WO2019107458A1 - Laminated glass - Google Patents

Laminated glass Download PDFInfo

- Publication number

- WO2019107458A1 WO2019107458A1 PCT/JP2018/043882 JP2018043882W WO2019107458A1 WO 2019107458 A1 WO2019107458 A1 WO 2019107458A1 JP 2018043882 W JP2018043882 W JP 2018043882W WO 2019107458 A1 WO2019107458 A1 WO 2019107458A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- heating wire

- glass plate

- layer

- laminated glass

- bus bars

- Prior art date

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60J—WINDOWS, WINDSCREENS, NON-FIXED ROOFS, DOORS, OR SIMILAR DEVICES FOR VEHICLES; REMOVABLE EXTERNAL PROTECTIVE COVERINGS SPECIALLY ADAPTED FOR VEHICLES

- B60J1/00—Windows; Windscreens; Accessories therefor

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60S—SERVICING, CLEANING, REPAIRING, SUPPORTING, LIFTING, OR MANOEUVRING OF VEHICLES, NOT OTHERWISE PROVIDED FOR

- B60S1/00—Cleaning of vehicles

- B60S1/02—Cleaning windscreens, windows or optical devices

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05B—ELECTRIC HEATING; ELECTRIC LIGHT SOURCES NOT OTHERWISE PROVIDED FOR; CIRCUIT ARRANGEMENTS FOR ELECTRIC LIGHT SOURCES, IN GENERAL

- H05B3/00—Ohmic-resistance heating

- H05B3/20—Heating elements having extended surface area substantially in a two-dimensional plane, e.g. plate-heater

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05B—ELECTRIC HEATING; ELECTRIC LIGHT SOURCES NOT OTHERWISE PROVIDED FOR; CIRCUIT ARRANGEMENTS FOR ELECTRIC LIGHT SOURCES, IN GENERAL

- H05B3/00—Ohmic-resistance heating

- H05B3/20—Heating elements having extended surface area substantially in a two-dimensional plane, e.g. plate-heater

- H05B3/22—Heating elements having extended surface area substantially in a two-dimensional plane, e.g. plate-heater non-flexible

- H05B3/26—Heating elements having extended surface area substantially in a two-dimensional plane, e.g. plate-heater non-flexible heating conductor mounted on insulating base

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05B—ELECTRIC HEATING; ELECTRIC LIGHT SOURCES NOT OTHERWISE PROVIDED FOR; CIRCUIT ARRANGEMENTS FOR ELECTRIC LIGHT SOURCES, IN GENERAL

- H05B3/00—Ohmic-resistance heating

- H05B3/84—Heating arrangements specially adapted for transparent or reflecting areas, e.g. for demisting or de-icing windows, mirrors or vehicle windshields

- H05B3/86—Heating arrangements specially adapted for transparent or reflecting areas, e.g. for demisting or de-icing windows, mirrors or vehicle windshields the heating conductors being embedded in the transparent or reflecting material

Definitions

- the present invention relates to laminated glass.

- Patent Document 1 discloses that a bus bar and a heating wire are disposed inside a windshield and heat generation removes fogging.

- the windshield is formed of laminated glass in which a bus bar and the like are disposed together with an adhesive layer between two glass plates. And when producing this laminated glass, after arrange

- the above-mentioned functional layer can be formed so that the outer peripheral edge may be in agreement with the outer peripheral edge of a glass plate, and since it does not produce the above-mentioned level difference if it does in this way, generation of bubbles is prevented. Can. However, in this case, since the outer peripheral edge of the functional layer is exposed from between the glass plates, there is a possibility that water may infiltrate between the glass plates from here. As a result, when the laminated glass is swollen, there is a risk of losing the original function of the laminated glass. There are also the following problems.

- each glass plate may be formed in a circular arc shape in cross section, if the outer periphery of the functional layer matches the outer periphery of the glass plate, the adhesive layers may not adhere to each other. However, this may cause wrinkles in the adhesive layer or the functional layer. Therefore, the entry of water can be prevented by positioning the position of the outer peripheral edge of the adhesive layer closer to the center than the position of the outer glass position (for example, about several mm to about 30 mm). However, when the position of the outer peripheral edge of the adhesive layer is located inside the outer peripheral edge of the glass plate as described above, the above-mentioned bubbles may occur.

- the present invention has been made to solve the above problems, and provides a laminated glass in which a functional layer is disposed between two glass plates, which can improve the quality of appearance. With the goal.

- Item 1 An outer glass plate having a first side and a second side opposite to the first side, An inner glass plate disposed opposite to the outer glass plate and having substantially the same shape as the outer glass plate; An interlayer disposed between the outer glass plate and the inner glass plate; A shielding layer formed on the surface of the outer glass plate; Equipped with The interlayer is Adhesive layer, A functional layer supported by the adhesive layer; Equipped with At least a part of the outer peripheral edge of the functional layer has an inner portion located inside the outer peripheral edge of the adhesive layer, The laminated glass, wherein the shielding layer is disposed to cover at least an inner portion of the functional layer and an outer peripheral edge of the adhesive layer.

- Item 2 The laminated glass of Item 1, wherein the shielding layer is located on the surface on the intermediate film side of the outer glass plate.

- Item 3 The laminated glass according to Item 2, further comprising a second shielding layer provided on the surface of the inner glass plate opposite to the intermediate film.

- Item 4 The laminated glass according to any one of Items 1 to 3, wherein the shielding layer is formed over the entire periphery of the outer peripheral edge of the outer glass plate.

- Item 5 The laminated glass according to any one of Items 1 to 4, wherein the shielding layer is disposed between the outer glass plate and the intermediate film.

- Item 6 The laminated glass according to any one of Items 1 to 5, wherein the thickness of the functional layer is 5 to 200 ⁇ m.

- the functional layer is A first bus bar, at least a portion of which extends along the end on the first side; A second bus bar, at least a portion of which extends along an end on the second side; A plurality of heating wires arranged to connect the first bus bar and the second bus bar; Equipped with A part of the outer peripheral edge of the first bus bar and the second bus bar constitutes the inner portion, 7.

- the functional layer further includes a support layer that supports both the bus bars and the heating wire, Item 8.

- Item 9 The laminated glass according to item 7 or 8, wherein both bus bars are formed by laminating a plurality of metal layers.

- Item 10 The laminated glass according to any one of Items 7 to 9, wherein the pitch of the heating wire is 1.25 to 4 mm.

- Item 11 The laminated glass according to any one of Items 7 to 10, wherein the calorific value of the heating wire is 2.0 W / m or less.

- Item 12 The laminated glass according to any one of Items 7 to 11, wherein the thickness of the heating wire is 30 ⁇ m or less.

- Item 13 The laminated glass according to any one of Items 7 to 12, wherein the width of the surface on the adhesive layer side in the heating wire is 1 to 30 ⁇ m.

- Item 14 The voltage applied to both the bus bars is less than 20 V, The width of the surface on the side of the adhesive layer in the heating wire has a length equal to or greater than the thickness of the heating wire, Item 14.

- Item 15 The voltage applied to the both bus bars is 20 to 50 V, The width of the surface on the side of the adhesive layer in the heating wire has a length equal to or greater than the thickness of the heating wire, Item 14.

- the quality of appearance can be improved.

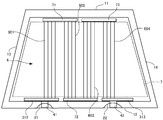

- FIG. 1 It is a front view of one embodiment of a laminated glass concerning the present invention. It is the sectional view on the AA line of FIG. It is a figure which shows an example of a heating wire. It is a side view of a furnace through which a forming die passes. It is a top view of a forming die. It is the photograph which image

- FIG. 18 is a table showing the specifications of heating wires according to Reference Examples 17 to 27.

- FIG. It is a front view which shows the other example of the laminated glass of FIG. It is a front view which shows the other example of the laminated glass of FIG.

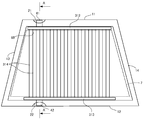

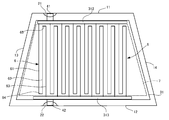

- FIG. 1 is a plan view of a windshield according to the present embodiment

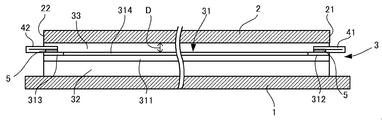

- FIG. 2 is a cross-sectional view of FIG.

- the windshield according to the present embodiment includes an outer glass plate 1, an inner glass plate 2, and an intermediate layer 3 disposed between the glass plates 1 and 2. Further, notches 21 and 22 are respectively formed at the upper end and the lower end of the inner glass plate 2, and the connecting members 41 and 42 extending from the intermediate layer 3 are exposed at the respective notches 21 and 22. doing. Each member will be described below.

- Each of the glass plates 1 and 2 is formed in a rectangular shape in which the lower side 12 is longer than the upper side 11. That is, it is formed in a trapezoidal shape surrounded by the upper side 11, the lower side 12, and both sides (left side 13 and right side 14). And as above-mentioned, the circular-arc-shaped notch part is formed in the upper end part and lower end part of the inner side glass plate 2, respectively.

- the notch formed in the upper end of the inner glass plate 2 will be referred to as a first notch 21 and the notch formed in the lower end will be referred to as a second notch 22.

- each glass plate 1 and 2 a well-known glass plate can be used and it can also form with heat ray absorption glass, general clear glass, green glass, or UV green glass.

- these glass plates 1 and 2 need to realize visible light transmittance in accordance with the safety standard of the country where the automobile is used.

- the required solar radiation absorptivity can be secured by the outer glass plate 1, and the visible light transmittance can be adjusted by the inner glass plate 2 so that the safety standard is satisfied.

- a composition of clear glass, heat ray absorption glass, and soda lime type glass is shown.

- the composition of the heat-absorbing glass for example, based on the composition of the clear glass, the proportion of the total iron oxide in terms of Fe 2 O 3 (T-Fe 2 O 3) and 0.4 to 1.3 wt%, CeO

- the ratio of 2 is 0-2% by mass

- the ratio of TiO 2 is 0-0.5% by mass

- the framework component of the glass (mainly SiO 2 or Al 2 O 3 ) is T-Fe 2 O 3

- CeO The composition can be reduced by the increase of 2 and TiO 2 .

- each of the glass plates 1 and 2 is formed in a rectangular shape, but the ratio of the lengths of the upper side 11 and the lower side 12 may be, for example, 1: 1.04 to 1: 1.5. it can.

- the lower side can be 1250 to 1800 mm.

- the upper side can be 1195 mm and the lower side can be 1435 mm.

- the ratio described above is a ratio in a two-dimensional plane when the windshield is projected from the front.

- the upper side 11 is applicable also to a long windshield.

- the lower side can be 350 to 450 mm.

- the upper side can be 500 mm and the lower side can be 425 mm.

- the thickness of the laminated glass according to the present embodiment is not particularly limited, but from the viewpoint of weight reduction, the total thickness of the outer glass plate 1 and the inner glass plate 2 is preferably 2.4 to 4.6 mm. It is more preferable to set the diameter to 2.6 to 3.4 mm, and it is particularly preferable to set the diameter to 2.7 to 3.2 mm.

- the thickness of each glass plate is not particularly limited,

- the thickness of the outer side glass plate 1 and the inner side glass plate 2 can be determined as follows.

- the outer glass plate 1 is mainly required to be resistant to external obstacles and impact resistance. For example, when this laminated glass is used as a windshield of an automobile, the impact resistance to flying objects such as pebbles is excellent. is necessary. On the other hand, the larger the thickness is, the more the weight increases. From this viewpoint, the thickness of the outer glass plate 1 is preferably 1.0 to 3.0 mm, and more preferably 1.6 to 2.3 mm. Which thickness is adopted can be determined according to the application of the glass.

- the thickness of the inner side glass plate 2 can be made equivalent to the outer side glass plate 1, for example, thickness can be made smaller than the outer side glass plate 1 for weight reduction of laminated glass. Specifically, in consideration of the strength of the glass, it is preferably 0.6 to 2.0 mm, more preferably 0.8 to 1.8 mm, and preferably 0.8 to 1.6 mm. Particularly preferred. More preferably, it is 0.8 to 1.3 mm. Also about the inner side glass plate 2, it can be determined according to the use of glass which thickness is employ

- middle layer 3 mentioned later is arrange

- the shape of the outer side glass plate 1 which concerns on this embodiment, and the inner side glass plate 2 may be curved shape.

- the dust amount is an amount indicating bending of the glass plate, and when the straight line L connecting the center of the upper side and the center of the lower side of the glass plate is set, the largest of the distances between the straight line L and the glass plate Define as a dust amount D.

- the amount of debris is preferably less than 30 mm, more preferably less than 25 mm, and particularly preferably less than 20 mm.

- the measurement position there are two positions on the center line extending in the vertical direction at the center in the horizontal direction of the glass plate.

- the measuring device is not particularly limited, but for example, a thickness gauge such as SM-112 manufactured by Teclock Co., Ltd. can be used.

- SM-112 manufactured by Teclock Co., Ltd.

- the curved surface of the glass plate is placed on a flat surface, and the edge portion of the glass plate is held and measured by the thickness gauge.

- the intermediate layer 3 is formed of three layers including a heat generating layer 31 and a pair of adhesive layers 32 and 33 having the same shape as the glass plates 1 and 2 sandwiching the heat generating layer 31.

- the adhesive layer disposed on the outer glass plate 1 side is referred to as a first adhesive layer 32

- the adhesive layer disposed on the inner glass plate 2 side is referred to as a second adhesive layer 33.

- the heat generating layer 31 includes a plurality of heating wires 314 as described later, thereby removing snow, ice and fog generated on the surface of the windshield.

- the heat generated by the heating wire 314 heats the adhesive layers 32, 33 and the like around it, which may cause flicker when looking out of the vehicle through the windshield.

- the heating wire 314 is required to have a calorific value capable of performing ice melting and the like, and prevention of flickering is also required. Therefore, in the present embodiment, as described later, the heating of the heating wire 314 is generated.

- the dimensions, such as amount, line width, pitch, etc., are set.

- the calorific value can be calculated by the following equation (1).

- the relationship between the resistance of the heating wire 314 and the length and cross-sectional area of the heating wire 314 is as shown in Formula (2).

- R ((L / A) (2)

- W power

- E voltage

- I current

- R resistance

- L length

- A cross-sectional area

- ⁇ electrical resistivity

- the resistance R is increased, the length L of the heating wire 314 is increased, and the cross-sectional area A of the heating wire 314 is decreased.

- a certain amount of calorific value is required for ice melting and the like. Therefore, when the calorific value of each heating wire 314 decreases, in order to maintain the calorific value of the whole windshield, it is necessary to increase the number of the heating wires 314.

- middle layer 3 is demonstrated hereafter, considering the above point.

- the heat generating layer 31 includes a sheet-like base (supporting layer) 311, and a first bus bar 312, a second bus bar 313, and a plurality of heating wires 314 disposed on the base 311.

- the plurality of heating wires 314 are connected in parallel so that both bus bars 312 and 313 serve as electrodes.

- the substrate 311 can be formed in a rectangular shape so as to correspond to the glass plates 1 and 2 and the adhesive layers 32 and 33, but may not necessarily have the same shape as the adhesive layers 32 and 33.

- the shape may be smaller than 1 and 2 (in this case, for example, in the periphery of the substrate 311, the portion inside the peripheral portion of the glass plate corresponds to the inner portion of the present invention).

- the length between the two notches 21 and 22 can be made shorter in the vertical direction so as not to interfere with the notches 21 and 22 of the inner glass plate 2.

- the length in the left-right direction of the base material 311 can also be shorter than the width of both the glass plates 1 and 2.

- the first bus bar 312 is formed to extend along the upper side of the base 311.

- the second bus bar 313 is formed to extend along the lower side of the base 311 but is formed to be longer than the first bus bar 312.

- each of the bus bars 312 and 313 is not provided with the notches 21 and 22 so as not to be exposed from the notches 21 and 22 described above when the intermediate layer 3 is sandwiched between the two glass plates 1 and 2. It is placed inside.

- the upper and lower widths of the bus bars 312 and 313 are preferably, for example, 5 to 50 mm, and more preferably 10 to 30 mm.

- the width of the bus bars 312 and 313 is smaller than 5 mm, the amount of heat generation in the bus bars increases, and the amount of heat generation of the heating wire 314 decreases, and a desired amount of heat generation can not be obtained.

- the width of the bus bars 312 and 313 is larger than 50 mm, the bus bars 312 and 313 may protrude from the shielding layer 7 and the visual field may be obstructed.

- the bus bars 312 and 313 may not be formed exactly along the substrate 311. That is, it does not have to be completely parallel to the edge of the substrate 311, but may be curved or the like.

- the bus bars 312 and 313 can be formed not only in one layer but in a plurality of layers.

- additional members may be formed in the same strip shape as the bus bars 312 and 313, and may be superimposed on the bus bars 312 and 313. Thereby, the thickness of the bus bars 312 and 313 is increased, so that the resistance value can be suppressed low. As a result, heat generation in the bus bars 312 and 313 can be suppressed.

- the material of the additional member is preferably the same as that of the bus bars 312 and 313, whereby the additional members and the bus bars 312 and 313 can be integrated when stacked. Further, the additional member can be fixed to the bus bars 312 and 13 by, for example, solder, but is not limited thereto.

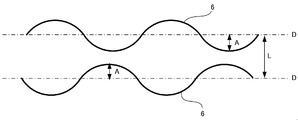

- the plurality of heating wires 314 are formed to extend in the vertical direction so as to connect the bus bars 312 and 313. Also, the plurality of heating wires 314 are disposed substantially in parallel. Each heating wire 314 can be formed in a straight line, or can have various shapes such as a waveform. In particular, by making each heating wire 314 into a sine wave shape, the distribution of heat becomes uniform, and it is possible to optically prevent the heating wire 314 from obstructing the field of view of the windshield. At this time, the crimp rate of the heating wire 314 can be, for example, 150% or less. The crimp rate is the ratio of the actual length of the heating wire 314 (the length following the curve) to the length between the heating wire 314 on the heat generating layer 31.

- the heating wire 314 is drawn in a straight line in the drawing, it may also include a waveform as described above.

- the line width of each heating wire 314 is preferably 1 to 30 ⁇ m, more preferably 5 to 20 ⁇ m, and particularly preferably 8 to 15 ⁇ m. Since the smaller the line width of the heating wire 314, the harder it is for visual recognition, it is suitable for the windshield according to the present embodiment. However, if the width of the heating wire 314 is reduced, the cross-sectional area is reduced, and thus the calorific value may be reduced as described above. Therefore, the lower limit of the line width of the heating wire 314 can be set as described above. On the other hand, when the line width of the heating wire 314 becomes large, it becomes easy to visually recognize, and the calorific value becomes large due to the increase of the sectional area. Therefore, the upper limit of the line width of the heating wire 314 is set as described above.

- the line width of the heating wire 314 is preferably 7 to 30 ⁇ m.

- the line width is preferably 7 to 30 ⁇ m.

- the line width is preferably 20 ⁇ m or less, and more preferably 15 ⁇ m or less.

- the voltage applied between both bus bars 312 and 313 is 20 to 50 V, it is preferably 1 to 10 ⁇ m.

- the heat generation amount can be increased by setting the line width to 1 ⁇ m or more.

- the line width refers to the line width of the largest portion of the cross-sectional shape of the heating wire 314.

- the cross-sectional shape of the heating wire 314 is trapezoidal, the width of the lower side is the line width, and when the cross-sectional shape of the heating wire 314 is circular, the diameter is the line width.

- the thickness of the heating wire 314 is preferably 30 ⁇ m or less, more preferably 20 ⁇ m or less, and particularly preferably 10 ⁇ m or less. As described above, when the thickness is reduced, the step between the heating wire 314 and the base member 311 is reduced, and generation of bubbles in the vicinity of the step can be suppressed at the time of manufacturing as described later. Further, the thickness of the heating wire 314 is preferably smaller than the line width of the heating wire 314. In other words, the aspect ratio of the cross section of the heating wire 314 is preferably 1 or less. This is because if the thickness is larger than the line width of the heating wire 314, for example, the heating wire 314 may fall over the base material 311, which may make manufacturing difficult or break.

- the thickness of the heating wire 314 is preferably thin in order to suppress the generation of bubbles as described above, but in order to achieve the required calorific value, the thickness of the heating wire 314 is increased It is preferable to increase the cross-sectional area. From this point of view, the thickness of the heating wire 314 is preferably 5 ⁇ m or more, although there is a possibility of generation of bubbles. In addition, as described later, if the thickness of the heating wire 314 is 10 ⁇ m or more, bubbles may be generated more. However, as the amount of heat generation per heating wire 3141 becomes large, flicker may occur, so it is desirable that the thickness be 30 ⁇ m or less as described above.

- the line width and thickness of the heating wire 314 can be measured, for example, by multiplying the microscope such as VHX-200 (manufactured by Keyence Corporation) by 1000 times.

- the pitch of the adjacent heating wires 314 is preferably 1.25 to 4.0 mm, more preferably 1.50 to 3.5 mm, and still more preferably 2.0 to 3.0 mm. preferable.

- the pitch is not the length of the gap between the adjacent heating wires 314, but is the length obtained by adding the line width of the heating wires 314 to the length of the gap between the adjacent heating wires 314.

- the upper limit value of the pitch By setting the upper limit value of the pitch in this manner, for example, when a predetermined calorific value (for example, 400 W / m 2 ) can be obtained in the entire windshield, the calorific value W of each heating wire 314 as described above Since the number of heating wires 314 can be increased by reducing the pitch, the reduction of the calorific value of the entire windshield can be prevented.

- the lower limit value of pitch has the following provisions as of November 2017 in Japan.

- Section 3 Item 5 (window glass) of the notification that defines the details of the safety standards for road transport vehicles, among the devices for preventing fogging of window glass, those embedded in the test area A , “The width of the device is 0.03 mm or less, and the density is 8 wires / cm (in the case where the conductor is embedded horizontally, 5 wires or less)”, but 8 wires / cm or less

- the pitch it is desirable for the pitch to be 1.25 mm or more.

- the distance L between the center lines of the heating wires 314 is the pitch of the heating wires 314.

- the distance L between the center lines D of the waves of the adjacent heating lines 314 can be twice or more the amplitude A of each heating line 314.

- the amplitude A is not particularly limited, but can be, for example, 3 mm or more.

- the pitch of heating wire 314 is preferably 1.25 mm or more, and more preferably 2.0 mm or more.

- the heating wire 314 may be formed in a sine wave.

- the positions of the concavities and convexities of the sine wave may be different between adjacent heating lines 314 or the pitch of the concavities and convexities may be different.

- region is in the range of the test area

- the length of the heating wire 314 can be, for example, 1000 mm or more. Alternatively, it may be 1100 mm or more, or 1200 mm or more. Furthermore, the resistance of the heating wire 314 is preferably 30 ⁇ or more, and more preferably 90 ⁇ or more. By thus increasing the length of the heating wire, the resistance R is increased based on the equation (2), so that the amount of heat generation is reduced, and flicker can be suppressed.

- measurement of resistance R of heating wire 314 is explained.

- measurement can be performed using a commercially available electrical resistance measuring instrument, as an example, digital multimeter 73200 series (made by YOKOGAWA) can be mentioned.

- digital multimeter 73200 series made by YOKOGAWA

- the measurement first select the heating wire to be measured.

- one terminal of the electrical resistance measuring instrument is connected to the vicinity of the bus bar 312 of the heating wire, and the other terminal is connected to the vicinity of the bus bar 313 of the heating wire.

- the heating wire is sandwiched between the outer glass plate 1 and the inner glass plate 2 and the terminal of the electrical resistance measuring device can not be connected to the heating wire, either the outer glass plate 1 or the inner glass plate 2 can be broken to measure the resistance R of the heating wire 314.

- the heating wire to be measured and the heating wire adjacent to the heating wire are connected by a bridge (not shown), the resistance R of the heating wire to be measured is cut after the bridge is cut. taking measurement.

- the calorific value per unit length in each heating wire 314 is, for example, 2.0 W / m or less when a voltage of 13.5 V or 48 V is applied between both bus bars 312 and 313, for example. Is more preferable, 1.5 W / m or less is more preferable, and 1.0 W / m or less is particularly preferable. When it is 2.0 W / m or less, flicker can be suppressed.

- the calorific value per unit area in the windshield is preferably 300 to 600 W / m 2 in order to effectively carry out antifogging and ice melting etc. More preferably, it is 400 W / m 2 or more, and particularly preferably 500 W / m 2 or more.

- the base material 311 is a transparent film supporting both the bus bars 312 and 313 and the heating wire 314, and the material is not particularly limited.

- the material is not particularly limited.

- it can be formed of polyvinyl butyral resin (PVB), ethylene vinyl acetate (EVA) or the like.

- both bus bars 312 and 313 and heating wire 314 can be formed of the same material, such as copper (or tin-plated copper), gold, aluminum, magnesium, cobalt, tungsten, silver or alloys of those metals, etc. And can be formed of various materials. Among these, it is preferable to use silver, copper, gold, and aluminum, which are materials having an electrical resistivity of 3.0 ⁇ 10 ⁇ 8 ⁇ m or less. As described above, when the electrical resistivity of the heating wire 314 is low, the resistance R is small based on the equation (2), and the amount of heat generation tends to be large. However, flicker can be suppressed by adjusting the pitch, length, cross-sectional area, and line width of the heating wire 314.

- the conductive materials may be printed directly on the glass plates 1 and 2 as long as the bus bars 312 and 313 and the heating wires 314 have a width of 10 ⁇ m or more.

- the glass sheet can be directly heated to form a heating wire, that is, since it is not necessary to heat the intermediate film at the time of forming the heating wire 314, the intermediate film is deformed to suppress the occurrence of perspective distortion. Can.

- the heating wire 314 can then be formed.

- the method is not particularly limited, but can be formed by various methods such as printing, etching, and transfer.

- the bus bars 312 and 313 and the heating wires 314 can be separately formed, or they can be integrally formed.

- integralally means that there is no break (seamless) between materials, and there is no interface.

- both bus bars 312 and 313 are formed on the base material 311, and the base material 311 of the portion corresponding to the bus bars 312 and 313 is peeled off and removed while leaving the base material 311 for the heating wire 314. The heating wire can then be placed on the substrate between the bus bars.

- metal foil is dry-laminated on the base material 311 via a primer layer.

- metal foil copper can be used, for example.

- by performing a chemical etching process using a photolithography method on the metal foil it is possible to integrally pattern both the bus bars 312 and 313 and the plurality of heating lines 314 on the base material 311.

- the line width of the heating wire 314 is to be reduced (for example, 15 ⁇ m or less)

- patterning may be performed by photolithography.

- the surface of the heating wire 314, ie, the surface by the side of the inner side glass plate 2, is blackened, and it can suppress that the heating wire 314 is visually recognized from vehicle inner side.

- a material for blackening there are copper nitride, copper oxide, nickel nitride, nickel chromium and the like, and blackening can be performed by plating using these materials.

- the two adhesive layers 32 and 33 are sheet-like members for sandwiching the heat generating layer 31 and bonding to the glass plates 1 and 2. Although both adhesive layers 32 and 33 are formed in the same size as both glass plates 1 and 2, both adhesive layers 32 and 32 are located at positions corresponding to the notches 21 and 22 of inner glass plate 2. Notches of the same shape are respectively formed.

- the adhesive layers 32 and 33 can be formed of various materials, and can be formed of, for example, polyvinyl butyral resin (PVB), ethylene vinyl acetate (EVA), or the like. In particular, polyvinyl butyral resin is preferable because it is excellent in penetration resistance as well as adhesiveness with each glass plate.

- a surfactant layer may be provided between the adhesive layers 32 and 33 and the heat generating layer 31. The surface of both layers can be modified by such surfactant, and the adhesion can be improved.

- the shape of the adhesive layers 32 and 33 is not particularly limited, and may be smaller than the glass plates 1 and 2.

- the interlayer 3 can have other configurations.

- the bus bars 312 and 313 and the heating wire 314 can be formed between the adhesive layers 32 and 33.

- the substrate 311 may have a high haze ratio depending on the material, which may reduce the transmittance of the laminated glass. Therefore, the transmittance of the laminated glass can be increased by not providing the substrate 311.

- the adhesive layers 32 and 33 may be either one. Therefore, for example, the intermediate film 3 can be configured by one adhesive layer, the bus bars 312 and 313, and the heating wire 314. When the number of adhesive layers is one, for example, when the first adhesive layer 32 is eliminated, the heating wire 314 comes in contact with the outer glass plate 1.

- the heating wire 314 comes in contact with the inner glass plate 2.

- it is suitable for removing the fogging that occurs on the inner glass plate 2.

- additional members may be stacked on the bus bars 312 and 313 to increase the thickness of the bus bars 312 and 313.

- the thickness of the additional member is not particularly limited, but the thickness may be determined according to the use in order to reduce the resistance value of the bus bars 312 and 313. For example, it can be 50 to 200 ⁇ m (eg, 100 ⁇ m). However, in the case of using an additional member, the above-described foam is easily generated.

- the total thickness of the intermediate layer 3 is not particularly limited, but is preferably 0.3 to 6.0 mm, more preferably 0.5 to 4.0 mm, and 0.6 to 2.0 mm. Being particularly preferred.

- the thickness of the base 311 of the heat generating layer 31 is preferably 5 to 200 ⁇ m, and more preferably 5 to 100 ⁇ m. Note that the provision of the base material 311 also has the possibility of the above-described generation of bubbles.

- the thickness of each of the adhesive layers 32 and 33 is preferably larger than the thickness of the heat generating layer 31. Specifically, it is preferably 0.05 to 2.0 mm, and 0.05 to 1.0 mm. It is further preferred that Furthermore, although the details will be described later, in consideration of the ease of heat radiation from the heating wire 314 to the glass plates 1 and 2, it is preferable that the thickness of each adhesive layer 32 and 33 be smaller. It is preferable that it is 05 to 0.4 mm. The thickness of both adhesive layers 32 and 33 may be the same or different.

- the thickness of the first adhesive layer 32 can be 30 to 70 ⁇ m (for example, 50 ⁇ m), and the thickness of the second adhesive layer 33 can be 500 to 900 ⁇ m (for example, 760 ⁇ m).

- the thickness of the first adhesive layer 32 is small, the heat from the heating wire 314 is easily transmitted to the outer glass plate 1, and the deicing performance is enhanced.

- this thickness is reversed between the first adhesive layer 32 and the second adhesive layer 33, the heat from the heating wire 314 is easily transmitted to the inner glass plate 2, and the antifogging performance is enhanced.

- the thickness of both the bus bars 312 and 313 and the heating wire 314 sandwiched therebetween be 3 to 20 ⁇ m.

- the thicknesses of the heat generating layer 31 and the adhesive layers 32 and 33 can be measured, for example, as follows. First, the cross section of the laminated glass is enlarged by 175 times and displayed by a microscope (for example, VH-5500 manufactured by Keyence Corporation). Then, the thicknesses of the heat generating layer 31 and the adhesive layers 32 and 33 are visually specified and measured. At this time, in order to eliminate variations due to visual observation, the number of measurements is made five times, and the average value is taken as the thickness of the heat generating layer 31 and the adhesive layers 32, 33.

- the thicknesses of the heat generating layer 31 and the adhesive layers 32 and 33 of the intermediate layer 3 do not have to be constant over the entire surface, and for example, they may be wedge-shaped for laminated glass used in a head-up display. In this case, the thickness of the heat generating layer 31 and the adhesive layers 32 and 33 of the intermediate layer 3 is measured at the place with the smallest thickness, that is, the lowermost side portion of the laminated glass.

- the intermediate layer 3 is wedge-shaped, the outer glass plate 1 and the inner glass plate 2 are not arranged in parallel, but such an arrangement is also included in the glass plate in the present invention.

- connection material 41 and 42 are for connecting the respective bus bars 312 and 313 and connection terminals (anode terminal or cathode terminal: not shown), and are formed in a sheet shape of a conductive material. Then, a voltage higher than 12 V, for example, a power supply voltage of 13.5 V is applied to this connection terminal.

- the connection material connected to the first bus bar 312 is referred to as a first connection material 41

- the connection material connected to the second bus bar 313 is referred to as a second connection material 42.

- the 1st connection material 41 is mainly demonstrated.

- the first connection member 41 is formed in a rectangular shape, and is sandwiched between the first bus bar 312 and the second adhesive layer 33. Then, the first bus bar 312 is fixed by the fixing material 5 such as solder.

- the fixing material 5 such as solder.

- the fixing material 5 it is preferable to use, for example, a solder having a low melting point of 150 ° C. or less so that it can be simultaneously fixed by an autoclave at the time of assembling the windshield described later.

- the first connecting member 41 extends from the first bus bar 312 to the upper end edge of the outer glass plate 1 and is exposed from the first notch 21 formed in the inner glass plate 2. And in this exposed part, the connection terminal to which the cable extended to the power supply is connected is connected by a fixing material such as solder.

- connection terminals are fixed to the portions exposed from the notches 21 and 22 of the inner glass plate 2 without the connection members 41 and 42 protruding from the end portions of both the glass plates 1 and 2 It has become.

- both the connection materials 41 and 42 are formed with thin material, after bending, as shown in FIG. 2, an edge part can be fixed to the bus-bar 312 with the fixing material 5.

- a shielding layer 7 is laminated on a dark ceramic such as black on the periphery of the laminated glass.

- the shielding layer 7 shields the view from inside and outside the vehicle, and is laminated along the four sides of the laminated glass.

- the bus bars 312 and 313 are disposed at positions covered by the shielding layer 7.

- the shielding layer 7 covers all the outer edges of the bus bars 312 and 313 and the vicinity thereof, and covers at least the step between the outer edges of the bus bars 312 and 313 and the base member 311 and the vicinity thereof.

- the base 311 is smaller than the adhesive layers 32 and 33, at least the step between the base 311 and the adhesive layers 32 and 33 and the vicinity thereof are covered.

- Reference numeral 7 in the figure indicates the inner edge of the shielding layer 7.

- the shielding layer 7 may have various modes such as only the outer surface of the outer glass plate 1, only the inner surface of the outer glass plate 1, or the inner surface of the outer glass plate 1 and the inner surface of the inner glass plate 2. In addition, if the shielding layer 7 is provided at least on the outer glass plate 1, it is possible to prevent the bubbles from being visually recognized from the outside of the vehicle. On the other hand, when the second shielding layer is provided on the inner glass plate 2, it is possible to prevent bubbles from being visually recognized from the inside of the vehicle. However, it depends on the structure of the vehicle whether the second shielding layer prevents the bubbles from being viewed from the inside of the vehicle. That is, when the foam is concealed by fitting the laminated glass into the vehicle body, the second shielding layer may be considered unnecessary. However, in order to improve the quality of the laminated glass itself, or when the foam is not hidden in the vehicle body, it is preferable to provide a second shielding layer to hide the foam also from the inside of the car.

- the ceramic can be formed by screen printing, but it can also be produced by transferring a baking transfer film onto a glass plate and baking it.

- screen printing for example, polyester screen: 355 mesh, coat thickness: 20 ⁇ m, tension: 20 Nm, squeegee hardness: 80 degrees, mounting angle: 75 °, printing speed: 300 mm / s, drying furnace Drying at 150 ° C. for 10 minutes can form a ceramic.

- the shielding layer 7 can also be formed by sticking a shielding film made of a dark resin, in addition to laminating ceramics.

- Windshield manufacturing method> Next, a method of manufacturing the windshield will be described. First, the manufacturing line of a glass plate is demonstrated.

- FIG. 4 is a side view of the furnace through which the mold passes

- FIG. 5 is a plan view of the mold.

- this forming die 800 is provided with a frame-like die main body 810 that substantially matches the outer shape of both the glass plates 1 and 2. Since the mold body 810 is formed in a frame shape, it has an internal space 820 penetrating in the vertical direction inside. Then, the peripheral edge portions of the flat glass plates 1 and 2 are placed on the upper surface of the mold body 810. Therefore, heat is applied to the glass plates 1 and 2 through the internal space 820 from a heater (not shown) disposed on the lower side.

- a heater not shown

- both the glass plates 1 and 2 are softened by heating and curved downward by their own weight.

- the shielding board 840 for shielding heat may be arrange

- the heater can be provided not only below the forming die 800 but also above it.

- both the glass plates 1 and 2 are stacked downward inside by the own weight than the peripheral portion and are formed into a curved surface.

- both the glass plates 1 and 2 are carried from the heating furnace 802 to the annealing furnace 803, and annealing is performed. Thereafter, both glass plates 1 and 2 are carried out of the annealing furnace 803 to the outside and allowed to cool.

- the intermediate layer 3 is sandwiched between the outer glass plate 1 and the inner glass plate 2.

- the outer glass plate 1, the first adhesive layer 32, the heat generating layer 31, the second adhesive layer 33, and the inner glass plate 2 are laminated in this order.

- the heat generating layer 31 directs the surface on which the first bus bar 312 and the like are formed to the second adhesive layer 33 side.

- the upper and lower end portions of the heat generating layer 31 are disposed inside the notches 21 and 22 of the inner glass plate 2.

- the notches of the first and second adhesive layers 32 and 33 are made to coincide with the notches 21 and 22 of the inner glass plate 2.

- connection members 41 and 42 are inserted between the heat generating layer 31 and the second adhesive layer 33 from the notch portions 21 and 22, respectively.

- a low melting point solder is applied to each of the connection members 41 and 42 as the fixing member 5 so that the solder is disposed on each of the bus bars 312 and 313.

- the laminated body in which both the glass plates 1 and 2, the intermediate layer 3, and the connecting members 41 and 42 are laminated is put in a rubber bag and prebonded at about 70 to 110 ° C. under vacuum suction.

- Other pre-adhesion methods are possible, and the following method may be adopted.

- the laminate is heated at 45 to 65 ° C. in an oven.

- this laminate is pressed by a roll at 0.45 to 0.55 MPa.

- the laminate is again heated at 80 to 105 ° C. in an oven, and then pressed again by a roll at 0.45 to 0.55 MPa.

- pre-adhesion is completed.

- the pre-adhered laminate is subjected to main adhesion by means of an autoclave at, for example, 8 to 15 atm at 100 to 150.degree.

- the main adhesion can be performed under the conditions of 14 ° C. and 135 ° C.

- the adhesive layers 32 and 33 are adhered to the glass plates 1 and 2 with the heat generating layer 31 interposed therebetween through the preliminary bonding and the main bonding described above. Further, the solder of the connection members 41 and 42 is melted, and the connection members 41 and 42 are fixed to the bus bars 312 and 313, respectively.

- the laminated glass according to the present embodiment is manufactured.

- the curved windshield can also be manufactured by methods other than this, for example, press work.

- connection terminals are fixed to the connection members 41 and 42, respectively. Thereafter, when each connection terminal is energized, a current is applied to the heating wire 314 through the connection members 41 and 42 and the bus bars 312 and 313 to generate heat. By this heat generation, it is possible to remove the fogging of the inner surface of the windshield or to de-ice the outer surface of the windshield.

- the shielding layer 7 covers all the outer edges of the bus bars 312 and 313 and the vicinity thereof, and covers at least the step between the outer edges of the bus bars 312 and 313 and the base member 311 and the vicinity thereof. ing. Therefore, bubbles generated in the step between the bus bars 312 and 313 and the base material 311 can be hidden by the shielding layer 7. Therefore, even if bubbles are generated, they can be viewed from outside the vehicle.

- the generation of bubbles can be suppressed.

- the example of the windshield which comprised the intermediate film 3 as follows is demonstrated.

- the following heat generating layer 31 is disposed between the adhesive layers 32 and 33.

- the numerical values in the table are thickness.

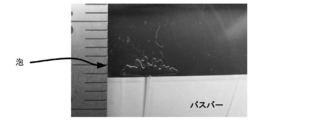

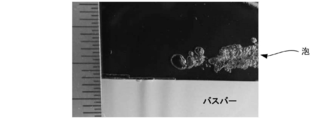

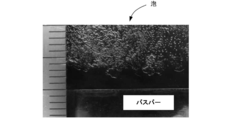

- the bus bars 312 and 313 and the heating wire 314 are integrally formed, and have the same thickness. Further, the appearance of the following table is obtained by photographing the vicinity of the bus bar.

- the base material 311 is not provided in the heat generating layer 31, a step is generated between the bus bars 312 and 313 and the heating wire 314 and the adhesive layers 32 and 33, air remains at the time of manufacture. , A bubble has occurred.

- the bubbles are not noticeable, but in the reference examples 3 and 4, the bubbles are noticeable and the range is wide. Therefore, although the bus bars 312 and 313 can be covered with the shielding layer 7 in the third and fourth embodiments, when the bubble range is wide, the shielding layer 7 must also be spread. Therefore, the thicknesses of the bus bars 312 and 313 and the heating wire 314 are preferably 30 ⁇ m or less.

- the thickness of the entire layer (functional layer) 31 is preferably in the range of 5 to 200 ⁇ m.

- the thickness is preferably in the range of 5 to 500 ⁇ m.

- the inventor has found that the above-mentioned flicker occurs especially when the temperature of the heating wire 314 and the temperature around it exceeds about 60 ° C. Therefore, the inventor of the present invention has determined that when a voltage of 13.5 V is applied between the bus bars 312 and 313 so that the temperature of the heating wire 314 and the surrounding temperature does not exceed about 60 ° C. It has been found that the flicker is prevented by setting the calorific value of no more than 2.0 W / m. Therefore, in the windshield according to the present embodiment, when a voltage of 13.5 V is applied between the bus bars 312 and 313, the calorific value per unit length of each heating wire 314 is 2.0 W / m or less. Because of this, the temperature of the heating wire 314 and its surroundings can be suppressed to about 60.degree. C. or less, and as a result, it is possible to prevent flicker when looking out of the vehicle through the windshield.

- heating wire for example, in the case of a windshield that requires 464 W / m 2 as the calorific value for a region of 1180 mm wide and 958 mm long at a voltage of 13.5 V, set as shown in FIG. Can.

- the shapes of the heating wires 314 for satisfying the calorific value are as shown in reference examples 5 to 16 shown in FIG.

- the pitch of the heating wire 314 is required to be 1.25 mm or more according to the above-mentioned definition, it is preferable to use the heating wire of Reference Examples 15 and 16. Therefore, in consideration of this pitch, the line width of the heating wire 314 is preferably 10 ⁇ m or more.

- the heating wire can be set as shown in FIG.

- the calorific value per unit length of each heating wire is preferably 2.0 W / m or less.

- the pitch is preferably 4.0 mm or less.

- the line width of the heating wire is preferably approximately 10 ⁇ m or less, and more preferably 8 ⁇ m or less.

- both bus bars 312 and 313 and heating wire 314 are formed of the same material, the linear expansion coefficients of both bus bars 312 and 313 and heating wire 314 become the same.

- both bus bars 312 and 313 and heating wire 314 are formed of different materials, they have different coefficients of linear expansion. For example, when these members are separately manufactured and fixed, severe conditions such as heat cycle test etc. Although there is a possibility that the heating wire may peel from the bus bar due to the environmental change, and the two glass plates constituting the laminated glass may float up due to this, as in this embodiment, both bus bars Such defects can be prevented if the layers 312 and 313 and the heating wire 314 are formed of the same material.

- the current value may be controlled so that the upper limit of the heating temperature is, for example, 70 to 80 ° C. to prevent the occurrence of glass cracks. Desired.

- the heating wire can not be controlled to generate heat sufficiently.

- the heating wire can also be controlled so as to be capable of generating heat as a whole.

- the two bus bars 312 and 313 are connected to the external terminals using two connection members 41 and 42.

- a wide bus bar is prepared, and It may be considered to replace the connection material by cutting unnecessary portions and exposing a part from the notches 21 and 22. However, this may cause local heat generation at the corners of the cut bus bar.

- the separate connecting members 41 and 42 are fixed to the bus bars 312 and 313, such local heat generation can be prevented.

- the heat generating layer 31 can have various shapes.

- the sheet-like heat generating layer 31 in which both the bus bars 312 and 313 and the heating wire 314 are formed on the base material 311 is prepared in advance, cut appropriately, and formed into an appropriate shape. It can be placed between 1 and 2. Therefore, for example, if the edge of the glass plates 1 and 2 is curved, the edge of the substrate 311 may be curved accordingly.

- various shapes such as a smaller shape than the glass plates 1 and 2 It can be shaped.

- the glass plates 1 and 2 can also be made into various shapes other than a perfect rectangle.

- both the bus bars 312 and 313 and the heating wire 314 are disposed on the base material 311, but at least the heating wire 314 may be disposed. Therefore, for example, both bus bars 312 and 313 can be disposed between the adhesive layers 32 and 33.

- the adhesive layers 32 and 33 may not be provided, and the bus bars 312 and 313 and the base material 311 supporting the heating wire 314 may be disposed between the two glass plates 1 and 2.

- the substrate 311 plays a role as an adhesive layer.

- the configuration of the heating wire 314 is not particularly limited, and various aspects are possible. This point will be described with reference to FIG.

- the example in FIG. 12 is different from the above embodiment mainly in the arrangement of the bus bars and the heating wires, so only the different parts will be described below, and the same configuration will be assigned the same reference numerals and the description will be omitted. Do.

- the plurality of heating wires 6 are arranged in parallel so as to connect both bus bars 312 and 313.

- Each heating wire 6 is composed of three portions and two folded portions. That is, a first portion 61 extending from the first bus bar 312 to a position approaching the second bus bar 313 and a position extending close to the first bus bar 312 from the lower end of the first portion 61 via the first folded portion 64.

- a second portion 62 extending up to the bottom, and a third portion 63 extending downward from the upper end of the second portion 62 via the second folded portion 65 and connected to the second bus bar 313 are provided.

- a plurality of heating wires 6 formed in this manner are arranged at predetermined intervals in the left-right direction of both bus bars 312, 313.

- each heating wire 6 can be made longer by providing the folded portions 64 and 65 in each heating wire. By these, the calorific value in each heating wire 6 can be made small.

- the form of the heating wire 6 is not particularly limited, and in the present embodiment, the two folded portions 64 and 65 are formed to have two or more folded portions.

- the length of the heating wire 6 extending between can also be made longer.

- each heating wire 314 a relay bus-bar like FIG. 13 can also be provided. This point will be described in detail.

- the first bus bar 312 is disposed on the left side of the lower side 12 of each glass plate 1, 2, and the second bus bar 313 is disposed along the right side of the lower side 12.

- the strip-like first relay bus bar 71 on the left side of the upper side 11 of the glass plates 1 and 2, and the strip-like second relay bus bar 72 between the first and second bus bars 312 and 313 on the lower side 12.

- a band-shaped third relay bus bar 73 is provided on the right side of the upper side 11 of the second.

- the first relay bus bar 71 is disposed at a position facing the first bus bar 312 and the second relay bus bar 72, and formed to have substantially the same length from the left end of the first bus bar 312 to the vicinity of the center of the second relay bus bar 72.

- the third relay bus bar 73 is disposed at a position facing the second relay bus bar 72 and the second bus bar 313, and has substantially the same length from the left end of the first bus bar 312 to the vicinity of the center of the second relay bus bar 72. It is formed.

- the plurality of heating wires 6 are constituted by four parts. That is, the plurality of heating wires 6 respectively have a first portion 601 connecting the first bus bar 312 and the first relay bus bar 71, a second portion 602 connecting the first relay bus bar 71 and the second relay bus bar 72, A third portion 603 connecting the second relay bus bar 72 and the third relay bus bar 73 and a fourth portion 604 connecting the third relay bus bar 73 and the second bus bar 313 are formed.

- the plurality of first portions 601 extend generally in parallel from the first bus bar 312 upward, and are connected to the left half of the first relay bus bar 71.

- the plurality of second portions 602 extend generally in parallel from the right half of the first relay bus bar 71 downward, and are connected to the left half of the second relay bus bar 72. Further, the plurality of third portions 603 extend generally in parallel from the left half of the second relay bus bar 72 upward, and are connected to the third relay bus bar 73. The plurality of fourth portions 604 extend generally in parallel from the right half of the third relay bus bar 73 downward, and are connected to the second bus bar 213.

- the three relay bus bars 71 to 73 are provided between the first bus bar 312 and the second bus bar 313, and the plurality of heating wires 6 arranged in parallel via these are the first bus bar 312 and the first bus bar 312 It is configured to connect the two bus bars 313. Therefore, the length of the heating wire 6 between the first bus bar 312 and the second bus bar 313 can be increased. By these, the calorific value in each heating wire 6 can be made small.

- both bus bars 312 and 313 are disposed along the lower side 12, but may be disposed along the upper side 11. That is, from FIG. 9, both bus bars 312 and 313 and three relay bus bars 71 to 73 can be disposed at vertically opposite positions.

- the number of relay bus bars is not particularly limited, and two or four or more relay bus bars may be provided, and both ends of the heating wire are connected to the first bus bar 312 and the second bus bar 313 through all the relay bus bars. It should just be.

- Adjacent heating wires 314 can also be connected by at least one bridge. Thereby, even if one heating wire 314 is disconnected, for example, it becomes possible to conduct electricity from the adjacent heating wire 314.

- the position and number of bridges are not particularly limited.

- the shape of the bridge is not particularly limited, and may be variously arranged such as being arranged to extend diagonally or to be corrugated.

- the bridge can be formed of the same metal material as the heating wire 314, and can be formed integrally with the heating wire 314.

- connection members 41 and 42 and the configuration of the notches 21 and 22 of the inner glass plate 2 are not particularly limited.

- small notches about the thickness of the connecting members 41 and 42 are formed in the inner glass plate 2, and the connecting members 41 and 42 extending from the bus bars 312 and 313 are folded at the notches. It can also be stuck on the surface. By doing this, it is possible to prevent the connection members 41 and 42 from projecting in the surface direction from the end of the laminated glass.

- the shape of the glass plates 1 and 2 is not particularly limited, and may be any shape that can identify the upper side 11, the lower side 12, the left side 13 and the right side 14 in the outer shape, and may not necessarily be rectangular.

- Each side 11 to 14 may be a straight line or a curved line.

- the bus bars 312 and 313 are respectively disposed along the upper side and the lower side of the glass plate, but the bus bars are arranged along the left side and the right side of the glass plate so that the heating line extends in the lateral direction. It can also be done.

- the heat generating layer 31 is provided as the functional layer according to the present invention, but a functional layer having other functions may be provided.

- a functional layer having other functions for example, an infrared reflective film, a light control film, a crime prevention sheet, a color film, a film for a head-up display, etc. can be provided. Then, even when such a functional layer is provided, if a step is formed between the adhesive layers 32 and 33, bubbles may be generated as described above, so the step is covered by the shielding layer 7 It will be necessary.

- the functional layer 31 when an infrared reflective film is used as the functional layer 31, there is a possibility that the edge of the film reacts with the plasticizer to discolor. Therefore, even when such a functional layer 31 is provided, the color change can be shielded by the shielding layer 7.

- Films such as an infrared light reflective film, a light control film, a security sheet, and a color film may cause wrinkles particularly at the edge portion of the laminated glass depending on the extension of the film. Even in such a case, the shielding layer 7 can shield the wrinkles.

- the shape of the shielding layer 7 is not particularly limited, and can be formed along the peripheral edge of the laminated glass as in the above embodiment, and at least at a position covering the step between the heat generating layer 31 and the adhesive layers 32 and 33 It should just be arrange

Abstract

Provided is a laminated glass in which a functional layer is disposed between two glass plates and which is capable of improving the quality of appearance thereof. The laminated glass according to the present invention is provided with: an outer glass plate having a first side and a second side opposite to the first side; an inner glass plate opposite to the outer glass plate and having substantially the same shape as the outer glass plate; an intermediate film disposed between the outer glass plate and the inner glass plate; and a shielding layer formed on a surface of the outer glass plate, wherein the intermediate film includes an adhesive layer and a functional layer supported by the adhesive layer, and at least a portion of an outer peripheral edge of the functional layer has an inner portion positioned further inside than an outer peripheral edge of the adhesive layer, and the shielding layer is at least disposed so as to cover between the inner portion of the functional layer and the outer peripheral edge of the adhesive layer.

Description

本発明は、合わせガラスに関する。

The present invention relates to laminated glass.

気温の低い日や寒冷地では、自動車のウインドシールドが曇ることがあり、運転に支障を来している。そのため、ウインドシールドの曇りを除去する種々の方法が提案されている。例えば、特許文献1には、ウインドシールドの内部に、バスバー及び加熱線を配置し、その発熱によって曇りを除去することが開示されている。

On cold days or in cold climates, windshields of cars can be overcast, which hinders driving. Therefore, various methods have been proposed for removing windshield fogging. For example, Patent Document 1 discloses that a bus bar and a heating wire are disposed inside a windshield and heat generation removes fogging.

ところで、上記ウインドシールドは、2枚のガラス板の間に接着層とともにバスバーなどを配置した合わせガラスにより形成されている。そして、この合わせガラスを作製する際には、接着層上にバスバーを配置した上で、これらを2枚のガラス板の間に挟み圧力を付与して接着する。しかしながら、バスバーと接着層との間には段差が生じるため、接着時に、この段差に空気が残るおそれがあった。そして、このような空気が残ると、完成した合わせガラスには、この空気が泡として視認可能となり、製品としての品質の低下を招いていた。なお、このような泡の発生は、バスバーだけではなく、2枚のガラス板の間に、例えば、赤外線反射フィルム、調光フィルムなどの機能層を挟んだ配置したときにも生じ得る問題である。

The windshield is formed of laminated glass in which a bus bar and the like are disposed together with an adhesive layer between two glass plates. And when producing this laminated glass, after arrange | positioning a bus-bar on an adhesive layer, these are pinched | interposed between two glass plates, pressure is applied and it adhere | attaches. However, since a step is generated between the bus bar and the adhesive layer, air may be left in the step during bonding. Then, when such air remains, this air can be visually recognized as bubbles in the finished laminated glass, resulting in deterioration of the product quality. In addition, generation | occurrence | production of such a bubble is a problem which may arise also when not only a bus-bar but the functional layer, such as an infrared reflective film and a light control film, is pinchedly arranged between two glass plates, for example.

ところで、上記機能層は、その外周縁がガラス板の外周縁と一致するように形成することができ、このようにすれば、上記のような段差が生じないため、泡の発生を防止することができる。しかしながら、このようにすると、機能層の外周縁がガラス板の間から露出するため、ここからガラス板の間に水が浸入するおそれがある。これにより、合わせガラスが膨れると、本来の合わせガラスの機能を失うおそれがある。さらに、次のような問題もある。すなわち、各ガラス板の端縁は、断面円弧状に形成されることがあるため、機能層の外周縁がガラス板の外周縁と一致していると、接着層同士が接着しない可能性があり、これによって、接着層や機能層にシワが生じる可能性がある。そこで、接着層の外周縁の位置を、外側ガラス位置の位置より中央側に位置させる(例えば、数mm~30mm程度)ことで、水の浸入を防止することができる。しかしながら、このように、接着層の外周縁の位置をガラス板の外周縁よりも内側にすると、上述した泡が生じるおそれがある。

By the way, the above-mentioned functional layer can be formed so that the outer peripheral edge may be in agreement with the outer peripheral edge of a glass plate, and since it does not produce the above-mentioned level difference if it does in this way, generation of bubbles is prevented. Can. However, in this case, since the outer peripheral edge of the functional layer is exposed from between the glass plates, there is a possibility that water may infiltrate between the glass plates from here. As a result, when the laminated glass is swollen, there is a risk of losing the original function of the laminated glass. There are also the following problems. That is, since the edge of each glass plate may be formed in a circular arc shape in cross section, if the outer periphery of the functional layer matches the outer periphery of the glass plate, the adhesive layers may not adhere to each other. However, this may cause wrinkles in the adhesive layer or the functional layer. Therefore, the entry of water can be prevented by positioning the position of the outer peripheral edge of the adhesive layer closer to the center than the position of the outer glass position (for example, about several mm to about 30 mm). However, when the position of the outer peripheral edge of the adhesive layer is located inside the outer peripheral edge of the glass plate as described above, the above-mentioned bubbles may occur.

本発明は、上記問題を解決するためになされたものであり、2枚のガラス板の間に機能層を配置した合わせガラスであって、見た目の品質を向上することができる、合わせガラスを提供することを目的とする。

The present invention has been made to solve the above problems, and provides a laminated glass in which a functional layer is disposed between two glass plates, which can improve the quality of appearance. With the goal.

項1:第1辺と、及び前記第1辺と対向する第2辺を有する外側ガラス板と、

前記外側ガラス板と対向配置され、前記外側ガラス板と略同形状の内側ガラス板と、

前記外側ガラス板と内側ガラス板との間に配置される中間膜と、

前記外側ガラス板の表面に形成される遮蔽層と、

を備え、

前記中間膜は、

接着層と、

前記接着層に支持される機能層と、

を備え、

前記機能層の外周縁の少なくとも一部は、前記接着層の外周縁よりも内側に位置する、内側部位を有しており、

前記遮蔽層は、少なくとも、前記機能層の内側部位と前記接着層の外周縁との間を覆うように配置されている、合わせガラス。 Item 1: An outer glass plate having a first side and a second side opposite to the first side,

An inner glass plate disposed opposite to the outer glass plate and having substantially the same shape as the outer glass plate;

An interlayer disposed between the outer glass plate and the inner glass plate;

A shielding layer formed on the surface of the outer glass plate;

Equipped with

The interlayer is

Adhesive layer,

A functional layer supported by the adhesive layer;

Equipped with

At least a part of the outer peripheral edge of the functional layer has an inner portion located inside the outer peripheral edge of the adhesive layer,

The laminated glass, wherein the shielding layer is disposed to cover at least an inner portion of the functional layer and an outer peripheral edge of the adhesive layer.

前記外側ガラス板と対向配置され、前記外側ガラス板と略同形状の内側ガラス板と、

前記外側ガラス板と内側ガラス板との間に配置される中間膜と、

前記外側ガラス板の表面に形成される遮蔽層と、

を備え、

前記中間膜は、

接着層と、

前記接着層に支持される機能層と、

を備え、

前記機能層の外周縁の少なくとも一部は、前記接着層の外周縁よりも内側に位置する、内側部位を有しており、

前記遮蔽層は、少なくとも、前記機能層の内側部位と前記接着層の外周縁との間を覆うように配置されている、合わせガラス。 Item 1: An outer glass plate having a first side and a second side opposite to the first side,

An inner glass plate disposed opposite to the outer glass plate and having substantially the same shape as the outer glass plate;

An interlayer disposed between the outer glass plate and the inner glass plate;

A shielding layer formed on the surface of the outer glass plate;

Equipped with

The interlayer is

Adhesive layer,

A functional layer supported by the adhesive layer;

Equipped with

At least a part of the outer peripheral edge of the functional layer has an inner portion located inside the outer peripheral edge of the adhesive layer,

The laminated glass, wherein the shielding layer is disposed to cover at least an inner portion of the functional layer and an outer peripheral edge of the adhesive layer.

項2:前記遮蔽層は、前記外側ガラス板の前記中間膜側の表面に位置している項1の合わせガラス。

Item 2: The laminated glass of Item 1, wherein the shielding layer is located on the surface on the intermediate film side of the outer glass plate.

項3:前記内側ガラス板の前記中間膜とは反対側の表面に設けられる第2遮蔽層をさらに備えている、項2に記載の合わせガラス。

Item 3: The laminated glass according to Item 2, further comprising a second shielding layer provided on the surface of the inner glass plate opposite to the intermediate film.

項4:前記遮蔽層は、前記外側ガラス板の外周縁の全周に亘って形成されている、項1から3のいずれかに記載の合わせガラス。

Item 4: The laminated glass according to any one of Items 1 to 3, wherein the shielding layer is formed over the entire periphery of the outer peripheral edge of the outer glass plate.

項5:前記遮蔽層は、前記外側ガラス板と前記中間膜との間に配置されている、項1から4のいずれかに記載の合わせガラス。

Item 5: The laminated glass according to any one of Items 1 to 4, wherein the shielding layer is disposed between the outer glass plate and the intermediate film.

項6:前記機能層の厚みが、5~200μmである、項1から5のいずれかに記載の合わせガラス。

Item 6: The laminated glass according to any one of Items 1 to 5, wherein the thickness of the functional layer is 5 to 200 μm.

項7:前記機能層は、

少なくとも一部が前記第1辺側の端部に沿って延びる第1バスバーと、

少なくとも一部が前記第2辺側の端部に沿って延びる第2バスバーと、

前記第1バスバーと第2バスバーとを連結するように配置された複数の加熱線と、

を備え、

前記第1バスバー及び第2バスバーの外周縁の一部が、前記内側部位を構成しており、

前記遮蔽層は、前記両バスバー及びその周縁近傍を覆うように形成されている、項1から6のいずれかに記載の合わせガラス。 Item 7: The functional layer is

A first bus bar, at least a portion of which extends along the end on the first side;

A second bus bar, at least a portion of which extends along an end on the second side;

A plurality of heating wires arranged to connect the first bus bar and the second bus bar;

Equipped with

A part of the outer peripheral edge of the first bus bar and the second bus bar constitutes the inner portion,

7. The laminated glass according to any one of items 1 to 6, wherein the shielding layer is formed to cover both the bus bars and the vicinity of the peripheral edge thereof.

少なくとも一部が前記第1辺側の端部に沿って延びる第1バスバーと、

少なくとも一部が前記第2辺側の端部に沿って延びる第2バスバーと、

前記第1バスバーと第2バスバーとを連結するように配置された複数の加熱線と、

を備え、

前記第1バスバー及び第2バスバーの外周縁の一部が、前記内側部位を構成しており、

前記遮蔽層は、前記両バスバー及びその周縁近傍を覆うように形成されている、項1から6のいずれかに記載の合わせガラス。 Item 7: The functional layer is

A first bus bar, at least a portion of which extends along the end on the first side;

A second bus bar, at least a portion of which extends along an end on the second side;

A plurality of heating wires arranged to connect the first bus bar and the second bus bar;

Equipped with

A part of the outer peripheral edge of the first bus bar and the second bus bar constitutes the inner portion,

7. The laminated glass according to any one of items 1 to 6, wherein the shielding layer is formed to cover both the bus bars and the vicinity of the peripheral edge thereof.

項8:前記機能層は、前記両バスバー及び加熱線を支持する支持層をさらに有しており、

前記支持層が、前記接着層と接触する、項7に記載の合わせガラス。 Item 8: The functional layer further includes a support layer that supports both the bus bars and the heating wire,

Item 8. The laminated glass according toitem 7, wherein the support layer is in contact with the adhesive layer.

前記支持層が、前記接着層と接触する、項7に記載の合わせガラス。 Item 8: The functional layer further includes a support layer that supports both the bus bars and the heating wire,

Item 8. The laminated glass according to

項9:前記両バスバーは、複数の金属層を積層することで形成されている、項7または8に記載の合わせガラス。

Item 9: The laminated glass according to item 7 or 8, wherein both bus bars are formed by laminating a plurality of metal layers.

項10:前記加熱線のピッチは、1.25~4mmである、項7から9のいずれかに記載の合わせガラス。

Item 10: The laminated glass according to any one of Items 7 to 9, wherein the pitch of the heating wire is 1.25 to 4 mm.

項11:前記加熱線の発熱量が、2.0W/m以下である、項7から10のいずれかに記載の合わせガラス。

Item 11: The laminated glass according to any one of Items 7 to 10, wherein the calorific value of the heating wire is 2.0 W / m or less.

項12:前記加熱線の厚みが、30μm以下である、項7から11のいずれかに記載の合わせガラス。

Item 12: The laminated glass according to any one of Items 7 to 11, wherein the thickness of the heating wire is 30 μm or less.

項13:前記加熱線における前記接着層側の面の幅は、1~30μmである、項7から12のいずれかに記載の合わせガラス。

Item 13: The laminated glass according to any one of Items 7 to 12, wherein the width of the surface on the adhesive layer side in the heating wire is 1 to 30 μm.

項14:前記両バスバーに印加される電圧が20V未満であり、

前記加熱線における前記接着層側の面の幅は、前記加熱線の厚み以上の長さを有しており、

前記加熱線の幅が9~20μmである、項7から13のいずれかに記載の合わせガラス。 Item 14: The voltage applied to both the bus bars is less than 20 V,

The width of the surface on the side of the adhesive layer in the heating wire has a length equal to or greater than the thickness of the heating wire,

Item 14. The laminated glass according to any one of Items 7 to 13, wherein the width of the heating wire is 9 to 20 μm.

前記加熱線における前記接着層側の面の幅は、前記加熱線の厚み以上の長さを有しており、

前記加熱線の幅が9~20μmである、項7から13のいずれかに記載の合わせガラス。 Item 14: The voltage applied to both the bus bars is less than 20 V,

The width of the surface on the side of the adhesive layer in the heating wire has a length equal to or greater than the thickness of the heating wire,

項15:前記両バスバーに印加される電圧が20~50Vであり、

前記加熱線における前記接着層側の面の幅は、前記加熱線の厚み以上の長さを有しており、

前記加熱線の幅が1~10μmである、項7から13のいずれかに記載の合わせガラス。 Item 15: The voltage applied to the both bus bars is 20 to 50 V,

The width of the surface on the side of the adhesive layer in the heating wire has a length equal to or greater than the thickness of the heating wire,

Item 14. The laminated glass according to any one of Items 7 to 13, wherein the width of the heating wire is 1 to 10 μm.

前記加熱線における前記接着層側の面の幅は、前記加熱線の厚み以上の長さを有しており、

前記加熱線の幅が1~10μmである、項7から13のいずれかに記載の合わせガラス。 Item 15: The voltage applied to the both bus bars is 20 to 50 V,

The width of the surface on the side of the adhesive layer in the heating wire has a length equal to or greater than the thickness of the heating wire,

本発明に係る合わせガラスによれば、2枚のガラス板の間に機能層を配置したものであっても、見た目の品質を向上することができる。

According to the laminated glass of the present invention, even when the functional layer is disposed between two glass plates, the quality of appearance can be improved.

以下、本発明に係る合わせガラスをウインドシールドに適用した一実施形態について、図面を参照しつつ説明する。図1は、本実施形態に係るウインドシールドの平面図、図2は図1の断面図である。図1及び図2に示すように、本実施形態に係るウインドシールドは、外側ガラス板1、内側ガラス板2、及びこれらガラス板1,2の間に配置される中間層3を備えている。また、内側ガラス板2の上端部及び下端部には、切欠き部21,22がそれぞれ形成されており、各切欠き部21,22では、中間層3から延びる接続材41,42がそれぞれ露出している。以下、各部材について説明する。

Hereinafter, an embodiment in which the laminated glass according to the present invention is applied to a windshield will be described with reference to the drawings. FIG. 1 is a plan view of a windshield according to the present embodiment, and FIG. 2 is a cross-sectional view of FIG. As shown in FIGS. 1 and 2, the windshield according to the present embodiment includes an outer glass plate 1, an inner glass plate 2, and an intermediate layer 3 disposed between the glass plates 1 and 2. Further, notches 21 and 22 are respectively formed at the upper end and the lower end of the inner glass plate 2, and the connecting members 41 and 42 extending from the intermediate layer 3 are exposed at the respective notches 21 and 22. doing. Each member will be described below.

<1.合わせガラスの概要>

<1-1.ガラス板>

各ガラス板1,2は、ともに、下辺12が上辺11よりも長い矩形状に形成されてする。すなわち、上辺11、下辺12、両側辺(左辺13,右辺14)で囲まれた台形状に形成されている。そして、上述したように、内側ガラス板2の上端部及び下端部には、円弧状の切欠き部がそれぞれ形成されている。以下では、内側ガラス板2の上端部に形成された切欠き部を第1切欠き部21、下端部に形成された切欠き部を第2切欠き部22と称することとする。また、各ガラス板1,2としては、公知のガラス板を用いることができ、熱線吸収ガラス、一般的なクリアガラスやグリーンガラス、またはUVグリーンガラスで形成することもできる。但し、これらのガラス板1、2は、自動車が使用される国の安全規格に沿った可視光線透過率を実現する必要がある。例えば、外側ガラス板1により必要な日射吸収率を確保し、内側ガラス板2により可視光線透過率が安全規格を満たすように調整することができる。以下に、クリアガラス、熱線吸収ガラス、及びソーダ石灰系ガラスの組成の一例を示す。 <1. Outline of laminated glass>

<1-1. Glass plate>

Each of theglass plates 1 and 2 is formed in a rectangular shape in which the lower side 12 is longer than the upper side 11. That is, it is formed in a trapezoidal shape surrounded by the upper side 11, the lower side 12, and both sides (left side 13 and right side 14). And as above-mentioned, the circular-arc-shaped notch part is formed in the upper end part and lower end part of the inner side glass plate 2, respectively. Hereinafter, the notch formed in the upper end of the inner glass plate 2 will be referred to as a first notch 21 and the notch formed in the lower end will be referred to as a second notch 22. Moreover, as each glass plate 1 and 2, a well-known glass plate can be used and it can also form with heat ray absorption glass, general clear glass, green glass, or UV green glass. However, these glass plates 1 and 2 need to realize visible light transmittance in accordance with the safety standard of the country where the automobile is used. For example, the required solar radiation absorptivity can be secured by the outer glass plate 1, and the visible light transmittance can be adjusted by the inner glass plate 2 so that the safety standard is satisfied. Below, an example of a composition of clear glass, heat ray absorption glass, and soda lime type glass is shown.

<1-1.ガラス板>

各ガラス板1,2は、ともに、下辺12が上辺11よりも長い矩形状に形成されてする。すなわち、上辺11、下辺12、両側辺(左辺13,右辺14)で囲まれた台形状に形成されている。そして、上述したように、内側ガラス板2の上端部及び下端部には、円弧状の切欠き部がそれぞれ形成されている。以下では、内側ガラス板2の上端部に形成された切欠き部を第1切欠き部21、下端部に形成された切欠き部を第2切欠き部22と称することとする。また、各ガラス板1,2としては、公知のガラス板を用いることができ、熱線吸収ガラス、一般的なクリアガラスやグリーンガラス、またはUVグリーンガラスで形成することもできる。但し、これらのガラス板1、2は、自動車が使用される国の安全規格に沿った可視光線透過率を実現する必要がある。例えば、外側ガラス板1により必要な日射吸収率を確保し、内側ガラス板2により可視光線透過率が安全規格を満たすように調整することができる。以下に、クリアガラス、熱線吸収ガラス、及びソーダ石灰系ガラスの組成の一例を示す。 <1. Outline of laminated glass>

<1-1. Glass plate>

Each of the

(クリアガラス)

SiO2:70~73質量%

Al2O3:0.6~2.4質量%

CaO:7~12質量%

MgO:1.0~4.5質量%

R2O:13~15質量%(Rはアルカリ金属)

Fe2O3に換算した全酸化鉄(T-Fe2O3):0.08~0.14質量% (Clear glass)

SiO 2 : 70 to 73% by mass

Al 2 O 3 : 0.6 to 2.4 mass%

CaO: 7 to 12% by mass

MgO: 1.0 to 4.5 mass%

R 2 O: 13 to 15% by mass (R is an alkali metal)

Fe total iron oxide in terms of 2 O 3 (T-Fe 2 O 3): 0.08 ~ 0.14 wt%

SiO2:70~73質量%

Al2O3:0.6~2.4質量%

CaO:7~12質量%

MgO:1.0~4.5質量%

R2O:13~15質量%(Rはアルカリ金属)

Fe2O3に換算した全酸化鉄(T-Fe2O3):0.08~0.14質量% (Clear glass)

SiO 2 : 70 to 73% by mass

Al 2 O 3 : 0.6 to 2.4 mass%

CaO: 7 to 12% by mass

MgO: 1.0 to 4.5 mass%

R 2 O: 13 to 15% by mass (R is an alkali metal)

Fe total iron oxide in terms of 2 O 3 (T-Fe 2 O 3): 0.08 ~ 0.14 wt%

(熱線吸収ガラス)

熱線吸収ガラスの組成は、例えば、クリアガラスの組成を基準として、Fe2O3に換算した全酸化鉄(T-Fe2O3)の比率を0.4~1.3質量%とし、CeO2の比率を0~2質量%とし、TiO2の比率を0~0.5質量%とし、ガラスの骨格成分(主に、SiO2やAl2O3)をT-Fe2O3、CeO2およびTiO2の増加分だけ減じた組成とすることができる。 (Heat absorbing glass)