WO2019009216A1 - Catalyst for voc treatment - Google Patents

Catalyst for voc treatment Download PDFInfo

- Publication number

- WO2019009216A1 WO2019009216A1 PCT/JP2018/024929 JP2018024929W WO2019009216A1 WO 2019009216 A1 WO2019009216 A1 WO 2019009216A1 JP 2018024929 W JP2018024929 W JP 2018024929W WO 2019009216 A1 WO2019009216 A1 WO 2019009216A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- catalyst

- cobalt

- platinum

- voc

- composite oxide

- Prior art date

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D53/00—Separation of gases or vapours; Recovering vapours of volatile solvents from gases; Chemical or biological purification of waste gases, e.g. engine exhaust gases, smoke, fumes, flue gases, aerosols

- B01D53/34—Chemical or biological purification of waste gases

- B01D53/74—General processes for purification of waste gases; Apparatus or devices specially adapted therefor

- B01D53/86—Catalytic processes

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J23/00—Catalysts comprising metals or metal oxides or hydroxides, not provided for in group B01J21/00

- B01J23/70—Catalysts comprising metals or metal oxides or hydroxides, not provided for in group B01J21/00 of the iron group metals or copper

- B01J23/89—Catalysts comprising metals or metal oxides or hydroxides, not provided for in group B01J21/00 of the iron group metals or copper combined with noble metals

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J37/00—Processes, in general, for preparing catalysts; Processes, in general, for activation of catalysts

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J37/00—Processes, in general, for preparing catalysts; Processes, in general, for activation of catalysts

- B01J37/08—Heat treatment

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02A—TECHNOLOGIES FOR ADAPTATION TO CLIMATE CHANGE

- Y02A50/00—TECHNOLOGIES FOR ADAPTATION TO CLIMATE CHANGE in human health protection, e.g. against extreme weather

- Y02A50/20—Air quality improvement or preservation, e.g. vehicle emission control or emission reduction by using catalytic converters

Definitions

- the present invention relates to a platinum directly supported cobalt-cerium composite oxide catalyst for volatile organic compound (VOC) processing.

- VOC Volatile Organic Compounds

- various methods such as direct combustion method, catalytic combustion method, physicochemical adsorption method, biological treatment method, plasma method, etc. have been proposed.

- catalytic combustion method has equipment and maintenance management It is widely used because it is relatively easy.

- the inventors of the present invention have proposed that a cobalt-cerium composite oxide catalyst is effective for VOC treatment and a new catalyst loading method in Patent Documents 1 to 3 shown below. As a result, low cost and performance equal to or higher than that of a platinum catalyst can be ensured.

- an aromatic compound such as toluene is about 200 to 250 ° C. Although it can be processed at relatively low temperature, ethyl acetate and the like not containing an aromatic ring need to be processed at a high temperature of about 300 to 350.degree.

- VOCs containing no aromatic ring can be treated at a relatively low temperature of about 200 to 250 ° C., but they are aromatic

- the treatment of the compound needs to be carried out at a high temperature of about 300.degree.

- new catalysts have been developed for new applications for simultaneously treating both VOCs in a temperature range lower than 300 ° C. Challenges have arisen.

- the inventors of the present invention who carried out earnest studies to solve the above problems directly support a cobalt-cerium composite oxide catalyst, more preferably support a predetermined amount of platinum by a method of using a colloidal solution as a raw material. It has been found that the low temperature activity of the cobalt-cerium composite oxide catalyst is further enhanced by the combination. The details will be described below. It should be noted that, regardless of the category of the invention, definitions of terms etc., which are performed when describing the invention according to any claim, are also included in the invention according to the other claims within the scope permitted by nature regardless of the description order etc. It shall apply.

- the present invention is intended to solve these problems, and is an invention relating to a catalyst for VOC treatment in which high activity at low temperature regardless of containing an aromatic ring is sustainable.

- the catalyst for treating VOCs proposed in the present invention By using the catalyst for treating VOCs proposed in the present invention, performance can be secured at a lower temperature as compared with commercially available platinum alumina catalysts and cobalt / cerium composite oxide catalysts. This makes it possible to reduce the cost of electricity and fuel by lowering the processing temperature in a factory or the like, and to put into practical use a compact catalyst processing apparatus for homes and offices. Furthermore, by expanding the application to the processing technology field of the low temperature specification catalyst, which could not be dealt with by the existing catalyst, it can contribute to the improvement of the air environment and the indoor environment. Further, according to the production method proposed in the present invention, the above-mentioned catalyst for treating VOC can be produced.

- the invention according to claim 1 is most characterized in that it relates to a VOC treatment catalyst in which platinum is directly supported on a cobalt-cerium composite oxide, for gas combustion treatment containing VOC.

- the mass ratio of the cobalt-cerium composite oxide in the mass of the entire catalyst is 80% or more, and the content of platinum in the mass of the cobalt-cerium composite oxide is a (unit: mass%).

- the range of 0 ⁇ a ⁇ 20 is preferable. That is, conventionally, platinum was supported on a carrier such as aluminum oxide, but the catalyst for treating VOC according to the present invention is a novel combination in which the catalyst is directly supported on a cobalt-cerium-based oxide. is there.

- the VOC treatment catalyst includes both of those which are not supported by the inert carrier, and the mass thereof when supported is the mass of the inert carrier.

- the invention according to claim 2 is characterized in that, as a preferable embodiment of the invention according to claim 1, the platinum relates to a catalyst for treating VOC which uses a solution of platinum colloid protected with a dispersant as a raw material. is there.

- a dispersing agent polyvinyl pyrrolidone (Polyvinylpyrrolidone, PVP) can be used suitably, for example.

- the catalyst is molded with a binder component, or stainless steel, steel, copper alloy, aluminum alloy, and ceramics having a desired shape.

- the carrier is characterized in that it is supported by any one carrier of the material.

- the invention according to claim 4 is the method for producing a catalyst for treating VOC according to any one of claims 1 to 3, wherein the cobalt-cerium composite oxide is a carbonate of cobalt and cerium as a precursor.

- the compound is characterized by being calcined at 300 to 500 ° C. in air and then pulverized.

- the invention according to claim 5 is a method for treating VOC using the catalyst for treating VOC according to any one of claims 1 to 3, wherein the operating temperature is 100 to 300 ° C.

- the catalyst for treating VOC according to any one of claims 1 to 3 it is possible to treat in the low temperature region.

- the catalyst for treating VOC according to the present invention is a catalyst in which platinum is directly supported on a cobalt-cerium composite oxide, for gas combustion treatment containing VOC.

- the mass ratio of the cobalt-cerium composite oxide occupying in the mass of the entire catalyst is 80% or more, and the content of platinum in the mass of the cobalt-cerium composite oxide is a (unit: mass%)

- the range of 0 ⁇ a ⁇ 20 is preferable. If it is outside the above range, platinum aggregation tends to occur, which is not desirable.

- the VOC treatment catalyst includes both of those which are not supported on an inert carrier (including a binder, hereinafter the same), and the mass when supported is the mass of the inert carrier described later. Not included.

- the cobalt-cerium composite oxide can be produced by calcining a compound having a carbonate of cobalt and cerium as a precursor at 300 to 500 ° C. in air, and then grinding. Pulverization process collapses pores, especially micropores, on the cobalt-cerium composite oxide, thereby improving the diffusivity of the platinum colloid protected by the dispersant described later and causticizing the platinum uniformly on the surface. It is believed that the amount will decrease. Micropores refer to pores having a pore diameter of 2 nm or less, but the amount of coking can be more efficiently reduced by collapsing the pores. The reduction of the amount of coking makes high activity sustainable at low temperatures.

- the platinum is preferably made of a solution of platinum colloid protected with a dispersant.

- the reason for using a platinum colloid solution as a raw material is considered to be advantageous in terms of enhancing the dispersibility of platinum particles to be supported.

- a protective agent of platinum colloid polyvinyl poloridone is suitable, but it does not prevent using polymers other than polyvinyl poloridone, a ligand, a micelle, etc. besides it, for example.

- the catalyst is formed by molding with a binder component, or supported on an inert carrier of stainless steel, steel, copper alloy, aluminum alloy, or ceramic material of a desired shape. You may In the former case, when the powder or powder molded catalyst is loaded into the catalyst packed bed, clogging of the packed bed due to the reduction of voids can be avoided.

- the operating temperature of the VOC treatment using the VOC treatment catalyst having the above-described structure is preferably in the range of 100 to 300.degree. This is because if the above-mentioned catalyst for VOC treatment is used, VOC treatment can be performed without exceeding 300 ° C. If this state is maintained, electricity costs and fuel costs can be reduced as compared with the conventional processing method. In other words, operating above 300 ° C. is not preferable unless there is a special circumstance, since it dilutes the characteristics that the above-mentioned VOC treatment catalyst can be treated even at low temperatures. Operating temperatures below 100 ° C. should be avoided as they are prone to coking buildup.

- the catalyst performance was evaluated in the following manner for both Example 1 and Comparative Examples 1 to 3.

- a catalyst-filled tube installed in a tubular electric furnace equipped with a heater as shown in FIG. 1 was filled with a VOC treatment catalyst, and a VOC-containing gas was allowed to flow continuously through this packed bed.

- the composition of the VOC-containing gas was such that dry air contained a vapor of toluene or ethyl acetate, and the concentrations of toluene and ethyl acetate were 400 ppm and 900 ppm, respectively, and the dry air flow rate was 100 mL ⁇ min ⁇ 1 .

- the prepared catalyst powder was pelletized, crushed to a suitable size, and packed so as not to clog the packing tube.

- the temperature of the catalyst packed bed was adjusted by adjusting the heater temperature of the tubular electric furnace. The temperature was raised to 300 ° C. in toluene combustion and to 400 ° C. in ethyl acetate combustion, and the temperature was maintained for 1 hour, and then the temperature was lowered by 1 ° C. in 1 minute to 30 ° C. When the temperature was lowered, the concentration of carbon dioxide in the gas and the concentration of toluene or ethyl acetate were measured using a gas chromatograph equipped with a thermal conductivity detector.

- the coking formation evaluation of the catalyst was performed as follows in both Example 1 and Comparative Example 4. Similarly, a catalyst filled tube installed in a tubular electric furnace shown in FIG. 1 was filled with a catalyst, and dry air (VOC-containing gas) containing a vapor of toluene was continuously circulated in the packed bed. The concentration of toluene was 400 ppm, and the flow rate of dry air was 100 mL ⁇ min ⁇ 1 . The prepared catalyst powder was pelletized, crushed to a suitable size, and packed so as not to clog the packing tube. The temperature of the catalyst layer was adjusted using a tubular electric furnace. After raising the temperature to 150 ° C.

- the temperature was maintained for 24 hours, dry air containing toluene vapor was continuously circulated, and combustion of toluene was continued. Thereafter, the temperature is lowered to 30 ° C. by flowing only dry air, and the temperature is raised by 1 ° C. per minute to 300 ° C. while flowing only the dry air, and the generation of carbon dioxide accompanying combustion of coking accumulated on the catalyst surface is It measured by the gas chromatograph with a conductivity detector.

- the catalyst processing temperature (combustion temperature) is largely different between the aromatic VOC and the VOC containing no aromatic ring.

- the test was conducted by selecting toluene as a typical VOC of aromatics and ethyl acetate as a typical VOC containing no aromatic ring. Focusing on the combustion temperature at which the generation rate of CO 2 reaches 90 to 100%, the temperature at which the catalyst can be processed was organized.

- the temperature at which the CO 2 generation rate of ethyl acetate reaches 90 to 100% is about 200 to 250 ° C.

- Cerium carbonate was calcined in air at 300 ° C. for 1 hour to prepare cerium oxide, and pulverized using a wet crusher (planet type ball mill Classic Line P-7 manufactured by Fritsch Japan Ltd.).

- the median diameter before grinding is 23.3 ⁇ m

- the median diameter after grinding is 0.415 ⁇ m It was m.

- the pore distribution before and after grinding was measured using BELSORP-max manufactured by Microtrac Bell Inc.

- the sample after grinding was immersed in an aqueous solution of platinum colloid (manufactured by Tanaka Kikinzoku Kogyo Co., Ltd.) protected by polyvinyl pyrrolidone, and the solution was evaporated and dried while being stirred and heated.

- the dried sample and cobalt oxide were mixed, the temperature was gradually raised by 0.9 ° C. in 1 minute in air, and the final catalyst was calcined at 300 ° C. for 1 hour to obtain a target catalyst.

- the platinum loading was 2% by weight relative to the cobalt-cerium composite oxide.

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Materials Engineering (AREA)

- Organic Chemistry (AREA)

- Environmental & Geological Engineering (AREA)

- Thermal Sciences (AREA)

- Physics & Mathematics (AREA)

- Health & Medical Sciences (AREA)

- Biomedical Technology (AREA)

- Analytical Chemistry (AREA)

- General Chemical & Material Sciences (AREA)

- Oil, Petroleum & Natural Gas (AREA)

- Catalysts (AREA)

- Exhaust Gas Treatment By Means Of Catalyst (AREA)

Abstract

[Problem] To provide a catalyst which enables a treatment of a VOC containing an aromatic group and a treatment of a VOC containing no aromatic group to be performed at the same time within a temperature range lower than 300°C. [Solution] A catalyst for VOC treatment, which is obtained by having platinum directly supported by a cobalt-cerium composite oxide and is used for a VOC-containing gas combustion treatment, and which is characterized in that: the proportion of the mass of the cobalt-cerium composite oxide in the whole mass of the catalyst is 80% or more; and if a (unit: mass%) is the content of the platinum in the mass of the cobalt-cerium composite oxide, a is within the range of 0 < a ≤ 20. This catalyst may be or may not be supported by an inert carrier.

Description

本発明は揮発性有機化合物(VOC)処理用の白金直接担持コバルト・セリウム系複合酸化物触媒に関する。

The present invention relates to a platinum directly supported cobalt-cerium composite oxide catalyst for volatile organic compound (VOC) processing.

塗装工場、印刷工場、化学工場等からの排ガスによる悪臭苦情や大気汚染の問題、家庭・オフィスで使用される建材から放散され健康被害の原因となりうる揮発性有機化合物(Volatile Organic Compounds:以下「VOC」と表記する)を簡易的に処理する技術が求められている。処理方法としては直接燃焼法、触媒燃焼法、物理化学的吸着法、生物処理法、プラズマ法等、各種の方法が提案されているが、これらの中で、触媒燃焼法は装置及び維持管理が比較的容易であることから特に広く用いられている。

Volatile Organic Compounds (Volatile Organic Compounds: hereinafter referred to as “VOC” that can be the cause of health hazards due to odor complaints and air pollution problems from exhaust gases from paint plants, printing plants, chemical plants, etc., and building materials used in homes and offices There is a need for a technique for simply processing As the treatment method, various methods such as direct combustion method, catalytic combustion method, physicochemical adsorption method, biological treatment method, plasma method, etc. have been proposed. Among them, catalytic combustion method has equipment and maintenance management It is widely used because it is relatively easy.

しかしながら、触媒燃焼法による処理には一般に300~350℃程度の温度が必要なため、加熱のための電気代、燃料費がかかるという問題点があった。またこの方法を家庭・オフィス向け装置に応用する場合においても電気代が高く、安全性確保や小型化実現等の課題が生じ、適用範囲が限定されていた。適応範囲を拡大するためにも、より低温で高活性を示す触媒が求められている。

However, since the treatment by the catalytic combustion method generally requires a temperature of about 300 to 350 ° C., there is a problem that the cost of electricity for heating and the cost of fuel are increased. Further, even when this method is applied to devices for home and office use, the electricity cost is high, and issues such as securing of safety and realization of miniaturization occur, and the application range is limited. In order to expand the application range, catalysts showing higher activity at lower temperatures are required.

発明者らは、次に示す特許文献1~3で、コバルト・セリウム系複合酸化物触媒がVOC処理に有効であることや新しい触媒担持方法を提案した。これらにより、低コスト且つ白金触媒と同等以上の性能を確保できるようになった。

The inventors of the present invention have proposed that a cobalt-cerium composite oxide catalyst is effective for VOC treatment and a new catalyst loading method in Patent Documents 1 to 3 shown below. As a result, low cost and performance equal to or higher than that of a platinum catalyst can be ensured.

VOCの種類によって処理性能に差が生じることが多く、たとえば、市販の白金担持アルミナ触媒(Pt/Al2O3)を用いた場合、トルエンのような芳香族の化合物は200~250℃程度の比較的低温で処理できるが、芳香環を含まない酢酸エチル等は300~350℃程度の高温で処理する必要がある。一方、コバルト・セリウム系複合酸化物触媒(Co3O4-CeO2)を用いた場合は、逆に芳香環を含まないVOCは200~250℃程度の比較的低温で処理できるが芳香族の化合物の処理は300℃程度の高温で処理する必要が生じる。このため、芳香環を含むVOCとそれを含まないVOCを個別に処理する場合はよいが、両者のVOCを300℃より低い温度領域で同時に処理するための新しい用途のために新たな触媒を開発する課題が生じた。

Depending on the type of VOC, processing performance often varies. For example, when using a commercially available platinum-supported alumina catalyst (Pt / Al 2 O 3 ), an aromatic compound such as toluene is about 200 to 250 ° C. Although it can be processed at relatively low temperature, ethyl acetate and the like not containing an aromatic ring need to be processed at a high temperature of about 300 to 350.degree. On the other hand, when a cobalt-cerium composite oxide catalyst (Co 3 O 4 -CeO 2 ) is used, VOCs containing no aromatic ring can be treated at a relatively low temperature of about 200 to 250 ° C., but they are aromatic The treatment of the compound needs to be carried out at a high temperature of about 300.degree. For this reason, although it is good to treat VOCs containing aromatic rings and VOCs not containing them separately, new catalysts have been developed for new applications for simultaneously treating both VOCs in a temperature range lower than 300 ° C. Challenges have arisen.

上記課題を解決するために鋭意研究を行った発明者らは、コバルト・セリウム系複合酸化物触媒に直接担持、さらに好ましくはコロイド溶液を原料とするという方法で所定量の白金を担持させるという新規な組み合わせにより、コバルト・セリウム系複合酸化物触媒の低温活性がより高まることを見出した。以下、具体的に説明する。なお、発明のカテゴリーに関わらず、何れかの請求項に係る発明を説明するにあたり行う用語の定義等は、その記載順などに関わらず性質上許される範囲で他の請求項に係る発明にも適用されるものとする。

The inventors of the present invention who carried out earnest studies to solve the above problems directly support a cobalt-cerium composite oxide catalyst, more preferably support a predetermined amount of platinum by a method of using a colloidal solution as a raw material. It has been found that the low temperature activity of the cobalt-cerium composite oxide catalyst is further enhanced by the combination. The details will be described below. It should be noted that, regardless of the category of the invention, definitions of terms etc., which are performed when describing the invention according to any claim, are also included in the invention according to the other claims within the scope permitted by nature regardless of the description order etc. It shall apply.

本件発明は、これらの課題を解決しようとするものであり、芳香環を含む含まないに関わらず低温で高い活性が持続可能なVOC処理用触媒に関する発明である。

The present invention is intended to solve these problems, and is an invention relating to a catalyst for VOC treatment in which high activity at low temperature regardless of containing an aromatic ring is sustainable.

本発明で提案するVOC処理用触媒を用いれば市販の白金アルミナ触媒やコバルト・セリウム系複合酸化物触媒と比較して低い温度で性能を確保できる。これにより、工場等での処理温度を低下させることによる電気代、燃料費の削減や家庭・オフィス向け小型触媒処理装置の実用化が可能となる。さらに既存の触媒では対応が困難であった低温仕様の触媒の処理技術分野への用途拡大を図ることで、大気環境、室内環境の改善に貢献できる。また、本発明で提案する製造方法によれば、上記VOC処理用触媒を製造することができる。

By using the catalyst for treating VOCs proposed in the present invention, performance can be secured at a lower temperature as compared with commercially available platinum alumina catalysts and cobalt / cerium composite oxide catalysts. This makes it possible to reduce the cost of electricity and fuel by lowering the processing temperature in a factory or the like, and to put into practical use a compact catalyst processing apparatus for homes and offices. Furthermore, by expanding the application to the processing technology field of the low temperature specification catalyst, which could not be dealt with by the existing catalyst, it can contribute to the improvement of the air environment and the indoor environment. Further, according to the production method proposed in the present invention, the above-mentioned catalyst for treating VOC can be produced.

(請求項1記載の発明の特徴)

請求項1記載の発明は、VOCを含有するガス燃焼処理用の、白金をコバルト・セリウム系複合酸化物上に直接担持させたVOC処理用触媒に係るものである点に最大の特徴がある。ここで 触媒全体の質量に占めるコバルト・セリウム系複合酸化物の質量割合が80%以上であり、コバルト・セリウム系複合酸化物の質量に占める白金の含有量をa(単位:質量%)とすると、0<a≦20の範囲であることが好ましい。すなわち、従来であれば、酸化アルミニウム等の担体に白金を担持させていたが、本件発明に係るVOC処理用触媒は、コバルト・セリウム系の酸化物上に直接担持させるという新規な組み合わせによるものである。なお、当該VOC処理用触媒は、不活性担体に担持してなるものとならないものの双方を含み、担持してなる場合の当該質量は不活性担体の質量を含まない。 (Features of the invention according to claim 1)

The invention according toclaim 1 is most characterized in that it relates to a VOC treatment catalyst in which platinum is directly supported on a cobalt-cerium composite oxide, for gas combustion treatment containing VOC. Here, the mass ratio of the cobalt-cerium composite oxide in the mass of the entire catalyst is 80% or more, and the content of platinum in the mass of the cobalt-cerium composite oxide is a (unit: mass%). The range of 0 <a ≦ 20 is preferable. That is, conventionally, platinum was supported on a carrier such as aluminum oxide, but the catalyst for treating VOC according to the present invention is a novel combination in which the catalyst is directly supported on a cobalt-cerium-based oxide. is there. The VOC treatment catalyst includes both of those which are not supported by the inert carrier, and the mass thereof when supported is the mass of the inert carrier.

請求項1記載の発明は、VOCを含有するガス燃焼処理用の、白金をコバルト・セリウム系複合酸化物上に直接担持させたVOC処理用触媒に係るものである点に最大の特徴がある。ここで 触媒全体の質量に占めるコバルト・セリウム系複合酸化物の質量割合が80%以上であり、コバルト・セリウム系複合酸化物の質量に占める白金の含有量をa(単位:質量%)とすると、0<a≦20の範囲であることが好ましい。すなわち、従来であれば、酸化アルミニウム等の担体に白金を担持させていたが、本件発明に係るVOC処理用触媒は、コバルト・セリウム系の酸化物上に直接担持させるという新規な組み合わせによるものである。なお、当該VOC処理用触媒は、不活性担体に担持してなるものとならないものの双方を含み、担持してなる場合の当該質量は不活性担体の質量を含まない。 (Features of the invention according to claim 1)

The invention according to

(請求項2記載の発明の特徴)

請求項2記載の発明は、請求項1記載の発明の好ましい態様として、前記白金は、分散剤で保護された白金コロイドの溶液を原料とするVOC処理用触媒に係るものであることに特徴がある。分散剤としては、たとえばポリビニルピロリドン(Polyvinylpyrrolidone、PVP)を好適に用いることができる。 (Features of the invention described in claim 2)

The invention according to claim 2 is characterized in that, as a preferable embodiment of the invention according toclaim 1, the platinum relates to a catalyst for treating VOC which uses a solution of platinum colloid protected with a dispersant as a raw material. is there. As a dispersing agent, polyvinyl pyrrolidone (Polyvinylpyrrolidone, PVP) can be used suitably, for example.

請求項2記載の発明は、請求項1記載の発明の好ましい態様として、前記白金は、分散剤で保護された白金コロイドの溶液を原料とするVOC処理用触媒に係るものであることに特徴がある。分散剤としては、たとえばポリビニルピロリドン(Polyvinylpyrrolidone、PVP)を好適に用いることができる。 (Features of the invention described in claim 2)

The invention according to claim 2 is characterized in that, as a preferable embodiment of the invention according to

(請求項3記載の発明の特徴)

請求項3記載の発明は、請求項1または2記載の発明の好ましい態様として、前記触媒は、バインダー成分とともに成型してなる、或いは所望形状のステンレス鋼、鉄鋼、銅合金、アルミニウム合金、及びセラミックス材の何れか1つの担体に担持されていることを特徴とする。 (Features of the invention described in claim 3)

According to a third aspect of the present invention, as the preferable aspect of the first or second aspect, the catalyst is molded with a binder component, or stainless steel, steel, copper alloy, aluminum alloy, and ceramics having a desired shape. The carrier is characterized in that it is supported by any one carrier of the material.

請求項3記載の発明は、請求項1または2記載の発明の好ましい態様として、前記触媒は、バインダー成分とともに成型してなる、或いは所望形状のステンレス鋼、鉄鋼、銅合金、アルミニウム合金、及びセラミックス材の何れか1つの担体に担持されていることを特徴とする。 (Features of the invention described in claim 3)

According to a third aspect of the present invention, as the preferable aspect of the first or second aspect, the catalyst is molded with a binder component, or stainless steel, steel, copper alloy, aluminum alloy, and ceramics having a desired shape. The carrier is characterized in that it is supported by any one carrier of the material.

(請求項4記載の発明の特徴)

請求項4記載の発明は、請求項1ないし3いずれか記載のVOC処理用触媒の製造方法であって、前記コバルト・セリウム系複合酸化物とは、コバルトとセリウムの炭酸塩を前駆体とする化合物を空気中300~500℃で焼成し、その後粉砕処理して作製することを特徴とする。 (Features of the invention according to claim 4)

The invention according to claim 4 is the method for producing a catalyst for treating VOC according to any one ofclaims 1 to 3, wherein the cobalt-cerium composite oxide is a carbonate of cobalt and cerium as a precursor. The compound is characterized by being calcined at 300 to 500 ° C. in air and then pulverized.

請求項4記載の発明は、請求項1ないし3いずれか記載のVOC処理用触媒の製造方法であって、前記コバルト・セリウム系複合酸化物とは、コバルトとセリウムの炭酸塩を前駆体とする化合物を空気中300~500℃で焼成し、その後粉砕処理して作製することを特徴とする。 (Features of the invention according to claim 4)

The invention according to claim 4 is the method for producing a catalyst for treating VOC according to any one of

(請求項5記載の発明の特徴)

請求項5記載の発明は、請求項1ないし3いずれか記載のVOC処理用触媒を用いたVOC処理方法であって、運転温度が、100~300℃であることを特徴とするVOC処理方法。請求項1ないし3いずれか記載のVOC処理用触媒を用いることにより、上記低温度領域において処理することができる。 (Features of the invention according to claim 5)

The invention according to claim 5 is a method for treating VOC using the catalyst for treating VOC according to any one ofclaims 1 to 3, wherein the operating temperature is 100 to 300 ° C. By using the catalyst for treating VOC according to any one of claims 1 to 3, it is possible to treat in the low temperature region.

請求項5記載の発明は、請求項1ないし3いずれか記載のVOC処理用触媒を用いたVOC処理方法であって、運転温度が、100~300℃であることを特徴とするVOC処理方法。請求項1ないし3いずれか記載のVOC処理用触媒を用いることにより、上記低温度領域において処理することができる。 (Features of the invention according to claim 5)

The invention according to claim 5 is a method for treating VOC using the catalyst for treating VOC according to any one of

本発明は上記のとおりの特徴をもつものであるが、以下に、本発明を実施するための形態を説明する。本発明のVOC処理用触媒は、VOCを含有するガス燃焼処理用の、白金をコバルト・セリウム系複合酸化物上に直接担持させた触媒である。ここで触媒全体の質量に占めるコバルト・セリウム系複合酸化物の質量割合が80%以上であり、コバルト・セリウム系複合酸化物の質量に占める白金の含有量をa(単位:質量%)とすると、0<a≦20の範囲であることが好ましい。上記範囲外であると白金の凝集が生じやすくなるため望ましくないからである。なお、当該VOC処理用触媒は、不活性担体(バインダーを含む。以下同じ)に担持してなるものとならないものの双方を含み、担持してなる場合の当該質量は後述する不活性担体の質量を含まない。

Although the present invention has the features as described above, a mode for carrying out the present invention will be described below. The catalyst for treating VOC according to the present invention is a catalyst in which platinum is directly supported on a cobalt-cerium composite oxide, for gas combustion treatment containing VOC. Here, assuming that the mass ratio of the cobalt-cerium composite oxide occupying in the mass of the entire catalyst is 80% or more, and the content of platinum in the mass of the cobalt-cerium composite oxide is a (unit: mass%) The range of 0 <a ≦ 20 is preferable. If it is outside the above range, platinum aggregation tends to occur, which is not desirable. The VOC treatment catalyst includes both of those which are not supported on an inert carrier (including a binder, hereinafter the same), and the mass when supported is the mass of the inert carrier described later. Not included.

コバルト・セリウム系複合酸化物は、コバルトとセリウムの炭酸塩を前駆体とする化合物を空気中300~500℃で焼成し、その後粉砕処理して作製することができる。粉砕処理によりコバルト・セリウム系複合酸化物上の細孔、特にミクロ孔が崩壊され、これによって後述する分散剤で保護された白金コロイドの拡散性が向上し白金が表面に均一に分散するためコーキング量が減少すると考えられる。ミクロ孔とは細孔の直径が2nm以下の細孔のことをいうが、この細孔を崩壊させることによってコーキング量をより効率的に減少させることができる。コーキング量の減少により低温で高い活性が持続可能となる。

The cobalt-cerium composite oxide can be produced by calcining a compound having a carbonate of cobalt and cerium as a precursor at 300 to 500 ° C. in air, and then grinding. Pulverization process collapses pores, especially micropores, on the cobalt-cerium composite oxide, thereby improving the diffusivity of the platinum colloid protected by the dispersant described later and causticizing the platinum uniformly on the surface. It is believed that the amount will decrease. Micropores refer to pores having a pore diameter of 2 nm or less, but the amount of coking can be more efficiently reduced by collapsing the pores. The reduction of the amount of coking makes high activity sustainable at low temperatures.

白金は、分散剤で保護された白金コロイドの溶液を原料とすることが好ましい。白金コロイド溶液を原料としたのは、担持される白金粒子の分散性を高くするという点で有利と考えられるからである。白金コロイドの保護剤としては、ポリビニルポロリドンが好適であるが、それ以外にも、たとえば、ポリビニルポロリドン以外の高分子、配位子、ミセル等を使用することを妨げない。

The platinum is preferably made of a solution of platinum colloid protected with a dispersant. The reason for using a platinum colloid solution as a raw material is considered to be advantageous in terms of enhancing the dispersibility of platinum particles to be supported. As a protective agent of platinum colloid, polyvinyl poloridone is suitable, but it does not prevent using polymers other than polyvinyl poloridone, a ligand, a micelle, etc. besides it, for example.

特に限定されるものではないものの、触媒は、バインダー成分とともに成型してなる、或いは所望形状のステンレス鋼、鉄鋼、銅合金、アルミニウム合金、及びセラミックス材の何れか1つの不活性担体に担持されていてよい。前者において粉末あるいは粉末成型触媒を触媒充填層に充填した場合、空隙が小さくなることによる充填層の閉塞を避けることができる。

Although not particularly limited, the catalyst is formed by molding with a binder component, or supported on an inert carrier of stainless steel, steel, copper alloy, aluminum alloy, or ceramic material of a desired shape. You may In the former case, when the powder or powder molded catalyst is loaded into the catalyst packed bed, clogging of the packed bed due to the reduction of voids can be avoided.

上記した構造のVOC処理用触媒を用いたVOC処理の運転温度が、100~300℃の範囲が好適である。上記VOC処理用触媒を用いれば300℃を超えなくてもVOC処理ができるからである。この状態を保持すれば、従来の処理方法に比べ電気代や燃料費を削減することができる。逆に言えば、300℃を超えて運転することは、上記VOC処理触媒の低温度でも処理できるという特徴を稀釈化してしまうので特段の事情がない限り好ましいことではない。100℃以下の運転温度は、コーキングの蓄積を招きやすいため避けるべきである。

The operating temperature of the VOC treatment using the VOC treatment catalyst having the above-described structure is preferably in the range of 100 to 300.degree. This is because if the above-mentioned catalyst for VOC treatment is used, VOC treatment can be performed without exceeding 300 ° C. If this state is maintained, electricity costs and fuel costs can be reduced as compared with the conventional processing method. In other words, operating above 300 ° C. is not preferable unless there is a special circumstance, since it dilutes the characteristics that the above-mentioned VOC treatment catalyst can be treated even at low temperatures. Operating temperatures below 100 ° C. should be avoided as they are prone to coking buildup.

触媒性能評価は実施例1、比較例1~3ともに以下のように行った。

図1に示すヒーター付の管状電気炉内に設置した触媒充填管内にVOC処理触媒を充填し、この充填層にVOC含有ガスを連続的に流通させた。VOC含有ガスの組成は乾燥空気にトルエン若しくは酢酸エチルの蒸気を含有させたものとし、トルエン、酢酸エチル濃度は、それぞれ400ppm、900ppm、乾燥空気流速は100mL・min-1とした。作製した触媒粉末はいったんペレット化し、それを適度な大きさに砕いて充填管内を閉塞しないように充填した。 The catalyst performance was evaluated in the following manner for both Example 1 and Comparative Examples 1 to 3.

A catalyst-filled tube installed in a tubular electric furnace equipped with a heater as shown in FIG. 1 was filled with a VOC treatment catalyst, and a VOC-containing gas was allowed to flow continuously through this packed bed. The composition of the VOC-containing gas was such that dry air contained a vapor of toluene or ethyl acetate, and the concentrations of toluene and ethyl acetate were 400 ppm and 900 ppm, respectively, and the dry air flow rate was 100 mL · min −1 . The prepared catalyst powder was pelletized, crushed to a suitable size, and packed so as not to clog the packing tube.

図1に示すヒーター付の管状電気炉内に設置した触媒充填管内にVOC処理触媒を充填し、この充填層にVOC含有ガスを連続的に流通させた。VOC含有ガスの組成は乾燥空気にトルエン若しくは酢酸エチルの蒸気を含有させたものとし、トルエン、酢酸エチル濃度は、それぞれ400ppm、900ppm、乾燥空気流速は100mL・min-1とした。作製した触媒粉末はいったんペレット化し、それを適度な大きさに砕いて充填管内を閉塞しないように充填した。 The catalyst performance was evaluated in the following manner for both Example 1 and Comparative Examples 1 to 3.

A catalyst-filled tube installed in a tubular electric furnace equipped with a heater as shown in FIG. 1 was filled with a VOC treatment catalyst, and a VOC-containing gas was allowed to flow continuously through this packed bed. The composition of the VOC-containing gas was such that dry air contained a vapor of toluene or ethyl acetate, and the concentrations of toluene and ethyl acetate were 400 ppm and 900 ppm, respectively, and the dry air flow rate was 100 mL · min −1 . The prepared catalyst powder was pelletized, crushed to a suitable size, and packed so as not to clog the packing tube.

管状電気炉のヒーター温度を調整することにより触媒充填層の温度を調整した。トルエン燃焼においては300℃、酢酸エチル燃焼においては400℃に昇温した後、1時間その温度を保持し、その後30℃まで1分間に1℃ずつ降温させた。降温時に熱伝導度検出器付きガスクロマトグラフを用いてガス中の二酸化炭素濃度、及びトルエン若しくは酢酸エチル濃度を測定した。トルエン若しくは酢酸エチルが完全燃焼した際のガス中の二酸化炭素濃度をC1、触媒充填層を通過したガス中の二酸化炭素濃度をC2とした時、CO2生成率(燃焼率)c(%)はc=C2/C1×100の式から求めた。

The temperature of the catalyst packed bed was adjusted by adjusting the heater temperature of the tubular electric furnace. The temperature was raised to 300 ° C. in toluene combustion and to 400 ° C. in ethyl acetate combustion, and the temperature was maintained for 1 hour, and then the temperature was lowered by 1 ° C. in 1 minute to 30 ° C. When the temperature was lowered, the concentration of carbon dioxide in the gas and the concentration of toluene or ethyl acetate were measured using a gas chromatograph equipped with a thermal conductivity detector. Assuming that the carbon dioxide concentration in the gas when the toluene or ethyl acetate is completely burned is C1, and the carbon dioxide concentration in the gas that has passed through the catalyst packed bed is C2, the CO 2 generation rate (combustion rate) c (%) is It calculated | required from the formula of c = C2 / C1x100.

触媒のコーキング生成評価は実施例1、比較例4ともに以下のように行った。

同じく図1に示す管状電気炉内に設置した触媒充填管内に触媒を充填し、この充填層にトルエンの蒸気を含有させた乾燥空気(VOC含有ガス)を連続的に流通させた。トルエン濃度は400ppm、乾燥空気流速は100mL・min-1とした。作製した触媒粉末はいったんペレット化し、それを適度な大きさに砕いて充填管内を閉塞しないように充填した。管状電気炉を用いて触媒層の温度を調整した。150℃若しくは170℃に昇温した後、24時間その温度を保持しトルエンの蒸気を含有させた乾燥空気を連続的に流通させ、トルエンの燃焼を継続させた。その後、乾燥空気のみを流して30℃まで降温し、乾燥空気のみを流したまま300℃まで1分間に1℃ずつ昇温させ、触媒表面に蓄積したコーキングの燃焼に伴う二酸化炭素の発生を熱伝導度検出器付きガスクロマトグラフで測定した。 The coking formation evaluation of the catalyst was performed as follows in both Example 1 and Comparative Example 4.

Similarly, a catalyst filled tube installed in a tubular electric furnace shown in FIG. 1 was filled with a catalyst, and dry air (VOC-containing gas) containing a vapor of toluene was continuously circulated in the packed bed. The concentration of toluene was 400 ppm, and the flow rate of dry air was 100 mL · min −1 . The prepared catalyst powder was pelletized, crushed to a suitable size, and packed so as not to clog the packing tube. The temperature of the catalyst layer was adjusted using a tubular electric furnace. After raising the temperature to 150 ° C. or 170 ° C., the temperature was maintained for 24 hours, dry air containing toluene vapor was continuously circulated, and combustion of toluene was continued. Thereafter, the temperature is lowered to 30 ° C. by flowing only dry air, and the temperature is raised by 1 ° C. per minute to 300 ° C. while flowing only the dry air, and the generation of carbon dioxide accompanying combustion of coking accumulated on the catalyst surface is It measured by the gas chromatograph with a conductivity detector.

同じく図1に示す管状電気炉内に設置した触媒充填管内に触媒を充填し、この充填層にトルエンの蒸気を含有させた乾燥空気(VOC含有ガス)を連続的に流通させた。トルエン濃度は400ppm、乾燥空気流速は100mL・min-1とした。作製した触媒粉末はいったんペレット化し、それを適度な大きさに砕いて充填管内を閉塞しないように充填した。管状電気炉を用いて触媒層の温度を調整した。150℃若しくは170℃に昇温した後、24時間その温度を保持しトルエンの蒸気を含有させた乾燥空気を連続的に流通させ、トルエンの燃焼を継続させた。その後、乾燥空気のみを流して30℃まで降温し、乾燥空気のみを流したまま300℃まで1分間に1℃ずつ昇温させ、触媒表面に蓄積したコーキングの燃焼に伴う二酸化炭素の発生を熱伝導度検出器付きガスクロマトグラフで測定した。 The coking formation evaluation of the catalyst was performed as follows in both Example 1 and Comparative Example 4.

Similarly, a catalyst filled tube installed in a tubular electric furnace shown in FIG. 1 was filled with a catalyst, and dry air (VOC-containing gas) containing a vapor of toluene was continuously circulated in the packed bed. The concentration of toluene was 400 ppm, and the flow rate of dry air was 100 mL · min −1 . The prepared catalyst powder was pelletized, crushed to a suitable size, and packed so as not to clog the packing tube. The temperature of the catalyst layer was adjusted using a tubular electric furnace. After raising the temperature to 150 ° C. or 170 ° C., the temperature was maintained for 24 hours, dry air containing toluene vapor was continuously circulated, and combustion of toluene was continued. Thereafter, the temperature is lowered to 30 ° C. by flowing only dry air, and the temperature is raised by 1 ° C. per minute to 300 ° C. while flowing only the dry air, and the generation of carbon dioxide accompanying combustion of coking accumulated on the catalyst surface is It measured by the gas chromatograph with a conductivity detector.

(白金担持コバルト・セリウム複合酸化物)

<1>触媒の作製

コバルト炭酸塩とセリウムの炭酸塩の前駆体を空気中、300℃で1時間焼成してコバルト・セリウム複合酸化物を作製した。これをポリビニルピロリドンで保護された白金コロイド(田中貴金属工業株式会社製)の水溶液に浸漬させ、撹拌及び加温しながら、溶液を蒸発させた。白金の担持率は、コバルト・セリウム複合酸化物に対して重量比で1、2、5%とした。乾燥した試料を空気中で1分間に0.9℃ずつ徐々に昇温して最終的に300℃で1時間焼成することにより目的触媒を得た。 (Platinum-supported cobalt-cerium composite oxide)

Preparation of <1> Catalyst A precursor of cobalt carbonate and cerium carbonate was calcined in air at 300 ° C. for 1 hour to prepare a cobalt-cerium composite oxide. This was immersed in an aqueous solution of platinum colloid (manufactured by Tanaka Kikinzoku Kogyo Co., Ltd.) protected by polyvinyl pyrrolidone, and the solution was evaporated while stirring and heating. The loading ratio of platinum was set to 1, 2, 5% by weight relative to the cobalt-cerium composite oxide. The dried sample was gradually heated by 0.9 ° C. per minute in air and finally calcined at 300 ° C. for 1 hour to obtain a target catalyst.

<1>触媒の作製

コバルト炭酸塩とセリウムの炭酸塩の前駆体を空気中、300℃で1時間焼成してコバルト・セリウム複合酸化物を作製した。これをポリビニルピロリドンで保護された白金コロイド(田中貴金属工業株式会社製)の水溶液に浸漬させ、撹拌及び加温しながら、溶液を蒸発させた。白金の担持率は、コバルト・セリウム複合酸化物に対して重量比で1、2、5%とした。乾燥した試料を空気中で1分間に0.9℃ずつ徐々に昇温して最終的に300℃で1時間焼成することにより目的触媒を得た。 (Platinum-supported cobalt-cerium composite oxide)

Preparation of <1> Catalyst A precursor of cobalt carbonate and cerium carbonate was calcined in air at 300 ° C. for 1 hour to prepare a cobalt-cerium composite oxide. This was immersed in an aqueous solution of platinum colloid (manufactured by Tanaka Kikinzoku Kogyo Co., Ltd.) protected by polyvinyl pyrrolidone, and the solution was evaporated while stirring and heating. The loading ratio of platinum was set to 1, 2, 5% by weight relative to the cobalt-cerium composite oxide. The dried sample was gradually heated by 0.9 ° C. per minute in air and finally calcined at 300 ° C. for 1 hour to obtain a target catalyst.

<2>触媒の性能評価

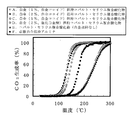

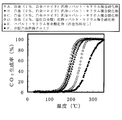

トルエン及び酢酸エチルに対するCO2生成率(燃焼率)の温度依存性 図2のA(トルエン、白金(1%、白金コロイド)担持コバルト・セリウム複合酸化物)、B(トルエン、白金(2%、白金コロイド)担持コバルト・セリウム複合酸化物)、C(トルエン、白金(5%、白金コロイド)担持コバルト・セリウム複合酸化物)、図3のA(酢酸エチル、白金(1%、白金コロイド)担持コバルト・セリウム複合酸化物)、B(酢酸エチル、白金(2%、白金コロイド)担持コバルト・セリウム複合酸化物)、C(酢酸エチル、白金(5%、白金コロイド)担持コバルト・セリウム複合酸化物)

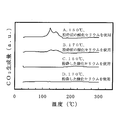

150℃で24時間燃焼を継続した後のコーキング生成評価 図4のA(150℃、粉砕前の酸化セリウムを使用)

170℃で24時間燃焼を継続した後のコーキング生成評価 図4のB(170℃、粉砕前の酸化セリウムを使用) <2> Performance evaluation of catalyst Temperature dependency of CO 2 generation rate (burning rate) to toluene and ethyl acetate A (toluene, platinum (1%, platinum colloid) supported cobalt-cerium composite oxide), B (FIG. 2) Toluene, platinum (2%, platinum colloid) supported cobalt-cerium composite oxide), C (toluene, platinum (5%, platinum colloid) supported cobalt-cerium composite oxide), A in FIG. 3 (ethyl acetate, platinum ( 1% (platinum colloid) supported cobalt-cerium composite oxide), B (ethyl acetate, platinum (2%, platinum colloid) supported cobalt-cerium composite oxide), C (ethyl acetate, platinum (5% platinum colloid) Supported cobalt-cerium composite oxide)

Evaluation of coking formation after continuing combustion at 150 ° C. for 24 hours A in FIG. 4 (150 ° C., using cerium oxide before grinding)

Evaluation of coking formation after continuing combustion at 170 ° C. for 24 hours B in FIG. 4 (170 ° C., using cerium oxide before grinding)

トルエン及び酢酸エチルに対するCO2生成率(燃焼率)の温度依存性 図2のA(トルエン、白金(1%、白金コロイド)担持コバルト・セリウム複合酸化物)、B(トルエン、白金(2%、白金コロイド)担持コバルト・セリウム複合酸化物)、C(トルエン、白金(5%、白金コロイド)担持コバルト・セリウム複合酸化物)、図3のA(酢酸エチル、白金(1%、白金コロイド)担持コバルト・セリウム複合酸化物)、B(酢酸エチル、白金(2%、白金コロイド)担持コバルト・セリウム複合酸化物)、C(酢酸エチル、白金(5%、白金コロイド)担持コバルト・セリウム複合酸化物)

150℃で24時間燃焼を継続した後のコーキング生成評価 図4のA(150℃、粉砕前の酸化セリウムを使用)

170℃で24時間燃焼を継続した後のコーキング生成評価 図4のB(170℃、粉砕前の酸化セリウムを使用) <2> Performance evaluation of catalyst Temperature dependency of CO 2 generation rate (burning rate) to toluene and ethyl acetate A (toluene, platinum (1%, platinum colloid) supported cobalt-cerium composite oxide), B (FIG. 2) Toluene, platinum (2%, platinum colloid) supported cobalt-cerium composite oxide), C (toluene, platinum (5%, platinum colloid) supported cobalt-cerium composite oxide), A in FIG. 3 (ethyl acetate, platinum ( 1% (platinum colloid) supported cobalt-cerium composite oxide), B (ethyl acetate, platinum (2%, platinum colloid) supported cobalt-cerium composite oxide), C (ethyl acetate, platinum (5% platinum colloid) Supported cobalt-cerium composite oxide)

Evaluation of coking formation after continuing combustion at 150 ° C. for 24 hours A in FIG. 4 (150 ° C., using cerium oxide before grinding)

Evaluation of coking formation after continuing combustion at 170 ° C. for 24 hours B in FIG. 4 (170 ° C., using cerium oxide before grinding)

前述のとおり、芳香族のVOCと芳香環を含まないVOCで触媒処理温度(燃焼温度)が大きく異なる。芳香族の典型的なVOCとしてトルエン、芳香環を含まない典型的なVOCとして酢酸エチルを選び試験を実施した。CO2の生成率が90~100%に達する燃焼温度に着目し、触媒処理可能な温度を整理した。ポリビニルピロリドンで保護された白金コロイドの水溶液を用いて白金を担持したコバルト・セリウム複合酸化物を用いた場合、酢酸エチルのCO2生成率が90~100%に達する温度は200~250℃程度に(図3のA、B、C)、トルエンの同温度は約200℃以下に(図2のA、B、C)減少した。白金担持率の増加に伴い、燃焼温度が減少することも見出された。芳香族のVOCと芳香環を含まないVOCを同時に概ね250℃以下で処理することが可能となった。

As described above, the catalyst processing temperature (combustion temperature) is largely different between the aromatic VOC and the VOC containing no aromatic ring. The test was conducted by selecting toluene as a typical VOC of aromatics and ethyl acetate as a typical VOC containing no aromatic ring. Focusing on the combustion temperature at which the generation rate of CO 2 reaches 90 to 100%, the temperature at which the catalyst can be processed was organized. When using a cobalt-cerium composite oxide loaded with platinum using an aqueous solution of platinum colloid protected by polyvinyl pyrrolidone, the temperature at which the CO 2 generation rate of ethyl acetate reaches 90 to 100% is about 200 to 250 ° C. The same temperature of (To A, B and C in FIG. 3) and toluene decreased to about 200 ° C. or less (A to B in FIG. 2). It has also been found that the combustion temperature decreases as the platinum loading increases. It has become possible to simultaneously process aromatic VOCs and VOCs that do not contain aromatic rings at approximately 250 ° C. or less.

トルエン燃焼により触媒表面に蓄積したコーキングの燃焼に伴うCO2の発生に関して、酸化セリウムを粉砕せず、コバルト・セリウム複合酸化物を合成し、ポリビニルピロリドンで保護された白金コロイドの水溶液を用いて白金を担持した触媒では、150℃・24時間のトルエン燃焼後の触媒(図4のA)、170℃・24時間のトルエン燃焼後の触媒(図4のB)ともにCO2が生成し、コーキングの存在が認められた。

With respect to the generation of CO 2 associated with the combustion of coking accumulated on the catalyst surface by toluene combustion, cerium oxide is not crushed, and a cobalt-cerium composite oxide is synthesized, and platinum is used with an aqueous solution of platinum colloid protected by polyvinylpyrrolidone. In the case of catalysts loaded with CO 2, CO 2 is generated with the catalyst after toluene combustion at 150 ° C. for 24 hours (A in FIG. 4) and the catalyst after toluene combustion at 170 ° C. for 24 hours (B in FIG. 4) The existence was recognized.

[比較例1]

白金担持コバルト・セリウム複合酸化物(塩化白金酸を用いた担持)

<1>触媒の作製

コバルト炭酸塩とセリウムの炭酸塩の前駆体を空気中、300℃で1時間焼成してコバルト・セリウム複合酸化物を作製した。これを塩化白金酸の水溶液に浸漬させ、撹拌及び加温しながら、溶液を蒸発させた。白金の担持率は、コバルト・セリウム複合酸化物に対して重量比で2%とした。乾燥した試料を水素雰囲気下において400℃で1時間還元することにより目的触媒を得た。 Comparative Example 1

Platinum-supported cobalt-cerium composite oxide (supported using chloroplatinic acid)

Preparation of <1> Catalyst A precursor of cobalt carbonate and cerium carbonate was calcined in air at 300 ° C. for 1 hour to prepare a cobalt-cerium composite oxide. This was immersed in an aqueous solution of chloroplatinic acid, and the solution was evaporated while stirring and warming. The platinum loading was 2% by weight relative to the cobalt-cerium composite oxide. The target sample was obtained by reducing the dried sample under hydrogen atmosphere at 400 ° C. for 1 hour.

白金担持コバルト・セリウム複合酸化物(塩化白金酸を用いた担持)

<1>触媒の作製

コバルト炭酸塩とセリウムの炭酸塩の前駆体を空気中、300℃で1時間焼成してコバルト・セリウム複合酸化物を作製した。これを塩化白金酸の水溶液に浸漬させ、撹拌及び加温しながら、溶液を蒸発させた。白金の担持率は、コバルト・セリウム複合酸化物に対して重量比で2%とした。乾燥した試料を水素雰囲気下において400℃で1時間還元することにより目的触媒を得た。 Comparative Example 1

Platinum-supported cobalt-cerium composite oxide (supported using chloroplatinic acid)

Preparation of <1> Catalyst A precursor of cobalt carbonate and cerium carbonate was calcined in air at 300 ° C. for 1 hour to prepare a cobalt-cerium composite oxide. This was immersed in an aqueous solution of chloroplatinic acid, and the solution was evaporated while stirring and warming. The platinum loading was 2% by weight relative to the cobalt-cerium composite oxide. The target sample was obtained by reducing the dried sample under hydrogen atmosphere at 400 ° C. for 1 hour.

<2>触媒の性能評価

トルエン及び酢酸エチルに対するCO2生成率(燃焼率)の温度依存性 図2のD(トルエン、白金(2%、塩化白金酸)担持コバルト・セリウム複合酸化物)、図3のD(酢酸エチル、白金(2%、塩化白金酸)担持コバルト・セリウム複合酸化物) <2> Performance evaluation of catalyst Temperature dependency of CO 2 generation rate (burning rate) to toluene and ethyl acetate D (toluene, platinum (2%, chloroplatinic acid) supported cobalt-cerium composite oxide) in FIG. 3 D (ethyl acetate, platinum (2%, chloroplatinic acid) supported cobalt-cerium composite oxide)

トルエン及び酢酸エチルに対するCO2生成率(燃焼率)の温度依存性 図2のD(トルエン、白金(2%、塩化白金酸)担持コバルト・セリウム複合酸化物)、図3のD(酢酸エチル、白金(2%、塩化白金酸)担持コバルト・セリウム複合酸化物) <2> Performance evaluation of catalyst Temperature dependency of CO 2 generation rate (burning rate) to toluene and ethyl acetate D (toluene, platinum (2%, chloroplatinic acid) supported cobalt-cerium composite oxide) in FIG. 3 D (ethyl acetate, platinum (2%, chloroplatinic acid) supported cobalt-cerium composite oxide)

従来から広く用いられている典型的な原料である塩化白金酸を用いて白金を担持したコバルト・セリウム複合酸化物を用いた場合、後述するコバルト・セリウム複合酸化物(白金担持なし)を用いた場合と比して、トルエンの燃焼温度はほとんど変わらず(図2のD)、酢酸エチルのCO2生成率が90~100%に達する温度は200~250℃程度に上昇し(図3のD)、白金を担持することにより性能がむしろ悪くなった。これは、比表面積が小さい、表面との親和性が低い等の理由によりコバルト・セリウム複合酸化物上に白金が均一に分散されず、凝集してしまったため、性能が悪くなったと考えられる。

When using cobalt-cerium composite oxide supporting platinum using chloroplatinic acid which is a typical raw material widely used conventionally, cobalt-cerium composite oxide (without platinum support) described later was used Compared with the case, the combustion temperature of toluene hardly changes (D in FIG. 2), the temperature at which the CO 2 generation rate of ethyl acetate reaches 90 to 100% rises to about 200 to 250 ° C. (D in FIG. ), The performance became worse by supporting platinum. It is considered that this is because the platinum is not uniformly dispersed on the cobalt-cerium composite oxide for the reason that the specific surface area is small, the affinity to the surface is low, and the like, and the performance is deteriorated.

[比較例2]

コバルト・セリウム複合酸化物(白金担持なし)

<1>触媒の作製

コバルト炭酸塩とセリウムの炭酸塩の前駆体を空気中、300℃で1時間焼成してコバルト・セリウム複合酸化物を作製した。 Comparative Example 2

Cobalt-cerium composite oxide (without platinum support)

Preparation of <1> Catalyst A precursor of cobalt carbonate and cerium carbonate was calcined in air at 300 ° C. for 1 hour to prepare a cobalt-cerium composite oxide.

コバルト・セリウム複合酸化物(白金担持なし)

<1>触媒の作製

コバルト炭酸塩とセリウムの炭酸塩の前駆体を空気中、300℃で1時間焼成してコバルト・セリウム複合酸化物を作製した。 Comparative Example 2

Cobalt-cerium composite oxide (without platinum support)

Preparation of <1> Catalyst A precursor of cobalt carbonate and cerium carbonate was calcined in air at 300 ° C. for 1 hour to prepare a cobalt-cerium composite oxide.

<2>触媒の性能評価

トルエン及び酢酸エチルに対するCO2生成率(燃焼率)の温度依存性 図2のE(トルエン、コバルト・セリウム複合酸化物(白金担持なし))、図3のE(酢酸エチル、コバルト・セリウム複合酸化物(白金担持なし)) <2> Performance evaluation of catalyst Temperature dependency of CO 2 generation rate (burning rate) to toluene and ethyl acetate E in FIG. 2 (toluene, cobalt-cerium composite oxide (without platinum support)), E in FIG. 3 (acetic acid) Ethyl, cobalt-cerium composite oxide (without platinum support))

トルエン及び酢酸エチルに対するCO2生成率(燃焼率)の温度依存性 図2のE(トルエン、コバルト・セリウム複合酸化物(白金担持なし))、図3のE(酢酸エチル、コバルト・セリウム複合酸化物(白金担持なし)) <2> Performance evaluation of catalyst Temperature dependency of CO 2 generation rate (burning rate) to toluene and ethyl acetate E in FIG. 2 (toluene, cobalt-cerium composite oxide (without platinum support)), E in FIG. 3 (acetic acid) Ethyl, cobalt-cerium composite oxide (without platinum support))

コバルト・セリウム複合酸化物(白金担持なし)を用いた場合、酢酸エチルのCO2生成率が90~100%に達する温度は約250℃付近であった(図3のE)が、トルエンでは300℃程度を必要とした(図2のE)。

When a cobalt-cerium composite oxide (without platinum support) was used, the temperature at which the CO 2 generation rate of ethyl acetate reached 90 to 100% was around 250 ° C. (E in FIG. 3), but 300 for toluene. It required about ° C (E in FIG. 2).

[比較例3]

白金担持アルミナ(日揮ユニバーサル株式会社製市販品)

<1>触媒

白金担持アルミナを適度な大きさに砕いて触媒充填管内を閉塞しないように充填した。 Comparative Example 3

Platinum-loaded alumina (commercially available from JGC Universal Corporation)

<1> Catalyst The platinum-supporting alumina was crushed to a suitable size and packed so as not to clog the catalyst-filled tube.

白金担持アルミナ(日揮ユニバーサル株式会社製市販品)

<1>触媒

白金担持アルミナを適度な大きさに砕いて触媒充填管内を閉塞しないように充填した。 Comparative Example 3

Platinum-loaded alumina (commercially available from JGC Universal Corporation)

<1> Catalyst The platinum-supporting alumina was crushed to a suitable size and packed so as not to clog the catalyst-filled tube.

<2>触媒の性能評価

トルエン及び酢酸エチルに対するCO2生成率(燃焼率)の温度依存性 図2のF(トルエン、市販白金担持アルミナ)、図3のF(酢酸エチル、市販白金担持アルミナ) <2> Performance evaluation of catalyst Temperature dependency of CO 2 generation rate (burning rate) to toluene and ethyl acetate F (toluene, commercially available platinum-supported alumina) in FIG. 2, F (ethyl acetate, commercially available platinum-supported alumina) in FIG.

トルエン及び酢酸エチルに対するCO2生成率(燃焼率)の温度依存性 図2のF(トルエン、市販白金担持アルミナ)、図3のF(酢酸エチル、市販白金担持アルミナ) <2> Performance evaluation of catalyst Temperature dependency of CO 2 generation rate (burning rate) to toluene and ethyl acetate F (toluene, commercially available platinum-supported alumina) in FIG. 2, F (ethyl acetate, commercially available platinum-supported alumina) in FIG.

市販の白金担持アルミナ触媒を用いた場合、トルエンのCO2生成率が90~100%に達する温度は200~250℃程度であった(図2のF)が、酢酸エチルでは約350℃付近となった(図3のF)。

When a commercially available platinum-supported alumina catalyst was used, the temperature at which the CO 2 production rate of toluene reached 90 to 100% was about 200 to 250 ° C. (F in FIG. 2), but for ethyl acetate it was about 350 ° C. It became (F of FIG. 3).

[比較例4]

白金担持コバルト・セリウム複合酸化物(粉砕した酸化セリウムを使用)

<1>触媒の作製

コバルト炭酸塩を空気中、300℃で1時間焼成することにより酸化コバルトを作製した。 Comparative Example 4

Platinum-supported cobalt-cerium composite oxide (using crushed cerium oxide)

<1> Preparation of Catalyst A cobalt oxide was prepared by calcining cobalt carbonate in air at 300 ° C. for 1 hour.

白金担持コバルト・セリウム複合酸化物(粉砕した酸化セリウムを使用)

<1>触媒の作製

コバルト炭酸塩を空気中、300℃で1時間焼成することにより酸化コバルトを作製した。 Comparative Example 4

Platinum-supported cobalt-cerium composite oxide (using crushed cerium oxide)

<1> Preparation of Catalyst A cobalt oxide was prepared by calcining cobalt carbonate in air at 300 ° C. for 1 hour.

セリウムの炭酸塩を空気中、300℃で1時間焼成して酸化セリウムを作製し、湿式粉砕機(フリッチュ・ジャパン株式会社製遊星型ボールミル クラシックラインP-7)を用いて粉砕した。粉砕前のメディアン径は23.3μm、粉砕後のメディアン径は0.415μ

mであった。粉砕前後の細孔分布はマイクロトラック・ベル株式会社製BELSORP-maxを用いて測定した。粉砕後の試料をポリビニルピロリドンで保護された白金コロイド(田

中貴金属工業株式会社製)の水溶液に浸漬させ、撹拌及び加温しながら、溶液を蒸発、乾燥させた。乾燥させた試料と酸化コバルトを混合し、空気中で1分間に0.9℃ずつ徐々に昇温して最終的に300℃で1時間焼成することにより目的触媒を得た。白金の担持率は、コバルト・セリウム複合酸化物に対して重量比で2%とした。 Cerium carbonate was calcined in air at 300 ° C. for 1 hour to prepare cerium oxide, and pulverized using a wet crusher (planet type ball mill Classic Line P-7 manufactured by Fritsch Japan Ltd.). The median diameter before grinding is 23.3 μm, and the median diameter after grinding is 0.415 μm

It was m. The pore distribution before and after grinding was measured using BELSORP-max manufactured by Microtrac Bell Inc. The sample after grinding was immersed in an aqueous solution of platinum colloid (manufactured by Tanaka Kikinzoku Kogyo Co., Ltd.) protected by polyvinyl pyrrolidone, and the solution was evaporated and dried while being stirred and heated. The dried sample and cobalt oxide were mixed, the temperature was gradually raised by 0.9 ° C. in 1 minute in air, and the final catalyst was calcined at 300 ° C. for 1 hour to obtain a target catalyst. The platinum loading was 2% by weight relative to the cobalt-cerium composite oxide.

mであった。粉砕前後の細孔分布はマイクロトラック・ベル株式会社製BELSORP-maxを用いて測定した。粉砕後の試料をポリビニルピロリドンで保護された白金コロイド(田

中貴金属工業株式会社製)の水溶液に浸漬させ、撹拌及び加温しながら、溶液を蒸発、乾燥させた。乾燥させた試料と酸化コバルトを混合し、空気中で1分間に0.9℃ずつ徐々に昇温して最終的に300℃で1時間焼成することにより目的触媒を得た。白金の担持率は、コバルト・セリウム複合酸化物に対して重量比で2%とした。 Cerium carbonate was calcined in air at 300 ° C. for 1 hour to prepare cerium oxide, and pulverized using a wet crusher (planet type ball mill Classic Line P-7 manufactured by Fritsch Japan Ltd.). The median diameter before grinding is 23.3 μm, and the median diameter after grinding is 0.415 μm

It was m. The pore distribution before and after grinding was measured using BELSORP-max manufactured by Microtrac Bell Inc. The sample after grinding was immersed in an aqueous solution of platinum colloid (manufactured by Tanaka Kikinzoku Kogyo Co., Ltd.) protected by polyvinyl pyrrolidone, and the solution was evaporated and dried while being stirred and heated. The dried sample and cobalt oxide were mixed, the temperature was gradually raised by 0.9 ° C. in 1 minute in air, and the final catalyst was calcined at 300 ° C. for 1 hour to obtain a target catalyst. The platinum loading was 2% by weight relative to the cobalt-cerium composite oxide.

<2>触媒の性能評価

150℃で24時間燃焼を継続した後のコーキング生成評価 図4のC(150℃、粉砕後の酸化セリウムを使用)

170℃で24時間燃焼を継続した後のコーキング生成評価 図4のD(170℃、粉砕後の酸化セリウムを使用)

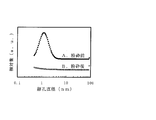

粉砕前の酸化セリウムの細孔分布 図5のA(粉砕前)

粉砕後の酸化セリウムの細孔分布 図5のB(粉砕後) <2> Performance evaluation of catalyst Evaluation of coking formation after continuing combustion for 24 hours at 150 ° C. C in FIG. 4 (150 ° C., using cerium oxide after grinding)

Evaluation of coking formation after continuing combustion at 170 ° C. for 24 hours D in FIG. 4 (170 ° C., using cerium oxide after grinding)

Pore distribution of cerium oxide before grinding A in FIG. 5 (before grinding)

Pore distribution of cerium oxide after grinding B in FIG. 5 (after grinding)

150℃で24時間燃焼を継続した後のコーキング生成評価 図4のC(150℃、粉砕後の酸化セリウムを使用)

170℃で24時間燃焼を継続した後のコーキング生成評価 図4のD(170℃、粉砕後の酸化セリウムを使用)

粉砕前の酸化セリウムの細孔分布 図5のA(粉砕前)

粉砕後の酸化セリウムの細孔分布 図5のB(粉砕後) <2> Performance evaluation of catalyst Evaluation of coking formation after continuing combustion for 24 hours at 150 ° C. C in FIG. 4 (150 ° C., using cerium oxide after grinding)

Evaluation of coking formation after continuing combustion at 170 ° C. for 24 hours D in FIG. 4 (170 ° C., using cerium oxide after grinding)

Pore distribution of cerium oxide before grinding A in FIG. 5 (before grinding)

Pore distribution of cerium oxide after grinding B in FIG. 5 (after grinding)

トルエン燃焼により触媒表面に蓄積したコーキングの燃焼に伴うCO2の発生に関して、酸化セリウムを粉砕後にコバルト・セリウム複合酸化物を合成し、ポリビニルピロリドンで保護された白金コロイドの水溶液を用いて白金を担持した触媒では、150℃・24時間のトルエン燃焼後の触媒(図4のC)、170℃・24時間のトルエン燃焼後の触媒(図4のD)ともにコーキングの存在が認められなかった。これは粉砕により細孔容積が減少し(図5のA、B)、白金を担持する際、分散剤で保護された白金コロイド(直径33nm)の拡散性が向上し白金が表面により均一に分散するため、コーキング量が減少すると考えられる。

With regard to the generation of CO 2 accompanying the combustion of coking accumulated on the catalyst surface by toluene combustion, the cerium oxide is crushed and then a cobalt-cerium composite oxide is synthesized, and platinum is supported using an aqueous solution of platinum colloid protected by polyvinyl pyrrolidone. In the catalysts obtained, coking was not found for the catalyst after toluene combustion at 150 ° C. for 24 hours (C in FIG. 4) and the catalyst after toluene combustion at 170 ° C. for 24 hours (D in FIG. 4). This reduces the pore volume by grinding (A, B in FIG. 5), improves the diffusivity of the dispersion-protected platinum colloid (diameter 33 nm) when platinum is supported, and the platinum is dispersed more uniformly on the surface To reduce the caulking amount.

Claims (5)

- VOCを含有するガス燃焼処理用の、白金をコバルト・セリウム系複合酸化物上に直接担持させたVOC処理用触媒であって、

触媒全体の質量に占めるコバルト・セリウム系複合酸化物の質量割合が80%以上であり、コバルト・セリウム系複合酸化物の質量に占める白金の含有量をa(単位:質量%)とすると、0<a≦20の範囲である

ことを特徴とするVOC処理用触媒。 A catalyst for treatment of VOC, wherein platinum is directly supported on cobalt-cerium composite oxide, for gas combustion treatment containing VOC,

Assuming that the mass ratio of the cobalt-cerium composite oxide occupying in the mass of the whole catalyst is 80% or more, and the content of platinum in the mass of the cobalt-cerium composite oxide is a (unit: mass%), 0 It is a range of <a ≦ 20. A catalyst for treating VOCs. - 前記白金は、分散剤で保護された白金コロイドの溶液を原料とする

ことを特徴とする請求項1に記載のVOC処理用触媒。 The catalyst for treating VOC according to claim 1, wherein the platinum is a solution of platinum colloid protected by a dispersant. - 前記触媒は、バインダー成分とともに成型してなる、或いは

所望形状のステンレス鋼、鉄鋼、銅合金、アルミニウム合金、及びセラミックス材の何れか1つの担体に担持されている

ことを特徴とする請求項1または2記載のVOC処理用触媒。 The catalyst is formed by molding with a binder component, or is supported on any one of a stainless steel, steel, copper alloy, aluminum alloy, and ceramic material having a desired shape. The catalyst for VOC treatment as described in 2). - 請求項1ないし3いずれか記載のVOC処理用触媒の製造方法であって、

前記コバルト・セリウム系複合酸化物は、コバルトとセリウムの炭酸塩を前駆体とする化合物を空気中300~500℃で焼成し、その後粉砕処理して作製する

ことを特徴とするVOC処理用触媒の製造方法。 A method for producing a catalyst for treating VOC according to any one of claims 1 to 3, wherein

The cobalt-cerium composite oxide is prepared by calcinating a compound having a carbonate of cobalt and cerium as a precursor in air at 300 to 500 ° C. and then pulverizing it. Production method. - 請求項1ないし3いずれか記載のVOC処理用触媒を用いたVOC処理方法であって、

運転温度が、100~300℃である

ことを特徴とするVOC処理方法。 A method of treating VOC using the catalyst for treating VOC according to any one of claims 1 to 3,

The operating temperature is 100 to 300 ° C. A VOC treatment method characterized in that

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201880029094.1A CN110621399A (en) | 2017-07-05 | 2018-06-29 | Catalyst for VOC treatment |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2017131884A JP7119256B2 (en) | 2017-07-05 | 2017-07-05 | Method for producing VOC treatment catalyst, VOC treatment method, and VOC treatment catalyst |

| JP2017-131884 | 2017-07-05 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2019009216A1 true WO2019009216A1 (en) | 2019-01-10 |

Family

ID=64950043

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2018/024929 WO2019009216A1 (en) | 2017-07-05 | 2018-06-29 | Catalyst for voc treatment |

Country Status (3)

| Country | Link |

|---|---|

| JP (1) | JP7119256B2 (en) |

| CN (1) | CN110621399A (en) |

| WO (1) | WO2019009216A1 (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN114269473A (en) * | 2019-08-14 | 2022-04-01 | 地方独立行政法人东京都立产业技术研究中心 | Method for producing catalyst for VOC treatment |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR102434675B1 (en) * | 2020-05-13 | 2022-08-19 | 주식회사 신성이엔지 | VOC removal system and its control method thereof |

Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH10511602A (en) * | 1994-12-30 | 1998-11-10 | エンゲルハード・コーポレーシヨン | Catalytic oxidation catalyst and method for controlling exhaust gas of volatile organic compounds, carbon monoxide and halogenated organic substances |

| JP2001187343A (en) * | 1999-03-29 | 2001-07-10 | Toyota Central Res & Dev Lab Inc | Cleaning catalyst at normal temperature and utilization thereof |

| JP2003225568A (en) * | 2002-02-05 | 2003-08-12 | Matsushita Electric Ind Co Ltd | Catalyst for purifying volatile organic compound and production method therefor |

| JP2008086987A (en) * | 2006-10-04 | 2008-04-17 | Christian Koch | Method and apparatus for oxidation and reduction of gas and vapor by catalyst of crystalline compound of heavy metal and rare earth element |

| US20080233039A1 (en) * | 2005-06-02 | 2008-09-25 | Symyx Technologies, Inc. | Catalysts For Co Oxidation,Voc Combustion And Nox Reduction And Methods Of Making And Using The Same |

| JP2011224546A (en) * | 2010-03-31 | 2011-11-10 | Tokyo Metropolitan Industrial Technology Research Institute | Inorganic oxide molded catalyst and method for manufacturing the same |

| CN105013508A (en) * | 2015-06-29 | 2015-11-04 | 浙江大学 | Catalyst for low temperature catalytic combustion of chlorinated volatile organic compounds and preparation method |

| JP6140326B1 (en) * | 2016-03-08 | 2017-05-31 | 株式会社流機エンジニアリング | Method for regenerating adsorbent of volatile organic compound |

Family Cites Families (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR100416735B1 (en) * | 1995-10-09 | 2004-03-26 | 삼성전기주식회사 | Catalyst for purifying exhaust gas from car and method for preparing thereof |

| JP2002219363A (en) * | 2001-01-26 | 2002-08-06 | Matsushita Electric Ind Co Ltd | Catalyst for cleaning volatile organic compound and method for preparing the same |

| CN1919455A (en) * | 2005-08-25 | 2007-02-28 | 中国科学院生态环境研究中心 | Process for eliminating volatile organic pollutant by catalytic oxidation |

| KR100989269B1 (en) * | 2005-11-01 | 2010-10-20 | 르노 에스.아.에스. | Catalyst for exhaust-gas purification and process for producing the same |

| JP5503155B2 (en) * | 2009-01-30 | 2014-05-28 | 新コスモス電機株式会社 | Carbon monoxide removal filter |

| CN102247867B (en) * | 2010-05-21 | 2013-06-19 | 中国石油化工股份有限公司 | Catalytic oxidation catalyst for methyl acetate in organic waste gas and preparation method thereof |

| CN104053503B (en) * | 2012-01-19 | 2016-11-02 | 丰田自动车株式会社 | Exhaust emission control catalyst and manufacture method thereof |

| JP5706476B2 (en) | 2013-07-01 | 2015-04-22 | 新コスモス電機株式会社 | Carbon monoxide oxidation catalyst and production method thereof |

| JP6315569B2 (en) | 2014-05-15 | 2018-04-25 | 国立研究開発法人産業技術総合研究所 | Combustion catalyst system |

| CN105964254A (en) * | 2016-06-20 | 2016-09-28 | 西南化工研究设计院有限公司 | Monolithic catalyst for catalyzing combustion of volatile organic compounds and preparation method of catalyst |

| CN106540714A (en) * | 2016-11-07 | 2017-03-29 | 上海纳米技术及应用国家工程研究中心有限公司 | A kind of cerium cobalt complex oxides loaded palladium catalyst and preparation and application for propane catalysis oxidation |

-

2017

- 2017-07-05 JP JP2017131884A patent/JP7119256B2/en active Active

-

2018

- 2018-06-29 WO PCT/JP2018/024929 patent/WO2019009216A1/en active Application Filing

- 2018-06-29 CN CN201880029094.1A patent/CN110621399A/en active Pending

Patent Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH10511602A (en) * | 1994-12-30 | 1998-11-10 | エンゲルハード・コーポレーシヨン | Catalytic oxidation catalyst and method for controlling exhaust gas of volatile organic compounds, carbon monoxide and halogenated organic substances |

| JP2001187343A (en) * | 1999-03-29 | 2001-07-10 | Toyota Central Res & Dev Lab Inc | Cleaning catalyst at normal temperature and utilization thereof |

| JP2003225568A (en) * | 2002-02-05 | 2003-08-12 | Matsushita Electric Ind Co Ltd | Catalyst for purifying volatile organic compound and production method therefor |

| US20080233039A1 (en) * | 2005-06-02 | 2008-09-25 | Symyx Technologies, Inc. | Catalysts For Co Oxidation,Voc Combustion And Nox Reduction And Methods Of Making And Using The Same |

| JP2008086987A (en) * | 2006-10-04 | 2008-04-17 | Christian Koch | Method and apparatus for oxidation and reduction of gas and vapor by catalyst of crystalline compound of heavy metal and rare earth element |

| JP2011224546A (en) * | 2010-03-31 | 2011-11-10 | Tokyo Metropolitan Industrial Technology Research Institute | Inorganic oxide molded catalyst and method for manufacturing the same |

| CN105013508A (en) * | 2015-06-29 | 2015-11-04 | 浙江大学 | Catalyst for low temperature catalytic combustion of chlorinated volatile organic compounds and preparation method |

| JP6140326B1 (en) * | 2016-03-08 | 2017-05-31 | 株式会社流機エンジニアリング | Method for regenerating adsorbent of volatile organic compound |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN114269473A (en) * | 2019-08-14 | 2022-04-01 | 地方独立行政法人东京都立产业技术研究中心 | Method for producing catalyst for VOC treatment |

Also Published As

| Publication number | Publication date |

|---|---|

| CN110621399A (en) | 2019-12-27 |

| JP7119256B2 (en) | 2022-08-17 |

| JP2019013871A (en) | 2019-01-31 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| Reddy et al. | Surface characterization of CeO2/SiO2 and V2O5/CeO2/SiO2 catalysts by Raman, XPS, and other techniques | |

| Yu et al. | Promoting effect of Ce in Ce/OMS-2 catalyst for catalytic combustion of dimethyl ether | |

| JP2003024798A (en) | Noble metal-containing supported catalyst and process for its preparation | |

| CN112717916B (en) | Rare earth monoatomic supported two-dimensional flaky titanium oxide composite photocatalytic material and preparation method and application thereof | |

| Klauke et al. | Enhancement of the SrTiO3 surface reactivity by exposure to electric fields | |

| CN104174425B (en) | It is a kind of for catalyst of volatile organic matter catalysis oxidation and preparation method thereof | |

| CN109225216B (en) | Anti-aging catalyst for purifying volatile organic compounds and preparation method thereof | |

| WO2019009216A1 (en) | Catalyst for voc treatment | |

| KR101182755B1 (en) | Catalyst composit for vocs oxidation and preparation process thereof | |

| Zhang et al. | Uncovering Original Z Scheme Heterojunctions of COF/MOx (M= Ti, Zn, Zr, Sn, Ce, and Nb) with Ascendant Photocatalytic Selectivity for Virtually 99.9% NO‐to‐NO3− Oxidation | |

| CN109395774B (en) | Cluster-supported catalyst and method for producing same | |

| Dyachenko et al. | Preparation and characterization of Ni–Co/SiO 2 nanocomposite catalysts for CO 2 methanation | |

| CN108658038A (en) | One kind being based on LiAlH4Hydrogen storage material and preparation method thereof | |

| CN106984318B (en) | Bimetal cobalt-based catalyst, preparation method and application | |

| CN109675559B (en) | Anti-deterioration catalyst for purifying volatile organic compounds and preparation method thereof | |

| EP3651898B1 (en) | Catalysts based on pd/ceo2 and preparation method thereof | |

| WO2021029410A1 (en) | Method for manufacturing catalyst for voc treatment | |

| JP5755124B2 (en) | Method for producing cathode catalyst for polymer electrolyte fuel cell | |

| CN112584926A (en) | Catalyst for exhaust gas purification | |

| JP2008207161A (en) | Method of manufacturing air purification material, air purification material, and apparatus and method of purifying air | |

| WO2016047504A1 (en) | Steam reforming catalyst composition and steam reforming catalyst | |

| JP2013034937A (en) | Method for producing platinum particle, method for producing platinum particle carrying catalyst, and purifying catalyst | |

| US11697109B2 (en) | Catalyst particles for treating vehicle exhaust gas, preparation method therefor, and method for treating vehicle exhaust gas by using same | |

| JP5134599B2 (en) | Catalyst for CO gas sensor, paste, and CO gas sensor | |

| KR102209190B1 (en) | Method for manufacturing vehicle exhaust gas treatment catalyst and vehicle exhaust gas treatment catalyst prepared by the same |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 18828045 Country of ref document: EP Kind code of ref document: A1 |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 18828045 Country of ref document: EP Kind code of ref document: A1 |