WO2019039149A1 - Air-conditioning control device - Google Patents

Air-conditioning control device Download PDFInfo

- Publication number

- WO2019039149A1 WO2019039149A1 PCT/JP2018/027163 JP2018027163W WO2019039149A1 WO 2019039149 A1 WO2019039149 A1 WO 2019039149A1 JP 2018027163 W JP2018027163 W JP 2018027163W WO 2019039149 A1 WO2019039149 A1 WO 2019039149A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- condensation

- dust

- dust concentration

- air conditioning

- dust sensor

- Prior art date

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60H—ARRANGEMENTS OF HEATING, COOLING, VENTILATING OR OTHER AIR-TREATING DEVICES SPECIALLY ADAPTED FOR PASSENGER OR GOODS SPACES OF VEHICLES

- B60H1/00—Heating, cooling or ventilating [HVAC] devices

- B60H1/24—Devices purely for ventilating or where the heating or cooling is irrelevant

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F11/00—Control or safety arrangements

- F24F11/89—Arrangement or mounting of control or safety devices

Definitions

- the present disclosure relates to an air conditioning control device used in an air conditioning unit.

- Patent Document 1 describes a ventilator having a dust sensor.

- the dust sensor has a light receiving unit and a light emitting unit, and detects suspended particles by reflection of light.

- a dust sensor and a sensor storage unit for storing the dust sensor are provided inside a housing of the ventilation device.

- the sensor storage unit is provided facing the air passage inside the housing. Further, a shutter that can be opened and closed is provided at the boundary between the air passage and the sensor storage unit.

- the shutter is normally closed and opened only when the dust sensor detects it.

- Patent Document 1 it is supposed that the time for which the dust sensor is exposed to the air in the air passage can be shortened and the dirt of the lens of the dust sensor can be alleviated.

- Patent Document 1 As described in Patent Document 1, if condensation occurs on the dust sensor, the dust sensor may cause erroneous detection. And if the shutter of patent document 1 is used, it is thought that dew condensation of a dust sensor can be suppressed. However, Patent Document 1 has not described how to avoid an inappropriate situation caused by dew condensation on a dust sensor when condensation occurs. As a result of the inventors' detailed studies, the above was found.

- the present disclosure aims to provide an air conditioning control device capable of avoiding an inappropriate situation caused by dew condensation of a dust sensor when dew condensation occurs.

- an air conditioning control device includes: Used in an air conditioning unit that has an air conditioning case in which a ventilating passage through which air is blown into the vehicle compartment is formed, and a dust sensor that detects the dust concentration in the ventilating passage when the light receiving unit receives light emitted from the light emitting unit.

- Air conditioning control device A dew condensation determination unit that determines whether dew condensation has occurred on the dust sensor; When it is determined by the condensation determination unit that condensation has occurred on the dust sensor, the dust concentration value detected during condensation that is treated as the concentration of dust during condensation is the dust concentration detected by the dust sensor before condensation occurs on the dust sensor And a value determination unit that determines based on the detection value before condensation which is the detection value of.

- the dust concentration is grasped as a size that is far from the actual value due to an inappropriate situation caused by the condensation, for example, an erroneous detection of the dust sensor. This can be avoided by using the dust concentration value during condensation.

- the air conditioning control device Used in an air conditioning unit that has an air conditioning case in which a ventilating passage through which air is blown into the vehicle compartment is formed, and a dust sensor that detects the dust concentration in the ventilating passage when the light receiving unit receives light emitted from the light emitting unit.

- Air conditioning control device A dew condensation determination unit that determines whether dew condensation has occurred on the dust sensor; A factor determination unit that determines whether or not a predetermined dust concentration increase factor that causes the dust concentration in the vehicle compartment to increase when it is determined by the condensation determination unit that condensation has occurred on the dust sensor; And a control execution unit that executes dust concentration reduction control when it is determined by the factor determination unit that a dust concentration increase factor has occurred.

- the dust concentration reduction control is control for operating the air conditioning unit such that the dust concentration in the vehicle compartment is reduced as compared to before the start of the dust concentration reduction control.

- FIG. 1 It is the block diagram which showed typically schematic structure with an air-conditioning unit and an air-conditioning control apparatus in 1st Embodiment. It is explanatory drawing for demonstrating easily the principle in which the dust sensor of FIG. 1 detects dust concentration. It is sectional drawing which showed typically schematic structure of the dust sensor of FIG. FIG. 2 is a block diagram simply showing an electrical configuration until the dust sensor of FIG. 1 detects a dust concentration and outputs a signal representing the dust concentration. In 1st Embodiment, it is the flowchart which showed the control processing which an air-conditioning control apparatus performs. FIG.

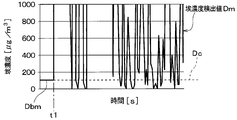

- FIG. 6 is a diagram exemplifying a waveform of a dust concentration detection value with an elapsed time taken as a horizontal axis in order to explain the control processing of FIG. 5 in the first embodiment.

- FIG. 6 is a view exemplifying a waveform of the dust concentration detection value when the change ratio of the dust concentration detection value with respect to the elapsed time suddenly changes to a side where the change processing of the dust concentration detection value increases with time in order to explain the control process of FIG.

- FIG. 6 is a view exemplifying a waveform of the dust concentration detection value when the change ratio of the dust concentration detection value with respect to the elapsed time suddenly changes to a smaller side in order to explain the control process of FIG. 5 in the first embodiment.

- FIG. 11 it is a diagram illustrating the waveform of the dust concentration detection value with the elapsed time as the horizontal axis, and an enlarged view of the same portion as the portion shown in FIG. It is.

- FIG. 14 is a diagram showing an addition amount map used to determine the addition amount based on the rate of increase of the dust concentration detection value before the occurrence of condensation in the second embodiment.

- FIG. 15 is a flowchart showing control processing executed by the air conditioning control device in the fourth embodiment, which corresponds to FIG. 14. It is the block diagram which showed the structure of the display apparatus in 4th Embodiment.

- 5th Embodiment it is the flowchart which showed the control processing which an air-conditioning control apparatus performs, Comprising: It is a figure corresponded in FIG.

- 6th Embodiment it is the flowchart which showed the control processing which an air-conditioning control apparatus performs, Comprising: It is a figure corresponded in FIG.

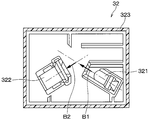

- the vehicle air conditioner 1 includes an air conditioning unit 2 and an air conditioning control device 40 used in the air conditioning unit 2.

- the air conditioning unit 2 is a vehicle air conditioning unit installed in a vehicle compartment and performing air conditioning of the vehicle interior.

- the air conditioning unit 2 is installed in an instrument panel disposed forward of the vehicle in the vehicle compartment.

- Arrows DR1 and DR2 in FIG. 1 indicate the direction of the vehicle on which the air conditioning unit 2 is mounted. That is, the arrow DR1 in FIG. 1 indicates the vehicle longitudinal direction DR1, and the arrow DR2 indicates the vehicle vertical direction DR2.

- These directions DR1 and DR2 are directions crossing each other, strictly speaking, directions perpendicular to each other.

- the air conditioning unit 2 includes an air conditioning case 21, an inside / outside air switching door 22, a blower 23, an evaporator 26, a heater core 27, an air mix door 28, an air filter 30, an outlet door 254, 255, 256, And a dust sensor 32 and the like.

- the air conditioning case 21 has a certain degree of elasticity and is formed of a resin excellent in strength.

- the resin that forms the air conditioning case 21 include polypropylene.

- the air conditioning case 21 forms an outer shell of the air conditioning unit 2, and an air passage, that is, an air passage 24 through which the air blown into the vehicle compartment flows is formed inside the air conditioning case 21. Further, the air conditioning case 21 introduces outside air into the air flow path 24 from the outside of the vehicle, inside air introduction port 241 for introducing the inside air into the air flow path 24 from a predetermined location in the vehicle room on the air flow direction upstream side of the air flow path 24 And an external air inlet 242 for Here, the inside air is the air inside the vehicle cabin, and the outside air is the air outside the vehicle cabin.

- the air conditioning case 21 has a plurality of outlet openings 251, 252, 253 for blowing air from the air passage 24 to the front seat area of the vehicle compartment on the downstream side of the air passage 24 in the air flow direction.

- the plurality of blowout openings 251, 252, 253 include a face blowout opening 251, a foot blowout opening 252, and a defroster blowout opening 253.

- the face blowout opening 251 is an opening that blows conditioned air toward the upper body of the occupant seated in the front seat.

- the foot blowing opening 252 is an opening that blows the conditioned air toward the feet of the occupant.

- the defroster blowout opening 253 is an opening that blows conditioned air toward the front window of the vehicle.

- an inside / outside air switching door 22 Inside the air conditioning case 21, an inside / outside air switching door 22, a blower 23, an evaporator 26, a heater core 27, an air mix door 28, an air filter 30, and the like are provided.

- the inside / outside air switching door 22 continuously adjusts the opening area of the inside air introduction port 241 and the opening area of the outside air introduction port 242.

- the inside / outside air switching door 22 is driven by an actuator such as a servomotor (not shown).

- the inside / outside air switching door 22 rotates so as to close one of the inside air introduction port 241 and the outside air introduction port 242 as the other introduction port is opened.

- the inside / outside air switching door 22 can adjust the ratio between the air volume of the inside air introduced into the air passage 24 and the air volume of the outside air.

- the inside / outside air switching door 22 is positioned at an operation position where the inside air introduction port 241 is opened and the outside air introduction port 242 is closed.

- the inside / outside air switching door 22 is positioned at an operation position in which the outside air introduction port 242 is opened while the inside air introduction port 241 is closed.

- the blower 23 is a centrifugal blower, and includes a centrifugal fan 231 disposed in the air passage 24 and a motor (not shown) that rotationally drives the centrifugal fan 231.

- a centrifugal fan 231 of the blower 23 When the centrifugal fan 231 of the blower 23 is rotationally driven, an air flow is formed in the air passage 24.

- the air introduced into the ventilation path 24 from the inside air introduction port 241 or the outside air introduction port 242 flows through the ventilation path 24, and any of the face outlet 251, the foot outlet 252 and the defroster outlet 253. It is blown out from the heel.

- the face blowout opening door 254 is provided in the face blowout opening 251 and adjusts the opening area of the face blowout opening 251.

- the foot blowout opening door 255 is provided in the foot blowout opening 252 and adjusts the opening area of the foot blowout opening 252.

- the defroster blowout opening door 256 is provided in the defroster blowout opening 253 and adjusts the opening area of the defroster blowout opening 253.

- the evaporator 26 is a heat exchanger for cooling the air flowing through the air passage 24.

- the evaporator 26 exchanges heat between the air passing through the evaporator 26 and the refrigerant, thereby cooling the air and evaporating the refrigerant.

- the heater core 27 is a heat exchanger for heating the air flowing through the air passage 24.

- the heater core 27 exchanges heat between, for example, the engine cooling water and the air passing through the heater core 27, and heats the air with the heat of the engine cooling water.

- the heater core 27 is disposed downstream of the evaporator 26 in the air flow direction.

- the air passage 24 of the air conditioning case 21 is formed in parallel to the heater core 27 and includes a bypass passage 24 a for bypassing the heater core 27 to allow air to flow.

- An air mix door 28 is provided between the evaporator 26 and the heater core 27 of the air conditioning unit 2.

- the air mix door 28 adjusts the ratio of the air volume passing through the evaporator 26 and bypassing the heater core 27 (that is, the air volume flowing through the bypass passage 24 a) and the air volume passing through the heater core 27 after passing through the evaporator 26 .

- the air filter 30 is disposed between the blower 23 and the evaporator 26 in the air passage 24 of the air conditioning case 21. In other words, the air filter 30 is disposed downstream of the blower 23 in the air flow direction and upstream of the evaporator 26 in the air flow direction.

- the air filter 30 captures dust and the like contained in the air passing through the air filter 30. Therefore, the air blown out from the blower 23 flows into the evaporator 26 after dust and the like in the air are removed to some extent by the air filter 30.

- the air conditioning control device 40 can operate the air conditioning unit 2 so as to reduce the dust concentration in the vehicle compartment. In the case of such operation, the air conditioning control device 40 operates the blower 23 after, for example, setting the air conditioning unit 2 to the inside air mode. And, the larger the air flow rate of the blower 23, the higher the dust removal ability of the air conditioning unit 2 for removing the dust in the passenger compartment.

- the dust sensor 32 is a detection device that detects the dust concentration at a predetermined sensing location. Then, the dust sensor 32 outputs a detection signal indicating the dust concentration to the air conditioning control device 40.

- the dust concentration is also referred to as dust concentration, and more specifically, is the mass concentration of dust contained in the air, and the unit of dust concentration is, for example, " ⁇ g / m 3 ". In short, the dust concentration is the mass of dust contained in a unit volume of air.

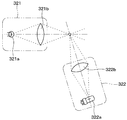

- the dust sensor 32 of the present embodiment is an optical dust sensor configured to detect dust concentration by a light scattering method. That is, as shown in FIG. 2 and FIG. 3, the dust sensor 32 accommodates the light emitting unit 321 that emits light, the light receiving unit 322 that receives the light emitted by the light emitting unit 321, and the light emitting unit 321 and the light receiving unit 322. And a sensor case 323. The dust sensor 32 detects the dust concentration of the air passage 24 by the light receiving portion 322 receiving the light emitted from the light emitting portion 321.

- the dust sensor 32 is disposed downstream of the centrifugal fan 231 of the blower 23 in the air flow direction and upstream of the air filter 30 in the air flow direction. Therefore, air is introduced into the sensor case 323 from between the centrifugal fan 231 and the air filter 30 in the air passage 24. That is, in the present embodiment, a portion between the centrifugal fan 231 and the air filter 30 in the ventilation path 24 is a sensing portion of the dust sensor 32.

- the light emitting portion 321 of the dust sensor 32 has a light emitting element 321 a formed of, for example, a light emitting diode, and an irradiation light lens 321 b.

- the light receiving section 322 has a light receiving element 322a configured by, for example, a photodiode, and a condensing lens 322b.

- the light emitted from the light emitting element 321a as shown by the arrow B1 in FIG. 3 and passing through the irradiation light lens 321b is reflected by the dust in the air introduced into the sensor case 323, and the reflected light is as shown by the arrow B2.

- the light is received by the light receiving element 322a through the condenser lens 322b.

- the light receiving element 322a generates a current by receiving light.

- the dust sensor 32 has a sensor circuit 324.

- the sensor circuit 324 amplifies the current of the light receiving element 322a and outputs it as a voltage output through an amplifier. The voltage output is converted to dust concentration.

- the dust sensor 32 detects the dust concentration in the air passage 24 in this manner.

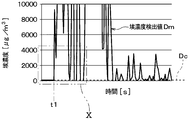

- the vertical axis of the graph GF in FIG. 4 represents the dust concentration converted from the voltage value, that is, the density conversion value, and the horizontal axis of the graph GF represents the elapsed time.

- the air conditioning control device 40 illustrated in FIG. 1 is a control device that controls the air conditioning unit 2.

- the air-conditioning control apparatus 40 is an electronic control apparatus including a storage unit configured by a non-transitional tangible storage medium such as a semiconductor memory and a processor.

- the air conditioning control device 40 executes a computer program stored in the storage unit.

- the computer program is executed to execute a method corresponding to the computer program. That is, according to the computer program, the air conditioning control device 40 executes various control processes such as the control process of FIG. 5 described later.

- the air conditioning control device 40 controls the operation of each actuator by outputting a control signal to each actuator included in the air conditioning unit 2.

- the air conditioning control device 40 performs various air conditioning control in the air conditioning unit 2.

- the air conditioner control device 40 drives and controls the blower 23, the inside / outside air switching door 22, the air mix door 28, the face outlet door 254, the foot outlet door 255, and the defroster outlet door 256 described above. .

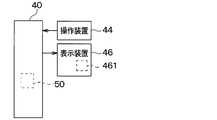

- an operation device 44 and a display device 46 are electrically connected to the air conditioning control device 40, for example.

- the operating device 44 is an operating unit operated by the occupant when adjusting the air volume, temperature, and the like of the conditioned air blown out from the air conditioning unit 2.

- the operating device 44 is disposed, for example, on an instrument panel of a vehicle.

- the air volume of the conditioned air, the target room temperature in the vehicle compartment, the outlet of the conditioned air, and the like can be set.

- the operating device 44 outputs, to the air conditioning control device 40, information indicating these settings, that is, operation information indicating an occupant operation performed on the operating device 44.

- the air conditioning control device 40 inputs the air flow of the blower 23 and the operation of the respective doors 22, 28, 254, 255, 256 from a plurality of sensors. Adjust or control automatically based on the signal.

- the display device 46 is a display unit that displays various information of the air conditioning unit 2. That is, a signal indicating various information of the air conditioning unit 2 is input from the air conditioning control device 40 to the display device 46, and the display device 46 performs display according to the input signal from the air conditioning control device 40.

- the display device 46 is disposed, for example, at a position where a passenger in the vehicle compartment can easily view, such as an instrument panel of a vehicle.

- the display device 46 may be included in the display device of another car-mounted device such as a car navigation device, or may be configured exclusively for the air conditioning unit 2.

- the air conditioning control device 40 functionally includes a dust sensor control unit 50 that performs control related to the dust sensor 32.

- the dust sensor control unit 50 executes, for example, the control process of FIG.

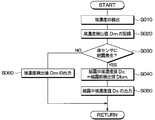

- FIG. 5 is a flowchart showing control processing executed by the dust sensor control unit 50.

- the dust sensor control unit 50 periodically and repeatedly executes the flowchart of FIG. 5 while the air conditioning unit 2 is operating, for example. As described above, being repeatedly and periodically executed during operation of the air conditioning unit 2 is the same as in the flowcharts of FIGS. 11, 14, 15, 17, and 18 described later.

- step S010 the dust sensor control unit 50 acquires the detection value Dm of the dust concentration detected by the dust sensor 32, that is, the dust concentration detection value Dm based on the detection signal from the dust sensor 32. . In short, the dust sensor control unit 50 performs the detection of the dust concentration in accordance with the detection signal from the dust sensor 32. After step S010, the process proceeds to step S020.

- step S020 the dust sensor control unit 50 records the dust concentration detection value Dm obtained in step S010.

- the dust concentration detection value Dm is stored, for example, in a storage unit configured of a semiconductor memory or the like. By repeatedly executing this step S020, it is possible to obtain a time change of the dust concentration detection value Dm as shown in FIG.

- the horizontal axis in FIG. 6 indicates the elapsed time, and the vertical axis in FIG. 6 indicates the dust concentration.

- step S030 the process proceeds to step S030.

- step S030 the dust sensor control unit 50 determines whether condensation occurs in the dust sensor 32 or not. For example, as shown in FIGS. 7 and 8, when the change rate of the dust concentration detection value Dm with respect to the elapsed time, that is, the slope of the dust concentration detection value Dm suddenly changes beyond a predetermined limit, condensation occurs in the dust sensor 32 It is determined that When dew condensation occurs on the dust sensor 32, the light emitted from the light emitting unit 321 is also reflected to the dew condensation water in the sensor case 323. That is, in step S030, it is determined whether the dust concentration detection value Dm is affected by condensation of the dust sensor 32. If the dust concentration detection value Dm is affected by condensation, the dust sensor 32 is detected.

- the time t1 is the dew condensation start time when dew condensation of the dust sensor 32 has started.

- the condensation elimination time point t2 at which the condensation of the dust sensor 32 is eliminated is recognized based on the elapsed time from the condensation start time point t1. Specifically, as shown in FIG. 6, when the elapsed time from the condensation start time t1 reaches the condensation continuation time Td experimentally set in advance, the dust sensor control unit 50 causes the condensation of the dust sensor 32 to Is determined to be eliminated. In short, the point at which the dew condensation continuation time Td has elapsed from the dew condensation start time t1 is recognized as the dew condensation elimination time t2.

- step S030 if condensation is determined to occur in the dust sensor 32 from the change in the gradient of the dust concentration detection value Dm, the condensation continuation time Td elapses from the condensation start time t1 regardless of the dust concentration detection value Dm. Until then, the determination that the dew sensor 32 has generated condensation is continued.

- step S030 If it is determined in step S030 that dew condensation has occurred on the dust sensor 32, the process proceeds to step S040. For example, in the period from the dew condensation start time t1 to the dew condensation elimination time t2 in FIG. 6, the process proceeds from step S030 to step S040.

- step S030 when it is determined in step S030 that condensation does not occur on the dust sensor 32, the process proceeds to step S060. For example, before the condensation start time t1 and after the condensation elimination time t2 in FIG. 6, the process proceeds from step S030 to step S060.

- the dust sensor control unit 50 determines the in-condensing dust concentration value Dc to be treated as the dust concentration in the occurrence of condensation based on the pre-condensation detection value Dbm.

- the pre-condensation detected value Dbm is a detected value Dm of the dust concentration detected by the dust sensor 32 before condensation occurs (that is, immediately before the condensation start time t1). Specifically, since the detection of the dust concentration by the dust sensor 32 is periodically and repeatedly performed in step S010 of FIG. 5, the pre-condensation detected value Dbm is the previous detection with respect to the condensation start time t1 of the dust sensor 32. It is the obtained dust concentration detection value Dm. In short, the pre-condensation detected value Dbm is the latest dust concentration detected value Dm among the dust concentration detected values Dm sequentially obtained before the condensation start time t1.

- the dew condensation dust concentration value Dc is determined based on the pre-condensation detection value Dbm, the dew condensation dust concentration value Dc is determined regardless of the dust concentration detection value Dm obtained during condensation occurrence. .

- the dust sensor control unit 50 determines the in-condensation dust concentration value Dc so that the in-condensation dust concentration value Dc becomes the pre-condensation detection value Dbm.

- the dust concentration value during condensation Dc is made the same value as the detection value before condensation Dbm.

- the dust sensor control unit 50 determines the dust concentration value during condensation Dc based on the pre-condensation detection value Dbm.

- step S ⁇ b> 050 the dust sensor control unit 50 outputs the dust concentration value during condensation Dc determined in step S ⁇ b> 040 as the dust concentration of the air passage 24 which is the sensing location of the dust sensor 32.

- the dew condensation dust concentration value Dc is output to the control unit other than the dust sensor control unit 50 in the air conditioning control device 40, for example, a control unit that controls a plurality of doors of the air conditioning unit 2 and the blower 23.

- the dust concentration in the air passage 24 can be obtained during the dew condensation occurrence in the air conditioning control device 40 by executing this step S050.

- the dust concentration detection value Dm it is recognized that the dust concentration value during condensation is Dc.

- step S060 the dust sensor control unit 50 outputs the dust concentration detection value Dm obtained in step S010 as it is as the dust concentration of the air passage 24.

- the flowchart of FIG. 5 starts again from step S010 when step S050 or step S060 is completed.

- Step S030 in FIG. 2 corresponds to the condensation determination unit

- step S040 corresponds to the value determination unit.

- the dust sensor control unit 50 included in the air conditioning control device 40 functionally includes the condensation determination unit and the value determination unit.

- the dust sensor control unit 50 included in the air conditioning control device 40 determines whether condensation occurs in the dust sensor 32. Then, as shown in FIG. 6 and FIG. 10, when the dust sensor control unit 50 determines that dew condensation has occurred in the dust sensor 32, the dust concentration value Dc during condensation treated as the dust concentration in the dew condensation occurrence is , And is determined based on the detection value before condensation Dbm.

- the dust concentration at the sensing location is grasped as a size far from the actual value due to an inappropriate situation caused by the dew condensation, for example, erroneous detection of the dust sensor 32. Can be avoided by using the dust concentration value Dc during condensation.

- the dust concentration close to the actual value during condensation is regarded as the dust concentration value Dc during condensation while avoiding the influence of erroneous detection of the dust sensor 32 caused by the condensation. It is possible to get.

- the dust removal capability for removing the dust in the vehicle interior by the air conditioning unit 2 is dust concentration It is possible to avoid a shortage due to false detection.

- the dust sensor control unit 50 determines the dew condensation dust concentration value Dc so that the dew condensation dust concentration value Dc becomes the pre-condensation detection value Dbm. . Therefore, it is possible to easily determine the in-condensation dust concentration value Dc so that the in-condensation dust concentration value Dc does not become a value far from the actual value of the dust concentration at the sensing location.

- the dust sensor control unit 50 determines whether condensation occurs in the dust sensor 32 or not. For example, as shown in FIGS. 7 and 8, the dust sensor control unit 50 determines that condensation occurs in the dust sensor 32 when the change ratio of the dust concentration detection value Dm with respect to the elapsed time changes beyond a predetermined limit. judge. Therefore, there is an advantage that no special device is required to determine the occurrence of condensation of the dust sensor 32.

- control processing executed by the air conditioning control device 40 is different from that of the first embodiment. Specifically, steps S031 and S041 of the flowchart of FIG. 11 are added to the flowchart of FIG. In the flowchart of FIG. 11, steps S010, S020, S030, S040, S050, and S060, which are the other steps, are the same as the flowchart of FIG.

- the control process of FIG. 11 is also executed by the dust sensor control unit 50 included in the air conditioning control device 40, similarly to the control process of FIG. 5 described above.

- step S031 the dust sensor control unit 50 determines whether the dust concentration detection value Dm has risen before the occurrence of condensation of the dust sensor 32 (that is, before the condensation start time t1 in FIG. 12). In other words, it is determined whether the dust concentration detection value Dm before the occurrence of the condensation tends to increase. For example, in the waveform of the dust concentration detection value Dm in FIG. 12, as shown in the A1 portion, the dust concentration detection value Dm rises before the condensation start time t1. In this case, the dust sensor control unit 50 It is determined that the concentration detection value Dm has risen before the occurrence of condensation of the dust sensor 32.

- the dew condensation start time t1 is the end time of the predetermined rise determination period, and in the transition of the dust concentration detection value Dm in the rise determination period up to the dew condensation start time t1, the gradient of the dust concentration detection value Dm with respect to the elapsed time Is calculated by a known method.

- the dust concentration detection value Dm is rising before the condensation start time t1. Is determined.

- step S031 in FIG. 11 If it is determined in step S031 in FIG. 11 that the dust concentration detection value Dm has risen before dew condensation occurs in the dust sensor 32, the process proceeds to step S041. On the other hand, when it is determined that the dust concentration detection value Dm has not risen before the occurrence of condensation of the dust sensor 32, the process proceeds to step S040.

- the case where the dust concentration detection value Dm is not rising means the case where the dust concentration detection value Dm is falling or the dust concentration detection value Dm is not changing.

- step S041 the dust sensor control unit 50 determines the in-condensing dust concentration value Dc so that the in-condensing dust concentration value Dc has a value larger than the pre-condensation detection value Dbm.

- the dust sensor control unit 50 of the present embodiment determines the dust concentration value Dc during condensation as such, specifically, based on the increase rate of the dust concentration detection value Dm within the increase determination period, as shown in FIG.

- the amount of addition Dx is determined using 13 addition amount maps.

- the dust sensor control unit 50 sets a value obtained by adding the determined predetermined addition amount Dx to the pre-condensation detection value Dbm as a dust concentration value Dc during condensation.

- the horizontal axis indicates the rate of increase of the dust concentration detection value Dm before dew condensation occurs in the dust sensor 32, that is, the rate of increase of the dust concentration detection value Dm within the increase determination period, and the vertical axis indicates the rate of increase

- An addition amount Dx is shown.

- the added amount Dx is set larger as the rate of increase of the dust concentration detection value Dm before the occurrence of dew condensation of the dust sensor 32 is larger. If the rate of increase of the dust concentration detection value Dm is larger than zero, the addition amount Dx is always larger than zero.

- step S040 in FIG. 11 the dust concentration value during condensation Dc is set to the same value as the pre-condensation detection value Dbm, as in step S040 in FIG. 5 of the first embodiment. Therefore, in step S040, the dust sensor control unit 50 determines that the dust concentration value Dc during condensation is smaller than in the case where it is determined in step S031 that the dust concentration detection value Dm is rising before condensation occurs in the dust sensor 32.

- the dust concentration value Dc during dew condensation is determined so as to The case where it is determined in step S031 that the dust concentration detection value Dm is rising before the occurrence of condensation of the dust sensor 32 is, in other words, the case where the dust concentration value during condensation Dc is determined in step S041.

- step S040 the process proceeds to step S050.

- the dust sensor control unit 50 controls the dust concentration value Dc during condensation determined in step S040 or S041 in the dust of the air passage 24 which is the sensing location of the dust sensor 32, as in the first embodiment. Output as concentration.

- step S010 The flowchart of FIG. 11 is started again from step S010 when step S050 or step S060 ends.

- Steps S040 and S041 in FIG. 11 correspond to the value determination unit, and step S031 corresponds to the dust concentration increase determination unit.

- the dust sensor control unit 50 included in the air conditioning control device 40 functionally includes a value determination unit and a dust concentration increase determination unit in addition to the condensation determination unit similar to the first embodiment.

- the present embodiment is the same as the first embodiment except for the above description. And in this embodiment, the effect show

- the dust sensor control unit 50 determines that condensation is generated in the dust sensor 32, and the dust concentration detection value Dm is before condensation generation of the dust sensor 32. If it is determined that the temperature is rising, the in-condensing dust concentration value Dc is determined so as to make the in-condensing dust concentration value Dc larger than the pre-condensation detection value Dbm. Therefore, it is possible to determine the dew condensation dust concentration value Dc so as to increase the accuracy of the dew condensation dust concentration value Dc with respect to the actual value of the dust concentration at the sensing location.

- the dust sensor control unit 50 determines that condensation has occurred in the dust sensor 32, it is assumed that the dust concentration detection value Dm has not risen before the occurrence of condensation of the dust sensor 32. If it is determined, the in-condensing dust concentration value Dc is determined so as to make the in-condensing dust concentration value Dc smaller than in the case where it is determined that the dust concentration detection value Dm is rising before the occurrence of condensation. Therefore, depending on whether the dust concentration detection value Dm has risen before the occurrence of condensation of the dust sensor, it is possible to appropriately make a difference in the magnitude of the dust concentration value during condensation Dc.

- the dew condensation dust concentration value Dc may be determined so that the dew condensation dust concentration value Dc does not easily fall below the actual value of the dust concentration. it can.

- the dust sensor control unit 50 sets the dust concentration value during condensation so that the dust concentration value during condensation Dc becomes a value larger than the detection value before condensation Dbm. Determine Dc.

- the dust sensor control unit 50 adds a predetermined addition amount Dx to the detection value before condensation Dbm to obtain a dust concentration value Dc during condensation. I assume. Then, as shown in FIG. 13, as the rate of increase of the dust concentration detection value Dm before the occurrence of condensation of the dust sensor 32 increases, the addition amount Dx for calculating the dust concentration value during condensation Dc is set larger. Therefore, it is possible to increase the accuracy of the in-condensing dust concentration value Dc with respect to the actual value of the dust concentration at the sensing location, as compared to the case where the added amount Dx is constant, for example.

- control processing executed by the air conditioning control device 40 is different from that of the first embodiment. Specifically, steps S072, S082, S092, and S102 of the flowchart of FIG. 14 are added to the flowchart of FIG.

- the flowchart of FIG. 14 does not include steps S020, S040, and S050 of FIG. Steps S010, S030, and S060 in FIG. 14 are the same as those in the flowchart in FIG.

- control process of FIG. 14 is executed by the air conditioning control device 40. More specifically, steps S010, S030 and S060 of FIG. 14 are executed by the dust sensor control unit 50 included in the air conditioning control device 40. Be done.

- step S030 If it is determined in step S030 that dew condensation has occurred on the dust sensor 32, the process proceeds to step S072. On the other hand, when it is determined in step S030 that condensation does not occur in the dust sensor 32, the flowchart of FIG. 14 is ended and the process is started again from step S010.

- step S072 the air-conditioning control device 40 determines whether an instruction to reduce the dust concentration in the vehicle compartment has been issued from the occupant (ie, the user). That is, the air conditioning control device 40 determines whether the execution of the dust concentration reduction control is instructed by the manual operation of the occupant.

- the dust concentration reduction control is control for operating the air conditioning unit 2 so that the dust concentration in the vehicle compartment is reduced as compared to before the start of the dust concentration reduction control.

- the air conditioning unit 2 is set to the inside air mode, and the air flow of the blower 23 is This is the maximum air flow rate within the variable range of the air flow rate.

- the operating device 44 of FIG. 1 includes, for example, a dust removing switch manually operated by the occupant.

- the occupant can instruct the execution of the dust concentration reduction control by turning on the dust removal switch manually.

- step S072 in FIG. 14 If it is determined in step S072 in FIG. 14 that the execution of the dust concentration reduction control has been instructed, for example, if the on operation for turning on the dust removal switch is performed, the process proceeds to step S092. On the other hand, if it is determined that execution of dust concentration reduction control is not instructed, for example, if the dust removal switch is not turned on, the process proceeds to step S082.

- the air conditioning control device 40 determines whether or not a predetermined dust concentration increase factor has occurred. Specifically, it is determined whether the dust concentration increase factor has occurred after the condensation start time t1 of FIG.

- the dust concentration rise factor is a situation that causes the dust concentration in the vehicle compartment to rise, and is predetermined. As an example of the dust concentration rising factor, it can be mentioned that any door of the vehicle is opened and that any window glass of the vehicle is opened. This is because dust may easily intrude from the outside of the vehicle compartment into the vehicle compartment if any of these things occur.

- the opening and closing of the above-described vehicle door can be recognized based on a signal from a door sensor that detects the opening and closing of the door. Further, the opening and closing of the window glass of the vehicle can be recognized based on the operation information of the power window switch operated by the occupant in order to open and close the window glass.

- step S082 If it is determined in step S082 that a dust concentration increase cause has occurred, the process proceeds to step S092. On the other hand, when it is determined that the dust concentration increase cause is not generated, the flowchart of FIG. 14 is ended and the process is started again from step S010.

- step S092 the air conditioning control device 40 carries out the dust concentration reduction control to reduce the dust concentration in the vehicle compartment.

- This dust concentration reduction control is performed regardless of the magnitude of the dust concentration detection value Dm, as can be understood from the implementation in accordance with the determination results of the above steps S030, S072, and S082.

- the dust concentration reduction control is performed to forcibly remove dust in the vehicle interior.

- step S102 the air conditioning control device 40 determines whether the dew condensation of the dust sensor 32 has been eliminated. This determination is performed in the same manner as the determination of condensation elimination of the dust sensor 32 in step S030. Then, if the dew condensation of the dust sensor 32 is eliminated, the air conditioning control device 40 determines whether or not a predetermined time has elapsed from the condensation elimination time at which the condensation of the dust sensor 32 is eliminated. The predetermined time is set experimentally in advance to a time that is sufficient to prevent the dust concentration reduction control in step S092 from ending before condensation is eliminated.

- step S102 If it is determined in step S102 that the dew condensation of the dust sensor 32 has not been eliminated yet, or if it is determined that the predetermined time has not yet elapsed from the condensation clearing of the dust sensor 32, the process returns to step S092. . That is, in this case, the execution of the dust concentration reduction control is continued in step S092.

- step S102 when it is determined in step S102 that the predetermined time has elapsed from the time when the condensation of the dust sensor 32 is eliminated, the flowchart of FIG. 14 is ended and the process is started again from step S010. That is, in this case, the dust concentration reduction control ends.

- Step S082 in FIG. 14 corresponds to the factor determination unit, and steps S092 and S102 correspond to the control execution unit.

- the air-conditioning control apparatus 40 is functionally provided with the factor determination part and control implementation part other than the condensation determination part similar to 1st Embodiment.

- the present embodiment is the same as the first embodiment except for the above description. And in this embodiment, the effect show

- the air conditioning control device 40 determines that dew condensation has occurred in the dust sensor 32

- the air conditioning control device 40 causes the dust concentration in the vehicle interior to increase. It is determined whether a dust concentration increase factor has occurred. Then, when it is determined that the dust concentration increase factor has occurred, the air conditioning control device 40 performs dust concentration reduction control.

- the dust concentration reduction control is control for operating the air conditioning unit 2 so that the dust concentration in the vehicle compartment is reduced as compared to before the start of the dust concentration reduction control. Therefore, when dew condensation occurs on the dust sensor 32, an inappropriate situation caused by the dew condensation of the dust sensor 32, for example, an incorrect detection of the dust sensor 32, can not accurately grasp the dust concentration, and the dust concentration in the vehicle cabin increases. It is possible to avoid the situation of the problem by implementing the dust concentration reduction control.

- the dust concentration reduction control is performed even when the air conditioning control device 40 instructs the execution of the dust concentration reduction control by the manual operation of the occupant. Therefore, the occupant can reduce the dust concentration in the vehicle compartment by the air conditioning unit 2 at any timing.

- control processing executed by the air conditioning control device 40 is different from that of the third embodiment. Specifically, steps S043, S053, S063 and S073 of the flowchart of FIG. 15 are added to the flowchart of FIG. Steps S010, S030, S060, S072, S082, S092, and S102 in FIG. 15 are the same as those in the flowchart of FIG.

- control process of FIG. Steps S010, S030, and S060 in FIG. 15 are executed by the dust sensor control unit 50 included in the air conditioning control device 40.

- step S030 If it is determined in step S030 that dew condensation has occurred on the dust sensor 32, the process proceeds to step S043. On the other hand, when it is determined in step S030 that condensation does not occur in the dust sensor 32, the process proceeds to step S063.

- step S ⁇ b> 043 the air conditioning control device 40 determines whether it is possible to notify the occupant of dew condensation occurrence of the dust sensor 32 by the dew condensation indicator 461 of FIG. 16.

- the dew condensation indicator 461 is a notification device for notifying the occupant of the dew condensation occurrence of the dust sensor 32, and constitutes a part of the display device 46.

- the dew condensation indicator 461 is provided in a vehicle mounted with the air conditioning control device 40, it is determined that the dew condensation indicator 461 can notify the occupant of dew condensation occurrence of the dust sensor 32.

- step S043 in FIG. 15 If it is determined in step S043 in FIG. 15 that the dew condensation indicator 461 can notify the occupant of dew condensation occurrence in the dust sensor 32, the process proceeds to step S053. On the other hand, when it is determined in step S043 that the dew condensation indicator 461 can not notify the occupant of dew condensation occurrence in the dust sensor 32, the process proceeds to step S073.

- step S 053 the air conditioning control device 40 notifies the occupant of the occurrence of dew condensation of the dust sensor 32 by the dew condensation indicator 461. Specifically, the air conditioning control device 40 turns on the dew condensation indicator 461 to thereby notify the occupant of the dew condensation occurrence of the dust sensor 32. If the condensation indicator 461 is already on, it will continue to be on. To turn on the condensation indicator 461 is, for example, to turn on or blink the condensation indicator 461. After step S053, the process proceeds to step S072.

- step S063 the air conditioning control device 40 switches the dew condensation indicator 461 off. If the condensation indicator 461 is already off, it will continue to be off. To turn off the condensation indicator 461 is, for example, to turn off the condensation indicator 461.

- the flowchart of FIG. 15 is started again from step S010 when step S063 is completed.

- step S073 the air conditioning control device 40 determines whether the air conditioning unit 2 is operated in the automatic air conditioning mode (in other words, the auto mode).

- step S092 when the dust concentration reduction control of step S092 is performed, the air conditioning unit 2 is automatically set to the inside air mode, and the air flow rate of the blower 23 is automatically adjusted. Therefore, this step S073 is provided to confirm in advance whether the occupant recognizes that the air conditioning unit 2 is in a state where the inside air mode and the outside air mode are automatically switched and the air flow rate is automatically adjusted. It is done.

- step S073 When it is determined in step S073 that the air conditioning unit 2 is operated in the automatic air conditioning mode, the process proceeds to step S082.

- the flowchart of FIG. It starts from step S010.

- the manual mode is an air conditioning mode in which the air volume adjustment of the air conditioning air, the temperature adjustment of the air conditioning air, and the selection of the inside air circulation or the outside air introduction are performed by the manual operation of the occupant on the operation device 44.

- step S072 of FIG. 15 the determination is made in the same manner as step S072 of FIG.

- the process proceeds to step S092.

- the flowchart of FIG. 15 is ended and the process is started again from step S010.

- step S082 of FIG. 15 the determination is performed in the same manner as step S082 of FIG. 14.

- step S092 the flowchart of FIG. 15 is ended and the process is started again from step S010.

- step S092 in FIG. 15 dust concentration reduction control is performed as in step S092 in FIG. After step S092 in FIG. 15, the process proceeds to step S102.

- step S102 of FIG. 15 the determination is made in the same manner as step S102 of FIG. That is, if it is determined in step S102 in FIG. 15 that the dew condensation of the dust sensor 32 has not been eliminated yet, or if it is determined that the predetermined time has not yet elapsed from the condensation elimination time of the dust sensor 32.

- step S092 the execution of the dust concentration reduction control is continued.

- the dust concentration reduction control ends.

- Steps S053 and S063 in FIG. 15 correspond to the dew condensation notification unit.

- the air-conditioning control device 40 functionally includes a condensation notification unit in addition to the condensation determination unit, the factor determination unit, and the control execution unit as in the third embodiment.

- the present embodiment is the same as the third embodiment except for the points described above. And in this embodiment, the effect show

- the air conditioning control device 40 determines that dew condensation has occurred in the dust sensor 32

- the dew condensation occurrence of the dust sensor 32 is given to the occupant by the dew condensation indicator 461. Inform. Therefore, it is possible to make the occupant recognize that the dust sensor 32 may not function properly due to condensation.

- the present embodiment is an embodiment roughly combining the first embodiment and the fourth embodiment described above. So, in this embodiment, points different from the above first embodiment and fourth embodiment will be mainly described.

- steps S010, S020, S030 and S040 of the flowchart shown in FIG. 17 are the same as the flowchart of FIG.

- Steps S043, S053, S063, S073, S072, S082, S092 and S102 in the flowchart shown in FIG. 17 are the same as those in the flowchart of FIG.

- control process of FIG. 17 is executed by the air conditioning control device 40 as in the fourth embodiment. Then, steps S010, S020, S030, and S040 in FIG. 17 are executed by the dust sensor control unit 50 included in the air conditioning control device 40.

- step S030 If it is determined in step S030 that dew condensation has occurred on the dust sensor 32, the process proceeds to step S040. On the other hand, if it is determined in step S030 that condensation is not generated in the dust sensor 32, the process proceeds to step S054.

- step S040 in FIG. 17 the same process as step S040 in FIG. 5 is performed. Then, after step S040, the process proceeds to step S044.

- step S044 in FIG. 17 the air-conditioning control device 40 regards the dew-in-condensing dust concentration value Dc determined in step S040 as the dust concentration of the air passage 24 which is the sensing location of the dust sensor 32. Then, the air conditioning control device 40 controls the air conditioning unit 2 so that dust is removed according to the dust concentration. If control of this air conditioning unit 2 is already implemented, it will be continued as it is. For example, in the control of the air conditioning unit 2 according to the dust concentration in step S044, the air conditioning unit 2 is set to the inside air mode, and the air flow of the blower 23 is increased as the dust concentration is higher. After step S044, the process proceeds to step S043.

- step S054 in FIG. 17 the control of the air conditioning unit 2 according to the dust concentration is performed as in step S044 described above.

- the air-conditioning control device 40 regards the dust concentration detection value Dm obtained in step S010 as the dust concentration at the sensing location of the dust sensor 32, not the dew condensation dust concentration value Dc.

- step S044 control of the air conditioning unit 2 according to the dust concentration value Dc during condensation is carried out in the above-mentioned step S044, but control of the air conditioning unit 2 according to the dust concentration detection value Dm is carried out in this step S054 .

- step S054 the process proceeds to step S063.

- step S092 the dust concentration reduction control in step S092 is performed prior to the control of the air conditioning unit 2 performed in step S044 or S054. That is, when the control process of FIG. 17 proceeds to step S092 while the control of the air conditioning unit 2 in step S044 or S054 is being carried out, instead of the control of the air conditioning unit 2 in step S044 or S054, Dust concentration reduction control is implemented.

- the present embodiment is the same as the first embodiment or the fourth embodiment except for what has been described above. And in this embodiment, the effect show

- FIG. 18 A flowchart of this embodiment is shown in FIG. 18, and steps S010, S020, S030, S040, S031, and S041 of the flowchart shown in FIG. 18 are the same as the flowchart of FIG. Steps S043, S053, S063, S073, S072, S082, S092, S102, S044, and S054 in the flowchart shown in FIG. 18 are similar to the flowchart in FIG.

- step S030 If it is determined in step S030 that dew condensation has occurred on the dust sensor 32, the process proceeds to step S031. On the other hand, if it is determined in step S030 that condensation is not generated in the dust sensor 32, the process proceeds to step S054.

- step S031 When it is determined in step S031 that the dust concentration detection value Dm has risen before the occurrence of condensation of the dust sensor 32, the process proceeds to step S041. Then, after step S041, the process proceeds to step S044. On the other hand, when it is determined in step S031 that the dust concentration detection value Dm has not risen before the occurrence of condensation of the dust sensor 32, the process proceeds to step S040. Then, after step S040, the process proceeds to step S044.

- step S044 in FIG. 18 the air conditioning control device 40 controls the dust concentration value Dc during condensation determined in step S040 or step S041 in the ventilation path 24 which is the sensing location of the dust sensor 32 as in step S044 in FIG. 17. It is regarded as dust concentration. And control of the air-conditioning unit 2 according to the dust concentration is implemented. After step S044, the process proceeds to step S043.

- the present embodiment is the same as the second embodiment or the fifth embodiment except for what has been described above. And in this embodiment, the effect show

- the air filter 30 is disposed downstream of the dust sensor 32 in the air flow direction and upstream of the evaporator 26 in the air flow path 24 of the air conditioning case 21. Although arranged, this is an example. As long as all or most of the air flowing through the air passage 24 passes through the air filter 30, the arrangement of the air filter 30 in the air passage 24 is not limited.

- the air-conditioning control apparatus 40 functionally contains the dust sensor control part 50, this is an example.

- the air conditioning control device 40 may be configured of a plurality of physically separated control devices.

- the dust sensor control unit 50 may be a control device separate from the control unit that controls the doors and the blower 23 in the air conditioning control device 40.

- the dust sensor control unit 50 and the dust sensor 32 may be integrally configured to constitute one dust sensor unit.

- step S030 of the flowchart shown in FIG. 5 it is determined in step S030 of the flowchart shown in FIG. 5 whether condensation has occurred in the dust sensor 32, and the presence or absence of the condensation generation is the dust concentration detection value Dm. And the elapsed time, which is an example.

- the presence or absence of dew condensation may be determined using the temperature and relative humidity of the air introduced into the sensor case 323 of the dust sensor 32, the ambient temperature of the dust sensor 32, and the like. The same applies to each of the second and subsequent embodiments.

- the dew condensation dust concentration value Dc is the same value as the pre-condensation detection value Dbm in step S040 of the flowchart shown in FIG. 5, the present invention is not limited thereto.

- the dew condensation dust concentration value Dc may be determined based on the pre-condensation detection value Dbm.

- the dew condensation dust concentration value Dc may be a value obtained by adding a certain value to the detection value before condensation Dbm, or may be obtained by subtracting a certain value from the detection value before condensation Dbm. It may be a value. The same applies to the dust concentration value during dew condensation Dc in each of the second and subsequent embodiments.

- step S072 the flowchart of FIG. 14 includes step S072, but it may be assumed that step S072 is not included in the flowchart of FIG. In the flowchart without step S072, when it is determined in step S030 that dew condensation has occurred in the dust sensor 32, the process proceeds to step S082.

- step S030 it is determined in step S030 that dew condensation has occurred in the dust sensor 32, and if an instruction to reduce the dust concentration in the vehicle compartment is issued from the occupant, the process proceeds to step S072. If it is determined, dust concentration reduction control is performed in step S092. However, this is an example. For example, even if condensation is not generated in the dust sensor 32, the dust concentration reduction control may be performed when an instruction to reduce the dust concentration in the vehicle compartment is issued from the occupant.

- the condensation indicator 461 is provided in the vehicle mounted with the air conditioning control device 40 in step S043 in FIG. It is determined that it is possible to notify the occupant by However, this is one example.

- the display device 46 is configured to be able to switch a plurality of display modes alternatively. When the display device 46 is turned on as such, when the display device 46 is switched to the display mode in which the dew condensation occurrence of the dust sensor 32 can be displayed by the dew condensation indicator 461, the dew condensation occurrence is displayed by the occupant using the dew condensation indicator 461. It is determined that it is possible to inform

- the condensation determination unit determines whether condensation has occurred in the dust sensor. If it is determined by the condensation determination unit that condensation has occurred on the dust sensor, the value determination unit determines the dust concentration value during condensation to be treated as the dust concentration during condensation generation before the condensation of the dust sensor occurs. It is determined based on the detection value before condensation which is the detection value of the dust concentration detected in

- the value determination unit determines the dust concentration value during condensation so as to set the dust concentration value during condensation to the detection value before condensation. Therefore, the dust concentration value during condensation can be easily determined so that the dust concentration value during condensation does not become a value far from the actual value of dust concentration at the sensing location of the dust sensor.

- the value determination unit determines that the detected value of the dust concentration is increased before condensation occurs in the dust sensor. If it is determined by the dust concentration increase determination unit, the in-condensation dust concentration value is determined so as to make the in-condensation dust concentration value larger than the pre-condensation detection value. Therefore, it is possible to determine the dust concentration value during condensation so as to increase the accuracy of the dust concentration value during condensation relative to the actual value of dust concentration.

- the value determination unit when it is determined by the condensation determination unit that condensation occurs on the dust sensor, the value determination unit increases the detection value of the dust concentration before condensation occurs on the dust sensor. If it is determined by the dust concentration rise judging unit, the dust concentration value during condensation is set to a smaller value than when it is determined that the detection value of the dust concentration has risen before the occurrence of condensation of the dust sensor. Determine the dust concentration value during condensation. Therefore, it is possible to appropriately differentiate the magnitude of the dust concentration value during condensation depending on whether the detection value of the dust concentration has risen before the occurrence of condensation of the dust sensor.

- the detection of the dust concentration by the dust sensor is periodically and repeatedly performed.

- the detection value before condensation is a detection value of the dust concentration obtained by the previous detection with respect to the dew condensation start time of the dust sensor.

- the factor determination unit when it is determined by the condensation determination unit that condensation has occurred in the dust sensor, the factor determination unit is configured to increase the dust concentration in the vehicle interior by a predetermined dust concentration increase factor It is determined whether or not has occurred.

- the control execution unit implements dust concentration reduction control when it is determined by the factor determination unit that a dust concentration increase factor has occurred.

- the dust concentration reduction control is control for operating the air conditioning unit so that the dust concentration in the vehicle compartment is reduced as compared to before the start of the dust concentration reduction control. The same applies to the seventh aspect.

- the condensation notification unit when it is determined by the condensation determination unit that condensation has occurred in the dust sensor, the condensation notification unit notifies the occupant of the occurrence of condensation of the dust sensor by the notification device. Therefore, it is possible to make the occupant aware that the dust sensor may not function properly due to condensation.

- control execution unit executes the dust concentration reduction control even when the execution of the dust concentration reduction control is instructed by the manual operation of the occupant. Therefore, the occupant can reduce the dust concentration in the vehicle compartment by the air conditioning unit at any timing.

- the dew condensation determining unit determines that dew condensation has occurred in the dust sensor when the change ratio of the detected value of the dust concentration to the elapsed time changes beyond a predetermined limit. Accordingly, there is an advantage that no special device is required to determine the occurrence of dew condensation on the dust sensor.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- General Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Air Conditioning Control Device (AREA)

- Air-Conditioning For Vehicles (AREA)

Abstract

The purpose of the present invention is to provide an air-conditioning control device that can avoid an inappropriate situation caused by condensation on a dust sensor when condensation occurs on the dust sensor. An air-conditioning unit (2) includes: an air-conditioner case (21) in which an air passage (24), through which air blown out into a vehicle cabin passes, is formed; and a dust sensor (32) in which light emitted from a light emitting part (321) is received by a light receiving part (322), thus detecting the dust concentration in the air passage. An air-conditioning control device used in the air-conditioning unit includes a condensation determination unit (S030) and a value determination unit (S040, S041). The condensation determination unit determines whether condensation has occurred on the dust sensor. If it is determined by the condensation determination unit that condensation has occurred on the dust sensor, the value determination unit determines an condensation-present dust concentration value (Dc), which is treated as the dust concentration at which condensation is occurring, on the basis of a pre-condensation detection value (Dbm), which is the detection value of the dust concentration detected by the dust sensor before the condensation has occurred on the dust sensor.

Description

本出願は、2017年8月23日に出願された日本特許出願番号2017-160340号に基づくもので、ここにその記載内容が参照により組み入れられる。

This application is based on Japanese Patent Application No. 2017-160340 filed on August 23, 2017, the contents of which are incorporated herein by reference.

本開示は、空調ユニットにおいて用いられる空調制御装置に関するものである。

The present disclosure relates to an air conditioning control device used in an air conditioning unit.

特許文献1には、埃センサを有する換気装置が記載されている。その埃センサは受光部と発光部とを有し、光の反射により浮遊粒子を検知する。換気装置の筐体内部には、埃センサと、この埃センサを格納するセンサ格納部とが設けられている。このセンサ格納部は、筐体内部の風路に面して設けられている。更に、その風路とセンサ格納部との境界には、開閉可能なシャッターが設けられている。

Patent Document 1 describes a ventilator having a dust sensor. The dust sensor has a light receiving unit and a light emitting unit, and detects suspended particles by reflection of light. A dust sensor and a sensor storage unit for storing the dust sensor are provided inside a housing of the ventilation device. The sensor storage unit is provided facing the air passage inside the housing. Further, a shutter that can be opened and closed is provided at the boundary between the air passage and the sensor storage unit.

このシャッターは通常時には閉じられ、埃センサが検知する時にのみ開かれる。これにより、特許文献1では、埃センサが風路内の空気に晒される時間を短縮し埃センサのレンズの汚れを緩和することができるとされている。

The shutter is normally closed and opened only when the dust sensor detects it. Thus, according to Patent Document 1, it is supposed that the time for which the dust sensor is exposed to the air in the air passage can be shortened and the dirt of the lens of the dust sensor can be alleviated.

特許文献1に記載されているように、埃センサに結露が発生すると、埃センサが誤検出を生じる場合がある。そして、特許文献1のシャッターを用いれば埃センサの結露を抑制できると思われる。しかしながら、埃センサに結露が発生した場合にその埃センサの結露に起因した不適切な事態を如何に回避するかということは、特許文献1には記載されていなかった。発明者らの詳細な検討の結果、以上のようなことが見出された。

As described in Patent Document 1, if condensation occurs on the dust sensor, the dust sensor may cause erroneous detection. And if the shutter of patent document 1 is used, it is thought that dew condensation of a dust sensor can be suppressed. However, Patent Document 1 has not described how to avoid an inappropriate situation caused by dew condensation on a dust sensor when condensation occurs. As a result of the inventors' detailed studies, the above was found.

本開示は上記点に鑑みて、埃センサに結露が発生した場合にその埃センサの結露に起因した不適切な事態を回避することが可能な空調制御装置を提供することを目的とする。

In view of the above-described point, the present disclosure aims to provide an air conditioning control device capable of avoiding an inappropriate situation caused by dew condensation of a dust sensor when dew condensation occurs.

上記目的を達成するため、本開示の1つの観点によれば、空調制御装置は、

車室内へ吹き出る空気が流通する通風路が形成された空調ケースと、発光部から発せされた光を受光部が受光することにより通風路の埃濃度を検出する埃センサとを有する空調ユニットにおいて用いられる空調制御装置であって、

埃センサに結露が発生したか否かを判定する結露判定部と、

埃センサに結露が発生したと結露判定部により判定された場合には、結露発生中の埃濃度として取り扱われる結露中埃濃度値を、埃センサがその埃センサの結露発生前に検出した埃濃度の検出値である結露前検出値に基づいて決定する値決定部とを備えている。 In order to achieve the above object, according to one aspect of the present disclosure, an air conditioning control device includes:

Used in an air conditioning unit that has an air conditioning case in which a ventilating passage through which air is blown into the vehicle compartment is formed, and a dust sensor that detects the dust concentration in the ventilating passage when the light receiving unit receives light emitted from the light emitting unit. Air conditioning control device,

A dew condensation determination unit that determines whether dew condensation has occurred on the dust sensor;

When it is determined by the condensation determination unit that condensation has occurred on the dust sensor, the dust concentration value detected during condensation that is treated as the concentration of dust during condensation is the dust concentration detected by the dust sensor before condensation occurs on the dust sensor And a value determination unit that determines based on the detection value before condensation which is the detection value of.

車室内へ吹き出る空気が流通する通風路が形成された空調ケースと、発光部から発せされた光を受光部が受光することにより通風路の埃濃度を検出する埃センサとを有する空調ユニットにおいて用いられる空調制御装置であって、

埃センサに結露が発生したか否かを判定する結露判定部と、

埃センサに結露が発生したと結露判定部により判定された場合には、結露発生中の埃濃度として取り扱われる結露中埃濃度値を、埃センサがその埃センサの結露発生前に検出した埃濃度の検出値である結露前検出値に基づいて決定する値決定部とを備えている。 In order to achieve the above object, according to one aspect of the present disclosure, an air conditioning control device includes:

Used in an air conditioning unit that has an air conditioning case in which a ventilating passage through which air is blown into the vehicle compartment is formed, and a dust sensor that detects the dust concentration in the ventilating passage when the light receiving unit receives light emitted from the light emitting unit. Air conditioning control device,

A dew condensation determination unit that determines whether dew condensation has occurred on the dust sensor;

When it is determined by the condensation determination unit that condensation has occurred on the dust sensor, the dust concentration value detected during condensation that is treated as the concentration of dust during condensation is the dust concentration detected by the dust sensor before condensation occurs on the dust sensor And a value determination unit that determines based on the detection value before condensation which is the detection value of.

このようにすれば、埃センサに結露が発生した場合に、その結露に起因した不適切な事態、例えば埃センサの誤検出に起因して埃濃度が実際値から懸け離れた大きさとして把握されるという事態を、結露中埃濃度値を用いることで回避することが可能である。

In this way, when condensation occurs on the dust sensor, the dust concentration is grasped as a size that is far from the actual value due to an inappropriate situation caused by the condensation, for example, an erroneous detection of the dust sensor. This can be avoided by using the dust concentration value during condensation.

また、本開示の別の観点によれば、空調制御装置は、

車室内へ吹き出る空気が流通する通風路が形成された空調ケースと、発光部から発せされた光を受光部が受光することにより通風路の埃濃度を検出する埃センサとを有する空調ユニットにおいて用いられる空調制御装置であって、

埃センサに結露が発生したか否かを判定する結露判定部と、

埃センサに結露が発生したと結露判定部により判定された場合に、車室内の埃濃度を上昇させる原因になる所定の埃濃度上昇要因が発生したか否かを判定する要因判定部と、

埃濃度上昇要因が発生したと要因判定部により判定された場合に埃濃度低減制御を実施する制御実施部とを備え、

埃濃度低減制御は、その埃濃度低減制御の開始前に比して車室内の埃濃度が低減されるように空調ユニットを作動させる制御である。 Also, according to another aspect of the present disclosure, the air conditioning control device

Used in an air conditioning unit that has an air conditioning case in which a ventilating passage through which air is blown into the vehicle compartment is formed, and a dust sensor that detects the dust concentration in the ventilating passage when the light receiving unit receives light emitted from the light emitting unit. Air conditioning control device,

A dew condensation determination unit that determines whether dew condensation has occurred on the dust sensor;

A factor determination unit that determines whether or not a predetermined dust concentration increase factor that causes the dust concentration in the vehicle compartment to increase when it is determined by the condensation determination unit that condensation has occurred on the dust sensor;

And a control execution unit that executes dust concentration reduction control when it is determined by the factor determination unit that a dust concentration increase factor has occurred.

The dust concentration reduction control is control for operating the air conditioning unit such that the dust concentration in the vehicle compartment is reduced as compared to before the start of the dust concentration reduction control.

車室内へ吹き出る空気が流通する通風路が形成された空調ケースと、発光部から発せされた光を受光部が受光することにより通風路の埃濃度を検出する埃センサとを有する空調ユニットにおいて用いられる空調制御装置であって、

埃センサに結露が発生したか否かを判定する結露判定部と、

埃センサに結露が発生したと結露判定部により判定された場合に、車室内の埃濃度を上昇させる原因になる所定の埃濃度上昇要因が発生したか否かを判定する要因判定部と、

埃濃度上昇要因が発生したと要因判定部により判定された場合に埃濃度低減制御を実施する制御実施部とを備え、

埃濃度低減制御は、その埃濃度低減制御の開始前に比して車室内の埃濃度が低減されるように空調ユニットを作動させる制御である。 Also, according to another aspect of the present disclosure, the air conditioning control device

Used in an air conditioning unit that has an air conditioning case in which a ventilating passage through which air is blown into the vehicle compartment is formed, and a dust sensor that detects the dust concentration in the ventilating passage when the light receiving unit receives light emitted from the light emitting unit. Air conditioning control device,

A dew condensation determination unit that determines whether dew condensation has occurred on the dust sensor;

A factor determination unit that determines whether or not a predetermined dust concentration increase factor that causes the dust concentration in the vehicle compartment to increase when it is determined by the condensation determination unit that condensation has occurred on the dust sensor;

And a control execution unit that executes dust concentration reduction control when it is determined by the factor determination unit that a dust concentration increase factor has occurred.

The dust concentration reduction control is control for operating the air conditioning unit such that the dust concentration in the vehicle compartment is reduced as compared to before the start of the dust concentration reduction control.

このようにすれば、埃センサに結露が発生した場合に、その埃センサの結露に起因した不適切な事態、例えば埃センサの誤検出で埃濃度を正確に把握できず車室内の埃濃度が上昇するという事態を、埃濃度低減制御の実施により回避することが可能である。

In this way, when dew condensation occurs on the dust sensor, an inappropriate situation caused by the dew condensation on the dust sensor, for example, the false detection of the dust sensor can not accurately grasp the dust concentration, and the dust concentration in the vehicle interior It is possible to prevent the situation of rising by implementing the dust concentration reduction control.

なお、各構成要素等に付された括弧付きの参照符号は、その構成要素等と後述する実施形態に記載の具体的な構成要素等との対応関係の一例を示すものである。

The reference numerals in parentheses attached to each component, etc., shows an example of a relationship of the specific component such as described in the following embodiments and their components, and the like.