrary, the protective member 46 is formed by processing, for example, a silicon (Si) single crystal substrate by a semiconductor manufacturing technique, like the communication plate 32 and the pressure chamber forming plate 34. obtain.

- a plurality of piezoelectric elements 44 are accommodated in a recess formed in the surface of the protection member 46 on the vibration part 42 side.

- the end of the wiring board 28 is joined to the surface of the vibrating part 42 opposite to the flow path forming part 30 (or the surface of the flow path forming part 30).

- the wiring board 28 is a flexible mounting component on which a plurality of wirings (not shown) that electrically connect the control unit 20 and the liquid ejection head 26 are formed.

- a flexible wiring board 28 such as FPC (Flexible Printed Circuit) or FFC (Flexible Flat Cable) is preferably used.

- the housing portion 48 is a case for storing ink supplied to the plurality of pressure chambers C (and the plurality of nozzles N).

- the surface on the positive side in the Z direction of the housing portion 48 is joined to the surface Fa of the communication plate 32 with an adhesive, for example.

- a known technique or manufacturing method can be arbitrarily employed for manufacturing the casing 48.

- the housing part 48 can be formed by injection molding of a resin material.

- a space Rb is formed for each of the first part P1 and the second part P2.

- the space Rb of the casing 48 and the space Ra of the communication plate 32 communicate with each other.

- a space constituted by the space Ra and the space Rb functions as a liquid storage chamber R (reservoir) that stores ink supplied to the plurality of pressure chambers C.

- the liquid storage chamber R is a common liquid chamber shared by the plurality of nozzles N.

- a liquid storage chamber R is formed in each of the first portion P1 and the second portion P2.

- the liquid storage chamber R of the first portion P1 is located on the positive side in the X direction when viewed from the virtual plane O, and the liquid storage chamber R of the second portion P2 is positioned on the negative side in the X direction when viewed from the virtual surface O.

- An inlet 482 for introducing the ink supplied from the liquid container 14 into the liquid storage chamber R is formed on the surface of the casing 48 opposite to the communication plate 32.

- a vibration absorber 54 is installed for each of the first part P1 and the second part P2.

- the vibration absorber 54 is a flexible film (compliance substrate) that absorbs pressure fluctuations of ink in the liquid storage chamber R.

- the vibration absorber 54 is installed on the surface Fb of the communication plate 32 so as to close the space Ra of the communication plate 32 and the plurality of supply passages 61 (specifically, the wall surface of the liquid storage chamber R (specifically, Constitutes the bottom surface.

- a space constituting the circulating fluid chamber 65 is formed on the surface Fb of the communication plate 32 facing the nozzle plate 52.

- the circulating liquid chamber 65 of the first embodiment liquid is a long groove-shaped bottomed hole extending in the Y direction in plan view. The opening of the circulating fluid chamber 65 is closed by the nozzle plate 52 joined to the surface Fb of the communication plate 32.

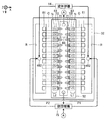

- FIG. 5 is a configuration diagram of the liquid discharge head 26 focusing on the circulating fluid chamber 65.

- the circulating fluid chamber 65 is continuous over a plurality of nozzles N along the first nozzle row L1 and the second nozzle row L2.

- the circulating fluid chamber 65 is formed between the arrangement of the plurality of nozzles N in the first nozzle row L1 and the arrangement of the plurality of nozzles N in the second nozzle row L2. Therefore, as shown in FIG. 2, the circulating fluid chamber 65 is located between the communication path 63 of the first part P1 and the communication path 63 of the second part P2.

- the circulating fluid chamber 65 extends in the Y direction so as to be continuous over the plurality of pressure chambers C or the plurality of piezoelectric elements 44 in each of the first portion P1 and the second portion P2.

- the circulating fluid chamber 65 and the liquid storage chamber R extend in the Y direction with a space therebetween, and the pressure chamber C, the communication path 63, and the nozzle N are disposed within the space. It is also possible that and are located.

- the flow path forming unit 30 of the first embodiment includes the pressure chamber C (example of the first pressure chamber) and the communication path 63 (example of the first communication path) in the first portion P1, and the second part P2. Circulation located between the pressure chamber C (example of the second pressure chamber) and the communication path 63 (example of the second communication path) and the communication path 63 of the first portion P1 and the communication path 63 of the second portion P2.

- This is a structure in which a liquid chamber 65 is formed.

- the flow path forming unit 30 according to the first embodiment includes a partition wall 69 that partitions the circulating fluid chamber 65 and each communication path 63.

- FIG. 6 is an enlarged plan view and cross-sectional view of a portion of the liquid discharge head 26 in the vicinity of the circulating fluid chamber 65.

- a plurality of first circulation paths 71 that connect the pressure chamber C to the circulating fluid chamber 65 are formed on the surface of the pressure chamber forming plate 34 that faces the communication plate 32.

- a plurality of first circulation paths 71 are arranged for each of the first portion P1 and the second portion P2.

- the plurality of first circulation paths 71 of the first portion P1 correspond to the plurality of pressure chambers C of the first nozzle row L1 on a one-to-one basis.

- the plurality of first circulation paths 71 in the second portion P2 correspond to the plurality of pressure chambers C in the second nozzle row L2 on a one-to-one basis.

- a plurality of second circulation paths 72 that communicate the communication path 63 with the circulating fluid chamber 65 are formed on the surface of the nozzle plate 52 that faces the flow path forming unit 30.

- a plurality of second circulation paths 72 are arranged for each of the first portion P1 and the second portion P2.

- the plurality of second circulation paths 72 of the first portion P1 correspond to the plurality of communication paths 63 of the first nozzle row L1 on a one-to-one basis.

- the plurality of second circulation paths 72 of the second portion P2 correspond to the plurality of communication paths 63 of the second nozzle row L2 on a one-to-one basis.

- Each of the first circulation path 71 and the second circulation path 72 is a groove portion (that is, a long bottomed hole) extending in the X direction, and functions as a flow path for circulating ink.

- the first circulation path 71 and the second circulation path 72 are formed away from the nozzle N on the circulating fluid chamber 65 side when viewed from the nozzle N in plan view. Since the plurality of first circulation paths 71 and the plurality of pressure chambers C are arranged on the pressure chamber forming plate 34, for example, the plurality of first circulation paths 71 and the plurality of pressure chambers C are collectively processed in a common process by a semiconductor manufacturing technique. Can be formed.

- the plurality of second circulation paths 72 and the plurality of nozzles N are arranged on the nozzle plate 52, the plurality of first circulation paths 71 and the plurality of nozzles N can be collectively formed in a common process by semiconductor manufacturing technology, for example. .

- the liquid ejection device 100 of the first embodiment includes a circulation mechanism 75.

- the circulation mechanism 75 is a mechanism for returning the ink in the circulation liquid chamber 65 to the liquid storage chamber R and circulating it.

- the circulation mechanism 75 of the first embodiment includes, for example, a suction mechanism (for example, a pump) for sucking ink from the circulating fluid chamber 65, a filter mechanism for collecting bubbles and foreign matters mixed in the ink, and thickening by heating the ink. And a heating mechanism for reducing (not shown). Ink from which bubbles and foreign matter have been removed by the circulation mechanism 75 and whose viscosity has been reduced is supplied from the circulation mechanism 75 to the liquid storage chamber R through the introduction port 482.

- the ink circulates through the path of the liquid storage chamber R ⁇ the supply path 61 ⁇ the pressure chamber C ⁇ the first circulation path 71 ⁇ the circulation liquid chamber 65 ⁇ the circulation mechanism 75 ⁇ the liquid storage chamber R. Further, the ink circulates through the path of the liquid storage chamber R ⁇ the supply path 61 ⁇ the pressure chamber C ⁇ the communication path 63 ⁇ the second circulation path 72 ⁇ the circulation liquid chamber 65 ⁇ the circulation mechanism 75 ⁇ the liquid storage chamber R.

- the circulation mechanism 75 of the first embodiment sucks ink from both sides of the circulating fluid chamber 65 in the Y direction. That is, the circulation mechanism 75 sucks ink from the vicinity of the negative end portion in the Y direction of the circulating fluid chamber 65 and the vicinity of the positive end portion of the circulating fluid chamber 65 in the Y direction.

- the circulation mechanism 75 sucks ink from the vicinity of the negative end portion in the Y direction of the circulating fluid chamber 65 and the vicinity of the positive end portion of the circulating fluid chamber 65 in the Y direction.

- a difference in ink pressure occurs between both ends of the circulating fluid chamber 65, and the pressure difference in the circulating fluid chamber 65 is reduced.

- the pressure of the ink in the communication path 63 may differ depending on the position in the Y direction.

- the ejection characteristics (for example, ejection amount and ejection speed) of ink from each nozzle N may differ depending on the position in the Y direction.

- the pressure difference inside the circulating fluid chamber 65 is reduced. Therefore, it is possible to approximate the ink ejection characteristics with high accuracy over the plurality of nozzles N arranged in the Y direction.

- the ink may be sucked from one end of the circulating fluid chamber 65.

- the nozzle N is discharged to the outside, and the remaining part flows into the circulating fluid chamber 65.

- the first embodiment not only the flow flowing from the communication path 63 into the circulating fluid chamber 65 via the second circulation path 72 (the flow indicated by the thick broken arrow in FIG. 6), but also the pressure circuit C to the first circulation path.

- a flow that flows into the circulating fluid chamber 65 via 71 also occurs.

- not only the communication path 63 but also the bubbles and the thickened ink that have entered the pressure chamber C can be discharged to the circulating fluid chamber 65, so that ejection failure of the nozzle N can be effectively suppressed.

- the ink may be circulated through the circulation liquid chamber 65. Ink flows through the first circulation path 71 and the second circulation path 72 in the same manner. Therefore, when ink sedimentation or thickening occurs in the communication path 63, it is difficult for foreign matter or thickened ink due to the sedimentation to be discharged to the circulating fluid chamber 65.

- the flow path resistance of the second circulation path 72 is made smaller than the flow path resistance of the first circulation path 71.

- ink that is likely to generate foreign matter due to sedimentation for example, pigment ink

- ink containing a solvent that is more volatile than moisture is likely to thicken, and drying tends to proceed at the meniscus in the nozzle N, which is the gas-liquid interface between the ink and air. Ink thickening is likely to proceed.

- ink flows more easily in the second circulation path 72 near the nozzle N than in the first circulation path 71 near the pressure chamber C. Foreign matter accumulated in the vicinity and ink having increased viscosity are easily discharged from the second circulation path 72 to the circulating fluid chamber 65 along the ink flow.

- the flow path cross-sectional area of the second circulation path 72 is larger than the flow path cross-sectional area of the first circulation path 71.

- the flow path width W2 in the Y direction of the second circulation path 72 shown in FIG. 6 is larger than the flow path width W1 in the Y direction of the first circulation path 71 (dimension in the Y direction).

- the flow path height H2 in the Z direction of the second circulation path 72 is larger than the flow path height H1 in the Z direction of the first circulation path 71.

- the second circulation path 72 is set by making the flow path width W2 and the flow path height H2 of the second circulation path 72 larger than the flow path width W1 and the flow path height H1 of the first circulation path 71.

- the flow path cross-sectional area of the first circulation path 71 can be made larger.

- the channel height H1 and the channel height H2 are constant over the entire length in the X direction.

- the flow path resistance of the second circulation path 72 can be made smaller than the flow path resistance of the first circulation path 71. Accordingly, the second circulation path 72 is easier to flow ink than the first circulation path 71, so that foreign matter accumulated in the vicinity of the nozzle N in the communication path 63 and thickened ink are removed from the second circulation path 72.

- the flow path length D2 in the X direction of the second circulation path 72 may be shorter than the flow path length D1 in the X direction of the first circulation path 71. Also with this configuration, the flow path resistance of the second circulation path 72 can be made smaller than the flow path resistance of the first circulation path 71.

- the cross-sectional area of the nozzle N of the first embodiment (the cross-sectional area of the cross section perpendicular to the Z direction) is larger than the cross-sectional area of the first circulation path 71 (the cross-sectional area of the cross section perpendicular to the X direction). It is larger than the cross-sectional area of the second circulation path 72 (the cross-sectional area of the cross section perpendicular to the X direction).

- the flow path cross-sectional area of the nozzle N is changed to the first circulation path 71. Larger than the cross-sectional area of the channel.

- the flow path sectional area of the nozzle N is made larger than the flow path sectional area of the second circulation path 72.

- the flow path resistance of the nozzle N can be made smaller than the flow path resistance of the first circulation path 71 and smaller than the flow path resistance of the second circulation path 72. Accordingly, when ink is ejected, the ink can flow more easily to the nozzle N than the first circulation path 71 and the second circulation path 72, so that the ink ejection amount from the nozzle N can be increased.

- the flow path length Nd in the Y direction of the nozzle N is shorter than the flow path length D1 in the X direction of the first circulation path 71, and the flow path in the X direction of the second circulation path 72. It may be shorter than the length D2. Also with this configuration, the flow path resistance of the nozzle N can be made smaller than the flow path resistance of the first circulation path 71 and smaller than the flow path resistance of the second circulation path 72.

- the pressure chamber C and the first circulation path 71 of the first embodiment are arranged as follows. That is, the pressure chamber C extends in the second direction along a plane orthogonal to the first direction.

- the first circulation path 71 extends from the pressure chamber C in a plan view (as viewed from the Z direction) and extends in a direction intersecting the first direction.

- the first direction is a direction serving as a reference for the extending direction of the pressure chamber C and the extending direction of the first circulation path 71, and is exemplified as the Z direction in the present embodiment.

- the second direction is a direction along the XY plane orthogonal to the Z direction, which is an example of the first direction, and is exemplified as the X direction in the present embodiment.

- the 1st direction (Z direction) of this embodiment was a perpendicular direction was illustrated, the 1st direction may not be a perpendicular direction.

- the direction in which the first circulation path 71 extends can be matched with the direction in which the pressure chamber C extends. Therefore, when the flow from the pressure chamber C to the first circulation path 71 is formed, the direction of the ink flow through the first circulation path 71 and the direction of the ink flow in the pressure chamber C do not change significantly. In other words, the flow from the pressure chamber C to the first circulation channel 71 can be formed at an angle smaller than 90 degrees.

- the direction of the ink flow through the first circulation path 71 and the direction of the ink flow in the pressure chamber C can be brought close to each other, the area where ink stagnates in the pressure chamber C can be reduced. Thereby, the bubbles in the pressure chamber C can be easily discharged to the circulating fluid chamber 65. In addition, it is possible to make it difficult for bubbles to enter the pressure chamber C from the first circulation path 71 as compared with the case where the circulating fluid chamber 65 is connected by a vertical flow path extending in the vertical direction from the lower side of the pressure chamber C.

- the first circulation path 71 extends in the X direction, which is the direction in which the pressure chamber C extends from the pressure chamber C in plan view.

- the first circulation path 71 extends in the same X direction as the direction of ink flow in the pressure chamber C. Therefore, the first circulation path 71 as indicated by a thick broken line arrow.

- the direction of the ink flow through the pressure chamber C can be the same X direction as the direction of the ink flow in the pressure chamber C.

- the circulating fluid chamber 65 is connected to the circulating fluid chamber 65 through the vertical flow path from the lower side of the pressure chamber C, it is possible to reduce the area where ink stagnates in the pressure chamber C.

- the liquid chamber 65 can be easily discharged.

- the first circulation path 71 is connected to one of the two side surfaces in the X direction of the pressure chamber C (the side surface closer to the virtual surface O). .

- the first circulation path 71 is connected to one of the two side surfaces in the X direction of the pressure chamber C (the side surface closer to the virtual surface O).

- the two side surfaces in the X direction of the pressure chamber C of the first embodiment are inclined surfaces that are inclined so that the height (dimension in the Z direction) of the pressure chamber C increases toward the inside of the pressure chamber C.

- Fc is formed.

- the inclined surface Fc is formed at a portion where each of the two side surfaces of the pressure chamber C in the X direction intersects with the upper surface of the pressure chamber C (the surface on the positive side in the Z direction of the vibration unit 42). The case is illustrated. That is, the inclined surface Fc is formed at the corner where the upper surface and the side surface of the pressure chamber C intersect.

- Each inclined surface Fc intersects the upper surface of the pressure chamber C and is inclined inward of the pressure chamber C so as to face the lower surface of the pressure chamber C obliquely.

- the inclined surface Fc may be a flat surface or a curved surface.

- the ink can easily flow. Further, by forming the inclined surface Fc on the side surface to which the first circulation path 71 is connected, it is easy to guide the bubbles that have entered the pressure chamber C to the first circulation path 71 along the inclined surface Fc. Accordingly, the bubbles that have entered the pressure chamber C are easily discharged from the first circulation path 71.

- the first circulation path 71 of the first embodiment is formed in the pressure chamber forming plate 34 of the flow path forming unit 30, the first circulation path 71 extends in a direction along the direction of ink flow in the pressure chamber C. Easy to place.

- the amount of ink discharged through the nozzle N is the first of the ink flowing through the communication path 63.

- the inertance of the communication path 63, the nozzle N, the first circulation path 71, and the second circulation path 72 is increased so as to exceed the circulation amount of the ink flowing into the circulation liquid chamber 65 via the circulation path 71 and the second circulation path 72. Selected.

- the communication path 63 and the nozzle are set so that the ratio of the circulation amount of the ink flowing through the communication path 63 from the pressure chamber C is 70% or more (the ratio of the discharge amount is 30% or less).

- N the flow path resistance of each of the first circulation path 71 and the second circulation path 72 is determined. According to the above configuration, it is possible to effectively circulate the ink in the vicinity of the nozzle N to the circulating liquid chamber 65 while ensuring the ink discharge amount.

- the ratio between the ink discharge amount and the circulation amount described above is not limited to 70%, and can be adjusted by the flow path resistance of the first circulation path 71 and the second circulation path 72.

- the discharge amount can be increased while the circulation amount is decreased, and the flow paths of the first circulation path 71 and the second circulation path 72 are increased.

- the flow path resistance of the second circulation path 72 is set to be different from that of the first circulation path by changing the flow path cross-sectional area or the flow path length between the first circulation path 71 and the second circulation path 72.

- the opening area A2 of the flow path opening on the pressure chamber C side of the second circulation path 72 is larger than the opening area A1 of the flow path opening on the communication path 63 side of the first circulation path 71. May also be increased.

- a throttle channel 712 having a narrow channel cross-sectional area may be provided in a part of the first circulation channel 71. 7 and 8, the flow path resistance of the second circulation path 72 can be made smaller than the flow path resistance of the first circulation path 71.

- the first circulation path 71 of the first embodiment overlaps the second circulation path 72 in plan view (as viewed from the Z direction).

- the first circulation path 71 may overlap the entire second circulation path 72 or may overlap a part thereof.

- the first circulation path 71 and the second circulation path 72 are arranged not to overlap in plan view.

- the liquid discharge head 26 can be downsized in the direction along the XY plane.

- the liquid discharge head 26 is turned upside down so that the nozzle N is on the top, the bubbles can be discharged.

- the case where the liquid discharge head 26 is turned upside down is not only the case where the liquid discharge head 26 is turned upside down while being removed from the liquid discharge apparatus 100 but also the case where the liquid discharge head 26 is turned upside down. included.

- the first circulation path 71 is disposed so as to overlap the second circulation path 72 in plan view. Therefore, when the liquid ejection head 26 is turned upside down, the bubbles in the pressure chambers move through the communication path 63 by buoyancy. Since it moves to the nozzle N side, it is discharged from the nozzle N.

- the first circulation path 71 and the second circulation path 72 are turned upside down by turning the liquid ejection head 26 upside down. Accordingly, since the first circulation path 71 is on the pressure chamber C side below the communication path 63, the foreign matter and the thickened ink dropped from the communication path 63 to the pressure chamber C are transferred from the first circulation path 71 to the circulating fluid chamber 65. It becomes easy to be discharged.

- the first circulation path 71 and the second circulation path 72 of the first embodiment are parallel to each other in the vertical direction and are arranged so as to extend in the horizontal direction, the liquid ejection head 26 can be turned upside down. The direction in which the first circulation path 71 and the second circulation path 72 extend does not change.

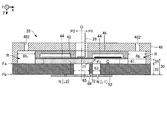

- FIG. 9 is a cross-sectional view of the liquid ejection head 26 according to the second embodiment cut along a cross section perpendicular to the Y direction, and corresponds to FIG.

- the liquid discharge head 26 of the second embodiment and the liquid discharge head 26 of the first embodiment have different flow path configurations. That is, in the first embodiment, the flow path configuration in which ink is introduced into the pressure chamber C by the supply path 61 extending in the Z direction from below the pressure chamber C is illustrated. In the second embodiment, a flow path configuration in which ink is introduced into the pressure chamber C by the supply path 61 extending in the X direction from the side of the pressure chamber C is illustrated.

- the first part P1 and the second part P2 shown in FIG. 9 have a flow path configuration corresponding to one nozzle N.

- the configuration of the first portion P1 and the second portion P2 reversed between the positive side and the negative side in the X direction with respect to FIG. 9 and the configuration of the first portion P1 and the second portion P2 similar to FIG. Are alternately arranged.

- a plurality of configurations of the first portion P1 and the second portion P2 similar to those in FIG. 9 may be arranged side by side in the Y direction.

- the liquid storage chamber R of the first portion P1 shown in FIG. 9 is configured by a space Rb formed in the first portion P1 of the casing 48.

- the liquid storage chamber R of the second part P2 is configured by a space Rb formed in the second part P2 of the casing 48.

- the supply path 61 of the first portion P1 in FIG. 9 communicates the liquid storage chamber R with the positive side surface of the pressure chamber C in the X direction.

- the second circulation path 72 of FIG. 9 penetrates the partition wall 69 from the communication path 63 on the positive side in the X direction to the circulating fluid chamber 65 on the negative side in the X direction on the surface of the communication plate 32 facing the nozzle plate 52. Formed.

- the second circulation path 72 may be formed in the nozzle plate 52 as in the configuration of FIG. 2.

- the first circulation path 71 shown in FIG. 9 is formed on the surface of the pressure chamber forming plate 34 facing the communication plate 32 as in the configuration of FIG. 2, and communicates the pressure chamber C with the circulating fluid chamber 65.

- the pressure chamber C, the supply path 61, the communication path 63, and the nozzle N are not formed in the 2nd part P2 of FIG.

- the flow path resistance of the second circulation path 72 can be made smaller than the flow path resistance of the first circulation path 71.

- foreign matter and thickened ink due to ink settling that tends to collect in the vicinity of the nozzles N in the communication path 63 are easily discharged from the second circulation path 72 to the circulating fluid chamber 65, so that the foreign matter and thickened ink are efficiently removed. It can be discharged.

- FIG. 10 is a cross-sectional view of the liquid ejection head 26 according to the third embodiment cut along a cross section perpendicular to the Y direction, and corresponds to FIG.

- the liquid ejection head 26 according to the third embodiment and the liquid ejection head 26 according to the first embodiment are different in the wiring structure for supplying a drive signal for the piezoelectric element 44. That is, in the first embodiment, the case where the drive signal is supplied to the piezoelectric element 44 by the wiring board 28 is illustrated.

- the third embodiment exemplifies a case where the drive IC 29 is mounted on the protection member 46 and wiring between the drive IC 29 and the piezoelectric element 44 is provided on the protection member 46.

- the drive IC 29 is electrically connected to the control unit 20 by a flexible wiring board such as an FPC (Flexible Printed Circuit) or FFC (Flexible Flat Cable).

- FPC Flexible Printed Circuit

- FFC Flexible Flat Cable

- the drive IC 29 is a substantially rectangular IC chip that drives each piezoelectric element 44 by generating and supplying a drive signal for the piezoelectric element 44 under the control of the control unit 20. At least a part of the piezoelectric elements 44 of the liquid discharge head 26 overlaps the drive IC 29 in plan view. 10 is provided with a plurality of connection terminals 464 and a plurality of wirings 466 for electrically connecting the drive IC 29 and each piezoelectric element 44, and the protection member 46 of the third embodiment includes: It also functions as a wiring board.

- the plurality of wirings 466 are divided into a wiring 466a and a wiring 466b.

- the connection terminal 464 is divided into a connection terminal 464a electrically connected to the wiring 466a and a connection terminal 464b electrically connected to the wiring 466b.

- the wiring 466a is a wiring connected to the output terminal of the base voltage of the drive IC 29, and is continuously formed in the Y direction across the plurality of piezoelectric elements 44.

- connection terminal 464a connects the first electrode 441, which is a common electrode of each piezoelectric element 44, and the wiring 466a. Accordingly, the first electrode 441 of each piezoelectric element 44 is connected to the output terminal of the base voltage of the drive IC 29 via the connection terminal 464a and the wiring 466a. Accordingly, the base voltage output from the output terminal of the drive IC 29 is applied to the first electrode 441 of each piezoelectric element 44 via the wiring 466a and the connection terminal 464a.

- connection terminal 464b connects the second electrode 442, which is an individual electrode of each piezoelectric element 44, and the wiring 466b.

- the second electrode 442 of each piezoelectric element 44 is connected to the drive signal output terminal of the drive IC 29 via the connection terminal 464b and the wiring 466b. Therefore, the drive signal output from the output terminal of the drive IC 29 is applied to the second electrode 442 of each piezoelectric element 44 via the connection terminal 464b and the wiring 466b.

- each of the connection terminals 464a and 464b is formed of a resin core bump in which a protrusion formed of, for example, a resin material is covered with a conductive material.

- the connection terminals 464a and 464b are not limited to resin core bumps, and may be formed of metal bumps.

- the connection terminal 464 of the present embodiment is disposed so as to overlap the first circulation path 71 or the circulating fluid chamber 65 in plan view (as viewed from the Z direction). According to this, even when the wiring 466 and the connection terminal 464 generate heat due to the current flowing through the wiring 466 and the connection terminal 464 by driving the piezoelectric element 44, the heat from the wiring 466 and the connection terminal 464 is transferred to the first circulation. It can be efficiently discharged to the circulating fluid chamber 65 by being put on the ink flow in the path 71.

- the flow path resistance of the second circulation path 72 can be made smaller than the flow path resistance of the first circulation path 71.

- foreign matter and thickened ink due to ink settling that tends to collect in the vicinity of the nozzles N in the communication path 63 are easily discharged from the second circulation path 72 to the circulating fluid chamber 65, so that the foreign matter and thickened ink are efficiently removed. It can be discharged.

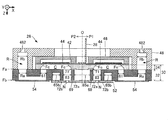

- FIG. 11 is a cross-sectional view of the liquid ejection head 26 according to the fourth embodiment cut along a cross section perpendicular to the Y direction, and corresponds to FIG.

- the liquid discharge head 26 according to the fourth embodiment and the liquid discharge head 26 according to the first embodiment have different flow path configurations. That is, in the first embodiment, the case where one circulating fluid chamber 65 is provided is illustrated, but in the fourth embodiment, a case where a plurality of circulating fluid chambers are provided is illustrated.

- FIG. 11 illustrates the case where one circulating fluid chamber 65a (first circulating fluid chamber) and two circulating fluid chambers 65b (second circulating fluid chamber) are formed on the communication plate 32.

- the circulating fluid chamber 65a is formed between the nozzle N of the first nozzle row L1 and the nozzle N of the second nozzle row L2 in the communication plate 32, and corresponds to the circulating fluid chamber 65 of FIG.

- One of the two circulating fluid chambers 65b is formed between the nozzle N of the first nozzle row L1 and the supply path 61 on the first portion P1 side of the communication plate 32.

- the other circulating fluid chamber 65b is formed between the nozzle N of the second nozzle row L2 and the supply path 61 on the second portion P2 side of the communication plate 32.

- the circulating fluid chamber 65b is a long bottomed hole (groove) that is formed on the opposite side of the circulating fluid chamber 65 with the communication passage 63 and the nozzle N interposed therebetween and extends in the Y direction.

- the nozzle plate 52 joined to the surface Fb of the communication plate 32 closes the openings of the circulating fluid chamber 65a and the circulating fluid chamber 65b.

- a plurality of first circulation paths 71 are formed on the surface of the pressure chamber forming plate 34 of FIG. 11 that faces the communication plate 32, and the pressure chamber C communicates with the circulating fluid chamber 65a.

- the plurality of first circulation paths 71 of the first portion P1 correspond to the plurality of pressure chambers C of the first nozzle row L1 on a one-to-one basis.

- the plurality of first circulation paths 71 in the second portion P2 correspond to the plurality of pressure chambers C in the second nozzle row L2 on a one-to-one basis.

- a plurality of second circulation paths 72a that connect the communication path 63 to the circulating fluid chamber 65a are formed on the surface of the nozzle plate 52 in FIG.

- a plurality of second circulation paths 72a are arranged for each of the first portion P1 and the second portion P2.

- the plurality of second circulation paths 72a of the first portion P1 correspond to the plurality of communication paths 63 of the first nozzle row L1 on a one-to-one basis.

- the plurality of second circulation paths 72a in the second portion P2 correspond to the plurality of communication paths 63 in the second nozzle row L2 on a one-to-one basis.

- a plurality of second circulation paths 72b that connect the communication path 63 to the circulating fluid chamber 65b are formed on the surface of the nozzle plate 52 of FIG.

- a plurality of second circulation paths 72b are arranged for each of the first portion P1 and the second portion P2.

- the plurality of second circulation paths 72b of the first portion P1 corresponds to the plurality of communication paths 63 of the first nozzle row L1 on a one-to-one basis.

- the plurality of second circulation paths 72b in the second portion P2 correspond to the plurality of communication paths 63 in the second nozzle row L2 on a one-to-one basis.

- the ink circulates through the path flowing from the communication path 63 to the circulating liquid chamber 65a via the second circulation path 72a, and from the communication path 63 via the second circulation path 72b.

- the ink also circulates through the path flowing through the circulating fluid chamber 65b. Accordingly, the foreign matter and the thickened ink due to the sedimentation of the ink that easily collects in the vicinity of the nozzle N in the communication path 63 can be discharged not only from the circulating fluid chamber 65a but also from the circulating fluid chamber 65b. Accordingly, it is possible to improve the dischargeability of foreign matter and thickened ink.

- the first circulation path 71 communicates the pressure chamber C with the circulating fluid chamber 65a, and the second circulation path 72b connects the communication passage 63 with the circulating fluid chamber 65b. It is also possible to have a configuration that communicates with.

- the second circulation paths 72 a and 72 b may be formed in the flow path forming unit 30.

- the case where the 2nd circulation paths 72a and 72b are formed in the communicating plate 32 is illustrated.

- the case where the second circulation path 72b is arranged along the X direction in the same manner as the second circulation path 72a is illustrated, but for example, as in the third modification shown in FIG.

- the two circulation paths 72b may be inclined so as to intersect the X direction.

- the piezoelectric liquid ejection head 26 using the piezoelectric element that imparts mechanical vibration to the pressure chamber as the pressure generating unit is exemplified, but bubbles are generated inside the pressure chamber by heating. It is also possible to employ a heat-type liquid discharge head using a heat generating element as a pressure generating unit.

- the liquid ejection apparatus 100 exemplified in the above-described embodiment can be employed in various apparatuses such as a facsimile apparatus and a copier, in addition to apparatuses dedicated to printing.

- the use of the liquid ejection apparatus 100 of the present invention is not limited to printing.

- a liquid ejection device that ejects a solution of a coloring material is used as a manufacturing apparatus that forms a color filter of a liquid crystal display device, an organic EL (Electro Luminescence) display, an FED (surface emitting display), or the like.

- a liquid discharge apparatus that discharges a solution of a conductive material is used as a manufacturing apparatus that forms wiring and electrodes of a wiring board. Further, it is also used as a chip manufacturing apparatus that discharges a bioorganic solution as a kind of liquid.

- SYMBOLS 100 Liquid ejection apparatus, 12 ... Medium, 14 ... Liquid container, 20 ... Control unit, 22 ... Conveyance mechanism, 24 ... Movement mechanism, 242 ... Carriage, 244 ... Conveyance belt, 26 ... Liquid ejection head, 28 ... Wiring board, DESCRIPTION OF SYMBOLS 29 ... Drive IC, 30 ... Flow path formation part, 32 ... Communication board, 34 ... Pressure chamber formation board, 42 ... Vibrating part, 44 ... Piezoelectric element, 441 ... 1st electrode, 442 ... 2nd electrode, 443 ... Piezoelectric body 46, protective member, 464 ... connecting terminal, 464a ...

Abstract

Provided is a liquid discharge head which can more efficiently discharge foreign matter and increased-viscosity ink. A liquid discharge head (26) comprises: a flow passage forming section (30) provided with a nozzle plate (52) to which a nozzle (N) is provided, a pressure chamber (C) to which liquid is supplied, a communication passage (63) which connects the pressure chamber (C) to the nozzle (N), and a circulation liquid chamber (65); a pressure generation section which generates a change in pressure in the pressure chamber (C); a first circulation passage (71) which connects the pressure chamber (C) to the circulation liquid chamber (65); and a second circulation passage (72) which connects the communication passage (63) to the circulation liquid chamber (65). The flow resistance of the second circulation passage (72) is lower than that of the first circulation passage (71).

Description

本発明は、インク等の液体を吐出する技術に関する。

The present invention relates to a technique for discharging a liquid such as ink.

圧電素子などの駆動素子によって圧力室内に圧力変化を生じさせることで圧力室内のインクなどの液体をノズルから吐出させる液体吐出ヘッドが知られている。このような液体吐出ヘッドでは、液体に気泡が混入したり、液体が増粘したりすることで、ノズルの吐出不良が発生する虞がある。例えば特許文献1では、圧力室の下側に循環流路(供給支流路と回収支流路)を配置し、圧力室とノズルとをそれぞれ別々の流路(第1の回収絞り流路、第2の回収絞り流路)で循環流路に連通する。これにより、循環流路を通って循環する液体の流れを形成することで、液体の増粘を抑制している。

A liquid discharge head that discharges a liquid such as ink in a pressure chamber from a nozzle by causing a pressure change in the pressure chamber by a driving element such as a piezoelectric element is known. In such a liquid discharge head, there is a possibility that nozzle discharge defects may occur due to bubbles mixed in the liquid or the viscosity of the liquid increasing. For example, in Patent Document 1, a circulation flow path (a supply branch flow path and a recovery branch flow path) is disposed below the pressure chamber, and the pressure chamber and the nozzle are separated from each other (a first recovery throttle flow path, a second recovery flow path). The recovery throttle channel) communicates with the circulation channel. Thereby, the increase in the viscosity of the liquid is suppressed by forming a flow of the liquid that circulates through the circulation flow path.

しかしながら、特許文献1のように複数の流路によって循環流路を圧力室やノズルに連通する場合には、循環流路に連通する各流路の流路抵抗がほとんど変わらないと、循環流路を介して液体を循環させても、各流路には同じように液体が流れてしまう。したがって、液体の沈降や増粘が発生した場合に、その沈降による異物や増粘した液体がノズル近傍から循環流路に排出され難くなってしまう。

However, when the circulation channel is communicated with the pressure chambers and nozzles by a plurality of channels as in Patent Document 1, the circulation channel is almost the same as the channel resistance of each channel communicating with the circulation channel is not changed. Even if the liquid is circulated through the channel, the liquid flows in the same way in each flow path. Therefore, when liquid sedimentation or thickening occurs, it becomes difficult for foreign matter or thickened liquid due to the sedimentation to be discharged from the vicinity of the nozzle to the circulation channel.

以上の課題を解決するために、本発明の好適な態様に係る液体吐出ヘッドは、ノズルが設けられたノズル板と、液体が供給される圧力室と、圧力室をノズルに連通する連通路と、循環液室とが設けられた流路形成部と、圧力室の圧力変化を発生させる圧力発生部と、圧力室を循環液室に連通する第1循環路と、連通路を循環液室に連通する第2循環路と、を備え、第2循環路の流路抵抗は、第1循環路の流路抵抗よりも小さい。

In order to solve the above problems, a liquid discharge head according to a preferred aspect of the present invention includes a nozzle plate provided with a nozzle, a pressure chamber to which a liquid is supplied, and a communication path that communicates the pressure chamber with the nozzle. A flow path forming portion provided with a circulating fluid chamber, a pressure generating portion that generates a pressure change in the pressure chamber, a first circulation path that connects the pressure chamber to the circulating fluid chamber, and a communicating passage as the circulating fluid chamber. A second circulation path that communicates, and the flow path resistance of the second circulation path is smaller than the flow path resistance of the first circulation path.

<第1実施形態>

図1は、本発明の第1実施形態に係る液体吐出装置100を例示する構成図である。第1実施形態の液体吐出装置100は、液体の例示であるインクを媒体12に吐出するインクジェット方式の印刷装置である。媒体12は、典型的には印刷用紙であるが、樹脂フィルムまたは布帛等の任意の材質の印刷対象を媒体12とすることもできる。図1に示すように、液体吐出装置100には、インクを貯留する液体容器14が設置される。例えば液体吐出装置100に着脱可能なカートリッジ、可撓性のフィルムで形成された袋状のインクパック、またはインクを補充可能なインクタンクが液体容器14として利用される。色彩が相違する複数種のインクが液体容器14には貯留される。インクは、色材として染料が含まれる染料インクでも、色材として顔料が含まれる顔料インクでもよい。 <First Embodiment>

FIG. 1 is a configuration diagram illustrating aliquid ejection apparatus 100 according to the first embodiment of the invention. The liquid ejection apparatus 100 according to the first embodiment is an ink jet printing apparatus that ejects ink, which is an example of a liquid, onto the medium 12. The medium 12 is typically a printing paper, but the medium 12 can be a printing target of an arbitrary material such as a resin film or a fabric. As shown in FIG. 1, the liquid ejection apparatus 100 is provided with a liquid container 14 that stores ink. For example, a cartridge that can be attached to and detached from the liquid ejection device 100, a bag-like ink pack formed of a flexible film, or an ink tank that can be refilled with ink is used as the liquid container 14. A plurality of types of inks having different colors are stored in the liquid container 14. The ink may be a dye ink containing a dye as a color material or a pigment ink containing a pigment as a color material.

図1は、本発明の第1実施形態に係る液体吐出装置100を例示する構成図である。第1実施形態の液体吐出装置100は、液体の例示であるインクを媒体12に吐出するインクジェット方式の印刷装置である。媒体12は、典型的には印刷用紙であるが、樹脂フィルムまたは布帛等の任意の材質の印刷対象を媒体12とすることもできる。図1に示すように、液体吐出装置100には、インクを貯留する液体容器14が設置される。例えば液体吐出装置100に着脱可能なカートリッジ、可撓性のフィルムで形成された袋状のインクパック、またはインクを補充可能なインクタンクが液体容器14として利用される。色彩が相違する複数種のインクが液体容器14には貯留される。インクは、色材として染料が含まれる染料インクでも、色材として顔料が含まれる顔料インクでもよい。 <First Embodiment>

FIG. 1 is a configuration diagram illustrating a

図1に示すように、液体吐出装置100は、制御ユニット20と搬送機構22と移動機構24と液体吐出ヘッド26とを具備する。制御ユニット20は、例えばCPU(Central Processing Unit)またはFPGA(Field Programmable Gate Array)等の処理回路と半導体メモリ等の記憶回路とを含み、液体吐出装置100の各要素を統括的に制御する。搬送機構22は、制御ユニット20による制御のもとで媒体12をY方向に搬送する。

As shown in FIG. 1, the liquid ejection device 100 includes a control unit 20, a transport mechanism 22, a movement mechanism 24, and a liquid ejection head 26. The control unit 20 includes, for example, a processing circuit such as a CPU (Central Processing Unit) or FPGA (Field Programmable Gate Array) and a storage circuit such as a semiconductor memory, and comprehensively controls each element of the liquid ejection apparatus 100. The transport mechanism 22 transports the medium 12 in the Y direction under the control of the control unit 20.

移動機構24は、制御ユニット20による制御のもとで液体吐出ヘッド26をX方向に往復させる。X方向は、媒体12が搬送されるY方向に交差(典型的には直交)する方向である。第1実施形態の移動機構24は、液体吐出ヘッド26を収容する略箱型のキャリッジ242(搬送体)と、キャリッジ242が固定された搬送ベルト244とを具備する。なお、複数の液体吐出ヘッド26をキャリッジ242に搭載した構成や、液体容器14を液体吐出ヘッド26とともにキャリッジ242に搭載した構成にしてもよい。

The moving mechanism 24 reciprocates the liquid ejection head 26 in the X direction under the control of the control unit 20. The X direction is a direction that intersects (typically orthogonal) the Y direction in which the medium 12 is conveyed. The moving mechanism 24 of the first embodiment includes a substantially box-shaped carriage 242 (conveyance body) that accommodates the liquid ejection head 26 and a conveyance belt 244 to which the carriage 242 is fixed. A configuration in which a plurality of liquid ejection heads 26 are mounted on the carriage 242 or a configuration in which the liquid container 14 is mounted on the carriage 242 together with the liquid ejection heads 26 may be employed.

液体吐出ヘッド26は、液体容器14から供給されるインクを制御ユニット20による制御のもとで複数のノズルN(吐出孔)から媒体12に吐出する。搬送機構22による媒体12の搬送とキャリッジ242の反復的な往復とに並行して各液体吐出ヘッド26が媒体12にインクを吐出することで、媒体12の表面に所望の画像が形成される。なお、X-Y平面(例えば媒体12の表面に平行な平面)に垂直な方向を以下ではZ方向と表記する。各液体吐出ヘッド26によるインクの吐出方向(典型的には鉛直方向)がZ方向に相当する。

The liquid discharge head 26 discharges ink supplied from the liquid container 14 to the medium 12 from a plurality of nozzles N (discharge holes) under the control of the control unit 20. Each liquid ejection head 26 ejects ink onto the medium 12 in parallel with the transport of the medium 12 by the transport mechanism 22 and the reciprocating reciprocation of the carriage 242, thereby forming a desired image on the surface of the medium 12. A direction perpendicular to the XY plane (for example, a plane parallel to the surface of the medium 12) is hereinafter referred to as a Z direction. The ink ejection direction (typically the vertical direction) by each liquid ejection head 26 corresponds to the Z direction.

図1に示すように、液体吐出ヘッド26の複数のノズルNはY方向に配列される。第1実施形態の複数のノズルNは、X方向に相互に間隔をあけて並設された第1ノズル列L1と第2ノズル列L2とに区分される。第1ノズル列L1および第2ノズル列L2の各々は、Y方向に直線状に配列された複数のノズルNの集合である。なお、第1ノズル列L1と第2ノズル列L2との間で各ノズルNのY方向に位置を相違させること(すなわち千鳥配置またはスタガ配置)も可能であるが、第1ノズル列L1と第2ノズル列L2とで各ノズルNのY方向の位置を一致させた構成を以下では便宜的に例示する。液体吐出ヘッド26においてY-Z平面に平行な平面を仮想面Oと表記する。

As shown in FIG. 1, the plurality of nozzles N of the liquid discharge head 26 are arranged in the Y direction. The plurality of nozzles N of the first embodiment are divided into a first nozzle row L1 and a second nozzle row L2 that are arranged in parallel in the X direction with a space therebetween. Each of the first nozzle row L1 and the second nozzle row L2 is a set of a plurality of nozzles N arranged linearly in the Y direction. It is possible to make the positions of the nozzles N different in the Y direction (that is, staggered arrangement or staggered arrangement) between the first nozzle array L1 and the second nozzle array L2, but the first nozzle array L1 and the second nozzle array L1 A configuration in which the positions of the nozzles N in the Y direction are matched with each other in the two-nozzle row L2 will be exemplified below for convenience. A plane parallel to the YZ plane in the liquid discharge head 26 is referred to as a virtual plane O.

図2は、液体吐出ヘッド26をY方向に垂直な断面で切断した場合の断面図であり、図3は、液体吐出ヘッド26の部分的な分解斜視図である。図2および図3に示すように、第1実施形態の液体吐出ヘッド26は、第1ノズル列L1の各ノズルN(第1ノズルの例示)に関連する要素と第2ノズル列L2の各ノズルN(第2ノズルの例示)に関連する要素とが仮想面Oを挟んで面対称に配置された構造である。すなわち、液体吐出ヘッド26のうち仮想面Oを挟んでX方向の正側の部分(以下「第1部分」という)P1とX方向の負側の部分(以下「第2部分」という)P2とで構造は実質的に共通する。第1ノズル列L1の複数のノズルNは第1部分P1に形成され、第2ノズル列L2の複数のノズルNは第2部分P2に形成される。仮想面Oは、第1部分P1と第2部分P2との境界面に相当する。

2 is a cross-sectional view of the liquid discharge head 26 taken along a cross section perpendicular to the Y direction, and FIG. 3 is a partial exploded perspective view of the liquid discharge head 26. As shown in FIGS. 2 and 3, the liquid ejection head 26 according to the first embodiment includes elements related to the nozzles N (illustrative examples of the first nozzles) of the first nozzle row L1 and the nozzles of the second nozzle row L2. This is a structure in which elements related to N (example of the second nozzle) are arranged symmetrically with respect to the virtual plane O. That is, a positive portion (hereinafter referred to as “first portion”) P1 in the X direction across the virtual plane O of the liquid ejection head 26 and a negative portion (hereinafter referred to as “second portion”) P2 in the X direction, The structure is substantially common. The plurality of nozzles N of the first nozzle row L1 are formed in the first portion P1, and the plurality of nozzles N of the second nozzle row L2 are formed in the second portion P2. The virtual plane O corresponds to a boundary surface between the first portion P1 and the second portion P2.

図2および図3に示すように、液体吐出ヘッド26は流路形成部30を具備する。流路形成部30は、複数のノズルNにインクを供給するための流路を形成する構造体である。第1実施形態の流路形成部30は、連通板32と圧力室形成板34(圧力室形成板)との積層で構成される。連通板32および圧力室形成板34の各々は、Y方向に長尺な板状部材である。連通板32のうちZ方向の負側の表面Faに、例えば接着剤を利用して圧力室形成板34が設置される。

2 and 3, the liquid discharge head 26 includes a flow path forming unit 30. The flow path forming unit 30 is a structure that forms a flow path for supplying ink to the plurality of nozzles N. The flow path forming unit 30 of the first embodiment is configured by stacking a communication plate 32 and a pressure chamber forming plate 34 (pressure chamber forming plate). Each of the communication plate 32 and the pressure chamber forming plate 34 is a plate-like member that is long in the Y direction. A pressure chamber forming plate 34 is installed on the negative surface Fa in the Z direction of the communication plate 32 using, for example, an adhesive.

図2に示すように、連通板32の表面Faの面上には、圧力室形成板34のほか、振動部42と複数の圧電素子44と保護部材46と筐体部48とが設置される(図3では図示略)。他方、連通板32のうちZ方向の正側(すなわち表面Faとは反対側)の表面Fbにはノズル板52と吸振体54とが設置される。液体吐出ヘッド26の各要素は、概略的には連通板32や圧力室形成板34と同様にY方向に長尺な板状部材であり、例えば接着剤を利用して相互に接合される。連通板32と圧力室形成板34とが積層される方向や連通板32とノズル板52とが積層される方向(あるいは板状の各要素の表面に垂直な方向)を、Z方向として把握することも可能である。

As shown in FIG. 2, on the surface Fa of the communication plate 32, in addition to the pressure chamber forming plate 34, a vibrating portion 42, a plurality of piezoelectric elements 44, a protective member 46, and a housing portion 48 are installed. (Not shown in FIG. 3). On the other hand, a nozzle plate 52 and a vibration absorber 54 are installed on the front surface Fb of the communication plate 32 on the positive side in the Z direction (that is, the side opposite to the surface Fa). Each element of the liquid discharge head 26 is a plate-like member that is long in the Y direction as in the case of the communication plate 32 and the pressure chamber forming plate 34, and is joined to each other by using, for example, an adhesive. The direction in which the communication plate 32 and the pressure chamber forming plate 34 are laminated and the direction in which the communication plate 32 and the nozzle plate 52 are laminated (or a direction perpendicular to the surface of each plate-like element) are grasped as the Z direction. It is also possible.

ノズル板52は、複数のノズルNが形成された板状部材であり、例えば接着剤を利用して連通板32の表面Fbに設置される。複数のノズルNの各々は、インクを通過させる円筒形状の貫通孔である。第1実施形態のノズル板52には、第1ノズル列L1を構成する複数のノズルNと第2ノズル列L2を構成する複数のノズルNとが形成される。具体的には、ノズル板52のうち仮想面OからみてX方向の正側の領域に、第1ノズル列L1の複数のノズルNがY方向に沿って形成され、X方向の負側の領域に、第2ノズル列L2の複数のノズルNがY方向に沿って形成される。第1実施形態のノズル板52は、第1ノズル列L1の複数のノズルNが形成された部分と第2ノズル列L2の複数のノズルNが形成された部分とにわたり連続する単体の板状部材である。第1実施形態のノズル板52は、ドライエッチングやウェットエッチングなどの半導体製造技術を利用してシリコン(Si)の単結晶基板を加工することで製造される。ただし、ノズル板52の製造には公知の材料や製法が任意に採用され得る。